Page 1

2650-1143-00

Rev. A

INSTALLATION INSTRUCTIONS

21/16" WIDE BAND AIR/FUEL RATIO MONITOR

®

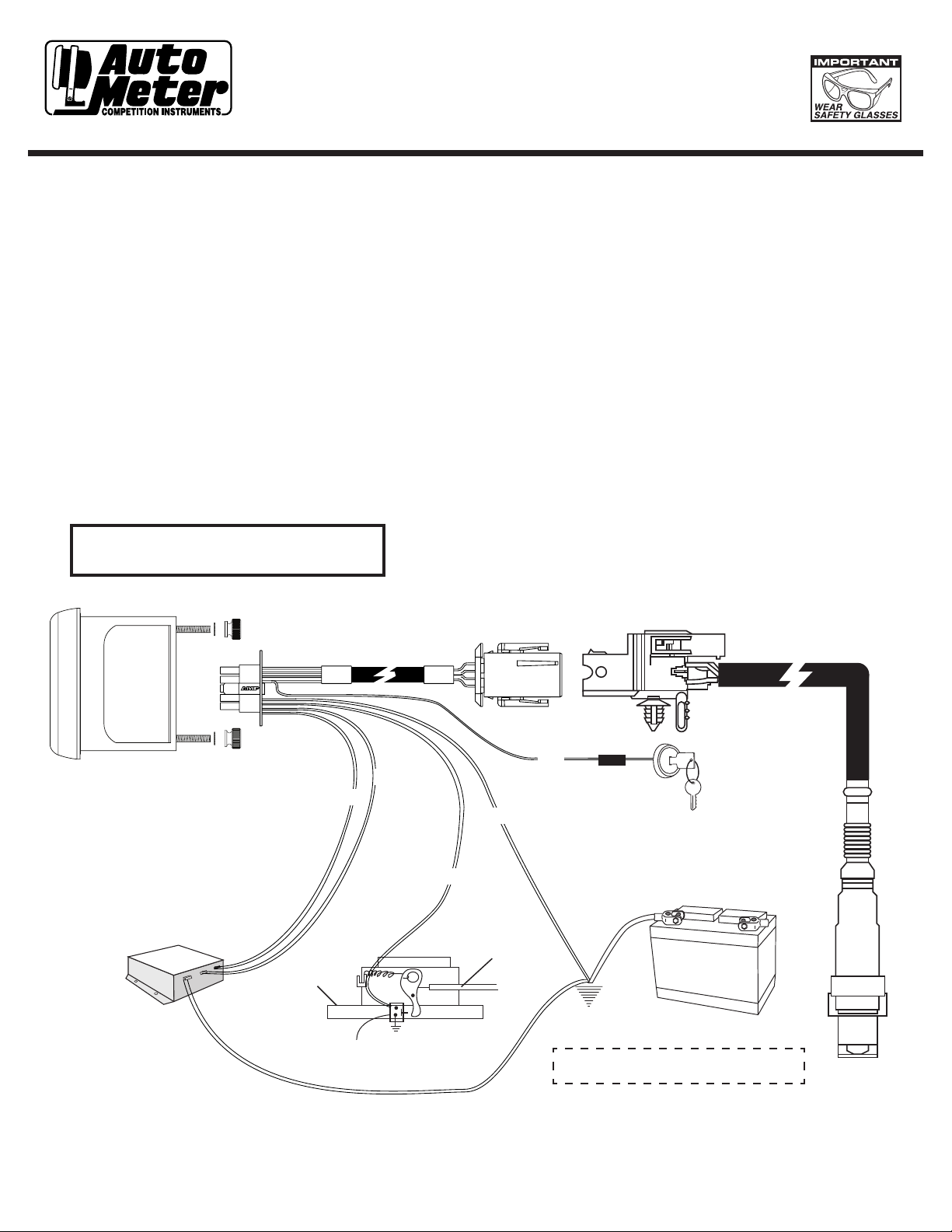

Installation

1. Disconnect the negative (-) battery cable.

2. Gauge can be mounted in a 21⁄16” dia. hole

with brackets supplied. Gauge can also be

mounted in Auto Meter Mounting Cup, or in

Auto Meter Gauge Works Pods.

3. Wire gauge as shown.

WARNING

Sender Will Get Very Hot During Operation.

