Autoquip DOUBLE PANTOGRAPH LIFT User Manual

INSTALLATION, OPERATION

AND SERVICE MANUAL

DOUBLE PANTOGRAPH

LIFT

P.O. Box 1058 • 1058 West Industrial Avenue • Guthrie, OK 73044-1058 • 888-811-9876 •

• 405-

Item #830DPL

Dec. 2011

Version 2.0

282-5200 • FAX: 405-282-3302 • www.autoquip.com

TABLE OF CONTENTS

Identification and Inspection 3

Responsibility of Owners/Users 4

Safety Signal Words 5

Safety Practices 6

Label Identification 11

Specifications 15

Lift Blocking Instructions 17

Installation Instructions 22

Operating Instructions 34

Routine Maintenance 35

General Maintenance 39

Replacement Parts List 56

Troubleshooting Analysis 67

Warranty 73

IMPORTANT

Please read and understand this manual prior to installation or operation of this lift. Failure

to do so could lead to property damage and/or serious personal injury. If questions arise,

call a local representative or Autoquip Corporation at 1-888-811-9876 or 405-282-5200.

2

IDENTIFICATION & INSPECTION

IDENTIFICATION

When ordering parts or requesting information or service on this lift, PLEASE REFER TO

THE MODEL AND SERIAL NUMBER. This information is on a nameplate attached to the

leg assembly. Replacement parts are available from a local Autoquip distributor.

LIFT MODEL No: _ _ _ _ _ _ _ LIFT SERIAL No: _ _ _ _ _ _ _ _

Date Purchased

INSPECTION

Immediately upon receipt of the lift, a visual inspection should be made to determine that

the lift has not been damaged in transit. Any damage found must be noted on the delivery

receipt. In addition to this preliminary inspection, the lift should be carefully inspected for

concealed damage. Any concealed damage found that was not noted on the delivery

receipt should be reported in writing to the delivering carrier within 48 hours.

3. After installation, raise the lift and inspect the base frame, platform, scissors

The following is a checklist that will aid in the inspection of the lift.

1. Examine entire unit for any signs of mishandling. Pay special attention to the power

unit and controls.

2. Thoroughly examine all connections, making sure they have not vibrated loose

during transit.

assembly, and cylinder plumbing connections.

LIFT DOCUMENTATION

: ___ /___ /___

PLANNED MAINTENANCE PROGRAM

A local Autoquip representative provides a Planned Maintenance Program (PMP) for this

equipment using factory-trained personnel. Call a local representative or Autoquip

Corporation at 1-888-811-9876 or 405-282-5200 for more information.

3

RESPONSIBILTY OF OWNERS/USERS

DEFLECTION

It is the responsibility of the user/purchaser to advise the manufacturer where deflection

may be critical to the application.

INSPECTION & MAINTENANCE

The lift shall be inspected & maintained in proper working order in accordance with this

manual and with other applicable safe operating practices.

REMOVAL FROM SERVICE

Any lift not in safe operating condition such as, but not limited to, excessive leakage,

missing rollers, pins, or fasteners, any bent or cracked structural members, cut or frayed

electric, hydraulic, or pneumatic lines, damaged or malfunctioning controls or safety

devices, etc. shall be removed from service until it is repaired to the original manufacturer’s

standards.

REPAIRS

All repairs shall be made by qualified personnel in conformance with Autoquip’s

instructions.

OPERATORS

Only trained personnel and authorized personnel shall be permitted to operate the lift.

BEFORE OPERATION

Before using the lift, the operator shall have:

• Read or have explained, and understood, the manufacturer’s operating instructions

and safety rules.

• Inspected the lift for proper operation and condition. Any suspect item shall be

carefully examined and a determination made by a qualified person as to whether it

constitutes a hazard. All items not in conformance with Autoquip’s specification shall

be corrected before further use of the lift.

DURING OPERATION

The lift shall only be used in accordance with Autoquip’s ‘DP’ O&M manual.

• Do not overload the lift.

• Ensure that all safety devices are operational and in place.

• Autoquip warrants this lift for 60,000 cycles each warranty year. This number of

cycles is meant to represent normal, single shift duty. Exceeding this number of

cycles shortens the life of the lift and the length of your warranty. It also indicates

that a more robust lift design for high cycle lift should have been requested.

MODIFICATIONS OR ALTERATIONS

Modifications or alterations to industrial lifting equipment shall be made only with written

permission of Autoquip. Autoquip does not foresee and does not anticipate unauthorized

modifications, and these changes or alterations are grounds for voiding all warranties.

4

SAFETY SIGNAL WORDS

SAFETY ALERTS (Required Reading!)

