PRFA Series

Full Metal, Cylindrical, Spatter-Resistance, Cable Type, Proximity Sensor

Features

High impact and wear resistance to friction with the work or metallic brush

(sensing face/housing material: stainless steel)

Reduced possibility of malfunction by aluminum scraps

Prevent malfunction due to spatter with PTFE coating

Excellent noise immunity with specialized sensor IC

Built-in surge protection circuit and output short over current

protection circuit

Excellent visibility with a 360° ring type of indicator (red LED)

(except for PRFAT08 model)

Equipped with the oil resistant cable

Protection structure: IP67 (IEC standard)

Please read “Safety Considerations”

in the instruction manual before using.

The Characteristic of Spatter-Resistance Type

The hot arc from arc welding machine is adhesive even with metals or plastics.

Therefore, normal proximity sensor might have malfunction even though there are no sensing object if the arcs are put on the sensing

surface. The arcs are not adhered on the sensing part of the spatter-resistance type proximity sensor as the part is coated with PTFE

against thermal resistance.

Also, the protection cover sold optionally has the same function.

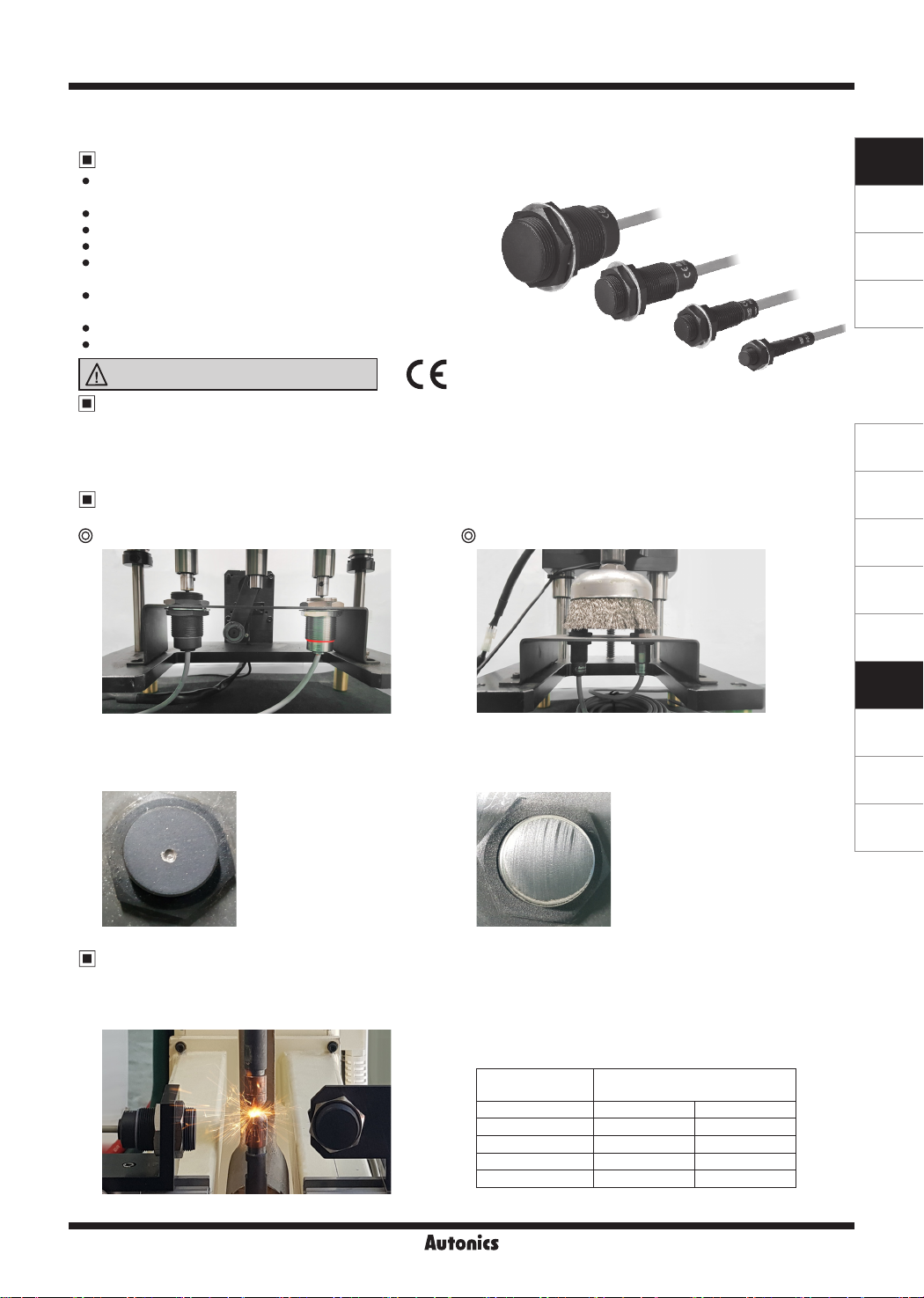

Durability Test

Highly resistant to the impact of removing welding sludge attached to the sensing face

Continuous hitting test Metallic brush test

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

(C)

LiDAR

Test conditions

Hitting object: 1.3kg of weight

Hitting speed: 48 times per 1 min

The number of hitting times: 300 thousand times

Test model: PRFA18

Test conditions

Testing object: stainless cup brush

Rotation speed: 80RPM

Testing time: 3 hours

Test model: PRFA18

<Test result> <Test result>

Electromagnetic Resistance Test

Large current from welding generates magnetic eld which can affect the proximity sensor to malfunction due to noise.

This product, however, can be used near strong noise without malfunctioning, thanks to excellent electromagnetic resistance.

This test is conducted in the environment of welding.

Test conditions

Welding current: 13,000A

Installation direction: front and side

Test model: PRFA Series

Diameter of

sensing side

Minimum sensing distance between

weld and sensor

Installation direction Front Side

8mm 60mm 70mm

12mm 30mm 60mm

18mm 10mm 50mm

30mm 120mm 120mm

※Minimum sensing distance can be different by welding

environment.

F-37

(D)

Door/Area

Sensors

(E)

Vision

Sensors

(F)

Proximity

Sensors

(G)

Pressure

Sensors

(H)