Red Wire(Power):

Connect to a fused and switched 12V positive source

that is turned on and off with the ignition switch. Place

a 3 amp automotive fuse (available commercially) in

line with this connection to protect your gauge. It is

recommended that vehicles without alternators connect

this wire to a separate switch or direct to the vehicle’s

master cutoff switch. (See Sensor Heating Element Section)

Black Wire(Ground):

Connect to good engine ground.

Brown Wire(Optional Peak/Recall & Warning WOT Switch):

Connect to Wide Open Throttle Switch. Required for

Peak Recall Functionality.

Blue Wire (Optional Data Logger Signal Output):

Connect to signal input(+) or Engine Management System

or Data Acquisition unit.

Blue/Black Wire (Optional Data Logger Signal Ground):

Connect to signal input(-) on Engine Management system

or Data Acquisition Unit.

Data Logger Output

Blue

Blue/Black

Carb or

Throttle Body

Wide Open Throttle Switch

(for WOT peak function)

Black

Brown

Throttle Cable

Red

Fuse

12V Ignition Switch

Good

Engine Ground

Connect Data Acquisition Unit and Air/Fuel

Ratio Monitor to a common grounding point

Page 2

Mounting Sensor

The heated oxygen sensor comes with a stainless steel weld-in bung,

plug, and wiring harness with a weather pack connector. The oxygen

sensor should be installed as close to the cylinder head as is reasonably

possible so that the sensor reaches operating temperature quickly. If

long tube headers are used, the oxygen sensor should be installed in

the collector. If cast iron manifold(s) or shorty headers are used, install

the sensor in the pipe just below the manifold. In multi-bank applications

mounting in the left or right side is acceptable. Turbocharged applications

should have sensor installed 4-5" after turbo on the down pipe.

Auto Meter recommends welding supplied

stainless steel bung with a TIG welder.

1. The exhaust pipe in front of the sensor should not contain any pockets, projections, protrusions, edges, flex-tubes etc. to avoid

accumulation of condensation. A downwards slope of the pipe is recommended. If the exhaust pipe is parallel to the ground, the

sensor must be installed in the top half of the pipe to avoid damage to due to condensation

2. Tightening torque: 30-44 ft Ibs.

3. Avoid excessive heating of the sensor cable. Route sensor cable away from exhaust pipe.

4. The maximum temperature of the sensor on the outside of the exhaust fitting should not exceed 900o F.

The Air / Fuel Ratio Monitor can be used with the following fuels.

Fuels

Unleaded Gasoline

Methanol

Ethanol

LPG (Propane)

CNG

NOTE: OK for use with Nitrous Oxide.

NOTE: Stoichiometric Air / Fuel Ratio is the chemically correct

ratio where theoretically all of the oxygen and all of the

fuel are consumed. The mixture is neither rich or lean.

Stoichiometric Air / Fuel Ratio

14.7:1

15.5:1

17.2:1

6.4:1

9.0:1

Operation Guide

This product has many features that can be adjusted for your specific application. Use the MODE (-) and SELECT (+) buttons to navigate

menu options, confirm selections, and fine tune options to your needs.

Acronyms:

A list of acronyms and abbreviations are defined below in order to help you more clearly understand the menu operations, functions, and

components available on your Auto Meter Wideband Air/Fuel gauge:

BGD – Bar Graph Display. This is the curved, multi-color, LED radial display used to indicate how “Rich” or “Lean” the current Air Fuel or

Lambda reading is relative to your Stoichiometric point with respect to your upper and lower range tolerances.

SSD – Seven Segment Display. This is the digital numeric display that indicates your current Air Fuel or Lambda reading. This display is

also used to help you navigate and make changes to your settings.

AFR – Air / Fuel Ratio. This is shown as a numeric value on the SSD, characterized by only having a single decimal place (i.e. 14.7). This

value is also visually represented on the BGD, indicating whether the value is “Rich” or “Lean” of the selected Stoiciometric value and relative to the upper and lower range tolerances. AFR, as the name implies, represents the ratio of Air to Fuel being mixed and consumed, in

real time, by the engine / vehicle upon which this instrument has been installed.

ʎ Lamda, is an alternate way of expressing AFR, assuming that the stoichiometric point selected equals one and readings “rich” or “lean”

will be expressed as values above or below one, characterized by a value displayed with two decimal places, (i.e. 1.00). The gauge can

display data in either AFR or Lambda as needed by the user.

