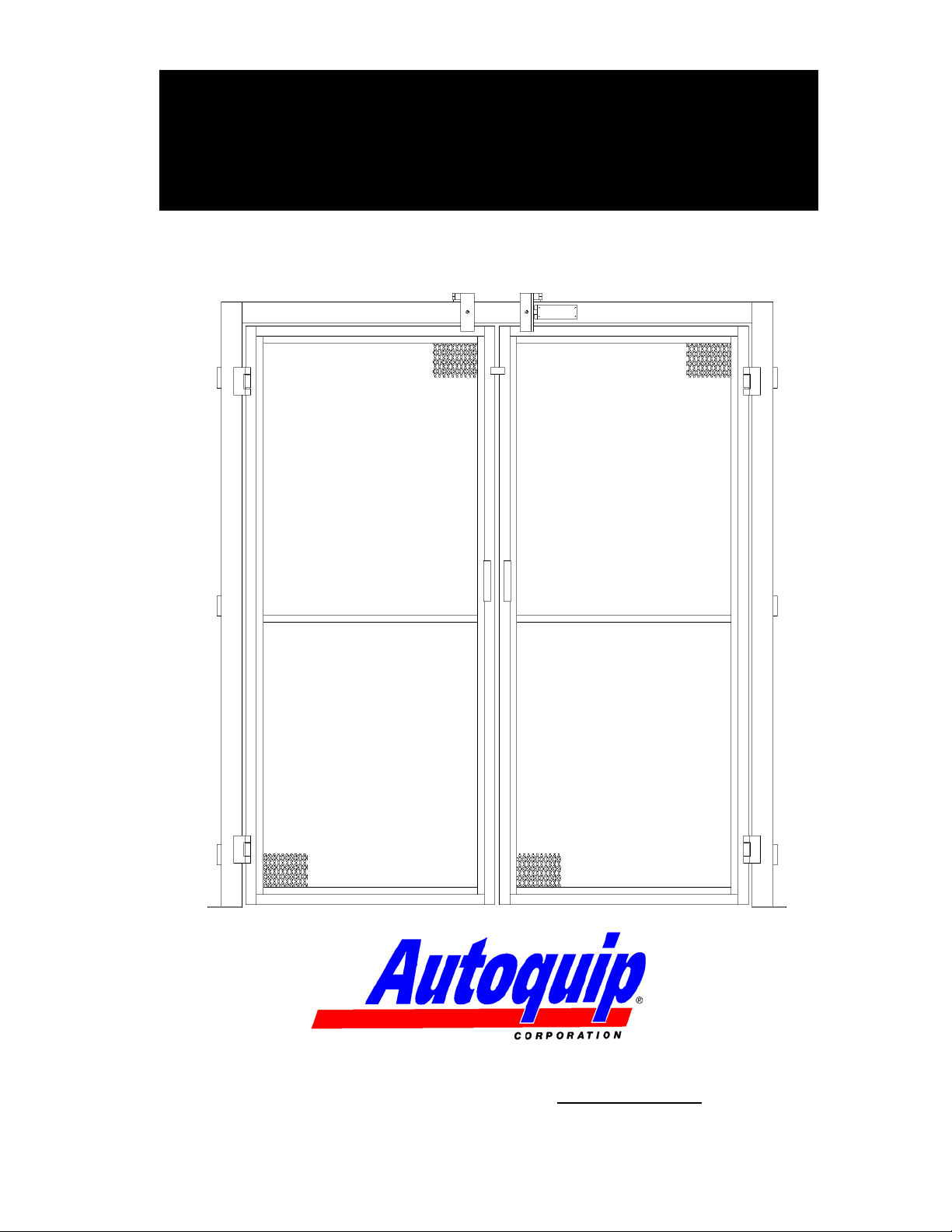

Autoquip GATES SWING User Manual

GATE & ENCLOSURE

INSTALLATION MANUAL

SWING GATES

P.O. Box 1058 • 1058 West Industrial Avenue • Guthrie, OK 73044-1058 • 888-811-9876 •

405-

282-5200 • FAX: 405-282-3302 • www.autoquip.com

Item # 830SG Version 2.0

01/2008

TABLE OF CONTENTS

Introduction 3

Inspection and Identification 4

Pre-Installation Site Visit 5

Responsibility of Owners/Users 6

Safety Signal Words 7

Safety Practices 8

Label Placement 10

Gate Installation Instructions 13

Enclosure Installation Instructions 33

Routine Maintenance 36

Replacement Parts List 37

Warranty 38

IMPORTANT

Please read and understand this manual prior to operation. If any questions should

arise, call a local representative or Autoquip Corporation at 1-888-811-9876 or 405-282-

5200.

