C3 Camera

Hardware Reference

Manual

Rev. 1.3.7

Automation Technology GmbH

C3 Camera Hardware Reference Manual Rev. 1.3.7 • iii

Table Of Contents

Table Of Contents iii

Overview 2

Introduction................................................................................................... 2

Measuring Principle........................................................................................ 2

Geometry 1 .......................................................................................3

Geometry 2 .......................................................................................3

Geometry 3 .......................................................................................4

Geometry 4 .......................................................................................4

The C3 Camera Algorithms ............................................................................ 5

The Image Mode (IMG) ...................................................................... 5

The Maximum Intensity Profile Mode (MAX)........................................... 6

The Threshold Mode (TRSH) ................................................................7

The Center Of Gravity Mode (COG).................................................... 8

The Camera AOIs.......................................................................................... 9

The Image Data Output Format .................................................................... 10

The Data Channel Assignment DC0-DC2........................................... 10

Image Acquisition ........................................................................................ 11

Sensor Modes .................................................................................. 11

Trigger Modes.................................................................................. 13

The External Trigger Enable line ......................................................... 14

Output of internal Trigger and Status signals .................................................. 15

Software Integration of C3 Camera ............................................................... 16

Register Description 20

The C3 Camera Register Set ......................................................................... 20

Register Reference........................................................................................ 20

CFG_REG .......................................................................................20

CL_X0_REG ..................................................................................... 21

CL_DX_REG..................................................................................... 22

CL_DY_REG .................................................................................... 22

JTAG_REG....................................................................................... 22

ITIME_L_REG ................................................................................... 23

ITIME_H_REG .................................................................................. 23

IRTIME_L_REG .................................................................................23

IRTIME_H_REG ................................................................................24

PTIME_L_REG ..................................................................................24

PTIME_H_REG .................................................................................24

iv • C3 Camera Hardware Reference Manual Rev. 1.3.7

SENSOR_REG.................................................................................. 24

SENSOR_X0_REG ............................................................................25

SENSOR_DX_REG ............................................................................ 25

TRIG_CNT_REG............................................................................... 26

CL_CFG_ REG................................................................................. 26

HWINFO_REG................................................................................. 26

NUM_AOIS_REG ............................................................................. 27

LINLOG_VAL0_REG (obsolete, C3-A1024-CL only .............................27

LINLOG_VAL1 (obsolete, C3-A1024-CL only)..................................... 27

LINLOG_TIME_L_REG (obsolete, C3-A1024-CL only) ......................... 28

LINLOG_TIME_H_REG (obsolete, C3-A1024-CL only .........................28

ADC0_REG (obsolete, C3-A1024-CL only)......................................... 28

ADC2_REG (obsolete, C3-A1024-CL only)......................................... 29

CTRL_REG ....................................................................................... 29

STATUS_REG ................................................................................... 30

MUX_REG ....................................................................................... 30

MUX_TRIG_STATUS.......................................................................... 31

MUX_SENSOR_READOUT_TIME .......................................................31

MUX_FRAME_OUTPUT_TIME_L......................................................... 31

MUX_FRAME_OUTPUT_TIME_H........................................................ 32

MUX_CAP_INFO.............................................................................. 32

MUX_REVISION ...............................................................................32

IO_REG........................................................................................... 33

DATAOUT_REG ............................................................................... 33

AOI0_Y0-AOI7_Y0 ..........................................................................34

AOI0_DY-AOI7_DY ......................................................................... 35

AOI0_TRSH-AOI7_TRSH................................................................... 35

Sensor DAC Channels ...................................................................... 35

LASER_CONTROL_REG (C3-CompactSensors only) ............................ 36

WIDTH_VALID_MIN_REG.................................................................. 37

WIDTH_VALID_MAX_REG ................................................................. 37

SUM_INT_VALID_MIN_REG .............................................................. 37

SUM_INT_VALID_MAX_REG.............................................................. 37

I/O Interface 39

The Camera I/O Interface ............................................................................39

The internal DIP-Switches.............................................................................. 40

Description of LEDs ...................................................................................... 40

The External I/O Panel ................................................................................. 41

The CameraLink Interface of C3 Camera 42

System Overview.......................................................................................... 42

Supported CameraLink Modes ...................................................................... 42

Output Modes of C3 Camera with CameraLink Interface ..................... 44

CameraLink Signal Assignment .......................................................... 44

Camera Control Signal Assignment.................................................... 44

The UART Configuration Protocol.................................................................. 45

CMD_WRITE_DAC ........................................................................... 45

CMD_WRITE_REG............................................................................ 45

CMD_READ_REG............................................................................. 46

CMD_PROM.................................................................................... 46

The CameraLink Connection......................................................................... 47

C3 Camera Hardware Reference Manual Rev. 1.3.7 • v

Technical Specifications 49

C3-1280-CL Sensor..................................................................................... 49

C3-2350-CL Sensor..................................................................................... 51

Operating Specifications .............................................................................. 53

Camera Specifications ......................................................................53

Electrical Specification of I/O Signals .................................................53

Mechanical Specifications............................................................................. 54

Service Information 55

Document Revision ......................................................................................55

Product Information and Updates .................................................................. 55

Warranty Conditions .................................................................................... 56

Index 57

C3 Camera Hardware Reference Manual Rev. 1.3.7 Table Of Contents • 1

© 2009 Automation Technology GmbH.

All rights reserved. No part of this document shall be reproduced, stored in a retrieval system, or

transmitted by any means, electronic, mechanical, photocopying, recording, or otherwise without

consent in writing from the owners, AT-Automation Technology GmbH.

Disclaimer

While care has been exercised in the preparation of this document to ensure that it is fully correct and

comprehensive, the owners assume no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained herein. No license is

granted under any patents or patent right of AT – Automation Technology GmbH.

Trademarks

3M™ is a registered trademark of the 3M Company.

Camera Link™ is a registered trademark of PULNIX America, Inc.

Channel Link™ is a registered trademark of National Semiconductor, Inc.

Matrox™ is a registered trademark of Matrox Electronic Systems Ltd.

LINLOG™ is a registered trademark of Photonfocus AG

All other nationally and internationally recognized trademarks and tradenames are hereby

acknowledged.

This document is subject to change without notification. All rights reserved.

2 • Overview C3 Camera Hardware Reference Manual Rev. 1.3.7

Overview

Introduction

The C3 camera series is a revolutionary product family of high speed intelligent sensors. It is optimised

for 3D shape measurement by means of laser triangulation technique. The 3D profile extraction is

performed in the camera by using high performance parallel hardware processors. At the same time

only the 3D profile data is sent to the PC over a standard interface (CameraLink). This extreme data

reduction boosts the measuring speed to unprecedented levels without affecting the performance of

the connected image processing unit.

Measuring Principle

The C3 camera acquires height profiles and height images based on the laser triangulation principle.

According to this method a laser line is projected on the object from one direction. The C3 camera

views the object from another angle defining the triangulation geometry. The resulting sensor image is

evaluated by the C3 camera core and converted into a single height profile. By scanning the laser line

over the object a complete height image can be acquired.

The figures below demonstrate some typical triangulation geometries. The following notation is used in

the approximation of height resolution:

∆X= resolution along the laser line (lateral),

∆Y= resolution perpendicular to the laser line (longitudinal in the direction of motion),

∆Z= height resolution.

C3 Camera Hardware Reference Manual Rev. 1.3.7 Overview • 3

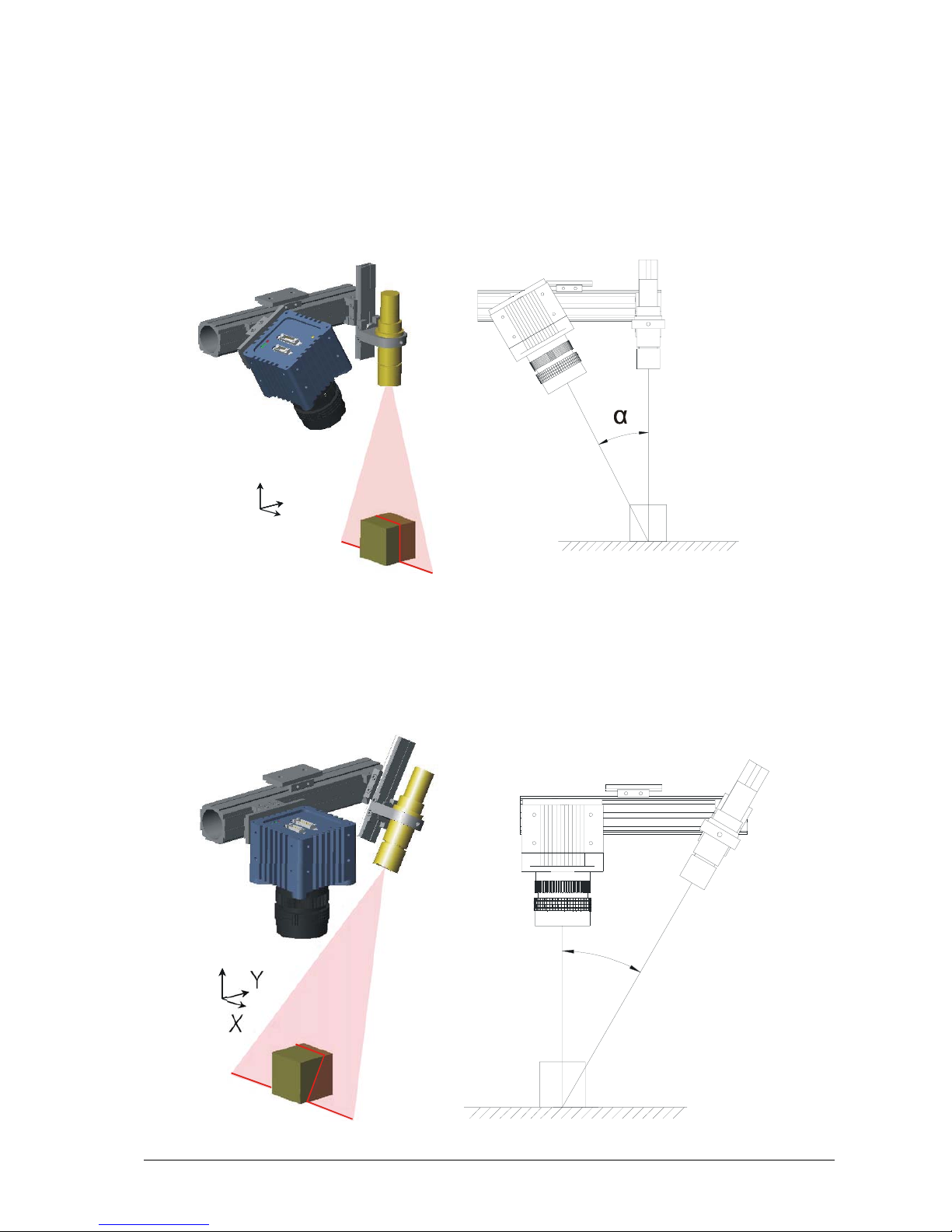

Geometry 1

The laser line is projected perpendicular to the object surface, while the camera views the object under

the triangulation angle α.

The height resolution can be approximated: ∆Z ≈ ∆X / sin(α)

Y

X

Z

Geometry 2

The camera views the object perpendicularly to its surface, while the laser line is projected under the

triangulation angle α.

The height resolution can be approximated: ∆Z ≈ ∆X / tan(α)

α

Y

X

Z

4 • Overview C3 Camera Hardware Reference Manual Rev. 1.3.7

Geometry 3

The camera views the object under an angle α, while the laser line is projected under a different

angle β.

The height resolution can be approximated: ∆Z ≈ ∆X * cos(β) / sin(α + β),

in case α= β (direct reflex) : ∆Z ≈ ∆X / 2* sin(α)

α

β

Y

X

Z

Geometry 4

The camera views the object under an angle α, while the laser line is projected under a different

angle β at the camera side.

The height resolution can be approximated: ∆Z ≈ ∆X * cos(β) / sin(α - β),

Y

X

Z

α

β

C3 Camera Hardware Reference Manual Rev. 1.3.7 Overview • 5

The C3 Camera Algorithms

The C3 camera can be operated both in a variety of 3D profile modes and in image mode. The

current operation mode can be chosen by setting the configuration bits of the CFG register.

The frame rate can be increased in all camera modes by reducing the AOI size. In the image mode

the frame rate is limited by the output rate of the camera interface (CameraLink). However, due to

reduced data size in profile mode the frame rate is limited only by the sensor output rate. As a matter

of principle the processing speed is independent of the chosen profile mode and is determined by the

AOI size.

In all profile modes only intensity values higher than the AOI intensity threshold AOI_TRSH

are

processed in order to suppress weak signal noise. In case that no position value can be found, e.g. no

intensity value is higher than threshold, the position value 0 is returned.

The Image Mode (IMG)

In the image mode the C3 camera is operated similar to a standard CMOS camera. In this mode grey

scale data of 8 or 10 bit resolution are acquired over the camera interface. Furthermore, the sensor

can be divided into multiple regions, whose data can be summarised in one output frame (see section

The Camera AOIs

for details).

