Automation Technology C5, C5-1280-GigE, C5-2040-GigE, C5-4090-GigE, C5-2040-4M-GigE User Manual

...

C5 Series

User Manual

for High Speed 3D Cameras

Rev 1.4

AT - Automation Technology GmbH

Copyright

© 2019 Automation Technology GmbH

All rights reserved. No part of this document shall be reproduced, stored in a retrieval

system, or transmitted by any means, electronic, mechanical, photocopying, recording,

or otherwise without consent in writing from the owners, AT-Automation Technology

GmbH.

Disclaimer

While care has been exercised in the preparation of this document to ensure that it is fully

correct and comprehensive, the owners assume no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information

contained herein. No license is granted under any patents or patent right of AT –

Automation Technology GmbH.

Trademarks

All nationally and internationally recognized trademarks and trade names are hereby

acknowledged. This document is subject to change without notification. All rights

reserved.

Table of Contents

TABLE OF CONTENTS ........................................................................................................................ 1

C5 SERIES OVERVIEW ........................................................................................................................ 5

Introduction ............................................................................................................................................................5

The C5 Series General Specifications .......................................................................................................................6

The Sensor Specifications .......................................................................................................................................... 8

C5-1280-GigE ........................................................................................................................................................ 8

C5-2040-GigE ........................................................................................................................................................ 9

C5-2040-4M-GigE ................................................................................................................................................ 10

C5-3360-GigE ...................................................................................................................................................... 11

C5-4090-GigE ...................................................................................................................................................... 12

The Sensors Spectral Response ............................................................................................................................... 13

Temperature Range (Operation/Storage) ............................................................................................................... 14

Heat Dissipation ...................................................................................................................................................... 14

General Guidelines for Heat Dissipation ............................................................................................................. 14

Using the C5 Heat Sink ........................................................................................................................................ 15

Mechanical Drawings .............................................................................................................................................. 16

C5-1280/2040/2040-4M/3360-GigE with M42x1 mount (Standard) ................................................................. 16

C5-4090-GigE with M42x1 mount (Standard) ..................................................................................................... 16

Part Number for C5 Series .................................................................................................................................. 16

C5-1280/2040/2040-4M-GigE with C-Mount Adapter (Option) ......................................................................... 17

C5-3360/4090-GigE with C-Mount Adapter (Option) ......................................................................................... 17

Part Number for C-Mount Adapter Option ......................................................................................................... 17

C5-1280/2040/2040-4M/3360-GigE with F-Mount Adapter (Option) ................................................................ 18

C5-4090-GigE with F-Mount Adapter (Option) ................................................................................................... 18

Part Number for F-Mount Adapter Option ......................................................................................................... 18

C5-1280/2040/2040-4M-GigE with integrated Scheimpflug Adapter (Option) .................................................. 19

C5-3360/4090-GigE with integrated Scheimpflug Adapter (Option) .................................................................. 19

Part Number for Scheimpflug Adapter Option ................................................................................................... 20

Lens Protection Tubes for the C5 Series.................................................................................................................. 21

C-Mount Lens Protection Tube with Ø 44mm .................................................................................................... 21

C-Mount Lens Protection Tube with Ø 55mm .................................................................................................... 21

Part Number for Lens Protection Tubes ............................................................................................................. 21

Subpixel Limitations ................................................................................................................................................ 22

C5 SERIES OPERATIONAL REFERENCE ............................................................................................. 23

Measuring Principle .............................................................................................................................................. 23

Geometry 1 ............................................................................................................................................................. 23

Geometry 2 ............................................................................................................................................................. 24

Geometry 3 ............................................................................................................................................................. 24

Geometry 4 ............................................................................................................................................................. 25

C5 Series User Manual Rev. 1.4 1

The C5 Sensor Algorithms ..................................................................................................................................... 26

The Image Mode (IMG) ........................................................................................................................................... 26

The Maximum Intensity Profile Mode (MAX) ......................................................................................................... 27

The Threshold Mode (TRSH) ................................................................................................................................... 28

The Center Of Gravity Mode (COG) ......................................................................................................................... 29

The FIR Peak Mode (FIR PEAK) ................................................................................................................................ 30

The FIR Filter Function .......................................................................................................................................... 31

The High Dynamic Range 3D Feature (HDR-3D) ..................................................................................................... 32

MultipleSlope Function ........................................................................................................................................... 32

Single Slope Mode (Default Mode) ..................................................................................................................... 33

Dual Slope Mode (1 Knee Point) ......................................................................................................................... 33

Triple Slope Mode (2 Knee Points) ...................................................................................................................... 33

Comparison of Slope Modes ............................................................................................................................... 34

Multi-Frame Readout Mode (NDR) ..................................................................................................................... 35

The Data Output Format ....................................................................................................................................... 36

The Data Channel Assignment DC0, DC1 and DC2 .................................................................................................. 36

The Output Frame Structure ................................................................................................................................... 38

Index Definition................................................................................................................................................... 39

Examples of Output Frame Structure ................................................................................................................. 39

The Advanced AOI Functions ................................................................................................................................ 42

AOI-Search ............................................................................................................................................................... 42

AOI-Tracking ............................................................................................................................................................ 42

The C5 Series Triggering Mode .............................................................................................................................. 43

Description of Profile Trigger Modes ...................................................................................................................... 43

Trigger Control – RS422 Resolver ............................................................................................................................ 44

Description of Modes for Triggering of Sequencer/Frame and Profile Acquisition ................................................ 46

The C5 Series Chunk Data Mode ........................................................................................................................... 48

General Description ................................................................................................................................................ 48

Payload Layout in Chunk Data Mode ...................................................................................................................... 49

XML Descriptors and ID’s ........................................................................................................................................ 50

Chunk Data Structure .............................................................................................................................................. 51

The GigE-Vision Events ......................................................................................................................................... 52

The Web Interface ................................................................................................................................................ 53

The External C5-IO-Panel (Breakout Board) .......................................................................................................... 55

Mechanical Drawings .............................................................................................................................................. 55

Clamp Configuration ............................................................................................................................................... 56

Mechanical Dimension ............................................................................................................................................ 57

The C5 Series I/O Schematics ................................................................................................................................ 58

I/O and Encoder with Differential TTL-Mode for RS422 (Standard) ....................................................................... 58

I/O and Encoder with Differential HTL-Mode for RS422 (Option) .......................................................................... 59

I/O and Encoder with Single Ended HTL or TTL Mode for RS422 (Option) .............................................................. 60

Part Number for I/O and Encoder Option ............................................................................................................... 61

Encoder / Resolver Input Specification ............................................................................................................... 61

Laser Connection with Analog and Digital Modulation ........................................................................................... 62

Master/Slave Connection ........................................................................................................................................ 63

Example configuration for Master/Slave Connection ......................................................................................... 63

2 C5 Series User Manual Rev. 1.4

The Digital Outputs ............................................................................................................................................... 64

The C5-GigE Interface ........................................................................................................................................... 65

The GigE Interface ................................................................................................................................................... 65

The I/O & Power Interface ...................................................................................................................................... 66

Description of LEDs ................................................................................................................................................. 67

The C5 Series Cables ............................................................................................................................................. 68

Cables for Power, I/O and Laser Control ................................................................................................................. 68

Wire Assignment of M12 17 pin Pigtail Cable ......................................................................................................... 69

Cables for GigE Interface ......................................................................................................................................... 70

Orientation of Angled Adapter Cable ...................................................................................................................... 72

The C5 Series GenICam Features ........................................................................................................................... 73

Device Control ......................................................................................................................................................... 73

Image Format Control ............................................................................................................................................. 73

Acquisition Control .................................................................................................................................................. 73

Camera Control ....................................................................................................................................................... 73

AOIs ..................................................................................................................................................................... 73

FIR Control .......................................................................................................................................................... 73

Mode and Algorithm Control .............................................................................................................................. 73

Sensor Control .................................................................................................................................................... 74

Data Output Channels ......................................................................................................................................... 74

Commands .......................................................................................................................................................... 74

Light Control ............................................................................................................................................................ 74

Camera IO ................................................................................................................................................................ 74

Trigger Control ........................................................................................................................................................ 75

RS422 Resolver ................................................................................................................................................... 75

AutoStart ............................................................................................................................................................. 75

Transport Layer Control .......................................................................................................................................... 75

GigE Vision .......................................................................................................................................................... 75

User Set Control ...................................................................................................................................................... 75

Chunk Data Control ................................................................................................................................................. 75

Event Control........................................................................................................................................................... 75

File Access Control .................................................................................................................................................. 75

Additional Features for Scatter Firmware ............................................................................................................. 76

C5-2040-SCT-GigE .................................................................................................................................................... 76

CXEXPLORER OVERVIEW ................................................................................................................. 80

The cxExplorer ...................................................................................................................................................... 80

cxExplorer Features .............................................................................................................................................. 81

Image Wizard .......................................................................................................................................................... 81

Image Mode ............................................................................................................................................................ 82

3D Wizard ................................................................................................................................................................ 82

3D Mode .................................................................................................................................................................. 83

QUICKSTART A C5 CAMERA ............................................................................................................. 84

CXSOFTWARE DEVELOPMENT KIT ................................................................................................... 85

SERVICE INFORMATION .................................................................................................................. 86

C5 Series User Manual Rev. 1.4 3

Product Information and Updates ........................................................................................................................ 86

Warranty Conditions............................................................................................................................................. 87

Warranty Period ...................................................................................................................................................... 87

Extended Warranty ................................................................................................................................................. 87

Return Policy ........................................................................................................................................................ 87

Document Revision ............................................................................................................................................... 88

4 C5 Series User Manual Rev. 1.4

C5 Series Overview

Introduction

The C5 series is a revolutionary product family of intelligent high speed sensors. It is

optimised for 3D profile measurement by means of laser triangulation technique. The 3D

profile extraction is performed in the camera by using high performance Field

Programmable Gate Array processors. At the same time the 3D profile data is sent to the

PC over a Gigabit Ethernet interface (GigE). This extreme data reduction boosts the

measuring speed to unprecedented levels without affecting the performance of the

connected image processing unit.

