Page 1

User Manual

Version 3.01

AUTOSTOP™ Suspension Meter

Page 2

E7474

DECLARATION OF CONFORMITY

We, AutoTest products Pty Ltd. declare under our sole responsibility that the product

AUTOSTOP™ Suspension Meter is in conformity with the provisions of the following Council

Directive: 1999/5/EC.

A copy of the Declaration of Conformity is available from http://www.autotest.net.au

© AutoTest Products Pty Ltd (AutoTest) [2019].

Copyright of the drawings, information and data recorded in this document (the information) is the

property of AutoTest Products. This document and the information are solely for the use of the

authorised recipient and this document may not be used, copied, or reproduced in whole or part

for any purpose other than that for which it was intended by Auto Test Products. Auto Test

Products makes no representation, undertakes no duty, and accepts no responsibility to any third

party who may use or rely upon this document or the information.

Under no circumstances shall Auto Test Products be responsible for any loss of data or income

or any special, incidental, consequential or indirect damages howsoever caused.

The contents of this document are provided "as is". Except as required by applicable law, no

warranties of any kind, either express or implied, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose, are made in relation to the

accuracy, reliability of contents of this document. Auto Test Products reserves the right to revise

this document or withdraw it at any time without prior notice.

10242

Page 3

Table of Contents

AUTOSTOPTM Suspension Meter

1 UNPACKING AND FIRST TIME USE ........................................................................................................... 1

1.1 Battery Charging ............................................................................................................................................ 1

1.2 Self Test and Battery Check ....................................................................................................................... 1

2 FOR YOUR SAFETY ......................................................................................................................................... 2

3 OPERATION ..................................................................................................................................................... 3

3.1 Set-Up on Vehicle ........................................................................................................................................... 3

3.2 Running the Test ............................................................................................................................................ 3

3.3 Test Instructions Summary ....................................................................................................................... 7

3.4 Display Last Test Result .............................................................................................................................. 8

3.5 Printing Last Test .......................................................................................................................................... 9

3.6 Using Reference Method ............................................................................................................................. 9

3.7 Changing Test Parameters ...................................................................................................................... 10

3.8 Menu Reference .......................................................................................................................................... 11

4 UPLOADING TEST DATA ........................................................................................................................... 12

4.1 Installing the Data Logger Software .................................................................................................... 13

4.2 Uploading Tests using the Data Logger Software ........................................................................... 13

4.2.1 Downloading via Bluetooth ............................................................................................................... 17

4.3 Using the Data Logger software ............................................................................................................ 22

5 TROUBLESHOOTING .................................................................................................................................. 24

6 WARRANTY ................................................................................................................................................... 25

7 AUTHORISED SERVICE AGENTS: ........................................................................................................... 26

Page 4

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 1

1 UNPACKING AND FIRST TIME USE

Congratulations on your choice of an AUTOSTOP™ Suspension Meter. Please take the time to

read this User’s Manual before using the AUTOSTOP™ Suspension Meter in the field.

Incorrect or inappropriate use of this instrument may void the warranty.

Please complete the warranty registration card and post it to AutoTest Products Pty Ltd,

alternatively visit our website www.autotest.net.au and complete your warranty registration

on line. Your warranty registration ensures that you are kept up-to-date on any software or

hardware changes to your AUTOSTOP™ Suspension Meter.

The packing box of your AUTOSTOP™ Suspension Meter should contain the following:

1. AUTOSTOP™ Suspension Meter

2. User Manual

3. Warranty Registration Card

4. Calibration Certificate

5. Power Adaptor

6. Suspension Meter Data logger software CD-ROM

7. Data Download USB Cable

Optional Accessories:

• Bluetooth printer

AUTOSTOP™ Suspension Meter determines the vertical suspension movement, measuring

damping coefficient and counting number of rebounds. AUTOSTOP™ Suspension Meter has a

twelve-button operation via a tactile membrane keypad with LCD display. It is lightweight

(500grms) and compact (200x90x30mm) and can be installed on the body of the vehicle

near the wheel that is to be tested.

1.1 Battery Charging

When you receive your new Meter, you should charge the device to full. The device can be

easily charged by connecting the provided Power Adaptor.

1.2 Self Test and Battery Check

The self-test function is activated each time the AUTOSTOP™ Suspension Meter is powered,

it checks the clock, the battery level and other hardware checks. If the battery does not have

sufficient charge to be used, then it will display “Warning: Battery Low”.

Page 5

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 2

2 FOR YOUR SAFETY

Read these simple guidelines. Not following them may be dangerous. Read the complete

user guide. Further detailed information is given in this manual.

SWITCH ON SAFELY

Do not switch the device on when wireless device use is prohibited or when it may

cause interference or danger.

INTERFERENCE

All wireless devices may be susceptible to interference, which could affect

performance.

SWITCH OFF WHEN REFUELING

Do not use the device at a refuelling point. Do not use near fuel or chemicals.

SWITCH OFF NEAR BLASTING

Follow any restrictions. Do not use the device where blasting is in progress.

USE SENSIBLY

Use only in the positions as explained in the product documentation.

QUALIFIED SERVICE

Only qualified personnel may install or repair this product.

ACCESSORIES AND BATTERIES

Use only approved accessories and batteries. Do not connect incompatible products.

WATER-RESISTANCE

Your device is not water-resistant. Keep it dry.

CONNECTING TO OTHER DEVICES

When connecting to any other device, read its user's guide for detailed safety

instructions. Do not connect incompatible products.

Page 6

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 3

3 OPERATION

3.1 Set-Up on Vehicle

The vehicle must be stationary (at a complete stop) prior to commencement of the test.

Mount the Suspension Meter to the body of the vehicle, placing it near the wheel that is to be

tested. The device uses rubber suction cups that grip onto the body of the vehicle. Please

note that dirt particles on suction cups might damage body paint as well as can result in

loose grip, which can result in device falling down on ground.

The AUTOSTOP™ Suspension Meter is self-aligning by identifying its orientation at the

beginning of each test. The suspension meter can be installed at any angle facing any

orientation, but must be well secured for the entire duration of the test as movement can

cause erroneous readings. Before commencing the test, give the vehicle a firm shake to bring

shock absorbers at their natural position.

