DRW171436AA

Autonics

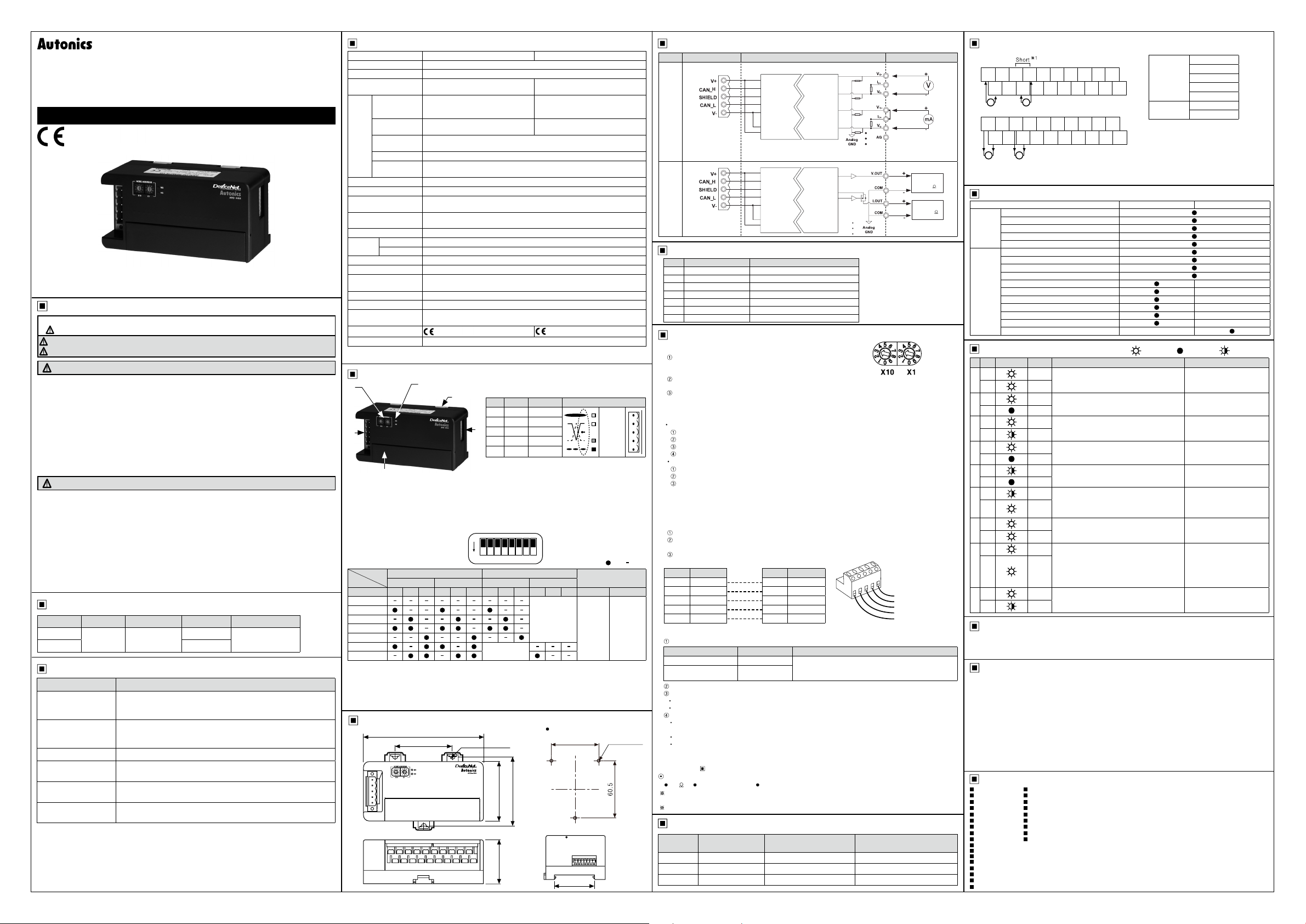

DeviceNet Analog Remote I/O

Standard Terminal Block Type

ARD SERIES

I N S T R U C T I O N M A N U A L

(only for ARD-A 04,

other models are

compatible)

Please read the following safety considerations before use.

