Autoquip TORKLIFT User Manual

INSTALLATION, OPERATION

AND SERVICE MANUAL

TORK LIFT

T1 – Models

P.O. Box 1058 1058 West Industrial Avenue Guthrie, OK 73044-1058 888-811-9876

405-282-5200 FAX: 405-282-3302 www.autoquip.com

Item #830AMT Version 2.0

April, 2010

TABLE OF CONTENTS

Identification and Inspection 3

Responsibility of Owners / Users 4

Safety Signal Words 5

Safety Practices 6

Label Identification 10

Specifications 13

Lift Blocking Instructions 16

Installation Instructions 19

Operating Instructions 24

Routine Maintenance 25

General Maintenance 27

Replacement Parts List 35

Troubleshooting Analysis 38

Warranty 42

IMPORTANT

Please read and understand this manual prior to installation or operation of this lift.

Failure to do so could lead to property damage and/or serious personal injury. If any

questions arise, call a local representative or Autoquip Corporation at 1-888-811-9876

or 405-282-5200.

Please record the following information and refer to it when calling your dealer or

Autoquip.

Model Number:________________Serial Number: ___________________

Installation Date _____/_____/_____

2

IDENTIFICATION & INSPECTION

IDENTIFICATION

When ordering parts or requesting information or service on this lift, PLEASE REFER

TO THE MODEL AND SERIAL NUMBER. This information is on a nameplate attached

to the leg assembly. Replacement parts are available from a local Autoquip distributor.

INSPECTION

Immediately upon receipt of the lift, a visual inspection should be made to determine

that it has not been damaged in transit. Any damage found must be noted on the

delivery receipt. In addition to this preliminary inspection, the lift should be carefully

inspected for concealed damage. Any concealed damage found that was not noted on

the delivery receipt should be reported in writing to the delivering carrier within 48 hours.

3. After installation, raise the lift and inspect the base frame, platform, scissors

The following is a checklist that will aid you in the inspection of this lift:

1. Examine entire unit for any signs of mishandling. Pay special attention to the

power unit and PUSH BUTTONS.

2. Thoroughly examine all connections, making sure they have not vibrated loose

during transit, and inspect wiring for any signs of damage.

assembly, and cylinder plumbing connections.

PLANNED MAINTENANCE PROGRAM

A local Autoquip representative provides a Planned Maintenance Program (PMP) for

this equipment using factory-trained personnel. Call a local representative or Autoquip

Corporation at 1-888-811-9876 or 405-282-5200 for more information.

3

RESPONSIBILTY OF OWNERS/USERS

DEFLECTION

It is the responsibility of the user/purchaser to advise the manufacturer where deflection

may be critical to the application.

INSPECTION & MAINTENANCE

The lift shall be inspected and maintained in proper working order in accordance with

Autoquip’s operating/maintenance (O&M) manual and with other applicable safe

operating practices.

REMOVAL FROM SERVICE

Any lift not in safe operating condition such as, but not limited to, excessive leakage,

missing rollers, pins, or fasteners, any bent or cracked structural members, cut or frayed

electric, hydraulic, or pneumatic lines, damaged or malfunctioning controls or safety

devices, etc. shall be removed from service until it is repaired to the original

manufacturer’s standards.

REPAIRS

All repairs shall be made by qualified personnel in conformance with Autoquip’s

instructions.

OPERATORS

Only trained personnel and authorized personnel shall be permitted to operate the lift.

BEFORE OPERATION

Before using the lift, the operator shall have:

Read and/or had explained, and understood, the manufacturer’s operating

instructions and safety rules.

Inspected the lift for proper operation and condition. Any suspect item shall be

carefully examined and a determination made by a qualified person as to

whether it constitutes a hazard. All items not in conformance with Autoquip’s

specification shall be corrected before further use of the lift.

DURING OPERATION

The lift shall only be used in accordance with Autoquip’s O&M manual.

Do not overload the lift.

Ensure that all safety devices are operational and in place.

Autoquip warrants this lift for 60,000 cycles each warranty year. This number of

cycles is meant to represent normal, single shift duty. Exceeding this number of

cycles shortens the life of the lift and the length of your warranty and indicates

that a more robust lift design for high cycle duty should have been requested.