C5 Series User Manual Rev. 1.4 5

Sensor Controls

Synchronization Modes

Free Running, Triggered, Software Triggered

Exposure Modes

Programmable, Pulse Controlled

Shutter Modes

Global Shutter

Digital Input

2 electrical isolated inputs, +5V to +24V DC

VIL, logic “0” Voltage < 1.5V

VIH, logic “1” Voltage > 3.5V

Max. frequency: 450 kHz

Min. pulse width: >2µs

Digital Output

2 electrical isolated outputs, +5 to +24V DC

VOL, logic “0” Voltage < 0.5V

VOH, logic “1” Voltage ≥ 3.8V

IOL, logic “0” drive current max. 100 mA

IOH, logic “1” drive current max. 100 mA

Analog Output

Range: 0V to +5V DC

Encoder/Resolver Input

A+,A-, B+,B-, Z+, ZHigh-Speed Triple RS-422 Receiver

Max. input voltage +5V DC (TTL level)

RS-422-Mode, max. frequency: 15 MHz

Min. pulse width: >32ns

Sensor Features

High Dynamic Range Imaging

Multiple Slope, Multi-Frame Readout

3D-Algorithms

MAX, TRSH, COG, FIR PEAK

3D-Scan Features

Automatic AOI-Tracking, Automatic AOI-Search,

Multiple AOIs, AutoStart

Optical Interface

Lens Mount

M42x1 with flange focal distance 6.52 mm

Adapter for C-Mount lens*

With flange focal distance 17.52 mm

Adapter for Nikon F-Mount lens

with Bayonet mount*

With flange focal distance 46.50 mm

Adapter for Scheimpflug*

For C-Mount lens

The C5 Series General Specifications

* Must be ordered separately. See section Part Number for Scheimpflug Adapter Option

6 C5 Series User Manual Rev. 1.4

Electrical Interface

Camera Supply

+10V to +24V DC (max. +27V DC)

Power consumption

6 W…10 W (depending on camera type)

Operating Temperature

0°C to +50°C (non-condensing)

Output Data Interface

Gigabit Ethernet (IEEE 802.3)

Communication Protocol

GigE Vision with GenICam

Mechanical Interface

Camera Size

55 mm x 55 mm x 66 mm

Mass (without optics)

250 g

Power connector

17 pin, M12 connector

Ethernet connector

8 pin, A-coded M12 connector

Mechanical Stress Specification

Vibration (sinusoidal each axis)

1 g, 10…2000Hz

IEC 60068-2-6

Vibration (random each axis)

5 g, 5…1000Hz

IEC 60068-2-64

Shock (each axis)

50 g

IEC 60068-2-27

Enclosure rating

IP67

IEC 600529

C5 Series User Manual Rev. 1.4 7

Parameters

Specifications

Responsivity

9.6 V/lux.s

Shutter Type

Pipelined Global Shutter

QE * FF

55% @ 525 nm

Resolution ( H x V )

1280 x 1024 pixels

Pixel Size

6.6 µm x 6.6 µm

Sensor Size

8.448 mm x 6.758 mm, diagonal: 10.82 mm

Optical Format

2/3”

Power Consumption

10 W

ADC Resolution

12 bit

Dynamic Range

57 dB

Extended Dynamic Range

Up to 90dB with HDR

Max. Internal Full-Frame Rate for Image

Mode

288 fps

Max. External Full-Frame Rate for Image

Mode

(limited due to GigE bandwidth)

94 fps

Effective Profile Rate (Hz) at Max. Row

Width

Number

of Rows

Effective Frame / Profile Rate (Hz)

1280 Pixel

688 Pixel1

8

16

32

64

128

256

512

1024

94700

56000

30840

16240

8340

4230

2130

1070

155000

95700

54200

29000

15000

7660

3870

1940

1

The Sensor Specifications

C5-1280-GigE

C5-1280-GigE can reduce the sensor width to increase the profile rate

8 C5 Series User Manual Rev. 1.4

Parameters

Specifications

Responsivity

5.56 V/lux.s

0.27 A/W

With micro lens

@ 550 nm

Shutter Type

Pipelined Global Shutter

QE * FF

60% @ 550 nm

Resolution ( H x V )

2048 x 1088 pixels

Pixel Size

5.5 µm x 5.5 µm

Sensor Size

11.264 mm x 5.984 mm, diagonal: 12.75 mm

Optical Format

2/3”

Power Consumption

6 W

ADC Resolution

10 bit

Dynamic Range

60 dB

Extended Dynamic Range

Up to 90dB with HDR

Max. Internal Full-Frame Rate for Image

Mode

170 fps

Max. External Full-Frame Rate for Image

Mode

(limited due to GigE bandwidth)

50 fps

Effective Profile Rate (Hz) at Max. Row

Width

Number of

Rows

Effective Frame / Profile Rate

(Hz)

8

16

32

64

128

256

512

1088

25000

16000

9540

5240

2700

1400

723

340

C5-2040-GigE

C5 Series User Manual Rev. 1.4 9

Parameters

Specifications

Responsivity

5.56 V/lux.s

0.27 A/W

With micro lens

@ 550 nm

Shutter Type

Pipelined Global Shutter

QE * FF

60% @ 550 nm

Resolution ( H x V )

2048 x 2048 pixels

Pixel Size

5.5 µm x 5.5 µm

Sensor Size

11.264 mm x 11.264 mm, diagonal: 15.93 mm

Optical Format

1”

Power Consumption

8 W

ADC Resolution

10 bit

Dynamic Range

60 dB

Extended Dynamic Range

Up to 90dB with HDR

Max. Internal Full-Frame Rate for

Image Mode

90 fps

Max. External Full-Frame Rate for

Image Mode

(limited due to GigE bandwidth)

25 fps

Effective Profile Rate (Hz) at Max.

Row Width

Number of Rows

Effective Frame / Profile Rate (Hz)

8

16

32

64

128

256

512

1088

2048

25000

16000

9540

5240

2700

1400

723

340

180

C5-2040-4M-GigE

10 C5 Series User Manual Rev. 1.4

Parameters

Specifications

Responsivity

5.56 V/lux.s

0.27 A/W

With micro lens

@ 550 nm

Shutter Type

Pipelined Global Shutter

QE * FF

60% @ 550 nm

Resolution ( H x V )

3360 x 2496 pixels

Pixel Size

5.5 µm x 5.5 µm

Sensor Size

18.48 mm x 13.728 mm, diagonal: 23.02 mm

Optical Format

4/3”

Power Consumption

8 W

ADC Resolution

10 bit

Dynamic Range

61 dB

Extended Dynamic Range

Up to 90dB with HDR

Max. Internal Full-Frame Rate for

Image Mode

52 fps

Max. External Full-Frame Rate for

Image Mode

(limited due to GigE bandwidth)

12 fps

Effective Profile Rate (Hz) at Max.

Row Width1

Number of Rows

Effective Frame / Profile Rate (Hz)

8

16

32

64

128

256

512

1024

2496

10100

7750

5300

3230

1815

970

500

255

106

1

C5-3360-GigE

With a FOT (Frame Overhead Time) = 16

C5 Series User Manual Rev. 1.4 11

Parameters

Specifications

Responsivity

4.64 V/lux.s

0.22 A/W

With micro lens

@ 550 nm

Shutter Type

Pipelined Global Shutter

QE * FF

50% @ 550 nm

Resolution ( H x V )

4096 x 3072 pixels

Pixel Size

5.5 µm x 5.5 µm

Sensor Size

22.528 mm x 16.896 mm, diagonal: 28.16 mm

Optical Format

4/3”

Power Consumption

10 W

ADC Resolution

10 bit

Dynamic Range

60 dB

Extended Dynamic Range

Up to 90dB with HDR

Max. Internal Full-Frame Rate for

Image Mode

32 fps

Max. External Full-Frame Rate for

Image Mode

(limited due to GigE bandwidth)

9 fps

Effective Profile Rate (Hz) at Max.

Row Width

Number of Rows

Effective Frame / Profile Rate (Hz)

8

16

32

64

128

256

512

1024

2048

3072

14500

9700

5800

3200

1700

900

450

225

113

75

C5-4090-GigE

12 C5 Series User Manual Rev. 1.4

0

10

20

30

40

50

60

70

300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000

QUANTUM EFFICIENCY [ % ]

WAVELENGTH [nm]

SPECTRAL RESPONSE

C5-1280-GigE C5-2040-GigE / C5-2040-4M-GigE C5-3360-GigE C5-4090-GigE

The Sensors Spectral Response

C5 Series User Manual Rev. 1.4 13

In case that it is not possible to mount the camera on any heat dissipating

carrier, then it is recommended to use a heat sink with the required

specification of AT.

