SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(Y)

Closed Loop

Stepper System

(Z)

Stepper Motors

(AA)

Drivers

(AB)

Motion

Controllers

PMC-1HS/PMC-2HS Series

1·2-Axis High Speed Programmable Motion Controller

▣ Features

● Max. 4Mpps high-speed operation

● 4 operation modes: Jog, Continuous, Index, Program mode

● 12 control command and 64 steps of operations

● Parallel I/O terminal built in which is connectable on PLC

● Create and edit operating programs, parameters by

dedicated software

● Easy to operation of X, Y stage with joy stick

● RS232C port for all types

● Teaching and monitoring function by using teaching unit

(PMC-2TU-232, sold separately)

Please read “Safety Considerations”

in the instruction manual before using.

▣ Manual

For the detail information and instructions, please refer to user manual and

be sure to follow cautions written in the technical descriptions

▣ Software (atMotion)

atMotion is a comprehensive motion device management program that can be used with Autonics motion controllers.

•

atMotion provides GUI control for easy and convenient parameter setting and monitoring data management of multiple devices.

•

PMC-1HS

(USB)

PMC-1HS

(232)

PMC-2HS

(USB)

PMC-2TU-232,

sold separately

PMC-2HS

(232)

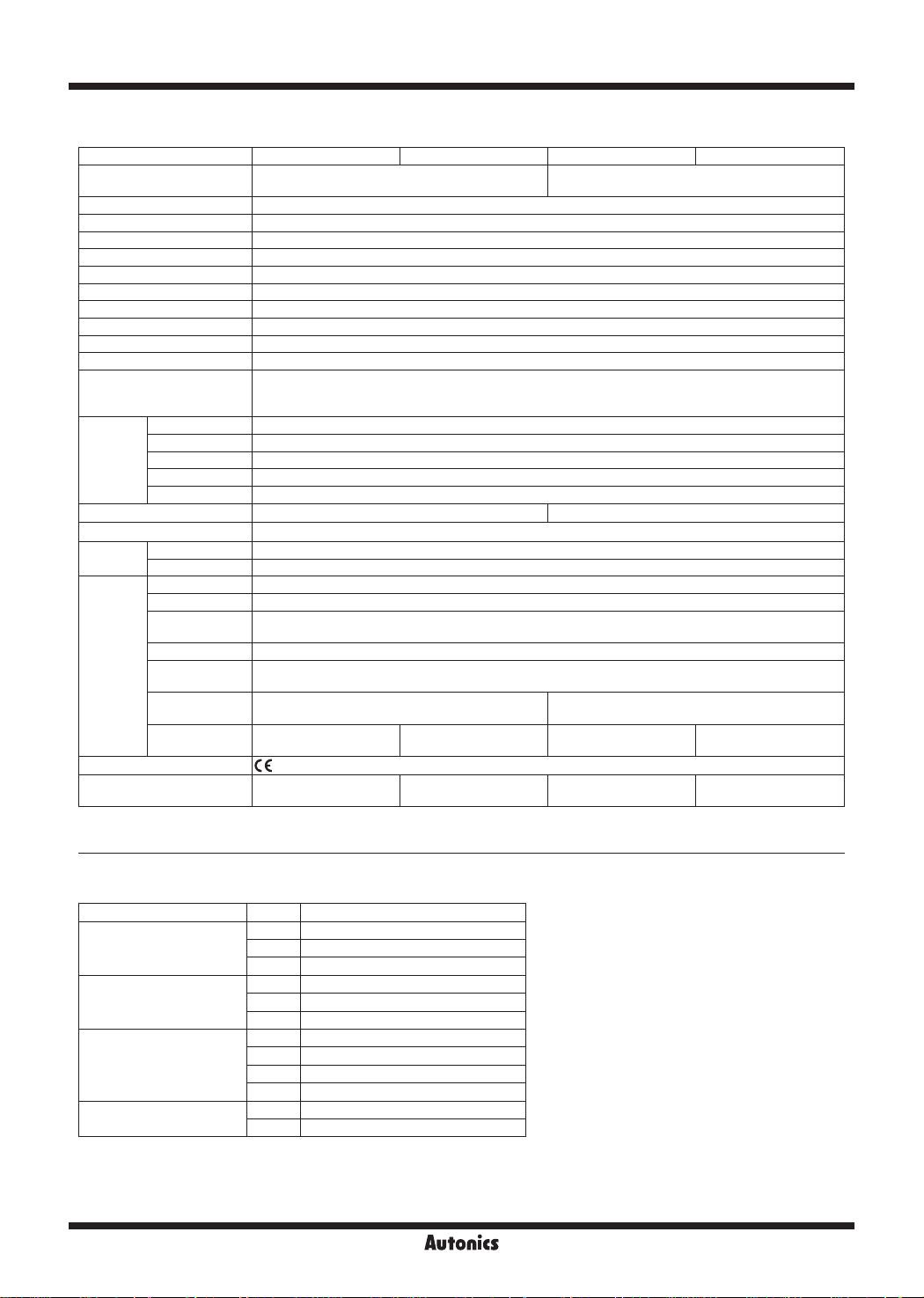

< Computer specification for using software>

Item Minimum requirements

System IBM PC compatible computer with Intel Pentium Ⅲ or above

Operations Microsoft Windows 98/NT/XP/Vista/7/8/10

Memory 256MB+

Hard disk 1GB+ of available hard disk space

VGA Resolution: 1024×768 or higher

Others RS-232 serial port (9-pin), USB port

< atMotion screen >

▣ Standard Operation Method

There are four methods to operate PMC-1HS/PMC-2HS.

● Start with PC