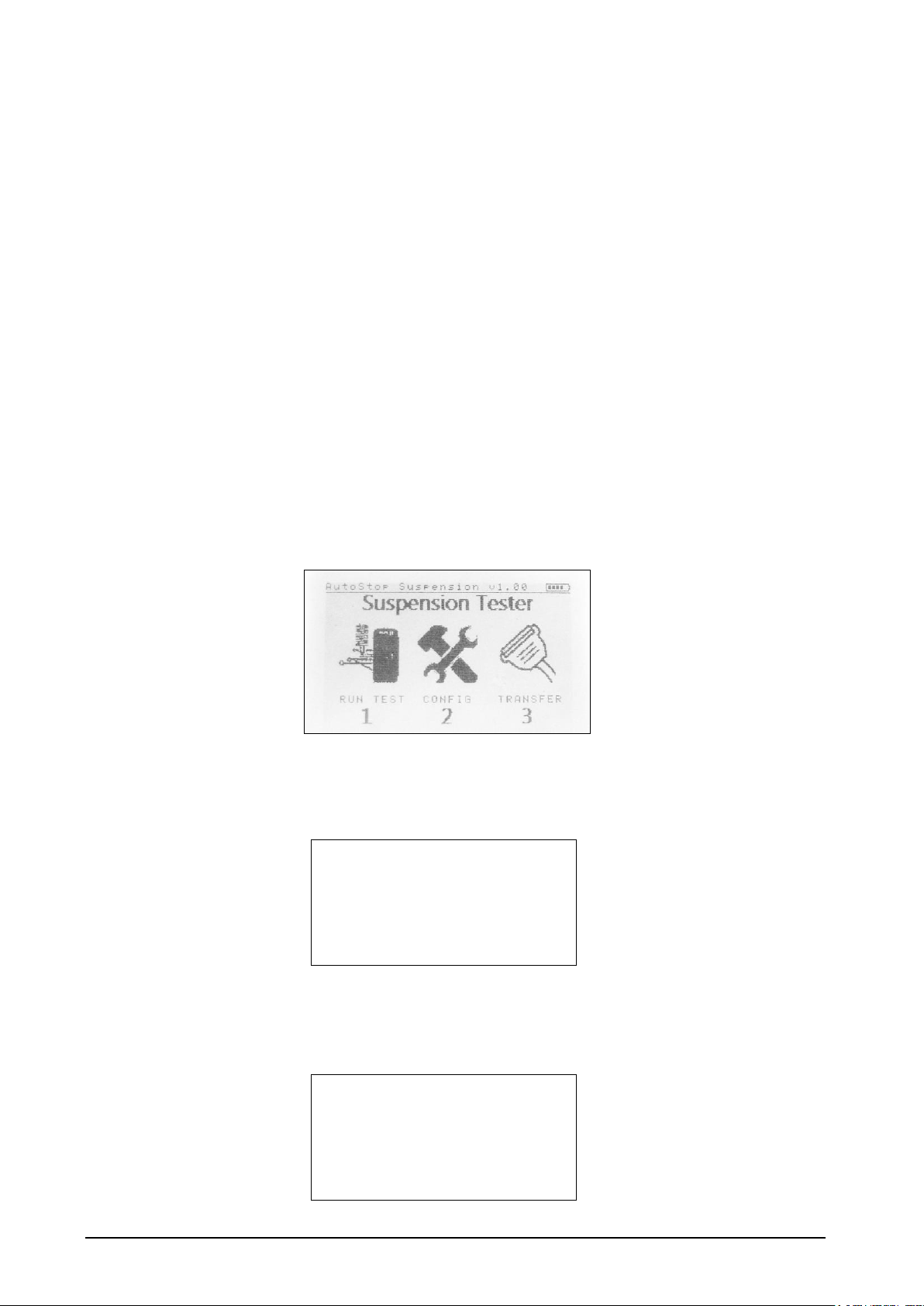

3.2 Running the Test

Turn on AUTOSTOP™ Suspension Meter by pressing the ON/OFF button if the device is

currently off. The Suspension Meter will go through a start-up procedure and will eventually

display Main Menu (a menu of three icons):

Before starting a test, make sure the device has sufficient (over 30%) battery life. To run a

suspension test, select “RUN TEST” by pressing ‘1’ from the keypad. The device will show

the following list of options on the screen:

1. Run New Test

2. Show Last Test

3. Print Last Test

4. Delete all Tests

5. Memory Usage

6. Return to Main Menu

Now select 1. Run New Test by pressing 1 once again. The device will ask the user to

confirm if the shock absorbers are warmed up or if the vehicle has been in motion for at

least 5 minutes during the last 30 minutes. Running a suspension test on a cold vehicle may

lead to erroneous result.

Has the vehicle been in

motion for at least 5 min

within the last 30 min?

1. Yes

2. No

Page 7

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 4

After the warm up confirmation, the device will prompt for Test Mode.

Select Test Mode?

1. By Driving

If you are selecting option 1. By Driving, please make sure you drive the vehicle forward

and suddenly apply foot bake for testing the front two wheels. For testing the rear two

wheels, please make sure you reverse the vehicle and suddenly apply hand brake. Please be

mindful of other people around while driving the vehicle.

After selecting the Test Mode, the device will prompt for Examiner ID (Operator Name).

Use the device’s keypad to type in the name of the person performing the test. The DEL key

behaves like the Backspace key in a PC keyboard and it can be used to erase the last

character in the input field.

Enter Examiner ID:

After entering the Examiner ID, press ENTER to continue. Now the device will prompt for

Vehicle Registration, type in the registration number of the vehicle that is to be tested.

Again, use the keypad to erase and type in the vehicle’s registration number.

Enter Vehicle

Registration:

After entering the Vehicle Registration Number, press ENTER to continue. If the registration

number you just entered has any wheel that was recently tested, the device will

automatically load the Customer Name from the database. Otherwise, for a new vehicle’s

entry, the device will prompt for Customer Name. Enter Customer’s name using the keypad

and press ENTER.

Enter Customer Name:

If reference method was used in the device configuration (see Section 3.6), the following

dialogue will be displayed:

Vehicle Chassis Type

1. Soft (Comfortable)

Page 8

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 5

2. Normal

3. Hard (Sporty)

4. Manuf. Defined

5. Unknown

If the vehicle being inspected has a chassis system that was designed to be soft or

comfortable, select option 1. For normal vehicles such as an average European vehicle, use

option 2. If the chassis system is designed be hard or has characteristics of a sports car, use

option 3. If the reference damping factor for a particular vehicle is known, user can select

option 4 (Manufacturer Defined) to specify reference damping data for that vehicle (see

Section 3.6). If the user is unsure about the chassis type, select option 5. By selecting option

‘5. Unknown’, reference method will not be used.

The device will now prompt for wheel selection. Select the wheel that you are currently

testing by pressing numbers from 1 to 4 using the keypad. Press 5 to cancel the test and

return to the RUN TEST menu.

If the vehicle registration number you just typed in has any wheel that was recently tested,

the device will not show those wheels that are already tested, instead it will only show

wheels that are yet to be tested. If you want to overwrite a test for a particular wheel that is

already tested, then select 6. List all wheels* and then select the wheel that you want to test

again.

1. Front Left

2. Front Right

3. Rear Right

4. Rear Left

5. Cancel Test

6. List all wheels*

* Option #6 will only be displayed if at least one of the wheels is not displayed.

Wheels that are not displayed in the list are those that have already been tested and stored.

After selecting the wheel that is being tested, the device will prompt for a ready trigger

Press any key when ready or press DEL to abort test. Hit ENTER from the keypad when

you are ready to run the suspension test.

Note: Before running a test on a wheel, give a shake to the wheel by bouncing the vehicle down

a few times.

Running a push-down test

Push down test can be conducted in two ways:

1. Single Push Method

2. Multiple Push Method (recommended)

1. Single Push Method

In single push method, push the vehicle a hard push and immediately release it, letting the

vehicle bounce up at its natural rate. If the push-down force was large enough for the

suspension meter to sense the trigger, the suspension meter will immediately start

sampling/recording the vehicle oscillation. After over 1.5 sec, the sampling will end and

suspension meter will process the result.

Page 9

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 6

If the vehicle was not pushed hard enough, or the suspension meter finds some problem

with obtained result, the device will display the following error message:

Abnormal results

obtained!

1. Run test again

2. Abort Test

Select 1. Run test again to redo the test with harder push down force.

2. Multiple Push Method

Multiple Push down method is similar to the single push down test, except the vehicle is

pushed down a number of times to excite the suspension system before pushing a final hard

push. When running a multiple push down test, be careful not to obstruct the upward

bounce of the vehicle. Only push the vehicle down when the vehicle is bounced back to its

top height and then release. Take extra care when making the last push. The last push should

have the maximum force compared with the previous pushes.

Note: Do not obstruct the upward motion of the vehicle.

For better consistency, multiple push down method is recommended.