Safety Considerations

Please observe all safety considerations for safe and proper product operation to avoid hazards.

※

※

symbol represents caution due to special circumstances in which hazards may occur.

Warning Failure to follow these instructions may result in serious injury or death.

Caution

Warning

1. Fail-safe device must be installed when using the unit with machinery that may cause serious

injury or substantial economic loss. (e.g. nuclear power control, medical equipment, ships,

vehicles, railways, aircraft, combustion apparatus, safety equipment, crime/disaster prevention

devices, etc.)

Failure to follow this instruction may result in re, personal injury, or economic loss.

2.

Do not disassemble or modify the unit.

Failure to follow this instruction may result in re.

3.

Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in re.

4.

Check 'Connections' before wiring.

Failure to follow this instruction may result in re.

Caution

1.

Use the unit within the rated specications.

Failure to follow this instruction may result in re or product damage.

Use dry cloth to clean the unit, and do not use water or organic solvent.

2.

Failure to follow this instruction may result in electric shock or re.

3.

Do not use the unit in the place where ammable/explosive/corrosive gas, humidity, direct

sunlight, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in re or explosion.

4. Keep metal chip, dust, and wire residue from owing into the unit.

Failure to follow this instruction may result in re or product damage.

5.

Do not disconnect terminal or power, when the product is operating.

Failure to follow this instruction may result in re or malfunction.

Model

Model Network Digital/Analog Input/Output Input/Output point

ARD-AI04

ARD-AO04 Output

DeviceNet Communication

tem Specication

Communication

Communication distance

Node address Max. 64 nodes

Communication speed

Insulation

Approval

The communication speed is automatically set to the communication speed of the Master (PC,

※1.

PLC, etc.) When changing the communication speed during operation, the network status (NS) LED

ashes in red and communication is not possible.

The above specications are subject to change and some models may be discontinued

※

without notice.

Be sure to follow cautions written in the instruction manual, user manual, and

※

the technical descriptions (catalog, homepage).

Thank you for choosing our Autonics product.

Failure to follow these instructions may result in personal injury or product damage.

DeviceNet Analog

I/O Slave messaging (Group 2 only slave)

Poll command: Yes Bit_strobe command: Yes

Cyclic command: Yes COS command: Yes

Max. 500m (125 kbps),

Max. 250m (250kbps),

Max.100m (500 kbps)

125 kbps 250 kbps

※1

500 kbps(automatically set when connecting with master)

I/O and inner circuit: Non-insulated,

DeviceNet and inner circuit: insulation, Power of DeviceNet: insulation

ARD-AI04 : DeviceNet conformance

ARD-AO04 : DeviceNet compatible

Input

4-point

Specications

Model ARD-AI04 ARD-AO04

Power supply Rated voltage: 24VDCᜡ, Voltage range: 12-28VDC

Power consumption Max. 3W

Output points

Voltage

Current

Control

Max. allowable

/O

control I/O

Resolution 14-bit, 1/16,000

Accuracy

Insulation resistance Min. 200MΩ (at 500VDC megger)

Noise resistance ±500V the square wave noise(pulse width: 1㎲) by the noise simulator

Dielectric strength

Vibration

Shock 500m/s

Ambient temp. -10 to 50℃, storage: -25 to 75

I

Environment

Ambient humi. 35 to 85%RH, storage: 35 to 85%RH

I

Protection structure IP20(IEC standard)

Protection circuit Surge, ESD protection, Reverse polarity protection circuit

Indicator

Material Front case, Body Case: PC

Mounting DIN rail or screw lock type

Insulation type

Approval

1

※

Weight

※

1: The weight includes packaging. The weight in parentheses is for unit only.

※

Environment resistance is rated at no freezing or condensation.

Unit Description

2

1

2. Rotary switch for node address

3. Status LED

4. Rail lock

5. DIP switch

~

0-5VDC

1-5VDC

0-10VDC

-

-

DC4-20mA

DC0-20mA

※

6. I/O terminal block

~

6

Two rotary switches are used for setting node address.

