Page 1

WEG CFW100 AC DrivEs sEriAl

CommuniCAtions QuiCk-stArt GuiDE

NOTE: This Quick-Start guide is intended for the sole purpose of establishing

communications connections between WEG CFW100 AC Drives and AutomationDirect

programmable controllers, or between the CFW100 and the USB port of a personal

computer. Please refer to WEG CFW100 documents for specifications and instructions

for using the WEG CFW100 AC Drives.

T

able of ConTenTs

Communications Parameters Summary � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �5–2

Summary – Serial Communication Parameters � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5–2

Explanation of Scaling/Count Frequency Command/Feedback � � � � � � � � � � � � � � � � � � �5–5

Connecting PC to CFW100 Using AutomationDirect Cable USB-485M� � � � � � � � � � � � � � �5–5

Connecting Communication Cables to CFW100 AC Drives � � � � � � � � � � � � � � � � � � � � �5–6

AutomationDirect PLCs as Modbus Master � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �5–7

Communication Cable Connections � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5–7

RS-232C to RS-485 Conversion� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5–8

AutomationDirect PLC Cable Connections � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5–9

AutomationDirect PLC Example Programs for WEG CFW100 AC Drive � � � � � � � � � � � � � � � � � � 5–12

CLICK PLC Example Program for WEG CFW100 AC Drive � � � � � � � � � � � � � � � � � � � � � � � � �5–12

Page 5–1CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition-10 25 2019 prelim

