INSTALLATION, OPERATION,

AND SERVICE MANUAL

TROJAN COIL CAR

P.O. Box 1058 • 1058 West Industrial Avenue • Guthrie, OK 73044-1058 • 405-282-5200 •

FAX: 405-282-8105 • www.autoquip.com

Item # 830CC Version 1.0

09/2001

TABLE OF CONTENTS

Identification and Inspection 3

Dangers, Warnings, and Cautions 4

Label Identification 8

Specifications 11

Lift Blocking Instructions 12

Installation Instructions 14

Operating Instructions 17

Routine Maintenance 19

General Maintenance 22

Replacement Parts List 31

Troubleshooting Analysis 32

IMPORTANT

Please read and understand this manual prior to installation or operation of this unit.

Failure to do so could lead to property damage and/or serious personal injury. If any

questions arise, call a local representative or Autoquip Corporation at 1-888-811-9876

or 405-282-5200.

PLANNED MAINTENANCE PROGRAM

A local Autoquip representative provides a Planned Maintenance Program (PMP) for

this equipment using factory-trained personnel. Call a local representative or Autoquip

Corporation at 1-888-811-9876 or 405-282-5200 for more information.

2

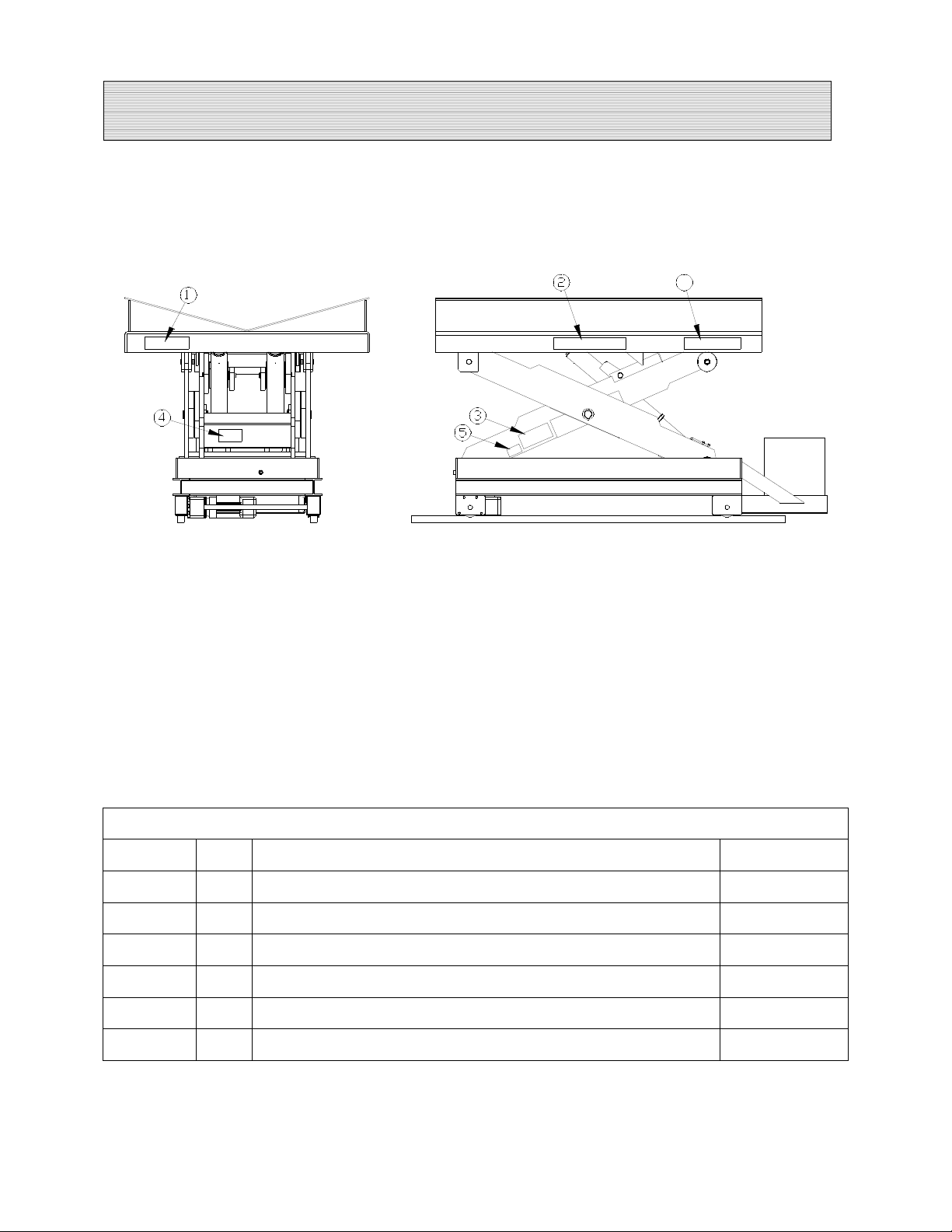

IDENTIFICATION & INSPECTION

IDENTIFICATION

When ordering parts or requesting information or service on this unit, PLEASE REFER

TO THE MODEL AND SERIAL NUMBER. This information is on a nameplate attached

to the leg assembly. Replacement parts are available from a local Autoquip distributor.

INSPECTION

Immediately upon receipt of the unit, a visual inspection should be made to determine

that it has not been damaged in transit. Any damage found must be noted on the

delivery receipt. In addition to this preliminary inspection, the unit should be carefully

inspected for concealed damage. Any concealed damage found that was not noted on

the delivery receipt should be reported in writing to the delivering carrier within 48 hours.

The following is a checklist that will aid in the inspection of the lift.

