Page 1

1-800-633-0405

Fuji Duo Series SC-E Contactors

Features

• 5 to 100 hp at 480 VAC

• cULus and CSA approval, CE mark, meets

JIS and IEC standards.

• Models SC-E02-xxx to SC-E4-xxx have

3-pole main circuits and come in three sizes

with widths of 43 mm, 54 mm, and

67 mm.

• Models SC-E1-xxx to SC-E7-xxx employ a

box terminal structure; allowing wires to be

connected directly to the main circuit.

• Has a finger-protection terminal structure

that prevents the exposure of live parts.

• Models SC-E5-xxx to SC-E7-xxx use a

SUPERMAGNETTM (AC-input/DC-output

operation) for high operating reliability

and requires no surge suppressor.

Small Size

• SC-E02-xxx to E05-xxx: 43mm wide

• SC-E1-xxx to E2S-xxx: 54mm wide

• SC-E3-xxx, E4-xxx: 67mm wide

• SC-E5-xxx: 88mm wide

SC-E2S

Safety

• Terminals with finger-touch protection (DIN

57106/VDE 0106 Teil100)

Utility

• Box lug terminal construction

• Long electrical life

• Easy to wire

Environmental

• Low power consumption

• Recycled thermoplastic resin used for

plastic parts.

• The names of materials are indicated on

all major parts to facilitate recycling

For the latest prices, please check AutomationDirect.com.