Temperature Range (Operation/Storage)

Housing temperature during operation: 0 °C to +50 °C (+32 °F to +122 °F)

Sensor chip temperature (on-board)

during operation: 0 °C to +65 °C (+32 °F to +149 °F)

Humidity during operation: 20 % to 80 %, relative, non-condensing

Storage temperature: -20 °C to +80 °C (-4 °F to +176 °F)

Storage humidity: 20 % to 80 %, relative, non-condensing

Heat Dissipation

The operation of the C5 camera requires sufficient heat dissipation. Depending on the

environmental conditions the sensor housing may not provide a sufficient cooling surface

to dissipate the thermal power loss, which is generated by the core electronics and the

sensor chip.

All 3D cameras of the C5 series feature high-speed CMOS sensor chips. A typical property

of a CMOS sensor is that it provides best image quality by low temperatures. High

temperatures will lead to an increase of dark current, noise and hence to a reduction of

signal-to-noise ratio (SNR).

To eliminate these effects it is often sufficient to mount the C5 sensor on a heat

conductive material, such as a metal surface.

General Guidelines for Heat Dissipation

- Mount the 3D camera to a heat conductive material with an absolute thermal

resistance of at least 6 K / W.

- Always monitor the temperature of the sensor (on-board, available over

GenICam) and make sure that the temperature does not exceed 65 °C.

- Keep in mind that dark current and noise performance for CMOS sensor will

degrade at higher temperature.

- The 3D camera of the C5 series will gradually become warmer during the first hour

of operation. After one hour of operation, the housing temperature as well as the

sensor temperature should be stable and no longer increase.

14 C5 Series User Manual Rev. 1.4

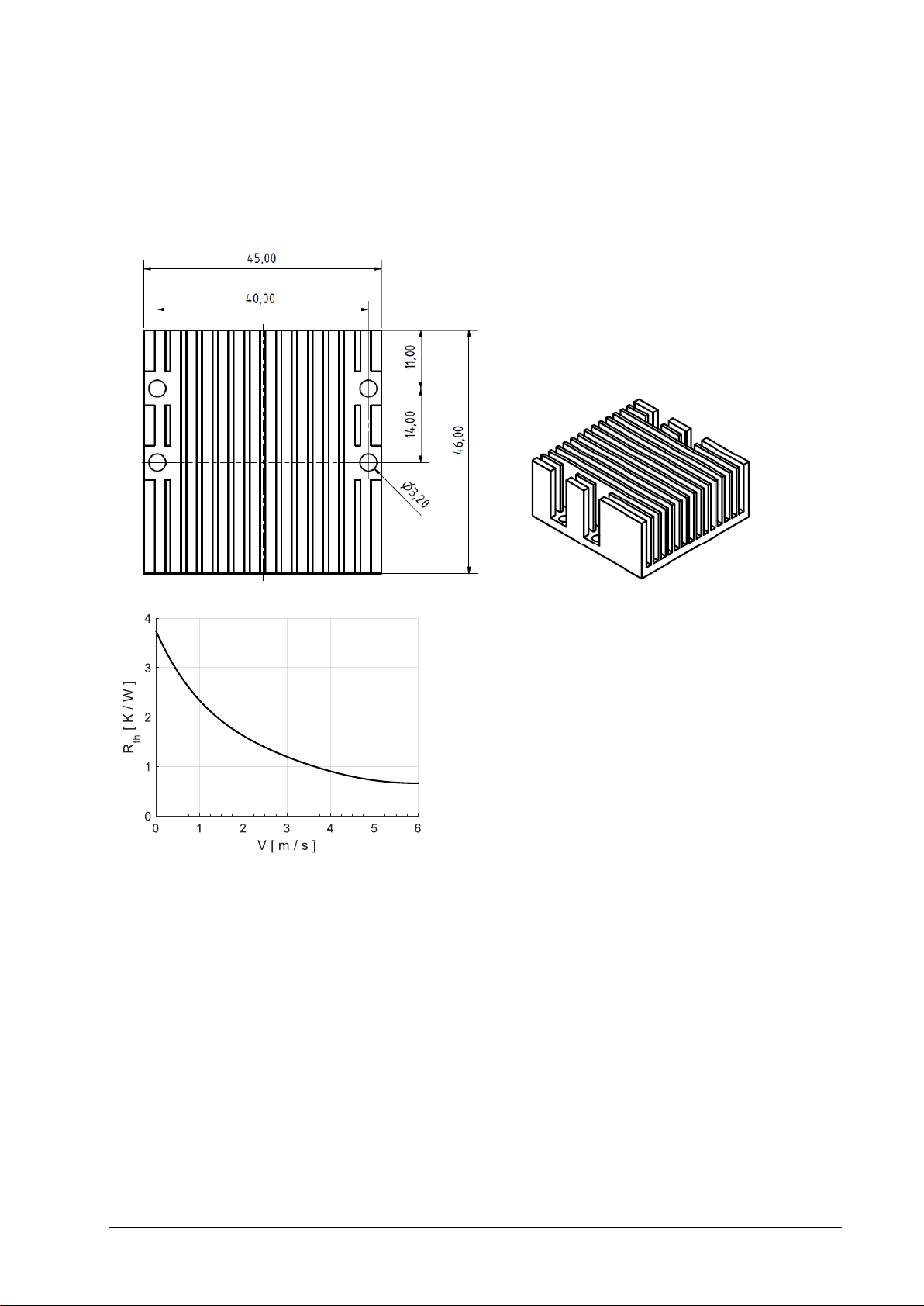

Using the C5 Heat Sink

AT provide a specially designed heat sink to improve the cooling of C5 cameras in

applications lacking sufficient thermal dissipation.

Absolute thermal resistance for camera housing: Rth = 5 [K / W]

Absolute thermal resistance for heat sink: Rth = 3.75 [K / W]

C5 Series User Manual Rev. 1.4 15

Part Number #

Product Name

202 203 001

C5-3360-GigE, lens mount M42x1

202 203 002

C5-4090-GigE, lens mount M42x1

202 203 003

C5-2040-GigE, lens mount M42x1

202 203 004

C5-2040-4M-GigE, lens mount M42x1

202 203 005

C5-1280-GigE, lens mount M42x1

Mechanical Drawings

C5-1280/2040/2040-4M/3360-GigE with M42x1 mount (Standard)

C5-4090-GigE with M42x1 mount (Standard)

Part Number for C5 Series

16 C5 Series User Manual Rev. 1.4

Part Number #

Product Name

202 188 001

C5 C-Mount: M42x1 adapter with thread for lens protective cover to use with

C-Mount type lens, for C5-3360-GigE/C5-4090-GigE

202 188 002

C5 C-Mount: M42x1 adapter with thread for lens protective cover to use with

C-Mount type lens, for C5-1280-GigE / C5-2040-GigE / C5-2040-4M-GigE

C5-1280/2040/2040-4M-GigE with C-Mount Adapter (Option)

C5-3360/4090-GigE with C-Mount Adapter (Option)

Part Number for C-Mount Adapter Option

C5 Series User Manual Rev. 1.4 17

Part Number #

Product Name

202 182 011

C4/C5 F-Mount: M42x1 adapter to use with Nikon-F Bayonet type lens

C5-1280/2040/2040-4M/3360-GigE with F-Mount Adapter (Option)

C5-4090-GigE with F-Mount Adapter (Option)

Part Number for F-Mount Adapter Option

18 C5 Series User Manual Rev. 1.4

C5-1280/2040/2040-4M-GigE with integrated Scheimpflug Adapter (Option)

C5-3360/4090-GigE with integrated Scheimpflug Adapter (Option)

C5 Series User Manual Rev. 1.4 19

Part Number #

Product Name

202 186 027

C5 Scheimpflug-Adapter 0° with C-Mount, for C5-1280-GigE/C52040-GigE/C5-2040-4M-GigE

202 186 025

C5 Scheimpflug-Adapter 2.4° with C-Mount, for C5-1280-GigE/C52040-GigE/C5-2040-4M-GigE

202 186 024

C5 Scheimpflug-Adapter 8.5° with C-Mount, for C5-1280-GigE/C52040-GigE/C5-2040-4M-GigE

202 186 023

C5 Scheimpflug-Adapter 10° with C-Mount, for C5-1280-GigE

202 186 022

C5 Scheimpflug-Adapter 35° with C-Mount, for C5-1280-GigE

202 186 021

C5 Scheimpflug-Adapter 5° with C-Mount, for C5-2040-GigE/C52040-4M-GigE

202 186 015

C5 Scheimpflug-Adapter 10° with C-Mount, for C5-2040-GigE/C52040-4M-GigE

202 186 014

C5 Scheimpflug-Adapter 25° with C-Mount, for C5-2040-GigE/C52040-4M-GigE

202 186 020

C5 Scheimpflug-Adapter 30° with C-Mount, for C5-2040-GigE/C52040-4M-GigE

202 186 016

C5 Scheimpflug-Adapter 35° with C-Mount, for C5-2040-GigE/C52040-4M-GigE

202 186 019

C5 Scheimpflug-Adapter 5° with C-Mount, for C5-3360-GigE

202 186 017

C5 Scheimpflug-Adapter 10° with C-Mount, for C5-3360-GigE

202 186 018

C5 Scheimpflug-Adapter 25° with C-Mount, for C5-3360-GigE

202 186 026

C5 Scheimpflug-Adapter 0° with C-Mount, for C5-4090-GigE

202 186 011

C5 Scheimpflug-Adapter 10° with C-Mount, for C5-4090-GigE

202 186 010

C5 Scheimpflug-Adapter 25° with C-Mount, for C5-4090-GigE

Part Number for Scheimpflug Adapter Option

20 C5 Series User Manual Rev. 1.4

Part Number #

Tube Ø

(mm)

Tube

Length

Y (mm)

Max. Lens Ø

(mm)

Max. Lens Length

(mm)

Camera Overall

Length

X (mm)

202 201 100

44

48

36

30

105

202 201 101

44

98

36

80

155

202 201 102

44

58

36

40

115

202 201 103

44

68

36

50

125

202 201 104

55

70

50

55

135

202 201 105

55

80

50

65

145

202 201 106

55

90

50

75

155

202 201 107

55

100

50

85

165

Y

X

Lens Protection Tubes for the C5 Series

The C5 series offers a high IP67 protection class. Therefore a wide range of C-mount lens

protection tubes are available for C-mount lenses with different sizes.