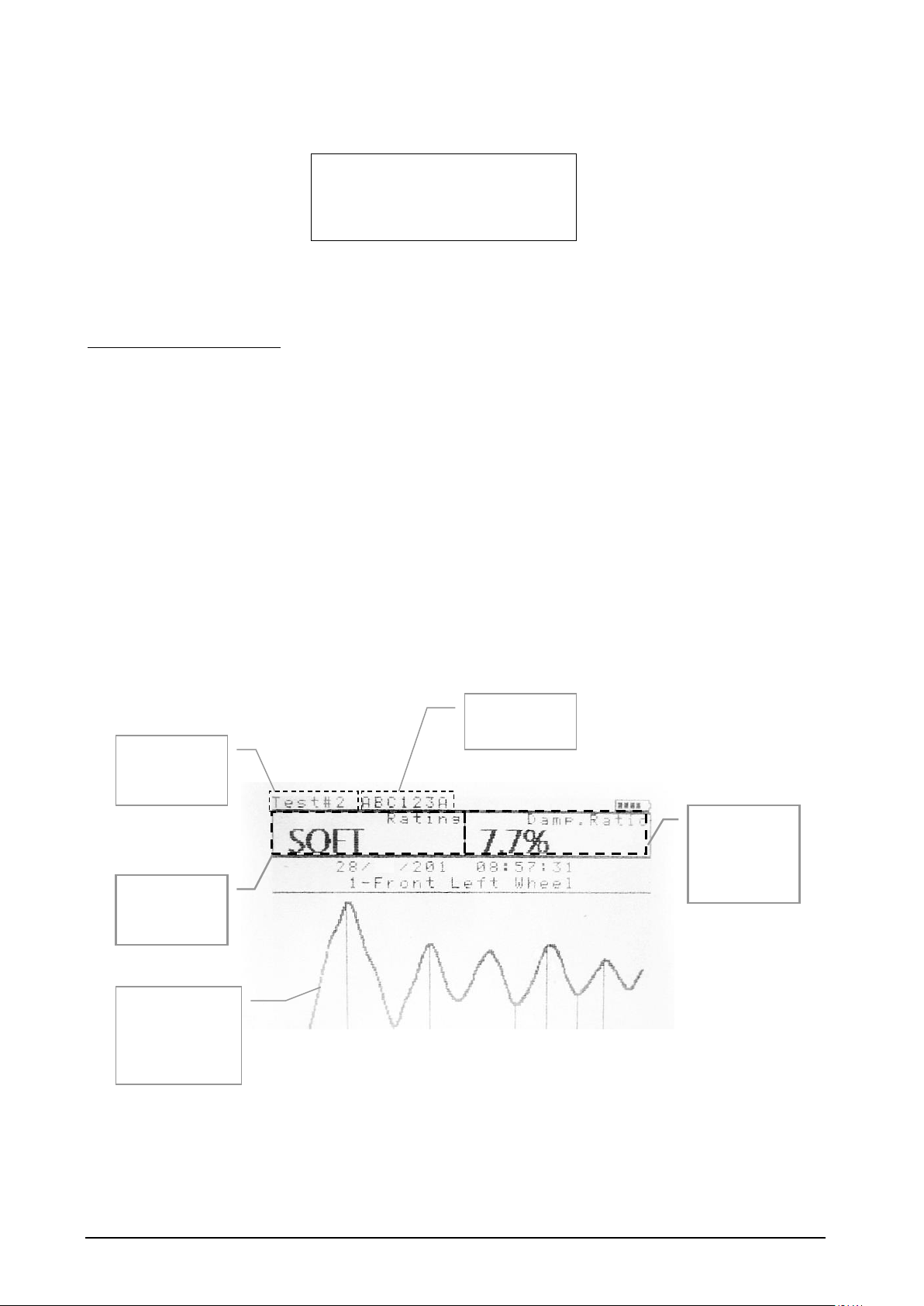

Results will be displayed on the screen after each test. The meter will ask user whether the

result should be saved. The user can save the test and continue to the next wheel, or user can

redo the test for the selected wheel.

** Suspension rating is evaluated based on Damping ratio., number-of-rebounds, and reference

method used (see section 3.6 & 3.7 for more information).

The graph will remain on the screen until the user presses any key from the keypad. Once a

key is pressed, the device will display the following menu:

Current Test

file no.

(record no)

Vehicle Reg.

No.

Suspension

Rating **

Damping

Ratio of the

vehicle’s

suspension

Plot of

vehicle’s

vertical

oscillation

Page 10

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 7

1. Save test

2. Don’t save

3. Redo Test

Press 1 to save the results obtained for the current wheel. Press 2 to discard and erase

results and return to the RUN TEST Menu. In case of odd results, press 3 to redo the test.

3.3 Test Instructions Summary

Screen Display

Instruction

Keys to Press

Blank Screen

Switch On

ON/OFF

Initial splash screen

Press any key to skip

Open Test Menu

Press 1 from the keypad

Examiner ID:

Enter Examiner ID or Operator’s

name

Use keypad to type Examiner ID.

When done, Press ENTER.

Enter Vehicle Registration:

Enter the Registration no

Use keypad to type Vehicle

Registration No. and press

ENTER

Enter Customer Name:

Enter Customer Name

Use keypad to type Customer

Name and press ENTER

Selection Chassis type

(only if reference method is

used)

Select vehicle chassis type.

Press a key from ‘1’ to ‘5’ to

select an option

Wheel to test:

Select a wheel to run test.

Press a key from ‘1’ to ‘4’ to

select a wheel

Press any key when ready or

press DEL to abort test

Press any key to commence the

test or DEL to cancel test and

return to Test Menu

Press any key to commence the

test

Waiting for a trigger…

Push down the vehicle (or drive)

Sampling…

Wait for the result

Processing…

Wait for the result

Graph Screen

Displays results from the

currently conducted suspension

test

Press ENTER

1. Save Test?

To save test result

Press 1 to save

2. Don’t Save?

To discard results and abort test

Press 2 to abort test and results

3. Redo Test?

To Redo the test

Press 3 to repeat the test

Page 11

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 8

Must:

– Fix Suspension Meter securely

– Install in a stationary vehicle

– Place it close to the wheel that is being tested

– Shake (push down) the vehicle before starting the actual test

– For driving test,

o For front wheels: must drive the vehicle forward and use foot brake

o For rear wheels: must drive the vehicle backward and use hand brake

Must not:

– Pull up the vehicle (let the vehicle bounce up naturally)

3.4 Display Last Test Result

After running a successful suspension test on a vehicle, the results for that vehicle can be

retrieved and a summary of all four wheels can be displayed on the suspension meter’s

screen. To view the results for all four wheels of the last tested vehicle, select RUN TEST

from the Main Menu by pressing 1. The device will then display the Test Menu. Select [2.

Show Last Test] from the Test Menu.

Test#2 ABC123A

Test Date: 18/01/2011

1-Front Left

SOFT

15:05

2-Front Right

GOOD

15:04

4-Rear Left

N/A

3-Rear Right

HARD

15:08

The above screen displays a brief summary of all four wheels of the latest vehicle that is

tested. In the above summary screen, the displayed ‘N/A’ for the 4th wheel (Read Left)

indicates that ‘Not available’, or no test was conducted or stored for that wheel.

Press a key from ‘1’ to ‘4’ to view the results for an individual wheel. Alternatively, press

ENTER to sequentially view results for all wheels. Keep pressing the ENTER key to switch to

the next screen. At the end of each cycle, the device will prompt “Print Results?”. Results can

be printed out using an optional Bluetooth printer. For more information regarding the

printing process, see Section 3.5. To return to the Test Menu screen, select ‘3. Return’ once

the print dialogue appears on the screen. Alternatively, by pressing any key from ‘5’-‘9’ and

‘0’ during an individual result screen will return to the Test Menu.

Test Number

(Record no)

Vehicle Reg. No.

Wheel

Suspension

Rating

Test Time

Page 12

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 9

3.5 Printing Last Test

Results for all four wheels for the latest tested vehicle can be printed out on a paper slip

using an optional Bluetooth printer.

In order to print the latest test results using a Bluetooth printer, first switch on the printer

and then place the device close to the Bluetooth printer.

Aligning the infrared port on Suspension Meter and the Bluetooth printer

Turn on the suspension meter if it’s switched off. From the Main Menu containing three

icons appears, select ‘RUN TEST’ by pressing 1 from the keypad. When the Test Menu

appears, select ‘3. Print Last Test’. The device will display “Printing Test #n”, where n is

the test number for the latest test.

Note: In case if the Bluetooth printer fails to print, please check the printer battery level.

3.6 Using Reference Method

Reference method allows results to be generated in reference to the original factory

performance of the shock absorbers. Since different vehicles have different factory ratings

for shock absorbers, it is impractical to have the factory-rating list for the shock absorbers of

all kinds of vehicles and models. Instead, the device groups all vehicles into three categories

and assigns reference data to each category:

Category

(Chassis type)

Standard Reference Data

Front Axle

Rear Axle

Soft (comfortable)

60

60

Normal

70

70

Hard (Sporty)

80

80

The default reference data listed in the above table can be modified in the suspension meter

to adopt the local regulations.

The reference method can be turned off from the configuration menu. To change the

reference data, or turn off reference method, see Section 3.8.

Page 13

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 10

3.7 Changing Test Parameters

AUTOSTOP™ Suspension Meter uses two ways to determine the performance of a shock

absorber. The first method uses Damping Ratio factor and the second method looks at the

number of rebounds of the suspension system. The device can be configured to use both

methods; thereby, the performance of the suspension system using the Damping Ratio

method and the Rebound methods is averaged.

The default calculation method for determining the performance of the suspension system is

using both ‘Damping Ratio’ and ‘Rebound’ methods. Users can change the calculation

method by taking the following steps:

• From the Main Menu, select ‘CONFIG’ by pressing 2 from the device keypad.

• Select 3. Result calculation by pressing 3

• Select 1. Calculation Method by pressing 1

• To use the Damping Ratio method only, select ‘1. Using Damping Ratio’

• To use the Rebound method only, select ‘2. Using Rebounds’

• To use both the Damping Ratio method and the Rebound method, select ‘3. Using Both’

• To return, select ‘4. Return’

To quantize and describe the performance of the vehicular suspension system, AUTOSTOP™

Suspension Meter uses a range table for each calculation method. The following table

contains default values or parameters for each method that are used to rate or describe the

performance of the vehicular suspension system.