Real-Time Mode:

Real-Time mode is the default mode of operation for this product. When Real-Time mode is active, the instrument will display the current

air/fuel ratio in either AFR or Lambda.

To toggle between AFR and Lambda display types, press the SELECT(+) button. Remember that AFR values have a single decimal place

(i.e. 14.7), and that Lambda values have two decimal places (i.e. 1.00).

Page 3

Menu Options:

There are several other features provided by your Auto Meter Wideband Air/Fuel Ratio gauge. Use the MODE (-) button to navigate

through the following options in order:

Peak/Recall - SSD will display “P”

Alarm/Warning - SSD will display “ALr”

Stoichiometric AFR Setting - SSD will display “AFr”

BGD Range – SSD will display “dSP”

Auto-Dim – SSD will display “Br”

Heater – SSD will display “Htr”

Once the desired option is displayed on the gauge, press the SELECT(+) button to confirm your selection. Specific Menu options are outlined in the following section.

If no selection is desired, you may continue to press MODE (-) until you return to Real-Time Mode or press neither button for 3 seconds

and the gauge will return to Real-Time Mode on its own.

Wide Open Throttle Peak/Recall Mode:

WOT Peak/Recall mode provides you with a quick and easy way to find out exactly how “Lean” your engine / vehicle got during the last pull,

run, or race. This value is recorded when the Brown Wire in the instrument harness is connected to a good engine ground via a normally

open, momentary closed wide open throttle switch (not included, see wiring diagram) such as may be used with a Nitrous Oxide application.

This allows peak readings to be sampled only during wide open throttle conditions. If the Air / Fuel Monitor gauge will not be used with a Wide

Open Throttle switch, connect the brown wire permanently to a good engine ground to continuously monitor for peak conditions.

To View:

From Real-Time Mode, press MODE (-) to scroll until the display indicates “P”, then press SELECT (+) to display your Peak.

To Clear:

When the Peak value is displayed, press SELECT (+) to clear your Peak value and return to Real-Time Mode. The SSD will display “---

“once the peak has been cleared and until a new peak value has been recorded.

If neither button is pressed for 3 seconds after the Peak Value is displayed, the gauge will return to Real-Time Mode.

Wide Open Throttle Alarm/Warning Mode:

Alarm/Warning mode enables you to program a visual alert point into the gauge in order to warn you of when air/fuel mixtures are running dangerously

lean in your vehicle’s engine. The visual alarm or warning activates when the AFR or Lambda reading reaches or exceeds your programmed alarm

point. When the alarm activates the BGD will blink rapidly to warn the driver of the Alarm condition. Similar to Peak/Recall Mode, this function only

operates when the Brown wire is grounded via a normally open, momentary closed, wide open throttle switch (not included , see wiring diagram) such

as may be wired with a Nitrous Oxide application.

To View your current Alarm Point Setting:

From Real-Time Mode, press MODE (-) to scroll until the display indicates “ALr”, then press SELECT (+) to display your current

Alarm set point.

If neither button is pressed for 3 seconds after the Alarm Point Setting is displayed, the gauge will return to Real-Time Mode.

To Change your Alarm Point Setting:

When the current Alarm set point is displayed, press SELECT (+) to increase your alarm point setting, and MODE (-) to decrease

your alarm point setting.

After you have selected your new alarm set point, the gauge will flash your new set point 5 times on the display and then the SSD

will display “S C” for Save/Cancel.

To confirm your new alarm point setting, press MODE (-). This will save your Alarm set point changes and return

the gauge to Real-Time mode.

To cancel the changes and return to your previous set point, press SELECT (+). This will cancel the Alarm set point changes and

Page 4

Stoichiometric AFR Setting Mode:

The Stoichiometric AFR setting allows you to adjust the gauge scale for alternate fuel types such as Ethanol. As a default this product is set up

for gasoline, with a stoichiometric AFR point of 14.7:1. If you would like to adjust this product for use on an alternate fuel type or would merely

like to adjust the “center” point of your BGD, please follow the instructions below.

To view your current Stoichiometric AFR setting:

From Real-Time Mode, press MODE (-) to scroll until the display indicates “AFr”, then press SELECT (+) to display your current

Stoichiometric set point.

If neither button is pressed for 3 seconds after the Alarm Point Setting is displayed, the gauge will return to Real-Time Mode.

To Change your Stoichiometric AFR setting:

When the current Stoichiometric set point is displayed, press SELECT (+) to increase your Stoichiometric AFR setting, and MODE (-) to

decrease your Stoichiometric AFR setting.