6 • Overview C3 Camera Hardware Reference Manual Rev. 1.3.7

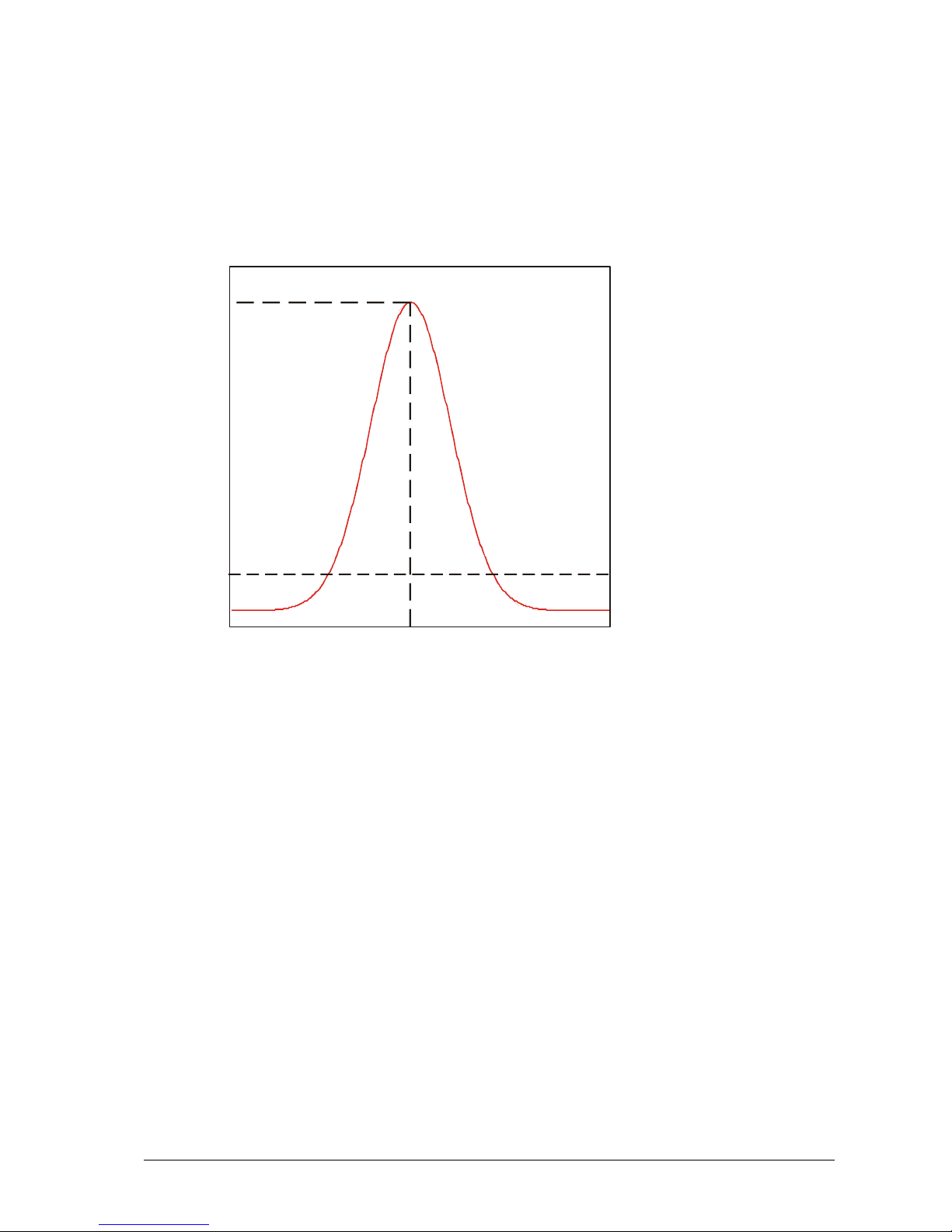

The Maximum Intensity Profile Mode (MAX)

In this mode the position of the maximum intensity of laser beam profile is calculated. The result

includes the position value of the maximum (P

MAX

) as well as the maximum intensity value (I

MAX

).

AOI_TRSH

P

MA

X

I

MAX

P

R

The calculation of position value is performed with simple pixel accuracy, i.e. the evaluation of 1024

rows delivers a position range from 0 to 1023 pixels (10 bit). If there is more than one local

maximum, the position of the first maximum (starting from row zero) is used.

C3 Camera Hardware Reference Manual Rev. 1.3.7 Overview • 7

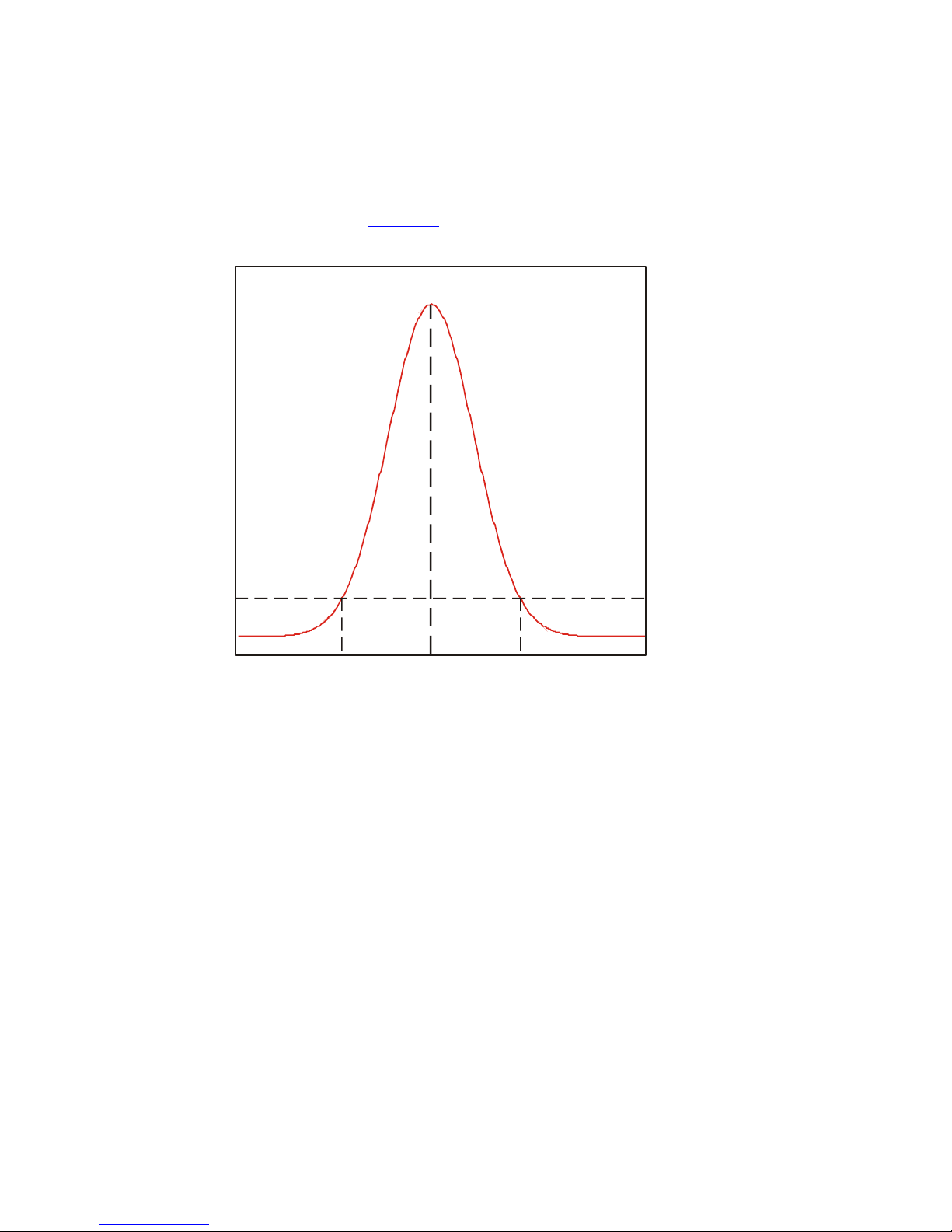

The Threshold Mode (TRSH)

In this mode the left (PL) and (PR) right edge position of the laser beam profile are calculated for a

given threshold value of intensity AOI_TRSH

.

AOI_TRSH

P

TRSH

P

L

P

R

The position value of the laser line is approximated: P

TRSH

= (PL+PR) / 2. In order to simplify the digital

representation the division over 2 is not performed and thus an integer representation with one

subpixel is realised. The evaluation of 1024 rows delivers a position range from 0 to 2047 pixels

(11 bit).

In threshold mode the camera can output either the left and right threshold position separately or the

subpixel position (P

L+PR

) and the line width (PR-PL). Moreover, the maximum intensity value can be

optionally delivered.

8 • Overview C3 Camera Hardware Reference Manual Rev. 1.3.7

The Center Of Gravity Mode (COG)

In this mode the center of gravity of laser beam profile is calculated. For this purpose the following

parameters are computed:

Position value of the left edge of laser beam profile for a given intensity threshold value P

L

,

Sum of intensity value I

s

= ∑ Ip,

Sum of first order moment M

s

= ∑Ip * P .

AOI_TRSH

P

CO

G

P

L

I

S

The position value of laser line (center of gravity of beam profile) is then obtained from:

P

COG

= PL + Ms / Is .

In addition the laser line width can be delivered over the Data Channel DC1

. The average intensity of

the illumination profile can be calculated by normalising the sum of intensity value I

s

with the line

width.

