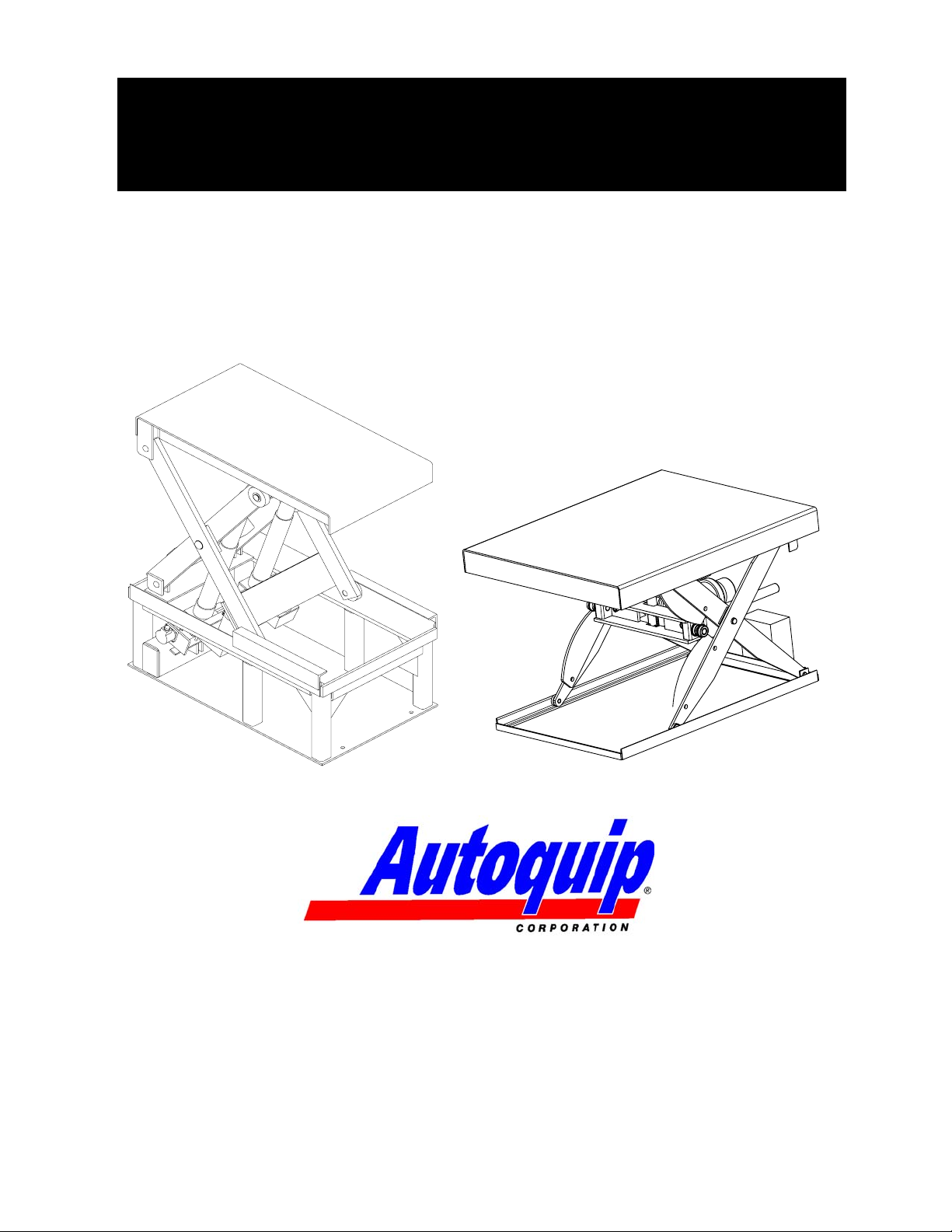

Autoquip HORIZONTAL BALL SCREW User Manual

V

INSTALLATION, OPERATION

AND SER

ICE MANUAL

MECHANICAL

SCISSORS LIFT

P.O. Box 1058 • 1058 West Industrial Avenue • Guthrie, OK 73044-1058 • 405-282-5200 •

FAX: 405-282-8105 • www.autoquip.com

Item # 830LA Version 1.0

09/2001

Identification and Inspection 3

Dangers and Warnings 4

Label Identification 8

Specifications 11

Lift Blocking Instructions 12

Installation Instructions 14

Operating Instructions 17

Routine Maintenance 18

General Maintenance 19

Replacement Parts List 21

Troubleshooting Analysis 22

IMPORTANT

Please read and understand this manual prior to installation or operation of this lift.

