Page 1

Terminator I/O

MODBUS

Base Controller

User Manual

Manual Number T1K–MODBUS–M

Page 2

WARNING

Thank you for purchasing automation equipment from Automationdirect.com. We want your new DirectLOGIC

automation equipment to operate safely. Anyone who installs or uses this equipment should read this publication (and

any other relevant publications) before installing or operating the equipment.

To minimize the risk of potential safety problems, you should follow all applicable local and national codes that regulate

the installation and operation of your equipment. These codes vary from area to area and usually change with time. It is

your responsibility to determine which codes should be followed, and to verify that the equipment, installation, and

operation is in compliance with the latest revision of these codes.

At a minimum, you should follow all applicable sections of the National Fire Code, National Electrical Code, and the

codes of the National Electrical Manufacturer’s Association (NEMA). There may be local regulatory or government

offices that can also help determine which codes and standards are necessary for safe installation and operation.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable codes and

standards. We do not guarantee the products described in this publication are suitable for your particular application,

nor do we assume any responsibility for your product design, installation, or operation.

If you have any questions concerning the installation or operation of this equipment, or if you need additional

information, please call us at 770–844–4200.

This publication is based on information that was available at the time it was printed. At Automationdirect.com we

constantly strive to improve our products and services, so we reserve the right to make changes to the products and/or

publications at any time without notice and without any obligation. This publication may also discuss features that may

not be available in certain revisions of the product.

Trademarks

This publication may contain references to products produced and/or offered by other companies. The product and

company names may be trademarked and are the sole property of their respective owners. Automationdirect.com

disclaims any proprietary interest in the marks and names of others.

Copyright 2001, Automationdirect.com Incorporated

All Rights Reserved

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior, written consent of

Automationdirect.com Incorporated. Automationdirect.com retains the exclusive rights to all information

included in this document.

Page 3

1

i

Table of Contents

Chapter 1: Introduction

Manual Overview 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Purpose of this Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplemental Manuals 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Who Should Read this Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Support 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Layout 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols Used 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction to MODBUS 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminator I/O System 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T1K–MODBUS Base Controller 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODBUS Base Controller Features 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2: T1K–MODBUS Base Controller Specifications

T1K–MODBUS Base Controller Specifications 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Indicators 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the DIP Switches 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch Settings 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Rotary Address Switches 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Converting HEX Addresses to Decimal 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODBUS Port Pin–out and Wiring 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RJ12 Serial Port Pin–out and Wiring 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using D2–DSCBL to Connect PC to RJ–12 Serial Port 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3: MODBUS RTU Functions and Addressing Modes

MODBUS RTU Function Codes 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODBUS Function Codes Supported 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DirectLogic Addressing Mode 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the T1K–MODBUS with a DirectLogic PLC Modbus Master 3–3. . . . . . . . . . . . . . . . . . . . . . .

584/984 Addressing Mode 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the T1K–MODBUS with a 584 / 984 MODBUS Master 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

ii

Table of Contents

Chapter 4: Using the T1K–MODBUS Setup Tool

Configuring the T1K–MODBUS Port 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Setup Tool 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Launching the Setup Tool 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select the PC Comm Port 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the MODBUS Port 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A: I/O Module Hot Swap

T1K–MODBUS I/O Module Hot Swap Feature A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check External 24VDC Wiring Before Hot Swapping! A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hot Swap: I/O Module Replacement A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outputs Enable / Disable Switch A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: Analog Output Module Configuration

Analog Output Module Control Byte B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

