Page 1

INSTALLATION INSTRUCTIONS

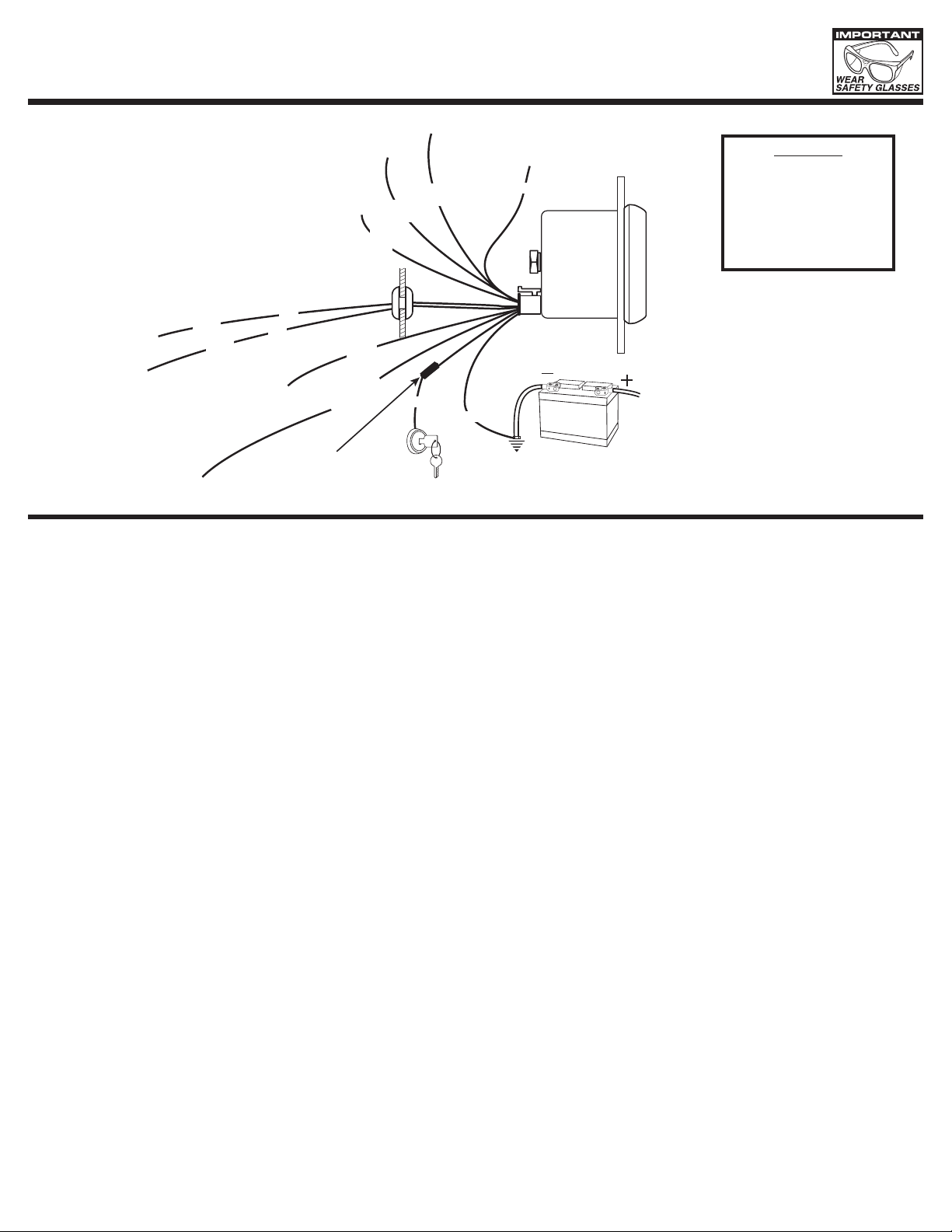

Lighting

High

PRNDL PLUS

2650-1705-00

Beam

Light

Green

Light

Blue

Red

+ 12V Connection

Set

Up

Brown

Black

Good Engine Ground

CAUTION!

As a safety precaution,

the +12V terminal of this

product should be fused

before connecting to the

12V ignition switch. We

recommend using a 3 Amp,

automotive type fuse.