Page 2

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

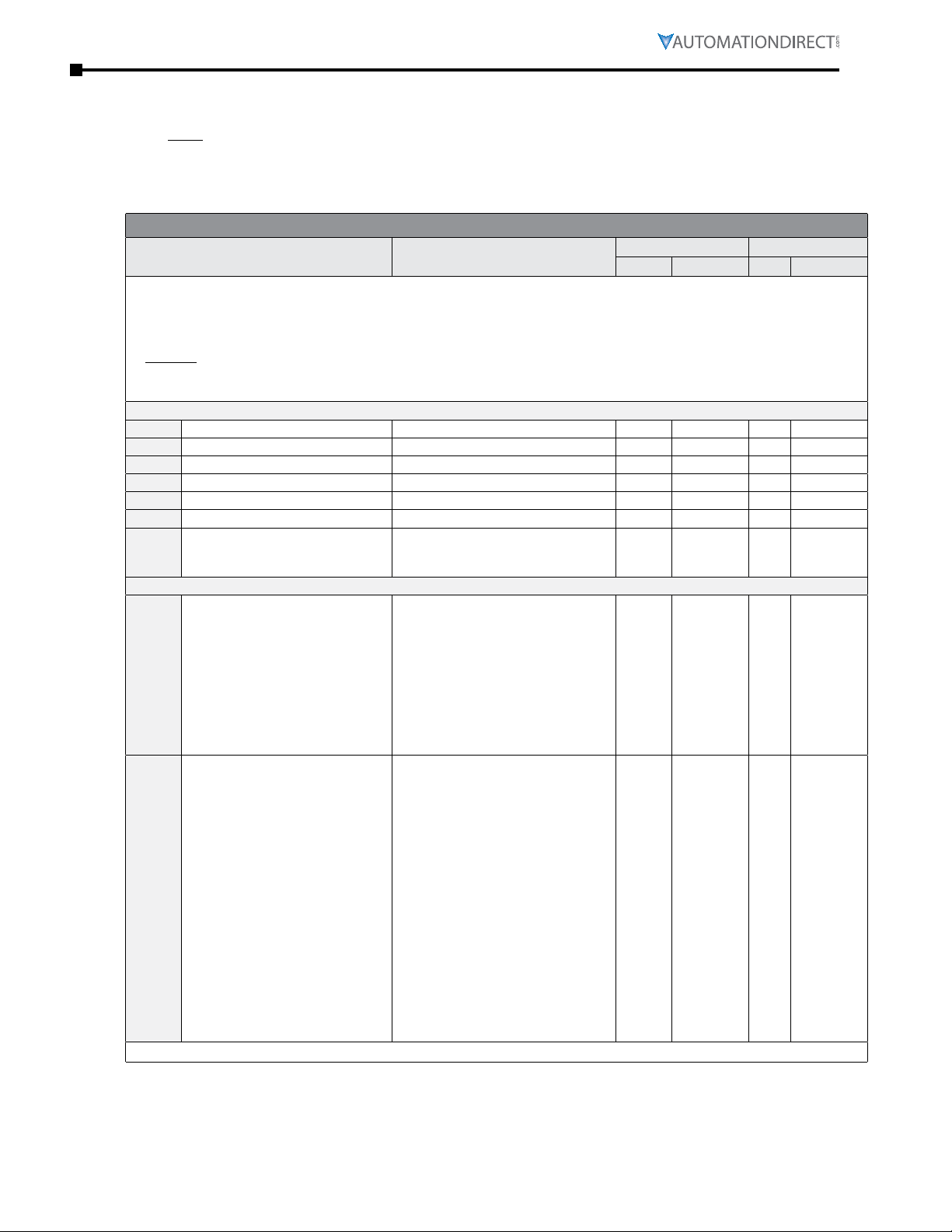

CommuniCations Parameters summary

A summary of the WEG CFW100 AC drives Communications Parameters is listed below.

NOTE: Refer to the WEG CFW100 Frequency Inverter Micro Mini Drives Programming Manual and the Modbus

RTU User’s Manual for a complete listing of all CFW100 AC drives parameters, including details and Modbus

addresses.

Summary – Serial CommuniCation ParameterS

WEG CFW100 Serial Communication Parameters Summary

Parameter

2

Range

1) To read parameters, use Function Code 3; To write parameters, use Function Code 6 or 16

2) ♦ indicates a parameter that can be changed only with a stopped motor

3) RO = Read Only

4) Modicon Modbus addressing for the CFW100 is 40000 + the Parameter Address;

Example: P222 Modicon Modbus address would be 40000 + 222 = 40222

5) Speed references and commands via Modbus RTU will always be Remote references; not Local

6) Baud rate in the PLC must match the baud rate in the AC drive (19200 bits/s)

General Parameters

P000

P001

P002

P003

P004

P005

♦P200

Access to Parameters 0 to 9999 1 0 40000

Speed Reference 0 to 9999 RO RO 1 40001

Output Speed (Motor) 0 to 9999 RO RO 2 40002

Motor Current 0�0 to 40�0 A RO RO 3 40003

DC Link Voltage (Ud) 0 to 524 V RO RO 4 40004

Output Frequency (Motor) 0�0 to 400�0 Hz RO RO 5 40005

0 = Inactive

Password

1 = Active

2 to 9999 = New Password

Parameters neccessary to communicate with the drive using module CFW-485

0 = Always Local

1 = Always Remote

2, 3 = not used

4 = DIx

♦P220

♦P222

LOC/REM Selection Source

REM Reference Selection

5)

5 = Serial/USB (LOC)

6 = Serial/USB (REM)

7, 8 = not used

9 = CO/DN/DP (LOC)

10 = CO/DN/DP (REM)

11 = SoftPLC

0 = HMI Keys

1 = AI1

2 = AI2

3 = not used

4 = FI

5 = AI1 + AI2 > 0

6 = AI1 + AI2

7 = E�P�

8 = Multispeed

9 = Serial/USB

10 = not used

11 = CO/DN/DP

12 = SoftPLC

13 = not used

14 = AI1 > 0

15 = AI2 > 0

16 = not used

17 = FI > 0

(table continued next page)