PLANNED MAINTENANCE PROGRAM

A local Autoquip representative provides a Planned Maintenance Program (PMP) for

this equipment using factory-trained personnel. Call a local representative or Autoquip

Corporation at 1-888-811-9876 or 405-282-5200 for more information.

2

Autoquip Corporation has designed and manufactured these gates and enclosures to

conform to ANSI Standard B20.1b in order to provide personnel protection from moving

loads on the lift and to ensure safe access to the lift at every operating level. They have

been built to provide many years of dependable service and proper installation of this

equipment is vital to personnel safety. It is vital for the installers to read and

understand this manual! These instructions have been prepared and organized to

assist the installers and it is important for these individuals to carefully follow the steps

in the order they are presented!

Situations may arise which are not covered in these installation instructions. If you have

questions, please call Autoquip Customer Service at (405) 282-5200 or 1-888-811-

9876.

NOTE: Unless otherwise stated, mechanical installation does not include

unloading, permits, seismic calculations, or extensive acceptance testing. The

requirements of each contract should be carefully reviewed for possible conflicts

of interpretation.

INTRODUCTION

3

INSPECTION & IDENTIFICATION

The following items are typically shipped loose within each manually operated Vertical

Gate order:

A. Gate with posts, header, and expanded metal panel(s)

B. Interlock Kits

C. Misc. Gate Mounting Hardware, Manual, and Signs/Labels

D. Varies – Expanded Metal Enclosure Panels per General Arrangement Drawing

E. Varies – Enclosure Panel Mounting Tek-Screws, Top Caps, Corner Angles

NOTE: The “Bill of Lading” will state the number of pieces shipped. TWO ITEMS

MAY BE BANDED TOGETHER AND COUNT AS ONE PIECE.

Upon receipt of the shipment, check for exposed damage or shortages and make note

of it on the trucking company Bill of Lading or the Shipping Papers. Reports of

concealed damage to items contained in crates must be reported within 48 hours. DO

NOT destroy the crating while opening it to inspect the contents. If damage is

suspected or found, report it directly to the carrier. DO NOT contact Autoquip

Corporation!! All shipments are FOB from the Autoquip plant. Any claims for damage

must be filed with the carrier. Any parts shipped from Autoquip that are intended

to replace damaged or lost items will be invoiced to the ordering party.

Assuming no damage has occurred to the crate, check the components against the

packing list. This will provide assurance that every item shipped has been received.

Everything needed for the installation should be available. If not, report any shortages to

Autoquip Corporation within 10 days. (Autoquip is not responsible for parts lost, stolen

or damaged during transportation, storage, installation, or during any other

circumstances or conditions that may be beyond corporate control.)

Before beginning the installation process, look at the skid that the gates and enclosures

arrived on. Check for any damage and compare the packing list to the gates and

enclosures to ensure that everything is on hand. If there are any missing pieces,

contact Autoquip Product Support Team at (405) 282-5200.

4

PRE-INSTALLATION SITE VISIT

SITE CONDITIONS

Whenever possible, make a pre-installation visit or call someone at the site. Installers

must be familiar with everything relative to proper installation of this equipment. Some

concerns are listed below, though listing every affecting contingency is impossible. It is

the installer’s responsibility to check the site for problems and work out solutions with

the appropriate people. Some of the areas of concern are:

1. Is the site accessible?

2. Can the equipment get through the existing doorways, halls, and shaft openings?

3. How will the unit be raised, set into position, and accessed?

4. Can a chain fall be hooked to an available overhead support?

5. Is there a forklift available?

6. Is bracing required?

7. Look for problem areas such as bracing and overhead interference from ducts,

joists, and pipes.