1. Examine the entire unit for any signs of mishandling. Pay special attention to the

power unit and pushbuttons.

2. Thoroughly examine all connections, making sure they have not vibrated loose

during transit.

3. After installation, raise the lift and inspect the base frame, platform, scissors

assembly, and cylinder plumbing connections.

3

DANGERS, WARNINGS & CAUTIONS

SAFETY ALERTS (Required Reading!)

The following SAFETY ALERTS are intended to create awareness of owners,

operators, and maintenance personnel of the potential safety hazards and the steps that

must be taken to avoid accidents. These same alerts are inserted throughout this

manual to identify specific hazards that may endanger uninformed personnel.

Identification of every conceivable hazardous situation is impossible. Therefore, all

personnel have the responsibility to diligently exercise safe practices whenever exposed

to this equipment.

____________________________________________________________

DANGER!

Identifies a hazardous situation that presents the imminent probability of

death or of severe personal injury!!

_____________________________________________________________

WARNING!

Identifies a hazardous situation that has the potential of causing death or

serious personal injury.

CAUTION!

Identifies a hazardous situation that could lead to the possibility of personal

injury of death, and/or may result in equipment damage.

_____________________________________________________________

4

DANGERS, WARNINGS & CAUTIONS

Read and understand this manual and all labels prior to operating or

servicing the scissors lift. All labels are provided in accordance with

ANSI Z535.4.

DANGER!

Do not work under lift without maintenance device! To avoid personal

injury, NEVER go under the lift platform until the load is removed and the

scissors mechanism is securely blocked in the open position. See the "Lift

Blocking Instructions" section.

DANGER!

To avoid personal injury, stand clear of scissors leg mechanism while lift is

in motion.

DANGER!

Do not install the lift in a pit unless it has a bevel toe guard or other

approved toe protection. A shear point can exist which can cause severe

injury to the foot.

DANGER!

HIGH VOLTAGE!! Disconnect and/or lock out the electrical supply to the

power unit prior to any maintenance being performed.

5

DANGERS, WARNINGS & CAUTIONS

DANGER!

Scissors lifts are designed individually for a specific load and application.

To avoid personal injury, do not change the load or application from the

original design.

WARNING!

NEVER stand, sit or ride on the lift!

WARNING!

All warning and information decals should be in place as outlined in the

“Label Identification” section. If decals are missing or damaged, they

should be replaced with new ones. Contact Autoquip for replacements.

WARNING!

Do not attempt to remove the velocity fuse until the maintenance block

securely supports the lift and all hydraulic pressure has been removed from

the lifting cylinders and hydraulic hoses. Failure to do so could results in

personal injury or death!

CAUTION!

Do not continue to depress the “UP” button on the controller if the lift is not

raising or if the lift has reached the fully raised position. To do so may

result in permanent damage to the motor or pump.

6

DANGERS, WARNINGS & CAUTIONS

CAUTION!

Never run the pump for more than a couple of seconds without pumping oil.

This applies to low oil conditions, improper motor rotation, running the

pump against the relief pressure after the lift is fully raised against the

physical stops, running overloaded beyond capacity, or running at reduced

speed because of pinched or obstructed hydraulic lines.

CAUTION!

Do not operate the power unit on relief for more than a few seconds. When

on relief, the valve will make a squealing sound.

CAUTION!

Precautions should be taken to prevent the introduction of contaminates

such as dirt or other foreign material into the system through open fittings,

pipes or disassembled components. Contamination will ruin the hydraulic

system.

CAUTION!

Use only approved oils in the lift. See “Specifications” section.