X10 switch represents the 10's multiplier and X1 switch represents the 1's multiplier.

It displays the status of unit (MS) and network (NS).

t is used for holding DIN rail and fixing screw holes.

Set the range of I/O.

(Factory default: All switches are OFF)

ARD-AI04 (input model) ARD-AO04 (output model)

/O range

5-5VDC

10-10VDC

1: Turn ON SW8 and I/O range can be set by D P switch(SW1 to SW6). Turn OFF SW8 and I/O range can be

t connects /O with external devices.

CH0, CH1 CH2, CH3 CH0, CH1 CH2, CH3

SW1 SW2 SW3 SW4 SW5 SW6 SW1

set by communication.

By DIP switch, CH0 and CH1(CH2 and CH3) cannot be set separately. By communication, each CH can be

set.

Dimensions

4 points of input

(enables to switch voltage/current)

0-10VDCᜡ, -10-10VDCᜡ,

0-5VDCᜡ, 1-5VDCᜡ, -5-5VDC

(input impedance: min. 1MΩ)

DC 4-20mA, DC0-20mA

(input impedance: 250Ω)

±5% for rated output range

At room temperature (25±5

Out of room temperature ranges: ±0.6% F.S.

500VAC 50/60Hz for 1 minute (between external terminals and case, between

output terminals and power terminals)

1.5mm amplitude at frequency of 10 to 55Hz (for 1 min.) in each X, Y, Z direction

for 2 hours

2

(approx. 50G) in each X, Y, Z direction for 3 times

Network status (NS) LED: Green, Red

Unit status (MS) LED: Green, Red

I/O and inner circuit: non-insulated, DeviceNet and inner circuit: insulated,

Power of DeviceNet: insulated

, , DeviceNet compatible

CE:

De"1c:eNe~

Approx. 210g (approx. 145g)

3

4

(iffl~

ON

- -

- - - - - - -

-

-

•

-

•

• •

- -

-

•

-

•

•

•

•

105

50

- -

•

- -

•

-

• • -•

- -

• -•

-

• •

- -

•

ᜡ

±0.3% F.S.

℃):

℃

1.

DeviceNet Connector

No. Color For Organization

5 Red 24VDC(+)

4 White CAN_H

!------1---1--__J

5

3 None SHIELD

2 Blue CAN_L

1------1---1--__J

1 Black 24VDC(-)

1 2 3 4 5 6 7 8

SW2 SW3 SW4 SW5 SW6

- -

•

Not supported

3-Ø4.5

- -

•

•

-

-

•

ᜡ

4 points of output

(voltage: 2CH, current: 2CH)

-0-10VDCᜡ, -10-10VDCᜡ,

0-5VDCᜡ, 1-5VDCᜡ, -5-5VDC ᜡ

(load resistance: min. 1kΩ)

DC4-20mA, DC0-20mA

(load resistance: max. 600Ω)

ICE:

V+

~

:V,·.~

i

[]

■

SW7 SW8

Not Used

(off

setting)

50

CAN_H

SHIELD

CAN_L

V-

( : ON, : OFF)

•

ON

Used DIP

switch

OFF

Not used

D P switch

(unit: mm)

3-M4 Tap

I

I

Not supported

- I - I -

• I - I -

Panel cut out

•

-./~'\

.

--\~!

• I

※

~

'

52

60.5

---L--

' 8

~

I

+

l~U

I

38.5

~

35.3

I•

•I

l/O Circuit Diagram

Item

Analog

input

Analog

output

Input/Output Range

No.

0 0-5VDC

1 1-5VDC 0 8-5.2VDC

2 0-10VDC

3

4

5 DC4-20mA DC3 2-20.8mA

6 DC0-20mA DC0-21mA

Setup and Installation

1) Setting of node address

Two rotary switches are used for setting node address.

X10 switch represents the 10's multiplier and X1 switch represents

the 1's multiplier. Node addresses are available from 0 to 63.