12V BATTERY

Sender

Sender

Ground

Violet

Black

+ 12V Dash

(With pre-crimped

terminal)

(With pre-crimped

terminal)

Check

Engine

(See Caution Right)

Right Turn

Indicator

Yellow

Illumination

White

Fuse

Left Turn

Indicator

Dark

Blue

Wiring

Gauge

The wire colors on this product were selected to best match the most popular aftermarket wire harnesses, steering columns, and GM vehicles to

simplify installation and wire color matching, though this can be used on nearly any 12 volt, negative ground vehicle.

Red: .............. +12V, (key on power). This can be connected to the same power supply you are using for your gauges, or to its own 3 Amp fused power

..................... source.

Black: ........... Engine ground.

Black: ........... Transmission gear position sender ground

Yellow: ......... Check engine light signal from your engine computer (if equipped).

White: ........... Lighting power from instrumentation/dash lights.

Violet: ........... Transmission gear position sensor signal.

Light Green: ..High beam indicator (this is power from high beam switch).

Brown: ......... Calibration set-up wire (only used during set up of gauge during installation). Momentary switch to ground.

Light Blue: ... Left turn indicator (this is power from your left turn signal circuit).

Dark Blue: .... Right turn indicator (this is power from your right turn signal circuit).

Check Engine Light

This will require checking the wiring diagram pertaining to the computer (ECM, PCM, ECU) that you are using. To activate the CEL, the yellow wire

to the gauge gets grounded by the computer. In other words, this is a ground activated circuit. If your vehicle is not computer equipped, then you may

simply seal the end of the wire, and do not use.

High Beam Indicator

This will require checking your vehicle or aftermarket (if used) wire harness diagram. To activate the Hi Beam, the light green wire gets powered by the

hi beam circuit. In other words this is a power activated circuit.

Left Turn Signal Indicator

This will require checking your vehicle or aftermarket (if used) wire harness diagram. To activate the Left Turn indicator, the light blue wire gets

powered by the left turn circuit. In other words this is a power activated circuit.

Right Turn Signal Indicator

This will require checking your vehicle or aftermarket (if used) wire harness diagram. To activate the Right Turn indicator, the dark green wire gets

powered by the right turn circuit. In other words this is a power activated circuit.

Helpful tips to determine which of your factory wires are turn signal, and high beam:

If you have easy access to the wires behind your gauge panel (most easily done with gauge panel removed), you can use a simple test light. With

power turned on, you can turn on your left turn signal, and probe each, un-used wire and when your test light starts to flash with the turn signals, you

have found the correct wire. Repeat the same for the right turn signal. For high beam, you can leave power off, but turn on your head lights. Activate

your high beams, and use your test light to determine which wire has power. When you find it, deactivate your high beams to make sure the test light

goes out. If it does not go out, then you have not found the correct wire yet. When performing the above tests, make sure your test light has a suitable

electrical ground on the vehicle. A poor ground connection for your test light can adversely affect the outcome of these tests.

1

Page 2

Gauge Lighting

This gauge has no actual back lighting as it is a digital display, however when power is applied to the white wire, the digital display brightness will be

reduced by about 30%. If this white wire is connected to a dash lights rheostat, or the Auto Meter 9114 dimming module, the display will also be able

to be dimmed further. When no power is detected on the white wire (either lights turned off, or in some cases dimmed 100%, the digital display will

return to full brightness.

Mounting Transmission Gear Position Sensor:

See Universal Gear Position Sensor section of instructions. Page 3.

Wiring Transmission Gear Position Sensor:

After the sending unit has been installed and the black and purple wire have been fed through the firewall, attach the purple and black wire to the

connector housing and add the lock.

1. Insert the terminals into the connector housing. It does 2. Add blue lock.

not matter on what side the black and purple wire goes.

The sensor is not polarity sensitive.

3. Plug into the mating connector on the sensor.

Mounting the gauge:

This gauge is meant to be mounted into a 2-1/16” hole, the same as most other 2-1/16” Auto Meter in-dash gauges. You may want to delay final

mounting until after the gauge has been calibrated so that you have access to the brown wire for calibration. Or you may choose to final mount your

gauge, then calibrate in which case you will want to maintain access to the brown calibration wire after mounting.