C-Mount Lens Protection Tube with Ø 44mm

C-Mount Lens Protection Tube with Ø 55mm

Part Number for Lens Protection Tubes

C5 Series User Manual Rev. 1.4 21

0

1 2 3 4 5

6

1023

2047

3072

0

1 2 3 4 5

6

3

7

15 31

63 127

255

More details regarding the operation of the C5-1280-GigE camera can be

found in a separate application note.

Subpixel Limitations

The range values of the 3D cameras are limited to 16bit which result to possible values

between 0 and 65535. Setting the subpixel value to 6 correspond to a factor of 2^6 = 64.

If the laser line appears at a sensor row higher than #1023 (with 6 subpixel) will result in a

bit overflow. For example: laser line at row #1500 -> 1500 x 2^6 = 96000.

Therefore it can be necessary to use a lower subpixel value to avoid a bit overflow. The

table below shows the maximum subpixel value in compare to the used number of rows

and the laser line appearance on the sensor ship without bit overflow.

Nevertheless it is still possible to use a higher subpixel value even when the laser line

appears on a sensor row >#1023. In that case make sure that the defined AOI is smaller

or even 1023/2047 rows and that the flag AbsOffsetPos (Camera Control -> Mode and

Algorithm Control -> AbsOffsetPos) is set to false. Then the offset position with respect to

the start row of the AOI is returned and thus the laser line can appear on sensor rows

>#1023.

With the release of the C5-1280-GigE camera some new features were implemented

based on the SFNC 2.3 standard as well as some AT specific features.

One new feature is the Mono8 mode in 3D line mode to reduce the amount of acquired

data to be able to increase the maximum profile frequency. This reduction leads to a

specific set up which is described in the table below.

Using number of rows with a higher subpixel accuracy then stated in the table above can

result in a bit overflow. That happen easy, when the pixel values go over the 8 Bit (2^8 - 1

= 255) range.

22 C5 Series User Manual Rev. 1.4

Scan direction

α

Y

Z

X

C5 Series Operational Reference

Measuring Principle

The C5 sensor acquires height profiles and height images based on the laser triangulation

principle. According to this method a laser line is projected on the object from one

direction. The C5 sensor views the object from another angle defining the triangulation

geometry. The resulting sensor image is evaluated by the C5 processing unit and

converted into a single height profile. By scanning the laser line over the object a

complete height image can be acquired.

The figures below demonstrate some typical triangulation geometries. The following

notation is used in the approximation of height resolution:

ΔX= resolution along the laser line (lateral),

ΔY= resolution perpendicular to the laser line (longitudinal in the direction of motion),

ΔZ= height resolution.

Geometry 1

The laser line is projected perpendicular to the object surface, while the camera views

the object under the triangulation angle α.

The height resolution can be approximated: ΔZ ≈ ΔX / sin(α)

C5 Series User Manual Rev. 1.4 23

Scan direction

α

Scan direction

α

β

Y

Z

X

Y

Z

X

Geometry 2

The camera views the object perpendicularly to its surface, while the laser line is

projected under the triangulation angle α.

The height resolution can be approximated: ΔZ ≈ ΔX / tan(α)

Geometry 3

The camera views the object under an angle α, while the laser line is projected under a

different angle β.

The height resolution can be approximated: ΔZ ≈ ΔX * cos(β) / sin(α + β),

in case α= β (direct reflex) : ΔZ ≈ ΔX / 2* sin(α)

24 C5 Series User Manual Rev. 1.4

Scan direction

α

β

Y

Z

X

Geometry 4

The camera views the object under an angle α, while the laser line is projected under a

different angle β at the camera side.

The height resolution can be approximated: ΔZ ≈ ΔX * cos(β) / sin(α)

C5 Series User Manual Rev. 1.4 25

The C5 Sensor Algorithms

The C5 series can be operated both in a variety of 3D profile modes and in image mode.

The current operation mode can be chosen by setting the following parameter:

Camera Controls→ ModeAndAlgorithmControls→CameraMode.

The frame rate can be increased in all camera modes by reducing the AOI size. In the

image mode the frame rate is limited by the output rate of the camera interface (GigE).

However, due to reduced data size in profile mode the frame rate is limited only by the

sensor output rate. As a matter of principle the processing speed is independent of the

chosen profile mode and is determined by the AOI size.

In all profile modes only intensity values higher than the AOI intensity threshold AOI_TRSH

are processed in order to suppress weak signal noise. In case that no position value can

be found, e.g. no intensity value is higher than threshold, the position value 0 is returned.

The Image Mode (IMG)

In the image mode the C5 camera series is operated similar to a standard CMOS camera.

In this mode grey scale data of 8 or 10 bit resolution are acquired over the camera

interface. Furthermore, the sensor can be divided into multiple regions, whose data can

be summarised in one output frame.

26 C5 Series User Manual Rev. 1.4

AOI_TRSH

P

MAX

I

MAX

P

R

The Maximum Intensity Profile Mode (MAX)

In this mode the position of the maximum intensity of laser beam profile is calculated. The

result includes the position value of the maximum (P

value (I

MAX

).

) as well as the maximum intensity

MAX

The calculation of position value is performed with simple pixel accuracy, i.e. the

evaluation of 1088 rows delivers a position range from 0 to 1087 pixels (11 bit). If there is

more than one local maximum (e.g. when the intensity is saturated), the position of the

first detected maximum is output. In order to avoid intensity saturation, it is recommended

to activate the Multiple Slope Mode of the camera.

The detection of the maximum intensity position can be improved by enabling the

smoothing mode of the FIR filter of the camera.

C5 Series User Manual Rev. 1.4 27

AOI_TRSH

P

TRSH

P

L

P

R

The Threshold Mode (TRSH)

In this mode the position of left (PL) and right (PR) edge of the laser beam profile are

detected for a given threshold value of intensity AOI_TRSH.

The position value of the laser line is approximated: P

= (PL+PR) / 2. In order to simplify

TRSH

the digital representation the division over 2 is not performed and thus an integer

representation with one subpixel is realised. The evaluation of 1088 rows delivers a position

range from 0 to 2174 pixels (11 bit).

In threshold mode the camera can output either the left and right threshold position

separately or the subpixel position (PL+PR) and the line width (PR-PL). Moreover, the

maximum intensity value can be optionally output.

The precision of the position calculation can be improved by enabling the smoothing

mode of the FIR filter of the camera.

28 C5 Series User Manual Rev. 1.4

AOI_TRSH

P

CO G

P

L

I

S

The Center Of Gravity Mode (COG)

In this mode the center of gravity of laser beam profile is calculated. For this purpose the

following parameters are computed:

Position value of the left edge of laser beam profile for a given intensity threshold value

PL ,

Sum of intensity value Is = ∑ Ip,

Sum of first order moment Ms = ∑Ip * P .

The position value of laser line (center of gravity of beam profile) is then obtained from:

P

= PL + Ms / Is .

COG

In addition the laser line width can be delivered over the Data Channel DC1. The average

intensity of the illumination profile can be calculated by normalising the sum of intensity

value Is with the line width.

The precision of the COG calculation can be improved by enabling the smoothing mode

of the FIR filter of the camera.

C5 Series User Manual Rev. 1.4 29

More details regarding the operation of the FIR Peak mode can be found in

a separate application note.

AOI_TRSH

Sensor row #

Sensor row #

Zero-Crossing

AOI_TRSH

0

AoiHeight

0

AoiHeight

1023

First

Derivative

Intensity

The FIR Peak Mode (FIR PEAK)

In this mode the first derivative of the intensity Gauss curve of laser beam profile is

calculated.

The position of zero-crossing of first derivative is detected and output with subpixel

accuracy (up to 6 subpixels). In this case the threshold AOI_TRSH is used to detect the first

rising edge of the derived intensity signal. Valid values of AOI_TRSH range from 513 to 1023

(Mono16).

30 C5 Series User Manual Rev. 1.4

More details regarding the operation of the FIR filter function can be found in

a separate application note.

Raw Gauss

Curve

Smoothed Gauss

Curve

Zero-Crossing of

First Derivative

The FIR Filter Function

The FIR filter is a signal processing function aiming to increase the precision of laser line

detection in the sensor image. It consists of a digital Finite Impulse Response filter (FIR) and

can be operated in a smoothing or differentiating mode.

FIR in smoothing mode (in combination with MAX, TRSH and COG algorithms):

FIR in derivative mode (FIR PEAK):

Pre-defined templates with 5, 7 or 9 coefficients let the FIR filter to be customized to the

Gauss size and shape of the application.