MODIFICATIONS OR ALTERATIONS

Modifications or alterations to industrial lifting equipment shall be made only with written

permission of Autoquip. Autoquip does not foresee and does not anticipate

unauthorized modifications, and these changes or alterations are grounds for voiding all

warranties.

4

SAFETY SIGNAL WORDS

SAFETY ALERTS (Required Reading!)

The following SAFETY ALERTS are intended to create awareness of owners,

operators, and maintenance personnel of the potential safety hazards and the steps that

must be taken to avoid accidents. These same alerts are inserted throughout this

manual to identify specific hazards that may endanger uninformed personnel.

Identification of every conceivable hazardous situation is impossible. Therefore, all

personnel have the responsibility to diligently exercise safe practices whenever exposed

to this equipment.

____________________________________________________________

Identifies a hazardous situation, which, if not avoided, will result in death or

severe personal injury.

_____________________________________________________________

DANGER!

WARNING!

Identifies a hazardous situation, which, if not avoided, could result in death

or serious personal injury.

CAUTION!

Identifies a hazardous situation, which, if not avoided, may result in minor

or moderate personal injury.

_____________________________________________________________

NOTICE!

Indicates a potentially hazardous situation, which, if not avoided, may result

in property or equipment damage.

____________________________________________________________

5

SAFETY PRACTICES

Read and understand this manual and all labels prior to

operating or servicing the scissors lift. All labels are

provided in accordance with ANSI Z535.4.

DANGER!

Do not work under lift without Maintenance Device! To avoid personal

injury, NEVER go under the lift platform until the load is removed and the

scissors mechanism is securely blocked in the open position. See "Lift

Blocking Instructions" section.

DANGER!

To avoid personal injury, stand clear of scissors mechanism while the lift is

in motion.

Do not install the lift in a pit unless it has a bevel toe guard or other

approved toe protection. A shear point can exist which can cause severe

injury to the foot.

DANGER!

DANGER!

HIGH VOLTAGE!! Disconnect and/or lock out the electrical supply to the power

unit prior to any maintenance being performed.

6

SAFETY PRACTICES

DANGER!

Scissors lifts are designed individually for a specific load and application.

To avoid personal injury, do not change the load or application from the

original design.

WARNING!

NEVER stand, sit or ride on the lift!

WARNING!

All warning and information decals should be in place as outlined in the

“Label Identification” section. If decals are missing or damaged, they

should be replaced with new ones. Contact Autoquip for replacements.

WARNING!

Do not attempt to remove the velocity fuse until the maintenance block

securely supports the lift and all hydraulic pressure has been removed from

the lifting cylinders and hydraulic hoses. Failure to do so could results in

personal injury or death!

WARNING!

Lift platforms traveling below floor levels may create openings, and the

shape of the load and how the load is arranged on the lift may create a toe

hazard as the load passes the top edge of the pit. Both situations may

require guarding in accordance with Federal Regulations. Any such

guarding must be installed prior to operating the lift.

7

SAFETY PRACTICES

WARNING!

The hydraulic velocity fuse (HVF) must be properly installed! The HVF

is attached to the elbow fitting in the rod port of the cylinder. Do not use a

swivel fitting between the HVF and cylinder. If the HVF is installed

improperly, it will not lock up in the event of a catastrophic hydraulic line

break.

WARNING!

Use properly rated hoses only! Never use fittings or hoses that are not

properly rated for the intended use.

WARNING!

Never exceed the rated capacity of the lift! Overloading, or uneven

loading, could result in load instability and cause serious personal injury.

CAUTION!

Any time that the velocity fuses have been tripped, owner must investigate

the cause of the trip and ensure any necessary corrective actions have

been taken prior to resumption of normal lift operation. Failure to do so

could result in personal injury or equipment damage.

CAUTION!

Spilled hydraulic fluid is very slippery, and may also present a fire hazard.

Clean up all spilled hydraulic fluid to prevent personal injury or equipment

damage.

8

SAFETY PRACTICES

NOTICE!