Setting Modbus Address

Comm Default

1 0 DC 40220

9 1 DE 40222

1

3

Hex Modicon

0 C8 40200

4

Page 5–2 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

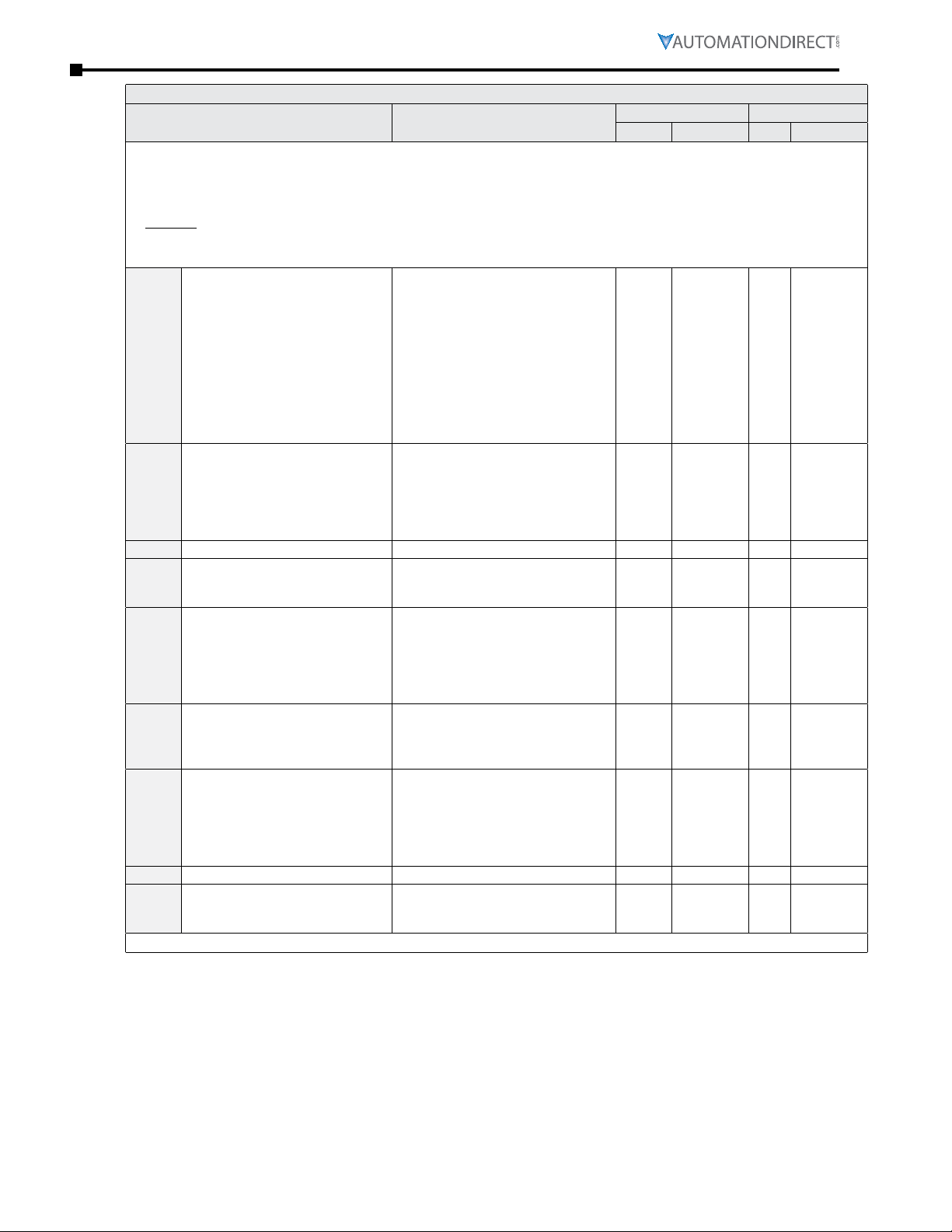

Page 3

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

WEG CFW100 Serial Communication Parameters Summary1 – (continued)

Parameter

2

Range

1) To read parameters, use Function Code 3; To write parameters, use Function Code 6 or 16

2) ♦ indicates a parameter that can be changed only with a stopped motor

3) RO = Read Only

4) Modicon Modbus addressing for the CFW100 is 40000 + the Parameter Address;

Example: P222 Modicon Modbus address would be 40000 + 222 = 40222

5) Speed references and commands via Modbus RTU will always be Remote references; not Local

6) Baud rate in the PLC must match the baud rate in the AC drive (19200 bits/s)

0 = Forward

1 = Reverse

2, 3 = not used

4 = DIx

5 = Serial/USB (FWD)

♦P226

♦P227

♦P308

♦P310

♦P311

♦P312

P313

♦P314

P316

REM FWD/REV Selection

REM Run/Stop Selection

Serial Address 1 to 247 1 1 134 40308

Serial Baud Rate

Serial Interface Byte Configuration

Serial Protocol

Action for Comm Error

Serial Watchdog 0�0 to 999�0 0�0 0�0 13A 40314

Serial Interface Status

6)

6 = Serial/USB (REV)

7, 8 = not used

9 = CO/DN/DP (FWD)

10 = CO/DN/DP (REV)