Connect a PC and the motion controller body via a communication cable, starts the operation program.

● Start with Parallel I/F

Connect a sequence controller or switch to the Parallel I/F.

● Start with teaching unit (PMC-2TU-232, sold separately)

Connect a communication cable annexed to a teaching unit (PMC-2TU-232).

It is available to execute Jog output, home output and programs by drive operation of teaching unit.

● Control by serial communication

The PMC-1HS/2HS Series provides serial communication commands.

The PMC-1HS/2HS is connected to a PC or a sequence controller via an USB cable or RS-232C communication cable and it can control

axes by means of user's independent program.

▣ Ordering Information

PMC 2HS

Axis/Type

Item

-I

USB

I

Communication type

232 RS232C

USB USB, RS232C multiple use

I I

1HS 1-axis high speed stand-alone

2HS 2-axis high speed stand-alone

PMC Programmable Motion Controller

Autonics

AB-3

PMC-1HS/PMC-2HS Series

▣ Specifications

Model PMC-1HS-232 PMC-1HS-USB PMC-2HS-232 PMC-2HS-USB

Control axes 1-axis

Motor for control Pulse train input stepper motor or servo motor

Power supply 24VDCᜡ ±10%

Power consump ion Max. 6W

Operation mode Jog / Continuous / Index / Program mode

In-Position setting ABSOLUTE / INCREMENTAL method

Number of index steps 64 indexes per axis

In-Position range -8,388,608 to +8,388,607 (supports pulse scaling function)

Number of drive speed 4

Drive Speed 1pps to 4Mpps (1 to 8,000×magnication 1 to 500)

Pulse output method 2-pulse output method (line driver output)

Home search mode

Save EEPROM

Program

function

General output 1-point 2-point

Control interface Parallel I/F

Environment

Accessory

Approval

Weight

1: The weight includes packing. The weight in parenthesis is for unit only.

※

※

Environment resistance is rated at no freezing of condensation.