Do not continue to depress the “UP” button on the controller if the lift is not

raising or if the lift has reached the fully raised position. To do so may

result in permanent damage to the motor or pump.

NOTICE!

Never run the pump for more than a couple of seconds without pumping oil.

This applies to low oil conditions, improper motor rotation, running the

pump against the relief pressure after the lift is fully raised against the

physical stops, running overloaded beyond capacity, or running at reduced

speed because of pinched or obstructed hydraulic lines.

NOTICE!

Do not operate the power unit on relief for more than a few seconds. When

on relief, the valve will make a squealing sound.

NOTICE!

Precautions should be taken to prevent the introduction of contaminates

such as dirt or other foreign material into the system through open fittings,

pipes or disassembled components. Contamination will ruin the hydraulic

system.

NOTICE!

Use only approved oils in the lift. See “Specifications” section.

9

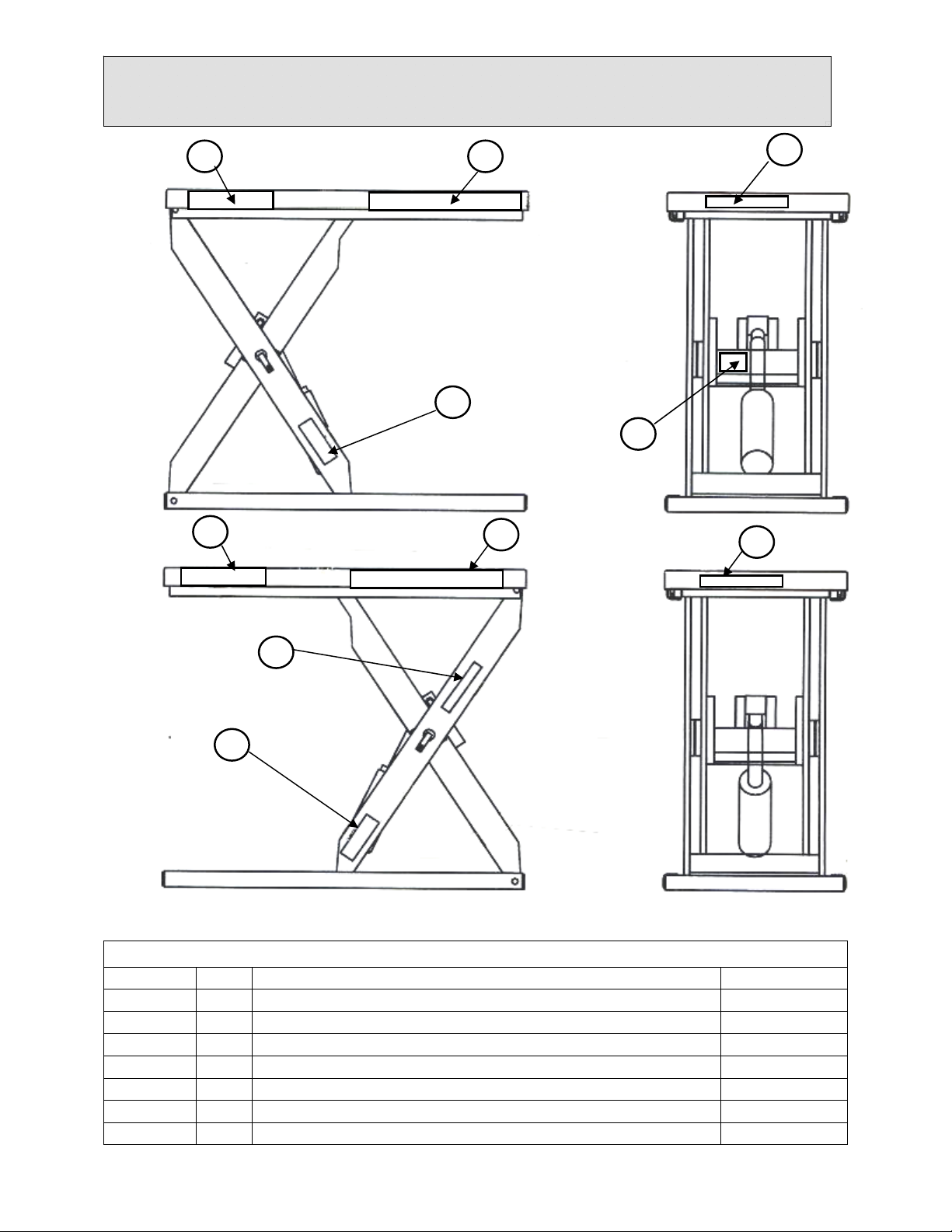

LABEL IDENTIFICATION

2 6

5

1

4

6

2

5

3

1

Figure 1 Label Placement

Tork Lift

Item No. Qty Description Part No.