Rating

Damping Ratio

(zeta, ζ)

Rebound Method

(No. of bounces)

POOR

0 ≤ ζ < 10%

Rebounds > 4

SOFT

10 ≤ ζ < 15%

3 ≤ Rebounds < 4

GOOD

15 ≤ ζ < 35%

2 ≤ Rebounds < 3

HARD

35 ≤ ζ < 100%

Rebounds ≤ 1

Users can change these parameter ranges by taking the following steps:

• From the Main Menu, select ‘CONFIG’ by pressing 2 from the device keypad.

• Select 3. Result calculation by pressing 3

• Select 2. Parameter Range by pressing 2

• To change the parameter values for the Damping Ratio method, select ‘1. Set Damping Ratio

Range’

• Or, to change parameter value for the Rebound method, select ‘2. Set Rebounds Range’

• Select the Rating for which you want to update the parameter range using keypad (1-4).

• When an input dialogue box appears, enter the new value and press ENTER.

Users can always revert back to the default parameters, in case of invalid range entries,

using the following steps:

• From the Main Menu, select ‘CONFIG’ by pressing 2 from the device keypad.

• Select 3. Result calculation by pressing 3

• Select 3. Reset Parameters by pressing 3

Page 14

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 11

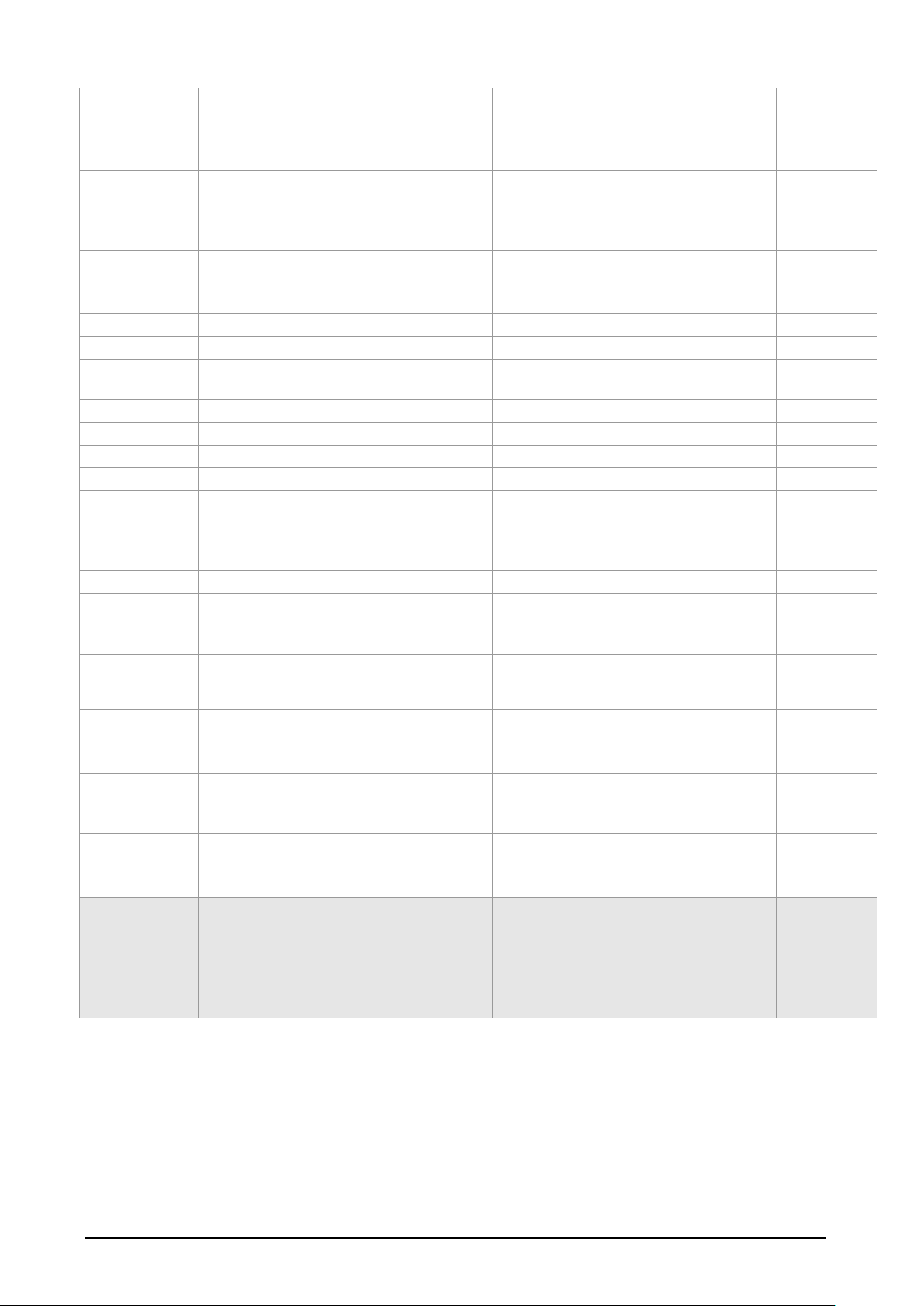

3.8 Menu Reference

Section

Sub Menu

Sub Menu 2

Description

Keys to

Press

MAIN MENU

RUN TEST

Suspension Test Menu. Contains all

options related to running and

viewing suspension tests

Press 1

1. Run New Test

Starts a new suspension test

Press 1

Warm

suspension

check

Prompts user to check if the vehicle

was in motion recently.

1-Yes

2-No

Examiner ID

Prompts for Examiner ID

Type then

press

ENTER

Vehicle Reg. No

Prompts for Vehicle Reg. No.

Type then

press

ENTER

Customer

Name

Prompts for Customer Name

Type then

press

ENTER

Chassis Type

Prompts for Vehicle Chassis Type

(only if reference method is used)

Press 1-4

Ready?

Prompts for Ready trigger

Press

ENTER

Graph Screen

Displays the current test’s result

Press

ENTER

Save?

Prompts for Save/Discard results

1-Save

2-Discard

3-Redo

2. Show Last Test

Displays the results for the latest

test.

Press 2

Summary Page

Display the summary of all four

wheels for the last tested vehicle

Press 1-4

or ENTER

Print Results?

Prompts user to print the current

(latest) results using optional IrDA

printer

1-Yes

2-No

3-Return

3. Print Last Test

Prints the latest results using

optional IrDA printer

Press 3

4. Delete all Tests

Warning! Clears the user memory

deleting all existing stored tests.

Users should upload data prior to

deleting all tests.

Press 4

Delete all

Tests?

Confirms if user really wants to

delete all stored tests.

1-Delete

2-Cancel

5. Memory Usage

Displays the number of stored tests.

Press 5

Memory Usage

page

Any key to

exit

6. Return to Main

Menu

Returns to the Main Menu

Press 6

CONFIG

Displays settings and result

calculation options

Press 2

1. Contrast

Adjusts the display brightness level

Press 1

2. Date/Time

Displays the current date and time

Press 2

Page 15

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 12

3. Result

Calculation

Allows result calculation parameter

adjustments

Press 3

1. Calculation

Method

Displays suspension rating

calculation methods

Press 1

1. Using Damping Ratio

2. Using Rebounds

3. Using Both

4. Return

Select 1-4

2. Reference

Method

Enables or disables reference

method.

Press 2

1. Enable Reference

Press 1

2. Disable Reference

Press 2

3. Return

Press 3

3. Parameter

Range

Allows suspension rating parameter

alteration

Press 3

1. Set Damping Ratio Range

Press 1

2. Set Rebounds Range

Press 2

3. Reference Damping

Press 3

4. Return

Press 4

4. Reset

Parameters

Resets Parameter Range values.

Also sets “1. Calculation Method” to

“3. Using Both” (i.e. using Damping

ratio and Rebounds method)

Press 4

5. Return

Return to the CONFIG menu

Press 5

4. Device Info

Displays device information such as

version, serial number, battery level,

date and time.

Press 4

Device

Information

Page

Press any

key to exit

5. Printer

Displays printing options

Press 5

1. Print

Graphs

Enables printing of graphs of

suspension tests.

Press 1

2. Disable

Graphs

Disables printing of graphs. This

option can be used to save printer

roll.