Steps 64-step

Control command ABS, INC, HOM, IJP, OUT, OTP, JMP, REP, RPE, END, TIM, NOP (12 types)

Start Available power ON program auto start setting

Home search Available power ON home search setting

Ambient temp. 0 to 45℃

Ambient humidity 35 to 85%RH

Common User manual, CD

Power connector [CN1] MC1, 5/2-ST-3.5 (PHOENIX): 1

RS-232C

connector

P I/F connector [CN3] 20P MIL standard, 2.54mm connector: 1

X-axis I/O

connector

Y-axis I/O

connector

USB connector

1

※

High speed near home search (Step 1) → Low speed near home search (Step 2)

→ Encoder Z-phase search (Step 3) → Oset movement (Step 4).

Conguring the detection direction and Enable/Disable in each step.

[CN2] RS-232C communication cable (1.5m): 1

[CN4] 16P MIL standard, 2.54mm connector: 1 (In case of 2HS, using 2)

-

-

CE:

Approx. 386g

(approx. 96.8g)

I I

2-axis

(Each axis can be independently programmed)

[CN5] 16P MIL standard, 2.54mm connector: 1

USB communication

cable (1m): 1

I I

Approx. 421.6g

(approx. 96.9g)

I I

-

Approx. 393.6g

(approx. 100.2g)

USB communication

cable (1m): 1

Approx. 432.2g

(approx. 100.4g)

▣ Program Commands

Command type Code Description

ABS Move absolute position

Drive commands

I/O commands

Program control commands

Others

AB-4

INC Move relative position

HOM Home search

IJP Jump input condition

OUT ON/OFF of output port

OTP ON pulse from output port (certain time)

JMP Jump

REP Start repetition

RPE End repetition

END End program

TIM Timer

NOP No operation

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(Y)

Closed Loop

Stepper System

(Z)

Stepper Motors

(AA)

Drivers

(AB)