1 2 Caution – Familiarize Yourself With Operators Manual 36401487

2 4 Danger – Do Not Put Hands or Feet . . . 36430050

3 1 Autoquip Serial Number Nameplate 36401560

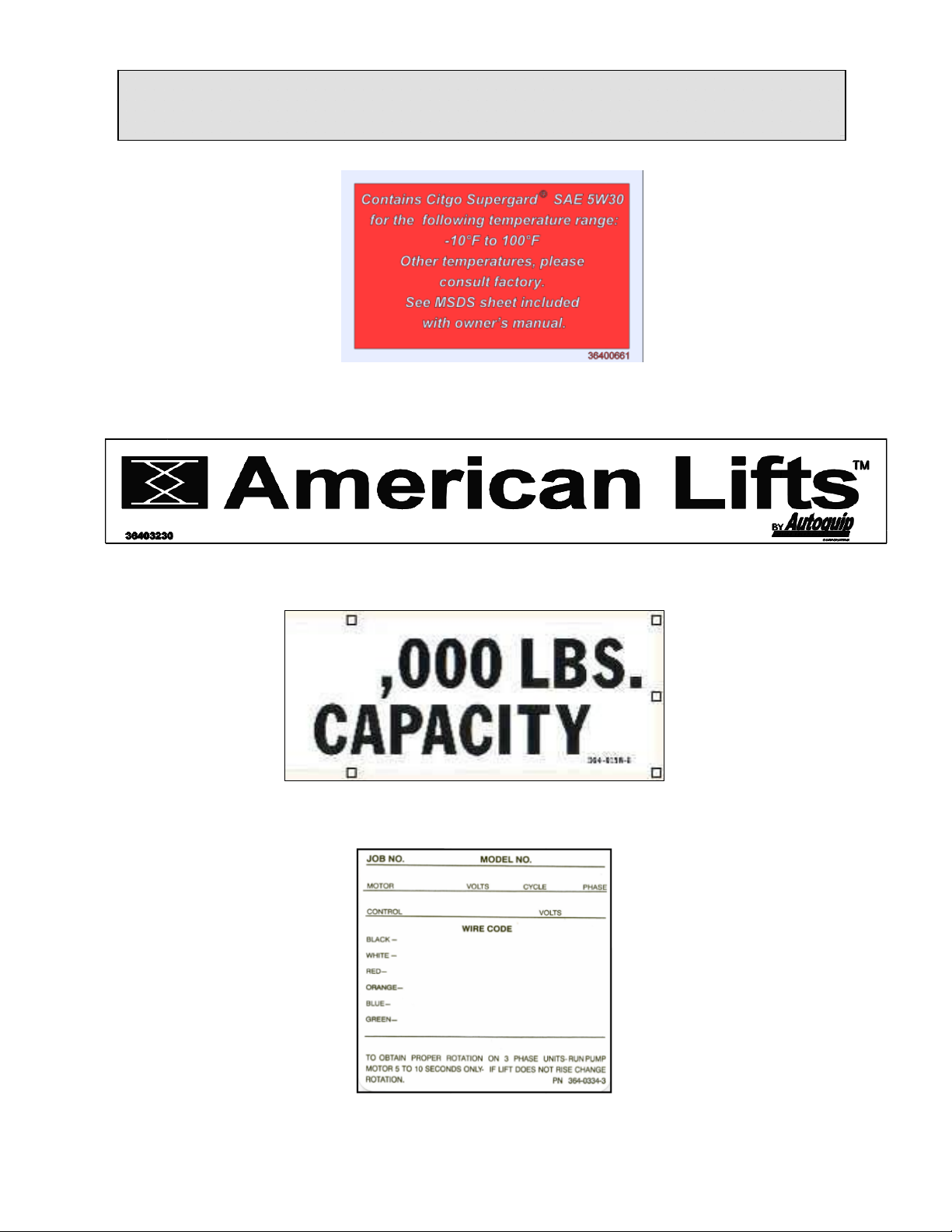

4 1 Fill with Recommended Oils Only 36400661

5 2 American Lifts by Autoquip 36403230

6 2 Capacity 36401586M

7 1 Wire Code Identification 36403343

10

LABEL IDENTIFICATION

Note: Labels shown here are not actual size.

Figure 3 Label 36401487

Figure 4 Label 36430050

Figure 5 Label 36401560

11

LABEL IDENTIFICATION

Figure 6 Label 36400661

Figure 7 Label 36403230

Figure 8 Label 36401586M

Figure 9 Label 36403343

12

Tork

Model

Capacity

(Lbs.)

Raised

Height

(In.)

Max

End

Load

(Lbs.)

Max

Side

Load

(Lbs.)

SPECIFICATIONS

Travel

(In.)

Lowered

Height

(In.)

Std Min.

Platform

(In.)

Raise

Time

(sec)

No

of

Cyl

Ship

Wt.

(Lbs.)

T36-022

T36-044

T36-060

T1-36-080

T1-36-100

T1-36-120

T1-36-160

T1-36-300

T1-48-020

T1-48-040

T1-48-060

T1-48-080

T1-48-100

T1-48-120

T1-48-160

2200 36 6.5 42.5 1100 1100 24 x 48 40 1 525

4400 36 6.5 42.5 2200 2200 24 x 48 32 2 600

6000 36 7 43 3000 3000 24 x 48 35 2 650

8000 36 12 48 4000 4000 48 x 61 43 2 2150

10000 36 14 50 5000 5000 36 x 64 47 2 2600