Press 2

3. Return

Return to the CONFIG menu

Press 3

6. Return to Main

Menu

Returns to the Main Menu

TRANSFER

This menu option allows device to

upload suspension test results and

to update firmware to a connected

PC. The device must be connected to

the PC using the optional serial

cable.

Press 3

4 UPLOADING TEST DATA

The AUTOSTOP™ Suspension Meter has a upload facility that allows users to transfer test

results from the unit onto a PC via a custom Serial Cable (optional accessory) for analysis

and printing. The Suspension Meter can hold up to 100 tests numbered one to a hundred. To

upload all tests stored in the suspension meter, AUTOSTOP™ Suspension Meter Datalogger

software must be installed and running on the PC.

Page 16

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 13

4.1 Installing the Data Logger Software

Before installing the AUTOSTOP™ Suspension Meter Datalogger software, make sure your

computer meets the minimum system requirements:

• Microsoft Windows XP or greater

• One unused USB port

• At least 50 MB of hard disk space

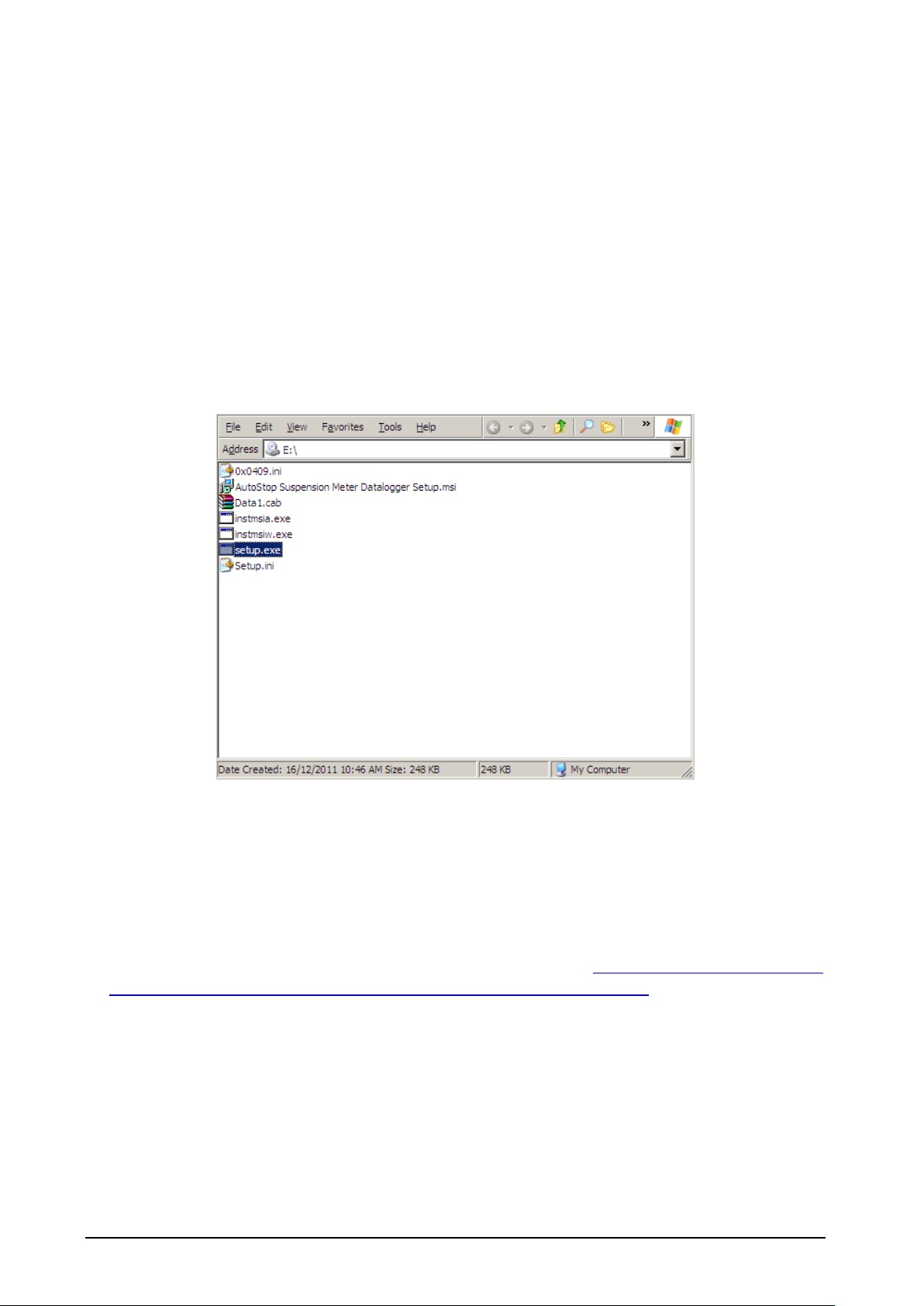

To install the data logger software from CD, please follow the following steps:

1. Insert the Suspension Test Data Logger Software CD-Rom installation disk into

your disk drive.

2. If the Data Logger software setup does not run automatically, then open your CD-

ROM drive in Windows Explorer

3. Select and run file “setup.exe”

4. Follow Setup prompts.

Note: If you already have a copy of an older version of suspension meter software installed,

you may have to uninstall it first.

The latest version of the data logger software for AUTOSTOP™ Suspension Meter can be

obtained from the Internet by going to the AutoTest website: http://www.autotest.net.au/

or http://www.autotest.net.au/products/autostop-suspension-meter/

4.2 Uploading Tests using the Data Logger Software

After successfully installing the data logger software, run the Data Logger software from the

desktop or from the start menu, and perform the following steps:

Step 1: Use the supplied USB cable and connect one of the cable to the meter and the other

end to your PC. Turn ON the suspension meter.

Page 17

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 14

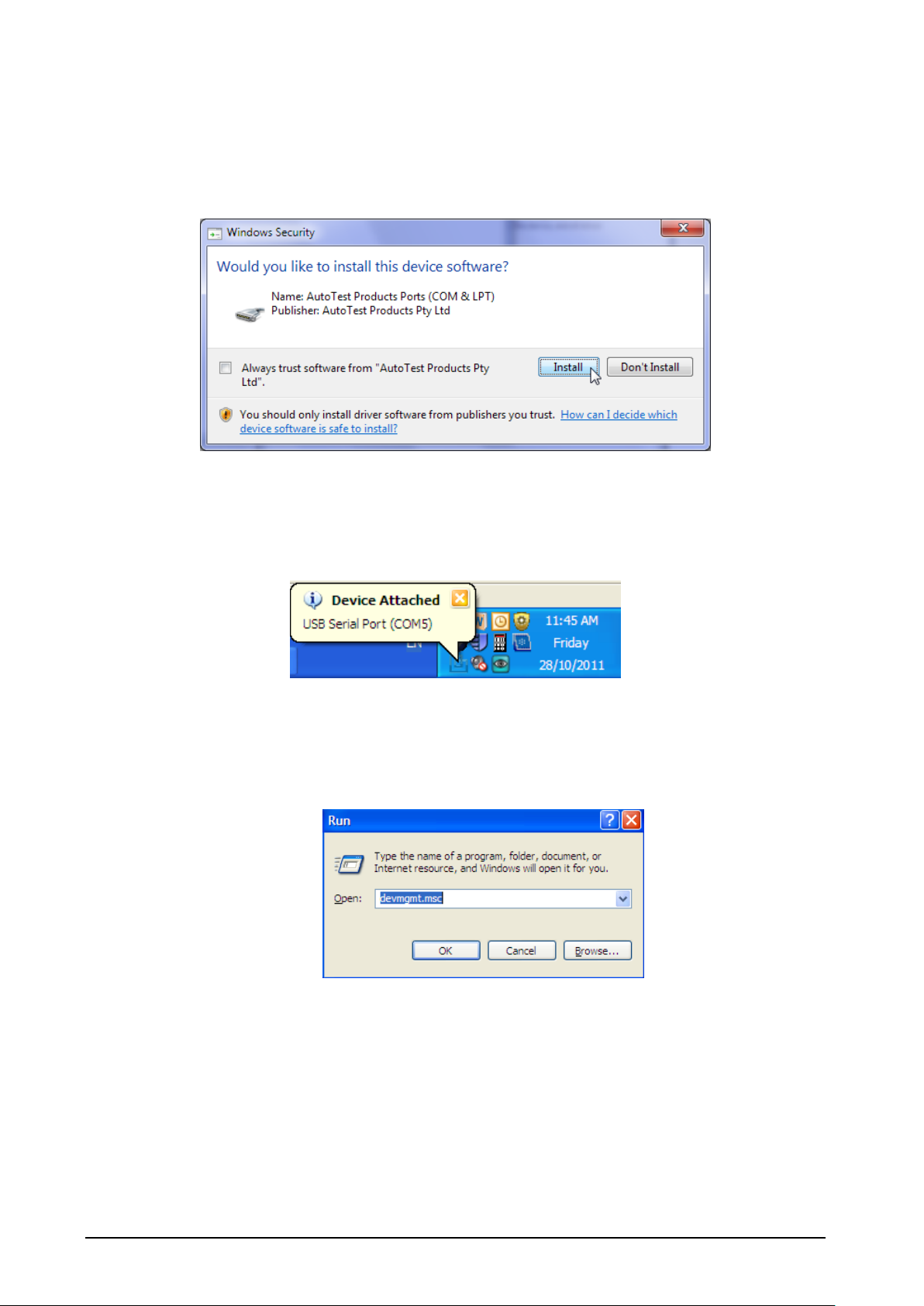

When the suspension meter is first connected, Windows will try to install drivers for it.