11 = not used

12 = SoftPLC

0 = HMI Keys

1 = DIx

2 = Serial/USB

3 = not used

4 = CO/DN/DP

5 = SoftPLC

0 = 9600 bits/s

1 = 19200 bits/s

2 = 38400 bits/s

0 = 8 bits, np, 1 stop bit

1 = 8 bits, even, 1 stop bit

2 = 8 bits, odd, 1 stop bit

3 = 8 bits, np, 2 stop bits

4 = 8 bits, even, 2 stop bits

5 = 8 bits, odd, 2 stop bits

0, 1 = reserved

2 = Slave Modbus RTU

3, 4 = reserved

5 = Master Modbus RTU

0 = Inactive

1 = Ramp Stop

2 = General Disable

3 = Go to LOC

4 = LOC Keep Enable

5 = Cause Fault

0 = Inactive

1 = Active

2 = Watchdog Error

(table continued next page)

Setting Modbus Address

Comm Default

2 1 E3 40227

1 1 136 40310

1 1 137 40311

2 2 138 40312

1 1 139 40313

RO RO 13C 40316

3

Hex Modicon

4 E2 40226

4

Page 5–3 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

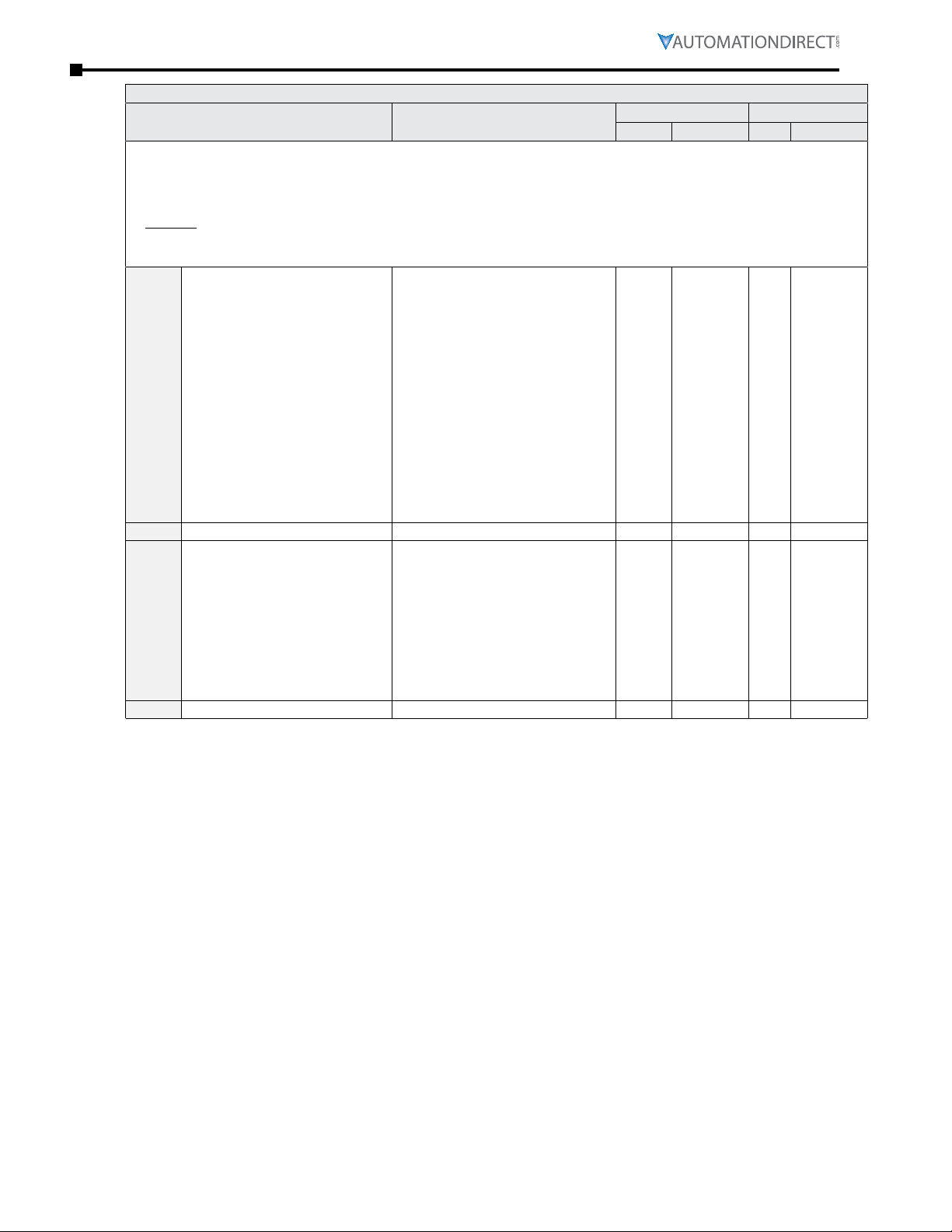

Page 4

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

WEG CFW100 Serial Communication Parameters Summary1 – (continued)