7

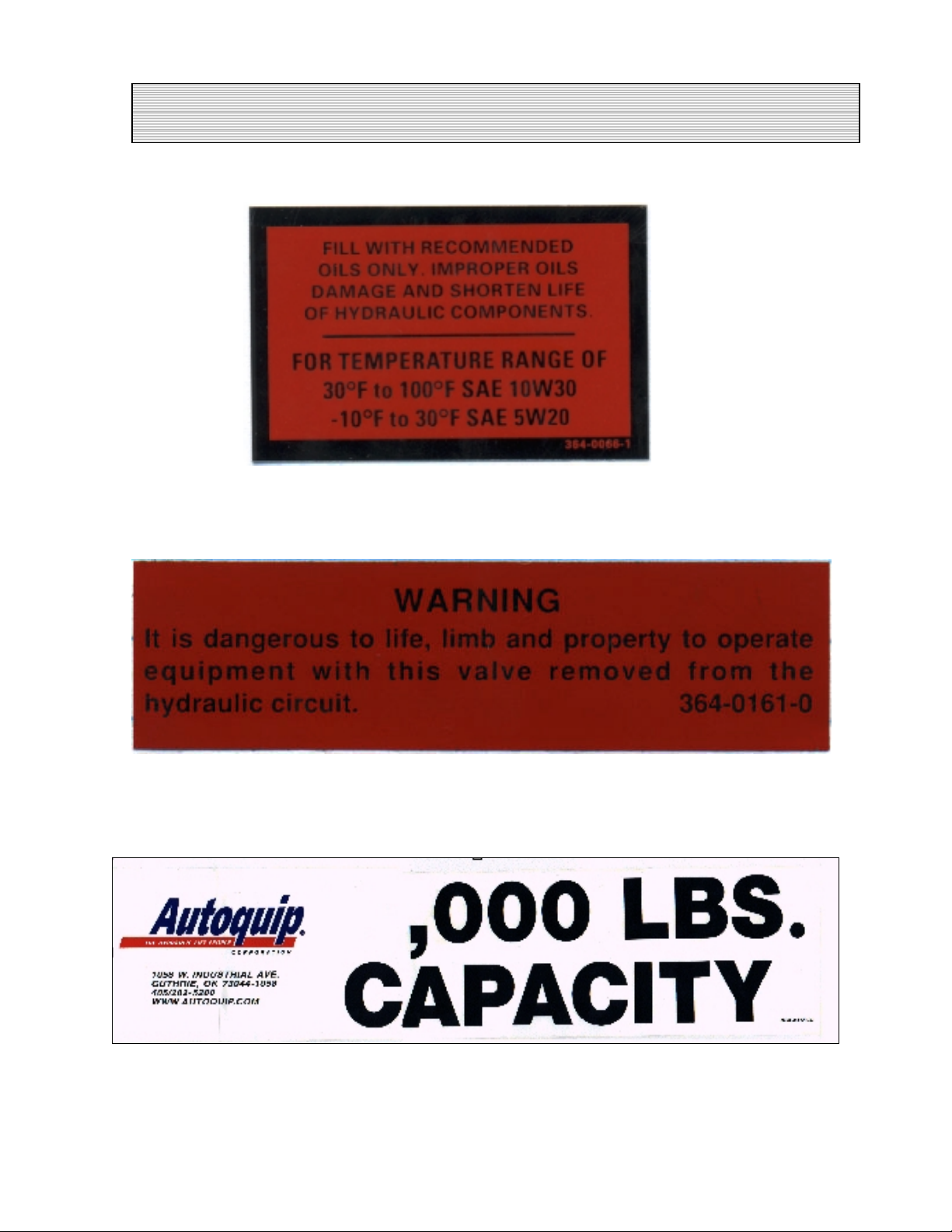

LABEL IDENTIFICATION

6

Figure 1 Label Placement

Coil Car

Item No. Qty Description Part No.

1 2 Caution! Familiarize Yourself With Operators Manual 36401487

2 4 Danger – Do Not Put Hands or Feet . . . 36430050

31Autoquip Serial Number Nameplate 36401511

4 1 Fill with Recommended Oils Only 36400661

5 2 UP – STOP Valve (when applicable) 36401610

6 2 Capacity 36401586

8

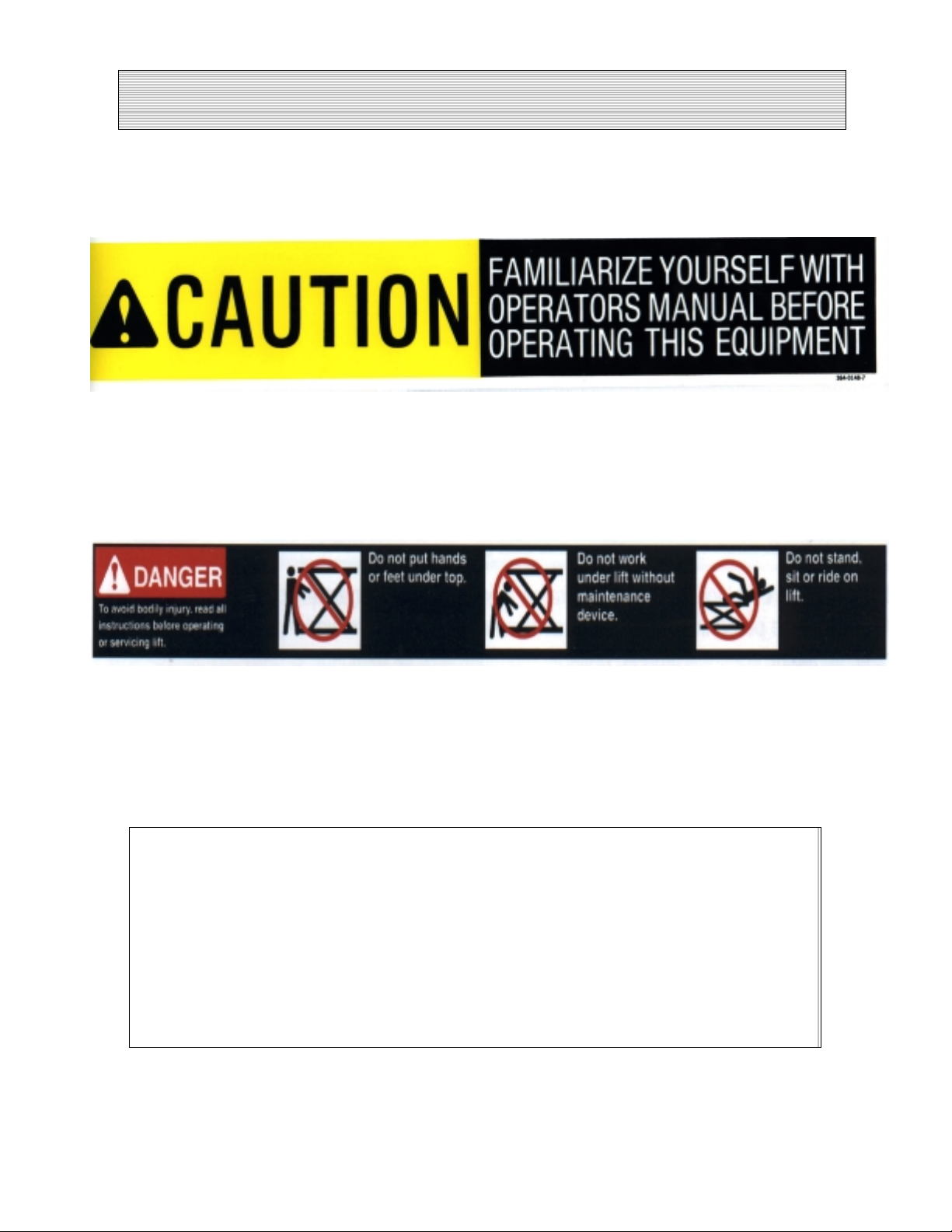

LABEL IDENTIFICATION

Note: Labels shown here are not actual size.