Please wait until Windows has finished installing drivers. You might see the following

message box during the installation of the USB drivers. Please select Install to install the USB

drivers.

Step 2: Once the drivers have been installed, you may see the following pop-up screen near

the system clock. The message box will display the COM port to which the suspension meter

is connected. You need to know this COM port number (for example COM5 in the following

image) when communicating and downloading data from the suspension meter.

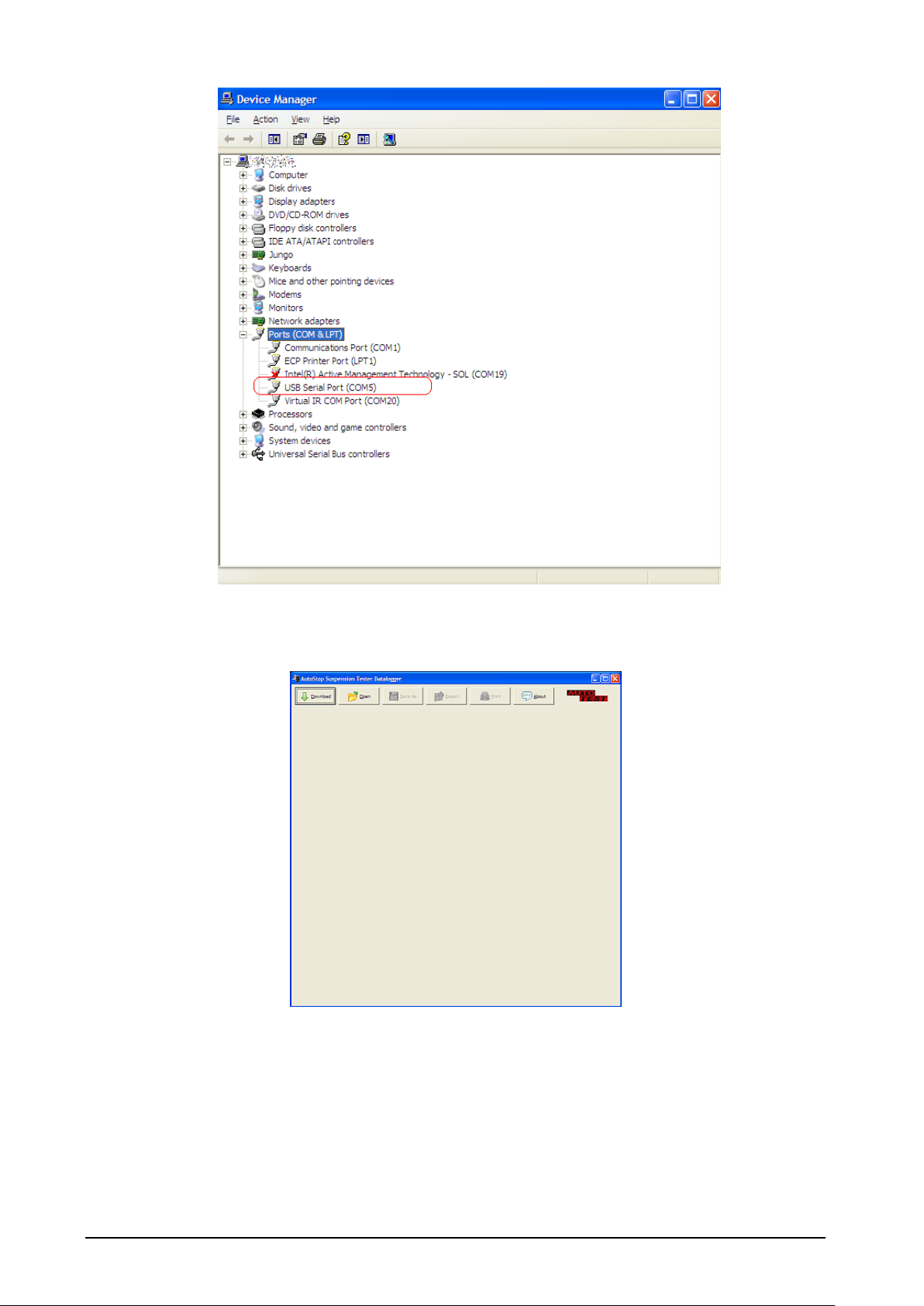

Alternatively, if you did not see the above ‘Device attached’ pop-up screen, you can check the

COM port number by taking the following steps:

• Open ‘Device Manger’ by going to Start -> Run -> Type ‘devmgmt.msc’ and click OK.

• Then in the Device Manger window, open Ports (COM & LPT) node and find ‘USB

Serial Port’ in the list. Note the COM port number appended next to ‘USB Serial

Port’.

Page 18

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 15

Step 3: Open the Suspension Meter Data logger window and click on DOWNLOAD. A

Download Wizard window will appear. Follow the download prompts.

Step 4: Select the right COM port to which the suspension meter is connected. The software

will display a list of detected COM ports. Select the appropriate COM port and click on NEXT.

Page 19

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 16

Note: For ordinary RS232 cable connection, it is very likely that the COM port would be

COM1 or COM2. If you are using a USB cable, you need to select the COM port you would

have figured out in STEP 2.

Step 5: When you see the above screen on your PC, switch ON the Suspension Meter. When

the Main Menu appears, select ‘TRANSFER’ by pressing 3 from the keypad on the device.

Download will automatically commence once the connection is successfully established.