Motion

Controllers

1·2-Axis High Speed Programmable Motion Controller

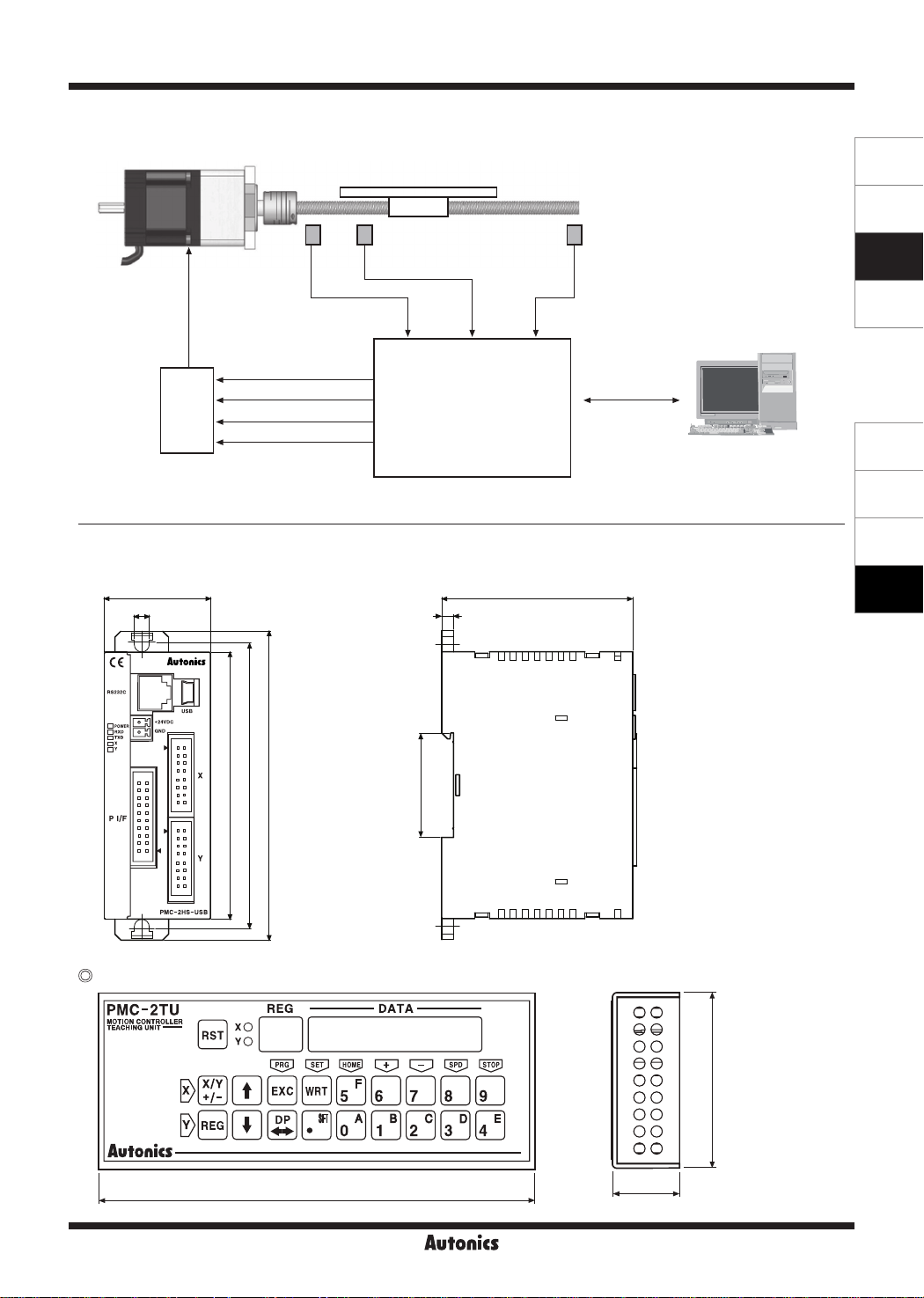

▣ Connections

5-phase stepper motor

+ direction

limit sensor

XLMT+XLMT- XSTOP1

RS232C

USB

PC

64

(unit: mm)

5-phase micro step

CW+

CW-

CCW+

CCW-

< Basic conguration of the motion controller (conguration only for X-axis) >

▣ Dimensions

35.5

5

- direction

limit sensor

motor driver

HOME sensor

XP+P

XP+N

XP-P

XP-N

PMC-1HS/

PMC-2HS

4

=

90

97

104

connectable

35mm DIN rail

Sold separately (teaching unit, PMC-2TU-232)

PMC-2TU

MOTION CONTROLLER

TEACHING

UNIT-

REG

[RsTJ~g

~~

□[

(el

[I] E]

CeJ

~

(el

CD

~

r;:J

DATA

8

EJ

CeJ

[;:]

~Bw~~~~[i::J~~

Autonics

150

Autonics

I

~

r;:J

=

I.

00

gg

00

ee

00

00

00

00

00

23

,-

,_

.I

61.7

AB-5

PMC-1HS/PMC-2HS Series

▣ Unit Descriptions

3

2

1

4

Used to indicate power, communication status of the

controller, and operation status of each axis.

2. Power connector terminal

Used to connect power for controller

3. RS232C connector terminal

1. Power / Status indicator

5

Used to connect RS232 serial (RJ12-DSUB9) connection cable

4. USB/RS485 connector terminal

Used to connect USB and RS485 connection cable

5. External I/O connector terminal

Used to operate various drives through input and output of

Parallel I/F, X, Y

▣ External I/O Terminal Connection

CN2

CN1

CN3

CN6

CN4

CN5

Connector No. Description

CN1 Power connector

CN2 RS232C connector (connect with PMC-2TU-232)

CN3 Parallel I/F connector

CN4 X-axis I/O connector

CN5 Y-axis I/O connector

CN6 USB connector

※

PMC-1HS-232 does not have CN5 and CN6,

PMC-1HS-USB does not have CN5, and

PMC-2HS-232 does not have CN6.