C3 Camera Hardware Reference Manual Rev. 1.3.7 Overview • 9

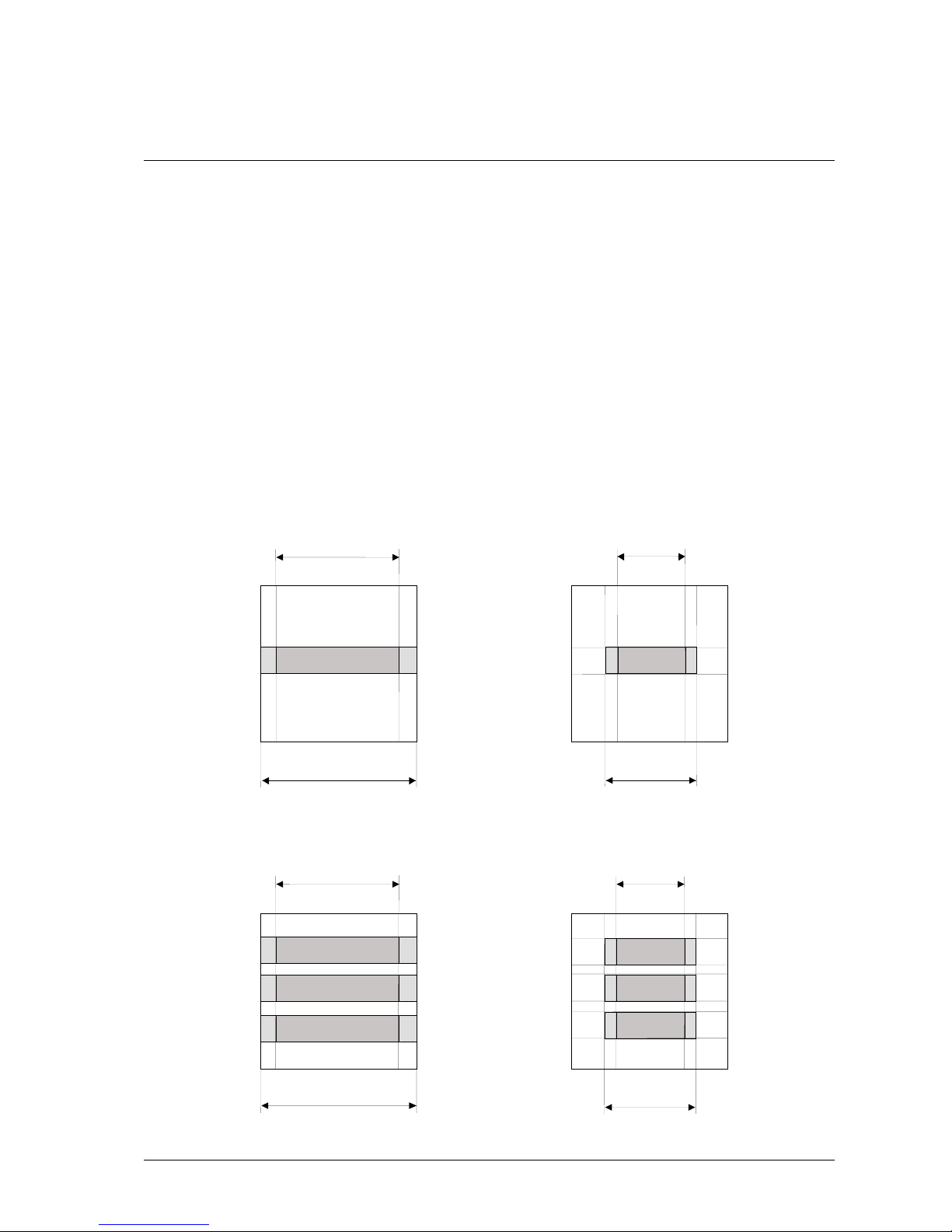

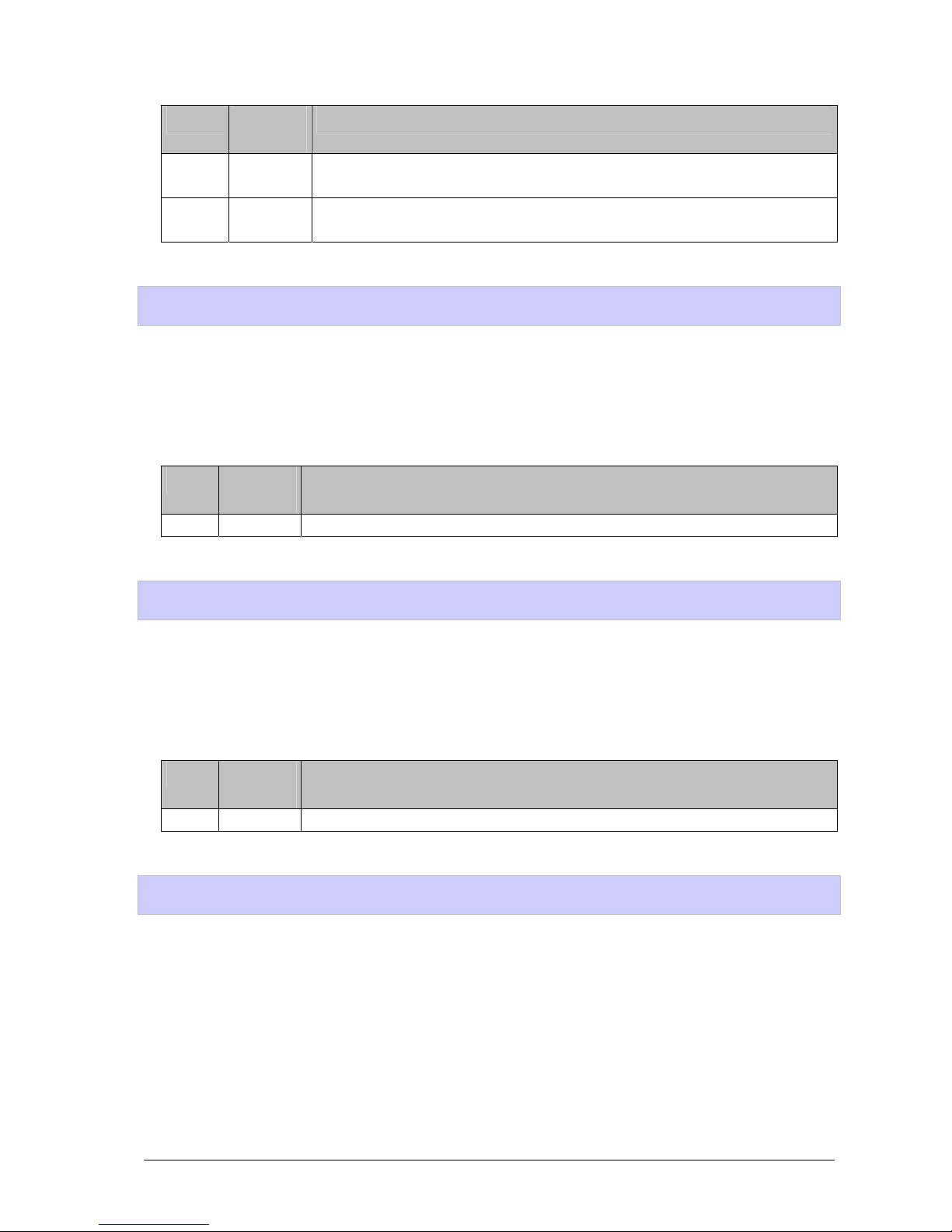

The Camera AOIs

The C3 camera series supports the operation of up to 8 none overlapping sensor Areas of Interest

(AOIs). Every AOI is defined by its starting row and total number of rows. A reduction of the AOI size

increases linearly the maximum frame rate. The AOI configuration is performed through the register

AOIX_Y0 and AOIX_DY. The camera outputs a single frame by putting together the individual AOIs.

Furthermore, the size of an AOI in the column direction can be also defined by setting the starting

column (CL_X0) and the number of output columns (CL_DX). Especially the camera C3-2350-CL

supports the reduction of the sensor output columns. For this sensor the read out speed and thus the

maximum frame rate increases linearly by reducing the number of pixels per row. Both the output

column position (CL_X0, CL_DX) and the sensor read out column position (SENSOR_X0, SENSOR_DX)

apply for all AOIs.

(0,0)

(1279,1023)

(0,0)

(1279,1023)

(0,0)

(1023,1023)

/

(2351,1727)

(0,0)

(1023,1023)

Length of sensor read out ro

w

Length of sensor read out row

Length of senso

r

read out row

(SENSOR_DX)

Length o

f

camera output row

(CL_DX)

A

OI0_Y0

A

OI0_Y0 + AOI0_DY

A

OI0_Y0

A

OI0_Y0 + AOI0_DY

A

OI0_Y0

A

OI0_Y0 + AOI0_DY

A

OI1_Y0

A

OI1_Y0 + AOI1_DY

A

OI2_Y0

A

OI2_Y0 + AOI2_DY

A

OI0_Y0

A

OI0_Y0 + AOI0_DY

A

OI1_Y0

A

OI1_Y0 + AOI1_DY

A

OI2_Y0

A

OI2_Y0 + AOI2_DY

12790

1279

0

Length o

f

camera output row

(CL_DX)

Length o

f

camera output row

(CL_DX)

Length o

f

camera output row

(CL_DX)

Length of senso

r

read out row

(SENSOR_DX)

SENSOR_X0

SENSOR_X0

CL_X0

CL_X0

CL_X0

CL_X0

SENSOR_X0

SENSOR_X0

C3-1280-CL C3-2350-CL

10 • Overview C3 Camera Hardware Reference Manual Rev. 1.3.7

The Image Data Output Format

The image and profile data output is performed by selecting the data channel DC0-DC2 (see

DATAOUT_REG

). Depending on the algorithm the data can be acquired by enabling the

corresponding output channel. Every channel is saved in a new image row. The data output can be

performed in 8 or 16 bit mode. In the 8 bit mode the DC0 (DATAOUT_DC0_SHIFT)

can be

configured to deliver the 8 most significant bits of the 10 bit intensity data. For the other channels the

8 most significant data bits are ignored.

In the CameraLink version with the compressed data output it is possible to use the CameraLink 2 tap

mode, in which two successive Pixel of 12 bit data width (DATAOUT_12BIT

) are transferred in one

cycle.

The Data Channel Assignment DC0-DC2

Alg. DC0 DC1 DC2

IMG Grey scale values Not used Not used

TRSH Maximum intensity Left edge of laser line

(PosL) or line width

(PosR-PosL)

Right edge of laser line (PosR) or

line position with 1/2 pixel

accuracy (PosL+PosR)

MAX Maximum intensity Left edge of laser line

(PosL)

Position of maximum intensity

(PosM)

COG

Sum of intensity values Is

Left edge of laser line

(PosL) or laser line width

(PosR-PosL)

Line position with 1/X pixel

resolution, where

X=1,2,4,8,16,32,64

Alg. Flags – Output over DC1 (16 bit mode):

Bit14 = LEFT_TRSH_FOUND_FLAG: indicates that the left edge of laser line was found

Bit15 = RIGHT_TRSH_FOUND_FLAG: indicates that the right edge of laser line was found

C3 Camera Hardware Reference Manual Rev. 1.3.7 Overview • 11

Image Acquisition

Sensor Modes

Freerun, untriggered Interleaved Mode (C3-1280-CL)

In this mode the acquisition (exposure) of the current image and the readout/processing of the

previous image is performed in parallel without external trigger. In 3D profile mode the maximum

frame rate is determined by the integration time or readout time of the sensor (whichever is longer).

On the contrary, in image mode the maximum frame rate is determined by the output time or

integration time of the sensor (whichever is longer). Comparing to readout or output time the

integration time (ITIME

) can be reduced by the parameter IRTIME (µs).

Integration

Frame N

Sensor Readout +

Output Frame N

Integration

Frame N+1

Output

Profile N

Sensor Readout +

Output Frame N+1

Integration

Frame N+2

3D Profile Mode

Image Mode

Sensor Readout

Frame N

Output

Profile N+1

Sensor Readout

Frame N+1

Triggered Interleaved Mode (C3-1280-CL)

In this mode the acquisition of the current image and the readout/processing of the previous image

can be performed in parallel depending on an external trigger. The maximum profile rate (camera is

running in profile mode) is determined by the sensor integration time and the sensor readout time. The

greater of both values corresponds to the time for the acquisition of one profile. In order to achieve a

constant integration time, even for asynchronous trigger pulses (e.g. from resolver interface) an

integration time greater or equal to the sensor readout time is recommended.

12 • Overview C3 Camera Hardware Reference Manual Rev. 1.3.7

Integration

Frame N

Sensor Readout

Frame N

Integration

Frame N+1

Output

Profile N

Sensor Readout

Frame N+1

Integration

Frame N+2

Output

Profile N+1

3D Profile Mode

Image Mode

external trigger (e.g. from digital input CC1 or

resolver interface ENC_A, ENC_B)

Sensor Readout +

Output Frame N

Sensor Readout +

Output Frame N+1

Freerun, untriggered Sequential Mode (C3-1280-CL)

In this mode the acquisition (exposure) and the readout / processing of the current image is performed

successively and without external trigger. The integration time is independent of the sensor readout

time and is determined only by the preset time ITIME

. In order to implement a predefined frame rate a

pause time (PTIME

) can by optionally used.

Integration

Frame N

Sensor Readout +

Frame N

optional

Pause Time

Integration

Frame N+1

Integration

Frame N

Sensor Readout

Frame N

optional

Pause Time

Integration

Frame N+1

Output

Profile N

3D Profile Mode

Image Mode

C3 Camera Hardware Reference Manual Rev. 1.3.7 Overview • 13

Triggered Sequential Mode (C3-1280-CL)

In this mode an external trigger initiates the image acquisition followed by the readout / processing.

The integration time is independent of the sensor readout time and is determined only by the preset

time ITIME

.

Pause Time

external trigger (e.g. from digital input CC1 or

resolver interface ENC_A, ENC_B)

Integration

Frame N

Sensor Readout +

Output Frame N

Integration

Frame N+1

Integration

Frame N

Sensor Readout

Frame N

Integration

Frame N+1

Output

Profile N

3D Profile Mode

Image Mode

Pause Time

Rolling Shutter, freerun (C3-2350 only)

In this mode the acquisition (exposure) of the current image and the readout/processing of the

previous image is performed row by row in parallel without external trigger. In 3D profile mode the

maximum frame rate is determined by the integration time or readout time of the sensor (whichever is

longer). On the contrary, in image mode the maximum frame rate is determined by the output time or

integration time of the sensor (whichever is longer). Comparing to readout or output time the

integration time (ITIME

) can be reduced by enabling the “Short Integration Mode”.

Rolling Shutter, triggered (C3-2350-CL only)

In this mode the acquisition of the current image and the readout/processing of the previous image

can be performed in parallel depending on an external trigger. The maximum profile rate in 3D mode

is determined by the integration time or readout time of the sensor (whichever is longer).

Trigger Modes

Image Acquisition Start

The image acquisition is initiated by a trigger when CFG_SEQ_FREERUN = 0 and

- „Start – Input“, when IO_START_STOP_SEQ_IO_EN

= 1 or

- CC(2) when IO_START_STOP_SEQ_CC_EN

= 1 or

14 • Overview C3 Camera Hardware Reference Manual Rev. 1.3.7

- CTRL_START bit of CTRL register

Image Acquisition Stop

The image acquisition is stopped by a trigger when CFG_SEQ_FREERUN = 0 and

- „Stop – Input“, when IO_START_STOP_SEQ_IO_EN

= 1 or

- CC(3) when IO_START_STOP_SEQ_CC_EN

= 1 or

- CTRL_STOP

bit of CTRL registers or

- automatic stop when a frame end is reached CFG_STOP_AT_FRAME_END

= 1

Profile Acquisition in 3D Profile Mode

The sensor integration or profile output is initiated by a trigger when CFG_INTEG_FREERUN = 0 and

- TRIG_CNT_MODE

= 0, use external trigger:

o „Start – Input“, when IO_TRIGGER_IO_EN

= 1, or

o CC(1), when IO_TRIGGER_CC_EN

= 1, or

o CTRL_TRIG

bit of CTRL register.

- TRIG_CNT_MODE

= 1, use external trigger of RS422 encoder interface.

External Triggering of Integration

The beginning and duration of sensor integration (exposure) can be determined by an external signal.

CFG_INTEG_FREERUN

= 0

CFG_EXT_INTEG_MODE

= 1

Use the following trigger:

- integration is active while IN1=H, when IO_TRIGGER_IO_EN

= 1, or

- integration is active while CC1=1, when IO_TRIGGER_CC_EN

= 1.

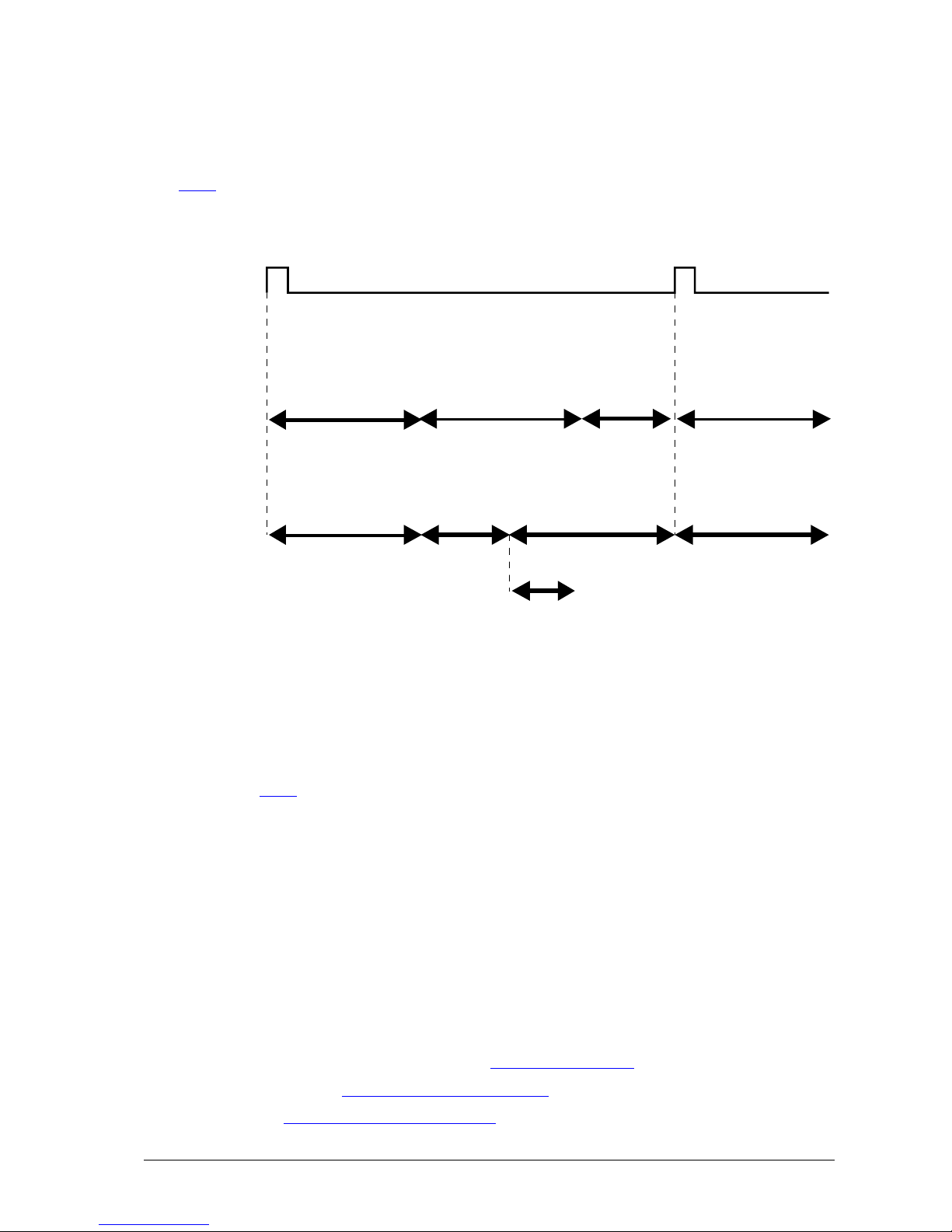

The External Trigger Enable line

By using camera input IN2 or the CameraLink line CC4 the internal trigger signal can be enabled or

disabled. This behaviour can be enabled by setting the corresponding configuration bits

(IO_TRIGGER_IO_EN

, IO_TRIGGER_CC_EN). With this signal any external trigger inputs (e.g.

resolver interface, camera input IN1 or CC1) can be enabled or disabled. At every low to high

transition of the trigger enable signal the trigger counter

is loaded with its start value. After a high to

low transition of the trigger enable line the currently active profile acquisition will be normally finished.