The following SAFETY ALERTS are intended to create awareness of owners, operators,

and maintenance personnel of the potential safety hazards and the steps that must be

taken to avoid accidents. These same alerts are inserted throughout this manual to identify

specific hazards that may endanger uninformed personnel. Identification of every

conceivable hazardous situation is impossible. Therefore, all personnel have the

responsibility to diligently exercise safe practices whenever exposed to this equipment.

____________________________________________________________

DANGER !

Identifies a hazardous situation which, if not avoided, will result in death or

severe personal injury.

_____________________________________________________________

WARNING !

Identifies a hazardous situation which, if not avoided, could result in death or

serious personal injury.

CAUTION !

Identifies a hazardous situation which, if not avoided, may result in minor or

moderate personal injury.

_____________________________________________________________

NOTICE !

Indicates a potentially hazardous situation which, if not avoided, may result in

property or equipment damage.

_____________________________________________________________

5

SAFETY PRACTICES

Read and understand this manual and all labels prior to

operating or servicing the lift. All labels are provided in

accordance with ANSI Z535.4.

DANGER !

Do not work under the lift without a Maintenance Device! To avoid personal

injury, NEVER go under the lift platform until the load is removed and the

scissors mechanism is securely blocked in the open position. See "Lift

Blocking Instructions" section.

DANGER !

Do not install the lift in a pit unless it has a bevel toe guard or other approved

toe protection. A shear point can exist which can cause severe injury to the

foot.

DANGER !

HIGH VOLTAGE!! Disconnect and/or lock out the electrical supply to the

power unit prior to any maintenance being performed.

DANGER !

Scissors lifts are designed individually for a specific load and application. To

avoid personal injury, do not change the load or application from the original

design.

DANGER !

Failure to relieve lift system pressure could result in the sudden and

unexpected release of pressure during maintenance and/or repair of the lift

and result in severe injury to the personnel and/or damage to the lift.

6

SAFETY PRACTICES

WARNING !

Do not make modifications to the lift such as extending the platform length

or width, this could cause the platform to tip. Do not add unauthorized or

unspecified components to the lift. Modifications to the lift can result in unsafe

operating conditions which could lead to serious injury or death.

WARNING !

If the lift is equipped with handrails, do not operate this equipment without handrails

and snap chains in place.

WARNING !

Under no circumstances should the down flow control valve be removed, from

the Contractor Power Unit or the Deltatrol on the Vertical Power Unit, to obtain

faster lowering speed. A loaded lift can reach dangerous and destructive

speed.

WARNING !

Do not attempt to remove the velocity fuse until the maintenance block

securely supports the lift and all hydraulic pressure has been removed from

the lifting cylinders and hydraulic hoses. Failure to do so could results in

personal injury or death.

WARNING !

To avoid personal injury, stand clear of scissors leg mechanism while lift is

in motion.

7

SAFETY PRACTICES

WARNING !

All warning and information decals should be in place as outlined in the “Label

Identification” section. If decals are missing or damaged, they should be

replaced with new ones. Contact Autoquip for replacements.

WARNING !

Lift platforms traveling below floor levels my create openings, and the shape

of the load and how the load is arranged on the lift may create a toe hazard as

the load passes the top edge of the pit. Both situations may require guarding

in accordance with Federal Regulations. Any such guarding must be installed

prior to operating the lift

WARNING !

The hydraulic velocity fuse (HVF) must be properly installed! The HVF is

attached to the elbow fitting in the trust angle port (casing end) of the cylinder.

Do not use a swivel fitting between the HVF and cylinder. If the HVF is

installed improperly, it will not lock up in the event of a catastrophic hydraulic

line break.

WARNING !

Use properly rated hoses only! Never use fittings or hoses that are not

properly rated for the intended use. Contact Autoquip for replacements.

WARNING !

Never exceed the rated capacity of the lift! Overloading, or uneven

loading, could result in load instability and cause serious personal injury.

8

SAFETY PRACTICES

WARNING !

Any lift which has a hinged throw-over bridge damaged to the point of hanging

more than 30 degrees below horizontal is in violation of the safety standards

set forth in ANSI MH29.1 and MUST be taken out of service until the bridge is

repaired or replaced. Failure to do so could result in severe personal injury.

WARNING !

Lifts should not be overloaded beyond the established capacity as damage

and/or personal injury may result.

WARNING !

Only trained and qualified personnel should operate this equipment.

WARNING !

Whenever raising or lowering the lift, personnel should maintain a safe

operating distance of at least 36” to avoid personal injury.

WARNING !

Any time the velocity fuses (HVF) have been tripped, the owner must

investigate the cause of the trip and ensure any necessary corrective actions

been taken, prior to resumption of normal lift operation. Failure to do so could

result in personal injury.

CAUTION !

Spilled oil is very slippery, and may also present a fire hazard. Clean up all

spilled oil to prevent personal injury or equipment damage.