Failure to do so could lead to property damage and/or serious personal injury. If any

questions arise, call a local representative or Autoquip Corporation at 1-888-811-9876

or 405-282-5200.

PLANNED MAINTENANCE PROGRAM

A local Autoquip representative provides a Planned Maintenance Program (PMP) for

this equipment using factory-trained personnel. Call a local representative or Autoquip

Corporation at 1-888-811-9876 or 405-282-5200 for more information.

2

IDENTIFICATION & INSPECTION

IDENTIFICATION

When ordering parts or requesting information or service on this equipment, PLEASE

REFER TO THE MODEL AND SERIAL NUMBER. This information is on a nameplate

attached to the leg assembly. Replacement parts are available from a local Autoquip

distributor.

INSPECTION

Immediately upon receipt of the unit, a visual inspection should be made to determine

that it has not been damaged in transit. Any damage found must be noted on the

delivery receipt. In addition to this preliminary inspection, the unit should be carefully

inspected for concealed damage. Any concealed damage found that was not noted on

the delivery receipt should be reported in writing to the delivering carrier within 48 hours.

1. Examine the entire unit for any signs of mishandling.

2. Pay special attention to gearboxes, mechanical actuators & wiring.

3. After installation, raise and block the lift and inspect the base frame, scissors

The following is a checklist that will aid in the inspection of this equipment.

assembly and mechanical drive system. See the “Lift Blocking Instructions” section.

3

DANGERS, WARNINGS & CAUTIONS

SAFETY ALERTS (Required Reading!)

The following SAFETY ALERTS are intended to create awareness of owners,

operators, and maintenance personnel of the potential safety hazards and the steps that

must be taken to avoid accidents. These same alerts are inserted throughout this

manual to identify specific hazards that may endanger uninformed personnel.

Identification of every conceivable hazardous situation is impossible. Therefore, all

personnel have the responsibility to diligently exercise safe practices whenever exposed

to this equipment.

____________________________________________________________

DANGER!

Identifies a hazardous situation that presents the imminent probability of

death or of severe personal injury!!

_____________________________________________________________

WARNING!

Identifies a hazardous situation that has the potential of causing death or

serious personal injury.

CAUTION!

Identifies a hazardous situation that could lead to the possibility of personal

injury of death, and/or may result in equipment damage.

_____________________________________________________________

4

DANGERS, WARNINGS & CAUTIONS

Read and understand this manual and all labels prior to operating or

servicing the scissors lift. All labels are provided in accordance with

ANSI Z535.4.

DANGER!

Do not work under lift without Maintenance Device! To avoid personal injury, NEVER go under the lift platform until the load is removed and the scissors mechanism is securely blocked in the open position. See "Lift Blocking Instructions" section.

DANGER!

To avoid personal injury, stand clear of scissors mechanism while the lift is

in motion.

Do not install the lift in a pit unless it has a bevel toe guard or other

approved toe protection. A shear point can exist which can cause severe

injury to the foot.

HIGH VOLTAGE!! Disconnect and/or lock out the electrical supply to the

power unit prior to any maintenance being performed.

DANGER!

DANGER!

5

DANGERS, WARNINGS & CAUTIONS

DANGER!

Scissors lifts are designed individually for a specific load and application.

To avoid personal injury, do not change the load or application from the

original design.

WARNING!

NEVER stand, sit or ride on the lift!

WARNING!

All warning and information decals should be in place as outlined in the

“Label Identification” section. If decals are missing or damaged, they

should be replaced with new ones. Contact Autoquip for replacements.

WARNING!

Do not attempt to remove the drive mechanism until the maintenance locks

securely support the empty lift. Failure to do so could results in personal

injury or death!

WARNING!

Lift platforms traveling below floor levels may create openings, and the

shape of the load and how the load is arranged on the lift may create a toe

hazard as the load passes the top edge of the pit. Both situations may

require guarding in accordance with Federal Regulations. Any such

guarding must be installed prior to operating the lift.

.

6

DANGERS, WARNINGS & CAUTIONS

CAUTION!

When moving the lift, do not attempt to pick it up by the platform; it is

hinged and could be damaged. Pick up from under the base frame ONLY.

CAUTION!

Do not continue to activate the “UP” button if the lift is not raising or if it has

reached the fully raised position. To do so may result in permanent

damage to the lift.

CAUTION!

Precautions should be taken to prevent the introduction of contaminates

such as dirt or other foreign material into the drive system through open

fittings, pipes or disassembled components. Contamination will ruin the

drive mechanism.

7

Loading...

Loading...