1

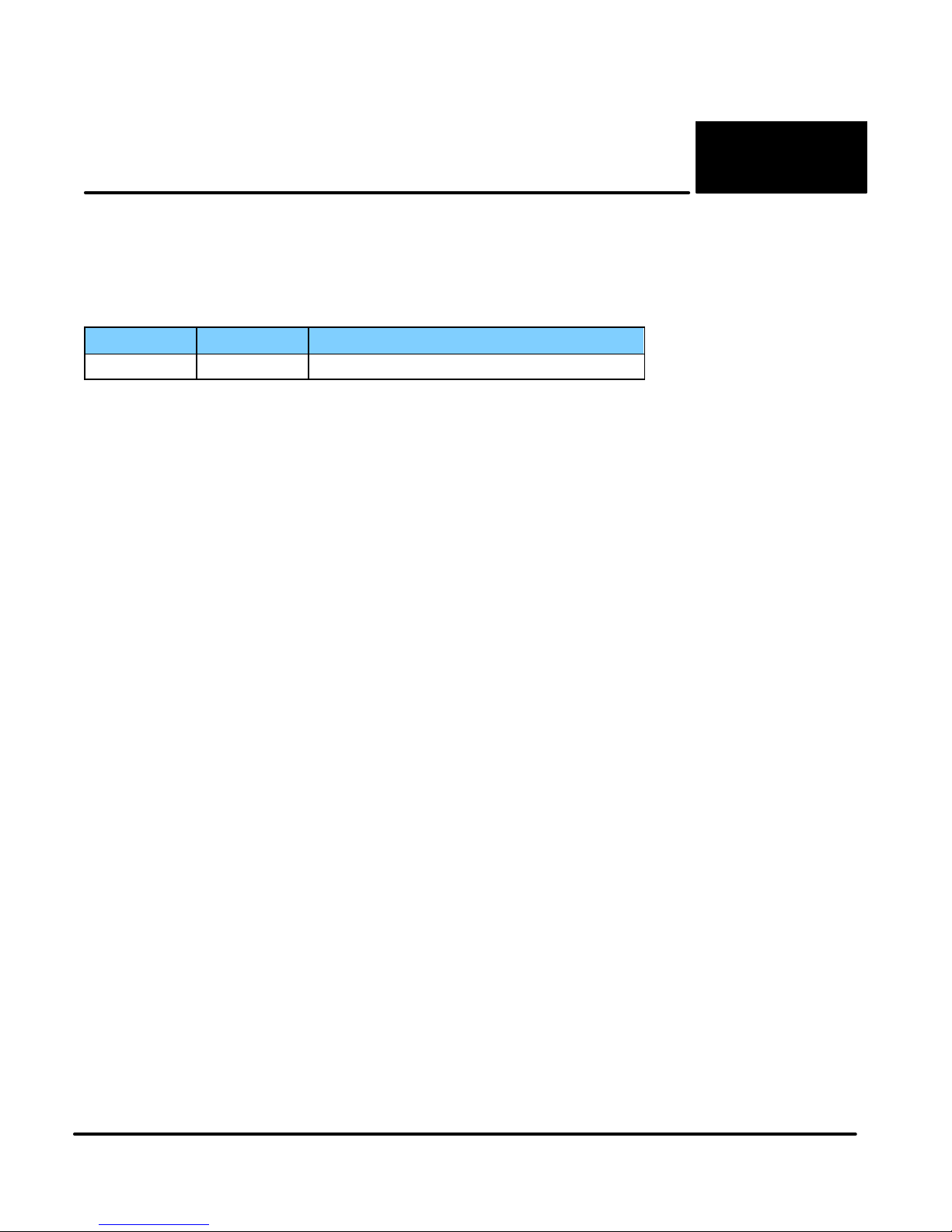

Manual Revisions

If you contact us in reference to this manual, be sure to include the revision number.

Title: Terminator I/O MODBUS Base Controller User Manual

Manual Number: T1K–MODBUS–M

Edition Date Description of Changes

1st Edition 08/01 Original Issue

i

Page 6

Introduction

In This Chapter. . . .

— Manual Overview

— Introduction to MODBUS

— Terminator I/O System

— T1K–MODBUS Base Controller

1

1

Page 7

1–2

Introduction

Manual Overview

The Purpose of

this Manual

Introduction

Supplemental

Manuals

Who Should Read

this Manual

Technical Support

This manual describes the installation and

operation of the Terminator I/O MODBUS

Base Controller (T1K–MODBUS).

The following manuals are essential to the proper use of your Terminator I/O

MODBUS Base Controller.

• Terminator Installation and I/O Manual part number T1K–INST–M

This manual contains very important information, including a complete

I/O Module Memory Map. The Memory Map is crucial in designing and

implementing a Terminator I/O system.

• The PLC User Manual (if PLC is used as master).

• The MODBUS Master manual (if other than PLC is used as master).

If you have a working knowledge of MODBUS networks, and the PLC or PC which

you are using, this manual will help you configure and install your T1K–MODBUS

Base Controller.

We strive to make our manuals the best in the industry and rely on your feedback in

reaching our goal. If you cannot find the solution to your particular application, or, if

for any reason you need additional technical assistance, please call us at

770–844–4200.

Installation and

Safety Guidelines

Our technical support team is glad to work with you in answering your questions.

They are available weekdays from 9:00 a.m. to 6:00 p.m. Eastern Time. We also

encourage you to visit our website where you can find technical and nontechnical

information about our products and our company.