▣ CN1: Power Connector

Pin No. Signal name

1 24VDC

2 GND (0V)

▣ CN2: RS232C Connector

Pin No. Signal name Input/Output Description

1 TXD Output Transmitting data

2 RXD Input Receiving data

3 GND

- -

4

- -

6

- -

The internal connection diagram of RS232C

※

-

communication cable is as shown below.

AB-6

Ground

N.C5

CN2 RS232C connector

1

TXD

2

RXD

GND

3

4

5

6

6P modular

connector

< Internal connection diagram of RS232C communication cable>

Cable length 1.5m

1

6

6P connector Cable

PC connection connector

Autonics

1

2

3

4

5

6

7

8

9

DE-9S

DCD

RXD

TXD

DTR

GND

DSR

RTS

CTS

RI

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(Y)

Closed Loop

Stepper System

(Z)

Stepper Motors

(AA)

Drivers

(AB)

Motion

Controllers

1·2-Axis High Speed Programmable Motion Controller

▣ CN3: Parallel I/F Connector

Motion controller is controlled via Parallel I/F connected with a sequencer or mechanical junction as the dedicated program.

'The input signal is in the ON state' means that the input signal and GEX terminal is connected via a mechanical junction or an open collector.

'The output is in the ON state' means that an open collector output transistor becomes high.

Pin No. Signal name Input/Output Description

1 RESET Input Reset

2 HOME Input Home search start

3 STROBE Input Drive start

4 X/JOG Y+ Input X-axis setting/Jog 2 mode Y+

5 Y/JOG Y- Input Y-axis setting/Jog 2 mode Y-

6 REGSL0/RUN+/JOG X+ Input Register setting 0/Run+/Jog 2 mode X+

7 REGSL1/RUN-/JOG X- Input Register setting 1/Run-/Jog 2 mode X-

8 REGSL2/SPD0 Input Register setting 2/Drive speed setting 0

9 REGSL3/SPD1 Input Register setting 3/Drive speed setting 1

10 REGSL4/JOG Input Register setting 4/Jog setting

11 REGSL5/STOP Input Register setting 5/Drive stop

12 MODE0 Input Operation mode setting 0

13 MODE1 Input Operation mode setting 1

14 X DRIVE/END Output X-axis drive/Drive end pulse

15 Y DRIVE/END Output Y-axis drive/Drive end pulse

16 X ERROR Output X-axis error

17 Y ERROR Output Y-axis error

18 GEX 0V GND

19 GEX 0V GND

20 VEX +24V Power output for sensor (less than 24VDC, 100mA)

<CN3 pin number>

20 19

■■

17

18

■■

15

16

■■

14

■■

12

■■

10

■■

8

■■

6

■■

4

■■

2

■■

▣ Input/Output Connections of CN3

[Hirose connector]: HIF3BA-20PA-2.54DS

[Connector socket specication]: Contact the manufacture for the socket and cable.

13

11

Connector socket H F3BA-20D-2 54R

9

/O cable (sold separately) CO20-HP -L, CO20-HP -R Autonics

7

Specifications Manufacture

Hirose Electric

□ □

5

3

1

◄

VEX (+24VDC)

+5V

2.7k

Inner circuit

Input

(1 to 13)

3.3k

10k

Inner

circuit

GEX

(18, 19)

< CN3 control input connections > < CN3 control output connections >

7.2k

+24V

Output

(14 to 17)

3k

GEX

(18, 19)

Autonics

AB-7

PMC-1HS/PMC-2HS Series

▣ CN4, CN5: X, Y-Axis Input/Output Connector

CN4 and CN5 are the I/O signal connector for X-axis and Y-axis respectively.

The pin arrangement of CN4 and CN5 are equal. PMC-1HS does not have CN5.

'n' in the below table means X for CN4 and Y for CN5.