The node address is changed when supplying the power to the unit.

0

Re-supply the power to the unit after changing the node address.

The address of the connected unit must not be duplicated.

When changing the address during operation, the unit status (MS) LED

flashes in red and the unit communicates to the address before the change.

2) Installation of Unit

Installation on panel

Pull two rail locks on the rear part of unit, and there are xing screw holes.

Place this unit on a panel to be mounted.

rn

-

1

Make holes on the each xing screw hole position.

Place this unit on the two xing screw holes and x them tightly with 0 5 N m tightening torque.

Installation on D N rail

Pull two rail locks on the rear part of unit.

Gl

Place this unit on a panel to be mounted.

0

(jJ

Press the rail locks and x it rmly.

3) I/O cable connection

Refer to the I/O circuit diagram and connections.

Connect a sensor or the signal cable of external I/O device to the terminals.

(Tightening torque: 0 5 N m)

4) DeviceNet cable connection

For stable system, it is recommended to use the DeviceNet cable.

Gl

Connect the DeviceNet cable to the DeviceNet connector and tighten the xed screw of the connector by

0

a driver. (Tightening torque: 0 5 N.m)

Connect the DeviceNet connector to the ARD unit and supply the power to the network.

P N No.

5 V+

4 CAN_H

3 SHIELD

2 CAN_L

1 V-

5) Setting of master unit

Check the LED status of ARD unit when power is ON. Normal operation is as below table.

Gl

tem Status LED Status description

Unit status LED (MS) Green LED is ON

Network status LED (NS)

Install the software from master unit manufacturing company.

0

Setting communication speed and node address in the software.

(jJ

Baud rate: 125/250/500 kbps

Node address of master unit: Usually it is set 00 address.

Resister connected unit in the network.

@

There are two methods to resister, automatically in on-line or manually in off-line.

(Refer to the manual of the master unit.)

ARD Series /O assignment: Usually it is automatically assigned by the software.

Setting of operation mode: Select among Poll, COS, Cyclic, Bit Strobe(Usually set Poll mode)

6) Check operating status

When installation and setting are completed, MS LED and NS LED turn ON in green.

(Refer to the Status LED'. )

Terminating resistance

0

120 1 % of metallic film

Q

•

Do not install terminating resistance on ARD unit, or it may cause network problem and malfunction.

*

(Impedance can be too high or low.)

Connect terminating resistance on the both ends of the trunk line.

*

Communication Distance

~

Baud Rate Max. network length Max. length of branch line

125 kbps 500m 6m 156m

250 kbps 250m 6m 78m

500 kbps 100m 6m 39m

I

DeviceNet Connector

CAN...H

SHIELD ,t}:

CAN_L

CAN_H

SHIELD

CAN_L

Input

/Output range Max. allowable input/output range

-

5-5VDC

-

10-10VDC

Master unit

Signal Name

i.i

•

V+

ft

,Q)+-----rt------1

f)+-----rt------1

:(,;)

f}+----i-----__J

JJ,

Inner circuit

Inner circuit Input circuit

Power circuit Power circuit

Inner circuit Output circuit

Power circuit

-

0.25-5 25VDC

-

0.5-10 5VDC

-

5.5-5 5VDC

-

11-11VDC

P N No. Signal Name

Red

5 V+

White

4 CAN_H

None

3 SHIELD

Blue

2 CAN_L

Black

1 V-

Green LED is ON /

ashes

1/4 W

•

ARD unit

When master unit status is communication standby, NS LED

ashes When master unit setting is completed, NS LED is

ON.

Power circuit

External connection

Short V□+ and I□+ and

※

it is current input.

LOAD

Min. 1k

LOAD

Max. 600

E.g.)

X10

The X10 and X1 switches point at "3".

Therefore, the node address is "33".