In free-run (untriggered) mode the external trigger enable signal enables the acquisition.

The external trigger enable has no function in external integration time control mode.

C3 Camera Hardware Reference Manual Rev. 1.3.7 Overview • 15

Output of internal Trigger and Status signals

The internal trigger and status signals can be monitored by using the digital outputs OUT1 and OUT2.

Setting IO_OUT2

to IO_OUT2_CNT_ZERO leads to the output of the internal trigger signal

generated from the resolver interface depending on the trigger count value TRIG_CNT

.

See Description of IO_REG

for further options.

A trigger overrun during external triggering can be detected by reading the TRIG_OVERRUN

flag of

the status register. This flag is set to one if a trigger pulse occurred during an active integration. By

means of this flag one can verify if the preset trigger count value is sufficient for the speed of an

external resolver and no trigger pulses are lost. The trigger overrun flag can be cleared by writing the

CTRL_TRIG_OVERRUN_CLR

bit.

16 • Overview C3 Camera Hardware Reference Manual Rev. 1.3.7

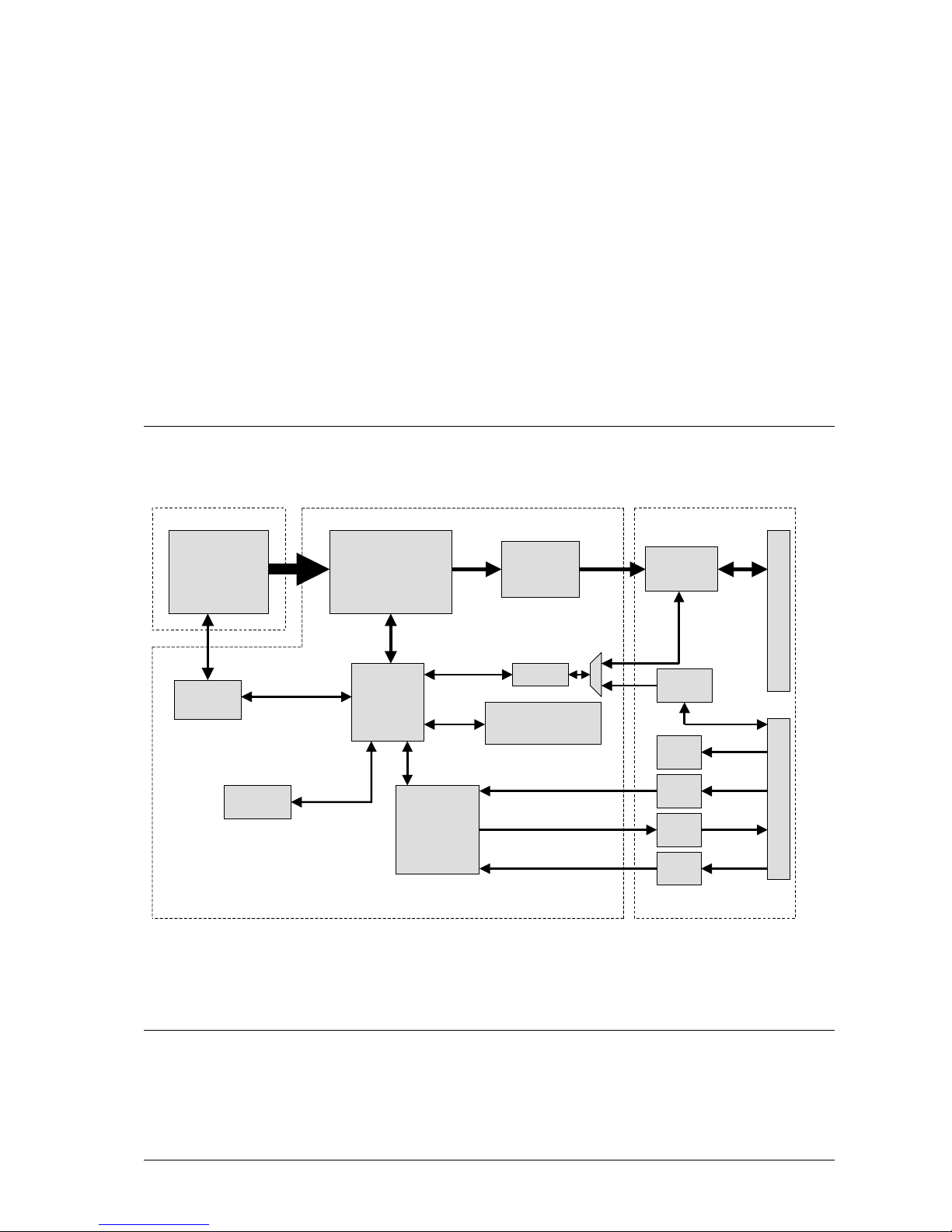

Software Integration of C3 Camera

There are four possible ways to integrate the C3 camera in a software application.

1. Operation as a Standard CameraLink-Camera in combination with One-Off Configuration

In this case the C3 camera is configured with the software tool “C3Explorer” and the configuration is

saved permanently in the camera EEPROM. This default configuration will be loaded automatically

each time the camera is connected to power.

For image acquisition, the camera can be operated as a standard CameraLink camera without any

additional camera specific configuration interface. The programming is limited to the application

specific image processing making use of library (e.g. SAPERA, IFC, MIL, MULTICAM, NI-IMAQ), which

supports the selected frame grabber.

User - Application

Image Processing Lib

with Frame Grabber API

(eg. SAPERA, MIL, CVB)

Frame Grabber driver

CameraLink Frame Grabber

Camera Image,

Height Image

Configuration Software,

eg. “C3-Explorer”

Offline C3-Camera

Configuration

C3Lib UART DLL

with UART interface

UART-Serial driver

Camera

Configuration

C3-Camera

C3 Camera Hardware Reference Manual Rev. 1.3.7 Overview • 17

2. Operation as a Standard CameraLink-Camera in combination with Serial Configuration (CLSER or

UART Protocol)

In this case the camera configuration can be modified by the application software using the CLSER or

UART protocol for serial communications. The provided CLSER/UART DLL can be used for the

implementation of camera specific protocol. Similar to case 1, the frame grabber can be accessed by

making use of a standard image processing library:

User - Application

C3Lib UART DLL

with UART interface

Image Processing Lib

with Frame Grabber API

(eg. SAPERA, MIL, CVB)

UART-Serial driver Frame Grabber driver

CameraLink Frame Grabber

Camera

Configuration

Camera Image

,

Height Image

C3-Camera

18 • Overview C3 Camera Hardware Reference Manual Rev. 1.3.7

3. Operation using the C3Lib API for camera configuration and image acquisition

Alternatively, the C3Lib API with implemented functions for the access to frame grabber and camera

registers can be used:

User - Application

C3Lib DLL with

Configuration-

and Grab-Interface

Image Processing Lib

with Frame Grabber API

(eg. SAPERA, MIL, CVB)

UART-Serial driver Frame Grabber driver

CameraLink Frame Grabber

C3-Camera

Camera

Configuration

Camera Image,

Height Image

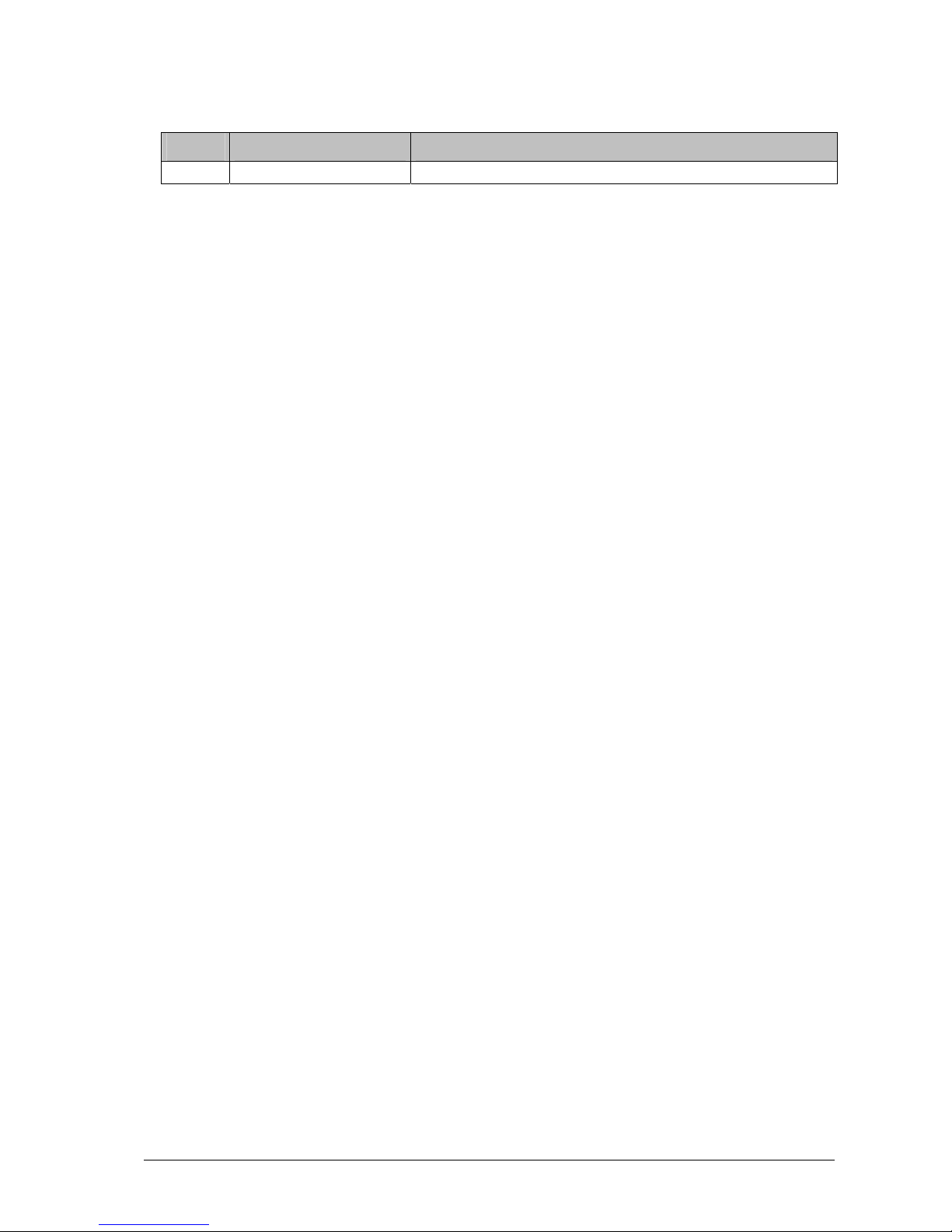

The C3Lib API supports the following frame grabbers:

Manufacturer Frame Grabber Image Processing Library

DALSA X64CL, X64CL-Ipro, X64CL-

IproLite, X64CL-Express, X64Xcelera-CL

SAPERA LT

Coreco (DALSA) PC-Camlink, PC2-Camlink IFC

Euresys Grablink Value, Grablink Expert Multicam

Matrox Meteor II/CL MIL

National Instruments PCI-1426, PCI-1428 NI-IMAQ

In addition, the C3Lib supports the Iport protocol of Pleora Technologies over Gigabit Ethernet

interface.

C3 Camera Hardware Reference Manual Rev. 1.3.7 Overview • 19

4. Camera configuration and image acquisition over GenIcam Transport Layer

A fourth method for integration of C3 camera in software applications is the use of the GenIcam API

standard with the XML functionality. Based on Dalsa X64CL-Ipro and Sapera library, AT has developed

a CameraLink Transport Layer, which allows the easy integration of C3 cameras into machine vision

applications. For each C3 camera model an XML parameter file is provided.