It is always best to be prepared, so do as much pre-planning as possible before the

installation procedure actually begins. Learn about the site, the equipment, and the

installation process.

5

RESPONSIBILTY OF OWNERS/USERS

CODE COMPLIANCE

Ultimate responsibility for gaining state and local code approval is the responsibility of

the buyer of the VRC. Please acquaint yourself with the permitting and/or licensing

expenses and requirements of the local regulatory agencies in the installation area.

.

INSPECTION & MAINTENANCE

The gates & enclosures shall be inspected & maintained in proper working order in

accordance with Autoquip’s operating/maintenance (O&M) manual and with other

applicable safe operating practices.

REMOVAL FROM SERVICE

Any gate not in safe operating condition such as, but not limited to, missing parts or

fasteners, any bent or cracked structural members, cut or frayed electric lines, damaged

or malfunctioning controls or safety devices, etc. shall be removed from service until it is

repaired to the original manufacturer’s standards.

REPAIRS

All repairs shall be made by qualified personnel in conformance with Autoquip’s

instructions.

OPERATORS

Only trained and authorized personnel shall be permitted to operate the lift and gate.

BEFORE OPERATION

Before using the lift and gate, the operator shall have:

• Read and/or had explained, and understood, the manufacturer’s operating

instructions and safety rules.

• Inspected the lift for proper operation and condition. Any suspect item shall be

carefully examined and a determination made by a qualified person as to

whether it constitutes a hazard. All items not in conformance with Autoquip’s

specification shall be corrected before further use of the lift.

DURING OPERATION

The lift and gate shall only be used in accordance with Autoquip’s O&M manual.

• Do not overload the lift.

• Ensure that all safety devices are operational and in place.

MODIFICATIONS OR ALTERATIONS

Modifications or alterations to this equipment shall be made only with written permission

of Autoquip. Autoquip does not foresee and does not anticipate unauthorized

modifications, and these changes or alterations are grounds for voiding all warranties.

6

SAFETY SIGNAL WORDS

SAFETY ALERTS (Required Reading!)

The following SAFETY ALERTS are intended to create awareness of owners, operators,

and maintenance personnel of the potential safety hazards and the steps that must be

taken to avoid accidents. These same alerts are inserted throughout this manual to

identify specific hazards that may endanger uninformed personnel. Identification of

every conceivable hazardous situation is impossible. Therefore, all personnel have the

responsibility to diligently exercise safe practices whenever exposed to this equipment.

____________________________________________________________

DANGER!

Identifies a hazardous situation which, if not avoided, will result in death or

severe personal injury.

_____________________________________________________________

WARNING!

Identifies a hazardous situation which, if not avoided, could result in death

or serious personal injury.

CAUTION!

Identifies a hazardous situation which, if not avoided, may result in minor or

moderate personal injury.

_____________________________________________________________

CAUTION!

Caution used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in property or equipment

damage.

7

SAFETY PRACTICES

DANGER!

High voltage! May cause personal injury or death. Repairs should only

be performed by a qualified service/control technician!!

DANGER!

Qualified personnel only!! Only qualified service

personnel should perform procedures labeled as “da

ngerous”!

DANGER!

Be sure of equipment stability! To avoid personal injury or

death, check for stability. If the supports seem unstable, do not operate!

Contact Autoquip immediately!

DANGER!

Turn off power! To avoid personal injury or death, be sure

the power is off and is locked out per OSHA Lock-Out, Tag-Out

procedures!

DANGER!

Practice field safety procedures! To avoid personal injury or death,

utilize all applicable precautions for steel erection and equipment assembly

in addition to OSHA regulations for lock-out, tag-out, etc.!

8

SAFETY PRACTICES

WARNING!

Support all posts and components! Illustrations in this manual may show

them unsupported. This is done in order to make the equipment and its

installation clearly understood. Be sure to properly secure all gate posts

and panels to ensure a safe and stable installation.

WARNING!

Never run the unit with the gates or doors open! The gates must not

open when the lift is in operation or when the platform is not present.