Pin No. Signal name Input/Output Description

1 nP+P Output CW +direction drive pulse

2 nP+N Output CW -direction drive pulse

3 nP-P Output CCW +direction drive pulse

4 nP-N Output CCW -direction drive pulse

5 n OUT0 Output General output 0/DCC

6 n INPOS Input Servo In-Position complete

7 n ALARM Input Servo alarm

8 GEX 0V GND

9 n STOP2 Input Encoder Z-phase

10 n STOP1 Input Home

11 n STOP0 Input Near Home

12 n LMT+ Input LMT+

13 n LMT- Input LMT-

14 EMG Input Emergency stop

15 GEX 0V GND

16 VEX +24V Power output for sensor (less than 24VDC, 100mA)

※

CN4, 5 input/output circuit except drive pulse is same as CN3 input/output circuit.

Drive pulse output of motion controller which input by motor driver is line driver output.

<CN4, CN5 pin number>

►

1 2

■■

4

3

■■

6

5

7

9

11

13

15

■■

■■

■■

■■

■■

■■

[Hirose connector]: HIF3BA-16PA-2 54DS

[Connector socket specica ion]: Contact he manufacture for the socket and cable.

8

10

Connector socket HIF3BA-16D-2.54R

12

14

16

Specifications Manufacture

Hirose Electric

E.g. Connection with a motor driver

CN4, CN5 Motor driver

1

nP+P

2

nP+N

3

nP-P

4

nP-N

AB-8

E.g. Connect of Limit and Home signal

CN4, CN5

nLMT+

nLMT-

GEX

16

12

13

10

15

VEX (+24V)

nSTOP1

Autonics

+ direction limit

- direction limit

Home

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(Y)

Closed Loop

Stepper System

(Z)

Stepper Motors

(AA)

Drivers

(AB)

Motion

Controllers

1·2-Axis High Speed Programmable Motion Controller

▣ Teaching Unit PMC-2TU-232 (sold separately)

The teaching unit (PMC-2TU-232) is a device that builds the operation mode parameter and operation program for the

main body without a PC. In addition, it can carry out the start of the operation program, the home search and Jog operation.

The teaching unit is used by connection the private cable (1.5m) to the RS-232C connector (CN2) of the main body.

- J

PMC-2TU-232

connection cable (accessory)

Teaching unit consists of data edit mode and drive operation mode.

The data edit mode displays a register number to the REG of the display part, and the drive handling mode displays dp (drive operation).

When turned on, it starts as the drive handling mode (dp display).

The [DP] button is used to convert the status of the data edit mode and the drive operation mode.

Mode Operation REG display

Data edit

Drive handling

The front panel of the teaching unit is as shown below;

2 3

1

• Adding operation mode parameter and operation program

• Index drive operation

• Displaying the current posi ion

• Jog operation

• Home search

• Program execu ion

I • •

Register number

DP

(drive operation)

4

... .. .

1. Reset:

2. X/Y display:

3. Register number display/dp

4. Data display

5. Input button

6. Button display for drive operation

____

6

Reset the controller and teaching unit.

Display the currently selected axis.

:

Displays the currently selected register number when data is editing and dp when operating drive.

:

Displays the data of each register when data is editing and the current position of the selected axis when operating

drive.

• X/Y: Converts the selecting axis. It is used to convert the sign of an input value when the value is entered and a mode

data that the mode data is entered.

• REG:

It is used to input the register number to display.

If this button is pressed on the data input, the data input is canceled and returns to the state before the data input.

• ↑↓: Increases / decreases the displayed register number.

• EXC: Runs the displayed command. However, this command is only valid for ABS, INC, OUT, OTP and HOM 1 to 4

commands.

• DP: Converts the drive handling status and the data edit status.

• WRT: Adds a value when data is editing.

:

Displays button function as yellow letters to the left or the top of the input button in drive handling status.

The top end and the bottom end of the button handle X-axis and Y-axis respectively.

!.

..

xn

8tJ

D i i i

1

!v m D

..........................................................................................

~

!I

Ii

■

Iii

"

.

.....

Ii

II

.. !!

Ii

i

.. ·

5

Autonics

AB-9

Loading...

Loading...