www.automationdirect.com

Page 8

Introduction

1–3

Manual Layout

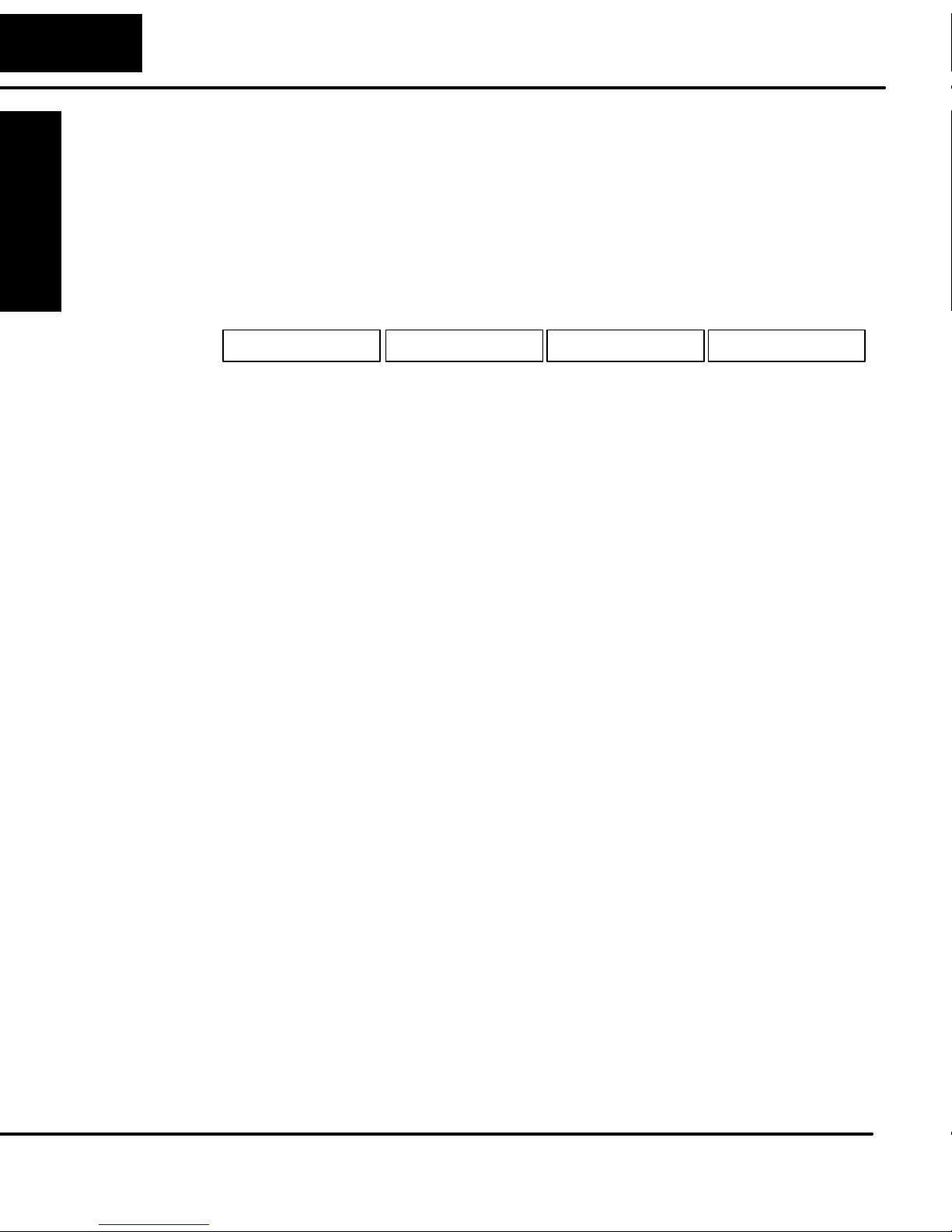

Chapter Title What’s covered

1

2

MODBUS RTU Functions

3

and Addressing Modes

Using T1K–MODBUS

4

Appendices

Appendix Title What’s covered

The contents of this user manual are as follows:

Introduction

T1K–MODBUS

Specifications

Setup Tool

Additional reference information for the T1K–MODBUS is available in the following

appendices.

introduces MODBUS and describes both the Terminator

I/O System and the T1K–MODBUS Base Controller

provides module specifications, dip switch settings, port

pin–outs and wiring information.

provides MODBUS RTU functions supported and use

with DirectLogic PLCs, or MODBUS 584/984 modes.

explains how to configure the MODBUS port using the

Setup Tool.

Introduction

A

Analog Output Module

B

Symbols Used

I/O Module

Hot Swap

Configuration

The “note pad” icon in the left–hand margin indicates a special note.

The “exclamation mark” icon in the left-hand margin indicates a warning or caution.

These are very important because the information may help you prevent serious

personal injury or equipment damage.

The “light bulb” icon in the left-hand margin indicates a tip or shortcut.

explains the T1K–MODBUS I/O module Hot Swap feature

and the Enable/Disable Outputs switch.

uses a memory map to explain how to configure an analog

output module.

Safety Guidelines

Installation and

Page 9

1–4

Introduction to MODBUS

Introduction

Introduction

MODBUS RTU (Remote Terminal Unit) Protocol is a messaging structure used to

establish master–slave communications between intelligent devices. When a

MODBUS master sends a message to a MODBUS slave, the message contains the

address of the slave, the function, the data and a check sum. The slave’s response

message contains fields confirming the master’s request, any data requested and

an error–checking field.

A typical MODBUS RTU frame consists of the following fields:

ADDRESS FUNCTION DATA CHECKSUM

The address field of a message contains 8 bits. Valid slave addresses are in the

range of 0– 247 decimal. The individual slave devices are set in the range of 1 – 247

decimal (address 0 is the broadcast to all slaves address). The master specifies a

slave by placing the slave address in the address field of the message. When the

slave responds, it places its own address in the address field to identify to the master

which slave is responding.

Installation and

Safety Guidelines

The function code field of a message contains 8 bits. V alid function codes are in the

range of 1 – 255 decimal. The function code instructs the slave what kind of action to

take. Some examples are to read the status of a group of discrete inputs; to read the

data in a group of registers; to write to an output coil or a group of registers; or to read

the diagnostic status of a slave.

When a slave responds to the master , it uses the function code field to indicate either

a normal response or that some type of error has occurred. For a normal response,

the slave echoes the original function code. In an error condition, the slave echoes

the original function code with its MSB set to a logic 1.

The data field is constructed using sets of two hexadecimal digits in the range of 00

to FF. According to the network’s serial transmission mode, these digits can be made

of a pair of ASCII characters or from one RTU character.

The data field also contains additional information that the slave uses to execute the

action defined by the function code. This can include internal addresses, quantity of

items to be handled, etc.

The data field of a response from a slave to a master contains the data requested if

no error occurs. If an error occurs, the field contains an exception code that the

master uses to determine the next action to be taken. The data field can be

nonexistent in certain types of messages.

The checksum field is used for error checking. Standard MODBUS serial networks

use two types of error checking.

Parity checking (even or odd) totals the number of logical 1 bits in the data field and

sets the parity bit to a 0 or 1 representing an odd or even total of logical 1 bits. Cyclical

Redundancy Check (CRC) checks the entire message and is applied regardless of

any parity check method used. The CRC field consists of two bytes, creating a 16 bit

binary value. The CRC is calculated in the transmitting device and is recalculated

and compared by the receiving device.

Both the character check and the message frame check are generated in the master

device and applied to the message before transmission. The slave device checks

each character and the entire message frame during receipt.