After you have selected your new Stoichiometric set point, the gauge will flash your new set point 5 times on the display and then the

SSD will display “S C” for Save/Cancel.

To confirm your new Stoichiometric setting, press MODE (-). This will save your Stoichiometric set point changes

and return the gauge to Real-Time mode.

To cancel the changes and return to your previous set point, press SELECT (+). This will cancel the Stoichiometric set point changes

and return the gauge to Real-Time mode.

BGD Range Setting Mode:

The Bar Graph Display (BGD) Range Setting Mode allows you to fine tune the resolution of this instrument for your specific application.

With upper and lower set point adjustability, you can set the BGD to utilize the exact range that the engine / vehicle operates within and

see exactly how rich or lean you are running in relation to your current set up and tune. Adjusting your BGD limits also adjusts the scaling

of the 0-4v data logger output supplied from the gauge. The selected low set point of the BGD Range becomes the 0v value of the data

logger output. The selected high set point of the BGD Range becomes the 4v value of the data logger output. Whenever you change these

points, the instrument adjusts the data logger output so that the 0-4v signal is always linear between your chosen set points.

To view your current BGD Range HI / Lean setting or LO / Rich setting:

From Real-Time Mode, press MODE (-) to scroll until the display indicates “dSP”, then press SELECT (+) to display your current

BGD Range set point.

The SSD of your display will show “HI” in the display to indicate that you will be viewing the “above Stoichiometric” or

“Lean”upper range boundary.

If you would like to view the LO / Rich setting, press MODE (-) when “HI” is shown on the SSD. The SSD should

now indicate “LO”.

When the desired setting, “HI” or “LO”, is displayed, confirm this selection by pressing SELECT (+). The upper or lower BGD range

value will then be displayed in the SSD of your gauge corresponding to your selection.

Note: When your selection is made and the numeric range value is shown, LEDs in the BGD will light to indicate which set point

you are viewing. If the LEDs to the left of center or Stoichiometric are lit, you are viewing the “LO” or Rich set point. If the LEDs

to the right of center or Stoichiometric are lit, you are viewing the “HI” or Lean set point.

If neither button is pressed for 3 seconds after the BGD Range “HI” Setting is displayed, the gauge will return to Real-Time Mode.

To Change your BGD Range setting:

When the current BGD Range “HI” or “LO” set point is displayed, press SELECT (+) to increase your chosen BGD Range setting,

and MODE (-) to decrease your BGD Range setting.

After you have selected your new BGD Range set point, the gauge will flash your new set point 5 times on the display and then the

SSD will display “S C” for Save/Cancel.

To confirm your new BGD Range setting, press MODE (-). This will save your BGD Range set point changes

and return the gauge to Real-Time mode.

To cancel the changes and return to your previous set point, press SELECT (+). This will cancel the BGD Range set point changes

and return the gauge to Real-Time mode.

Page 5

Auto-Dim Mode:

This product incorporates an Auto-Dimming feature that allows it to adjust automatically for varying lighting conditions. This is accomplished

with a sensor light embedded in the dial. You may enable or disable this feature depending upon your viewing preference. When Auto-Dim

mode is disabled, the product and LED’s operate at maximum brightness regardless of atmospheric lighting conditions. The auto-dim mode

is set to “off” from the factory.

To view your current Auto-Dim setting:

From Real-Time Mode, press MODE (-) to scroll until the display indicates “Br” for brightness, then press SELECT (+) to display your

current Auto-Dim setting which will be indicated as either “ON” or “OFF” in the SSD.

If neither button is pressed for 3 seconds after the Auto-Dim Setting is displayed, the gauge will return to Real-Time Mode.

To Change your Auto-Dim setting:

When the current Auto-Dim setting is displayed, press MODE (-) to toggle between “On” and “OFF”.

After you have selected your new Auto-Dim setting, the gauge will flash your new setting 5 times on the display and then the SSD

will display “S C” for Save/Cancel.

To confirm your new Auto-Dim setting, press MODE (-). This will save your Auto-Dim setting changes and return

the gauge to Real-Time mode.

To cancel the changes and return to your previous set point, press SELECT (+). This will cancel the Auto-Dim setting changes and

return the gauge to Real-Time mode.