C5 Series User Manual Rev. 1.4 31

The High Dynamic Range 3D Feature (HDR-3D)

One of the most powerful features of the C5 series is the HDR-3D (High Dynamic Range)

functionality, which allows scanning materials and surfaces with inhomogeneous

reflection properties. Using HDR-3D the dynamic range of image intensity is extended up

to 90dB, thus avoiding intensity saturation.

The HDR-3D comprises two independent sensor functions:

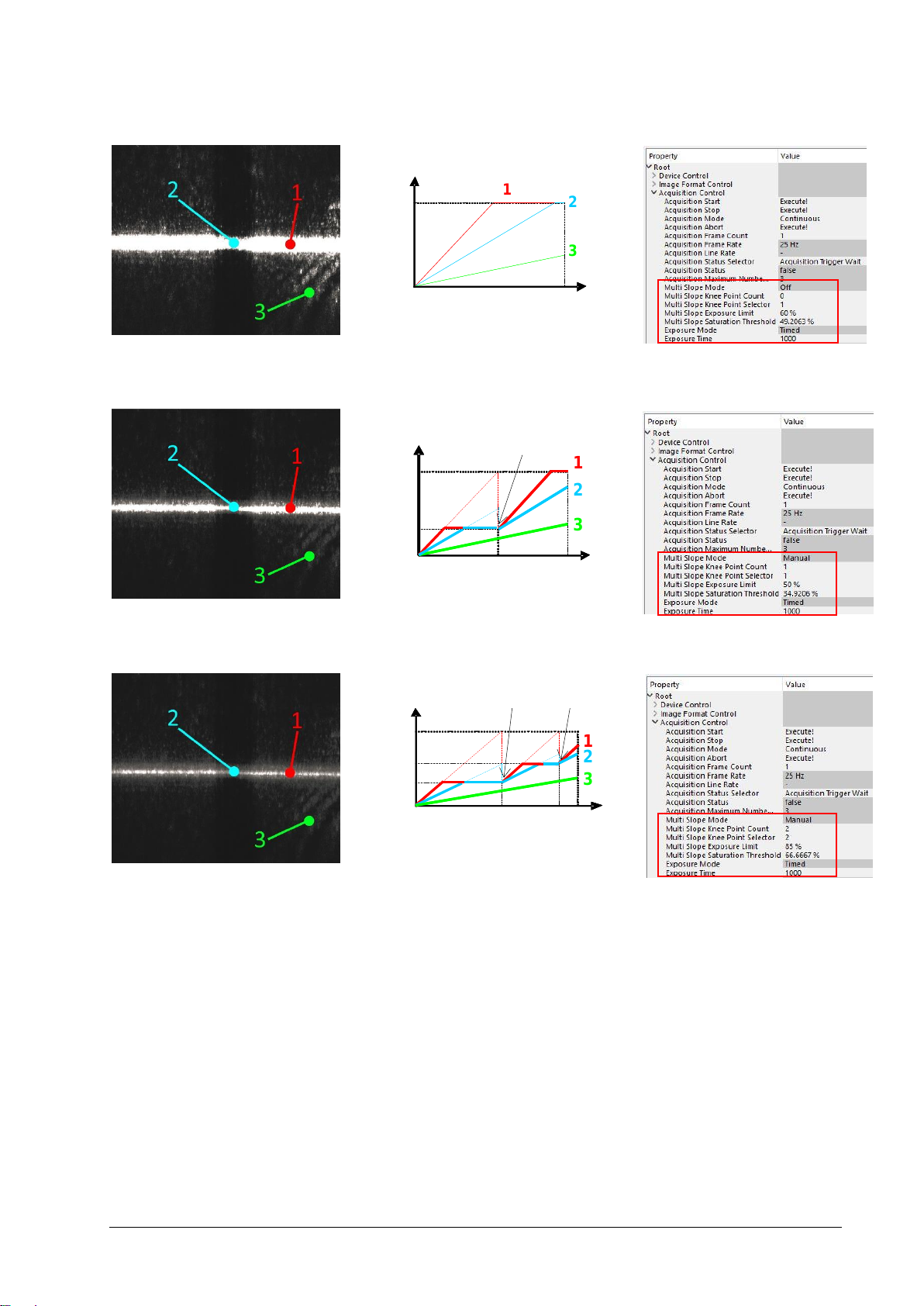

MultipleSlope Function

The aim of the Multiple Slope function is to avoid the saturation of pixels during sensor chip

exposure. This high optical dynamic range is achieved by using a piecewise linear

response. The intensity of illuminated pixels, which reach a certain level, is clipped, while

darker pixels remain untouched. The clipping level can be adjusted 2 times within one

exposure time to achieve a maximum of 3 slopes in the response curve. The points of the

curve, where the slope changes, are called “knee points”. The latter are defined through

the setting of clipping levels for the intensity (thresholds) and time points within the

exposure time.

These parameters can be adjusted using the GenIcam registers Multi Slope Exposure Limit

and Multi Slope Saturation Threshold of the Acquisition Control (XML grid visibility must be

set to “Expert”). A knee point time is defined as percentage of the overall exposure time.

A clipping level is defined as percentage of the maximum sensor intensity (saturation).

32 C5 Series User Manual Rev. 1.4

Intensity

1

3

2

Saturation

1

3

2

Exposure Time

100%

0%

Exposure

Time

Intensity

3

Saturation

1

2

Saturation

Threshold 1

3

1

2

100%

0%

Exposure

Limit 1

Knee Point 1

3 1 2

Intensity

3 1 2

Saturation

Saturation

Threshold 1

Saturation

Threshold 2

100%

0%

Exposure

Limit 1

Exposure

Limit 2

Exposure

Time

Knee Point 1

Knee Point 2

Single Slope Mode (Default Mode)

Weld Seam

Dual Slope Mode (1 Knee Point)

Weld Seam

Triple Slope Mode (2 Knee Points)

Weld Seam

C5 Series User Manual Rev. 1.4 33

More details regarding the operation of the MultipleSlope function can be

found in a separate application note.

0 5 10

15

20

25

30

35

40

100

200

300

400

500

600

700

800

900

1000

1100

Sensor row #

0 5 10

15

20

25

30

35

40

100

200

300

400

500

600

700

800

900

1000

1100

Sensor row #

Sensor row #

0 5 10

15

20

25

30

35

40

100

200

300

400

500

600

700

800

900

1000

1100

y

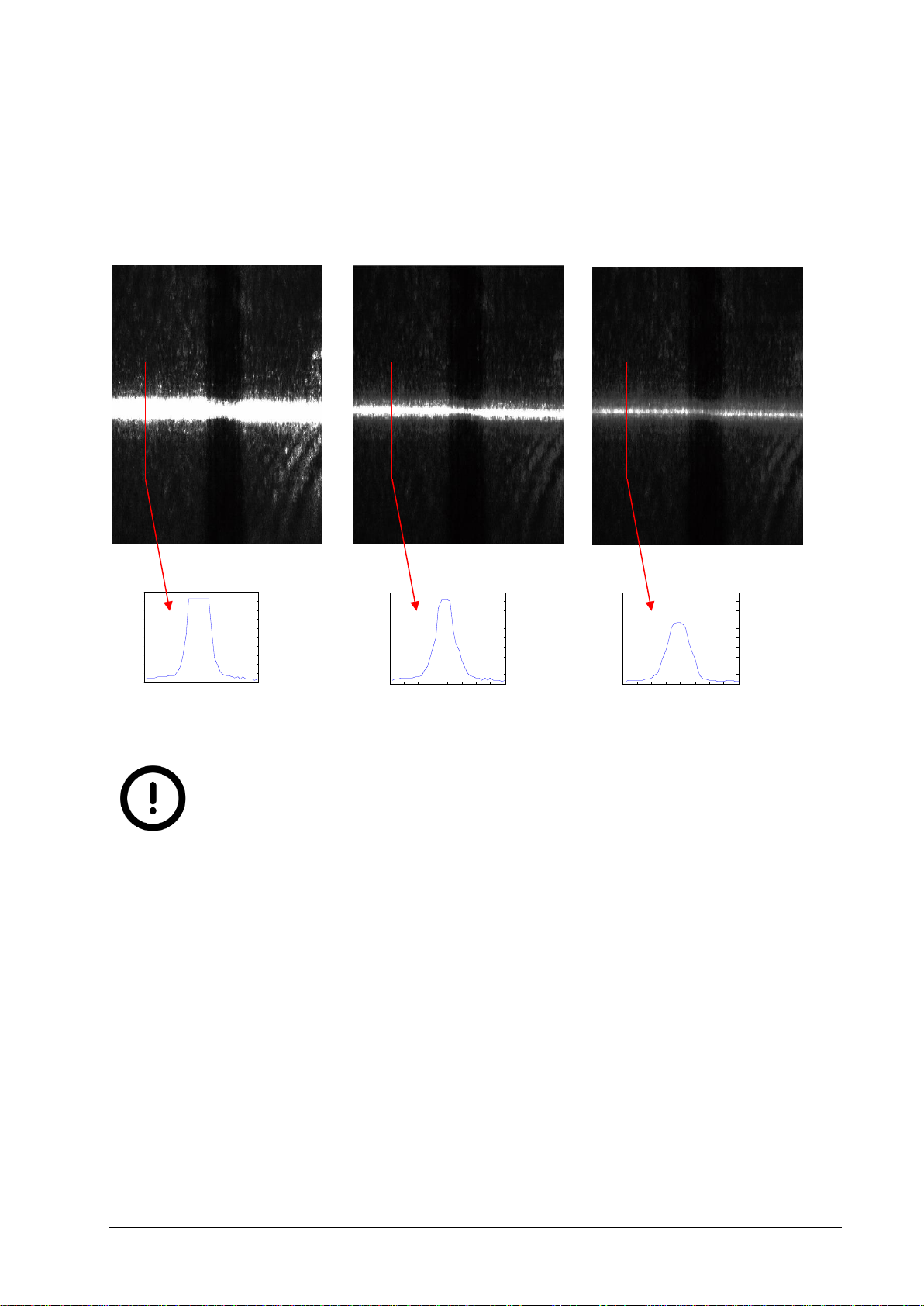

Comparison of Slope Modes

Application of MultipleSlope function on the image of a laser line projected on a surface

with non-homogeneous reflectivity (weld seam).

