Page 1

INSTALLATION INSTRUCTIONS

31/8" SPEEDOMETER

2650-1180

If after completely reading these instructions you have questions regarding the operation or installation of your instrument(s),

please contact Auto Meter Technical Service at 815-899-0801. You may also email us at service@autometer.com.

Additional information can also be found at http://www.autometer.com

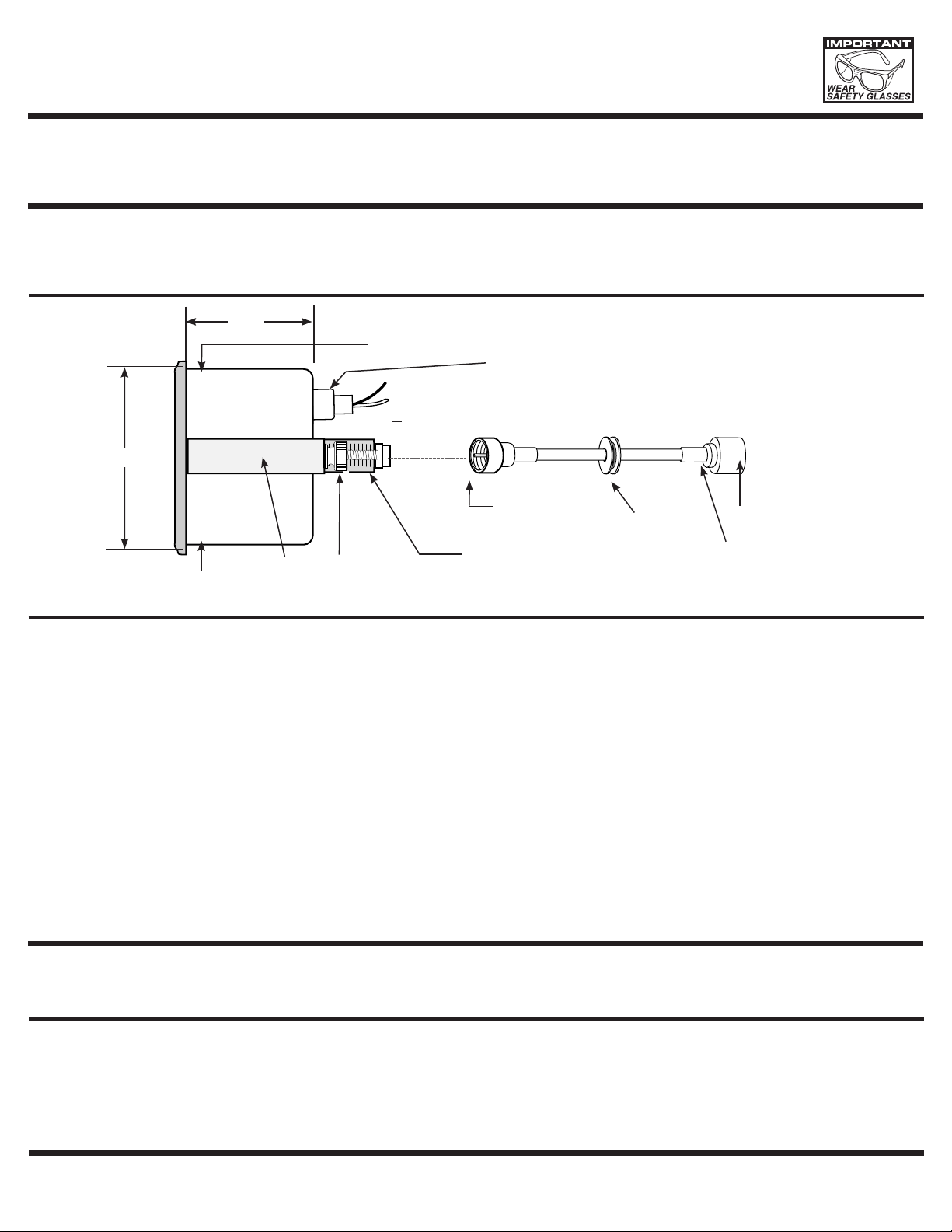

Mounting

Can be mounted in a 3 5⁄32" dia. hole in the dashboard. (Take care that hole is not cut too large.)

Can also be mounted in a standard aftermarket street rod panel.

21⁄ 4

QUESTIONS:

Hookup

3.300"

"

3.145" Dia.

9

64

(3

⁄

" ref.)

To Ground (-) neg.

Light wire connects to dash lighting circuit

or 12 volts (+).