SC-E7

Standards & Approvals

• UL listed , file E42419, Standard UL 508

• cUL listed, file E42419,

Standard CSA C 22.2 No.14

• VDE 0660

• JIS C 8201-4-1

• IEC 60947-4-1 / EN 60947-4-1

• CE compliant

Optional accessories

• Auxiliary contact blocks

• Coil surge suppression units

• Replacement coils for contactor sizes

SC-E5 and larger

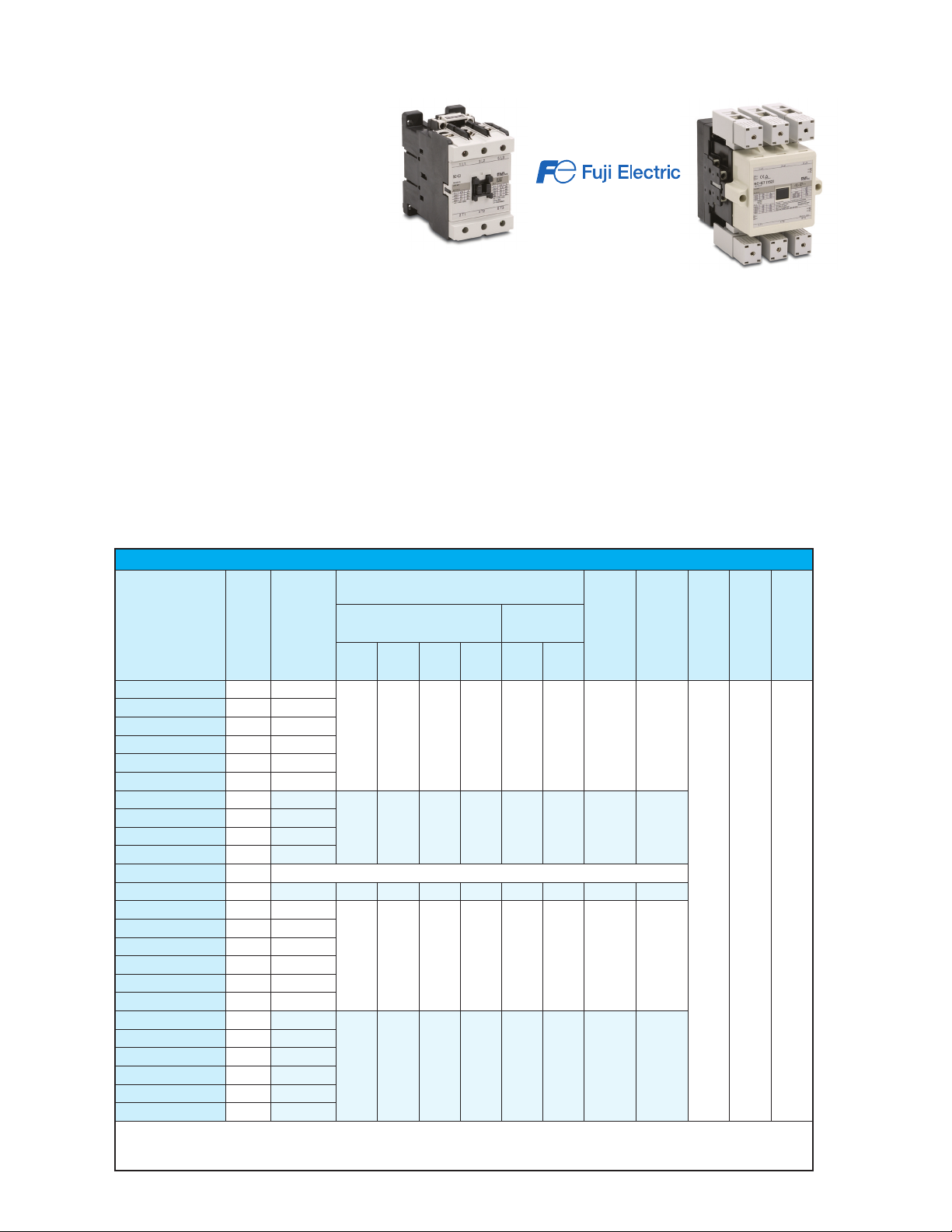

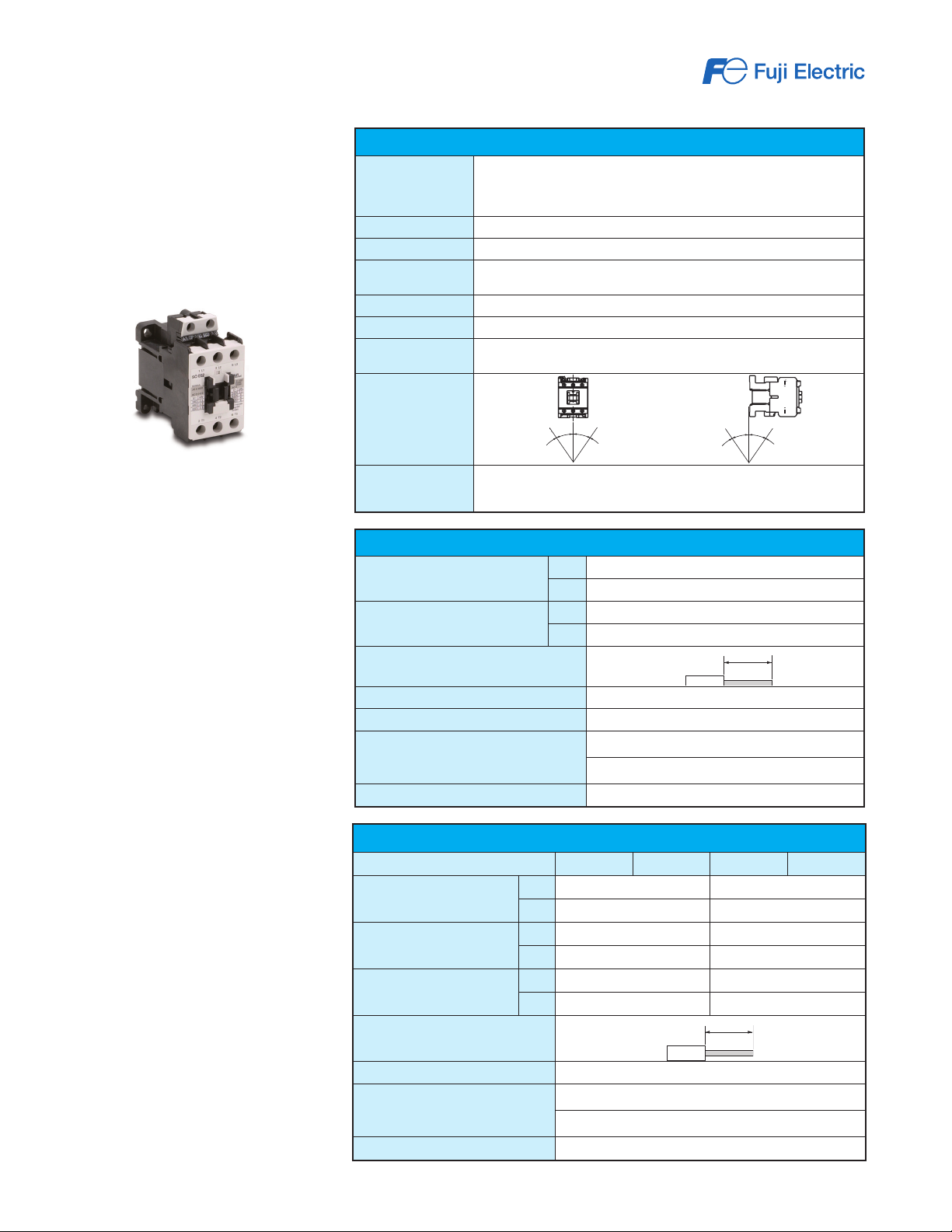

SC-E Series Contactors Specifications - UL and CSA

Nominal Coil

Voltage

Rated Capacity (HP)

550–

600V

1-Phase

Motor

100–

120V

220–

240V

Model Price

SC-E02-24VAC

SC-E02-110VAC

SC-E02-220VAC

SC-E02-440VAC

SC-E02-500VAC

SC-E02G-24VDC

SC-E03-24VAC

SC-E03-110VAC

SC-E03-220VAC

SC-E03-440VAC

SC-E03-500VAC

SC-E03G-24VDC

SC-E04-24VAC

SC-E04-110VAC

SC-E04-220VAC

SC-E04-440VAC

SC-E04-500VAC

SC-E04G-24VDC

SC-E05-24VAC

SC-E05-110VAC

SC-E05-220VAC

SC-E05-440VAC

SC-E05-500VAC

SC-E05G-24VDC

TABLE CONTINUED NEXT PAGE

Notes: 1. AC3 type loads consist of squirrel cage three-phase motors; occasional, limited jogging duty.

2. AC1 non-inductive or slightly inductive loads. Typically resistive loads (i.e. furnaces, ovens, etc.)

$17.00 24VAC

$17.00 110VAC

$17.00 220VAC

$17.00 440-480VAC

$17.00 500-550VAC

$19.00 24VDC

$21.50 24VAC

$21.50 110VAC

$21.50 220VAC

$21.50 440-480VAC

retired Please consider the Fuji Electric SC-E series as comparable replacement

$30.50 24VDC 3 3 7.5 7.5 1/2 2 12 20

$27.00 24VAC

$27.00 110VAC

$27.00 220VAC

$27.00 440-480VAC

$27.00 500-550VAC

$37.50 24VDC

$35.00 24VAC

$35.00 110VAC

$35.00 220VAC

$35.00 440-480VAC

$35.00 500-550VAC

$45.00 24VDC

3-Phase Motor

220–

240V

440–

480V

200V

2 2 5 5 1/3 1 9 20

3 3 7.5 7.5 1/2 2 12 20

5 5 10 10 1 3 18 25

5 7.5 15 15 2 3 25 32

Rated AC-3 Cur-

rent (A) [note 1]

mal Current (A)

[note 2]

Rated AC-1 Ther-

SCCR Ratings

(KA)

5 690 43

Rated Insulation

Voltage (V)

Frame Width (mm)

www.automationdirect.com

Motor Controls

28

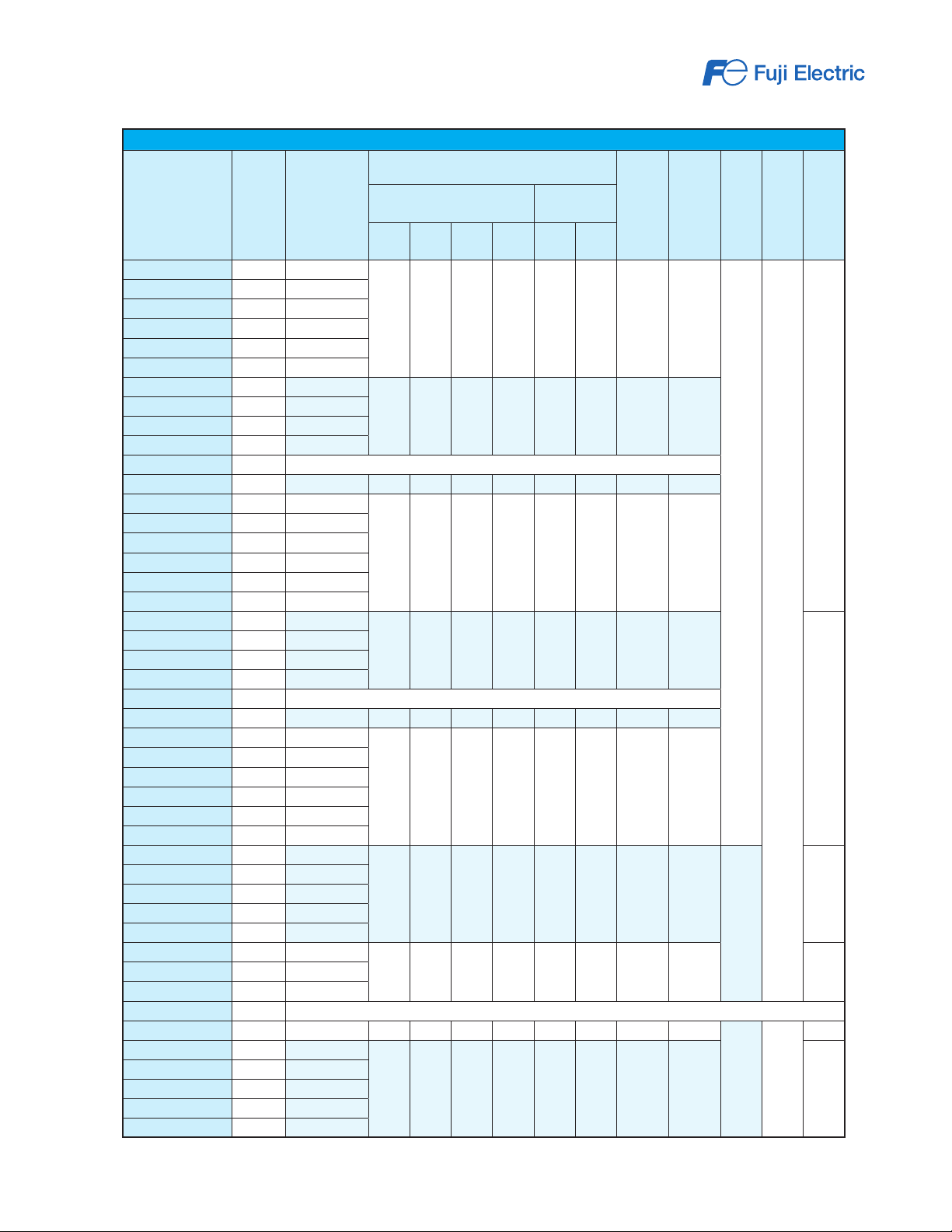

Page 2

1-800-633-0405

Fuji Duo Series SC-E Contactors

SC-E Series Contactors Specifications - UL and CSA

Nominal Coil

Voltage

Rated Capacity (HP)

For the latest prices, please check AutomationDirect.com.

