Autoquip PDQ DOCK LIFT User Manual

INSTALLATION, OPERATION

AND SERVICE MANUAL

PDQ PORTABLE DOCK

SCISSORS LIFT

P.O. Box 1058 • 1058 West Industrial Avenue • Guthrie, OK 73044-1058 • 405-282-

5200 • FAX: 405-282-8105 • www.autoquip.com

Item # 830PDQ Version 1.0

09/2001

TABLE OF CONTENTS

Identification and Inspection 3

Dangers, Warnings, and Cautions 4

Label Identification 8

Specifications 11

Lift Blocking Instructions 13

Installation Instructions 15

Operating Instructions 16

Routine Maintenance 19

General Maintenance 21

Replacement Parts List 31

Troubleshooting Analysis 33

IMPORTANT

Please read and understand this manual prior to installation or operation of this lift.

Failure to do so could lead to property damage and/or serious personal injury. If

questions arise, call a local representative or Autoquip Corporation at 1-888-811-9876

or 405-282-5200.

PLANNED MAINTENANCE PROGRAM

A local Autoquip representative provides a Planned Maintenance Program (PMP) for

this equipment using factory-trained personnel. Call a local representative or Autoquip

Corporation at 1-888-811-9876 or 405-282-5200 for more information.

2

IDENTIFICATION & INSPECTION

IDENTIFICATION

When ordering parts or requesting information or service on this lift, PLEASE REFER

TO THE MODEL AND SERIAL NUMBER. This information is on a nameplate attached

to the leg assembly. Replacement parts are available from a local Autoquip distributor.

INSPECTION

Immediately upon receipt of the lift, a visual inspection should be made to determine

that it has not been damaged in transit. Any damage found must be noted on the

delivery receipt. In addition to this preliminary inspection, the lift should be carefully

inspected for concealed damage. Any concealed damage found that was not noted on

the delivery receipt should be reported in writing to the delivering carrier within 48 hours.

The following is a checklist that will aid you in the inspection of this lift:

1. Examine entire unit for any signs of mishandling. Pay special attention to the power

unit and pushbuttons.

2. Thoroughly examine all connections, making sure they have not vibrated loose

during transit, and inspect wiring for any signs of damage.

3. After installation, raise the lift and inspect the base frame, platform, scissors

assembly, and cylinder plumbing connections.

3

DANGERS, WARNINGS & CAUTIONS

SAFETY ALERTS (Required Reading!)

The following SAFETY ALERTS are intended to create awareness of owners,

operators, and maintenance personnel of the potential safety hazards and the steps that

must be taken to avoid accidents. These same alerts are inserted throughout this

manual to identify specific hazards that may endanger uninformed personnel.

Identification of every conceivable hazardous situation is impossible. Therefore, all

personnel have the responsibility to diligently exercise safe practices whenever exposed

to this equipment.

____________________________________________________________

DANGER!

Identifies a hazardous situation that presents the imminent probability of

death or of severe personal injury!!

_____________________________________________________________

WARNING!

Identifies a hazardous situation that has the potential of causing death or

serious personal injury.

CAUTION!

Identifies a hazardous situation that could lead to the possibility of personal

injury of death, and/or may result in equipment damage.

_____________________________________________________________

4

DANGERS, WARNINGS & CAUTIONS

Read and understand this manual and all labels prior to operating or

servicing the lift. All labels are provided in accordance with ANSI

Z535.4.

DANGER!

Do not work under lift without maintenance device! To avoid personal

injury, NEVER go under the lift platform until the load is removed and the

scissors mechanism is securely blocked in the open position. See "Lift

Blocking Instructions" section.

DANGER!

To avoid personal injury, stand clear of scissors leg mechanism while lift is

in motion.

DANGER!

Do not install the lift in a pit unless it has a bevel toe guard or other

approved toe protection. A shear point can exist which can cause severe

injury to the foot.

DANGER!

HIGH VOLTAGE!! Disconnect and/or lock out the electrical supply to the

power unit prior to any maintenance being performed.