AT-CL Transport Layer

Camera Link Frame Grabber

Sapera CLAllSerial.dll

CLSerXXX.dll

CLProtocolC3.dll

C3 Camera XML

User Software

APIAPI

20 • Register Description C3 Camera Hardware Reference Manual Rev. 1.3.7

Register Description

The C3 Camera Register Set

The C3 camera can be configured by means of a programmable register set. In this way e.g. the

camera operation (image mode of 3D profile mode) can be changed by setting the register contents

to appropriate values. As a rule all registers have a data width of 16 bits. The register addressing takes

place in 16 bit steps, i.e. the address of register 0 is 0, the address of register 1 is 1 etc. The register

address space comprises 6 bits, which correspond to 64 possible register addresses.

The addresses 56-63 are reserved for the sensor DAC channels, which can be accessed over the

functions DacRead and DacWrite.

All camera settings can be saved as a start-up configuration in a parameter EEPROM, which is

integrated in the camera. There are 64 PROM addresses available and the addressing is similar to

that of register set. The parameter EEPROM can be accessed over a set of special functions:

PromRead, PromWrite and PromWriteEnable/Disable.

Register Reference

The individual registers of the C3 camera series are described in the following sections.

Unimplemented register addresses and bits are presently not used and are for future enhancements

reserved. The return value of unimplemented register bits is undefined.

CFG_REG

Description

Address: 0

Access: R/W

Register Bit Description

Bit Bit Name Description

0 CFG_ALG_IMG Image mode

1 CFG_ALG_TRSH 3D profile mode: Threshold algorithm (TRSH)

2 CFG_ALG_MAX 3D profile mode: Maximum intensity algorithm (MAX)

C3 Camera Hardware Reference Manual Rev. 1.3.7 Register Description • 21

Bit Bit Name Description

3 CFG_ALG_COG 3D profile mode: Center of gravity algorithm (COG)

4 Reserved

5 CFG_ALG_TEST_IMAGE 1: Generates an artificial laser line image (Debug)

6 CFG_ALG_VERTICAL_INVERT 1: Flips the image vertically

7 CFG_ALG_CLEAR_INVALID_POS 1: Validates the position result of an image column

The validation is performed at the end of column evaluation

using tolerances for width and area of Gaussian intensity

distr ibut ion ( register C3_WIDTH_VALID_MIN_REG,

C3_WIDTH_VALID_MAX_REG,

C3_SUM_INT_VALID_MIN_REG ,C3_SUM_INT_VALID_MAX_REG)

Invalid results are suppressed and their values are set to 0 in all

DCs.

8 CFG_ALG_ABS_POS 1: Absolute row position is returned

0: Offset position with respect to the start row of AOI is returned

9 CFG_ALG_ POS_VALIDATION_EN 1: Validates every Gaussian curve detected along an image

column.

The validation is performed using tolerances for width and area

of Gaussian intensity distribution (register

C3_WIDTH_VALID_MIN_REG, C3_WIDTH_VALID_MAX_REG,

C3_SUM_INT_VALID_MIN_REG ,C3_SUM_INT_VALID_MAX_REG)

Invalid results are ignored.

If CFG_ALG_TRSH_FIRST_FALLING=0, then no validation of

minimum Gaussian area is performed (tolerance in register

C3_SUM_INT_VALID_MIN_REG).

10 CFG_ALG_TRSH_FIRST_FALLING 1: Stops the position evaluation after the falling edge of the first

valid detected Gaussian curve.

11 CFG_SEQ_FREERUN 1: Free-run image acquisition

0 : The image acquisition start is performed by a trigger

12 CFG_INTEG_FREERUN 1: Free-run integration / profile acquisition

0 : Triggered integration / profile acquisition

13 CFG_EXT_INTEG_MODE Triggers the sensor exposure. The integration lasts as long as an

external signal is applied.

14 CFG_START_STOP_MODE Use the external trigger to start / stop the sequencer

15 CFG_STOP_AT_FRAME_END Stop the sequencer when the frame end is reached

CL_X0_REG

Description

Address: 1

Access: R/W

This register defines the starting column of the output frame with respect to the internal buffer of the

camera.

Register Bit Description

22 • Register Description C3 Camera Hardware Reference Manual Rev. 1.3.7

Bit Bit

Name

Description

0-3 CL_X0_L C3-1280-CL: Bits 0-3 of starting column

C3-2350-CL: Bits 0-3 of starting column

4-11 CL_X0_H C3-1280-CL: Bits 4-10 of starting column

C3-2350-CL: Bits 4-11 of starting column

CL_DX_REG

Description

Address: 2

Access: R/W

Register Bit Description

Bit Bit

Name

Description

0-11 CL_DX Set the number of pixels per row (frame width).

CL_DY_REG

Description

Address: 3

Access: R/W

Register Bit Description

Bit Bit

Name

Description

0-15 CL_DY Set the number of output rows per frame.

JTAG_REG

Description

Address: 4

Access: R/W

Register Bit Description

The access to this register is reserved for commissioning and maintenance tasks of the

manufacturer.

C3 Camera Hardware Reference Manual Rev. 1.3.7 Register Description • 23

Bit Bit Name Description

0 JTAG_CFG_TDI Input of camera JTAG – Chain is connected to TDO Output of the last chip in JTAG-

Chain.

1 JTAG_CFG_TDO Output of camera JTAG-Chain is connected to TDI Input of the first chip in JTAG-Chain.

2 JTAG_CFG_TCK JTAG-TCK signal

3 JTAG_CFG_TMS JTAG-TMS signal

4 JTAG_CFG_ENABLE Enables JTAG port.

ITIME_L_REG

Description

Address: 5

Access: R/W

Register Bit Description

Bit Bit Name Description

0-15 ITIME_L Sensor integration time (low Word) in µs

ITIME_H_REG

Description

Address: 6

Access: R/W

Register Bit Description

Bit Bit Name Description

0-7 ITIME_H Sensor integration time (high Word).

IRTIME_L_REG

Description

Address: 7

Access: R/W

Register Bit Description

Bit Bit Name Description

0 – 15 IRTIME_L Reduction of sensor integration time (low Word) in µs

0-10 IRTIME C3-2350-CL only: Number of rows needed when „Short Integration Mode“ is enabled

24 • Register Description C3 Camera Hardware Reference Manual Rev. 1.3.7

IRTIME_H_REG

Description

Address: 8

Access: R/W

Register Bit Description

Bit Bit Name Description

0 – 7 IRTIME_H Reduction of sensor integration time (high Word)

PTIME_L_REG

Description

Address: 9

Access: R/W

Register Bit Description

Bit Bit Name Description

0 – 15 PTIME_L Pause time (low Word) in µs

PTIME_H_REG

Description

Address: 10

Access: R/W

Register Bit Description

Bit Bit Name Description

0 – 7 PTIME_H Pause time (high Word)

SENSOR_REG

Description

Address: 11

Access: R/W

C3 Camera Hardware Reference Manual Rev. 1.3.7 Register Description • 25

Register Bit Description

Bit Bit Name Description

0 CURR_ON

DARK_OFF_EN

obsolete (C3-A1024-CL)

C3-1280-CL only

1 HIGH_VB1 obsolete (C3-A1024-CL)

2 HIGH_VB2 obsolete (C3-A1024-CL)

3 HIGH_VB3 obsolete (C3-A1024-CL)

4 SENSOR_CORRECT_ECLIPSE 1: corrects the eclipse effect of CMOS sensor (C3-1280-CL only)

5 reserved always 0

6 SENSOR_DUMMY_ROW_EN obsolete (C3-A1024-CL)

7-8 SENSOR_SHUTTER_MODE SENSOR_INTERLEAVED = 0x0000, The sensor integration and readout is

performed in parallel

SENSOR_SHORT_INTEG_MODE = 0x0080 (C3-2350-CL only)

SENSOR_SEQ = 0x0100, Sequential acquisition: 1. Sensor integration, 2.

Sensor readout. 3. Pause when PTIME

> 0

9 SENSOR_SKIMMING_ON obsolete (C3-A1024-CL)

10 SENSOR_LINLOG_ON obsolete (C3-A1024-CL)

11 SENSOR_LOG_MODE obsolete (C3-A1024-CL)

15 SENSOR_STDBY 1 = low power mode, sensor is in standby

0 = sensor is active

SENSOR_X0_REG

Description

Address: 12

Access: R/W

Register Bit Description

Bit Bit Name Description

0-11 SENSOR_X0 Starting column of sensor readout, (C3-2350-CL only). For C3-1280-CL = 0.

SENSOR_DX_REG

Description

Address: 13

Access: R/W

Register Bit Description

Bit Bit Name Description

0-11 SENSOR_DX Row width of sensor readout (C3-2350-CL only). For C3-1280-CL = 1279.

26 • Register Description C3 Camera Hardware Reference Manual Rev. 1.3.7

TRIG_CNT_REG

Description

Address: 14

Access: R/W

Register Bit Description

Bit Bit Name Description

15 TRIG_CNT_BIDIR RS422 Resolver:

1= count resolver pulses in both directions

2 = count resolver pulses in positive direction only

14 TRIG_CNT_INV RS422 Resolver: reverse the resolver count direction

13 TRIG_CNT_CNT_MODE 1 = Use the counter output to trigger (i.e. to initiate the sensor integration)

0 = Use the external trigger input (i.e. to initiate the sensor integration)

12 TRIG_CNT_LOAD_AT_START Load the value from trigger counter TRIG_CNT when the next trigger

occurs

11,10 Reserved

9-0 TRIG_CNT Trigger counter

CL_CFG_ REG

Description

Adresse: 15

Zugriff: R/W

Registerbit Description

Bit Bit Name Description

15 CL_CFG_FVAL_PULSE 1= output of CameraLink FVAL-Signals as pulse

0 = output of CameraLink FVAL-Signals as Frame Enable-Signal

(default)

14 CL_CFG_LVAL_PULSE 1= output of CameraLink LVAL-Signals as pulse

0 =output of CameraLink LVAL-Signals as Line Enable-Signal (default)

13-8 CL_CFG_ROW_END_PAUSE number of additional CameraLink pulse at end of output row

7-0 CL_CFG_FRAME_END_PAUSE number of additional Anzahl CameraLink pulse at end of frame

HWINFO_REG

Description

Address: 16

Access: R/W

C3 Camera Hardware Reference Manual Rev. 1.3.7 Register Description • 27

Register Bit Description

NUM_AOIS_REG

Description

Address: 17

Access: R/W

Register Bit Description

Bit Bit Name Description

3-0 NUM_AOIS Number of used sensor AOIs –1

LINLOG_VAL0_REG (obsolete, C3-A1024-CL only

Description

Address: 18

Access: R/W

Register Bit Description

Bit Bit Name Description

0-9 LINLOG_VAL0 LINLOG-DAC-Value1 for LinLog2 mode. This value is enabled in the beginning of integration

and remains active until LINLOG_TIME expires.

LINLOG_VAL1 (obsolete, C3-A1024-CL only)

Description

Address: 19

Access: R/W

Register Bit Description

Bit Bit Name Description

0-3 HWINFO_NUM_AOIS Number of maximum definable sensor AOIs –1

4-7 HWINFO_PROM_SIZE Size of the internal CFG-PROM in 64 Words, i.e. 1=64 Words

8-11 HWINFO_CAM_TYPE HWINFO_CAM_1280 = 0100H = C3-1280-CL

HWINFO_CAM_1024 = 0200H = C3-A1024-CL

HWINFO_CAM_2350 = 0300H = C3-2350-CL

12-15 HWINFO_CAM_INTERFACE CameraLink Interface = 1000H

28 • Register Description C3 Camera Hardware Reference Manual Rev. 1.3.7

Bit Bit Name Description

0-9 LINLOG_VAL1 LINLOG-DAC-Value2 for LinLog2 mode. This value is enabled after the expiration of

LINLOG_TIME and remains active until the end of integration.

LINLOG_TIME_L_REG (obsolete, C3-A1024-CL only)

Description

Address: 20

Access: R/W

Register Bit Description

Bit Bit Name Description

0-15 LINLOG_TIME_L Time interval for LinLog2 mode (low Word) in µs.

LINLOG_TIME_H_REG (obsolete, C3-A1024-CL only

Description

Address: 21

Access: R/W

Register Bit Description

Bit Bit Name Description

0-7 LINLOG_TIME_H Time interval for LinLog2 mode (high Word) in 65535 µs.