Figure 2 Label 36401487

Figure 3 Label 36430050

Figure 4 Label 36401511

9

LABEL IDENTIFICATION

Figure 5 Label 36400661

Figure 6 Label 36401610

Figure 7 Label 36401586

10

SPECIFICATIONS

LOAD CAPACITY

The load capacity rating is stamped on a metal plate attached to one side of the lift.

This figure is a net capacity rating for a lift furnished with the standard platform. The

relief valve of the pumping unit has been set to raise the weight, plus a small amount for

overload. Where gravity roll-sections, special tops, etc, are installed on the lift after

leaving the plant, deduct the weight of these from the load rating to obtain the net

capacity. Lifts should not be overloaded beyond the established capacity as

damage and/or personal injury may result.

UNBALANCED LOADING

The stabilization provided is basically for balanced loads. If special attachments extend

beyond the length and/or width dimensions of the platform, the end and/or side load

capacity is reduced 2% for each one-inch extension from the center.

PUMP PRESSURE

This lift incorporates a positive displacement pump machined to a high degree of

accuracy and specially adapted to requirements of higher-pressure ranges over that of

a standard pump. Therefore, standard factory models of the same manufacture cannot

replace it.

The pump can operate efficiently at intermittent pressures up to 3200 PSI and

continuous duty to 2500 PSI. The safety relief valve in the pump assembly is factoryset to stay within the parameters of the pump and lift requirements.

DEMAG DRIVE SYSTEM

The Coil Car incorporates an electric traverse drive system with a motor and gearbox

speed reducer directly driving a splined shaft and two drive wheels in high capacity

wheel “pockets” attached to each side of the lift. Most components in this Demag drive

system are specially machined, high precision, and metric; they should not be replaced

with non-Demag components.

11

LIFT BLOCKING INSTRUCTIONS

1. Remove all load from the platform. Never block the lift when loaded.

2. Raise the platform sufficiently for the base rollers to rollback past the flip-over

maintenance locks, located on the base frame of the lift.

3. Engage both maintenance locks by flipping them into the base frame (see Figure 8).

4. Lower the platform until the base rollers come into contact with and rest against the

maintenance locks. Always hold the “DOWN” switch a few seconds more until all

pressure is gone and the platform is supported entirely and safely by the

maintenance locks.

5. Always shut off the main electrical switch, when blocked, to prevent someone from

turning it on.

DANGER!

To avoid personal injury, NEVER go under the platform until the load is

removed and the lift is securely blocked in the open position.

6. To remove the maintenance locks, raise the platform by activating the “UP” valve to

provide sufficient clearance for the removal of the maintenance locks.

DANGER!

Maintenance locks that are bent, damaged, or non-functional must be

replaced immediately to avoid personal injury. Contact the Autoquip

Service Department for replacement parts and installation instructions.

12

LIFT BLOCKING INSTRUCTIONS

FLIP-OVER MAINTENANCE

LOCKS, ON BOTH SIDES OF

THE BASE FRAME.

Figure 8 Maintenance Locks

13

INSTALLATION INSTRUCTIONS

INSTALLATION

1. Make sure installation area is clean before starting.

2. If the permanent electrical work is not complete, some means of temporary lines with

an on-off device for the motor should be set up for testing purposes.

3. Place the lift in the installation area, typically on tracks or rails which are supplied

and installed by the customer or installer.

CAUTION!

When moving the lift, do not attempt to pick it up by the platform; it is

hinged and could be damaged. Pick up the lift from under the base frame

ONLY using a strap sling.

4. Make temporary electrical connections. Raise the lift to the top of its travel and

check for the proper height.

DANGER!

Do not work under lift without Maintenance Device! To avoid personal

injury, NEVER go under the lift platform until the load is removed and the

scissors mechanism is securely blocked in the open position. See "Lift

Blocking Instructions" section.

5. Run the lift in forward and reverse and check for proper motor rotation and speed.

6. Make permanent electrical connections and operate the lift through a few cycles.

7. Check the oil in the reservoir and add oil, if necessary. See “Routine Maintenance”

section.

8. Clean up any debris from the area. A clean installation makes a good impression

and creates a much safer environment!

14

INSTALLATION INSTRUCTIONS

PROCEDURE FOR A LIFT ORDERED WITH AN ACCORDION SKIRT

1. Position the platform in the raised position. Install the maintenance locks (see “Lift

Blocking Instructions” section). Position the accordion with the weight rod pocket at

the bottom and the mounting collar at the top. The breathable material when

provided must be positioned at the top of the skirt with the mounting collar.

2. Slip the skirt over the end of the platform. Turn the skirt as required to slide over the

other end of the platform and leg assembly. The skirt should be in position under

the platform while enveloping the base assembly.

3. See Figure 10 and select the correct mounting configuration (Figure 1, 2, or 3).

Figure #1: Mounting an Accordion Skirt Onto the Platform Side

Raise one side of the skirt along with a skirt -mounting bar (1/8” x 1”) to (1) side of

the platform. When possible, center the skirt-mounting collar and skirt-mounting bar

(1/8” x 1”) on the platform side. Align the pre-drilled holes in the side of the platform

with the skirt-mounting bar holes and punch holes in the skirt-mounting collar. Push

a nylon drive rivet through each hole in the skirt-mounting bar. Hammer the

aluminum pin into the rivet until flush with the rivet head. Repeat mounting process

for the remaining sides of the accordion skirt.