9

SAFETY PRACTICES

NOTICE!

Do not continue to depress the “UP” button on the controller if the lift is not

raising or if the lift has reached the fully raised position. To do so may result

in permanent damage to the motor or pump.

NOTICE!

Never run the pump for more than a couple of seconds without pumping oil.

This applies to low oil conditions, improper motor rotation, running the pump

against the relief pressure after the lift is fully raised against the physical

stops, running overloaded beyond capacity, or running at reduced speed

because of pinched or obstructed hydraulic lines.

NOTICE!

Do not operate the power unit on relief for more than a few seconds. When

on relief, the valve will make a squealing sound.

NOTICE!

Precautions should be taken to prevent the introduction of contaminates such

as dirt or other foreign material into the system through open fittings, pipes or

disassembled components. Contamination will ruin the hydraulic system.

NOTICE!

Use only approved oils in the lift. See “Specifications” section.

10

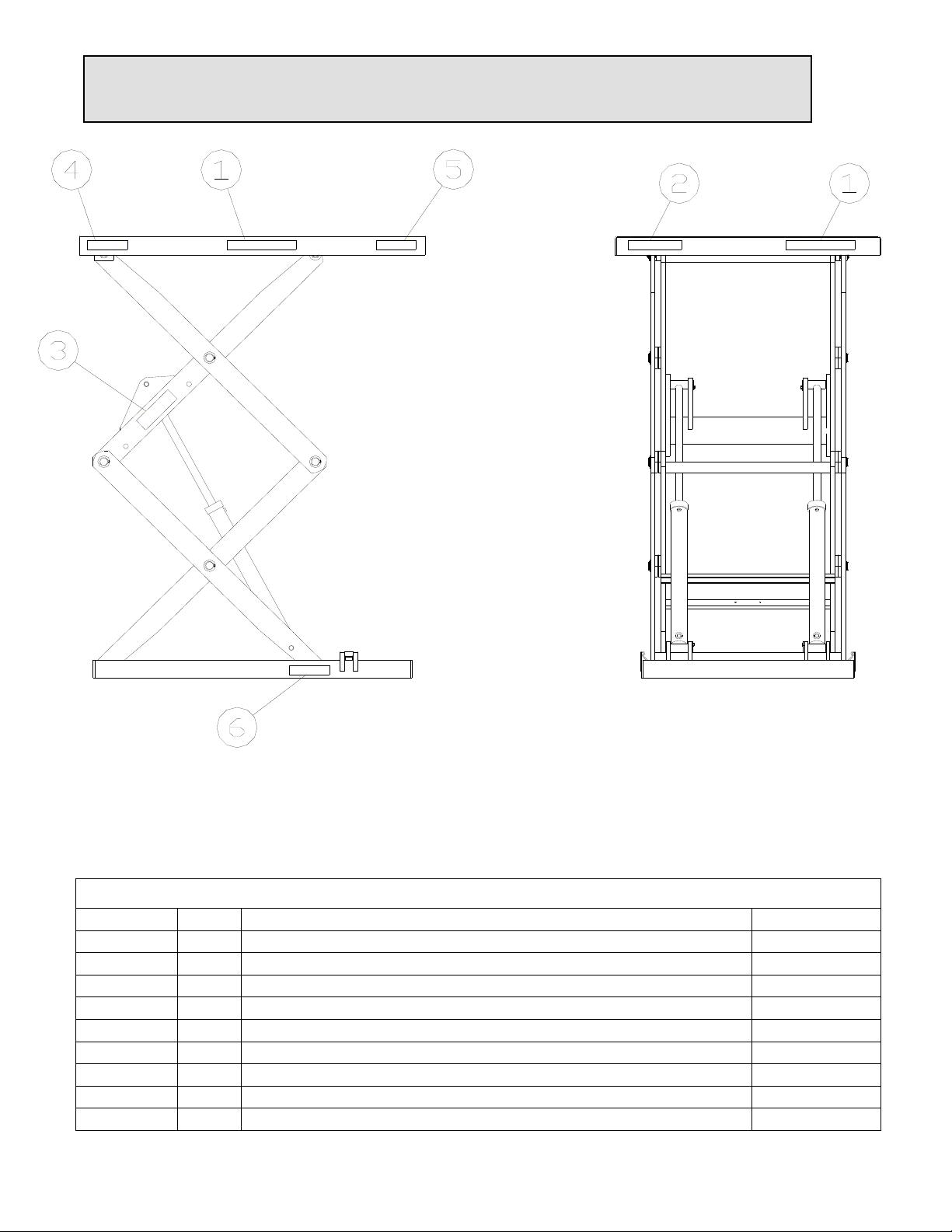

LABEL IDENTIFICATION

Figure 1: Label Placement

Double Pantograph Labels

Label No. Qty Description Part No.