Parameter

2

Range

1) To read parameters, use Function Code 3; To write parameters, use Function Code 6 or 16

2) ♦ indicates a parameter that can be changed only with a stopped motor

3) RO = Read Only

4) Modicon Modbus addressing for the CFW100 is 40000 + the Parameter Address;

Example: P222 Modicon Modbus address would be 40000 + 222 = 40222

5) Speed references and commands via Modbus RTU will always be Remote references; not Local

6) Baud rate in the PLC must match the baud rate in the AC drive (19200 bits/s)

0 to FFFF (hex)

Bit 0 = reserved

Bit 1 = Run Command

Bit 2 = Fire Mode

Bits 3 and 4 = reserved

Bit 5 = 2nd Ramp

Bit 6 = Config� Status

P680

P681

P682

P683

Logical Status

Motor Speed in 13 bits 0 to FFFF (hex) RO RO 2A9 40681

Serial//USB Control

Serial/USB Speed Reference 0 to FFFF (hex) RO RO 2AB 40683

Bit 7 = Alarm

Bit 8 = Running

Bit 9 = Enabled

Bit 10 = Forward

Bit 11 = JOG

Bit 12 = Remote

Bit 13 = Undervoltage

Bit 14 = reserved

Bit 15 = Fault

0 to FFFF (hex)

Bit 0 = Ramp Enable

Bit 1 = General Enable

Bit 2 = Run Forward

Bit 3 = JOG Enable

Bit 4 = Remote

Bit 5 = 2nd Ramp

Bit 6 = reserved

Bit 7 = Fault Reset

Bit 8 to 15 = reserved

Setting Modbus Address

Comm Default

RO RO 2A8 40680

RO RO 2AA 40682

3

Hex Modicon

4

Page 5–4 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Page 5

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

exPlanation of sCaling/Count frequenCy Command/feedbaCk

•

When using WEG CFW100 drives, speed/frequency is shown in counts� In order to convert to Hz/

rpm, it is needed to know that the Base Frequency (P403) is equivalent to 8192 (2^13)� Also, the

Motor Rated speed (P402) can be scaled using the same method�

•

Actual Frequency (P681) and Command Frequency (P683) can be calculated using that ratio�

•

For instance: P681 = 2048(dec)�

•

Freq = 2048*60�00/8192 = 15�00 Hz

•

RPM = 2048*1740/8192 = 435�00 rpm

ConneCting PC to CfW100 using automationdireCt Cable usb-485m

An AutomationDirect cable, part number USB-485M, provides a quick and easy method of

communicating to a WEG CFW100 AC Drive from a PC which has WEG CFW-WPS software installed.

NOTE: Refer to the WEG WPS Software User Manual for information and instructions regarding using the WPS

software to configure CFW100 AC Drives.

AutomationDirect USB-485M

Connector

6 RS485 = A (-)

7 RS485 = B (+)

8 GND

9 Shield

10 GND

To

RS-485

Port

Page 5–5 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Page 6

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

Figure A2: C FW100 -CRS485 dimensi ons in mm [i n] and conn ectors l ocation

Ref (0 V) Ref (0 V)

Shield

6 7 8 9 10

Shield

B B

A A

Figure A3: Example of connection of the a ccessor y to the RS48 5 networ k

1 SAFETY INFORMATION

1.1 SAFETY WARNI NGS

NOTE!

Only use the RS485 module (CF W100-C RS485) on WEG CF W100

series inve rter s.

It is re commend ed read ing th e CFW100 user ’s manual before

installing or operating this acce ssor y.

The content of this guide provide s important info rmation for the full

under standing and proper oper ation of this module.

1.2 PRE LIMINARY RECOMMENDATIONS

ATTENTION!

Always disconnect the gene ral power supply before connecting or

disconnec ting the accessories of the CFW100 fre quency inver ter.

Wait for at least 10 minute s for the full discharge of th e inverter.

5 CONFIGURATIONS

The RS485 interf ace connections mu st be done on the conn ector as per Table 1.