Figure #2: Mounting an Accordion Skirt Underneath the Platform

Raise one side of the skirt along with a skirt-mounting bar (1/8" x 1") to the

underside of the platform skirt support bar. When possible, center the skirt mounting

collar and the skirt-mounting bar (1/8” x 1”) on the platform support bar. Align the

pre-drilled holes in the skirt support bar (picture frame) with the skirt -mounting bar

holes and punch holes in the skirt-mounting collar. Push a nylon drive rivet through

each hole in the skirt-mounting bar. Hammer the aluminum pin into the rivet until

flush with the rivet head. Repeat mounting process for the remaining sides of the

accordion skirt.

Figure #3: Mounting an Accordion Skirt Onto the Bevel Toe Guard

Raise one side of the skirt along with a skirt-mounting bar (1/8” x 1”) to the side of

the bevel toe guard. When possible, center the skirt mounting collar and the skirtmounting bar (1/8” x1”) on the platform bevel toe guard. Align the pre-drilled holes in

the bevel toe guard with the skirt-mounting bar holes and punch holes in the skirtmounting collar. Push a nylon drive rivet through each hole in the skirt-mounting

bar. Hammer the aluminum pin into the rivet until flush with the rivet head. Repeat

mounting process for the remaining sides of the accordion skirt.

4. Install weight rods into the weight rod pockets at the bottom of the accordion skirt.

Install the spring tempered wire rods into the pocket of black convolutions.

15

INSTALLATION INSTRUCTIONS

Figure 9 Skirt Installation

16

OPERATING INSTRUCTIONS

Familiarize yourself with this operator’s manual before operating this equipment.

CAUTION!

Do not continue to depress the “UP” button on the controller if the lift is

not raising or if the lift has reached the fully raised position. To do so may

result in permanent damage to the motor or pump.

Scissors lifts are designed primarily for in-plant applications and are furnished with

constant pressure pushbutton and footswitch controls. Actuating the "UP" button

causes the coil on the contactor to energize, closing the line contacts and allowing the

line voltage to be applied to the motor. The motor will drive a gear pump, which in turn

draws oil from the reservoir through the pump and forces it at a constant volume under

pressure required by the load. The oil flows through the valves and piping into the

hydraulic cylinder. The hydraulic cylinder is attached to structural members of the lift

causing the scissor mechanism of the legs to open as the cylinder rod extends.

When the desired height or upward travel of the platform is attained, the "UP" button is

deactivated by releasing pressure from the pushbutton or footswitch. The power unit

will stop pumping oil, and the check valve will close preventing reverse flow of the oil.

This maintains the desired raised position

To lower the lift, the operator simply depresses the "DOWN" button on the pushbutton

control energizing the down valve solenoid. The solenoid activates the valve to open.

Once opened, the down valve allows oil in the hydraulic cylinder to flow through the

velocity fuse, the flow control, and the down valve at a controlled rate and return to the

reservoir. The downward travel of the lift platform may be stopped at a desired

elevation by releasing pressure from the "DOWN” button.

NOTE: The motor does not operate during downward travel.

CAUTION!

Do not operate the power unit on relief for more than a few seconds. When

on relief, the valve will make an audible squealing sound.

17

OPERATING INSTRUCTIONS

To traverse the lift the operator simply depresses either the “FORWARD” or

“REVERSE” button on the pushbutton control energizing the reversing motor starter in

the control panel. The motor starter activates the motor in either direction, which then

turns the gearbox reducer. The splined output shaft runs through the gearbox and

drives the drive wheels mounted on each side of the lift. When the desired travel is

achieved, release the pressure from either the “FORWARD” or “REVERSE” button.

Note: Even though the motor has a brake, there will be slight forward motion

after the button is released while the lift “coasts” to a complete stop.

18

ROUTINE MAINTENANCE

Normally coil cars will require very little maintenance. However, a routine maintenance

program could prevent costly replacement of parts and/or downtime.

WARNING!

To avoid personal injury, NEVER go under the lift platform or perform any

maintenance on the lift until the load is removed and the scissors

mechanism is securely blocked in the open position. See "Lift Blocking

Instructions" section.

MONTHLY INSPECTION

1. Check the hydraulic oil level (see oil recommendations in this section) and add

appropriate oil when necessary.

2. Check for any visible leaks. Correct as necessary.

3. Check any unusual noise when it occurs. Determine the source and correct as

necessary.

4. Check the snap rings at all rollers, if not in place, and/or secure, replace or repair

immediately.

5. Check all rollers for signs of wear. Replace as necessary.

6. Do not grease roller or axles; they have lifetime-lubricated bearings.

7. Check all wiring for looseness or wear. Repair at once.

8. Check gearbox “non-rotator” bracket and its connection to the structure of the base

frame to ensure it has not vibrated loose or shows signs of excessive wear.

HYDRAULIC OIL REQUIREMENTS

Change oil yearly, or more frequently if it darkens materially or feels gummy or gritty.

Do not use hydraulic-jack oil, hydraulic fluids, brake fluids, or automatic

transmission fluid.

19

ROUTINE MAINTENANCE

Oil Viscosity Recommendations

Environment

(Ambient Temperatures)

Indoor location, variable

temperatures (30 - 100° F)

Indoor location, consistent

Temperatures (70° F)

Outdoor location, (-10 - 100° F) SAE 5W30

Cold-storage warehouse

(10 - 40° F)

Freezer (-40° F to 0° F) Consult Factory

Recommended Oil

10W30 or 10W40

Multiviscosity motor oil

SAE-20W motor oil

Multiviscosity motor oil

5W30 Multiviscosity motor oil

GEARBOX LUBRICATION REQUIREMENTS

Under normal operating conditions the oil should be changed after 10,000 hours of

service. The oil should, however, be changed at least every four years.