1 4 Danger – Do Not Put Hands or Feet . . . 36430050

2 2 Caution – Familiarize Yourself with Operators Manual 36401487

3 1 Autoquip Serial Number Nameplate 36401560

4 2 Capacity 36401586

5 2 Autoquip Logo 36403220

6 2 Maintenance Device 36400257

7 4 Warning: Do Not Operate This Equipment Without . . . 36403715

8 4 Danger – Do Not Put Hands Or Feet (Modified). . . 36403715M

NOTE: Label No. 7 & 8 are used on units with riders

11

LABEL IDENTIFICATION

Note: Labels shown here are not to actual size,

see Figure 1 for location of label on lift.

Label 1: General Purpose Decal (36430050)

(Do Not Put Hands or Feet …)

Label 2: Familiarize Yourself Decal (36401487)

Label 3: Serial Number Nameplate (36401560)

12

LABEL IDENTIFICATION

Note: Labels shown here are not to actual size,

see Figure 1 for location of label on lift.

Label 4: CAPACITY Decal (36401586)

Label 5: AUTOQUIP LOGO Decal (36403220)

Label 6: Maintenance Device Label (36400257)

13

LABEL IDENTIFICATION

Note: Labels shown here are not to actual size,

see Figure 1 for location of label on lift.

Label 7: Handrail Label (36403715)

Add label to top rail of the Handrail if equipped with Handrails

Cut Line

Label 8: Modified General Purpose Decal (36430050M)