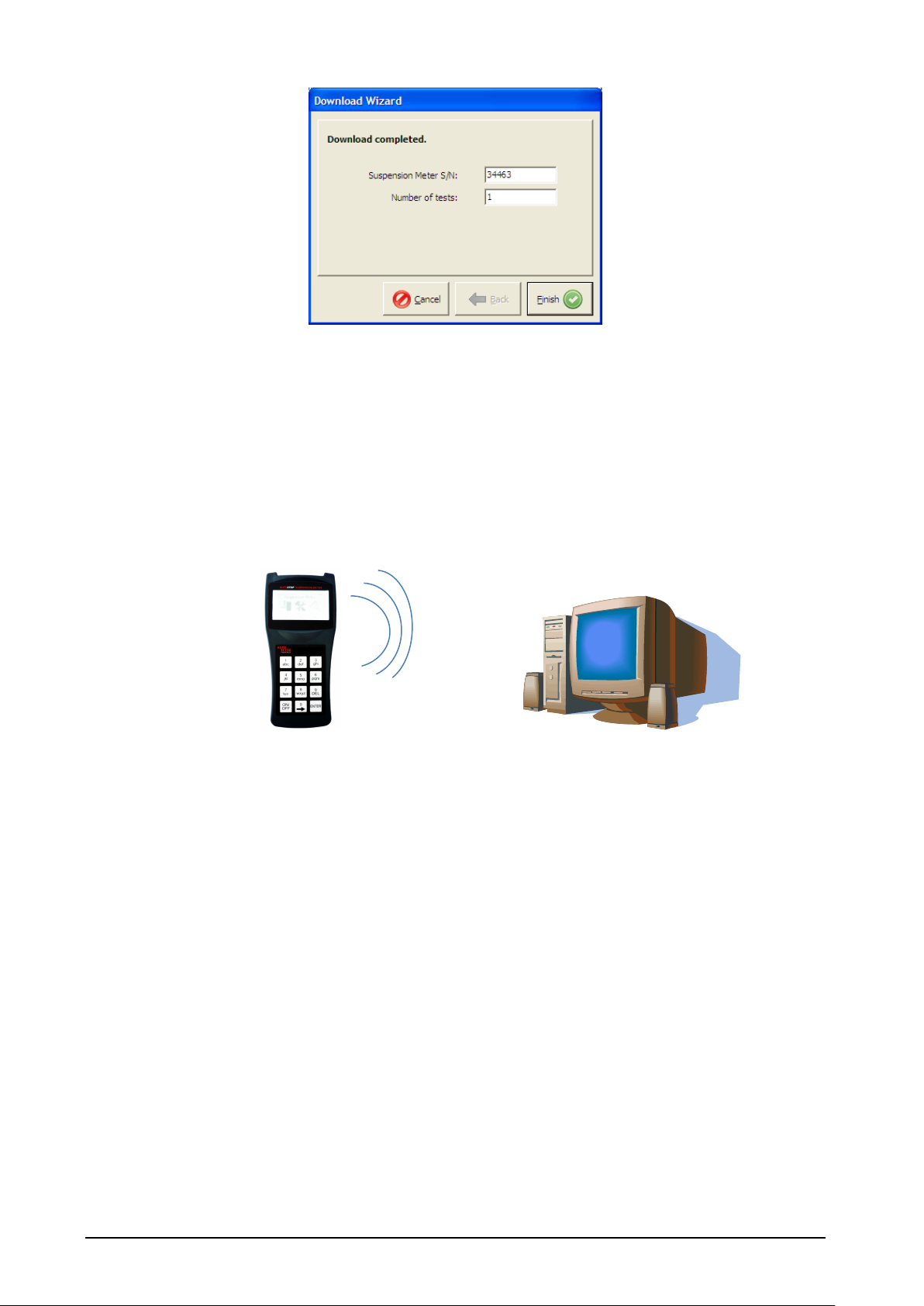

Step 6: The Download Wizard window will display the download progress. Wait until the

download finishes.

Step 7: After test data has been downloaded a small window will appear that says

‘Download completed’. Click on FINISH to view the downloaded tests.

Page 20

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 17

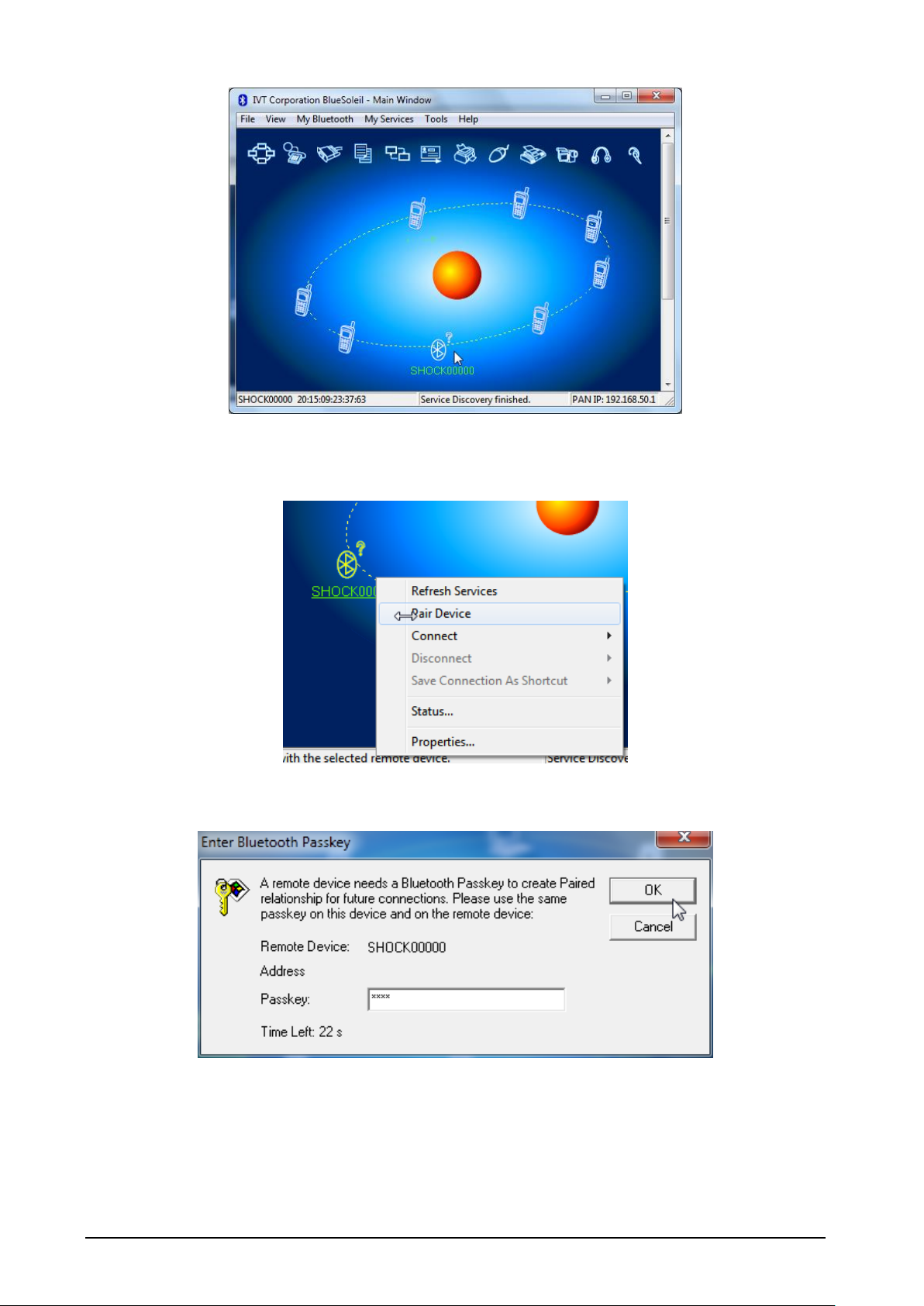

4.2.1 Downloading via Bluetooth

Before connecting the suspension meter to the PC using the Bluetooth interface, make sure

the PC supports Bluetooth connectivity.

Once the Data Logger software has been installed, run the software on the PC and switch ON

the suspension meter by pressing the ON/OFF key.

When connecting the Suspension Meter for the first time using the Bluetooth interface, user

will need to configure the Bluetooth connection. To configure the Bluetooth connection,

open your Bluetooth manager program on your PC and search for Shock##### device,

where '#####' is the serial number of the suspension meter.

Note: the screenshots provided below many not be the same on your PC.

For information regarding Bluetooth device pairing on your PC, please refer to the

documentation of your Bluetooth Manager.

Bluetooth

Page 21

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 18

Select the device Shock##### from the list of discovered Bluetooth devices and create

pairing.

When prompted for the pairing code or pin number, enter “0000”.

Page 22

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 19

Once the pairing is established, refresh device services and connect using Bluetooth serial

port service.

If the following message appears, note down the serial port and press Yes. The serial port

will be later used by the datalogger software.

Page 23

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 20

Users can also check the COM port of the Bluetooth device by viewing the status of the

device.