5

DANGERS, WARNINGS & CAUTIONS

DANGER!

Extending the platform length or width beyond the factory limit could cause

the unit to tip, which could result in personal injury or death.

DANGER!

Do not attempt to remove the velocity fuse until the maintenance locks

securely support the lift and all hydraulic pressure has been removed from

the lifting cylinders and hydraulic hoses. Failure to do so could result in

personal injury or death!

WARNING!

Do not operate this equipment without handrails and snap chains in place.

WARNING!

Under no circumstances should the speed control orifice be removed from

the Deltatrol to obtain faster lowering speed. A loaded lift can reach

dangerous and destructive speed!!

WARNING!

All warning and information decals should be in place as outlined in the

“Label Identification” section. If decals are missing or damaged, they

should be replaced with new ones. Contact an Autoquip representative for

replacements.

6

DANGERS, WARNINGS & CAUTIONS

CAUTION!

Never run the pump for more than a couple of seconds without pumping oil.

This applies to low oil conditions, improper motor rotation, running the

pump against the relief pressure after the lift is fully raised against the

physical stops, running overloaded beyond capacity, or running at reduced

speed because of pinched or obstructed hydraulic lines.

CAUTION!

Do not continue to depress the “UP” button on the controller if the lift is not

raising or if the lift has reached the fully raised position. To do so may

result in permanent damage to the motor or pump.

CAUTION!

Do not operate the power unit on relief for more than a few seconds. When

on relief, the valve will make a squealing sound.

CAUTION!

Precautions should be taken to prevent the introduction of

contaminates such as dirt or other foreign material into the system through

open fittings, pipes or disassembled components. Contamination will ruin

the hydraulic system.

CAUTION!

Use only approved oils in the lift. See “Specifications” section.