Replaces label 1 if lift is equipped with Handrails

14

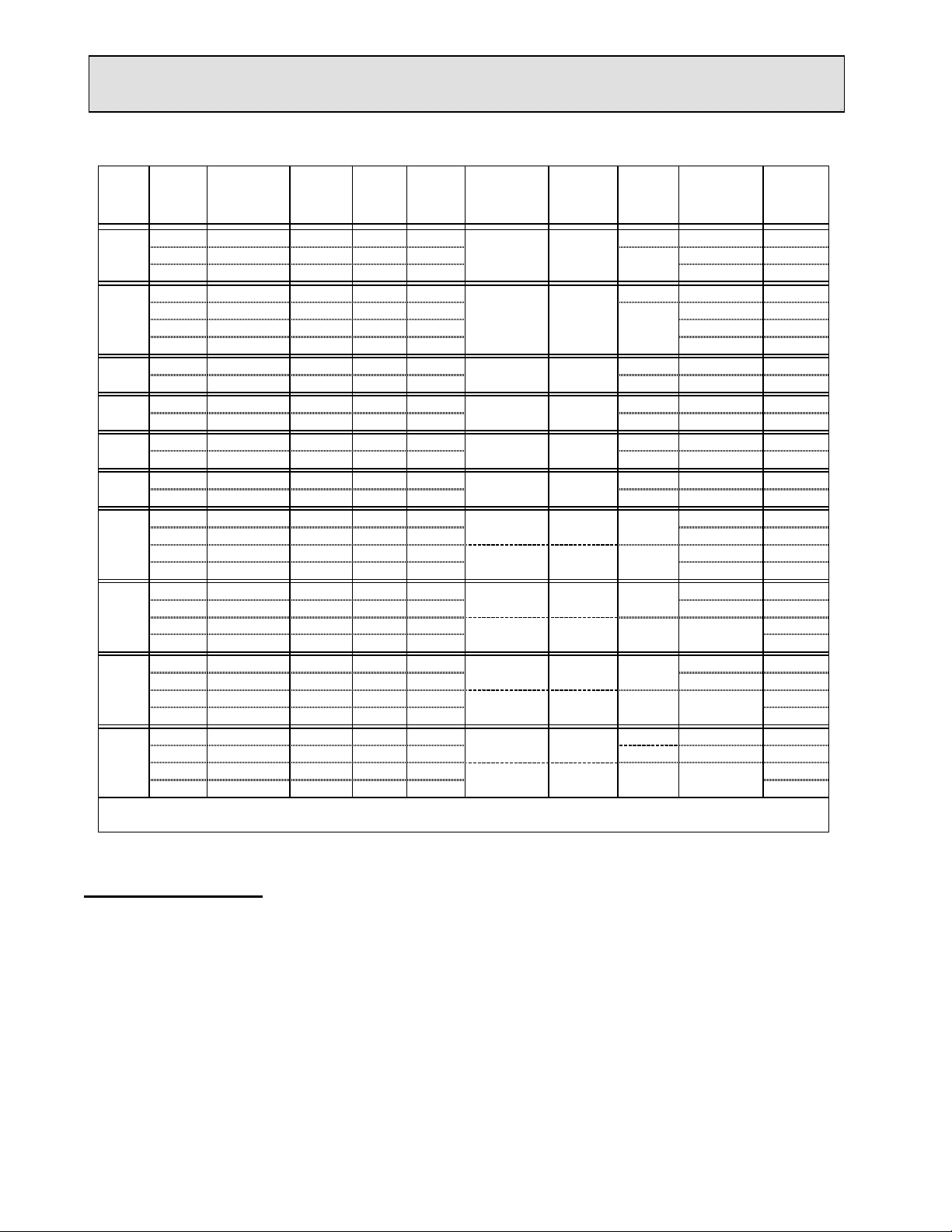

SPECIFICATIONS

Travel

36*

48*

60 36 x 54 48 x 84

72

84

96 48 x 80 60 x 104

108

120

132

144

Cap.

(lbs.)

500 36DP05*** 8.5 500 200 3/4 27 / 7 350

1500 36DP15 9.25 1000 500 25 / 8 400

3000 36DP30 10.75 1500 1000 12 / 16 500

3000 48DP30 11.25 2000 1000 1 1/2 7 / 33 800

6000 48DP60 12.75 2500 1200 11.5 / 22 850

9000 48DP90 15 3000 1500 9 / 38 1200

12000 48DP120 16.5 4000 1500 5.5 / 44 1450

9000 60DP90 16.5 3000 1500 5C 8 / 37 1600

12000* 60DP120 18 4000 1500 5V* 8.5 / 36 1700

9000 72DP90 17 3000 1500 5C 8 / 47 1800

12000* 72DP120 18.5 4000 1500 5V* 8 / 46 2300

9000 84DP90 18 3000 1500 5C 7.5 / 56 2400

12000* 84DP120 19.5 4000 1500 5V* 8 / 55 3000

9000 96DP90 19.5 3000 1500 5C 7 / 70 2950

12000* 96DP120 20.5 4000 1500 5V* 7 / 68 3500

3000 108DP30 17.25 2000 1000 8 / 67 2650

6000 108DP60 17.25 2500 1200 8 / 67 2650

9000* 108DP90 20.5 3000 1500 11.75 / 46 3300

12000* 108DP120 22 4000 1500 7.5 / 72 3900

3000 120DP30 18.75 2000 1000 6.8 / 88 3400

6000 120DP60 18.75 2500 1200 6.8 / 88 3400

9000* 120DP90 21 3000 1500 4400

12000* 120DP120 23 4000 1500 5000

3000 132DP30 17.5 2000 1000 14 / 47 2850

6000 132DP60 20 2500 1200 8 / 84 3650

9000* 132DP90 22 3000 1500 5300

12000* 132DP120 24 4000 1500 6050

3000* 144DP30 18.75 2000 1000 5C 11 / 64 3450

6000* 144DP60 21 2500 1200 5V* 7.5 / 93 4000

9000* 144DP90 23 3000 1500 5950

12000* 144DP120 25 4000 1500 6700

STD. Power Unit = Internal

* Remote PU (5V=5HP Vert)

Model

Ld Ht

(in.)

Max

End

Load

Max

Side

Load

*** Single Cylinder

Std Min

Platform

24 x 32

30 x 43 42 x 72

36 x 62 48 x 84

48 x 70

54 x 82

54 x 88

60 x 92

60 x 96

60 x 102 84 x 124

60 x 106

72 x 108

72 x 113

Max

Platform

36 x 48

60 x 96

78 x 106

78 x 112

84 x 116

84 x 120

84 x 128

96 x 132

96 x 136

*Remote PU 5V(HT)= High Travel Tank

HP

1 1/2

5C

5C

5V*

5C

5V*

5C

5V*

5V(HT)*

Speed

fpm/sec

8 / 73

8 / 82

8 / 91

Ship Wt.

(min.

Platf)

LOAD CAPACITY

The load capacity rating is stamped on a metal nameplate that is attached to one side of

the lift Leg assembly. This load capacity rating is a net rating for a lift furnished with the

standard minimum platform. Each platform size listed above in Lift Specifications is the

Standard (Minimum) platform size for each model lift. The relief valve on the power unit

has been set to raise the lift capacity, plus a small amount for overload. When gravity roller

conveyors, fixtures, or special tops, etc, are installed on the lift platform,

after leaving the plant, deduct the weight of these components from the load rating to

obtain the net lifting capacity.

15

SPECIFICATIONS

CAUTION!

Lifts should not be overloaded beyond the established capacity as

damage and/or personal injury may result and will void its

warranty.

DANGER!

Do not make modifications to the lift without authorization

from the manufacturer. Autoquip cannot foresee and is

not responsible for injury or damage which results from

the unauthorized modifications or misuse of the lift.