Calibration/Set up:

The PRNDL gauge must be set up, or calibrated before use. To do this, the sender unit must be installed on the transmission linkage, the

transmission linkage must be properly adjusted, and the gauge must be wired up. Before getting started, determine what letters and numbers

you want to use. The list of available options can be found below. This gauge comes with the following letters and numbers that can be used in

programming your gauge:

P, R, N, D, L, od, O, 5, 4, 3, 2, 1.

Any of the above can be easily skipped by letting the number or letter time-out while flashing, while in calibration mode. Some common examples of

what you might use, are listed below, however you can program it to read any way you like.

A typical 4-speed over-drive automatic may use: P, R, N, od, D, 2, 1.

Or may use : P, R, N, D, 3, 2, 1. another option would be P, R, N, O, 3, 2, 1. In this case, the large-case “O” would stand for over drive.

A typical 3-speed automatic may use P, R, N, D, 2, 1, or P, R, N, 3, 2, 1.

A Powerglide 2-speed might use P, R, N, D, L, or P, R, N, D, 1, or P, R, N, 2, 1.

These are just a few examples, and you can program however you choose. It also does not matter if your vehicle is equipped with a reverse valve

body. You simply have to be in the correct gear when you capture the reading that you are programming.

PROGRAMMING the Gear Selection Display:

During the set up procedure it will be necessary to connect the brown set up wire momentarily to ground. This can be done by connecting it to one

terminal of a normally open, momentary push button switch, and connecting the other terminal of the button to ground. Alternatively, the bare end of

the wire can be manually touched to a good ground. When doing this, make a solid connection to ground for one second, then remove the wire from

ground. The power to the gauge needs to be off in order to enter calibration mode. Connect the set up wire to ground (or push and hold calibration

button), then switch power on to the gauge, (hold ground connection on brown wire for 1 second after power up) then remove the connection to

ground. The display will flash 'P' for 5 seconds. Connect the brown set up wire momentarily to ground and release. The 'P' will now be on steady

until your next button push. Put the vehicle in Park and connect the brown set up wire momentarily to ground to capture the Park setting. Then the

gauge will flash 'R'. Connect the brown wire momentarily to ground and release. The 'R' will now be on steady until your next button push. Move gear

position selector to reverse and connect brown set up wire momentarily to ground to capture the reverse settings. Repeat for all gear positions. If a

letter or number is to be skipped, simply do not connect the wire to ground while the character is flashing. After 5 seconds it will move on to the next

position.

2

Page 3

INSTALLATION INSTRUCTIONS

UNIVERSAL GEAR POSITION SENSOR

Component Picture

Sender, with

harness

Bracket

Arm

Linkage

Shift bracket

Qty.

1

1

1

1

1

Stop-nut, 1/4-20

Screw, 1/4-20,

0.875"

Spacer

Washer, plastic

Connector housing

2

2

1

4

1

Shipping kit

Screw, #8-32

TOOLS REQUIRED: Hacksaw, Metal file, a drill, a drill bit

set, Phillips and flat head screw driver, a socket set or open

end wrenches. A well lit workbench with a vise would also

be helpful.

1

1

Lock

Screw

5/16" - 18 X 1.25"

1

1

3

Page 4

Basics

The sending unit is mounted to the transmission/oil pan flange via a rugged bracket and connects to the shift select lever on

the transmission through a linkage.

While there are many installation scenarios possible, the following four pictures give you an overview of the more common

ones. (some of the fasteners that are already on the vehicle are not shown).

1. Floor shifter-cable,

aftermarket, shift lever

pointing down.

2. Column shifter,

U-bracket attached to

the transmission, install shift bracket

pointing down

3. Floor shifter, factory

setup, shift lever

pointing down.

4. Floor shifter, after

market, shift lever

pointing upward.

By making simple modifications to the shift bracket and the linkage, the sender can be adapted to fit to many transmission configurations. The

linkage comes with a preset offset. Adjustments can be made by simply in creasing or decreasing the pre-existing bends.

Shift Bracket

linkage

4

Page 5

Mounting the Sender to the Transmission

Mount the sender to the sender bracket by using the two #8 screws, #8 washers and #8 lock washers. The screws will engage into brass inserts

that are part of the sender housing.