Page 10

Terminator I/O System

MODBUS

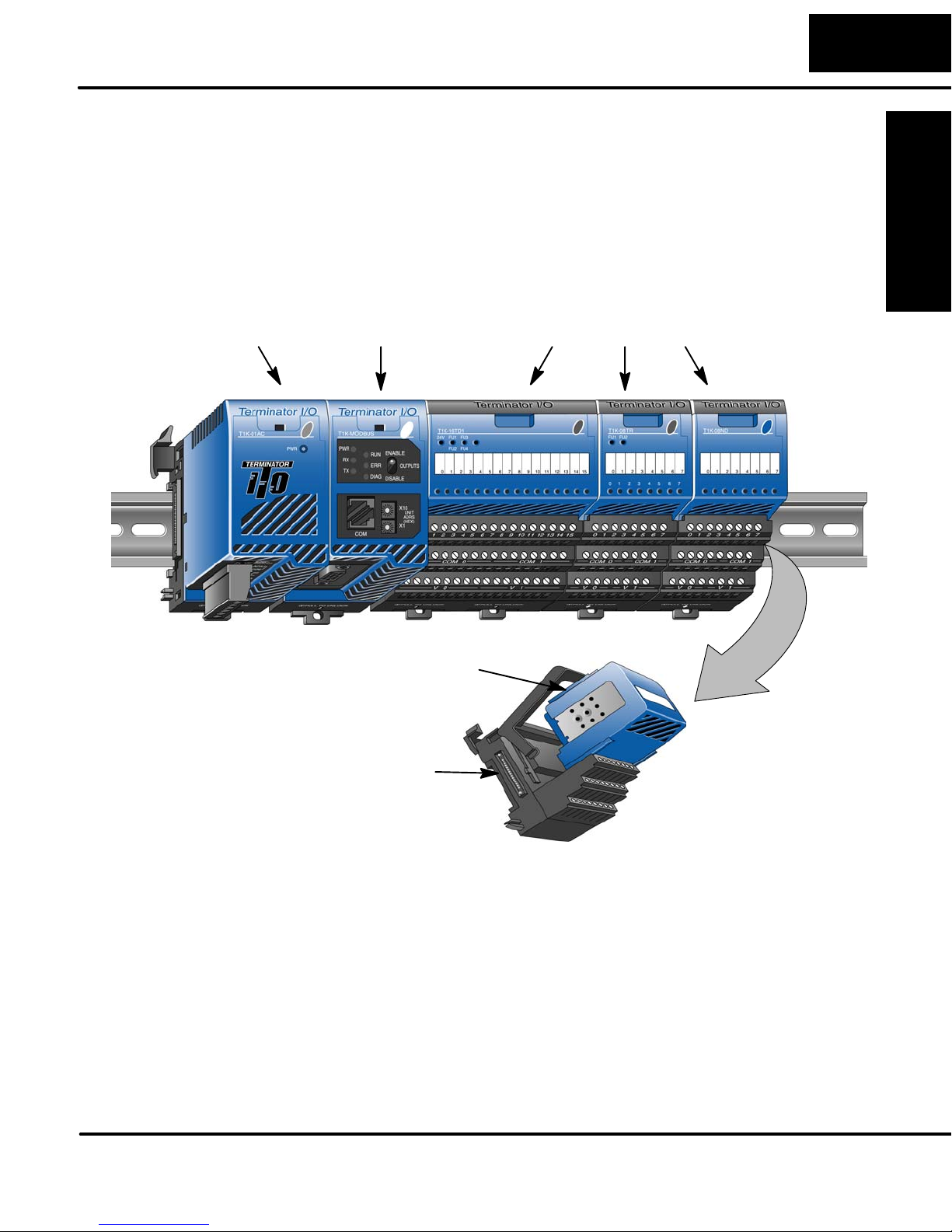

Terminator I/O is a modular system which combines the functions of terminal blocks

and I/O modules for distributed I/O. Each Terminator I/O system has the following

components: a Power Supply, a Base Controller, and one or more I/O Modules and

I/O bases.

1–5

Introduction

Introduction

Power Supply

Base

Controller

I/O Module

I/O Modules

Safety Guidelines

Installation and

I/O Base

Page 11

1–6

Introduction

T1K–MODBUS Base Controller

The T1K–MODBUS Base Controller is a slave module that functions as a controller

for Terminator I/O on a MODBUS network.

Introduction

MODBUS Base

Controller Features

Note: It is recommended to use the T1K–MODBUS Base Controller in a “scan

based” (polled) control system rather than in an “event–driven” control system. As a

slave, the Base Controller does not have the ability to report an error condition to the

MODBUS network master . Thus, polling a slave on a regular basis will detect a slave

error condition promptly, whereas an event–driven control system will not detect a

slave error condition until the next event is addressed to a slave in error.

The Base Controller has the following features:

• Status LEDs

• MODBUS Port

• Serial Port (RJ12)

• Unit Address Switches

• Output Enable/Disable Switch

• DIP Switch (located on right side of unit)

Output

Enable/Disable

Switch

Installation and

Safety Guidelines

Status LEDs

RJ12

Serial Port

Unit Rotary

Address

Switches

MODBUS Port

Page 12

T1K–MODBUS

Base Controller

Specifications

In This Chapter. . . .

— T1K–MODBUS Base Controller Specifications

— Setting the DIP Switches

— Setting the Rotary Address Switches

— MODBUS Port Pin–out and Wiring

1

2

— RJ12 Serial Port Pin–out and Wiring

Page 13

2–2

T1K–MODBUS Base Controller Specifications

Specifications

T1K–MODBUS

T1K–MODBUS Specifications

General

Operating Temperature 32° F to 131° F (0° C to 55° C)

Storage Temperature –4° F to 158° F (–20° C to 70° C)

Ambient Humidity 30% – 95% relative humidity (non–condensing)

Voltage Withstand 1500VAC, 1 minute (15–pin connector internal)

Insulation Resistance 500VDC, 10MΩ

Vibration Resistance MIL STD 810C, Method 514.2

Shock Resistance MIL STD 810C, Method 516.2

Noise Immunity NEMA (ICS3–304) Impulse noise 1µs, 1000V

FCC class A RFI (145MHz, 435MHz 10W, 10cm)

Atmosphere No corrosive gases

Environmental Pollution Level is 2.