UNBALANCED LOADING

The stabilization provided is basically for balanced loads. If special attachments extend

beyond the length and/or width dimensions of the platform, the end and/or side load

capacity must be reduced (contact an Autoquip Sales representative).

LIFT DUTY

Autoquip standard lift designs as described in the specifications typically include

intermittent duty motors and are designed to “cycle” (one complete “up” and one complete

“down” lift operation) no more frequently than every two minutes – or approximately 60,000

times (cycles) per year. This is considered “normal” duty.

It is the responsibility of the user to notify Autoquip whenever a specific application is likely

to demand “above normal” duty from the lift - in excess of 60,000 cycles per year. Above

normal duty typically requires supplemental design features to enhance the serviceable life

of the lift & to avoid loss of warranty.

PUMP PRESSURE

This lift incorporates a positive displacement pump machined to a high degree of accuracy

and specially adapted to requirements of higher-pressure ranges over that of a standard

pump. Therefore, standard factory models of the same manufacture cannot replace it.

The pump can operate efficiently at intermittent pressures up to 3200 PSI and continuous

duty to 2500 PSI. The safety relief valve in the pump assembly or Deltatrol Valve is

factory-set to stay within the parameters of the pump and lift requirements.

16

LIFT BLOCKING INSTRUCTIONS

WARNING !

Only authorized personnel should perform inspection or

maintenance and service procedures. Unauthorized personnel

attempting these procedures do so at the risk of personal injury or

death.

DANGER !

Failure to properly adhere to lift blocking procedures is to risk the

sudden and uncontrolled descent of the lift during maintenance or

inspection. A falling lift can cause severe injury or death.

LIFT BLOCKING PROCEDURE

This procedure describes the only factory-approved method of working under a lift. Follow

these instructions EVERY time you plan to reach or crawl beneath the lift to

perform service or maintenance – no matter how momentary that might be.

If the factory-provided maintenance device is damaged or missing, stop immediately and

consult the factory for assistance. The manufacturer is not liable for your failure to use the

approved maintenance devices and procedures that have been provided.

1. All loads must be removed from the lift prior to engaging the maintenance device.

The maintenance device is designed to support an unloaded lift only. Failure to

remove the load from the lift prior to blocking could cause the failure of the

maintenance device and allow the lift to fall unexpectedly. This can result in

personal injury or death, or permanent damage to the maintenance device and/or

the lift.

2. Raise the lift to its fully raised position. If you do not, the maintenance device may

not be able to be placed properly in its designed blocking position.

3. Locate and engage all maintenance devices.

a. Flip-over maintenance locks are permanently welded on the side the base

frame on the roller end of the lift base frame. Both locks must be flipped over

and resting inside the base frame and thus blocking the path of the base

rollers. (See Figure 9A).

– (Reference Figures: 2A & 2B)

