AUTOPILOT SYSTEMS DIG-220 Service Manual

Swimming Pool and Spa Purification System

™

Pool Pilot

Digital

by AUTOPILOT SYSTEMS

INC.

Owners Manual

Pool Owner, save this manual for reference.

Installer, leave this manual with the Pool Owner.

DIG-220

Installation and Operation

(For Indoor or Outdoor Use)

IMPORTANT

Read This Manual Before Installing & Operating

Section 1a – GENERAL PRODUCT INFORMATION

™

Pool Pilot

Digital

by AUTOPILOT SYSTEMS

INC.

Record The Following Information

Installer: _________________________ Date of Installation: __________________________

Control Unit Control Unit

Model Number: DG-220 ____ Serial Number: # ____________________________

Cell Cell

Model Number: SC- ___ Serial Number: # ____________________________

Factory Direct Customer Assistance…

HOTLINE: 1.800.922.6246 or 1.954.772.2255

FAX: 1.954.772.4070

e-mail to: AutoPilotTechSupport@teamhorner.com

Visit Us On The Internet @

http://www.autopilot.com

Manufactured by

AutoPilot Systems, Inc.

5755 Powerline Road • Fort Lauderdale • Florida 33309-2074, U.S.A.

™

Pool Pilot

Digital

by AUTOPILOT SYSTEMS

INC.

1

Section 1b – GENERAL PRODUCT INFORMATION

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

INSTALLATION AND EQUIPMENT RELATED

Installation of all Pool Pilot™ Digital models:

When installing and using your Pool Pilot™ Digital Control Box, basic safety precautions must always

be followed, including the following:

1. DANGER – Risk of electrical shock. To avoid serious injury or death,

¾ Ensure that the electrical panel or filter pump circuit is turned OFF prior to installation or servicing inside any

Autopilot unit.

¾ Mount your control box to ensure the least amount of direct exposure to rain, garden sprinkler water, direct

sunlight or any corrosive environment.

¾ Install Control Box at least 10’ (3 m) for 115VAC Units, from the inside wall of the pool or spa using non-

2. DANGER – To avoid serious injury or death, do not permit children to use this product unless they are closely

supervised at all times. Children should not use spas, hot tubs or pools without permanent adult supervision.

3. WARNING – To avoid personal injury, maintain water chemistry in accordance with manufacturer’s instructions.

4. All field-installed metal components such as rails, ladders, drains or similar hardware within 10’ (3 m) of the spa or hot tub

shall be bonded to the equipment grounding bus with copper conductors not smaller than No. 8 AWG (8.4 mm²).

1 A wire connector is provided on your Pool Pilot™ Digital to connect a minimum No. 8 AWG (8.4 mm²) solid copper

bonding conductor between this unit and any metal equipment, metal enclosures of electrical equipment, metal water pipe

or conduit within 5’ (1.5 m) of the unit.

2 A bonding terminal is located inside your Pool Pilot™ Digital. To reduce the risk of electrical shock, this terminal must

be connected to the grounding means provided in the electrical supply panel with a continuous copper wire equivalent size

to the circuit conductors supplying your Pool Pilot™ Digital.

3 A disconnection device from the power source, with a contact separation of at least 0.12” (3mm) in all poles, must be

incorporated in the fixed wiring for permanently wired units.

4 The input voltage to the Pool Pilot™ Digital must match the 115/230VAC jumper terminals on the Circuit board, marked

“TRANSFORMER PRIMARY”, shown on Page 5.

metallic plumbing. 5’ (1.5 m) minimum distance for 230VAC Units.

Equipment Related

115/230VAC, 50/60 Hz Models (fixed wiring)

SAVE THESE INSTRUCTIONS

2

Section 1c – GENERAL PRODUCT INFORMATION

Table of Contents

Pool Pilot™

Digital

by AUTOPILOT SYSTEMS

INC.