7

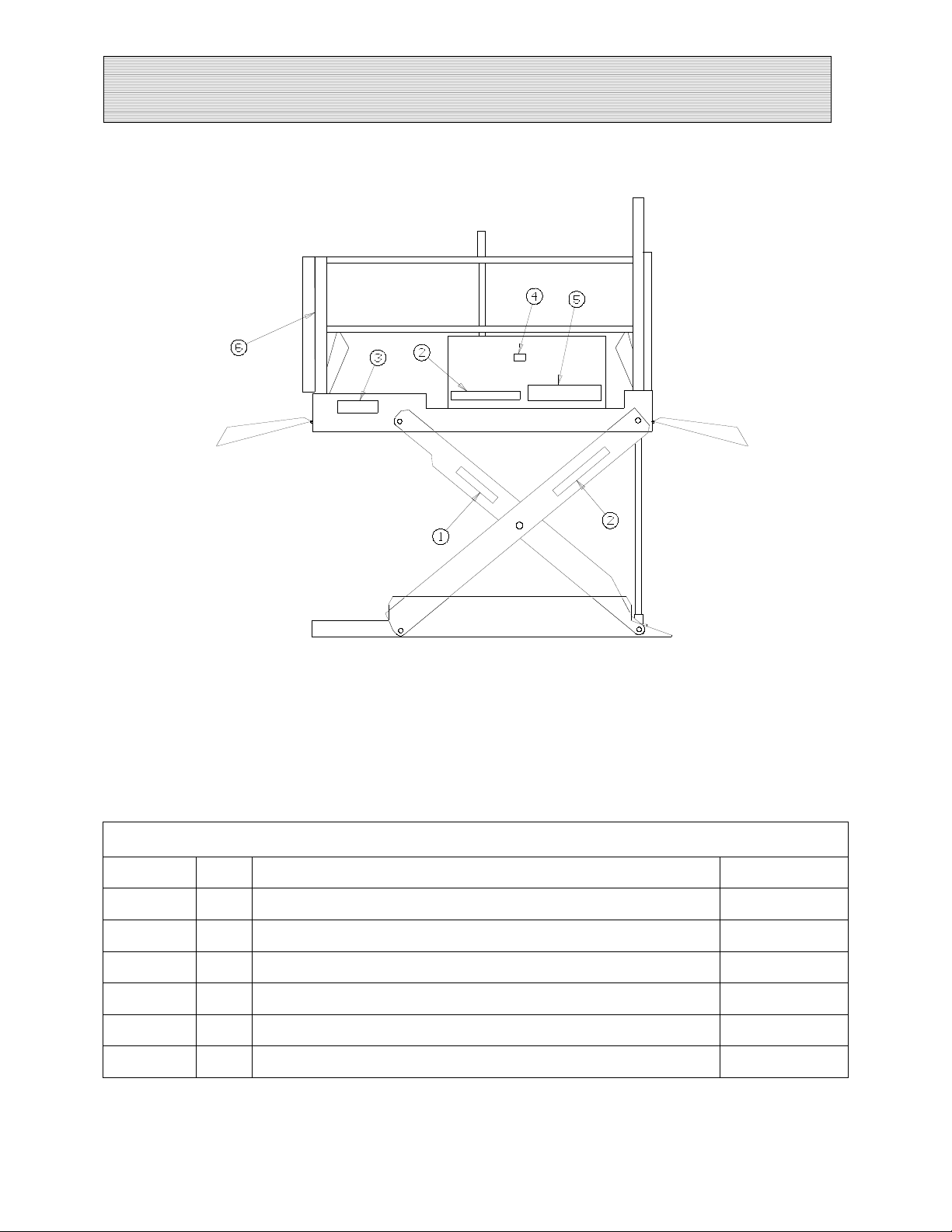

LABEL IDENTIFICATION

Figure 1 Label Placement

PDQ Scissors Lift

Item No. Qty Description Part No.

1 2 Caution: Familiarize Yourself With Operators Manual 36401487

2 3 Danger – Do Not Put Hands Or Feet . . . 36430050M

31Autoquip Serial Number Nameplate 36401511

4 1 Fill with Recommended Oils Only 36400661

5 1 Capacity 36401594

6 1 Black & Yellow Striped Tape 06100010

8

LABEL IDENTIFICATION

Note: Labels shown here are not actual size.