Table 1: Conne ctor sign als of the R S485 inte rface

Conn ector Desc riptio n

6 RS 485-B RS485 ( Terminal B)

7 RS485-A RS485 ( Terminal A)

8 0V Refere nce 0V

9 PE Grounding connection

10 – –

The location of the DIP sw itch to select the RS485 network term ination can b e

better viewed in Figure A2 and it must be configure as per Table 2. . Figure A3

shows a connection example of the CFW100-CRS 485 accessory to a RS485

network. The connection compli es with the directions of the use r's manual of the

Modbus RTU for the CF W100.

Table 2: C onfigur ation of th e switche s to configure t he RS485

Comun icati on Switch Swit ch Set tin g Opti on

RS485

S1

(*)

S1.1 = OFF and S1.2 = OFF RS 485 terminat ion off

S1.1 = ON and S1.2 = ON

RS485 ter minati on on

(**)

(*) Any other combinat ion of the sw itches is n ot allowed.

(**) It is recommend ed to use thi s terminatio n with cable s longer than 3 m.

The CFW100-CRS485 m odule has the ne cessar y resources to perform set ting,

command and m onitor ing of the inver ter by mean s of the WPS sof tware - WEG

Programming Suite (www.automationdirect.com). For further detai

ls, refer to chapter

7 of the use r's manua l of the CF W100.

IMPORTANT NOTE!

The mini USB connector (se e Figure A2) is used for communicati on

with the C FW100-KHMIR k it only.

The use of the mini USB connector for other connecti ons is n ot

permitted.

For PC to USB Connections to the CFW100 use the CFW100-CUSB

Module only.

CFW100-CRS485

Please read “IMPORTANT NOTE”!

Lorem ipsum

ConneCting CommuniCation Cables to CfW100 aC drives

The CFW100-CRS485 drive communication module includes a DIP switch that will switch in a 120Ω

terminating resistor for the RS-485 network.

The CFW100 serial communication port is an RS-485 input. Please note that terminals A(-) and B(+) are

shared with the USB connector. CFW100 to CFW100 serial connections can be accomplished with standard

RS-485 cable (L19827-1 or similar). RS-232 signals can be converted to RS-485 by using a separate converter

(see the FA-ISOCON drawings on page 5–8).

CFW100-CrS485 Serial CommuniCationS module

WARNING: Do NoT use ThIs usB poRT foR ANy pC CoNNeCTIoNs foR ANy ReAsoN, As IT mAy veRy Well DAmAGe The

DRIve AND youR pC. IT Is foR CoNNeCTIoN of The RemoTe KeypAD KIT CfW100-KhmIR oNly.

Page 5–6 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Recommended RS-485 cable: Belden 9842, AutomationDirect L19954 series, or equivalent.

Page 7

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

automationdireCt PlCs as modbus master

CommuniCation Cable ConneCtionS

Serial Modbus-capable AutomationDirect PLCs can communicate with CFW100 drives which have

an optional communication card installed.

Serial Modbus control is easier to accomplish from a PLC that supports dedicated Modbus

messaging. [Older PLCs may require programming to construct the Modbus strings.] We

recommend PLCs with dedicated Modbus serial commands: CLICK (with RS-485 ports), P1000,

P2000, P3000, BRX/Do-more, DirectLogic (DL06 or D2-260). Other PLC-Drive connectivity is

possible: Please refer to the “Typical ADC PLC to CFW100 Serial Connectivity Matrix” below.