Rotary

Encoders

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

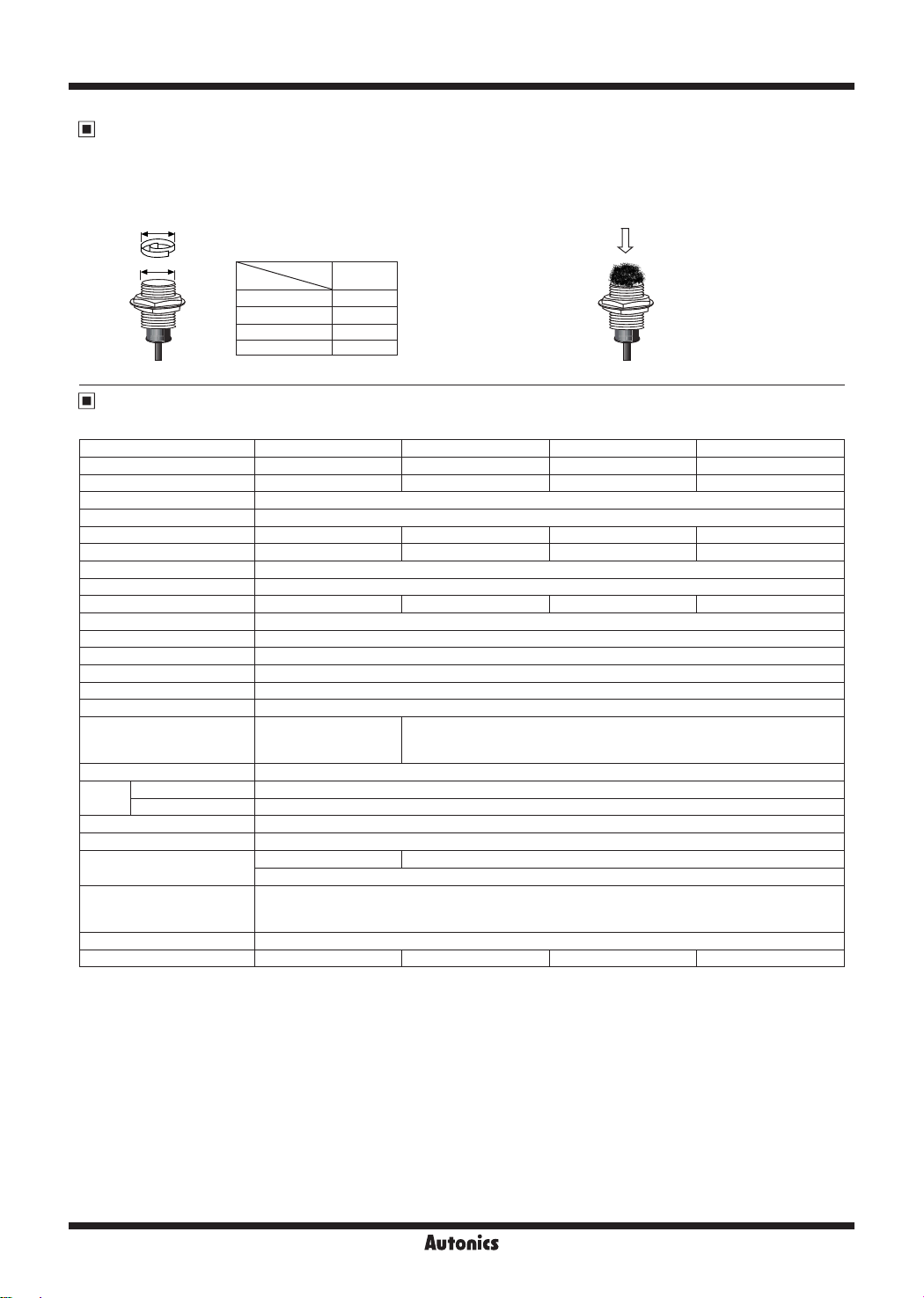

PRFA Series

Effect of Aluminum Scraps

When aluminum scraps are attached or stacked at sensing side, the proximity sensor does not detect and sensing signal is OFF.

However, the below cases may occur to sensing signal. In this case, remove the scraps.

(1) When the size of aluminum scraps (d) is bigger than 2/3 of the

sensing side size (D)

(d)

(D)

Model

PRFAT08 6

PRFAT12 10

PRFAT18 16

PRFAT30 28

Size

D (mm)

Specifications

● DC 2-wire type

Model

Diameter of sensing side 8mm 12mm 18mm 30mm

Sensing distance

※

1

Installation Shield (ush)

Hysteresis Max. 15% of sensing distance

Standard sensing target 8×8×1mm (iron) 12×12×1mm (iron) 30×30×1mm (iron) 54×54×1mm (iron)

Setting distance 0 to 1.05mm 0 to 1.4mm 0 to 3.5mm 0 to 7mm

Power supply (operating voltage)

Leakage current Max. 0.8mA

Response frequency

※

2

Residual voltage Max. 3.5V

Affection by Temp. Max. ±20% for sensing distance at ambient temperature 20

Control output Max. 3 to 100mA

Insulation resistance Over 50MΩ (at 500VDC megger)

Dielectric strength 1,000VAC 50/60Hz for 1 min

Vibration 1.5mm amplitude at frequency 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Shock

Indicator Operation indicator: Red LED

Ambient temperature -25 to 70℃, storage: -25 to 70

Environ-

ment

Ambient humidity 35 to 95%RH, storage: 35 to 95%RH

Protection circuit Surge protection circuit, output short over current protection circuit

Protection IP67 (IEC standard)

※

3

Cable

Material

Approval

※

5

Weight

※

1: Use accessories (nut, washer) made of SUS. Or, sensing distance cannot be guaranteed.

2: The response frequency is the average value. The standard sensing target is used and the width is set as 2 times of the standard

※

sensing target, 1/2 of the sensing distance for the distance.