Rated AC-3 Cur-

rent (A) [note 1]

mal Current (A)

[note 2]

Rated AC-1 Ther-

SCCR Ratings

(KA)

Rated Insulation

Voltage (V)

(mm)

Frame Width

550–

600V

1-Phase

Motor

100–

120V

Model Price

SC-E1-24VAC

SC-E1-110VAC

SC-E1-220VAC

SC-E1-440VAC

SC-E1-500VAC

SC-E1G-24VDC

SC-E2-24VAC

SC-E2-110VAC

SC-E2-220VAC

SC-E2-440VAC

SC-E2-500VAC

SC-E2G-24VDC

SC-E2S-24VAC

SC-E2S-110VAC

SC-E2S-220VAC

SC-E2S-440VAC

SC-E2S-500VAC

SC-E2SG-24VDC

SC-E3-24VAC

SC-E3-110VAC

SC-E3-220VAC

SC-E3-440VAC

SC-E3-500VAC

SC-E3G-24VDC

SC-E4-24VAC

SC-E4-110VAC

SC-E4-220VAC

SC-E4-440VAC

SC-E4-500VAC

SC-E4G-24VDC

SC-E5-24V

SC-E5-100V

SC-E5-200V

SC-E5-400V

SC-E5-500V

SC-E6-24V

SC-E6-100V

SC-E6-200V

SC-E6-400V

SC-E6-500V

SC-E7-24V

SC-E7-100V

SC-E7-200V

SC-E7-400V

SC-E7-500V

Notes: 1. AC3 type loads consist of squirrel cage three-phase motors; occasional, limited jogging duty.

2. AC1 non-inductive or slightly inductive loads. Typically resistive loads (i.e. furnaces, ovens, etc.)

$42.00 24VAC

$42.00 110VAC

$42.00 220VAC

$42.00 440-480VAC

$42.00 500-550VAC

$49.50 24VDC

$59.00 24VAC

$59.00 110VAC

$59.00 220VAC

$59.00 440-480VAC

retired Please consider the Fuji Electric SC-E series as comparable replacement

$72.00 24VDC 10 15 30 30 3 5 40 60

$72.00 24VAC

$72.00 110VAC

$72.00 220VAC

$72.00 440-480VAC

$72.00 500-550VAC

$85.00 24VDC

$81.00 24VAC

$81.00 110VAC

$81.00 220VAC

$81.00 440-480VAC

retired Please consider the Fuji Electric SC-E series as comparable replacement

$99.00 24VDC 20 25 50 50 5 15 65 100

$83.00 24VAC

$83.00 110VAC

$83.00 220VAC

$83.00 440-480VAC

$83.00 500-550VAC

$102.00 24VDC

$206.00 24VAC/VDC

$206.00 110VAC/VDC

$206.00 220VAC/VDC

$206.00 380-450VAC

$206.00 460-575VAC

$262.00 24VAC/VDC

$262.00 110VAC/VDC

$262.00 220VAC/VDC

Retired Discontinued item. Please consider the Fuji Electric SC-E series as comparable replacements

$262.00 460-575VAC 40 40 75 100 10 20 125 150

$306.00 24VAC/VDC

$306.00 110VAC/VDC

$306.00 220VAC/VDC

$306.00 380-450VAC

$306.00 460-575VAC

3-Phase Motor

220–

240V

440–

480V

200V

7.5 10 25 25 2 3 32 50

10 15 30 30 3 5 40 60

15 20 30 30 3 10 50 65

20 25 50 50 5 15 65 100

25 30 50 50 5 15 80 105

30 30 60 75 7.5 15 105 150

40 40 75 100 10 20 125 150 100

50 50 100 125 15 25 150 200 115

220–

240V

54

5

690

67

88

10

100

10 690

www.automationdirect.com

Motor Controls

29

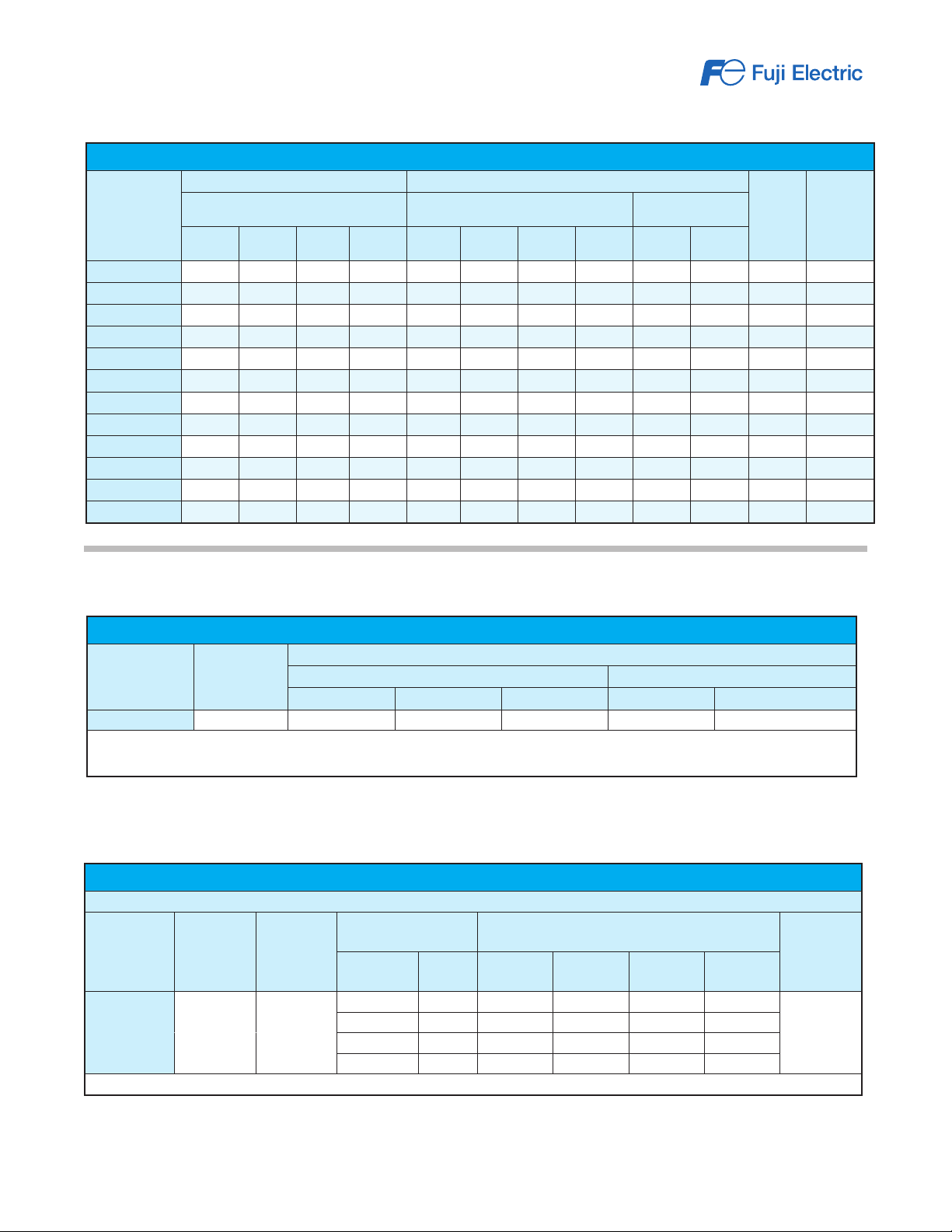

Page 3

1-800-633-0405

Fuji Duo Series SC-E Contactors

SC-E Series Contactors Specifications - IEC

Rated Capacity (kW) Rated Operating Current (A)