Allowable expansion length of

branch line

X1

5(Red): V+

4(White): CAN_H

3(None): SHIELD

2(Blue): CAN_L

1(Black): V-

Connections

1. ARD-A 04

V

I0V1I1V2I2V3I

0

l~JI

V

0-

I I

V

2. ARD-AO04

V0V1I0I

I I

COM COM COM COM

B I I I I I I I I I

V

When wiring the communication connector, use cable and tap which meet the DeviceNet standard

※

and tighten the connector screw with a tightening torque of 0.5N.m.

When wiring the input/output terminal, tighten the connector screw with a tightening torque of 0 5N m.

※

1

Short

*

1111

V

AG AG AG AG

1g

V

1-

~

I I I I I I I

mA

N.C N.C N.C N.C N.C N.C

1

I I I I I I

mA

3

V

2-

3-

N.C N.C

N.C N.C

0-5VDC

1-5VDC

Voltage

Current

※1:

N.CN.CN.CN.CN.CN.C

-5-5VDC

0-10VDC

-10-10VDC

DC0-20mA

DC4-20mA

For current input, short between

+

V□

and I□+.

Functions

Model ARD-A 04(Input) ARD-AO04(Output)

Communication speed auto-detection

Network power voltage

Power on total time

Basic

Unit comment

Last maintenance date stored

Scaling

/O comment

Adjustment gradient

Adjustment offset

Number of AD Conversion Points Setting

Analog

Moving Average Filter of Number

Peak/Bottom hold

Disconnected cable detection

Comparator

Hysteresis

Fault state

Status LED

~

No Type LED status Color Description Troubleshooting

MS

1

2

3

4

5

6

7

8

9

~

For the detail information and instructions, please refer to user manual, and be sure to follow cautions

written in the technical descriptions (catalog, homepage).

~

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. 24VDC power supply should be insulated and limited voltage/current or Class 2, SELV power supply

3. Keep away from high voltage lines or power lines to prevent inductive noise.

4. This unit may be used in the following environments.

~

■ ■

■ ■

■ ■

■ ■

■ ■

■ ■

■ ■

■ ■

■ ■

■

■

■

■

■

■

■

■

-¢-

NS Green

-¢-

MS

-¢-

NS

•

MS

-¢-

NS Green

MS

-¢-

*

NS

•

MS

NS

*

•

MS

NS

-¢-

*

MS

-¢-

NS

-¢-

MS

-¢-

NS

-¢-

MS

-¢-

NS

*

Manual

Caution during Use

device.

In case installing power line and input signal line closely, use line filter or varistor at power line and

shielded wire at input signal line.

Do not use near the equipment which generates strong magnetic force or high frequency noise.

Indoors (in the environment condition rated in 'Specifications')

①

Altitude max. 2,000m

②

Pollution degree 2

③

Installation category II

④

Major Products

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSR/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse(Rate)Meters

Rotary Encoders Display Units

Connector/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System(Fiber, Co₂, Nd:yag)

Laser Welding/Soldering System

Normal operation

Green

Output communication or message

communication is working.

Standby duplicated node address check

Green

The status of standby for receiving message of

-

duplicated node address check from master unit.

Standby normal operation

Green

The status of standby for establish connection

from master unit.

Red

Watchdog timer error

Watchdog timer error occurs at the slave unit.

-

Switch setting error

Red

The status that DIP switch or another switch

-

setting is invalid.

Changed node address during normal

Red

operation

The status that node address is changed while it

Green

is operating normally.

Green

Invalid node address

The status of setting node address wrongly.

Red

Red

Duplicated node address

There is duplicated node address in the network.

Bus-Off error

Red

The communication is stopped with Bus-Off.

Green

Input/Output Connection time out

Red

•

•

•

•

•

•

-

:LED ON :LED OFF :LED Flash

-¢-

•

•

•

•

•

•

•

•

•

-

-

-

-

-

-

•

•

*

-

-

-

Change the slave unit.

Change the switch with valid

value and re-supply the

power.

Change the initial node

address when suppling the

power.

Change valid node address

and re-supply the power.

Change node address not

duplicated. Power on the

slave unit again. Check

master unit, communication,

cable, terminating resistance

and noise of network.

Check the master setting and

the user program.

DRW171436AA

Loading...

Loading...