17

LIFT BLOCKING INSTRUCTIONS

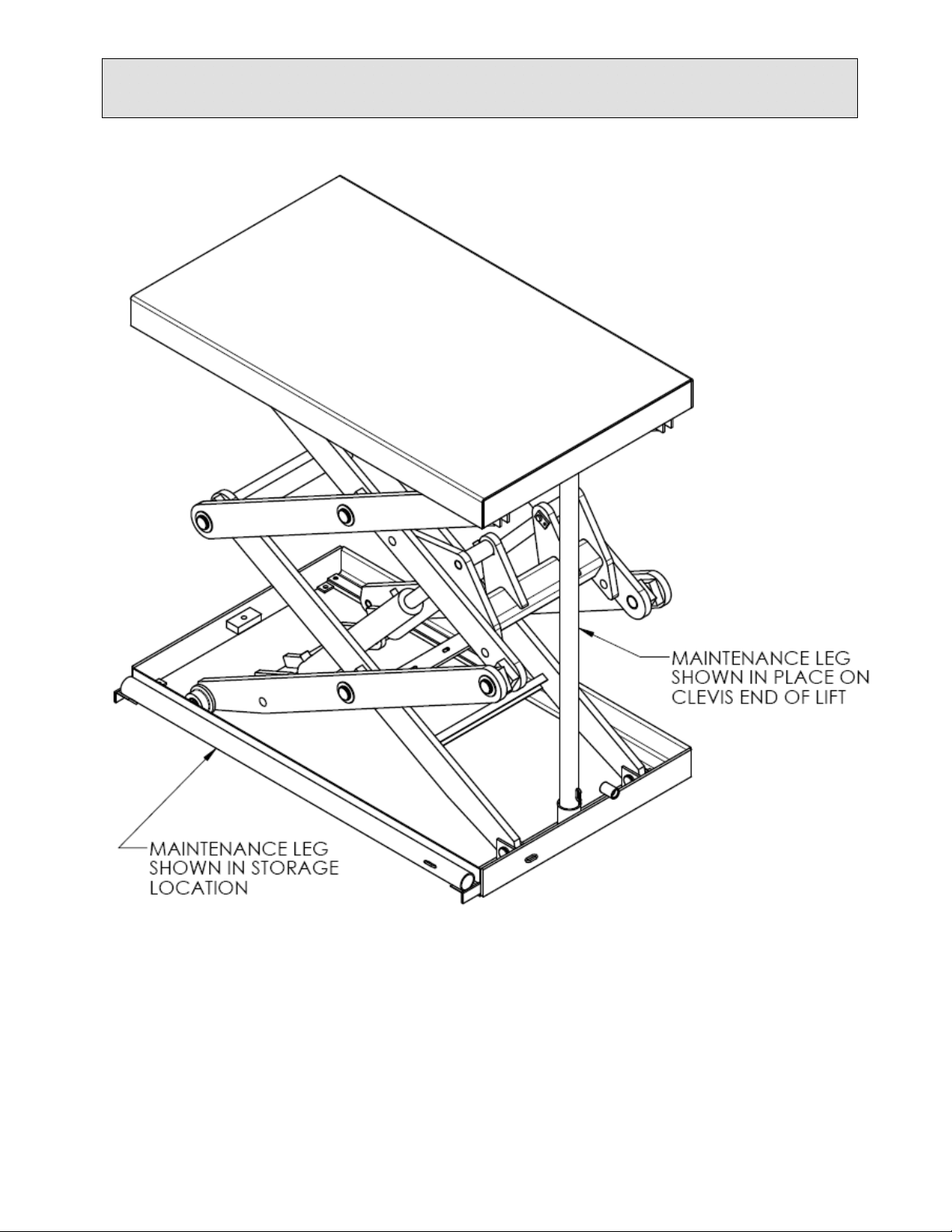

LIFT BLOCKING PROCEDURE– (Reference Figures: 9A & 9B)

b. Maintenance leg is connected to the base frame by a chain. Remove the

maintenance leg from its storage location. Place one end of the maintenance

leg in the leg socket located in the base frame on the Clevis End, (See Figure

9B). Lower the lift platform until it comes down and makes contact with the

maintenance leg. The maintenance leg should be centered in the platform

maintenance leg socket, located underneath the platform on the Clevis End.

Re-check to ensure that the maintenance leg device is inside the platform

maintenance socket and in contact with the platform deck surface. If the

maintenance leg is not fully engaged the lift could fall unexpectedly, resulting

in permanent damage to the devices or the lift.

DANGER !

Do not work under lift, without Maintenance Device! To avoid

personal injury, NEVER go under the lift platform until the load is

removed and the scissors mechanism is securely blocked in the

open position and the appropriate OSHA lock-out/tag-out

procedure is followed. See "Lift Blocking Instructions" section.

DANGER !

If for any reason you are unable to lower the lift completely onto

the maintenance device(s), stop immediately and consult the

factory. Failure to properly use the factory approved maintenance

device(s) could result in severe injury or death.

4. Once the maintenance device(s) is properly and securely engaged continue to

press the down button for an additional 5-10 seconds to relieve all pressure in the

system (it could take longer in a pneumatic system).

WARNING !

Failure to relieve the system operating pressure could result in the

sudden and unexpected release of high-pressure fluids (or air)

during maintenance and/or repair of the lift and result in severe

injury or death.