Should this condition exist, the interlock is not functioning properly due to

incorrect installation or damage. This condition must be corrected

immediately. Failure to correct this condition may result in serious injury or

death.

WARNING!

Never operate unit when parts are defective! Do not operate this

equipment when substandard or defective parts are in use! Contact an

Autoquip Service Representative to rectify all such situations.

9

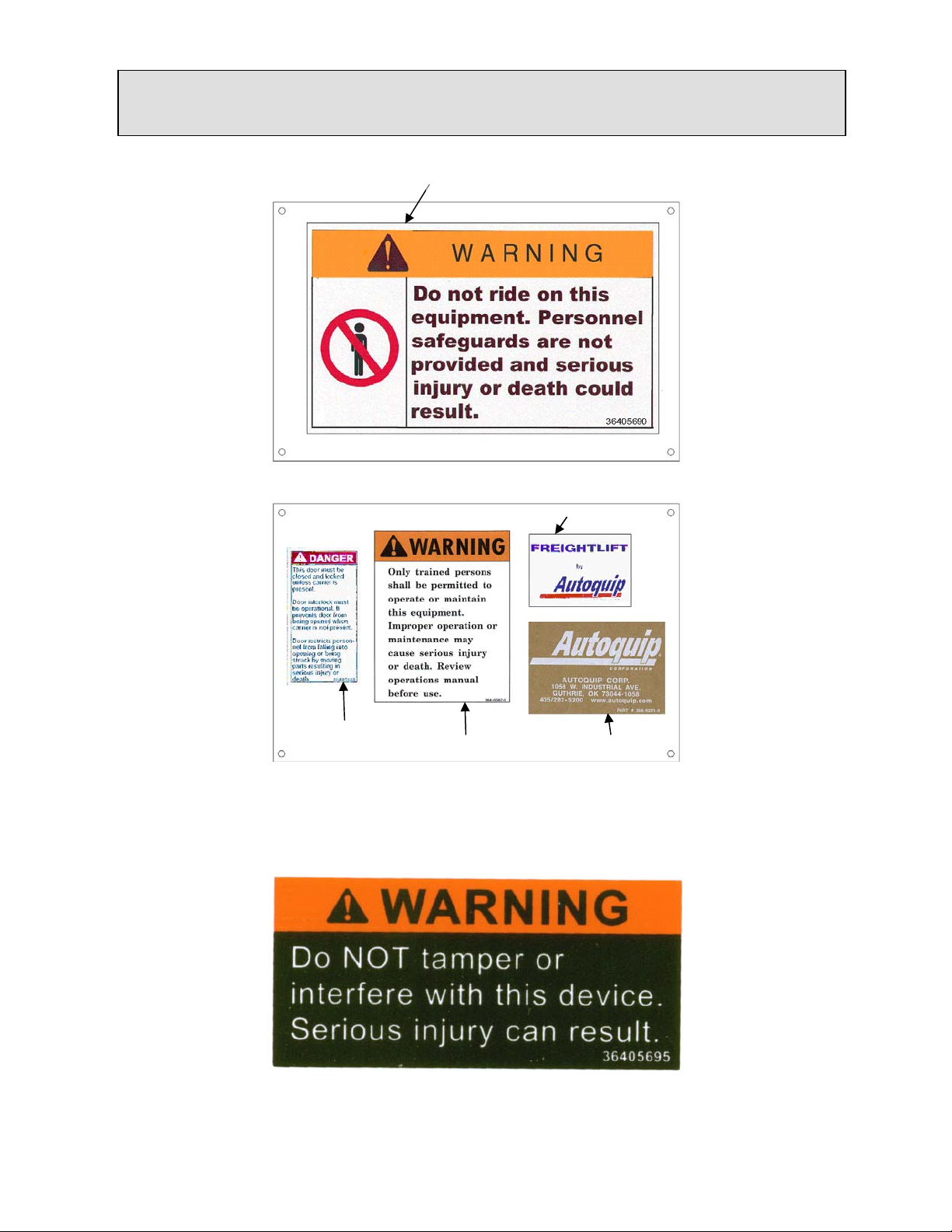

LABEL PLACEMENT

36405690

36402680

36405680

Figure 1 - Label Placement

36405670 36403210

Figure 2 – 36405695

10

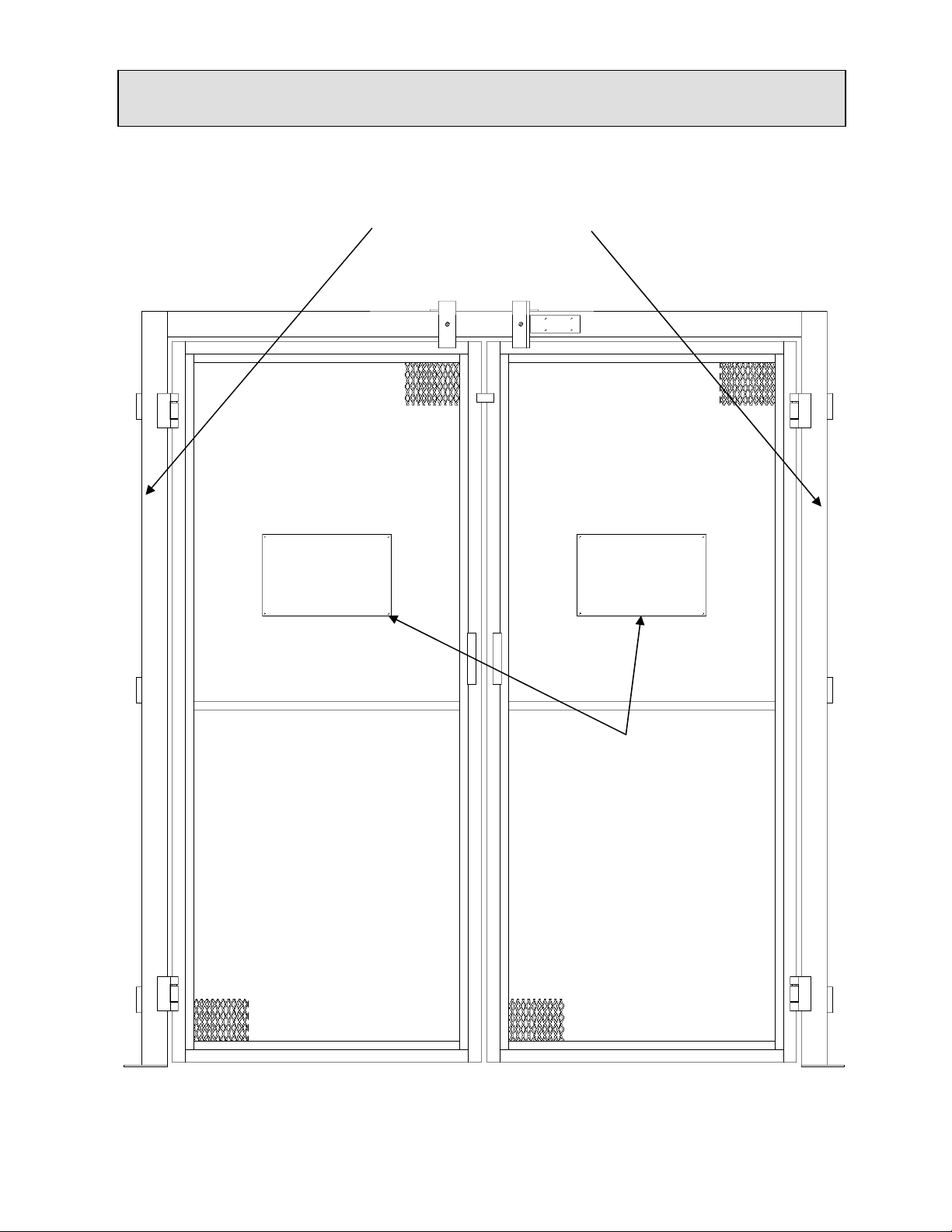

LABEL PLACEMENT

Additional 36405680

Decal installed on the

Gate Post, Same side

as the Push-Button

Station

Decal Plates shown in

Figure 1 should be

attached to gate in