Section 1 GENERAL PRODUCT INFORMATION

1a Product Information and Contact Numbers ................................................................. 1

1b Important Safety Instructions ................................................................. 2

1c Table of Contents ................................................................. 3

Section 2 INSTALLATION

2a Main Components ................................................................. 4

Control Box Installation ................................................................. 4

Electrical Connections

Cell Cord and Tri-Sensor Connections

ORP Connections

2b Cell and Manifold Installation ................................................................. 6

Verification of Flow Switch Protection ................................................................. 6

Section 3 OPERATION

3a Key Features – Display Panel ................................................................. 7-9

3b Pool Water Preparation ................................................................. 10

Salt Requirement Chart

Start-Up Procedures

3c Monitoring and Maintenance ................................................................. 11

Water Chemistry Parameters

Saturation Index

Section 4 SERVICE and MAINTENANCE

4a Control Box and Fuse Locations ................................................................. 12

Tri-Sensor Assembly ................................................................. 12

4b Cell ................................................................. 13

Removal and Inspection

Maintenance and Cleaning

Filter Backwashing ................................................................. 13

4c Parts Explosion ................................................................. 14

Section 5 TROUBLESHOOTING

5a Troubleshooting ................................................................. 15

3

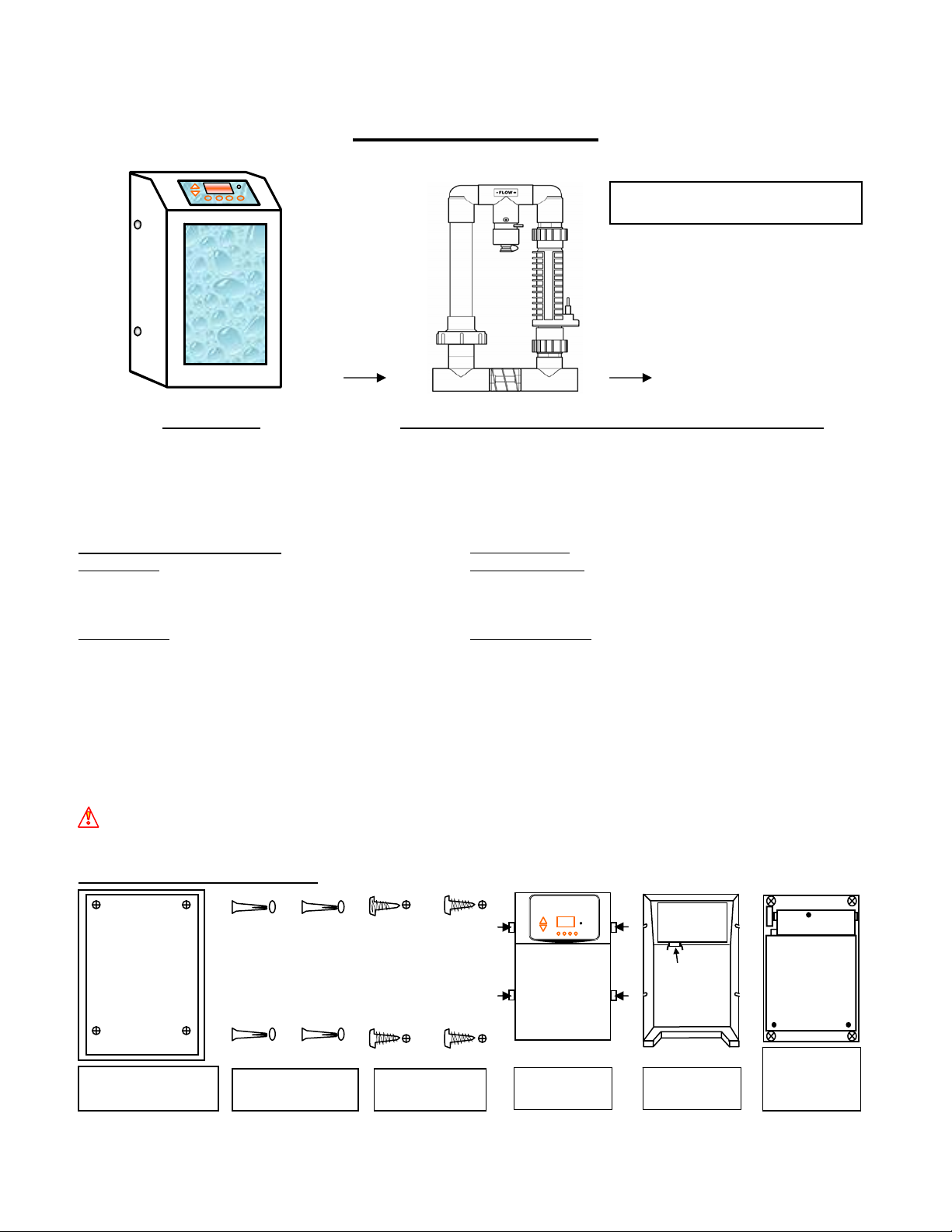

Section 2a – INSTALLATION

g

Main Components

Control Box Patented Automatic Flow Bypass Manifold Assembly

converts incoming AC power to a Low ELECTROLYTIC SUPERCELL TRI-SENSOR ASSEMBLY

Voltage DC current, which energizes the receives Low Voltage DC current from ensures that adequate Flow,