SingleSlope DualSlope TripleSlope

34 C5 Series User Manual Rev. 1.4

It1

R1

It2

It1

It2

R2

R1

R2

Trigger Sensor

Frame 1

Trigger Sensor

Frame 2

It1 : Exposure Time 1

It2 : Exposure Time 2

R1 : Readout Frame It1

R2 : Readout Frame It2

Frame 1 Frame 2

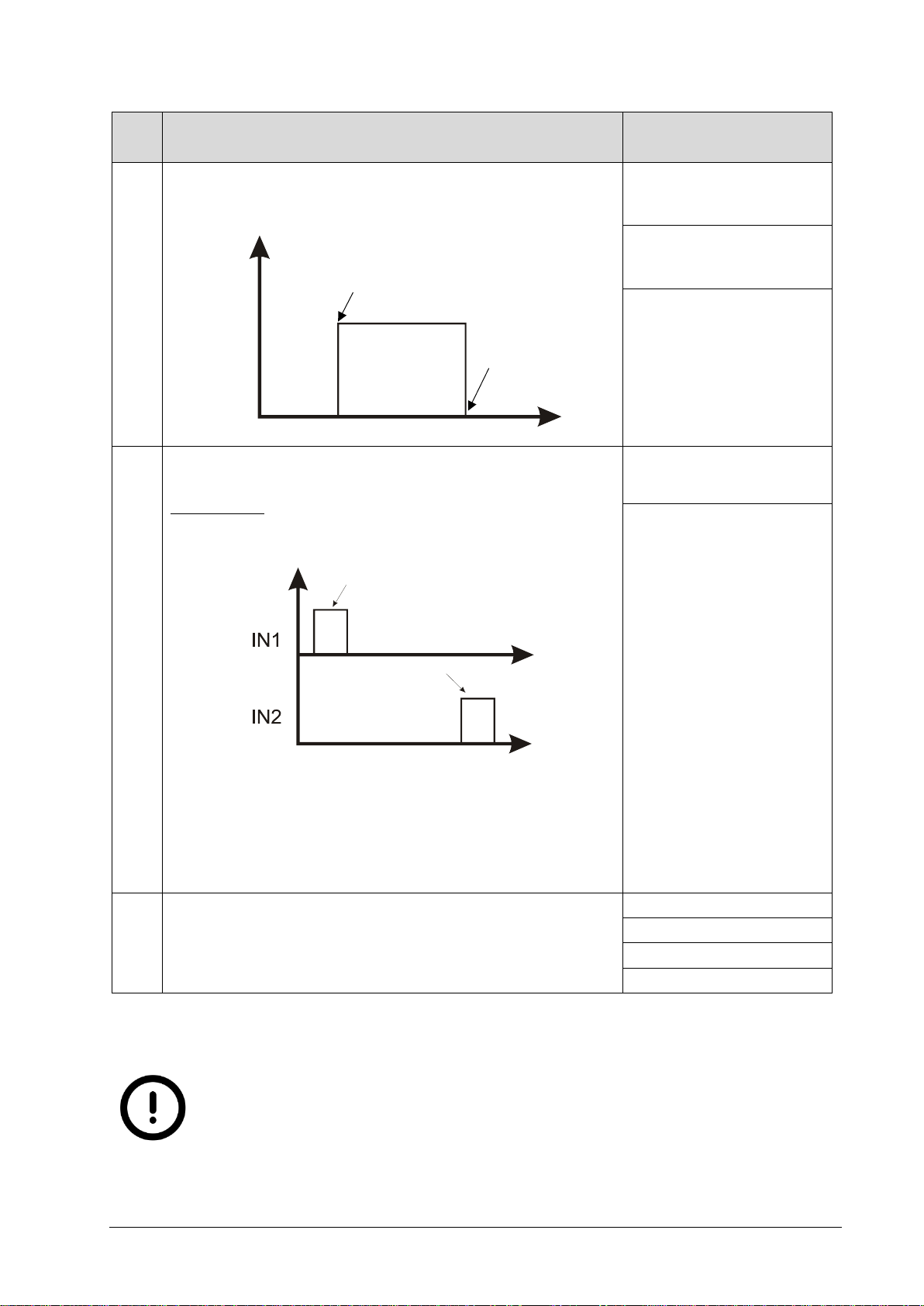

Multi-Frame Readout Mode (NDR)

With the Non-Destructive Readout (NDR) mode it is possible to readout up to 4 images at

different exposure times. It allows the combination of profile data from different

integration levels and it ensures accurate profile data even for difficult surfaces with

strong changes in reflectance.

The following timing diagram shows the function of NDR with 2 frames, when subsequent

sensor images are acquired. The exposure times for NDR frame 1 and 2 are depicted with

It1 and It2 respectively. Please note that the readout of the second frame R2 cannot

begin unless the first frame R1 has been readout. The same applies also between two

subsequent sensor images, i.e. the first NDR frame of sensor image 2 cannot be readout

unless the last NDR frame of sensor image 1 has been readout.

C5 Series User Manual Rev. 1.4 35

Camera Mode

FIR

FIRMode

DC0

DC1

DC2

Image

False

-

Sensor intensity

Not used

Not used

True

Derivative

First derivative of sensor

intensity

Not used

Not used

True

Smoothing

Smoothed sensor intensity

Not used

Not used

MaximumIntensity

False

-

Maximum intensity of

Gauss

Position of rising edge of Gauss

(PosL)

Position of maximum intensity of

Gauss (PosM)

True

Smoothing

Maximum intensity of

Gauss detected in

smoothed sensor image

Position of rising edge of Gauss

(PosL) detected in smoothed

sensor image

Position of maximum intensity of

Gauss (PosM) detected in

smoothed sensor image

Threshold

False

-

Maximum intensity of

Gauss

- Position of rising edge of

Gauss (PosL)

or

- Gauss width (PosR-PosL)

- Position of falling edge of

Gauss (PosR)

or

- Position of Gauss with 1/2

pixel resolution (PosL+PosR)

True

Smoothing

Maximum intensity of

Gauss detected in

smoothed sensor image

- Position of rising edge of

Gauss (PosL)

or

- Position of falling edge of

Gauss (PosR)

or

The Data Output Format

The image and 3D data output is performed by selecting the data channel DC0-DC2 (node Camera Controls→DataOutput).

Depending on the algorithm the data can be acquired by enabling the corresponding output Data Channel (DC). Every DC is saved

in a new image row. The bit depth of output data depends on the selected algorithm. In 3D mode the camera outputs data with 16

bit. In Image mode the camera can output 8 or 16 bit data. When in 8 bit Image mode, the DC0 delivers the 8 most significant bits

of the 10 bit intensity data.

The Data Channel Assignment DC0, DC1 and DC2

36 C5 Series User Manual Rev. 1.4

Camera Mode

FIR

FIRMode

DC0

DC1

DC2

- Gauss width (PosR-PosL)

detected in smoothed

sensor image

- Position of Gauss with 1/2

pixel resolution (PosL+PosR)

detected in smoothed

sensor image

CenterOfGravity

False

-

Sum of intensity values of

Gauss Is

- Position of rising edge of

Gauss (PosL)

or

- Gauss width (PosR-PosL)

Position of center of gravity of

Gauss with 1/(2N) pixel resolution,

where N=number of subpixel bits

(0-6)

True

Smoothing

Sum of intensity values of

Gauss I

s

in smoothed

sensor image

- Position of rising edge of

Gauss line (PosL)

or

- Gauss width (PosR-PosL)

Position of center of gravity of

Gauss in smoothed sensor

image with 1/(2N) pixel

resolution, where N=number of

subpixel bits (0-6)

FIRPeak

True

Derivative

Zero-crossing slope

(Absolute value)

- Index of next sensor row to

the left of zero-crossing

or

- maximum value of intensity

first derivative

Position of Gauss peak with

1/(2N) pixel resolution, where

N=number of subpixel bits (0-6)

C5 Series User Manual Rev. 1.4 37

for(profile_idx=1; profile_idx <=ProfilesPerFrame; profile_idx ++)

{

for(AOI_idx=1; AOI_idx<=NumAOIs; AOI_idx++)

{

if(EnableDC0==true)

write_data_of_DC0(AOI_idx);

if(EnableDC1==true)

write_data_of_DC1(AOI_idx);

if(EnableDC2==true)

write_data_of_DC2(AOI_idx);

}

}

for (profile_idx=1; profile_idx <=ProfilesPerFrame/2; profile_idx ++)

{

for(AOI_idx=1; AOI_idx<=NumAOIs; AOI_idx++)

{

for(NDR_idx=1: NDR_idx <= NumberOfNDRFrames; NDR_idx ++)

{

if(EnableDC0==true)

write_data_of_DC0(AOI_idx,NDR_idx);

if(EnableDC1==true)

write_data_of_DC1(AOI_idx,NDR_idx);

if(EnableDC2==true)

write_data_of_DC2(AOI_idx,NDR_idx);