Figure 2 Label 36401487

CUT LINE

Figure 3 Label 36430050M

Figure 4 Label 36401511

9

LABEL IDENTIFICATION

Figure 5 Label 36400661

Figure 6 Label 36401594

Figure 7 Label 06100010

10

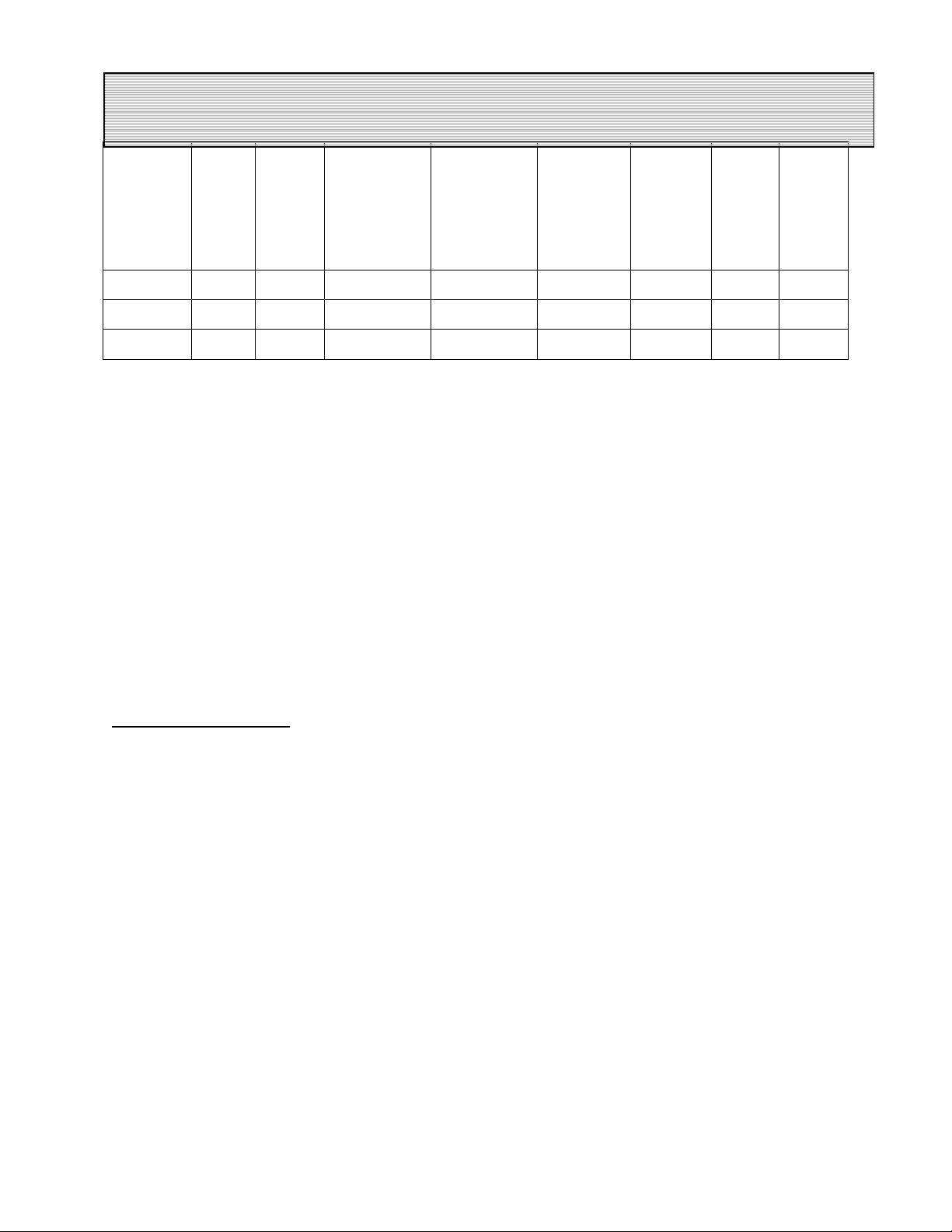

SPECIFICATIONS

*Model Low.

Ht.

(In.)

PDQ-40 4 1/2 4,000 2,000 2,000 60 x 80 76 x 84 55 1/2 2,700

PDQ-50 4 1/2 5,000 3,000 3,000 60 x 80 76 x 84 55 1/2 2,800

PDQ-60 4 1/2 6,000 3,000 3,000 60 x 80 76 x 84 55 1/2 2,900

Lift

Cap

(lbs)

Axle Load

Capacity

Over

Bridge

End

(lbs)

Axle Load

Capacity

Opposite

Bridge

End

(lbs)

Platform

Size

(In)

Base

Frame

Size

(In)

Max

Travel

(In.)

Ship

Wt.

NOTE: All PDQ Models have a standard 5 HP motor (230/60/3) with a nominal standard

speed of 15 fpm, and have two rams.

All PDQ Scissors Lifts have a rollover capacity equal to twice the lifting capacity when in

the fully lowered position.

The PDQ can handle pallets, carats, electric walkie and hand trucks. Although the PDQ

is designed to unload freight, it can also be used for loading. Using a PDQ, one person

can load or unload a full trailer safely in 25 to 30 minutes, using a pallet jack.

LOAD CAPACITY

The load capacity rating is stamped on a metal plate attached to the lift. This figure is a

net capacity rating for a lift furnished with the standard platform. The relief valve of the

pumping unit has been set to raise the weight, plus a small amount for overload. Where

gravity roll-sections, special tops, etc, are installed on the lift after leaving the plant,

deduct the weight of these from the load rating to obtain the net capacity. Lifts should

not be overloaded beyond the established capacity as damage and/or personal

injury may result.

11

Loading...

Loading...