Cell(s). the Power Circuit Board, which initiates Salt Level, and Water

the electrolytic process. Temperatures are satisfactory to

prevent abusive conditions for the

cell to operate.

SPECIFICATION RATINGS: Maximum daily

Input Power: 115 VAC (3.0 AC amps) Cl2 Output Rating: SC-60 1.92 lbs/day (0.88 kg/day)

230 VAC (1.5 AC amps) @ Cell Power 3 SC-48 1.56 lbs/day (0.71 kg/day)

50/60 Hz (8 amps DC) SC-36 1.28 lbs/day (0.58 kg/day)

Output Power: Cell Power 1 (5.0* DC amps) Agency Approvals: NSF, ETLUS, ETLC, CE

Cell Power 2 (6.5* DC amps)

Cell Power 3 (8.0* DC amps) Internal Pump Relay is rated for 30-amp max.

*Indicates nominal amperage output. The dual axis controller will slightly vary the amps to optimize the power to the cell.

12’ (3.6 m) of Cell and Tri-Sensor cords are provided with the unit. Ensure that the manifold is located within that distance

from the control box with enough slack to allow for removal for service or maintenance.

The Digital display provides full information and diagnostics for maintenance and operation of your system. The

programmable settings are retained on a microprocessor chip with the clock setting backed-up with a CR-2025 lithium battery.

CAUTION: To avoid over-saturation conditions of your spa, it is suggested to locate the cell downstream of all other

equipment and on the pool return line only. For applications other than as recommended, contact the factory.

CONTROL BOX INSTALLATION

DRILL ¼” (6mm) DRILL ¼” (6mm)

DRILL ¼” (6mm) DRILL ¼” (6mm)

mounting location. Level,

TOP

TEMPLATE FOR DRILLING

POOL PILOT SOFT TOUC H

& POOL PILOT DIGITAL

MOUNTING HOLES.

DRILL 4 ¼” (6mm) H OLES FOR

WALL ANCHORS WHERE SHOWN.

mark holes and drill.

P/N 18550

BOTTOM

Place Template on

Use the (4) provided

plastic anchors and

insert into drilled holes.

provided screws,

leavin

Tri-Sensor Assembly

Attach the (4)

a ¼” gap.

Super Cell

POOL PILOT

DIGITAL

Loosen four

fastening screws

and lift off cover.

Maximum Operating Pressure: 50 psi

Maximum Flow Rate: 100 gpm

Mount the Control

Disconnect wire

harness.

Box and tighten

the (4) mounting

screws.

4

Loading...

Loading...