Size 1.89”Wx3.15”Hx3.26”D (48Wx80Hx83D)mm

Weight 6.0 oz. (170 g)

Installation and

Safety Guidelines

MODBUS Port Specifications

Connector 15–pin female D–shell connector

Connection Port Type RS232C, RS–422/485

Protocol MODBUS RTU

Station Number 1 to F7h (247) Rotary Switch Setting

Number of I/O Points Inputs: 1024; Outputs: 1024

B

aud Rate (bps)

Communication Data 8 Bit (Fixed)

Start Bit 1 Bit (Fixed)

Stop Bit 1 Bit (Default), 2 Bit

Parity Bit ODD (Default) / EVEN / NONE;

Communication Timeout 500ms, 1s (Default), 2.5s, 5s, 10s, 25s, 60s

RTS On / RTS Off Delay Time 0 (Default) / 2 / 5 / 10 /50 /100 / 500 ms

Communication Status Indicators RUN, ERR, TX, RX

Module Status Indicators PWR, DIAG

300, 600, 1200, 2400, 4800, 9600, 19200,

3

8400 (Dip Switch 1–3 selectable)

Selectable with Dip Switch 4 ON (Option Mode)

Use T1K–MODBUS Setup Tool

Selectable with Dip SW 4 ON (Option Mode)

Use T1K–MODBUS Setup Tool

Selectable with Dip SW 4 ON (Option Mode)

Use T1K–MODBUS Setup Tool

Selectable with Dip SW 4 ON (Option Mode)

Use T1K–MODBUS Setup Tool

Page 14

T1K–MODBUS Specifications

(Green)

(Green)

(Green)

S

RJ12 Serial Port Specifications

Connector 6–pin female modular (RJ12 phone jack)

Connection Port Type RS232C

Protocol MODBUS RTU;

Use to configure the MODBUS port using the

T1K–MODBUS Setup Tool. Also use for firmware

upgrades.

Station Number 1 (Fixed)

Baud Rate 9600bps, 19200bps (Dip Switch 6 selectable)

Communication Data 8 Bit (Fixed)

Start Bit 1 Bit (Fixed)

Stop Bit 1 Bit (Fixed)

Parity Bit ODD (Fixed)

Base Controller I/O Specifications

Number of I/O Points (max.) Discrete: Inputs: 1024, Outputs: 1024

Analog: Inputs 64 Channels, Outputs 64 Channels

Number of Slots 1 to 31

Self–Diagnostics Watchdog Timer, Memory Check

I/O Module Type Supported Discrete Input, Discrete Output

Analog Input, Analog Output

Hot Swap Yes

Internal Power Consumption 250mA @ 5VDC

Allowable External Power Drop to 0V for 10ms max.

2–3

Specificaions

T1K–MODBUS

tatus Indicators

The status indicator LEDs on the Base Controller’s front panel have specific

functions which can help in programming and troubleshooting.

Indicator Status Description

PWR

(Green)

RX

TX

RUN

ERR ON Communication error

DIAG ON I/O system error

ON Power good

ON Data is being received by the Base Controller

OFF No data is being received by the Base Controller

ON Data is being transmitted by the Base Controller

OFF No data is being transmitted by the Base Controller

ON Starting communication to Master Module

OFF LED will turn OFF 1 second after failing to

communicate with master module

Flashing at

1 sec intervals

OFF I/O sytem good

ERR LED will begin flashing after the master stops

communicating with the Base Controller. The

Communication Time–out period can be set using

the T1K–MODBUS Setup Tool.

Safety Guidelines

Installation and

Page 15

2–4

DIP SW

T1K–MODBUS Specifications

Setting the DIP Switches

DIP Switch

Settings

Specifications

T1K–MODBUS

The T1K–MODBUS controller has an eight position DIP Switch which controls baud

rates, addressing modes, the state of the outputs in an error condition, etc. The DIP

Switch is located on the side of the unit, opposite the power supply.

Note: Be sure to look closely at the DIP Switch default settings below.

OFF ON

SW1

SW2

SW3

SW4

SW5

The DIP

Switch is on

this side.

Factory Default Settings Shown (all OFF)

SW6

SW7

SW8

MODBUS Port Baud Rate

Communication Setting Mode

Hold Outputs (on Comm. Error)

RJ12 Serial Port Baud Rate

MODBUS RTU Addressing Mode

CTS Control Enable/Disable

for RJ12 Serial Port

Installation and

Safety Guidelines

DIP Switches 1–3 select the MODBUS port baud rate.

SW 1–3 MODBUS Port Baud Rate

Baud Rate SW 1 SW2 SW3

300 bps OFF OFF OFF

600 bps ON OFF OFF

1200 bps OFF ON OFF

2400 bps ON ON OFF

4800 bps OFF OFF ON

9600 bps ON OFF ON

19200 bps OFF ON ON

38400 bps ON ON ON

Page 16

2–5

T1K–MODBUS Specifications

The Communications Setting mode, DIP Switch 4, enables some of the MODBUS

port communication parameters to be user set using the T1K–MODBUS Set Up

Tool. The following tables describe the default and option modes.

SW 4 Communication Setting Mode

OFF Default Mode

ON Option Mode

Default Mode:

The following table lists the MODBUS port default settings when DIP Switch 4 is in

the OFF position.

SW 4 OFF MODBUS Port / Default

Mode

Item Default Setting

Communication Data 8 Bit

Start Bit 1 Bit

Stop Bit 1 Bit

Parity Bit ODD

Communication Timeout 1s

RTS ON Delay Time 0ms

RTS OFF Delay Time 0ms

T1K–MODBUS

Specificaions

Option Mode:

The following items are user selectable using the T1K–MODBUS Set Up T ool* when

DIP Switch 4 is in the ON position.