Contactor Type

SC-E02(G)-xxx

SC-E03(G)-xxx

SC-E04(G)-xxx

SC-E05(G)-xxx

SC-E1(G)-xxx

SC-E2(G)-xxx

SC-E2S(G)-xxx

SC-E3(G)-xxx

SC-E4(G)-xxx

SC-E5-xxx

SC-E6-xxx

SC-E7-xxx

3-Phase Motor AC-3 / AC-4 3-Phase Motor AC-3 / AC-4

200240V

2.2 / 2.2 4 / 4 4 / NA 4 / NA 9 / 9 9 / 9 7 / NA 5 / NA 20 20 20 -

7.5 / 7.5 15 / 15 15 / NA 11 / NA 32 / 32 32 / 32 24 / NA 15 / NA 50 50 50 -

18.5 / 18.5 30 / 30 37 / NA 30 / NA 68 / 68 65 / 65 60 / NA 38 / NA 100 100 100 -

22 / 18.5 40 / 30 37 / NA 37 / NA 80 / 68 80 / 65 60 / NA 44 / NA 105 105 105 -

380440V

3 / 3 5.5 / 5.5 5.5 / NA 5.5 / NA 12 / 12 12 / 12 9 / NA 7 / NA 20 20 20 -

4 / 4 7.5 / 7.5 7.5 / NA 7.5 / NA 18 / 18 18 / 18 13 / NA 9 / NA 25 25 25 -

5.5 / 4 11 / 7.5 11 / NA 7.5 / NA 25 / 18 25 / 18 17 / NA 9 / NA 32 32 32 -

11 / 11 18.5 / 18.5 18.5 / NA 15 / NA 40 / 40 40 / 40 29 / NA 19 / NA 60 60 60 -

15 / 11 22 / 18.5 25 / NA 22 / NA 50 / 40 50 / 40 38 / NA 26 / NA 65 65 65 -

30 / 30 55 / 55 5 5/ NA 55 / NA 105 / 105 105 / 105 85 / NA 64 / NA 150 150 150 2NO+2NC

37 / 37 60 / 60 6 0 / NA 60 / NA 125 / 125 125 / 125 90 / NA 72 / NA 150 150 150 2NO+2NC

45 / 45 75 / 75 75 / NA 90 / NA 150 / 150 150 / 150 120 / NA 103 / NA 200 200 200 2NO+2NC

500550V

600690V

200240V

380440V

500550V

600690V

For the latest prices, please check AutomationDirect.com.

Resistive Load

AC-1

200240V

380440V

Rated

Thermal

Current

(A)

Internal

Auxilliary

Contact

Arrangement

Internal Auxiliary Contact Ratings

Internal Auxiliary Contact Ratings - UL and CSA

Frame Size

( note 1 )

E5 to E7-xxx

Notes:

1. E02(G) to E4(G) do not have internal auxiliary contact.

2. NEMA ICS 5-2000. For more information, refer to Control Circuit Contact Electrical Ratings, see page MRC-111.

Rated

Insulation Voltage (V)

690 A600 7200 720 Q300 69

Based on IEC 60974-4-1, EN 60947-4-1, JIS C 8201-4-1

Frame Size

( note 1 )

E5 to E7-xxx

Note 1: E02(G) to E4(G) do not have internal auxiliary contact.

Rated

Insulation

Voltage (V)

690 10

NEMA ICS 5-2000 Ratings ( note 2 )

AC Ratings DC Ratings

Designation Making VA Breaking VA Designation Making/Breaking VA

Internal Auxiliary Contact Ratings - IEC, JIS

Rated

Thermal

Current (A)

Making and Breaking

Capacity (A)

AC Voltage Amps AC Voltage

120V 60 120V 6 24V 3

220V 30 220V 3 48V 1.5

440V 15 440V 1.5 110V 0.55

600V 12 600V 1.2 220V 0.27

Rated Operational Current (A)

AC-15

(Ind. load)

DC Voltage

DC-13

(Ind. load)

Minimum

Operating

Voltage and

Current

5VDC, 3mA

www.automationdirect.com

Motor Controls

30

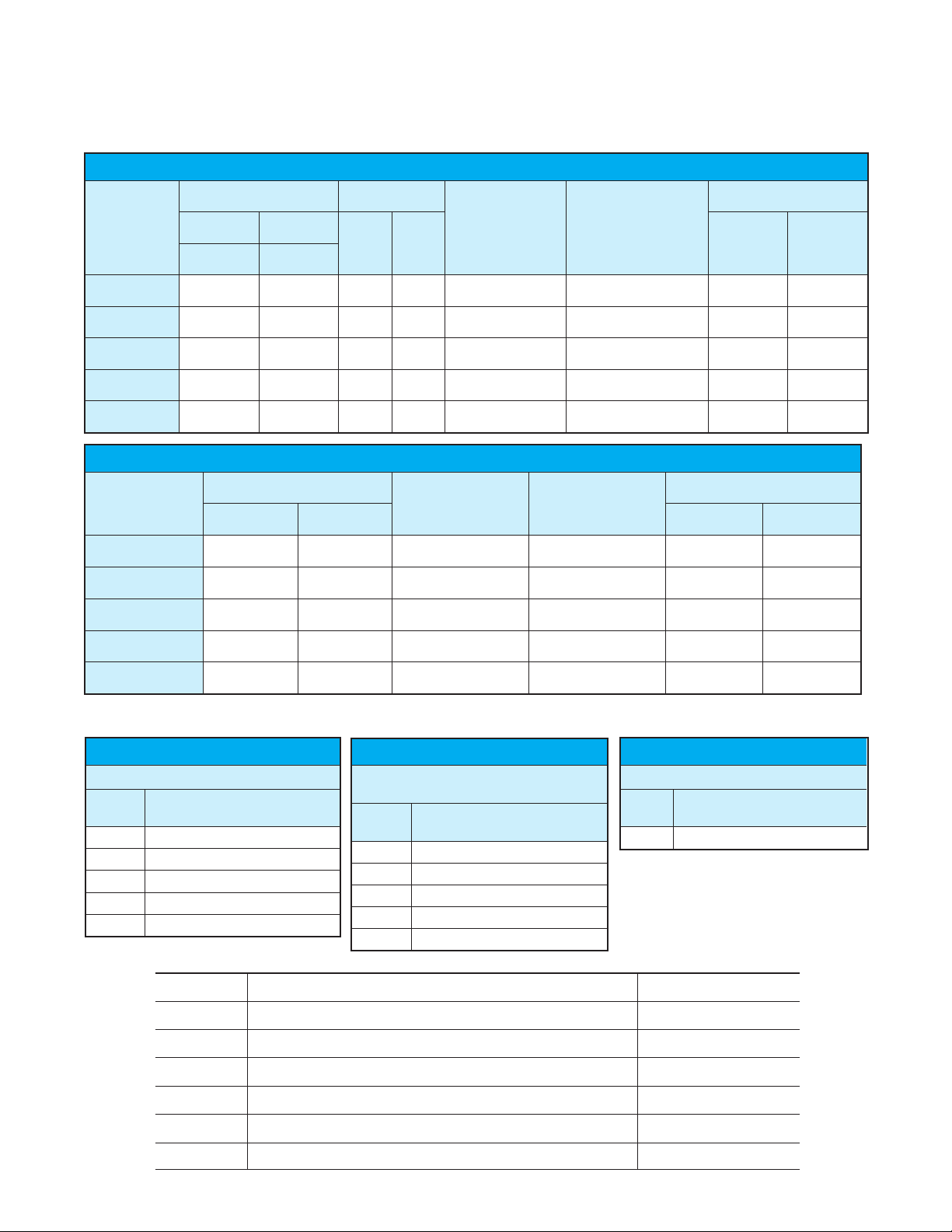

Page 4

1-800-633-0405

Fuji Duo Series SC-E Contactors

Coil Characteristics

AC Coil Characteristics

For the latest prices, please check AutomationDirect.com.