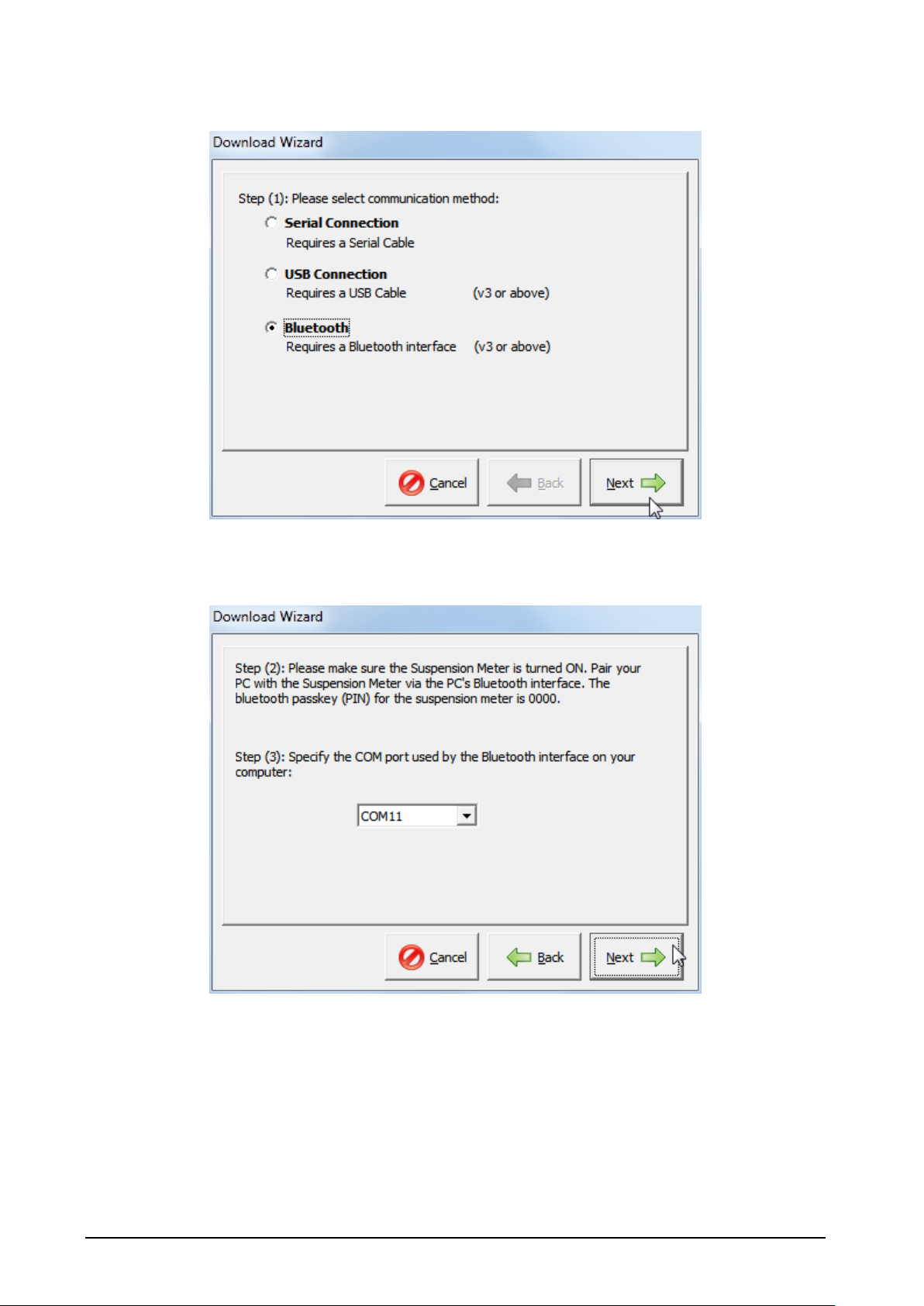

Once the Bluetooth connection is setup, the user can now download test results from

AutoStop Suspension Meter using the Bluetooth interface. To download the results, open

AutoStop Suspension Meter Datalogger software and click on “Download” button.

Page 24

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 21

When the following connection window appears, select “Bluetooth” connection and press

Next.

Select the COM port number of the Bluetooth connection connected with the suspension

meter. The COM port number is the same COM port obtained during the Bluetooth pairing

process.

Make sure the suspension meter is ON. Press Next to continue. Once the connection is

established, the datalogger software will acquire a list of all tests currently stored on the

device.

Page 25

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 22

Select the tests that need to be downloaded and press Next. Datalogger software will then

download the selected tests.

Once the desired tests have been downloaded, press Finish to return to the main window

and view test results.

4.3 Using the Data Logger software

The Data logger will display all the saved tests and you can view the results of the particular

test and view corresponding graph for each test.

Page 26

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 23

There are options on the data logger such as:

1. Open: in order to open a saved file on your PC

2. Save: to save the results onto your PC

3. Export: this option can be used to view and save the test result in Microsoft Excel

compatible format.

4. HTML Report: displays the suspension test report for the selected vehicle in a text

format that can be selected and copied to another application such as Microsoft

Word.

5. Print: this option can be used to print the test result. There are options to print unit

details, test details and the data table.

List of all uploaded tests

Page 27

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 24

6. About: to view information about Data logger.

5 TROUBLESHOOTING

Problem

Potential Cause and Action Necessary

Suspension Meter will not turn on

Internal electronics have failed - return unit for

servicing.

Suspension Meter not recording

keypad input

Keypad damaged- return unit for servicing.

Suspension Meter turns itself off

during use

Battery flat-battery needs to be recharged.

Suspension Meter Displays

“Battery Flat”

Battery flat-battery needs to be recharged.

Suspension Meter displays Clock

failed

The in-built clock has failed. It might be an electronic

fault, or the unit needs to be recalibrated. Please return

unit for servicing & inspection.

Page 28

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 25

6 WARRANTY

AutoTest Products Pty Ltd or any Authorised AutoTest Service Centre warrants this product

against defects in material and workmanship for a period of 12 months from the original

date of purchase. This warranty applies only to products and components supplied by

AutoTest Products which can be identified by the trade name or logo affixed to them or by

other documents. AutoTest Products does not warrant any products not supplied by

AutoTest Products.

During the warranty period, AutoTest Products or any Authorised Service Centre will repair

(or at its option replace) any defective component(s) without charge for parts or labour,

provided the product is returned freight prepaid to an authorised AutoTest Service Centre.

Transit insurance and return freight will be at the owner’s expense.

In order to obtain calibration, warranty or non-warranty service, ship the product, freight

and insurance prepaid go to your nearest AutoTest Service Centre. Attach to the product

your name, address, contact phone numbers, description of the problem and if a warranty

claim, proof of purchase (dated sales receipt or invoice).

AutoTest Products or any Authorised AutoTest Service Centre reserves the right to refuse

warranty repair if accident, abuse, misuse or misapplication has damaged the product. In

transit or as a result of service or modification by other than an Authorised Service Centre,

nor are any other warranties expressed or implied, including any regarding merchantability

or fitness for any other particular purpose.

AutoTest Products or any Authorised Service Centre is not responsible for incidental or

consequential damages resulting from the breach of any express or implied warranty,

including damage to property and, to the extent permitted by law, damages for personal

injury.

Page 29

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 26

7 AUTHORISED SERVICE AGENTS:

AUSTRALIA

AutoTest Products

61-63 parsons St, Kensington, Victoria 3031

Australia. Phone: +61 3 88403016.

CHINA

Itach Autotech Corp

Room 703 Building A,Guo Run Commercial Plaza, No.46 West,. Feng Tai District, Beijing

100073

PH: (+10) 8365 9442

DENMARK

BM Autoteknik A/S

Erhvervsparken 7, 9632 Moldrup,

PH: (+ 45) 8669 2022

FRANCE

Actia Muller Services

Rue Des Tourneballets, Luce,

PH: (+332) 3733 3536

FRENCH POLYNESIA

Cogicat snc.

51 Rue Des Remparts Prolongee, B.P 2828, Papeete, TAHITI, 98 713

PH: (+ 6) 8942 8175

MACEDONIA

Velmar d.o.o.

Gjorce Petrov 10, 1000 Skopje, Makedonija.

PH: (+389) 2204 0288

MALAYSIA

Tritech Safety Sdn Bdn

No38, 2nd Floor, Jalan Pandan Indah, Kawasan Industri Ampang Tambahan, 68000

Ampang, Selangor D.E.

PH: (+603) 4291 0988

NEW ZEALAND

Brake & Transmission NZ

21-27 Omega St., Albany, Auckland

PH: (+ 64) 9414 3205

SOUTH AFRICA

Brakecore Supply Co

5 Oosthuise St, Ermelo, 2350.

PH: (+271) 7819 3412

Page 30

AUTOSTOP™ Suspension Meter - User Manual v3.01 Page 27

UNITED KINGDOM

Tecalemit Garage Equip. Co. Ltd

Unit 2,Eagle Road, Langage Bus Pk., Plympton, Plymoth, Devon, PL7 5JY

PH: (+017) 5221 9150

UNITED STATES OF AMERICA

Commercial Vehicle Consultants Inc.

144 Overlook Ave, Staten Island, NEW YORK, 10304.

PH: (+171) 8980 3651

Page 31

AUTO

TEST

Products Pty Ltd

61-63 Parsons St Kensington VIC 3031 Australia

Phone: (+61 3) 8840 3000 Sales:(+61 3) 8840 3017

Service: (+61 3) 8840 3016 Fax: (+61 3) 8840 3099

Email: service@autotest.net.au info@autotest.net.au

Email: sales@autotest.net.au www.autotest.net.au

Loading...

Loading...