Page 1

2650-598A

12V B

A

TTER

Y

INSTALLATION INSTRUCTIONS

ELECTRIC VACUUM &

®

BOOST/VAC GAUGES

PRESSURE

PORT

TUBING ADAPTER

VACUUM “T”

MAP

SENSOR

NYLON

TUBING

OPTIONAL

SLIT TUBING

RECOMMENDED

(AVAILABLE AT MOST

HARDWARE STORES)

MAP Sensor should be mounted with PRESSURE PORT facing

down. Failure to do so could result in inaccurate readings due to

condensation in the line. (Bracket fabrication may be required.)

GOOD ENGINE

GROUND

GROMMET

FIREWALL

FUSE

(SEE CAUTION

BELOW)

+ 12v DASH

LIGHTING

WHITE

BLACK

+ 12v CONNECTION

*SEE STEP 8 BELOW

NOTE:

RED

BLACK

GOOD ENGINE

GROUND

As a safety precaution, the +12V terminal of this product should be fused before connecting to the 12V ignition switch.

We recommend using a 1 Amp, 3AG fast-acting type cartridge fuse (Littlefuse® # 312 001 or an equivalent).

CAUTION!

Installation

1. Check that you have all parts required for installation, and the engine is cool.

2. Disconnect the negative (-) battery cable.

3. Gauge mounts in a 25⁄8” hole for 25⁄8” gauges, and a 21⁄16” hole for 21⁄16” gauges. Use supplied brackets and nuts to secure gauge to dash.

4. Drill 1” diameter hole where wires pass through sheet metal (such as firewall) and install rubber grommet provided.

(Grommet will require slit.)

5. Securely mount the MAP sensor to the firewall or inner fender with pressure port facing down. (Bracket fabrication may be required.)

6. Install T-Fitting in a manifold vacuum hose. Attach one end of the nylon tubing to the T-Fitting using a tubing adapter. Connect the other

end of the nylon tubing to the MAP sensor with the other tubing adapter.

7. Connect the white wire to dash lighting or switchable 12v light source, and connect the black wire to a good ground.

8. Connect the red power wire to a switched +12 volt source that maintains power during engine cranking. Most vehicles break the electrical

connection to accessories while the engine is being started. If the boost gauge is connected to one of these circuits, the auto zero

function will not work properly and inaccurate readings will result. To determine whether a switched source maintains power during

starting, look for electrical accessories in the vehicle that remain on while the engine is being started. Connect the red power wire to the

same circuit that powers one of these accessories. The connection can be tested by turning the key switch from off to on, the pointer will

move backward to the stop pin and then move to zero. Once the pointer has reached zero, start the engine. If the pointer reads vacuum

without returning to the stop pin, a suitable connection has been found. If the pointer moves to the stop pin and then reads vacuum,

another power circuit must be found.

Power-Up

The pointer will move backward to the stop pin and then move to the zero box. This procedure is an auto-calibration function and is

performed on every power-up. While this test is being performed, the gauge may make a clicking sound. This is normal.

Electronic Boost/Vac gauges are equipped with an auto zero function used to compensate for operation at varying altitudes. This function

takes a pressure reading during the time that the key switch “flies through” from the ON position to the START position. The reading

represents 0 pressure and is used to set the zero point on the gauge each time the engine is started.