Typical ADC PLC to WEG CFW100 RS-485 Serial Communications Connectivity

Typical ADC PLC to WEG CFW100 RS-485 Serial Communications Connectivity Matrix

Recommended PLC Connectivity

PLC Port # Port Type Port Type

CLICK

D2-260

DL06

BRX/Do-more

Do-more H2-DM1

P2-550

P3-530

P3-550

P3-550E

Other PLC Connectivity

D2-250-1

D4-450/D4-454

DL05

DL06 + DCM

Do-more H2-DM1 + H2-SERIO-4

Do-more T1H-DM1

P2-SCM

P3-SCM

3 3 screw terminals RS-485 L19954 cable

2 HD15 RS-485 D2-DSCBL-2

2 HD15 RS-485 D2-DSCBL-2

RS-485 3 screw terminals RS-485 L19954 cable

RS-232 RJ12 RS-232 to RS-485

RS-485 3 screw terminals RS-485 L19954 cable

RS-485 3 screw terminals RS-485 L19954 cable

RS-485 3 screw terminals RS-485 L19954 cable

RS-485 3 screw terminals RS-485 L19954 cable

2 HD15 RS-485 D2-DSCBL-2

1 DB25 RS-232 to RS-485

2 RJ12 RS-232 to RS-485

2 HD15 RS-485 D2-DSCBL-2

3 5 screw terminals RS-485 L19954 cable

RS-232 RJ12 RS-232 to RS-485

4 4 screw terminals RS-485 L19954 cable

4 4 screw terminals RS-485 L19954 cable

Communication Direct Cable

– –

FA-ISOCON with

L19954 cable

FA-ISOCON with

L19954 cable

FA-ISOCON with

L19954 cable

FA-ISOCON with

L19954 cable

CFW100

CFW100-

CRS485

screw

terminals

A(-)

B(+)

Ref(0V)

Page 5–7 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Page 8

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

FA-ISOCON RJ-12 Serial Comm Port A

6: Signal Ground

rS-232C to rS-485 ConverSion

An RS-485 network cable can span up to 1000 meters (4000feet). However, many

AutomationDirect PLCs have only RS-232C communication ports and require an FA-ISOCON

(RS-232C to RS-422/485 network adapter) in order to make an RS-485 connection.

If an FA-ISOCON module is used, set the module DIP switches as required.

Refer to the FA-ISOCON manual for more detailed information.

FA-ISOCON Switch Settings:

•

S21–S23: OFF, ON, ON (19200 baud)

•

S24–S27: OFF (Automatic Network Transmit Enable)

•

Terminate: ON (end of run term resistors)

•

Bias (2): ON (end of run bias resistors)

•

1/2 DPX (2): ON (RS-485 TXD/RXD jumpers)

Helpful Hint: Some applications require that the FA-ISOCON

baud rate is set faster than the drive/network baud rate.

FA-ISOCON Wiring

RS-232 to RS-485 Conversion Wiring Schematic

C

+V

TXD

RXD

CTS

RTS

[CFW100 has a built-in 120Ω terminating resistor controllable by switch SW5 above the I/O terminal strip]

3 RXD

4 TXD

2 CTS

6 GNDGND

A

FA-ISOCON

RS-232 to RS-485 converter with ANTE

Connect shield

to signal ground

at one end only

D

COM A

TXD +

TXD RXD RXD +

COM B

120Ω Termination Resistor at both ends of network

[FA-ISOCON has a built-in terminating resistor

controllable by switch settings]

24VDC +

24VDC -

Ref (0V)

Ref (0V)

120Ω Termination Resistor at both ends of network

RS-232 Input Port

16

CFW100-CRS485

Comm Terminals

B (+)

A (-)

B (+)

A (-)

6

Lo

7

8

Node 1

CFW100-CRS485

Comm Terminals

6

7

8

Node 2

1: Signal Ground

2: CTS (input)

3: RXD (input)

4: TXD (output)

5: +5VDC in

For information regarding configuration of AutomationDirect PLCs or other PLCs, please refer to

the applicable PLC user manual for your application.

Page 5–8 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Page 9

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

automationdireCt PlC Cable ConneCtionS

CliCK SerieS Port 3 via rS-485

6

7

8

9

Note: Use the above wiring diagram to make your own cable. We recommend AutomationDirect part number L19954-1 shielded cable or equivalent.

Use 120 ohm termination resistor on each end. CRS485 has built-in termination that can be enabled by DIP switches.

Connector

6 RS485=B (+)

7 RS485=A (–)

8 GND

9 Shield

10 –

Page 5–9 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Page 10

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

direCtlogiC SerieS d2-250-1, d2-260, dl06 Port 2 via rS-485

AutomationDirect D2-250-1, D2-260 or DL06 Port 2

6

7

8

9

e connection above can be accomplished with AutomationDirect part number ZL-CMA15L

connector and L19954-1 shielded cable or equivalent. Use termination jumper of ZL-CMA15L

and termination DIP switches on last CRS485.

Connector

6 RS485=B (+)

7 RS485=A (–)

8 GND

9 Shield

10 –

do-more brX SerieS via rS-485

AutomationDirect D0-more BRX CPU

Connector

6

7

8

9

Note: Use the above wiring diagram to make your own cable. We recommend AutomationDirect part number L19954-1 shielded cable or equivalent.

Use 120 ohm termination resistor on each end. CRS485 has built-in termination that can be enabled by DIP switches.