Heater Control Mode:

All O2 sensors must be heated before an accurate signal is produced. Potential sensor damage can occur if the gauge begins to heat the

sensor before the engine is running due to condensation that forms on the sensor tip and in the exhaust. To accommodate this, an internal

trigger within the gauge will automatically begin heating the sensor when 13.5 volts or higher is seen on the Red wire (“Normal” operating

mode). While the gauge does not require 13.5 volts to operate (12 volts will suffice), this voltage is used to indicate to the gauge that the

engine is running, as most regulated charging systems will maintain 14 volts or higher. Once the gauge sees 13.5 volts, it will begin

heating the sensor and transition from (---) to a 20 second countdown on the seven-segment display. When the countdown is complete,

the sensor is heated, and the gauge will begin reading air/fuel ratio in real-time.

In applications where a standard charging system is not used (vehicles without a regulated alternator, for example) there is an override

available that will allow sensor heating to occur without the gauge reading a 13.5 volt trigger. This can be accomplished while the sevensegment display shows (---) (thereby overriding “Normal” operating mode) or set to trigger when 12 volts is applied on the Red wire

(“On” operating mode).

To View your current Heater Operating Mode:

From Real-Time Mode, press MODE (-) to scroll until the display indicates “Htr”, then press SELECT (+) to display your current

Heater Operating Mode.

If neither button is pressed for 3 seconds after the Heater Operating Mode is displayed, the gauge will return to Real-Time Mode.

To Override “Normal” Operating Mode:

While displaying (---), press any button to begin the 20-second heater process.

To Switch Between Heater Operating Modes:

When the current heater operating mode is displayed (either “Nor” or “On”), press SELECT (+) to choose the current setting or

MODE (-) to switch to the alternate setting.

After you have selected your new Heater Operating Mode, the SSD will display “S C” for Save/Cancel.

To confirm your new Heater Operating Mode, press MODE (-). This will save your current Heater Operating Mode and return the

gauge to Real-Time mode.

To cancel the changes and return to your previous Heater Operating Mode, press SELECT (+). This will cancel the Heater

Operating Mode change and return the gauge to Real-Time mode.