Frame Size

E02 to E05-xxx

E1 to E2S-xxx

E3, E4-xxx

E5-xxx

E6, E7-xxx

Frame Size

E02G to E05G-xxx

E1G to E2SG-xxx

E3G, E4G-xxx

E5-xxx

E6, E7-xxx

Power Consumption (VA) Power Loss (W)

Inrush Sealed

50Hz 60Hz

50/60Hz 50/60Hz

90/95 9/9 2.7 2.8

120/135 12.7/12.4 3.6 3.8

180/190 13.3/13.4 4.5 5

80/95 4/4.6 3.2 3.6

190/230 4.9/5.8 3.4 3.7

DC Coil Characteristics

Power Consumption (W)

Pick-Up Voltage (V) Drop-Out Voltage (V)

Inrush Sealed

7 7

9 9

12 12

90 2.8

225 3.2

Pick-Up Voltage (V) Drop-Out Voltage (V)

0.85 - 1.1 x U.S.

rated coil voltage

0.85 - 1.1 x U.S.

rated coil voltage

0.85 - 1.1 x U.S.

rated coil voltage

0.85 - 1.1 x U.S.

rated coil voltage

0.8 - 1.1 x U.S.

rated coil voltage

0.85 - 1.1 x U.S.

rated coil voltage

0.85 - 1.1 x U.S.

rated coil voltage

0.85 - 1.1 x U.S.

rated coil voltage

0.85 - 1.1 x U.S.

rated coil voltage

0.8 - 1.1 x U.S.

rated coil voltage

0.2 - 0.75 x U.S.

rated coil voltage

0.2 - 0.75 x U.S.

rated coil voltage

0.2 - 0.75 x U.S.

rated coil voltage

0.2 - 0.75 x U.S.

rated coil voltage

0.1 - 0.65 x U.S.

rated coil voltage

0.1 - 0.75 x U.S.

rated coil voltage

0.1 - 0.75 x U.S.

rated coil voltage

0.1 - 0.75 x U.S.

rated coil voltage

0.1 - 0.75 x U.S.

rated coil voltage

0.1 - 0.65 x U.S.

rated coil voltage

Operating Time (ms)

Coil ON to

Contact ON

9-20 5-16

10-17 6-13

10-18 8-18

39-45 27-33

31-37 30-36

Operating Time (ms)

Coil ON to

Contact ON

45-49 10-26

40-50 8-17

60-70 14-21

35-41 26-32

28-34 27-33

Coil OFF to

Contact OFF

Coil OFF to

Contact OFF

Operating Coil

AC Coil, SC-E02-xxx to SC-E4-xxx

Voltage

Code

24VAC 24VAC 50Hz / 24-26VAC 60Hz

110VAC 100-110VAC 50Hz / 110-120VAC 60Hz

220VAC 200-220VAC 50Hz / 220-240VAC 60Hz

440VAC 415-440VAC 50Hz / 440-480VAC 60Hz

500VAC 480-500VAC 50Hz / 500-550VAC 60Hz

Coil Operating Voltage / Frequency

Performance Data

Frame size Making current (A)Breaking current (A)Operating cyclesDurability (operations)

SC-E02 108108 90 90 1800 2 million 10 million

SC-E03 144144 120120 1800 1.5 million 10 million

SC-E04 216216 180180 1800 1.5 million 10 million

SC-E05 250250 200200 1200 1.5 million 10 million

SC-E1384 384320 320 1200 1.5 million 10 million

SC-E2480 480400 400 1200 1.5 million 10 million

SC-E2S 500500 400400 1200 1.5 million 10 million

SC-E3816 780680 650 1200 1.5 million 5 million

SC-E4816 800680 650 12001 million 5 million

SC-E5 1260 12601050105012001 million 5 million

SC-E6 1500 15001250125012001 million 5 million

SC-E7 1800 18001500150012001 million 5 million

www.automationdirect.com

220V440V 220V 440V per hour Electrical Mechanical

Operating Coil

AC/DC Coil (SUPERMAGNET),

SC-E5-xxx to SC-E7-xxx

Voltage

Code

24V 24-25VAC 50/60Hz; 24VDC

100V 100-127VAC 50/60Hz; 100-120VDC

200V 200-250VAC 50/60Hz; 200-240VDC

400V 380-450VAC 50/60Hz

500V 460-575VAC 50/60Hz

Coil Operating Voltage / Frequency

Operating Coil

DC Coil, SC-E02G-xxx to SC-E4G-xxx

Voltage

Code

24VDC 24VDC

Coil Operating Voltage

Motor Controls

31

Page 5

10 mm

11 mm

1-800-633-0405

Fuji Duo Series SC-E Contactors

For the latest prices, please check AutomationDirect.com.

Standard operating

conditions

The magnetic contactors are manufactured for use in the standard operating

conditions given in the table.

Wiring

Be sure to perform wiring correctly with

reference to the wiring diagrams. Main

terminals for models SC-E02 to SC-E7

are wired using solid wires or stranded

wires. Stranded wires or flexible stranded

wires can be connected by twisting them

together and crimping a sleeve (ferrule)

onto them before connecting.

Tightening torque

If wires are not tightened sufficiently, they

may become hot or loosen, resulting in a

fire, short-circuit, electric shock, or other

potentially dangerous situation. Tighten

wires to the torques specified in these

tables.

Standard Operating Conditions

Ambient

Temperature

Humidity

Altitude

Atmosphere

Vibration

Shock

Mounting

Mounting Angle

Standard

No sudden temperature changes resulting in condensation or icing

(The average temperature over a 24-hour period must not exceed 35°C)

No excessive dust, smoke, corrosive gases, flammable gases, steam, or salt

mounting (SC-E02 to SC-E4), screw mounting

30˚

Operating: -5 to 55°C

Storage: -40 to 65°C

45 to 85%RH

2000m or lower

10 to 55Hz 15m/s

50m/s

35mm IEC DIN rail

2

2

30˚

30˚

IEC 947-4-1, EN 60947-4-1, VDE 0660

JIS C 8201-4-1, JEM 1038

UL 508, file E42419; CSA C22.2, file 20479

30˚

Wire Sizes, Tightening Torques - Control Circuit

Solid or Stranded Wire (mm²)

AWG

Insulation Stripping Length

Fork Terminal

Terminal Screw Size

Tool

Tightening Torque (N.m)

One

Two

One

Two

0.75 to 2.5 (1 to 1.6 mm diameter)

0.75 to 2.5 (1 to 1.6 mm diameter)

18 to 14

18 to 14

0.39 in

Max. 7.7mm wide

M3.5

Phillips screwdriver, H-type, No. 2 (ISO 8764);

ADC part number DN-SP1 or DN-SP2

Flat-blade screwdriver, 1 x 5.5 x L-type, B (ISO 2830);

ADC part number DN-SS5

0.8 to 1

Wire Sizes, Tightening Torques - Main Circuit

Contactor Type SC-E02-xxx SC-E03-xxx SC-E04-xxx SC-E05-xxx

Solid Wire (mm²)

Stranded Wire (mm²)

AWG

One

Two

One

Two

One

Two

0.75 to 4 0.75 to 6

1 to 4 1.5 to 6

0.75 to 4 0.75 to 6

1 to 4 1.5 to 6

12 max. 10 max.