Connector

6 RS485=B (+)

6 RS485=B (+)

7 RS485=A (-)

7 RS485=A (-)

8 GND

8 GND

9 Shield

9 Shield

10 –

10 –

Page 5–10 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Page 11

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

ProduCtivity SerieS P1 via rS-485

AutomationDirect Productivity Series P1

Connector

Connector

6 RS485=B (+)

6 RS485=B (+)

7 RS485=A (-)

7 RS485=A (-)

8 GND

8 GND

9 Shield

9 Shield

10 –

10 –

RS-485

6

7

8

9

Note: Use the above wiring diagram to make your own cable. We recommend AutomationDirect part number L19954-1 shielded cable or equivalent.

Use 120 ohm termination resistor on each end. CRS485 has built-in termination that can be enabled by DIP switches.

ProduCtivity SerieS P2/P3 via rS-485

AutomationDirect Productivity Series P2/P3

Connector

6

7

8

9

Note: Use the above wiring diagram to make your own cable. We recommend AutomationDirect part number L19954-1 shielded cable or equivalent.

Use 120 ohm termination resistor on each end. CRS485 has built-in termination that can be enabled by DIP switches.

Connector

6 RS485=B (+)

6 RS485=B (+)

7 RS485=A (-)

7 RS485=A (-)

8 GND

8 GND

9 Shield

9 Shield

10 –

10 –

Page 5–11 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Page 12

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

automationdireCt PlC eXamPle ProgramS For Weg CFW100 aC drive

Example programs for various AutomationDirect PLCs are available for free download from

AutomationDirect: https://support.automationdirect.com/examples.html.

Also, an example CLICK PLC ladder diagram is show in the following section.

CliCK PlC eXamPle Program For Weg CFW100 aC drive

ThIs INfoRmATIoN pRovIDeD By AuTomATIoNDIReCT.Com TeChNICAl suppoRT Is

pRovIDeD “As Is” WIThouT ANy GuARANTee of ANy KIND.

These DoCumeNTs ARe pRovIDeD By ouR TeChNICAl suppoRT DepARTmeNT To AssIsT oTheRs. We Do

NoT GuARANTee ThAT The DATA Is suITABle foR youR pARTICulAR ApplICATIoN, NoR Do We Assume ANy

RespoNsIBIlITy foR Them IN youR ApplICATIoN.

CLICK PLC Example Program for WEG CFW100 AC Drive

1

(program continued next page)

Page 5–12 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Page 13

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

CLICK PLC Example Program for WEG CFW100 AC Drive (continued)

(program continued next page)

Page 5–13 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Page 14

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

CLICK PLC Example Program for WEG CFW100 AC Drive (continued)

This rung reads STATUS registers from Drive #1

(Modbus address 400681=Status word)

(Modbus address 400682=Output frequency in counts. 8192=60Hz)

This rung writes control register and Frq to Drive #1

Modbus address 400683=Control word

For Run command must write value 3: [Bit1:ON+Bit0:ON]

Modbus address 400684=Freq Counts. 8192=60Hz

(program continued next page)

Page 5–14 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Page 15

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

CLICK PLC Example Program for WEG CFW100 AC Drive (continued)

This rung reads STATUS registers from Drive #2

(Modbus address 400681=Status word)

(Modbus address 400682=Output frequency in counts. 8192=60Hz.

Scaling Drive #1 freq (counts) to 0.01 Hz

In this example Base Freq=60Hz. This is equal to 8192 counts 2^13)

In order to convert to Hz: multiply by 60 and divide by 8192.

(program continued next page)

Page 5–15 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Page 16

WEG CFW100 AC Drives Serial Communications Quick-Start Guide

CLICK PLC Example Program for WEG CFW100 AC Drive (continued)

Scaling Drive#1 freq (Hz) to counts:

In this example Base Freq=60Hz. This is equal to 8192 counts (2^13)

In order to convert to counts: multiply by 8192 and divide by 60Hz.

Scaling Drive#2 freq (counts) to 0.01Hz:

In this example Base Freq=60Hz. This is equal to 8192 counts (2^13)

In order to convert to Hz: multiply by 60Hz and divide by 8192.

Scaling Drive#2 freq (Hz) to counts

In this example Base Freq=60Hz. This is equal to 8192 counts (2^13)

In order to convert to counts: multiply by 8192 and divide by 60Hz.

Page 5–16 CFW100 AC Drives Serial Communications Quick-Start Guide – 1st Edition

Loading...

Loading...