Autonics PRFD Series Catalog Page

PRFD Series

Full Metal, Cylindrical, Long Sensing Distance,

Cable Type Proximity Sensor

Features

Long sensing distance

High impact and wear resistance to friction with the work or

metallic brush (sensing face/housing material: stainless steel)

Reduced possibility of malfunction by aluminum scraps

Excellent noise immunity with specialized sensor IC

Built-in surge protection circuit and output short over current

protection circuit

Stability indicator (green LED) and operation indicator (red LED)

:excellentvisibilitywiththe360˚ringtypeindicator(except for PRFDT08 model)

Equipped with the oil resistant cable

Protection structure: IP67 (IEC standard)

Please read “Safety Considerations”

in the instruction manual before using.

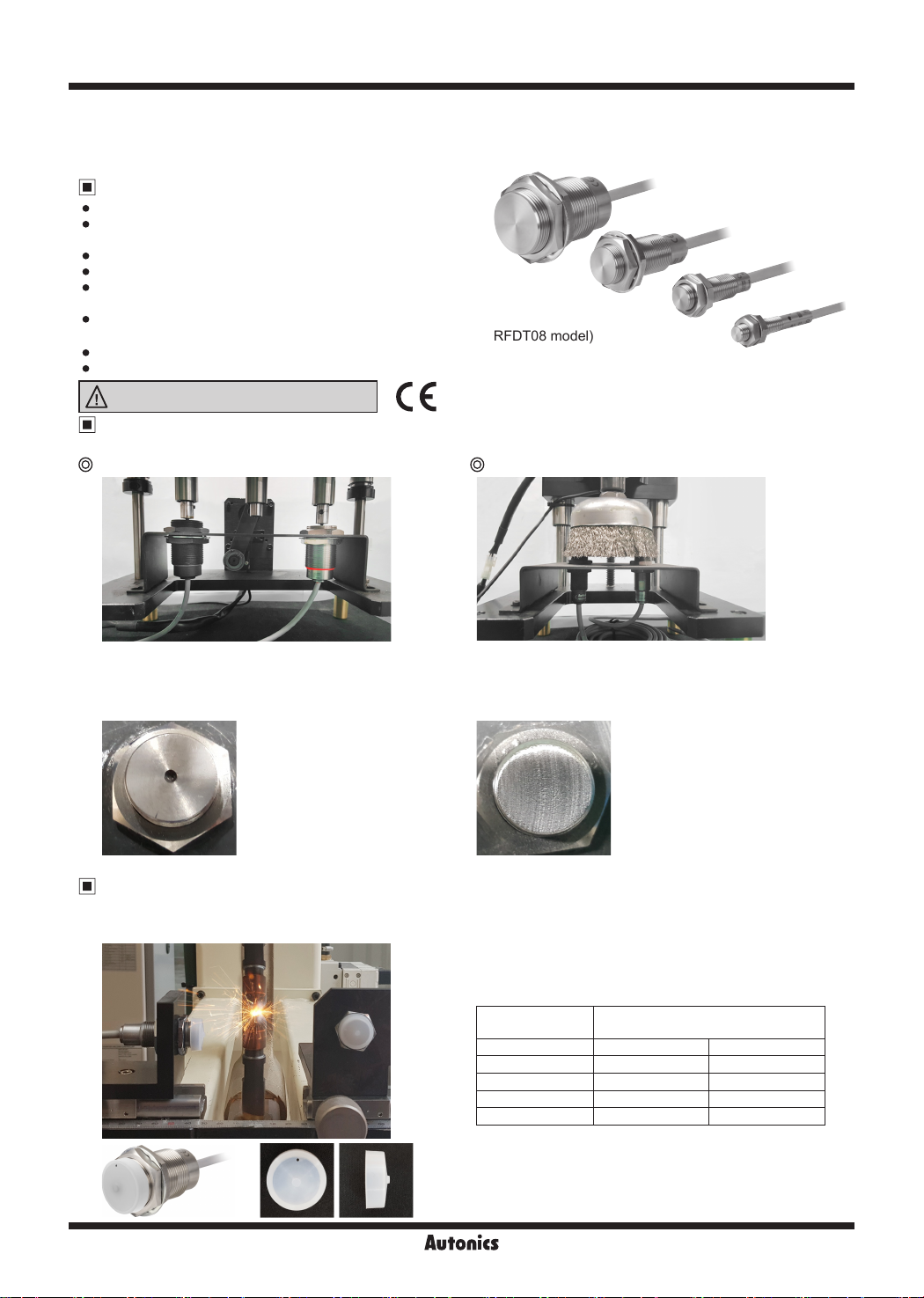

Durability Test

High resistance to the impact of removing Welding sludge attached to the sensing face

Continuous hitting test Metallic brush test

Test conditions

Hitting object: 1.3kg of weight

Hitting speed: 48 times per 1 min

The number of hitting times: 300 thousand times

Test model: PRFD18

<Test result> <Test result>

Electromagnetic Resistance Test

Largecurrentfromweldinggeneratesmagneticeldwhichcanaffecttheproximitysensortomalfunctionduetonoise.