Page 6

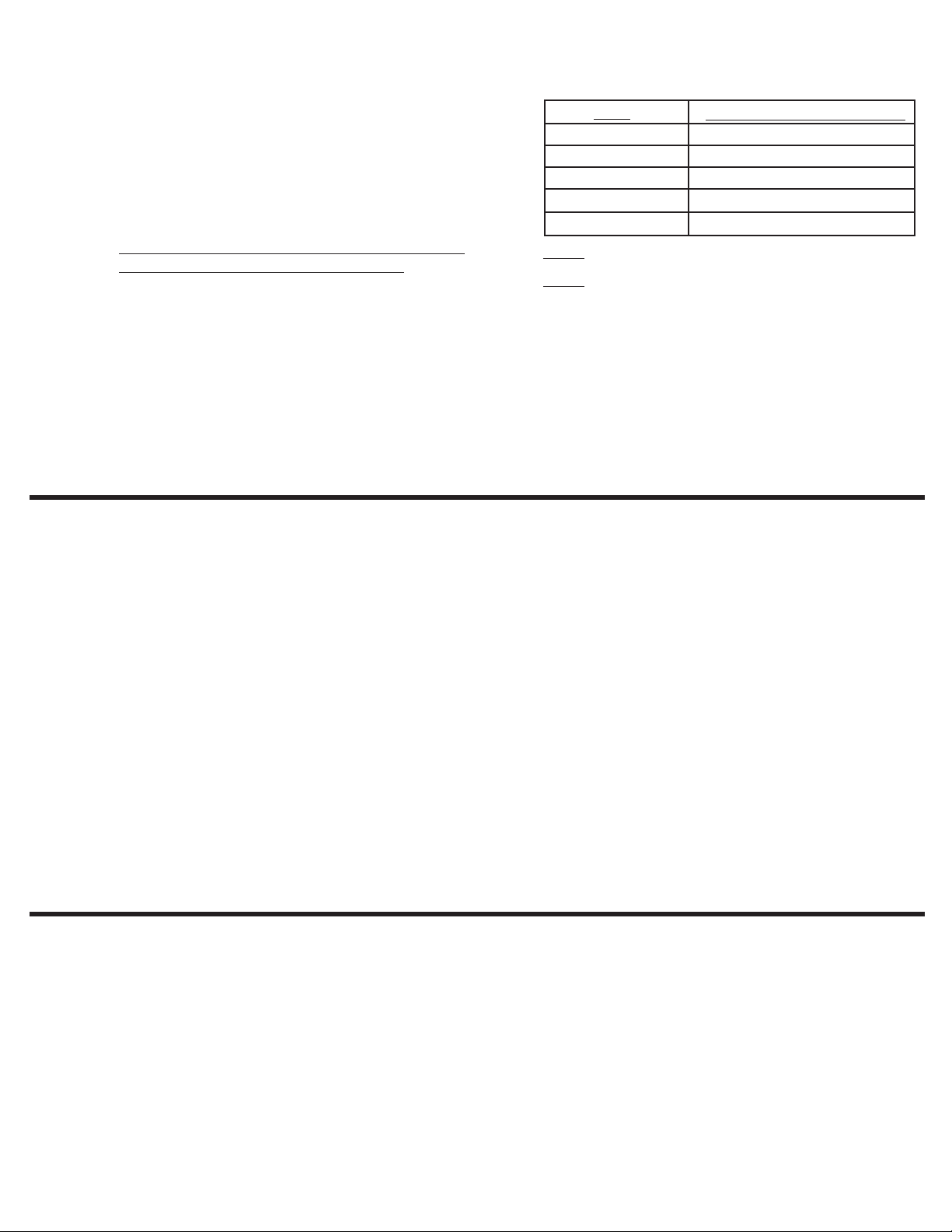

Red

Green

Amber

MODE SELECT

-

+

Data Logger Output Range:

The Auto Meter Wideband Air / Fuel gauge has a signal output for supplying information to a Data Logger or engine management system. The signal

provided is a linear 0-4v output. See the BGD Range Setting Mode for information about how to define the air/fuel mixture values for low (0v) and high

(4v) ranges of the output in order to scale this linear signal output for best operation with your Data Logger or engine management.

Warning

Fouling and/or permanent damage to the oxygen sensor

over time will result if used with any of the following:

• Leaded gasoline and fuel additives containing lead

• 2 cycle gasoline (gas/oil mix)

• Diesel Fuel

• Nitromethane

• Excessively rich mixtures

If the Air/Fuel Ratio Monitor responds sluggish, the oxygen

sensor is probably partially fouled and should be replaced.

LED Chart

Lean Range Eight red LED’s

Stoichiometric Range Fourteen green LED’s

Rich Range Eight amber LED’s

For service send your product to Auto Meter in a well packed shipping carton. Please include a note explaining what the problem is along with your phone number. Please specify

when you need the product back. If you need it back immediately mark the outside of the box “RUSH REPAIR,” and Auto Meter will service product within two days after receiving

it. ($10.00 charge will be added to the cost of “RUSH REPAIR.”) If you are sending product back for warranty adjustment, you must include a copy (or original) of your sales

Auto Meter Products, Inc. warrants to the consumer that this product will be free from defects in material and workmanship for a period of twelve (12) months from date of the original purchase. Products that

fall within this 12 month warranty period will be repaired or replaced at Auto Meter’s option to the consumer, when it is determined by Auto Meter Products, Inc. that the product failed due to defects in material

or workmanship. This warranty is limited to the repair or replacement of parts in the Auto Meter instruments. In no event shall this warranty exceed the original purchase price of the Auto Meter instruments nor

shall Auto Meter Products, Inc. be responsible for special, incidental or consequential damages or costs incurred due to the failure of this product. Warranty claims to Auto Meter must be transpotation prepaid

and accompanied with dated proof of purchase. This warranty applies only to the original purchaser of product and is non-transferable. All implied warranties shall be limited in duration to the said 12 month

warranty period. Breaking the instrument seal, improper use or installation, accident, water damage, abuse, unauthorized repairs or alterations voids this warranty. Auto Meter Products, Inc. disclaims any liability

for consequential damages due to breach of any written or implied warranty on all products manufactured by Auto Meter.

receipt from the place of purchase.

12 MONTH LIMITED WARRANTY

SERVICE

FOR SERVICE SEND TO: AUTO METER PRODUCTS, INC. 413 W. Elm St., Sycamore, IL 60178 (815) 899-0801

The “Super Bezel” is a registered trademark of Auto Meter Products, Inc.

For Email: Service@autometer.com

© 2007 Auto Meter Products. Inc. 2650-1143-00 Rev. A 10/27/06

Loading...

Loading...