Oil Change

1. Drain the old oil at operating temperature.

2. Remove the vent plug located at the top of the gearbox.

3. Remove the plug at the bottom, which will allow the oil to run out.

4. The oil used to flush the gearbox should have a viscosity of ISO 46 – 68 at 40ºC. To

flush the gearbox, use twice the amount of oil specified for lubrication. After a few

minutes of idle running, the oil may be drained.

5. Repeat the flushing operation several times, preferably in both directions of rotation,

and again without a load, to ensure that all remains of the old lubricant are drained

with the flushing oil.

6. Fill the gearbox with the quantity of new oil specified on the gearbox data plate.

20

ROUTINE MAINTENANCE

Oil Grades

For ambient temperatures of approximately -10ºC to +50ºC (14º to 122ºF) a gear oil

of ISO 220 at 40ºC with mild high-pressure additives should be used, DIN 51502

CLP 220, e.g. BP ENERGOL GR-XP 220, Esso Spartan EP 220, SHELL Omala Oel

220, Mobilgear 630, or Aral Degol BG 220.

At high or lower ambient temperatures, the type of oil used should be adapted to the

specific conditions. Contact the Autoquip Customer Assurance department.

Grease Lubrication

If the gearbox casing is filled with low-viscosity grease, it is recommended that this

be changed after every 10,000 hours of service.

1. Open the gearbox casing and flush it thoroughly with a commercial cleaning agent.

2. Fill the casing with new grease. The required quantity of grease is indicated on the

gearbox data plate.

Grease Quality

For ambient temperatures ranging from approximately –10ºC to +50ºC (14º to 122ºF) a

low-viscosity gear grease with a dripping point of approximately 150ºC (300ºF) and a

worked penetration of 380 to 430 1/10 mm should be used, e.g., DIN 51502 GP 00F,

z.B. BP Energrease HT EP00, SHELL Special low-viscosity gear grease H, Esso Fibrax

EP 370, or Aralub FD 00.

21

GENERAL MAINTENANCE

HYDRAULIC CYLINDER REPACKING

1. Raise the lift to its full height and block securely. See “Lift Blocking Instructions”.

2. Hold the “DOWN” control for several seconds to make sure pressure in the lines is

bled down.

3. Disconnect the cylinder hose at the power unit end and insert into the oil-fill hole of

the reservoir.

4. Remove the thrust angle clip from the ram (plunger) end of the cylinder and force

the ram slowly back to its fully closed position to push oil back into the reservoir.

5. Pull the ram all of the way out of the cylinder. Support it carefully so that it does

not drop when it clears the cylinder end. Lay it down in a safe, clean place. Some

oil may drip from the end of the cylinder so have waste cloth or paper beneath the

lift to protect the floor.

6. Remove the seal ring and backup ring.

7. After all of the internal components are removed, use a bright light to inspect the

inner walls of the barrel. Use a cylinder hone to remove any apparent nicks or

scratches. Clean and flush the barrel after honing.

8. Inspect the ram and seal groove for nicks or scratches that could affect the seal or

barrel walls; remove as necessary.

9. Clean the groove thoroughly and install the new seal and backup. Make sure the

backup ring is toward the open end of the cylinder.

10. Clean the ram of all foreign materials.

11. Liberally lubricate the ram and seal with CLEAN grease or oil.

12. Insert the ram carefully back into the cylinder taking precaution against pinching or

tearing the seal ring.

13. Reinstall the clip over the thrust angle.

14. Reconnect the cylinder hose.

22

GENERAL MAINTENANCE

15. Restore the oil level.

16. Loosen the bleeder plug at the top end of the ram casing and operate the pump to

remove trapped air from the ram. When clear oil appears, tighten the plug and

raise the lift slightly to remove the maintenance locks.

17. Lower the lift completely and hold the “DOWN” button for 30-40 seconds to allow

air in the lines to bleed back into the tank.

18. Cycle the lift 10 – 15 times.

19. Check the oil level.

20. Clean the oil fill breather cap.

21. Clean up any debris and/or spilled oil from the area.

NOTE: Depending on experience, the job should take 1 – 2 hours.

PIPE THREAD SEALANT

Loctite PST #567 pipe thread sealant or equivalent is recommended. Do not use

Teflon tape. Tape fragments can cause malfunctioning of the hydraulic system.

23

GENERAL MAINTENANCE

CYLINDER VELOCITY FUSE REPLACEMENT

DANGER!

Do not attempt to remove the velocity fuse until the lift is securely

supported with the maintenance locking devices and all hydraulic pressure

has been removed from the lifting cylinders and hydraulic hoses. Failure

to follow these instructions could result in personal injury or death!

Never attempt to take a velocity fuse apart and repair it. These are precision devices

that are factory assembled under exacting conditions. Velocity fuses should always be

replaced.

1. The arrow on the exterior surface of the velocity fuse shows the direction of the

restriction to the oil flow. The arrow should always point away from the cylinder.

2. Do not use Teflon tape on the threaded connections of a velocity fuse. Tape

fragments can cause malfunctioning of the fuse.

3. Check all fitting connections for hydraulic leaks and tighten as necessary.

HOSE ORIENTATION

To prevent damage to the cylinder hose and possible failure of lift, it is necessary to

establish a correct hose shape and pattern of movement as follows:

1. Raise the lift to its full height and block securely. See “Lift Blocking Instructions”.

2. Install one end of the new hose to the cylinder elbow fitting for single cylinder lifts, or

to the hosing tee or cross for multiple cylinder lifts.

3. Since some hoses are fixed at both ends, it is possible to put a twist in the hose that

will allow it to describe the same pattern each time the lift is operated. This twist will

allow the hose to travel about half way between the cylinder on the right side and the

inner leg on the right side.