This product, however, can be used near strong noise without malfunctioning, thanks to excellent electromagnetic resistance.

This test is conducted in the environment of welding.

F-48

Test conditions

Testing object: stainless cup brush

Rotation speed: 80RPM

Testing time: 3 hours

Test model: PRFD18

Test conditions

Welding current: 13,000A

Installation direction: front and side

Test model: PRFD Series

Diameter of

sensing side

Installation direction Front Side

8mm 80mm 80mm

12mm No effect from noise 50mm

18mm 30mm 50mm

30mm 120mm 110mm

※

Minimum sensing distance can be different by welding

environment.

※

When using PRFD Series in the environment of welding, use the

spatter-resistant protection cover.

The protection cover is sold separately. Refer to the 'Proper Usage'

in (F) Proximity Sensors for usage of the protection cover.

Minimum sensing distance between

weld and sensor

Full Metal, Cylindrical, Long Sensing Distance, Cable Type

Effect of Aluminum Scraps

When aluminum scraps are attached or stacked at sensing side, the proximity sensor does not detect and sensing signal is OFF.

However, the below cases may occur to sensing signal. In this case, remove the scraps.

(1) When the size of aluminum scraps (d) is bigger than 2/3 of the

sensing side size (D)

(d)

(D)

Model

PRFDT08 6

PRFDT12 10

PRFDT18 16

PRFDT30 28

Size

D (mm)

(2) When aluminum scraps are attached on the sensing side by

external pressure

External pressure

Aluminum scraps

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

Specifications

● DC 2-wire type

Model

Diameter of sensing side 8mm 12mm 18mm 30mm

Sensing distance

※

1

Installation Shield (ush)

Hysteresis Max. 15% of sensing distance

Standard sensing target 12×12×1mm (iron) 12×12×1mm (iron) 30×30×1mm (iron) 54×54×1mm (iron)

Setting distance 0 to 1.4mm 0 to 2.1mm 0 to 4.9mm 0 to 8.4mm

Power supply (operating voltage)

Leakage current Max. 0.8mA

Response frequency

※

Residual voltage Max. 3.5VDC

Affection by Temp. Max. ±20% for sensing distance at ambient temperature 20

Control output Max. 3 to 100mA

Insulation resistance Over 50MΩ (at 500VDC megger)

Dielectric strength 1,000VAC 50/60Hz for 1 min

Vibration 1.5mm amplitude at frequency 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Shock

Indicator Stability indicator: green LED, Operation indicator: Red LED

Ambient temperature

Environ-

ment

Ambient humidity 35 to 95%RH, storage: 35 to 95%RH

Protection circuit Surge protection circuit, output short over current protection circuit

Protection IP67 (IEC standard)

※

3

Cable

Material

Approval

※5

Weight

※

1: Use accessories (nut, washer) made of SUS. Or, sensing distance cannot be guaranteed.

2: The response frequency is the average value. The standard sensing target is used and the width is set as 2 times of the standard

※

sensing target, 1/2 of the sensing distance for the distance.

※

3: Do not pull the Ø4mm cable with a tensile strength of 30N or over and the Ø5mm cable with a tensile strength of 50N or over.

It may result in fire due to the broken wire. When extending wire, use AWG22 cable or over within 200m.

※

4: Option is 5m.

5: The weight includes packaging. The weight in parenthesis is for unit only.

※

※

Environment resistance is rated at no freezing or condensation.

PRFDT08-2DO-V PRFDT12-3DO-V PRFDT18-7DO-V PRFDT30-12DO-V

2mm 3mm 7mm 12mm

12-24VDCᜡ (10-30VDCᜡ)

2

150Hz 80Hz 80Hz 50Hz

ᜡ

℃

500m/s2 (approx. 50G)

in each X, Y, Z direction

1,000m/s2 (approx. 100G) in each X, Y, Z direction for 10 times

for 10 times

-25 to 70℃, storage: -25 to 70

※

Ø4mm, 2-wire, 2m

4

℃

Ø5mm, 2-wire, 2m

※

4

AWG22, core diameter: 0.08mm, no. of cores: 60, insulator diameter: Ø1.25mm

Case/Nut: Stainless steel 303(SUS 303), Washer: Stainless steel 304(SUS 304),

Sensing side: Stainless steel 303 (SUS 303, thickness of PRFDT08: 0.2mm, PRFDT12/18: 0.4mm,

PRFDT30: 0.5mm), Oil resistant cable (gray): Oil resistant polyvinyl chloride (PVC)

ᜢ

Approx. 80g (approx. 55g) Approx. 110g (approx. 83g) Approx. 132g (approx. 97g)

Approx. 225g (approx. 170g)

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

(C)

LiDAR

(D)

Door/Area

Sensors

(E)

Vision

Sensors

(F)

Proximity

Sensors

(G)

Pressure

Sensors

(H)

Rotary

Encoders

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

F-49

Loading...

Loading...