12 max. 10 max.

www.automationdirect.com

Insulation Stripping Length

Terminal Screw Size

Tool

Tightening Torque (N.m)

0.43 in

M4

Phillips screwdriver, H-type, No. 2 (ISO 8764);

ADC part number DN-SP1 or DN-SP2

Flat-blade screwdriver, 1 x 5.5 x L-type, B (ISO 2830);

ADC part number DN-SS5

1.2 to 1.5

Motor Controls

32

Page 6

1-800-633-0405

For the latest prices, please check AutomationDirect.com.

Fuji Duo Series SC-E Contactors

Wire Sizes, Tightening Torques - Main Circuit

Contactor Type SC-E1, E2, E2S-xxx SC-E3, E4-xxx SC-E5, E6-xxx SC-E7-xxx

Top-Only

Connection

Bottom-Only

Connection

Solid or stranded wire (mm 2)

Flexible stranded wire

with sleeve (mm 2)

1

Flexible stranded wire

without sleeve (mm 2)

AWG

Solid or stripping length (mm)

Single stranded wire (mm 2)

Flexible stranded wire

with sleeve (mm 2)

1

Flexible stranded wire

without sleeve (mm 2)

AWG

Sheath stripping length (mm)

Solid or stranded wire

1

(mm 2)

1

1

Top/

bottom

0.75 to 35 1.5 to 70 4 to 70 4 to 120

0.75 to 25 1.5 to 50 2.5 to 50 2.5 to 95

0.75 to 25 1.5 to 50 4 to 50 4 to 95

18 to 2 16 to 2/0 12 to 2/0 12 to 250MCM

15 19.5 26.5 28.5

0.75 to 25 1.5 to 50 4 to 70 4 to 120

0.75 to 16 1.5 to 35 2.5 to 50 2.5 to 95

0.75 to 16 1.5 to 35 4 to 50 4 to 95

18 to 3 16 to 1/0 12 to 2/0 12 to 250MCM

12.5 16 26.5 28.5

0.75 to 25 1.5 to 50 4 to 70 4 to 120

Top/Bottom

Connection

Flexible stranded wire with

sleeve (mm 2)

Flexible stranded wire

1

without sleeve (mm 2)

AWG

Tool

Tightening Torque (Nm)

Self-locking Torque (Nm)

Note 1: Stranded wire (0 to 25mm2) consists of 7 wires or less.

Stranded wire (35 to 120mm2) consists of 19 wires or less.

Flexible stranded wire consists of more number wires than

the above.

2

Top/

bottom

Top/

bottom

Top/

bottom

0.75 to 16 1.5 to 35 2.5 to 50 2.5 to 95

0.75 to 16 1.5 to 35 4 to 50 4 to 95

18 to 3 16 to 1/0 12 to 2/0 12 to 250MCM

Phillips screwdriver, H-type, No.2

(ISO 8764);

ADC part number DN-SP1 or

DN-SP2

Flat-blade screwdriver, 1 x 5, 5xL-

type, B (ISO 2830);

ADC part number DN-SS5

2.5 8 10

1 2

Note 2: T he tightening bolt must be loosened in order to insert the wire. However, stop

loosening the bolt when the anti-drop attachment on the bottom of the bolt reaches the

top edge of the terminal. If a torque exceeding that given in the table is applied in this

state, the retaining bracket may loosen.

Hex. wrench 4 (ISO 2936)

www.automationdirect.com

Motor Controls

33

Page 7

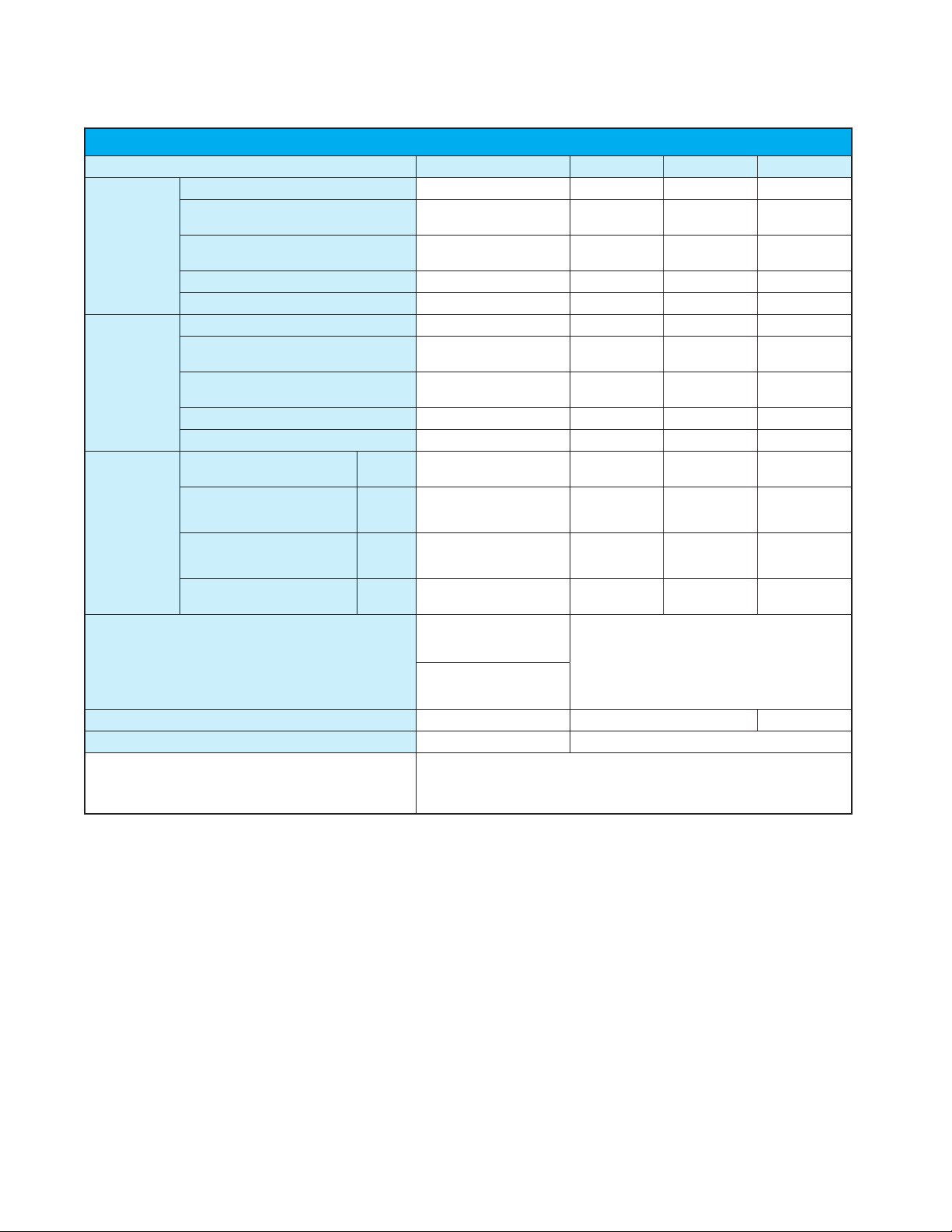

AC-3 duty / SC-E1 to SC-E7-xxx

A

Breaking current (A)

A

C-3 duty / SC-E02 to SC-E05-xxx

1-800-633-0405

Fuji Duo Series SC-E Contactors

Electrical durability

For the latest prices, please check AutomationDirect.com.