4. Lower the lift carefully and check to see that the hose is free and clear of the cylinder

and the inner leg assembly. If not, twist the hose in the direction necessary to clear

it of any obstruction and then lock the swivel fitting securely.

24

GENERAL MAINTENANCE

LIFTING

CYLINDERS

(1) VELOCITY FUSE PER CYLINDER.

QUANTITY OF CYLINDERS AND

VELOCITY FUSES DEPENDS ON

MODEL OF LIFT USED.

VELOCITY FUSES

PRESSURE LINE

RETURN

LINE FILTER

RELIEF

VALVE

LOWERING VALVE AND PRESSURE LINE FILTRATION.

DELTATROL VALVE PROVIDES COMPLETE,

COMPENSATED FLOW CONTROL, SOLENOID

THE FUNCTION OF CHECK, RELIEF, PRESSURE

CHECK VALVE

P.F.

RESTRICTOR

DOWN SPEED

LINE

SUCTION

FILTER

RESERVOIR

SEPERATE FILTER IS SPECIFIED.

SUCTION LINE FILTER IS INTERNAL

TO DELTATROL BLOCK UNLESS A

M

Figure 10 Hydraulic Schematic – Heavy Duty Motor

25

GENERAL MAINTENANCE

Figure 11 Hydraulic Schematic – Super Torque Motor

26

GENERAL MAINTENANCE

WIRING AUTOQUIP "SUPER TORQUE' MOTORS

Because Autoquip "Super-Torque" motors actually deliver substantially more

horsepower than their nameplate rating, they must always be wired for heavier currentdraw than standard motors of the same nameplate rating. However, because of the

starting efficiency and superior running characteristics of the "Super-Torque" motor,

circuit components do not have to be as large as for standard motors of equal delivered

horsepower.

The following chart should be referenced in connecting these motors to power sources,

remembering that, where 115-Volt operation is contemplated, the current-draw is too

heavy for plugging into ordinary lighting circuits. Heavy wire must be used all the way to

the power-source.

HP and Source Fuse

1_ HP / 208-230 V/60 CY/3 PH 15 A 10 A

1_ HP / 460 V/60 CY/ 3 PH 7.5 A 5 A

NOTE: For larger horsepower motors, consult factory.

MOTOR CONNECTION DIAGRAMS

Size

Circuit

Breaker

27

GENERAL MAINTENANCE

LIFT UP-STOP VALVE (when used)

The up-stop valve is bolted to a mounting plate that is permanently welded near the end

of the scissors leg on the clevis end of the lift. A mechanical plunger is located on the

end of the valve which, when depressed, blocks the flow of oil until physically released.

An adjustable striker bolt is mounted to a plate that is welded to the base frame, which

is also at the clevis end of the lift. As the lift travels upward, the scissors leg and upstop valve assembly swings into the adjustable striker bolt until the up-stop plunger is

depressed and thereby blocking the flow of oil to the cylinders. Once blocked, any

further oil pumped from the power unit will pass over the relief back to the tank.

CAUTION!

Do not operate the power unit on relief for more than a few seconds. When

on relief, the valve will make an audible squealing sound.

The up-stop system can be adjusted to modify vertical travel by:

1. Loosen the holding nuts on either side of the adjustable striker bolt.

2. Screw the adjustable striker bolt in (to shorten travel) or out (to raise travel).

3. Retighten the holding nuts.

CAUTION!

Setting the up-stop valve for travel beyond catalogue limits will cause the lift

to fully raise against physical stops and, if the pump is allowed to continue to

run, cause irreversible damage to the lift structure.

28

UP-STOP VALVE

MOUNTING PLATE

OUTPUT PRESSURE

HOSE (TO CYLINDERS)

GENERAL MAINTENANCE

LEG

UP-STOP VALVE

PLUNGER

HOSE (FROM POWER UNIT)

INPUT PRESSURE

UP-STOP VALVE

MOUNTING SCREW

ADJUSTABLE STRIKER

BOLT / BAR

BASE CLEVIS

BLOCK

UP-STOP VALVE

Figure 12 Up-Stop Valve System

29

GENERAL MAINTENANCE

Figure 13 Electro-Hydraulic Schematic; Lift & Traverse Combination

30

REPLACEMENT PART

S

LIST

Specific part numbers vary from job to job, depending on the model and options chosen

for the application. Call the Autoquip Service Department with the serial number of the

specific equipment to order the appropriate parts.

DRIVEN

WHEEL

DRIVEN

WHEEL

DRIVE

WHEEL

DEMAG

GEAR BOX

DEMAG

BREAK MOTOR

DEMAG

BREAK MOTOR

DRIVE

SHAFT

DEMAG

GEAR BOX

IDLE

WHEEL

IDLE

WHEEL

IDLE

WHEEL

POWER

SUPPLY

POWER

SUPPLY

IDLE

WHEEL

POWER

SUPPLY

IDLE

WHEEL

DRIVEN

WHEEL

IDLE

WHEEL

Figure 14 Typical Demag Drive Asembly

31

POWER

SUPPLY

TROUBLESHOOTING ANALYSIS

DANGER!

To avoid personal injury, NEVER go under the lift platform until the load is

removed and the scissors mechanism is securely blocked in the open position.

See "Lift Blocking Instructions" section.

PROBLEM POSSIBLE CAUSE AND SOLUTION

Lift raises, then lowers back

slowly.

• The "Down" solenoid may not be seating. Remove

the solenoid coil and check again. If the lift does

not hold with the solenoid coil removed, the down

valve cartridge should be removed and cleaned or

replaced as necessary.