BRACKET, THUMBNUTS,

LOCKWASHERS FOR SECURING IN DASH

Replace light bulb with the same bulb

number that was removed.

.104” SQ. MALE DRIVE

CABLE

(5/8” x 18” THREAD)

CABLE INPUT

(5/8” x 18” THREAD)

RUBBER GROMMET

IN FIREWALL

SPEEDOMETER CABLE

(must be purchased separately)

(See Installation 2B below)

TO TRANSMISSION

TAKE-OFF

Installation

1. To connect the speedometer cable:

A. If existing speedo cable in vehicle is being used, connect it to the cable

input on back of speedometer.

Important: Make sure cable fits properly into .104" sq. female cable

input before tightening or speedometer may be damaged.

B. If a new speedo cable is required, purchase a “custom made” cable

from an auto parts store or speedometer specialty shop. If unable to

obtain a speedometer drive cable locally, contact Auto Meter at

address below. Indicate the size and type of cable end to fit in the

transmission speedometer drive, type of attachment to the

transmission and length of cable needed. The cable input on back of

speedometer accepts only .104” sq. male drive. Make sure

connections fit properly before tightening.

2. Cut a 1

1

/6" diameter hole in engine firewall where cable will be routed.

Route cable from speedo through dash, through firewall and connect to

transmission take-off. Use the rubber grommet provided (slit) to support

the cable in the firewall. Make sure all connections fit properly and that

the rotating cable is not too long or short for proper engagement

before tightening.

SERVICE

For service send your product to Auto Meter in a well packed shipping carton. Please include a note explaining what the problem is along with your phone number. Please specify when you

need the product back. If you need it back immediately mark the outside of the box “RUSH REPAIR,” and Auto Meter will service product within two days after receiving it. ($10.00 charge will be

added to the cost of “RUSH REPAIR.”) If you are sending product back for Warranty adjustment, you must include a copy (or original) of your sales receipt from the place of purchase.

12 MONTH LIMITED WARRANTY

The manufacturer warrants to the consumer that this product will be free from defects in materials and workmanship for a period of twelve (12) months from the date of the original purchase. Products

that fail within this 12 month warranty period will be repaired or replaced at the manufacturer’s option to the consumer, when determined by the manufacturer that the product failed because of defects

in material or workmanship. This warranty is limited to the repair or replacement of parts in the instrument and the necessary labor done by the manufacturer to affect the repair or replacement of the

instrument. In no event shall this warranty exceed the original purchase price of the instrument, nor shall the manufacturer be responsible for special, incidental or consequential damages or costs

incurred due to failure of this product. Warranty claims to the manufacturer must be transportation prepaid and accompanied with dated proof of purchase. This warranty applies only to the original

purchaser of product and is non-transferable. All implied warranties shall be limited in duration to the said 12 month warranty period. Breaking the instrument seal, improper use or installation, accident,

water damage, abuse, unauthorized repairs or alterations voids this warranty. The manufacturer disclaims any liability for consequential damages due to breach of any written or implied warranty on all

products made by the manufacturer.

3. Secure the speedometer in the dashboard by using the bracket, thumb

nuts and star lockwashers provided.

4. Install light in back of gauge and connect one wire to dash lighting circuit

or to other 12V source. Connect other wire to (-) negative ground.

Specifications: This speedometer is set up for a 1:1 drive ratio (60 MPH at

1,000 RPM input to speedometer head) and a

requires a .104

" sq. male drive. If vehicle tire size and/or rear-end differential are

5

⁄8" x 18 threaded cable input that

not stock (original), a different driven gear in the transmission may be required

for speedo accuracy. If a change in the driven gear is made, you very likely will

have to change the drive gear in the transmission to maintain the proper gear

tooth engagement. Another approach is to use a “correcting ratio” drive joint to

adjust the speedometer input to 60 MPH at 1,000 RPM. If one is needed, the

appropriate ratio can be easily determined by comparing your speedometer

reading against another car having an accurate speedometer and dividing the

speeds. (Accurate speed ÷ Your speed = Ratio needed) Auto parts stores or

speedometer specialty shops carry “correcting ratio” drive joints or contact Auto

Meter at the address or phone below.

FOR SERVICE CONTACT: AUTO METER PRODUCTS Inc. 413 W. Elm St., Sycamore, IL 60178 USA (815)899-0801 or

© 2006 Auto Meter Products, Inc.

Email us at service@autometer.com

2650-1180 7/11/06

Loading...

Loading...