}

}

}

The Output Frame Structure

Depending on configuration, the C5 sensor writes data to the output frame according to

following scheme:

1) NDR mode disabled (NDRMode=”Off”)

2) NDR mode enabled (NDRMode=”On”)

38 C5 Series User Manual Rev. 1.4

Index #

Range

Description

Profile_idx

1-17475

Index of Profile

AOI_idx

1-8

Index of sensor AOI

NDR_idx

1-4

Index of NDR frame

Row #

Description

Profile #

1

Data of DC2 readout from AOI1

1

2

Data of DC2 readout from AOI1

2

3

Data of DC2 readout from AOI1

3

4

Data of DC2 readout from AOI1

4

5

Data of DC2 readout from AOI1

5

6

Data of DC2 readout from AOI1

6

Index Definition

Examples of Output Frame Structure

1) Configuration with single AOI, single DC, disabled NDR mode and output of 6 profiles

resulting to a frame height of 6 rows:

ProfilesPerFrame = 6

NumAOIs = 1

EnableDC0 = false

EnableDC1 = false

EnableDC2 = true

NDRMode = ”Off”

C5 Series User Manual Rev. 1.4 39

Row #

Description

Profile #

1

Data of DC0 readout from AOI1

1

2

Data of DC2 readout from AOI1

3

Data of DC0 readout from AOI2

4

Data of DC2 readout from AOI2

5

Data of DC0 readout from AOI1

2

6

Data of DC2 readout from AOI1

7

Data of DC0 readout from AOI2

8

Data of DC2 readout from AOI2

9

Data of DC0 readout from AOI1

3

10

Data of DC2 readout from AOI1

11

Data of DC0 readout from AOI2

12

Data of DC2 readout from AOI2

13

Data of DC0 readout from AOI1

4

14

Data of DC2 readout from AOI1

15

Data of DC0 readout from AOI2

16

Data of DC2 readout from AOI2

17

Data of DC0 readout from AOI1

5

18

Data of DC2 readout from AOI1

19

Data of DC0 readout from AOI2

20

Data of DC2 readout from AOI2

2) Configuration with two AOIs, two DCs, disabled NDR mode and output of 5 profiles

resulting to a frame height of 20 rows:

ProfilesPerFrame = 5

NumAOIs = 2

EnableDC0 = true

EnableDC1 = false

EnableDC2 = true

NDRMode = ”Off”

40 C5 Series User Manual Rev. 1.4

Row #

Description

Profile #

1

Data of DC2 extracted from NDR1, readout from AOI1

1

2

Data of DC2 extracted from NDR2, readout from AOI1

3

Data of DC2 extracted from NDR1, readout from AOI1

2

4

Data of DC2 extracted from NDR2, readout from AOI1

5

Data of DC2 extracted from NDR1, readout from AOI1

3

6

Data of DC2 extracted from NDR2, readout from AOI1

3) Configuration with single AOI, single DC, NDR mode with two NDR frames and output of

3 profiles resulting to a frame height of 6 rows:

ProfilesPerFrame = 3

NumAOIs = 1

EnableDC0 = false

EnableDC1 = false

EnableDC2 = true

NDRMode = ”On”

NumberOfNDRFrames = 2

C5 Series User Manual Rev. 1.4 41

A detailed description of these functions can be found in a separate

application note.

The Advanced AOI Functions

The C5 series features an area CMOS sensor, whose frame rate depends on the number

of pixels to readout. By defining a sensor Area of Interest (AOI) the frame rate and hence

the profile speed will be significantly increased due to the smaller number of pixels to

readout.

In some cases the AOI position may not be constant and it should follow the image of

laser line on the camera sensor. The C5 series features functions for performing an

automatic AOI positioning (AOI-Search) as well as line tracking (AOI-Tracking).

AOI-Search

The AOI-Search mode can be used in 2D mode as well as in 3D mode and has the benefit

to adjust the AOI at the start of the acquisition to the optimal position of the laser line. In

that case the laser line is automatically centered to the AOI.

The user must only define the minimum required AOI Height (number of required sensor

rows) for the expected laser line and afterwards the camera will adjust the vertical AOIOffset (AoiOffsetY) value to the best position.

AOI-Tracking

The automatic AOI-Tracking is the dynamic version of the static AOI-Search mode. While

the AOI-Search is only working at the beginning of each 3D acquisition, the AOI-Tracking

mode is working continuously during 3D image acquisition.

Thus 3D profile acquisition with AOI-Tracking is able to cover the complete image/sensor

size although the defined AOI size could be much smaller. This is very useful in case of

applications involving continuous profile measurements with variable distances to the

surface.

42 C5 Series User Manual Rev. 1.4

No.

Profile Trigger Mode (PTM)

0

Free-run (PTM0)

1

Camera input 1 (PTM1)

2

Camera input 2 (PTM2)

3

Encoder/Resolver Interface (PTM3)

t

Profile

Acquisition 1

Profile

Acquisition 2

Profile

Acquisition 3

IN1

Profile

Acquisition 4

t

Profile

Acquisition 1

Profile

Acquisition 2

Profile

Acquisition 3

IN2

Profile

Acquisition 4

Profile

Acquisition 1

A

B

RS422

Example: Trigger after number of steps = 4

Counter

Internal

Trigger

Profile

Acquisition 2

Profile

Acquisition 3

t

ENC_A

ENC_B

The C5 Series Triggering Mode

Description of Profile Trigger Modes

C5 Series User Manual Rev. 1.4 43

Name

Interface

Access

Visibility

Description

TriggerDivider

(*)

IInteger

RW

Beginner

Trigger divider

Min: 1

Max: 65535

Increment: 1

TriggerCoord

IInteger

RO

Beginner

Trigger coordinate

TriggerDirectionMode

IBoolean

RW

Beginner

Count resolver pulses in both directions

TriggerReverseDirection

IBoolean

RW

Beginner

Reverse the resolver count direction

TriggerSingleChannelMode

(*)

IEnumeration

RW

Guru

Enable resolver in single channel mode

(1): Disabled (Value= 0)

(2): EnableIn1 (Value= 1)

(3): EnableIn2 (Value= 2)

TriggerDividerLoadAtStart

(*)

IBoolean

RW

Beginner

Load trigger divider upon start trigger

LoadTriggerDivider

(*)

ICommand

WO*

Beginner

Load trigger divider

ClearTriggerCoord

ICommand

WO*

Beginner

Reset trigger coordinate

ResetTriggerCoordZeroPos

IEnumeration

RW

Beginner

Reset the Trigger Coordinate/Counter at Zero Position (Index, ZChannel)

Trigger Control – RS422 Resolver

The TriggerCoord node always counts all the raw trigger signals arriving at the camera -> rising AND falling edge!

The TriggerDivider is used internally by the camera. The camera doesn’t change its behavior if the TriggerDivider is set to another

value. A TriggerDivider of 10 for example will use every tenth incoming trigger for one profile measurement.

If single-ended encoder signals are required it is set over TriggerSingleChannelMode. Triggering over Channel A or B or over Input1

and Input2 is then possible.

If other encoder signals than RS422 are needed, use the Inputs of the camera instead of the encoder inputs and set

UseAlternateResolverInputs to true.

44 C5 Series User Manual Rev. 1.4

(1): Off (Value= 0)

(2): On (Value= 1)

TriggerCoordinateCountAlways

IBoolean

RW

Guru

TRUE: Count trigger coordinate always, FALSE: Count trigger

coordinate during image acquisition only

UseAlternateResolverInputs

(*)

IBoolean

RW

Guru

Use IN1/IN2 instead of A/B as inputs

UseAlternateResolverInputsInverted

(*)

IBoolean

RW

Guru

Use inverted IN1/IN2

C5 Series User Manual Rev. 1.4 45

No.

Sequencer/Frame Trigger Mode

Profile Trigger Mode

(PTM)

0

Free-run

PTM0 (free-run)

PTM1 (IN1)

PTM2 (IN2)

1

Start/stop over camera input 1/2

Continuous frame acquisition is started with the rising

edge of camera input 1 (IN1) and stopped with rising

edge of camera input 2 (IN2)

When “stop” occurs, the frame is not transmitted

immediately over the GigE interface but the camera

continues to acquire profile data, until the predefined

frame height is reached.

PTM0 (free-run)

PTM3 (RS422)

2

Trigger one frame over camera input 1

Single frame acquisition is triggered over the rising

edge of camera input 1 (IN1)

PTM0 (free-run)

PTM2 (IN2)

PTM3 (RS422)

trigger start of sequencer

(frame trigger)

t

trigger stop of sequencer

trigger start of sequencer

(frame trigger)

t

IN1

Description of Modes for Triggering of Sequencer/Frame and Profile

Acquisition

46 C5 Series User Manual Rev. 1.4

No.

Sequencer/Frame Trigger Mode

Profile Trigger Mode

(PTM)

3

Gate over camera input 1

Continuous frame acquisition is performed as long as

the camera input 1 is on high state

PTM0 (free-run)

PTM2 (IN2)

PTM3 (RS422)

4

Start/stop with instant transmission over camera input

1/2

Continuous frame acquisition is started with rising edge

of camera input 1 (IN1) and stopped with rising edge

of camera input 2 (IN2)

When “stop” occurs, the frame is transmitted

immediately over the GigE interface. Using the Chunk

Data mode of C5 camera, it is possible to determine

how many rows of the frame contain valid data (see

ChunkImageInfo for details).