this area with

hardware provided

Figure 3a – Bi-Part Gate Label Placement

11

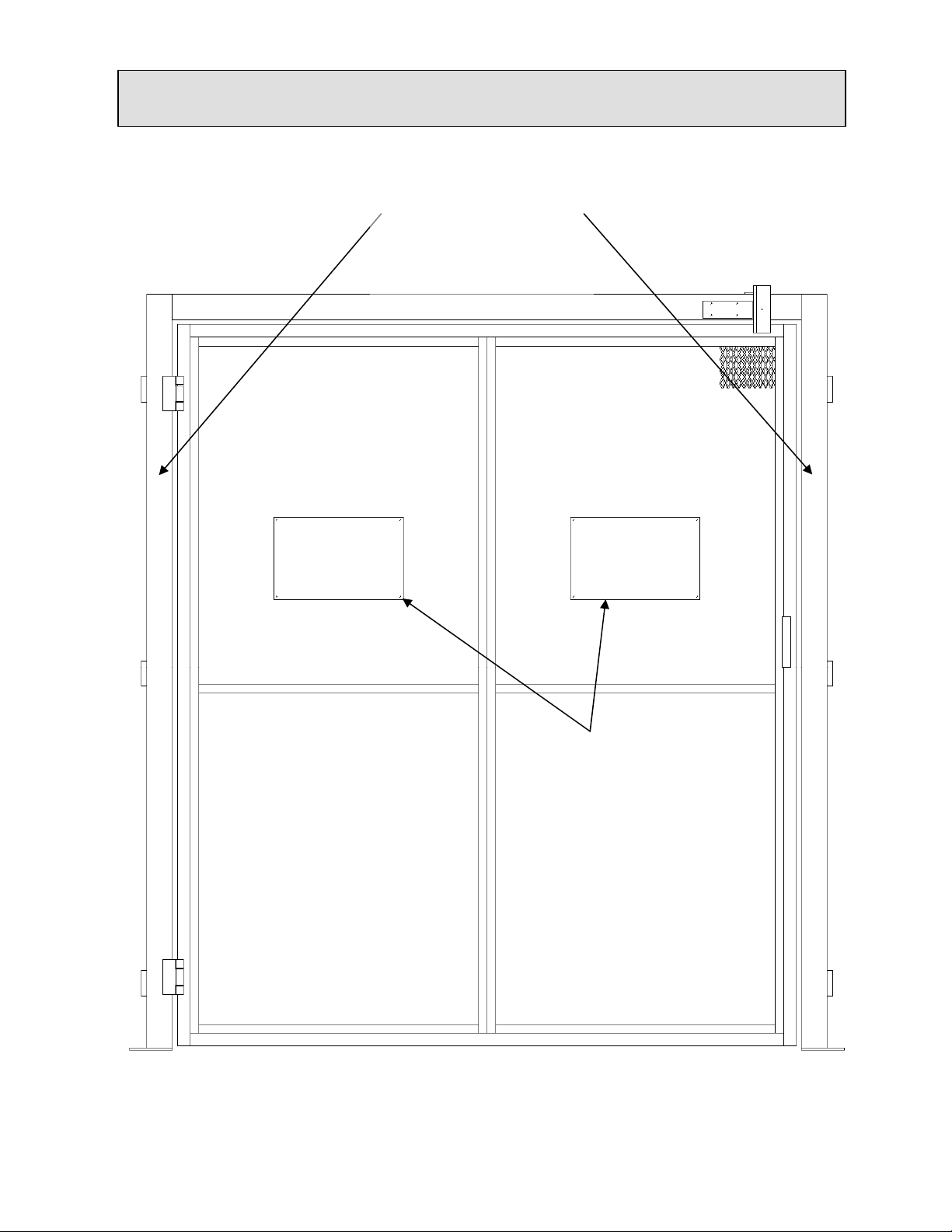

LABEL PLACEMENT

Additional 36405680

Decal installed on the

Gate Post, Same side

as the Push-Button

Station

Decal Plates shown in

Figure 1 should be

attached to gate in

this area with

hardware provided

Figure 3b – Single Swing Gate Label Placement

12

Loading...

Loading...