12000 36 14 50 6000 6000 36 x 64 47 2 2800

16000 36 16 52 8000 8000 36 x 72 39 2 3000

30000 36 18 54 15000 15000 24 x 80 60 4 3200

2000 48 8 56 1000 1000 30 x 72 55 1 1200

4000 48 8 56 2000 2000 30 x 72 40 2 1250

6000 48 9 57 3000 3000 30 x 72 52 2 1350

8000 48 13.25 61.25 4000 4000 32 x 80 70 2 3200

10000 48 15 63 5000 5000 42 x 82 70 2 3600

12000 48 16 64 6000 6000 42 x 82 70 2 3600

16000 48 16 64 8000 8000 42 x 82 97 3 3600

T1-48-200

T1-48-300

T1-60-025

T1-60-040

T1-60-060

T1-60-090

T1-60-120

T1-60-160

T1-60-200

T1-60-300

T1-72-020

T1-72-040

T1-72-060

20000 48 16 64 10000 10000 42 x 82 97 3 4400

30000 48 18 66 15000 15000 44 x 84 46 4 6000

2500 60 9.75 69.75 1250 1250 50 x 98 40 2 2100

4000 60 9.75 69.75 2000 2000 48 x 84 40 2 2100

6000 60 11.75 71.75 3000 3000 56 x 102 80 2 2300

9000 60 14.5 74.5 4500 4500 56 x 102 80 2 3200

12000 60 14.5 74.5 6000 6000 56 x 102 80 2 4000

16000 60 15.5 75.5 8000 8000 64 x 104 80 4 5000

20000 60 15.5 75.5 10000 10000 64 x 104 80 4 5600

30000 60 18.5 78.5 15000 15000 64 x 104 75 4 6300

2000 72 9.75 81.75 1000 1000 48 x 110 64 2 2300

4000 72 11.25 83.25 2000 2000 48 x 110 45 1 2600

6000 72 12.75 84.75 3000 3000 48 x 110 80 2 3400

13

Loading...

Loading...