SW 4 ON MODBUS Port / Option Mode

Item Default Setting

Communication Data 8 Bit (Fixed)

Start Bit 1 Bit (Fixed)

Stop Bit* 1 Bit / 2 Bit

Parity Bit* ODD / EVEN / NONE

Communication Timeout* 500ms, 1s, 2.5s, 5s, 10s, 25s, 60s

RTS ON Delay Time* 0ms, 2ms, 5ms, 10ms, 20ms, 50ms, 100ms, 500ms

RTS OFF Delay Time* 0ms, 2ms, 5ms, 10ms, 20ms, 50ms, 100ms, 500ms

Safety Guidelines

Installation and

Page 17

2–6

Specifications

T1K–MODBUS

T1K–MODBUS Specifications

The Hold Outputs DIP Switch 5 determines the slave outputs’ response to a

communications failure. If DIP switch 5 is in the ON position, the outputs in that slave

unit will hold their last state when a communication error occurs. If OFF, the outputs

in that slave unit will turn off in response to a communications error.

SW 5 Hold Outputs

OFF Turn OFF

ON Hold Last State

WARNING: Selecting “HOLD LAST STATE” means that outputs in that slave

will not be under program control in the event of a communications failure.

Consider the consequences to process operation carefully before selecting

this mode.

DIP Switch 6 selects the baud rate for the RJ12 serial port. All other serial port

communication parameters are fixed. The port defaults are listed in the

specifications tables in the beginning of this chapter.

Installation and

Safety Guidelines

SW 6 RJ12 Serial Port

Baud Rate

OFF 9600 bps

ON 19200 bps

DIP Switch 7 selects the T1K–MODBUS addressing mode. Select the OFF

position if the T1K–MODBUS is to be used with a MODBUS master that operates in

the 584/984 addressing mode. Select the ON position if the T1K–MODBUS is to be

used with a DirectLogic PLC CPU operating as the MODBUS master. The modes

are discussed in Chapter 3.

SW 7 MODBUS RTU

Addressing Mode

OFF 584/984 MODBUS Slave

ON DirectLogic PLC MODBUS Slave

DIP Switch 8 either enables or disables the CTS pin on the RJ12 serial port. Place

the switch in the ON position if the connected serial device requires RTS/CTS

control. Otherwise place the switch in the OFF position if only 3–wire

communication (TX, RX, GND) is required.

SW 8 CTS for RJ12 Serial Port

OFF Disable

ON Enable

Page 18

Setting the Rotary Address Switches

HEX Format

0 1 2 3 4 5 6 7 8 9 A B C D E F

The T1K–MODBUS unit address is set by the two rotary switches on the front of the

unit. Addresses are in hexadecimal format with valid address from 00 to F7, which is

equivalent to 0 t o 247 decimal. The addresses do not have to be sequential, but each

station address must be unique.

The top rotary switch is used to set the most significant digit of the HEX address. The

lower switch is used to set the least significant digit in the HEX address.

2–7

T1K–MODBUS Specifications

Converting HEX

Addresses to

Decimal

.

X10

UNIT

X1

ADRS

(HEX)

.

Eventhough the T1K–MODBUS unit address is set in HEX, it’s not difficult to

calculate the equivalent decimal address used by the MODBUS protocol.

To calculate the equivalent HEX address:

1) Divide the decimal address desired by 16. This provides the X10 HEX digit.

2) The remainder will be a number less than 16, resulting in a HEX number between

0–F. The remainder provides the X1 HEX digit. Two examples are given below.

T1K–MODBUS

Specificaions

Safety Guidelines

Installation and

0 1 2 3 4 5 6 7 8 9

60 decimal

60 ÷ 16 = 3

24 decimal

24 ÷ 16 = 1

10 11 12 13 14 15

with remainder of 12 = C

with remainder of 8 = 8

Decimal format

So 60 decimal = 3C

So 24 decimal = 18

HEX

HEX

Page 19

2–8

MODBUS Port Pin–out and Wiring

Specifications

T1K–MODBUS

RS–232C

Point-to-point

DTE Device

T1K–MODBUS Specifications

6

1

10

5

15-pin Female

D Connector

11

15

PC/PLC

MODBUS

Master

MODBUS Port Pin Descriptions

1 5V 5 VDC

2 TXD2 Transmit Data (RS232C)

3 RXD2 Receive Data (RS232C)

4 RTS2 Ready to Send (RS–232C)

5 CTS2 Clear to Send (RS–232C)

6 RXD2– Receive Data – (RS–422)

7 0V Logic Ground

8 0V Logic Ground

9 TXD2+ Transmit Data + (RS–422)

10 TXD2 – Transmit Data – (RS–422)

11 RTS2 + Request to Send + (RS–422)

12 RTS2 – Request to Send – (RS–422)

13 RXD2 + Receive Data + (RS–422)

14 CTS2 + Clear to Send + (RS422)

15 CTS2 – Clear to Send – (RS–422)

TXD

RXD

Signal GND

2 TXD

3 RXD

4RTS

5 CTS

70V

MODBUS

Port

RS–422

Network

Installation and

Safety Guidelines

RS–485

Network

RXD+

RXD–

TXD+

TXD–

Signal GND

PC/PLC

MODBUS

Master

PC/PLC

MODBUS

Master

The recommended cable

for RS422 is Belden

9729 or equivalent.

TXD+ / RXD+

TXD– / RXD–

Signal GND

9 TXD+

10 TXD–

13 RXD+

6 RXD–

11 RTS+

12 RTS–

14 CTS+

15 CTS–

70V

9 TXD+

13 RXD+

6 RXD–

10 TXD–

11 RTS+

14 CTS+

12 RTS–

15 CTS_

70V

Termination

Resistor on

last slave only

MODBUS

Port

Termination

Resistor on

last slave only

MODBUS

Port

Page 20

RJ12 Serial Port Pin–out and Wiring

Use D2–DSCBL

The Base Controller’s MODBUS port can be configured using the T1K–MODBUS

Setup Tool via the RJ12 serial port. The “Using the T1K–MODBUS Setup Tool”

chapter later in this manual discusses using the Setup Tool. The RJ12 port is also

used to upgrade the firmware in the base controller.