18

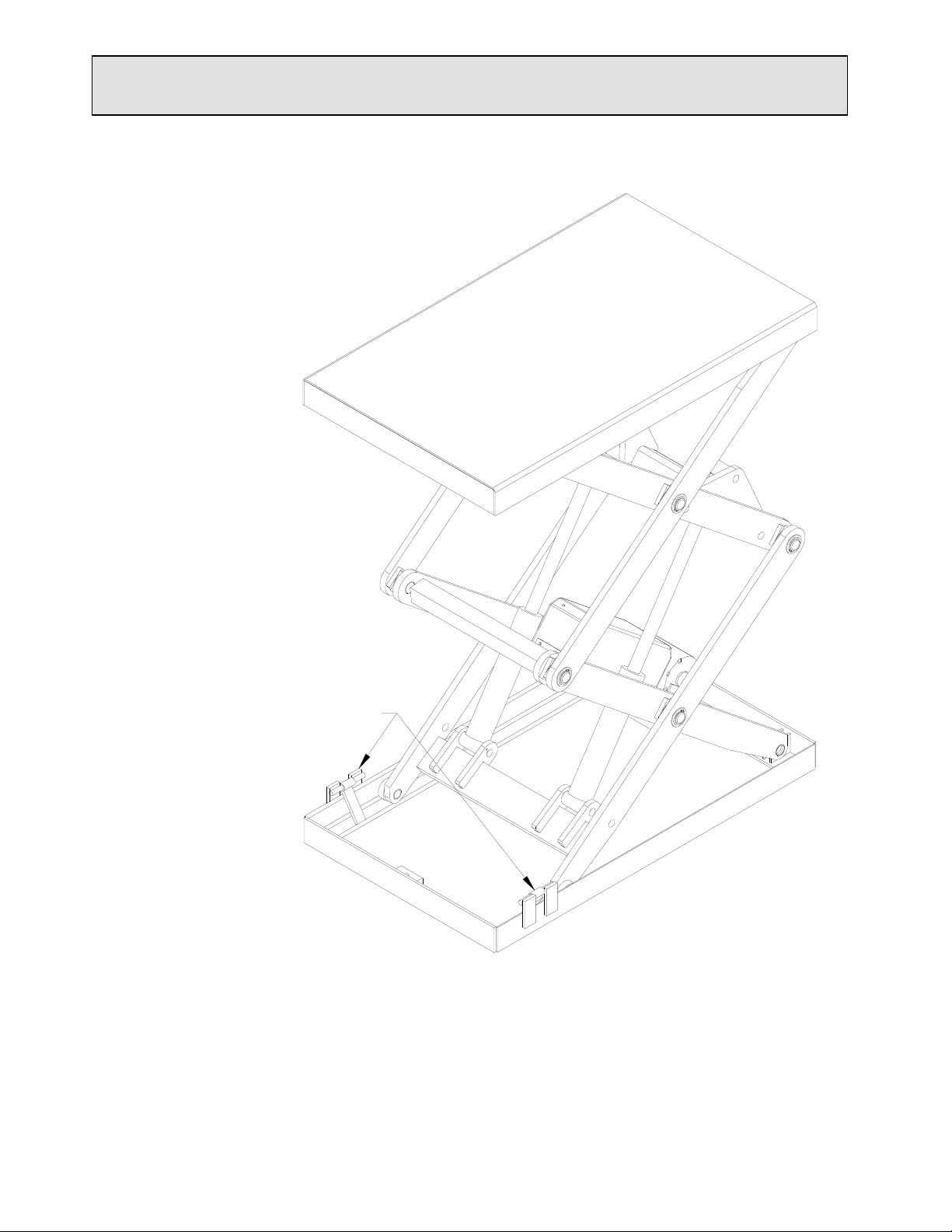

FLIP-OVER MAINTENANCE

LOCKS SHOWN IN PLACE ON

BOTH SIDES OF BASE FRAME

LIFT BLOCKING INSTRUCTIONS

Figure 2A: Flip-Over Maintenance Locks

19

LIFT BLOCKING INSTRUCTIONS

Figure 2B: Maintenance Leg – High Capacity or High Travel Models

20

LIFT BLOCKING INSTRUCTIONS

LIFT BLOCKING PROCEDURE– (continued)

5. Follow OSHA electrical lock-out/tag-out procedures. Disconnect and tag all

electrical and/or other power sources to prevent an unplanned or unexpected

actuation of the lift.

6. Once inspection or work is complete reverse steps 1-5 above, raise the lift off the

maintenance device and place the maintenance device back into the designated

storage position.

21

INSTALLATION INSTRUCTIONS

WARNING!

Before installing the lift, read & follow the recommended safety practices

in the Safety Practices section. Failure to follow these safety practices

could result in death or serious injury

FLOOR INSTALLATION

1. Make sure the installation area is clean before starting. Check the mounting

surface of the floor with a level or straight edge. If the floor is not level, add

shims or grout under the lift base frame along the entire perimeter of the base to

achieve a level and flat base installation. A level base will ensure proper wheel

tracking and smooth lift operation.

2. If the permanent electrical work is not complete, some means of temporary lines

with an on-off device for the power supply should be set up for testing purposes.

3. Place the lift in the installation area and level the base frame per note #1.

NOTICE !

When moving the lift, do not attempt to pick it up by the

platform, the platform is hinged and could be damaged. Pick up

the lift from under the base frame ONLY using a strap sling.

4. Make temporary electrical connections and permanent hydraulic connections.

Raise the lift approximately one foot using the “UP” button. Then lower the lift

back to fully collapse, holding the “DOWN” button for approximately 60 seconds.

Repeat this process five to seven times to bleed any air out of the hydraulic

system.

DANGER !

HIGH VOLTAGE!! – Disconnect and/or lock out the electrical supply

to the power unit per OSHA regulations prior to any installation or

maintenance being performed.

5. Raise the lift to the top of its travel and make positioning adjustments. Check for

the proper height. If needed, shim to the desired height. DO NOT “spot” shim.

Shim the full length of the base frame. This will prevent the frame from sagging

under an exceptionally heavy load.

22

Loading...

Loading...