※

3: Do not pull the Ø4mm cable with a tensile strength of 30N or over and the Ø5mm cable with a tensile strength of 50N or over.

It may result in fire due to the broken wire. When extending wire, use AWG22 cable or over within 200m.

※

4: Option is 5m.

5: The weight includes packaging. The weight in parenthesis is for unit only.

※

※

Environment resistance is rated at no freezing or condensation.

PRFAT08-1.5DO-V PRFAT12-2DO-V PRFAT18-5DO-V PRFAT30-10DO-V

1.5mm 2mm 5mm 10mm

12-24VDCᜡ (10-30VDCᜡ)

200Hz 100Hz 80Hz 50Hz

500m/s2 (approx. 50G)

in each X, Y, Z direction

1,000m/s2 (approx. 100G) in each X, Y, Z direction for 10 times

for 10 times

℃

※

Ø4mm, 2-wire, 2m

4

Ø5mm, 2-wire, 2m

AWG22, core diameter: 0.08mm, no. of cores: 60, insulator diameter: Ø1.25mm

Case/Nut: Stainless steel 303 (SUS303, PTFE coated), Washer: Stainless steel 304 (SUS304),

Sensing side: Stainless steel 303 (SUS303 , PTFE coated, thickness is 0.8mm, in case of PRFAT08 is 0.4mm),

Oil resistant cable (gray): Oil resistant polyvinyl chloride (PVC)

ᜢ

Approx. 80g (approx. 55g) Approx. 110g (approx. 83g)

(2) When aluminum scraps are attached on the sensing side by

external pressure

External pressure

Aluminum scraps

℃

※

4

Approx. 132g (approx. 97g)

Approx. 225g (approx. 170g)

F-38

Full Metal, Cylindrical, Spatter-Resistance, Cable Type

Dimensions

Ø15

13

PRFAT18-5DO-V

Ø29

24

Control Output Diagram & Load Operating

● DC 2-wire type

Main circuit

48

28

Operation

M8×1

4

4

36

50

M18×1

indicator (red)

Operation

indicator (red)

Ø4, 2m

Ø5, 2m

Normally Open (N.O.)

Brown

Load

+V

Sensing

target

Load

Blue

0V

Opreration

Indicator

(red LED)

PRFAT12-2DO-V PRFAT08-1.5DO-V

Ø21

17

PRFAT30-10DO-V

Ø42

36

Presence

Nothing

Operation

Return

ON

OFF

(unit: mm)

SENSORS

46

33

4

5

indicator (red)

54

40

Operation

M30×1.5

indicator (red)

Operation

M12×1

Ø5, 2m

Ø5, 2m

CONTROLLERS

MOTION DEVICES

SOFTWARE

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

(C)

LiDAR

(D)

Door/Area

Sensors

(E)

Vision

Sensors

(F)

Proximity

Sensors

(G)

Pressure

Sensors

(H)

Rotary

Encoders

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

Connections

● DC 2-wire type

Brown

Load

Blue

Brown

Blue

Load

※

Load can be wired to any direction.

+24VDC

0V

+24VDC

0V

F-39

PRFA Series

Sensing Distance Feature Data by Target

Material and Size

PRFAT08-1.5DO-V

1.80

1.60

1.40

1.20

1.00

0.80

0.60

Sensing distance X (mm)

0.40

0.20

0.00

4 8 10 12 15 18 20 25

※

1: Aluminum(ALS052), Copper(C1100)

PRFAT18-5DO-V

One side length of sensing target d (mm)

12.00

10.00

8.00

6.00

4.00

2.00

Sensing distance X (mm)

0.00

4 8 10 12 15 18 20 25

※

1: Aluminum(ALS052), Copper(C1100)

One side length of sensing target d (mm)

30

35 40

30

35 40

45 50

45 50

60

60

70

70

75 80

75 80

90 100

90 100

Iron (SS401)

Stainless steel 364

(SUS364)

Brass (C3601)

※

1

Iron (SS401)

Stainless steel 364

(SUS364)

Brass (C3601)