ADC0_REG (obsolete, C3-A1024-CL only)

Description

Address: 22

Access: R/W

Register Bit Description

Bit Bit Name Description

0-4 ADC_A_GAIN ADC channel A Gain (0-1FH), 0=0dB, 1FH =18.06dB

5-9 ADC_B_GAIN ADC channel B Gain (0-1FH) , 0=0dB, 1FH =18.06dB

10 ADC_SELB always 0

11 ADC_MODE always 1

12 ADC_TWOS always 0

14-13 reserved always 0

C3 Camera Hardware Reference Manual Rev. 1.3.7 Register Description • 29

Bit Bit Name Description

15 ADC_LOAD 1 : load sensor ADC0_REG in ADC0 CHA/B and ADC1_REG in ADC1 CHA/B

ADC2_REG (obsolete, C3-A1024-CL only)

Description

Address: 23

Access: R/W

Register Bit Description

Bit Bit Name Description

0-4 ADC_A_GAIN ADC channel A Gain (0-1FH), 0=0dB, 1FH =18.06dB

5-9 ADC_B_GAIN ADC channel B Gain (0-1FH) , 0=0dB, 1FH =18.06dB

10 ADC_SELB always 0

11 ADC_MODE always 1

12 ADC_TWOS always 0

14-13 reserved always 0

15 ADC_LOAD 1 : load sensor ADC0_REG in ADC0 CHA/B and ADC1_REG in ADC1 CHA/B

CTRL_REG

Description

Address: 24

Access: R/W

Register Bit Description

Bit Bit Name Description

0 CTRL_RST_ALL SW reset camera

1 CTRL_RST_SEQ SW reset sequencer and sensor

2 CTRL_RST_REGS SW reset register set

3 CTRL_START SW start pulse

4 CTRL_STOP SW stop pulse

5 CTRL_TRIG SW trigger pulse

6 CTRL_LOAD_TRIG_CNT SW pulse to load the trigger counter

7 CTRL_TRIG_OVERRUN_CLR SW pulse for clearing Trigger - Overrunflag

30 • Register Description C3 Camera Hardware Reference Manual Rev. 1.3.7

STATUS_REG

Description

Address: 25

Access: R/W

Register Bit Description

Bit Bit Name Description

0 STATUS_STOP indicates the current state of stop input

1 STATUS_START indicates the current state of start input

2-5 STATUS_CC indicates the current state of CameraLink control signals CC(1-4)

6 STATUS_ENC_ALARM indicates the state of encoder alarm signals

7 STATUS_ENC_Z reserved

8 STATUS_ENC_B indicates the state of encoder signal B

9 STATUS_ENC_A indicates the state of encoder signal A

10 STATUS_STARTUP_EN indicates that the loading of PROM configuration during the sensor reset is

enabled

11 STATUS_SENSOR_CAL reserved

12-15 STATUS_MUX_SEL defines which data can be read over the MUX_REG

0: CurrTrigCnt

1: reserved

2: SensorReadoutTime

3: reserved

4: FrameOutputTimeL

5: FrameOutputTimeH

6: Capability Info

7: Revision

MUX_REG

Description

Address: 26

Access: RO

Register Bit Description

Bit Bit Name Description

0-15 STATUS_MUX returns data according to STATUS_MUX_SEL bits of STATUS_REG register

C3 Camera Hardware Reference Manual Rev. 1.3.7 Register Description • 31

MUX_TRIG_STATUS

Description

Adresse: MUX_REG = 26

STATUS_MUX_SEL = 0

Zugriff: RO

Registerbit Description

Bit Bit Name Description

15 TRIG_CNT_UP Status of the current count direction of the resolver counter

14 TRIG_EN Status of the internal Trigger Enable signal

13 TRIG_EN_MODE

12 TRIG_OVERRUN Status of the Trigger-Overrun flag. Can be cleared by writing the CTRL_REG

register.

11, 10 reserved

9-0 TRIG_CNT contents of current trigger counter

MUX_SENSOR_READOUT_TIME

Description

Address: MUX_REG = 26

STATUS_MUX_SEL = 2

Access: RO

Register Bit Description

Bit Bit Name Description

0 – 15 SENSOR_READOUT_TIME sensor readout time in µs

MUX_FRAME_OUTPUT_TIME_L

Description

Address: MUX_REG = 26

STATUS_MUX_SEL = 4

Access: RO

Register Bit Description

Bit Bit Name Description

0-15 FRAME_OUTPU_TIME_L frame output time in µs (low word)

32 • Register Description C3 Camera Hardware Reference Manual Rev. 1.3.7

MUX_FRAME_OUTPUT_TIME_H

Description

Address: MUX_REG = 26

STATUS_MUX_SEL = 5

Access: RO

Register Bit Description

Bit Bit Name Description

0-15 FRAME_OUTPU_TIME_H frame output time in µs (high word)

MUX_CAP_INFO

Description

Address: MUX_REG = 26

STATUS_MUX_SEL = 6

Access: RO

Register Bit Description

Bit Bit Name Description

0 – 3 CAP_DIN_CLK_FLAG 0 = 40MHz

1 = 60MHz

2 = 66MHz

3 = 70 MHz

4 – 7 CAP_DOUT_CLK_FLAG 0 = DIN_CLK

1 = ½ DIN_CLK

2 = 2/3 DIN_CLK

3 = 40MHz

4 = 50MHz

8 CAP_IMG 1 = default; image mode is implemented

9 CAP_MAX 1 = 3D profile mode; maximum intensity algorithm (MAX) is implemented

10 CAP_TRSH 1 = 3D profile mode; threshold algorithm (TRSH) is implemented

11 CAP_COG 1 = 3D profile mode; center of gravity algorithm (COG) is implemented

12-15 reserved

MUX_REVISION

Description

Address: MUX_REG = 26

C3 Camera Hardware Reference Manual Rev. 1.3.7 Register Description • 33

STATUS_MUX_SEL = 7

Access: RO

Register Bit Description

Bit Bit Name Description

0-7 MINOR_REVISION MinorRevision number

8–15 MAJOR_REVISION Major Revision number

IO_REG

Description

Address: 28

Access: R/W

Register Bit Description

Bit Bit Name Description

0-1 IO_OUT1 defines the content of Output1 signal

IO_OUT1_INTEG_ACTIVE : 0x0000

IO_OUT1_SEQ_ACTIVE : 0x0001

IO_OUT1_READOUT_ACTIVE : 0x0002

2-4 IO_OUT2 defines the content of Output2 signal

IO_OUT2_FRAME_VALID : 0x0000

IO_OUT2_LINE_VALID : 0x0004

IO_OUT2_CNT_DIR : 0x0008

IO_OUT2_CNT_ZERO : 0x000C

IO_OUT2_OVR: 0x0010

8 IO_TRIGGER_IO_EN enables the external trigger input IN1 for profile triggering

9 IO_TRIGGER_CC_EN enables the triggering over CameraLink control signal CC1

10 IO_START_STOP_SEQ_IO_EN enables the start / stop mode of sequencer over the external

inputs IN1, IN2

11 IO_START_STOP_SEQ_CC_EN enables the start / stop mode of sequencer over the

CameraLink control signals CC2 and CC3

12 IO_ TRIGGER_ENABLE_IN2 configure input IN2 as Triggerenable.

13 IO_ TRIGGER_ENABLE_CC4 configure CameraLink Control Signale CC4 as

Triggerenable.

DATAOUT_REG

Description

Address: 29

34 • Register Description C3 Camera Hardware Reference Manual Rev. 1.3.7

Access: R/W

Register Bit Description

AOI0_Y0-AOI7_Y0

Description

Address: AOI0_Y0=30, AOI0_Y1=33, .. AOI0_Y7=51

Access: R/W

Register Bit Description

Bit Bit Name Description

0-9 Y0 starting row of AOI

Bit Bit Name Description

0 DATA_OUT_DC0 activates the output data channel DC0

1 DATA_OUT_DC1 activates the output data channel DC1

2 DATA_OUT_DC2 activates the output data channel DC2

4-6 DATAOUT_NUM_SP number of subpixel bits of COG output (1-6)

7 DATAOUT_DC2_TRSH_SP controls the output in channel DC2, when TRSH algorithm is

selected:

1: DC2 outputs the line position value with one subpixel.

0: DC2 outputs the right edge position.

8 DATAOUT_DC1_TRSH_WIDTH controls the output in channel DC1, when TRSH algorithm is

selected:

1: DC1 outputs the laser line width

0: DC1 outputs the left edge position.

9 DATAOUT_DC1_WIDTH controls the output in channel DC1, when COG algorithm is

selected:

1: DC1 outputs the laser line width

0: DC1 outputs the left edge position.

10 DATAOUT_DC1_FLAGS when in 16 bit mode, the bits 12-15 of output channel DC1

contain additional algorithm flags

11 DATAOUT_16BIT enables 16 bit mode in all output data channels

12 DATAOUT_12BIT enables 12 bit mode in all output data channels

13 DATAOUT_8BIT enables 8 bit mode in all output data channels

14 DATAOUT_DC0_SHIFT right shift twice the intensity value in DC0, i.e. convert to 8 bit

(recommended for use only with intensity values when

DATAOUT_8BIT=1)

15 DATAOUT_TWO_PIXEL_OUT output two pixel values in one cycle

C3 Camera Hardware Reference Manual Rev. 1.3.7 Register Description • 35

AOI0_DY-AOI7_DY

Description

Address: AOI0_DY=31, AOI1_DY=34, ..., AOI7_DY=52

Access: R/W

Register Bit Description

Bit Bit Name Description

0-9 DY number of rows in AOI

AOI0_TRSH-AOI7_TRSH

Description

Address: AOI0_TRSH=32, AOI1_TRSH=35, ..., AOI7_TRSH=53

Access: R/W

Register Bit Description

Bit Bit Name Description

0-9 TRSH intensity threshold value (used in the evaluation algorithms)

Sensor DAC Channels

Description

Address: 56-63

Access: R/W

Register Bit Description

Bit Bit Name Description

0-9 DAC_VAL 10 bit DAC – output

0 – 1023 correspond to 0...2.7V

12-15 DAC_ADDR DAC channel code:

0 = no modification

1= DAC1

2= DAC2

...

8 = DAC8

15 = load all DAC channels (1-8) with the same value

36 • Register Description C3 Camera Hardware Reference Manual Rev. 1.3.7

Description of DAC channels (C3-1280-CL only)

DAC Range Default Description

1 0.2-1.5 1.0 VREF1 : ADC reference voltage

2 0.8-1.1 1.0 VLN2 : bias for ADC

3 0.3-1.5 0.8 VREF2 : reference voltage for ADC calibration

4 0.5-2.7 1.9 VLP : bias for column buffer

5 0-2.6 0 VCLAMP3 : determines the dark offset together with VREF3, when

DARK_OFF_EN=1

6 0-2.5 0.6 VREF3: determines the dark offset together with VCLAMP3, when

DARK_OFF_EN=1

7 0.8-1.1 1.0 VLN1 : bias for pixel source follower

8 0.2-1.5 0.25 VREF4 : ADC reference voltage should be equal to ¼ VREF1

Description of DAC channels (C3-2350-CL only)

DAC Range Default Description

1 0.25-1.5 0.8 VREF1 : ADC reference voltage

2 0.4-1.5 0.7 VREF2 : reference voltage for ADC calibration

3 0-3.0 0.15 VREF3: determines the dark offset together with VCLAMP3, when

DARK_OFF_EN=1

4 0-3.0 0.6 VCLAMP3 : determines the dark offset together with VREF3, when

DARK_OFF_EN=1

5 2.9-3.3 3.1 VRSTPIX

6 0.5-1.2 1.05 VLN1 : bias for pixel source follower

7 1.0-2.3 2.29 VLP : bias for column buffer

8 0.25-1.5 0.2 VREF4 : ADC reference voltage should be equal to ¼ VREF1

LASER_CONTROL_REG (C3-CompactSensors only)

Description

Address: 54

Access: R/W

Registerbit Description

Bit Bit Name Description

0-9 LASER_POWER 10 Bit Laser Power: 0-1023 correspond to 0...100%

15 LASER_ON 0 = Laser turn off

1= Laser turn on

C3 Camera Hardware Reference Manual Rev. 1.3.7 Register Description • 37

WIDTH_VALID_MIN_REG

Description

Address: 64

Access: R/W

Registerbit Description

Bit Bit Name Description

0-15 WIDTH_VALID_MIN_VAL Minimum width of valid Gaussian intensity distribution in 3D-mode

WIDTH_VALID_MAX_REG

Description

Address: 65

Access: R/W

Registerbit Description

Bit Bit Name Description

0-15 WIDTH_VALID_MAX_VAL Maximum width of valid Gaussian intensity distribution in 3D-mode

SUM_INT_VALID_MIN_REG

Description

Adresse: 66

Access: R/W

Registerbit Description

Bit Bit Name Description

0-15 SUM_INT_VALID_MIN _VAL Minimum area of valid Gaussian intensity distribution in 3D-mode

SUM_INT_VALID_MAX_REG

Description

Adresse: 67

Access: R/W

38 • Register Description C3 Camera Hardware Reference Manual Rev. 1.3.7

Registerbit Description

Bit Bit Name Description

0-15 SUM_INT_VALID_MAX _VAL Maximum area of valid Gaussian intensity distribution in 3D-mode