2–9

T1K–MODBUS Specifications

Modular Connector

to connect PC to

RJ12 Serial Port

6

1

6-pin Female

3 TXD

2 RXD

5 GND

7 RTS

8 CTS

RJ12 Serial Port Pin Descriptions

1 0V Power (–) connection (GND)

2 5V Power (+) connection

3 RXD Receive Data (RS232C)

4 TXD Transmit Data (RS232C

5 RTS Request to Send

6 CTS Clear to Send

4 TXD

3 RXD

1 GND

DIP Switch 8 in the OFF

Position to Disable CTS

T1K–MODBUS

Specificaions

6

1

Safety Guidelines

Installation and

Page 21

MODBUS RTU

Functions and

Addressing Modes

In This Chapter. . . .

— T1K–MODBUS RTU Function Codes

— Using T1K–MODBUS with DirectLogic PLC

— Using T1K–MODBUS with MODBUS 584/984

1

3

Page 22

3–2

MODBUS RTU Functions and Addressing Modes

MODBUS RTU Function Codes

MODBUS Function

Codes Supported

and Addressing Modes

MODBUS RTU Functions

The following MODBUS RTU functions are supported by the T1K–MODBUS base

controller.

MODBUS RTU

Function Code

01 Read Output Table

02 Read Input Table

03 Read Holding Registers (when addressing

mode is 584/984, this function is used to access analog output registers)

04 Read Input Registers (when addressing mode

is 584/984, this function is used to access

analog input registers)

05 Force Single Output

06 Preset Single Registers

07 Read Exception Status

08 Loop back / Maintenance

09 – 14 –

15 Force Multiple Outputs

16 Preset Multiple Registers

17 Report Device Type

18 – 64 –

65 not supported

66 not supported

68–70 not supported

72 not supported

73 – 127 –

Function

Installation and

Safety Guidelines

Page 23

MODBUS RTU Functions and Addressing Modes

DirectLogic Addressing Mode

3–3

Using the

T1K–MODBUS with

a DirectLogic PLC

Modbus Master

The DirectLogic Addressing mode is set by placing Dip Switch 7 in the ON position. The

following memory locations are supported by the T1K–MODBUS base controller in the

DirectLogic Addressing Mode.

• X0 – X1777 Discrete Inputs

• Y0 – Y1777 Discrete Outputs

• V0 – V177 Analog Inputs

• V1400 – V1577 Analog Outputs

T1K–Modbus

Memory Type

For Discrete Data Type

Inputs (X) 1024 X0 – X1777 V40400 – V40477

Outputs (Y) 1024 Y0 – Y1777 V40500 – V40577

For Word (16–bit) Data Types

Analog Input

Data Register (V)

Analog Output

Data Registers (V)

QTY.

(Dec.)

128 V0 – V177

128 V1400 – V1577

PLC Range

(Octal)

V Memory Range

MODBUS RTU Functions

and Addressing Modes

Safety Guidelines

Installation and

Page 24

3–4

Data Type

Coil

Input

Modbus Data Type

Input Register

Hold Register

MODBUS RTU Functions and Addressing Modes

584/984 Addressing Mode

Note: ModScan32 is a Windows based application program that can be used as a

MODBUS master to access and change data points in a connected slave device

(T1K–MODBUS). The utility is ideally suited for quick and easy testing of MODBUS

network slave devices. Visit ww w.win–tech.com to download a free ModScan32 trial

demo and for more information on ModScan32.

Using the

T1K–MODBUS

with a 584 / 984

MODBUS Master

and Addressing Modes

MODBUS RTU Functions

The 584 / 984 Addressing mode is set by placing Dip Switch 7 in the OFF position. The

following decimal memory locations are supported by the T1K–MODBUS base controller in

the 584 / 984 Addressing Mode.

1 – 1024 Discrete Outputs

•

• 10001 – 11024 Discrete Inputs

• 30001 – 30128 Analog Input Registers

• 30201 – 30264 Bit Input Registers

• 40001 – 40128 Analog Output Registers

• 40201 – 40264 Bit Output Registers

Modbus

Range (Decimal) Points Memory Type

1 – 1024 1024 Discrete Output

1025 – 9999 – not supported

10001 – 11024 1024 Discrete Input

11025 – 19999 – not supported

Range (Decimal) Words

T1K–MODBUS

V Memory Range

Channel

(16– bit)

(32– bit)

Memory Type

Analog Input 30001 – 30128 128 64 Analog Input Register

Input Register 30129 – 38999 – – not supported

Installation and

Safety Guidelines

Bit Input Register 30201 – 30264 64 – Discrete Input Bit

Input Register 39129 – 39999 – – not supported

Analog output 40001 – 40128 128 64 Analog Output

Hold Register 40129 – 40200 – – not supported

Bit Output

Register

Hold Register 40265 – 49000 – – not supported

Hold Register 49001 – 49128 128 – Special Register

Hold Register 49129 – 49999 – – not supported

Register

Register

40201 – 40264 64 Discrete Output Bit

Register

Page 25

Using the

T1K–MODBUS

Setup Tool

In This Chapter . . . .

— Configuring the T1K–MODBUS Port

1

4

Page 26

4–2

Using the T1K–MODBUS Set Up Tool

Configuring the T1K–MODBUS Port

T1K–MODBUS Setup Tool (included with this manual) can be used to configure some of the

MODBUS port communication parameters via the RJ12 serial port. The T1K–MODBUS DIP

switch 4 must be in the ON position in order to use the Setup Tool to configure the

MODBUS port parameters. The configurable parameters include the Stop Bit, Parity Bit, On

Delay Time, Off Delay Time and Communication Time–out. If the DIP switch is in the Off

position, the factory defaults will apply. The Tool allows the T1K–MODBUS Firmware version,

Rotary Address Switches and DIP switches to be read only.