※

1

※

Detecting

Method

PRFAT12-2DO-V

2.50

2.00

1.50

1.00

Sensing distance X (mm)

0.50

0.00

4 8

10 12 15 18

1: Brass(C3601), Aluminum(ALS052), Copper(C1100)

PRFAT30-10DO-V

20 25 30 35 40

One side length of sensing target d (mm)

12.00

10.00

8.00

6.00

4.00

2.00

Sensing distance X (mm)

0.00

4 8 10 12 15 18 20 25

One side length of sensing target d (mm)

30

35 40

45

45 50

50

60

60

70

70 75 80

75 80

Sensing

distance (X)

90 100

90 100

d

target

Sensing

Iron (SS401)

Stainless steel 364

(SUS364)

※

1

Iron (SS401)

Stainless steel 364

(SUS364)

Brass (C3601)

Aluminum (ALS052)

Copper (C1100)

length

One side

Sensing Distance Feature Data by

Parallel (Left/Right) Movement

PRFAT08-1.5DO-V

1.5

1.3

1.1

0.9

0.7

Sensing area (mm)

0.5

0.3

0.1

3.0 2.0 1.0 0.0 1.0 2.0 3.0

Left ← Center → Right

Sensing area Y (mm)

PRFAT12-2DO-V

2.0

1.5

Sensing area (mm)

1.0

0.5

3.0 2.0 1.0

0.0 1.0

Left ← Center → Right

Sensing area Y (mm)

2.0 3.0

PRFAT18-5DO-V

5.0

4.0

3.0

Sensing area (mm)

2.0

1.0

6.0 4.0

2.0

0.0

Left ← Center → Right

Sensing area Y (mm)

2.0

4.0 6.0

Sensing

area (Y)

Detecting

Method

PRFAT30-10DO-V

10.0

9.0

8.0

7.0

6.0

5.0

Sensing area (mm)

4.0

3.0

2.0

1.0

15.0 10.0 5.0 0.0 5.0 10.0 15.0

Left ← Center → Right

Sensing area Y (mm)

Sensing

target

Sensing

distance (X)

F-40

Full Metal, Cylindrical, Spatter-Resistance, Cable Type

Proper Usage

Load connections

Brown

+

POWER

Blue

-

<DC 2-wire type> <DC 2-wire type>

When using DC 2-wire type proximity sensor, the load must be connected, otherwise internal components may be

damaged. The load can be connected to either wire.

In case of the load current is small

● DC 2-wire type

Brown

Load

+

Bleeder resistor(R)

Blue

Vs

-

Vs: Power supply,

[

Ioff: Return current of load,

Please make the current on proximity sensor smaller than the return current of load by connecting a bleeder resistor in

parallel.

※

W value of Bleeder resistor should be bigger for proper heat dissipation.

R ≤

Io-Ioff

Brown

Load

+

24VDC

-

Load

Blue

V

s

(kΩ)

P >

V

R

s

2

(W)

Io: Min. action current of proximity sensor,

P: Number of Bleeder resistance watt

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

]

(C)

LiDAR

(D)

Door/Area

Sensors

Mutual-interference & Influence by surrounding metals

When several proximity sensors are mounted close to one another a malfunction of the may be caused due to mutual

interference. Therefore, be sure to keep a minimum distance between the two sensors as below chart indicates.

Parallel

A

Face to Face

B

When sensors are mounted on metallic panel, it is required to protect the sensors from being affected by any metallic

object except target. Therefore, be sure to provide a minimum distance as below chart indicates.

m

Ød

ℓ

Item

ℓ

Model

PRFAT08-1.5DO-V PRFAT12-2DO-V PRFAT18-5DO-V PRFAT30-10DO-V

A 35 40 65 110

B 30 35 60 100

ℓ 0 0 0 0

Ød 8 12 18 30

m 4.5 8 20 40

n 30 40 60 100

n

ℓ

(unit: mm)

(E)

Vision

Sensors

(F)

Proximity

Sensors

(G)

Pressure

Sensors

(H)

Rotary

Encoders

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

F-41

Loading...

Loading...