Page 2

INSTALLATION INSTRUCTIONS

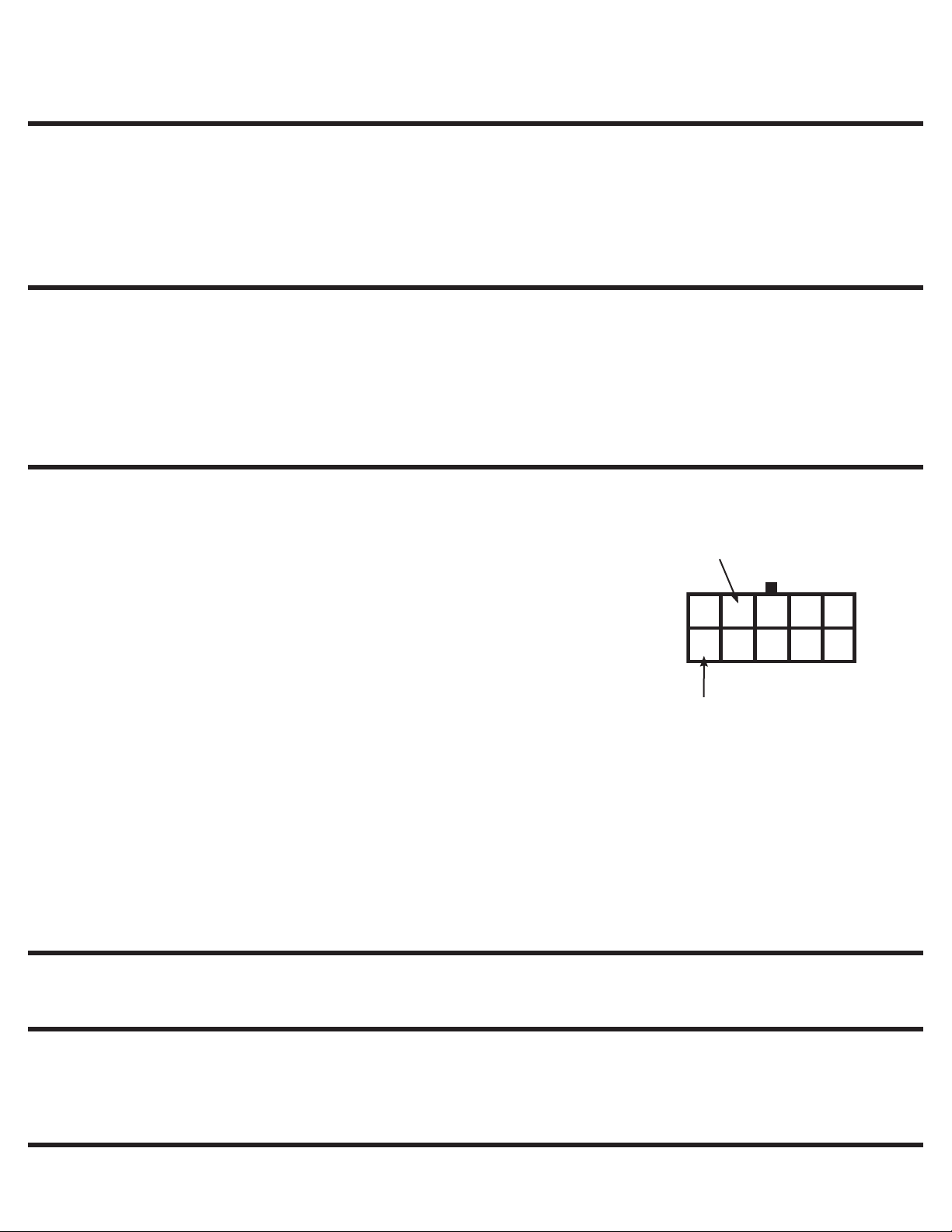

5 4 3 2 1

10 9 8 7 6

ELECTRIC BOOST/VAC with Warning Light and Peak Recall

Warning Indicator

To adjust the warning set point, momentarily press and release the WARN button. The warning light will begin to flash and

the pointer will move to the previous set point signifying that warning set mode has been selected. Once in set mode, press

the WARN button to move the pointer down, or press the PEAK button to move the pointer up. Warning set points can only

be set in the pressure range. Three seconds after the last button press, the warning light will stop blinking and the pointer

will return to the current pressure reading. The warning set point is retained when power is removed from the gauge.

Peak Recall

Press and hold the PEAK button to recall the highest pressure reading since the memory was last cleared. To clear the

memory, press and hold the PEAK button, and while still holding the PEAK button, press the WARN button. The pointer

will move to 0 psi to indicate that the memory has been cleared. Release the PEAK and WARN buttons to resume normal

operation. The peak recall point is retained when power is removed from the gauge.

Data Logger Output

This gauge is equipped to output the sensor signal to an Auto Meter Data

Logger. This feature allows you to use the same sensor for both the gauge

and the data logger. With this gauge it is no longer necessary to install two

sensors to measure the same function.

To use this feature, you must have an Auto Meter Data Logger installed in

the vehicle and purchase a cable kit (Model #9420) to connect the gauge

to the Data Logger. Pins number 4 & 10 (see illustration to right) in the

connector on the back of the gauge are the sensor signal and ground that

must be connected to the data logger.

After connecting the gauge to the data logger, the data logger must be

calibrated to the sensor.

Instructions for wiring and calibration are included with the cable kit.

Ground Neg.(-)

Sensor Signal (+)

(Back of Gauge)

For service send your product to Auto Meter in a well packed shipping carton. Please include a note explaining what the problem is along with your phone number. Please specify when you

need the product back. If you need it back immediately mark the outside of the box “RUSH REPAIR,” and Auto Meter will service product within two days after receiving it. ($10.00 charge will be

added to the cost of “RUSH REPAIR.”) If you are sending product back for Warranty adjustment, you must include a copy (or original) of your sales receipt from the place of purchase.

12 MONTH LIMITED WARRANTY

Auto Meter Products, Inc. warrants to the consumer that all Auto Meter High Performance products will be free from defects in material and workmanship for a period of twelve (12) months from date of the

original purchase. Products that fail within this 12 month warranty period will be repaired or replaced at Auto Meter’s option to the consumer, when it is determined by Auto Meter Products, Inc. that the product

failed due to defects in material or workmanship. This warranty is limited to the repair or replacement of parts in the Auto Meter instruments. In no event shall this warranty exceed the original purchase price of

the Auto Meter instruments nor shall Auto Meter Products, Inc. be responsible for special, incidental or consequential damages or costs incurred due to the failure of this product. Warranty claims to Auto Meter

must be transportation prepaid and accompanied with dated proof of purchase. This warranty applies only to the original purchaser of product and is non-transferable. All implied warranties shall be limited in

duration to the said 12 month warranty period. Breaking the instrument seal, improper use or installation, accident, water damage, abuse, unauthorized repairs or alterations voids this warranty. Auto Meter

Products, Inc. disclaims any liability for consequential damages due to breach of any written or implied warranty on all products manufactured by Auto Meter.

SERVICE

FOR SERVICE SEND TO: AUTO METER PRODUCTS, INC. 413 W. Elm St., Sycamore, IL 60178 USA (815) 899-0801

© 2004 Auto Meter Products, Inc.

Email us at service@autometer.com

2650-598A 4/16/04

Loading...

Loading...