Installing the

Setup Tool

The Setup Tool can run on Windows 95/98/2000/MEt or Windows NTt (but not

Windows 3.1xt). The Tool is included with this manual on three 3.5” diskettes. It is

also available for download from the AutomationDirect web site

(www.automationdirect.com). The installation process places the files in the

C:\Program Files\T1K–MODBUS Setup Tool directory (default).

Place disk 1 of 3 in Drive A or Drive B. Click on the Windows Start button and then

select Run. Type in the path and filename (ex. A:\setup), or click on the Browse

button to find the directory and filename (ex. if the Setup Tool was downloaded from

the web). A series of windows will step through the installation process for disks 1, 2

and 3.

Launching the

Setup Tool

Set Up Tool

Using the T1K–MODBUS

Use the Windows Start menu Programs>T1K–MODBUS Setup Tool>

T1K–MODBUS Setup Tool as shown below to launch the Setup Tool.

Page 27

Using the T1K–MODBUS Set Up Tool

4–3

Selecting the PC

Comm Port

Configuring the

MODBUS Port

Select the PC port that will be used to connect to the T1K–MODBUS base controller’s RJ12

serial port.

The following window will be displayed when the Tool is communicating with the base

controller’s RJ12 serial port.

Using The T1K–MODBUS Installation and

Set Up Tool

T1K–MODBUS

Firmware Version

READ ONLY

Rotary Address Switches

DIP Switch Settings

These MODBUS Port

Parameters can be

configured

Write the New Settings to

the base controller

Safety Guidelines

Page 28

Appendix A

I/O Module

Hot Swap

In This Appendix. . . .

— T1K–MODBUS I/O Module Hot Swap Feature

1

A

Page 29

A–2

T1K–MODBUS I/O Module Hot Swap Feature

Appendix AAppendix B

I/O Module Hot Swap

The “Hot Swap” feature allows Terminator I/O modules to be replaced with

Terminator I/O system power ON. Be careful not to touch the terminals with your

hands or any conductive material to avoid the risk of personal injury or equipment

damaged. Always remove power if it is equally convenient to do so.

I/O Module Hot Swap

Check External

24VDC Wiring

Before Hot

Swapping!

WARNING: Only authorized personnel fully familiar with all aspects of the

application should replace an I/O module with system power ON.

The following module types can be “Hot Swapped”.

Module

Power Supply No

Base Controller No

I/O Modules (discrete / analog) Yes

Before “Hot Swapping” an analog I/O module or a DC output module in a

Terminator I/O system, make sure that each of the analog I/O and DC output

module’s 24VDC and 0VDC base terminals are wired directly to the external

power supply individually (see diagram below). If the external 24VDC / 0VDC is

jumpered from base to base in a daisy chain fashion, and an analog I/O or DC output

module is removed from its base, the risk of disconnecting the external 24VDC to the

subsequent I/O modules exists.

Appendix E

Do not jumper

modules together

creating 24VDC

bus for Hot Swap.

Wire each analog I/O and DC

output module independently

to the external power supply.

Page 30

Hot Swap:

I/O Module

Replacement

A–3

I/O Module Hot Swap

I/O Module Hot Swap

The following steps explain how to “Hot Swap” an I/O module.

Appendix A

1. Remove I/O module from base. (If necessary, refer to the Terminator I/O

Installation & I/O Manual for steps on removing an I/O module).

2. The T1K–MODBUS DIAG LED will turn ON.

3. Install a new I/O module with the exactly the same part number.

4. Verify that the T1K–MODBUS Base Controller LEDs have returned to normal.

Outputs

Enable/Disable

Switch

A feature that may be used in a non–continuous process application is the Outputs

Enable/Disable switch. The switch is located on the front of the T1K–MODBUS base

controller. This feature may be used at a convenient time during the process

application to replace an I/O module.

When the switch is in the Disable position:

Sall outputs are Disabled (OFF)

Sthe Base Controller’s output status memory is cleared

Sthe Base Controller ignores any outputs command from the Master Module

Page 31

Appendix B:

Analog Output

Module Configuration

In This Appendix. . . .

— Analog Output Module Control Byte

1

B

Page 32

B–2

Size

Read/Write

Analog Output Module Control Byte

Appendix BAppendix B

Analog Output Module Configuration

The Terminator I/O analog output modules are configured using the Module

Control Byte located in the most significant byte of the most significant word of

channel 1 of the module. The “I/O Memory Map and Analog Module Resolution”

chapter in the Terminator Installation and I/O Manual (T1K–INST–M) covers

memory mapping for the Terminator I/O modules.

Analog Output Module

Channel 1 Memory Map

of 8&16-Channel Analog Output Module

(T1F–08DA, T1F–016DA)

Decimal Bit 07 06 05 04 03 02 01 00

Octal Bit 07 06 05 04 03 02 01 00

Analog Value Channel 1 Write Byte 1

Analog Value Channel 1 Write Byte 2

not used Byte3

Module Control Byte Write Byte 4

Module Control Byte of 8&16-Channel Analog Output Module

(T1F–08DA, T1F–16DA)

Decimal Bit 31 30 29 28 27 26 25 24

Octal Bit 37 36 35 34 33 32 31 30

Outputs Enable

Bit 24

Bit 25

Bit 26

Bit 27

Bit 28 – 31 Reserved for system use –

0 = All outputs OFF

1 = All outputs Enabled

Unipolar / Bipolar

0 = Unipolar selected

1 = Bipolar selected

5V / 10V Range

0 = 5V range

1 = 10V range

0 – 20mA / 4–20mA Range

0 = 0 – 20mA range

1 = 4 – 20mA range

Write

Write

Write

Write

Appendix E

Loading...

Loading...