• The oil line, hose, or fitting may be leaking. Check

and repair if necessary.

• The check valve may not be seating. This is

indicated by the pump shaft and motor turning

backward on their own with no power applied.

Generally, this condition can be heard. Replace

the pump assembly.

Lift lowers very slowly. • The down-solenoid is not operating properly due to

dirt or damage.

• Check for pinched tubing or hose. Where pipe is

used, check for obstruction in the line.

• The oil is extremely viscous due to low ambient

temperatures. Add or replace with lower weight oil

that stays thinner in cold conditions (5W-15, etc.)

32

TROUBLESHOOTING ANALYSIS

PROBLEM POSSIBLE CAUSE AND SOLUTION

Lift does not raise. • The motor rotation for a 3-phase motor may be

reversed. Reverse only two motor electrical leads.

• Check for a line or hose leak.

• Check for oil shortage in the reservoir. Add oil as

necessary (See Oil Requirements in the “Routine

Maintenance” section.)

• The load may exceed the rating. (See the

“Specifications” section.) Remove the excess load.

• The suction screen may be clogged, starving the

pump. Remove and clean the screen. Drain and

replace the oil.

• The suction line may be leaking air due to a loose

fitting. Tighten as needed.

• The breather holes in the reservoir fill plug may be

clogged. Remove and clean.

• The voltage at the motor terminals may be too low to

run the pump with the existing load. Check by

measuring the voltage at the motor terminals, or as

near as possible, while the pump is running under

load. Reading the source voltage or pump-idling

voltage is meaningless. Inadequate or incorrect

wiring can starve the motor when the source voltage

is ample. Correct as necessary.

• The "Down" valve may be energized by faulty wiring

or stuck open. Remove the solenoid and check.

• The motor may be single phasing. Check wiring,

fuses, etc.

• The pump may be seized if motor is humming or

blowing fuses on overload protection devices.

Remove the pump. The pump should be able to be

rotated by hand. Check for cracks in the housing.

33

TROUBLESHOOTING ANALYSIS

PROBLEM POSSIBLE CAUSE AND SOLUTION

Lift won’t lower. • The solenoid coil may be incorrectly wired,

burned out, not rated for the voltage, or the line

voltage may be excessively low. Check voltage

near the coil.

• The velocity fuse may be locked. Do not

attempt to remove the velocity fuse. The

following steps should be followed:

1. Remove the load from the lift. Inspect all

fittings, hoses, and other hydraulic components

for leads or damage.

2. If no leak or damage is noticed, attempt to

pressurize the lifting cylinder by depressing the

“UP” button on the controller for a few seconds.

Immediately up releasing the “UP” button,

depress the “DOWN” button. If the lift starts to

lower, continue pressing the “DOWN” button

until the lift is in the fully lowered position.

3. If the lift does not lower after trying Step 2,

wait approximately 10 – 15 minutes for the

pressure in the hydraulic system to equalize.

Then, depress the “DOWN” button until the lift is

in the fully lowered position.

4. Once the lift is in the fully lowered position,

bleed the air from the hydraulic system by

depressing the “DOWN” button. Hold the

“DOWN” button for approximately 60 seconds.

This step may need to be repeated several

times to fully remove the air in the system by

raising the lift to 50% of its travel and then

lowering it. For the ram-style cylinder, oil may

also bled from the bleed screw located on the

end of each cylinder casing.

• Should the above steps not correct the problem,

contact Autoquip to obtain instruction for further

action.

34

TROUBLESHOOTING ANALYSIS

PROBLEM POSSIBLE CAUSE AND SOLUTION

Lift seems bouncy during

operation.

• Lower the lift to collapsed position and continue to hold

“DOWN” button an additional 10-30 seconds to bleed

air from the bleed screws. Do not confuse spongy or

jerky operation with small surges that may occur when

operating on rough or uneven floors

WARNING!

Do not remove the bleed screw! This could cause

the lift to drop rapidly, resulting in damage to the lift

or cause personal injury. Loosen the screw

carefully to let air out of the system.

• Check for oil starvation.

Motor labors or heats

excessively.

• The voltage may be low. Check at the motor terminals

while the pump is running loaded, not at the line source

or while the pump is idling. Inadequate wiring can

starve the motor even when the source voltage is

ample.

• Most of Autoquip’s standard motors are rated for

intermittent duty (two minute run times with two minute

rests). If a single-phase motor is being run more than

15 – 20 motor starts per hour, or a 3-phase motor more

than 200 starts per hour, the problem may be motor

over-heating.

• Running against relief pressure unnecessarily due to

over loaded lift or hitting physical stops.

• Failure to observe wiring diagram on nameplate for

proper voltage connections.

• The pump may be binding from oil starvation, which

develops high internal heat. Check for low oil level or

closed breather holes in the reservoir fill plug. The

pump can be irreparably damaged by oil starvation and

may have to be replaced.

35

TROUBLESHOOTING ANALYSIS

PROBLEM POSSIBLE CAUSE AND SOLUTION

Lift won’t go forward or

reverse

• The traverse path may be blocked with debris or

other obstacle. Look under the base and

remove any obstacle that may impede travel.

• The axle may be “high centered” on some

obstacle, preventing the wheels from gaining

enough traction. Inspect under the axles and

remove any obstruction.

• The non-rotation devise may have broken or

vibrated loose. Reattach or replace bracket.

• The load may exceed the nameplate capacity

and exceed the horsepower ratings for the drive

train. Ensure the load is within the rated limits.

• There may not be enough amps available.

Check the supply amperage to ensure it

provides the minimum amperage needed per the

vendor’s specifications.

• There may be a loose electrical connection.

Make sure all electrical connections are intact

and check for shorts.

36

Loading...

Loading...