C3 Camera Hardware Reference Manual Rev. 1.3.7 I/O Interface • 39

I/O Interface

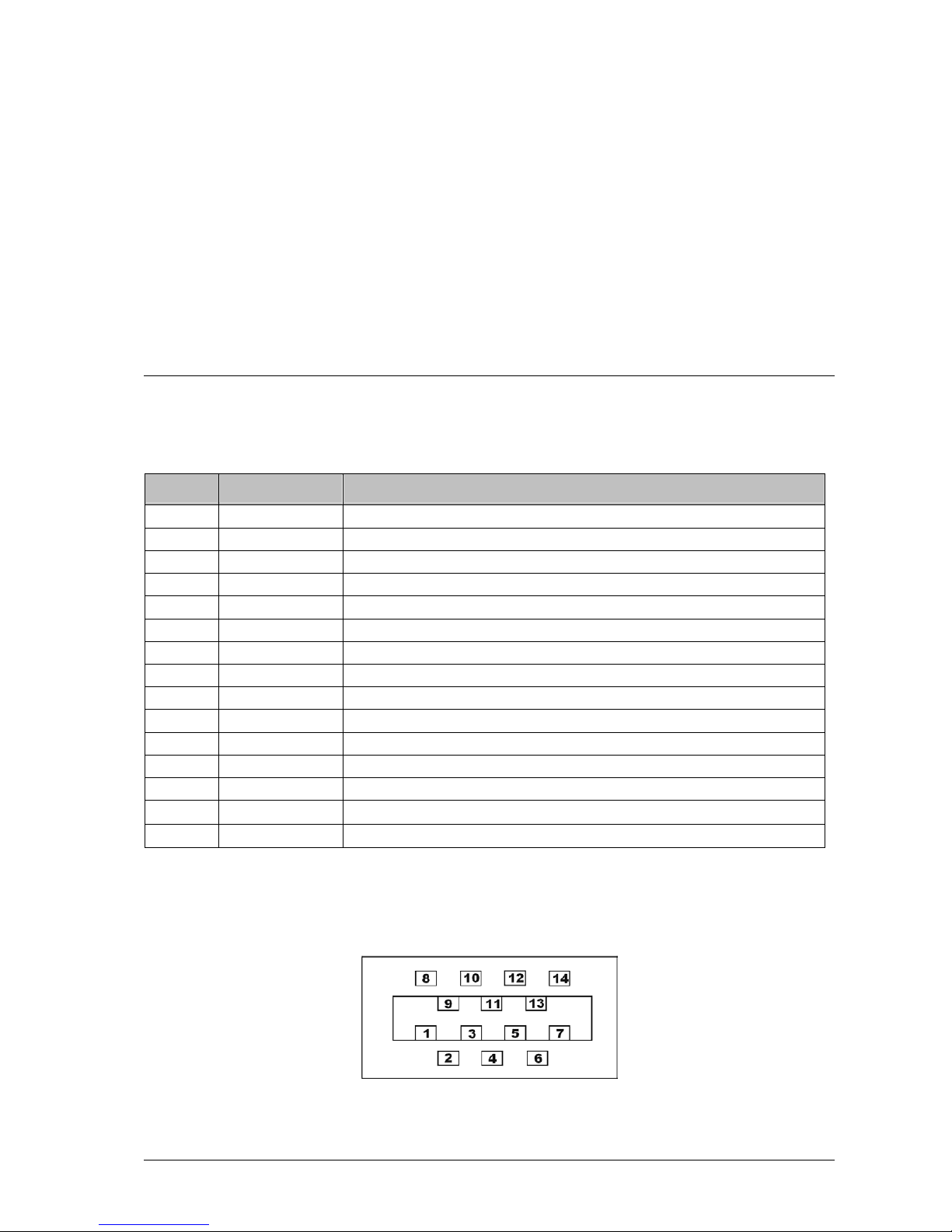

The Camera I/O Interface

Pin Assignment

Pin Nr. Signal Name Description

1 GND camera ground

2 GND IO I/O signal ground

3 RS232 TX / IN3 reserved

4 ENC A+ encoder Track1 RS422 none reversible input (A+ )

5 ENC B+ encoder Track2 RS422 none reversible input (B+ )

6 IN1 optoisolated Input1*

7 IN2 optoisolated Input2*

8 VCC IN camera supply voltage (7-24V DC)

9 VCC IO supply voltage for optoisolated I/O (5-24V DC)

10 RS232 RX / OUT3 reserved

11 ENC A- encoder Track1 RS422 reversible input (A- )

12 ENC B- encoder Track2 RS422 reversible input (B- )

13 OUT1 optoisolated Output1

14 OUT2 optoisolated Output2

Shield SCHIRM is connected to camera case

*a series resistor 3.6k is required for operation with 24V signals (included in the external

I/O-Panel)

I/O Connector Pin Assignment (View from solder side of connector)

40 • I/O Interface C3 Camera Hardware Reference Manual Rev. 1.3.7

Part Numbers for I/O Connector MDR 14

Description Part Number 3M

14-pin Connector 10114-3000VE

lockable connector case 10314-52F0-008

The internal DIP-Switches

Firmware Version 4.2 does not support the direct calculation of line position with COG algorithm.

Description of LEDs

LED Description

1 (red) on = power supply good

2 (green) on = camera sequencer is active

off = camera sequencer is inactive, e.g. it is waiting for external trigger signal.

3 (green) on = camera start up completed.

DIP-Switch

1 2 3 4 5 6 7 8

Boot Firmware

Version

Baudrate Prom-Nr.

off on off off on on on on 4.8 115k 0

off on off off on off on on 4.7 9.6k 1

off on off off on on off on 4.4 115k 2

on on off off on off off on 4.2 115k 3

off on off off off off off on 4.8 115k 0 (default)

C3 Camera Hardware Reference Manual Rev. 1.3.7 I/O Interface • 41

The External I/O Panel

The optoisolated inputs of the I/O panel, which are provided with a series resistance, can be operated

directly with 24 V DC. In order to use input signals with 5V level, the jumpers JP2 and JP3 on the

panel must be set.

I/O Panel Clamp Connection

Clamp Pin

Nr.

Signal

Name

Description

P1 / 1 SCHIRM camera shield

P1 / 2 GND camera ground

P1 / 3 VCC IN camera supply voltage (7-24V DC)

P2 / 1 ENC B- encoder Track2 RS422 reversible input (B- )

P2 / 2 ENC B+ encoder Track2 RS422 none reversible input (B+ )

P2 / 3 ENC A- encoder Track1 RS422 reversible input (A- )

P2 / 4 ENC A+ encoder Track1 RS422 none reversible input (A+ )

P2 / 5 GND encoder ground is connected to camera ground

P4 / 1 TX / IN3 reserved

P4 / 2 RX / Out3 reserved

P4 / 3 IN1 optoisolated Input1

P4 / 4 IN2 optoisolated Input2

P4 / 5 OUT1 optoisolated Output1

P4 / 6 OUT2 optoisolated Output2

P4 / 7 GND IO I/O signal ground

P4 / 8 VCC IO supply voltage for the optoisolated inputs and outputs (5-24V DC)

P1/1

P2/1

P4/1

42 • The CameraLink Interface of C3 Camera C3 Camera Hardware Reference Manual Rev. 1.3.7

The CameraLink Interface of C3

Camera

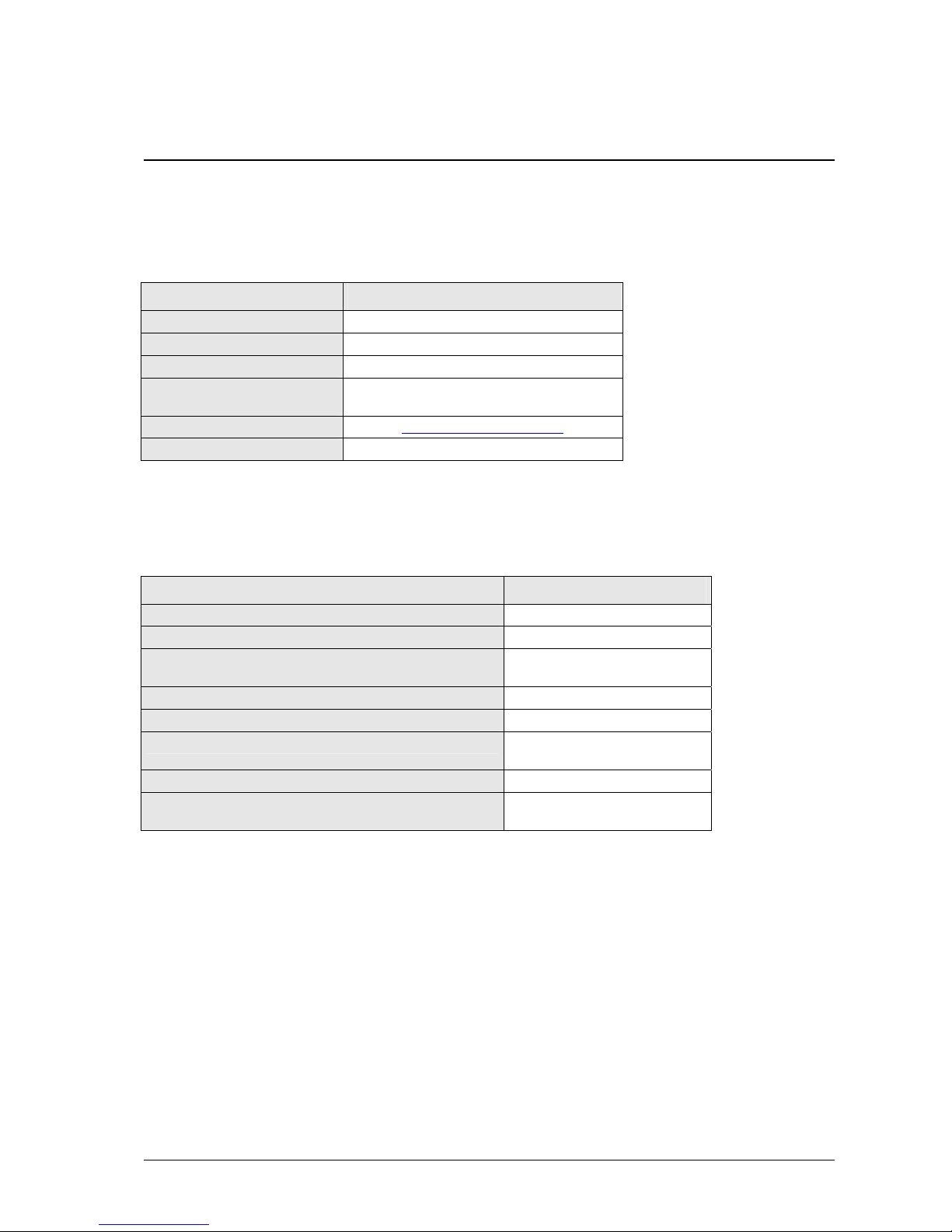

System Overview

Supported CameraLink Modes

A CameraLink compatible frame grabber with at least one Base CameraLink connection is required in

order to operate the C3-Camera with CameraLink interface. The CameraLink pixel frequency of the

Parameter

EE-Prom

CMOS

Sensor

Sensor

Sequencer

Parallel Image

Data Processor

with Image Memory

Camera

Controller

CameraLink

Controller

I/0 Interface

Trigger /

Synchronization

Controller

UART

User Programmable

Register

Table

CameraLink

Interface

Opto In

2x

Opto Out

2x

RS 422

Resolver

Interface

Sensor Board

RS232

Interface

Data Processing Board IO Board

MDR26 CameraLink Connector MDR 14 I/O Connector

Power

Supply

C3 Camera Hardware Reference Manual Rev. 1.3.7 The CameraLink Interface of C3 Camera • 43

camera is factory preset to 40MHz (C3-2350-CL 50MHz). Camera versions with different CameraLink

pixel frequency are available on request. In all versions the frame grabber must support the

corresponding pixel frequency of the camera.

The following frame grabbers have been tested with the C3 camera.

Frame

Grabber

Manufacturer Remarks

MeteorII-CL Matrox Imaging maximum pixel frequency: 50MHz

access of UART functions is possible only over the MIL library.

PcCamLink Dalsa maximum pixel frequency: 62.5MHz

UART interface as standard PC serial port (COM X) is available

Pc2CamLink Dalsa without On-Board memory !

UART interface as standard PC serial port (COM X) is available

X64CL

X64CL-Ipro/Lite

X64CL-Express

X64-Xcelera-CL

Dalsa

maximum pixel frequency: 85MHz

UART interface as standard PC serial port (COM X) is available

X64CL-Ipro/Lite

X64CL-Express

Dalsa

maximum pixel frequency: 85MHz

UART interface as standard PC serial port (COM X) is available

GrabLink Value

Euresys

UART interface as standard PC serial port (COM X) is available

GrabLink

Expert2

Euresys

frame grabber for asynchronous operation of two cameras.

UART interface as standard PC serial port (COM X) is available

PCI-1428

National

Instruments

access of UART functions is possible only over clserial or NI-

IMAQ functions. The 115200 baud mode is not supported by

the board.

Configuration files for the above listed frame grabbers are available.

44 • The CameraLink Interface of C3 Camera C3 Camera Hardware Reference Manual Rev. 1.3.7

Output Modes of C3 Camera with CameraLink Interface

DC Mode Assignment of CameraLink Ports A, B, C

8 bit mode with 2 taps

(always with parallel output of two pixels)

pixel N = port A (7...0)

pixel N+1 = port B (7...0)

12 bit mode with 2 taps

(always with parallel output of two pixels

)

pixel N = port B (3..0) + port A (7..0)

pixel N+1 = port B (7..4) + port C (7..0)

16 bit mode with 1 tap pixel N = port B (7..0) + port A (7..0)

CameraLink Signal Assignment

Signal Name Description

FEN FieldEnable : 1 = frame enabled, 0 = disabled, rising edge indicates the frame beginning

LEN LineEnable : 1 = row enabled, 0 = disabled, rising edge indicates row beginning

DVAL DataEnable : 1 = pixel data enabled, 0 = disabled

SPVAL reserved, always 0

See CL_CFG_REG for additional timing – configuration of CameraLink interface.

Camera Control Signal Assignment

Signal Function

Camera Control 1 (CC1) external trigger input for frame and 3D profile acquisition

Camera Control 2 (CC2) Start-Input for frame sequencer

Camera Control 3 (CC3) Stop-Input for frame sequencer

Camera Control 4 (CC4) Trigger enable signal

C3 Camera Hardware Reference Manual Rev. 1.3.7 The CameraLink Interface of C3 Camera • 45

The UART Configuration Protocol

Apart from the image data transmission line, an additional serial UART channel is available for the

communication with the C3 CameraLink version. This can be implemented by using the hardware

integrated CameraLink UART interface or the separate RS232 lines in the I/O panel. A specific serial

protocol is defined for the access to camera registers, sensor DAC and configuration EEPROM. As a

rule one byte is used for addressing and two bytes for data. An additional command byte in the

beginning of the data block defines the access mode. The following command and error codes are

defined:

Error codes of UART protocol Name Code

Data transmission and command is successfully finished CMD_ACK 80H

Data transmission or command has caused an error CMD_NAK 7FH

Command codes of UART protocol Name Code

write into the sensor DAC CMD_WRITE_DAC 01H

write into a register CMD_WRITE_REG 02H

read from a register CMD_READ_REG 04H

execute a PROM command CMD_PROM 08H

execute a NOP command (to resynchronise the protocol in an error case) CMD_UNKNOWN 80H

After the execution of a command, the camera returns an acknowledgment byte (CMD_ACK,

CMD_NAK) at the end of the data block.