200 - 240V

200 - 240V

)

3

Make/break operations ( 10

380 - 440V

10000

10000

)

3

Make/break operations ( 10

10000

5000

3000

2000

1000

500

300

200

100

5000

5000

3000

3000

2000

2000

1000

50

30

20

10

1000

500

500

300

300

200

200

100

100

50

50

30

30

20

20

10

10

3-phase motor capacity (kW)

and full-load current (A)

1 2 3

3-phase motor capacity (kW)

and full-load current (A)

380 - 440V

200 - 240V

380 - 440V

10000

5000

3000

2000

1000

500

300

200

100

50

30

20

10

10 20 30

380 - 440V

SC-E1

SC-E2

SC-E2S

SC-E02

32A

SC-E03

SC-E3

15kW

SC-E4

40A

18.5kW

SC-E5

50A

SC-E04

SC-E6

22kW

SC-E7

65A

30kW

SC-E05

20 30 50 100 200300 500 1000

105

9A

12A

18A

4kW

2.2kW

80A

40kW

10050

105A

25A

5.5kW 7.5kW

11kW

3kW

4kW

5.5kW

200 300 500 1000 2000 3000 5000 10000

125A

150A

55kW

60kW

75kW

Breaking current (A)

Breaking current (A)

www.automationdirect.com

200 - 240V

7.5kW

C-1 duty / SC-E02 to SC-E7-xxx

200 - 240V

380 - 440V

10000

)

3

5000

3000

2000

1000

Make/break operations ( 10

10000

500

300

200

100

5000

3000

2000

1000

500

300

200

100

1 2 3

SC-E02

SC-E03

SC-E04

SC-E05

SC-E1

37kW

22kW

30kW

18.5kW

11kW

15kW

SC-E2

SC-E2S

SC-E3

20 30 50 100200 300 500 1000

105

45kW

SC-E4

20A

SC-E5

25A

SC-E6

32A

SC-E7

50A

65A

60A

100A

105A

150A

200A

Motor Controls

34

Page 8

1-800-633-0405

Fuji Duo Series SC-E Contactors

Accessories

Optional accessories

For the latest prices, please check AutomationDirect.com.

SZ-Z coil surge

SZ-AS1T auxiliary con-

tact block

SZ-A22T auxiliary con-

tact block

suppression unit

Auxiliary contact blocks

with terminal covers

Maximum auxiliary contact blocks: 2

side mounted (1 per side) OR 1 front

mounted. The front and side blocks

cannot be mounted together on the

same contactor.

Caution on use:

1. Front mounting auxiliary contact

block and side mounting block

cannot be attached to one contactor at the same time.

2. Only one front mounting block can

be attached to one contactor.

3. Where interlock unit is already attached, side mounting auxiliary

contact block can be attached on

one side only.

SC-E Contactor

SZ-AS1T auxiliary con-

tact block

SZ-A22T SZ-A11T SZ-AS1T SZ-AS2T

Auxiliary Contact Blocks with Terminal Covers

Part Number Price Applicable Contactor Mounting

SZ-A22T

SZ-A20T

SZ-A11T

SZ-AS1T

SZ-AS2T

$14.50

$9.00

$9.00 1NO + 1NC

$14.50 SC-E02(G)-xxx to E4(G)-xxx

$14.50

SC-E02(G)-xxx to E4(G)-xxx Front mounting

SC-E5, E6, E7-xxx, SC-N4, N5,

N6, N7, N8, N10, N11, N12, SC-

E5(G)-xxx to E7(G)-xxx

Side mounting

Number of

Contacts

Contact

Arrangement

4 2NO + 2NC

2

2 1NO + 1NC

2 1NO + 1NC

2NO

Accessory Auxiliary Contact Ratings - UL and CSA

NEMA ICS 5-2000 Ratings ( note 1 )

AC Ratings DC Ratings

Designation Making VA Breaking VA Designation Making/Breaking VA

A600 7200 720 Q300 69

For more information, refer to Control Circuit Contact Electrical Ratings, page MRC-111

Accessory Auxiliary Contact Ratings - IEC and JIS continued on next page.

www.automationdirect.com

Motor Controls

35

Page 9

IC-circuit

1-800-633-0405

Fuji Duo Series SC-E Contactors

Accessories

Accessory Auxiliary Contact Ratings - IEC and JIS

Rated

Thermal

Current (A)

10

Making and

Breaking Capacity

at AC (A)

120V 60 120V 6 24V 3

220V 30 220V 3 48V 1.5

440V 15 440V 1.5 110V 0.55

600V 12 600V 1.2 220V 0.27

Rated operational current (A)

AC DC

Voltage AC-15 (Ind. load) Voltage DC-13 (Ind. load)

For the latest prices, please check AutomationDirect.com.

Minimum

Operating Voltage

and Current

5VDC, 3mA

Coil surge suppression units

SZ-Z1 SZ-Z37

Suppress surge voltage due to contactor

ON-OFF operations; easily connect to

contactor coil terminals.

Important: When driving 24VDC Fuji contactors

with a PLC solid-state output, we recommend

using diode terminal block part number

DN-D10DR-A or ZL-TSD8-24. Please see

application note AN-MISC-032 for additional

information located on Automationdirect.com/

technotes.

Coil Surge Suppression Units

Part Number Price

SZ-Z1

SZ-Z2

SZ-Z31

SZ-Z32

SZ-Z4

SZ-Z5

SZ-Z34

SZ-Z35

SZ-Z36

SZ-Z37

Applicable Contactor

AC Operated DC Operated

$11.50

SC-E02-xxx to E05-xxx

$11.50 100-250V AC/DC

$15.50

$15.50 100-250V AC/DC

$12.50

$13.00 100-250V AC/DC

$15.50

$15.50 100-250V AC/DC

$15.50

$15.50 100-250V AC/DC

SC-E1-xxx to -E4xxx

SC-E02-xxx to E05-xxx

SC-E1-xxx to E4-xxx -

-

SC-E02G-xxx to

E05G-xxx

SC-E1G-xxx to

E4G-xxx

SC-E02G-xxx to

E05G-xxx

SC-E1G-xxx to

E4G-xxx

SC-E02 to E05

SC-E1 to E4

Note: Super Magnet Coils on SC-E5, SC-E6, and SC-E7 contactors have internal surge suppression.

See diagram below.

Power

supply

AC or DC

Surge

suppression

circuit

Rectifier

circuit

Voltage

detector

Closing

signal

circuit

Sealing

signal

circuit

Operating Coil

Voltage

24-48V AC/DC

24-48V AC/DC

24-48V AC/DC

24-48V AC/DC

24-48V AC/DC

380-440V AC/DC

380-440V AC/DC

Power

switching

circuit

Device

varistor

capacitor /

resistor

COILINPUT

Replacement contactor coils

SC-E Series Replacement Contactor Coils

Part Number Price Applicable Contactor Coil Voltage

SZ-GSN6-100

SZ-GSN5-200

SZ-GSN6-200

SZ-GSN5-24

SZ-GSN6-24

www.automationdirect.com

Retired

Retired

Retired

Retired

Retired

Discontinued item. No replacement available.

Motor Controls

36

Page 10

1-800-633-0405

Fuji Duo Series SC-E Accessories

Connection kits for reversing SC-E contactors

For the latest prices, please check AutomationDirect.com.

SZ-ERW1A

Line Side

Wiring

SZ-ERW2D SZ-ERW3A

Load Side

Wiring

SZ-ERW1B SZ-ERW1D

Load Side

Wiring

Line Side

Wiring

Load Side

Wiring

SZ-ERW3B

Load Side

Wiring

SZ-ERW2A

Line Side

Wiring

Load Side

Wiring

SZ-ERW2B

Load Side

Wiring

SZ-ERW3D

Connection Kits

Part Number Price Description Use with Contactors

SZ-ERW1A

SZ-ERW1B*

SZ-ERW1D

SZ-ERW2A

SZ-ERW2B*

SZ-ERW2D

SZ-ERW3A

SZ-ERW3B*

SZ-ERW3D

* When using the SZ-ERWxB, a TK-E thermal overload relay must be separately mounted and wired using an SZ-HxE base. To

assemble a TK-E overload directly to the contactor use a SZ-ERWxD load side connection kit.

$5.75 Line side reversing connection kit.