PTM0 (free-run)

PTM3 (RS422)

5

AutoStart (no external signal is required)

PTM0 (free-run)

PTM1(IN1)

PTM2 (IN2)

PTM3 (RS422)

A detailed description of the AutoStart function can be found in a separate

application note.

t

stop trigger of sequencer

IN1

start trigger of sequencer

Gate Function

trigger start of sequencer

(frame trigger)

t

trigger stop of sequencer

Start trigger of sequencer

Stop trigger of

sequencer

Remarks:

The above table (except AutoStart) applies also to acquisition in image mode. In this case

the camera delivers a gray scale sensor image for every profile trigger.

C5 Series User Manual Rev. 1.4 47

The C5 Series Chunk Data Mode

General Description

The C5 series features a Chunk Data mode for providing additional information to the

acquired image data. The implementation of XML nodes is performed according to SFNC

1.4:

Category ChunkDataControl

ChunkModeActive

ChunkModeSelector (OneChunkPerFrame, OneChunkPerProfile)

The ChunkData generated by the camera have the following format:

ChunkImage

1…N x ChunkAcqInfo

ChunkImageInfo

Depending on camera mode (image or 3D) the ChunkData block („ChunkAcqInfo“) can

be sent as follows:

In image mode, the camera can send only one ChunkAcqInfo block per image

frame.

In 3D mode, the camera can send one ChunkAcqInfo block either per 3D frame

(“OneChunkPerFrame”) or per 3D profile (“OneChunkPerProfile”).

The „ChunkImageInfo“ is the last ChunkData sent by the camera and contains following

data:

Number of valid rows in ChunkImage

Number of valid ChunkAcqInfo blocks

Flags identifying the current frame as „Start“ or „Stop“ and the buffer status in

AutoStart mode

The ChunkAcqInfo block consists of totally 32 bytes containing following data

64 bit timestamp

32 bit frame counter

32 bit trigger coordinate

8 bit Trigger status

32 bit I/O Status

72 bit AOI information

The data of timestamp, frame counter, trigger coordinate, trigger status and I/O status

are assigned at the start of every image integration.

When ChunkMode is disabled, the camera uses the “regular“ GEV image protocol, in

which the optional transfer of frames with variable height and payload is supported.

Furthermore, when ChunkMode is enabled, the camera sends the full payload, even if

the ChunkImage or ChunkAcqInfo blocks contain partially valid data. The number of

valid ChunkImage rows and ChunkAcqInfo blocks can be read from ChunkImageInfo.

48 C5 Series User Manual Rev. 1.4

Chunk Image Data

GV_ChunkDescriptorData

for Image Data

N x GV_ChunkAcqInfo

GV_ChunkDescriptorData

for ChunkAcqInfo

GV_ChunkImageInfo

GV_ChunkDescriptorData

for ChunkImageInfo

For example, when in Start/Stop mode with instant frame transmission, the camera stops

the frame acquisition as soon as the stop trigger occurs and transfers the complete

contents of internal image buffer. Using the ChunkImageInfo data block, it is possible to

detect how many image rows and ChunkAcqInfo blocks are valid in the payload buffer.

The tag of ChunkData has big endian byte order. The data of ChunkData has little endian

byte order. An endian converter for ChunkData is not supported.

Payload Layout in Chunk Data Mode

C5 Series User Manual Rev. 1.4 49

XML Descriptors and ID’s

ChunkImageInfo

<Port Name="FrameInfoPort">

<ChunkID>11119999</ChunkID>

</Port>

ChunkAcqInfo

<Port Name="CameraChunkPort">

<ChunkID>66669999</ChunkID>

</Port>

ChunkImage

<Port Name="ImageInfoPort">

<ChunkID>A5A5A5A5</ChunkID>

</Port>

50 C5 Series User Manual Rev. 1.4

Chunk Data Structure

#pragma pack(push)

#pragma pack(1)

#define CHUNKACQINFO_TRIGGERSTATUS_BIT_TRIGGER_OVERRUN 0x01

#define CHUNKACQINFO_TRIGGERSTATUS_BIT_RESOLVER_CNT_UP 0x02

#define CHUNKACQINFO_TRIGGERSTATUS_BIT_IN0 0x10

#define CHUNKACQINFO_TRIGGERSTATUS_BIT_IN1 0x20

#define CHUNKACQINFO_TRIGGERSTATUS_BIT_OUT0 0x40

#define CHUNKACQINFO_TRIGGERSTATUS_BIT_OUT1 0x80

typedef struct _GV_ChunkAcqInfo

{

unsigned int timeStamp64L; // 0..3

unsigned int timeStamp64H; // 4..7

unsigned int frameCnt; // 8..11

signed int triggerCoord; // 12..15

unsigned char triggerStatus; // 16

unsigned short DAC; // 17..18

unsigned short ADC; // 19..20

unsigned char INT_idx; // 21

unsigned char AOI_idx; // 22

unsigned short AOI_ys; // 23..24

unsigned short AOI_dy; // 25..26

unsigned short AOI_xs; // 27..28

unsigned short AOI_trsh; // 29..30

unsigned char AOI_alg; // 31

} GV_ChunkAcqInfo;

#define CHUNKIMAGEINFO_FLAG_BIT_START_FRAME 0x01

#define CHUNKIMAGEINFO_FLAG_BIT_STOP_FRAME 0x02

#define CHUNKIMAGEINFO_FLAG_BIT_BUFFER_OVERRUN 0x04

typedef struct _GV_ChunkImageInfo

{

unsigned int mSizeYReal;

unsigned int numChunkAcqInfo;

unsigned int flag;

} GV_ChunkImageInfo;

typedef struct _GV_ChunkDescriptor

{

unsigned int descriptor;

unsigned int length;

} GV_ChunkDescriptorData;

#pragma pack(pop)

C5 Series User Manual Rev. 1.4 51

Event Name

Event ID , (Hex)

Description

AcquisitionStart

36882 , (9012)

Frame Acquisition is started

AcquisitionEnd

36883 , (9013)

Frame Acquisition is terminated

TransferStart

36884 , (9014)

Frame transfer is started from the camera

TransferEnd

36885 , (9015)

Frame transfer is terminated

AoiTrackingOn

36886 , (9016)

The AOI tracking process is started and the laser line

image is valid for AOI alignment

AoiTrackingOff

36887 , (9017)

The AOI tracking process is stopped and the AOI position

is not updated anymore

AoiSearchFailed

36888 , (9018)

AOI-Search failed to detect the laser line

AutoStarted

36889 , (9019)

Frame Acquisition is initiated through AutoStart

The GigE-Vision Events

The C5 series supports a number of events that can be monitored by a software

application by means of a callback function. Events provide real time notification on

various stages of the acquisition sequence and data transfer.

52 C5 Series User Manual Rev. 1.4

The Web Interface

The service web interface gives access to basic device and runtime information aside

from the common GenICam interface. It can be accessed with an ordinary web browser,

by simply typing the cameras IP address into the browsers URL field, e.g.:

http://169.254.64.2. A login window appears, as the following figure shows. The static

password “admin” gives access to the camera service web interface.

Connect via web browser by using the set IP e.g. “http://169.254.64.2/”.

The static password for login is “admin”.

In the header bar is the manufacture info, the model name and the serial number.

Every info panel has an Update Button in the panel header. Each button updates the

data for the specific panel. Collapsing and opening the panel by clicking the Arrow on

the right hand side.

At the “System Log” panel is an additional button which starts an update process and will

fetches every two seconds the log data. The state of auto update process is shown by

Spinning Button (ON) or not spinning (OFF). The Autoscroll flag enable an automatically

scroll down to the latest log entry. Over Export the complete log and JSON data of each

panel data, wrapped in a single text file.

The “Device Info” panel displays model specific information.

The “Status” panel shows runtime status information.

The “Memory Statistics” have an overview of used memory for each component

displaying current usage, memory size, maximum usage and error.

The “System Log” shows the complete serial log of the device.

C5 Series User Manual Rev. 1.4 53

54 C5 Series User Manual Rev. 1.4

Fuse Specification

Current

2A

Dimension

5 x 20mm

Characteristic

T

Operating Temperature

-50°C…+125°C

Don´t connect C5 cameras to the CS-IO-Panel. Wrong wiring can cause

damage to the camera.

The External C5-IO-Panel (Breakout Board)

The C5-IO-Panel (#202 202 006) provides a user friendly way to connect the power and

the I/O functionality of the C5 sensor. The power supply includes a reverse voltage

protection and features a 2A (two ampere) micro-fuse.

Mechanical Drawings

C5 Series User Manual Rev. 1.4 55

Clamp No.

Signal Name

Description

J2/1

SHIELD

Camera shield

J2/2

GND_EXT ( - )

Camera supply ground

J2/3

GND_EXT ( - )

Camera supply ground

J2/3

VCC_EXT ( + )

Camera supply voltage (10-24V DC)

J2/4

VCC_EXT ( + )

Camera supply voltage (10-24V DC)

J3/1

Z-

Differential encoder/resolver index track Z-

J3/2

Z+

Differential encoder/resolver index track Z+

J3/3

B-

Differential encoder/resolver track B-

J3/4

B+

Differential encoder/resolver track B+

J3/5

A-

Differential encoder/resolver track A-

J3/6

A+

Differential encoder/resolver track A+

J3/7

RGND

Encoder/Resolver ground

J3/8

SHIELD

Encoder/Resolver shield

J4/1

IO_GND