Find location for the sender on the transmission. Either in front of the shifter lever (1) or behind the shifter lever (2)

DESCRIPTION PICTURE

Mount the sender via the bracket to the underside of the

transmission/oil pan flange with a 5/16 bolt. The exact spot

depends on your application. Make sure that the "foot" of the

bracket is aligned with the transmission. The spacer is used

in applications where the transmission pan has a lip that

needs to be cleared.

Locate the shift bracket. Using the previous BASICS SECTION for ideas, determine how you may need to modify this bracket to make it work for

your application. In several cases this bracket can be secured to your existing shift lever via the existing shift lever.

5

Page 6

Orientation of the sender shaft and position of the arm:

The arm can be attached to the sender shaft with the #8 screw pointing either to the left or the right and without having the sender firmly

mounted to the transmission. Having the #8 screw on the left or the right, will affect the offset between the arm and the shift lever on the

transmission. If needed the factory offset in the linkage can be adjusted by simply increasing or decreasing the bends.

DESCRIPTION PICTURE

IMPORTANT:

Start with putting the transmission in Park. Once the shift lever

and arm are connected with the linkage, the arm should be

close to parallel with the shift lever, one possible example is

shown to the right.

1. If the arm needs to point down:

Turn the sender shaft clock wise until it stops. Then turn

the sender shaft back counter clock wise 1/8 of a full turn.

NOTE: Place the arm on the sender shaft and tighten it in a

position where it is as parallel to the shift lever as possible.

2. If the arm needs to point up:

Turn the sender shaft counter clock wise until it stops. Then

turn the sender shaft clock wise 1/8 of a full turn.

NOTE: Place the arm on the sender shaft and tighten it in a

position where it is as parallel to the shift lever as possible.

6

Page 7

Connect the linkage to the arm and bracket:

DESCRIPTION PICTURE

Also depending on your setup, you may have to make an

adjustment to the linkage to allow for a clean transfer of

motion from the shift lever to the sender. That includes the

length of the linkage.

Make sure the offset in the linkage is adjusted to have the

mating surfaces (highlighted in blue) in the linkage, arm and

bracket as parallel as possible.

Attach linkage fasteners. Regardless of your particular

setup, below is a picture how the linkage gets attached

to the arm AND the bracket. Use the two provided plastic

washers, the 1/4 nut and screw.

IMPORTANT: Do NOT over tighten the fasteners and leave

small gaps (min 0.02"; max 0.05")

Feed the two sender wires , (purple and black) coming from the sender harness, through the fire wall and attach them to the connector.

Secure the sender wire to appropriate places on the vehicle to prevent it from getting damaged by heat or any moving components.

Connect the sender and gauge harness, program the gauge.

For service send your product to Auto Meter in a well packed shipping carton. Please include a note explaining what the problem is along with your phone number. If you are sending product

back for Warranty adjustment, you must include a copy (or original) of your sales receipt from the place of purchase.

12 MONTH LIMITED WARRANTY

Auto Meter Products, Inc. warrants to the consumer that all Auto Meter High Performance products will be free from defects in material and workmanship for a period of twelve (12) months from date of the

original purchase. Products that fail within this 12 month warranty period will be repaired or replaced at Auto Meter’s option to the consumer, when it is determined by Auto Meter Products, Inc. that the product

failed due to defects in material or workmanship. This warranty is limited to the repair or replacement of parts in the Auto Meter instruments. In no event shall this warranty exceed the original purchase price of

the Auto Meter instruments nor shall Auto Meter Products, Inc. be responsible for special, incidental or consequential damages or costs incurred due to the failure of this product. Warranty claims to Auto Meter

must be transportation prepaid and accompanied with dated proof of purchase. This warranty applies only to the original purchaser of product and is non-transferable. All implied warranties shall be limited in

duration to the said 12 month warranty period. Breaking the instrument seal, improper use or installation, accident, water damage, abuse, unauthorized repairs or alterations voids this warranty. Auto Meter

Products, Inc. disclaims any liability for consequential damages due to breach of any written or implied warranty on all products manufactured by Auto Meter.

SERVICE

FOR SERVICE SEND TO: AUTO METER PRODUCTS, INC. 413 W. Elm St., Sycamore, IL 60178 USA (866) 248-6357

© 2013 Auto Meter Products, Inc.

Email us at service@autometer.com

http://www.autometer.com

The Super Bezel is a registered trademark of Auto Meter Products, Inc.

2650-1705-00 10/9/13

Loading...

Loading...