CMD_WRITE_DAC

Byte Description

TX 1 CMD_WRITE_DAC (01H)

TX 2-3 16 bit data word (first high byte, then low byte)

RX 1-2 16 bit data word (first high byte, then low byte), includes the last output word to DAC

RX 3 CMD_ACK / CMD_NAK

CMD_WRITE_REG

Byte Description

TX 1 CMD_WRITE_REG (02H)

TX 2 register address (0-64)

TX 3-4 16 bit data word (first high byte, then low byte), new register contents

RX 1 CMD_ACK / CMD_NAK

46 • The CameraLink Interface of C3 Camera C3 Camera Hardware Reference Manual Rev. 1.3.7

CMD_READ_REG

Byte Description

TX 1 CMD_READ_REG (04H)

TX 2 register address (0-64)

RX 1-2 16 bit data word (first high byte, then low byte), current contents of register

RX 3 CMD_ACK / CMD_NAK

CMD_PROM

Byte Description

TX 1 CMD_PROM (08H)

TX 2 PROM operation code + Address

PROM_OPCODE_WR (40H) + Address (bit 5-0) : write PROM

PROM_OPCODE_RD (80H) + Address (bit 5-0) : read PROM

PROM_OPCODE_EWEN (30H) : enable write

PROM_OPCODE_EWDS (00H) : disable write

TX 3-4 16 bit data word (16 bit)

RX 1-2 16 bit data word (first high byte, then low byte)

RX 3 CMD_ACK / CMD_NAK

C3 Camera Hardware Reference Manual Rev. 1.3.7 The CameraLink Interface of C3 Camera • 47

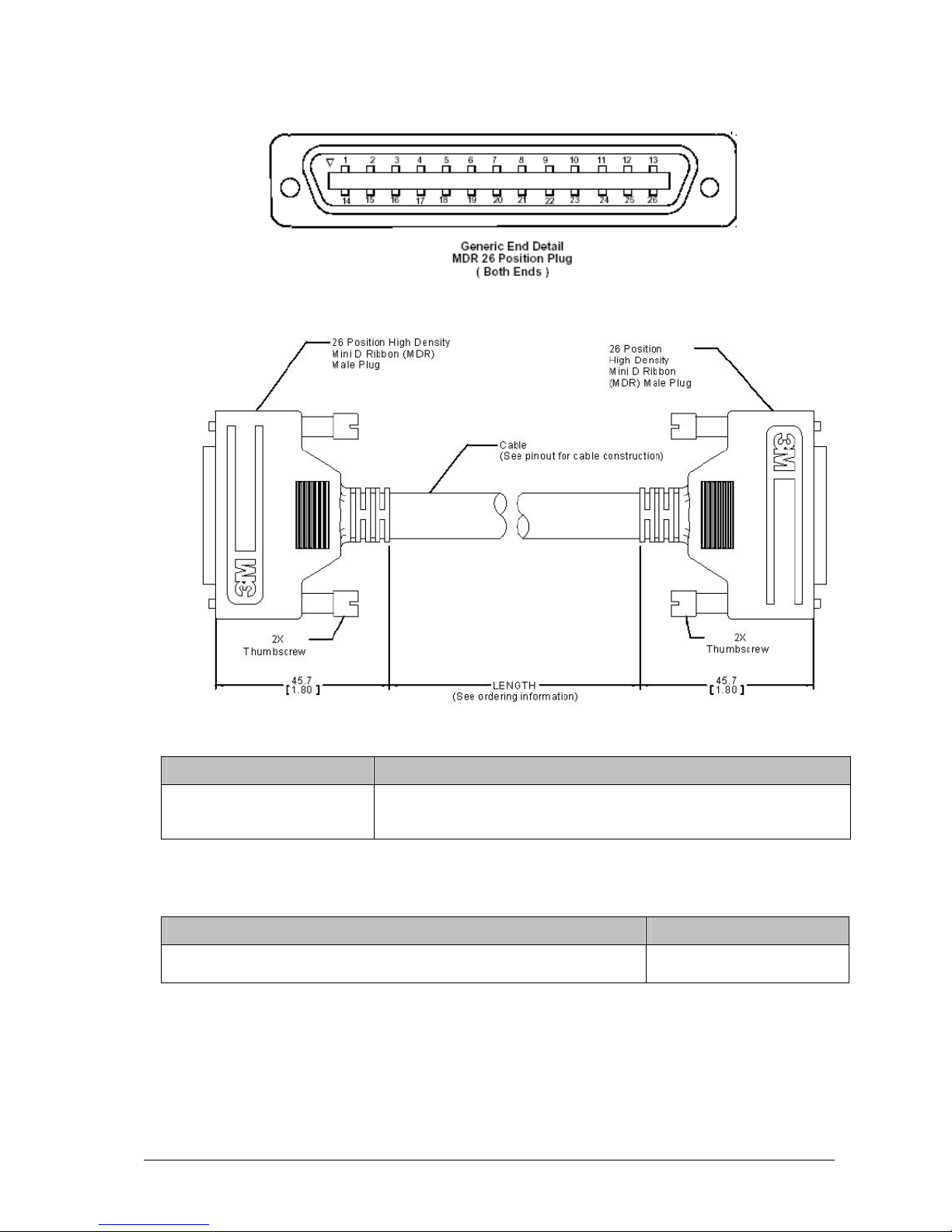

The CameraLink Connection

The signal ground (GND) is connected with the CameraLink inner shield in the camera over a 0 Ohm

jumper, which can be removed if required.

CameraLink Cable Assignment

Camera

Connector Pin

Nr.

Frame Grabber

Pin Nr.

CameraLink Signal Name

1 1 inner shield

14 14 inner shield

2 25 X0-

15 12 X0+

3 24 X1-

16 11 X1+

4 23 X2-

17 10 X2+

5 22 Xclk-

18 9 Xclk+

6 21 X3-

19 8 X3+

7 20 SerTC+

20 7 SerTC-

8 19 SerTFG-

21 6 SerTFG+

9 18 CC1-

22 5 CC1+

10 17 CC2+

23 4 CC2-

11 16 CC3-

24 3 CC3+

12 15 CC4+

25 2 CC4-

13 13 inner shield

26 26 inner shield

SCHIRM SCHIRM is connected to the camera case

48 • The CameraLink Interface of C3 Camera C3 Camera Hardware Reference Manual Rev. 1.3.7

CameraLink Connector (Front View)

CameraLink Cable

3M Part Number for CameraLink Cable

Description Part Number 3M

CameraLink cable (0.5m – 10m) 14T26-SZLB-XXX-0LC wobei XXX:

050 = 0.5 m, 100 = 1 m, 150 =1.5 m, 200 = 2 m, 250 = 2.5 m, 300 = 3 m, 350 = 3.5m,

450 = 4.5 m, 500 = 5 m, 600 = 6 m, 700 = 7 m, 800 = 8m, 900 = 9m, A00 = 10 m

Helukabel Part Number of dragchain cable

Bezeichnung Helukabel Part Number

shielded dragchain cable Supertronic-C-PVC (14 x 0,14mm²) with diameter 7mm

and bending radius 70mm

49627

C3 Camera Hardware Reference Manual Rev. 1.3.7 Technical Specifications • 49

Technical Specifications

C3-1280-CL Sensor

Parameters Specifications

Sensitivity at peak response 1600 LSB / lux s @ 550 nm

corresponds to 10695 LSB / µJ / cm²

Resolution 1280 x 1024

Pixel Size 12µm x 12µm

Sensor Size 15.4mm x 12.3mm, diagonal: 19.7mm

Optics 1 inch (C-Mount)

Sensor ADC Resolution 10 bit

Sensor Dynamic Range 59dB

Max. Internal Full-Frame Rate 450fps

Max. External Full-Frame Rate 61fps (40MHz-CameraLink, 2Tap-Mode)

91fps (60MHz-CameraLink, 2Tap-Mode)

Max. Internal Row Frequency at

1280 Pixels/Row

139kHz

Max. Profile Rate at Max. Row

Length = Max. Internal Row

Frequency / Number of Rows

28800 Hz (16 rows)

14400 Hz (32 rows)

7200 Hz (64 rows)

3600 kHz (128 rows)

1800 Hz (256 rows)

900 Hz (512 rows)

450 Hz (1024 rows)

50 • Technical Specifications C3 Camera Hardware Reference Manual Rev. 1.3.7

Spectral sensitivity of C3-1280-CL sensor

C3 Camera Hardware Reference Manual Rev. 1.3.7 Technical Specifications • 51

C3-2350-CL Sensor

Parameters Specifications

Sensitivity at peak response 2500 LSB / lux s @ 610 nm

Resolution 2352 x 1728

Pixel Size 7µm x 7µm

Sensor Size 16.46mm x 12.10mm, diagonal: 20.43mm

Optics 1” C-Mount and F-Mount

Sensor ADC Resolution 10 bit

Sensor Dynamic Range 59dB

Max. Internal Full-Frame Rate 190fps

Max. External Full-Frame Rate 20fps (40MHz-CameraLink, 2Tap-Mode)

30fps (60MHz-CameraLink, 2Tap-Mode)

Max. Internal Row Frequency at

2352 Pixels/Row

115kHz

Max. Profile Rate at Max. Row

Length = Max. Internal Row

Frequency / Number of Rows

23450 Hz (14 rows)

12160 Hz (27 rows)

3040 Hz (108 rows)

1520 Hz (216 rows)

760 Hz (432 rows)

380 Hz (864 rows)

190 Hz (1728 rows)

52 • Technical Specifications C3 Camera Hardware Reference Manual Rev. 1.3.7

Spectral sensitivity of C3-2350-CL sensor

C3 Camera Hardware Reference Manual Rev. 1.3.7 Technical Specifications • 53

Operating Specifications

Camera Specifications

Parameters C3-1280-CL / C3-2350-CL

Supply Voltage VCC IN 7V – 24V

Power Consumption VCC IN 4W

Operating Temperature 0°C – 50°C

CameraLink –UART

configuration interface

9600 baud or 115200 (default) baud (DIP-

switch) 1 Startbit, 1 Stopbit, no parity

Dimensions see mechanical specifications

Mass 350g

Electrical Specification of I/O Signals

Parameters Specifications

I/O Supply Voltage VCC I/O 5V – 24V DC

VOL, optoisolated outputs, logic ‚0’ Voltage 0.5V

VOH, optoisolated outputs, logic ‚1’ Voltage OC output with 4.7kOhm pull-up

to VCC I/O

VIL, optoisolated inputs, logic ‚0’ Voltage < 2.5V

VIH, optoisolated inputs, logic ‚1’ Voltage > 3.5V

IOH, optoisolated outputs, logic ‚1’ output current OC output with 4.7kOhm pull-up

to VCC I/O

IOL, optoisolated outputs, logic ‚0’ output current 8mA

Encoder interface ENC_A, ENC_B RS422 Standard with 100 Ohm

termination

54 • Technical Specifications C3 Camera Hardware Reference Manual Rev. 1.3.7

Mechanical Specifications

All units are in mm.

C3-1280-CL & C3-2350-CL

(C-Mount)

Hole mounting pattern is identical in all 4 sides

C3-1280-CL & C3-2350-CL

(F-Mount)

Hole mounting pattern is identical in all 4 sides

F-Mount

Bajonett

C3 Camera Hardware Reference Manual Rev. 1.3.7 Service Information • 55

Service Information

Document Revision

Product Information and Updates

Updates

www.AutomationTechnology.de

Service and Support

service@AutomationTechnology.de

In order to process your support inquiries immediately, we always need the serial number of the

camera, a dump of configuration EEPROMs, a snapshot and a precise problem description.

Product Inquiries and Price Quotations

info@AutomationTechnology.de

Rev. Nr. Date Modification

1.0 25.08.2003 Version for C3-A1024-CL, C3-1280-CL

1.1 29.04.2004 Modification of output channel configuration added

1.3.1 01.02.2005 Added changes of Firmware version 3.5

1.3.2 21.03.2007 Update (direct COG height calculation, Laser Register, operating and

mechanical specifications, USB2.0 version removed)

1.3.3 13.02.2008 Update (added C3-2350-CL)

1.3.4 29.05.2008 Update (added new registers for 3D validation, digital output of OVR flag,

Correct Sensor Eclipse)

1.3.5 26.11.08 Update (added new features of Rev. 4.8)

1.3.6 26.05.09 Update (minor corrections)

1.3.7 11.08.09 Update (C3-A1024-CL removed, drawing of camera housing with C-Mount

modified)

56 • Service Information C3 Camera Hardware Reference Manual Rev. 1.3.7

Warranty Conditions

Only the manufacturer can recognize the conditions of warranty. Should other parties than the

manufacturer be responsible for the malfunctioning, we consider the right of warranty as void. This is

the case if the unit is modified electrically or mechanically, particularly in its wiring/soldering, or if the

unit is used for purposes not intended by the manufacturer, or if the unit's external wiring is faulty, or if

the unit is used under conditions outside those stated in its manual.

C3 Camera Hardware Reference Manual Rev. 1.3.7 Index • 57

Index

C

CameraLink 43

Camera Control Signal 45

CameraLink – Kabel 49

Pixeltakt 44

D

DAC 1280 36

DAC 2350 36

I

I/O – Anschluß 39

I/O – Panel 42

R

Register 20

AOI_DY 35

AOI_TRSH 35

AOI_Y0 34

CFG_REG 20

CL_CFG_ REG 26

CL_DX_REG 22

CL_DY_REG 22

CL_X0_REG 21

CTRL_REG 29

DAC_REG 35

DATAOUT_REG 33

HWINFO_REG 26

IO_REG 33

IRTIME_H_REG 24

IRTIME_L_REG 23

ITIME_H_REG 23

ITIME_L_REG 23

JTAG_REG 22

LASER_CONTROL_REG 36, 37

MUX_FRAME_OUTPUT_TIME_H 32

MUX_FRAME_OUTPUT_TIME_L 31

MUX_REG 30

MUX_TRIG_STATUS 31

NUM_AOIS_REG 27

PTIME_H_REG 24

PTIME_L_REG 24

SENSOR_DX_REG 25

SENSOR_REG 24

SENSOR_X0_REG 25

STATUS_REG 30

TRIG_CNT_REG 26

S

Status

Output 15

T

Trigger

Trigger Enable 14

Loading...

Loading...