$5.75 Load side reversing connection kit. For wiring load side when using contactors only or with a MMS device.

$5.75 Load side reversing connection kit. For wiring load side when using two contactors with a thermal overload relay.

$11.50 Line side reversing connection kit.

$11.50 Load side reversing connection kit. For wiring load side when using contactors only or with a MMS device.

$11.50 Load side reversing connection kit. For wiring load side when using two contactors with a thermal overload relay.

$20.50 Line side reversing connection kit.

$20.50 Load side reversing connection kit. For wiring load side when using contactors only or with a MMS device.

$20.50 Load side reversing connection kit. For wiring load side when using two contactors with a thermal overload relay.

SC-E02-xxx to SC-E05-xxx

SC-E1-xxx to SC-E2S-xxx

SC-E3-xxx to SC-E4-xxx

Mechanical interlock unit

Part

Number

SZ-RM

SZ-RM

NOTE: Mechanical interlock unit cannot be used with SC-E5-xxx through E7-xxx contactors.

Parts for reversing Fuji SC-E contactors

• SC-E (Contactors - qty. 2)

• SZ-ERWxA (Line side connection kit - qty. 1)

• SZ-ERWxB* (Load side connection kit - qty. 1)

• SZ-RM (Mechanical interlock - qty. 1)

• SZ-AxxT (Auxiliary contact blocks - qty. 1)

www.automationdirect.com

Mechanical Interlock Unit

Price Description Use with Contactors

Used when building a reversing starter. Prevents both contactors

$14.50

from being pulled in at once.

SC-E02-xxx to SC-E4-xxx

Motor Controls

37

Page 11

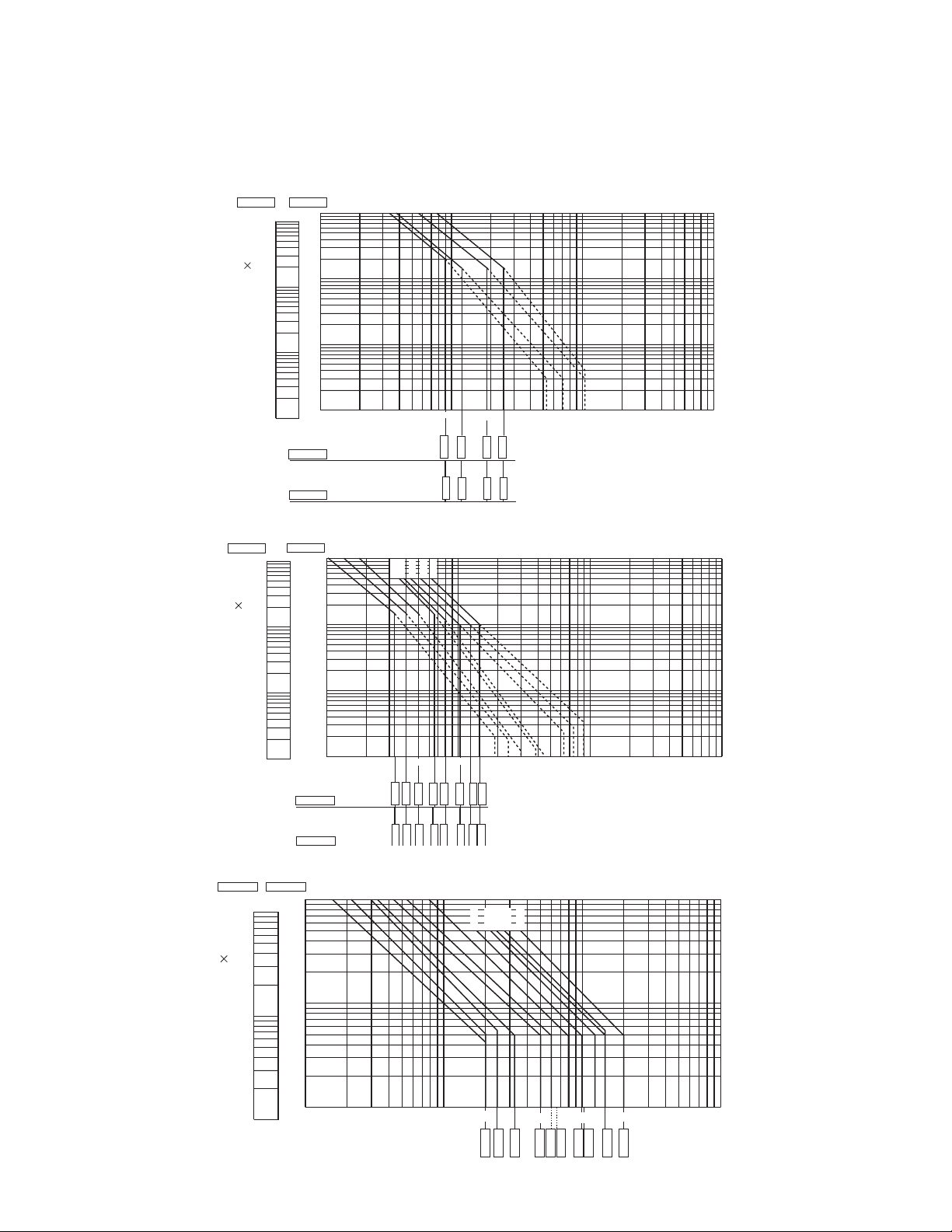

SC-E02, E03, E04, E05-xxx

: 35 60 : 35 (48 to) 52

SC-E1, E2, E2S-xxx

: 45 75 : 45 (38 to 46) 80

SC-E3, E4-xxx

: (55 to) 60 90 : (54 to) 60 90

1-800-633-0405

Fuji Duo Series SC-E Contactors

For the latest prices, please check AutomationDirect.com.

Dimensions (mm)

Contactors

(Rail height 15)

91

81

61

8.5

Weight: 0.33 kg

Mass: 0.33kg

106 (Rail height 15)

96

65.5

10.5

Weight: 0.58 kg

Mass : 0.58kg

2

(28)

(28)

2

*

2

*

Main

terminal

2

*

13

*

16.5

(68)

43

1

1

*

Coil terminal

M3.5

10.5

Coil terminal

M3.5

18.5

90

57

80

2

*

Main

terminal M4

49 20

1

*

Use the two mounting holes on a diagonal line

or to mount contactor

(79)

54

1

*

Use the two mounting holes on a diagonal line

or to mount contactor

18.5(to 20.5)

(48 to)52

Mounting hole

2-M4

Panel drilling

5

80

Mounting hole

2-M4

Panel drilling

34

1

2

35

45(38 to 46)

2

1

45

75

9.5

14.5

60

Wiring diagrams

Contactors

SC-E02 to E05-xxx

SC-E1 to E4-xxx

SC-E02G to E05G-xxx

SC-E1G to E4G-xxx

SC-E2S, E2SG-xxx

1

*

53 61 1/L1 3/L2 5/L3 83 71

*1 In case of aux. contact 2NO+2NC

SC-E5, E6, E7-xxx

1

*

53 61 13 21 1/L1 3/L2 5/L3 43 31 83 71

1

*

In case of aux. contact 4NO+4NC

1

*

6/T3 4/T2 2/T1

72846254

6/T3 4/T2 2/T1

1

*

A1 A2

A1 A2

7284324422146254

2

121 (Rail height 15)

72.5

10.5

Mass: 1.1kg

Weight: 1.1 kg

111

2.5

(28)

*

2

*

www.automationdirect.com

1

Coil terminal

Main

terminal

1

*

Use the two mounting holes on a diagonal line

or to mount contactor

(91)

67

20.5

*

M3.5

19.5

77

112

Mounting hole

2-M4

Panel drilling

(54 to)60

2

1

(55 to)60

90 13

Motor Controls

38

Page 12

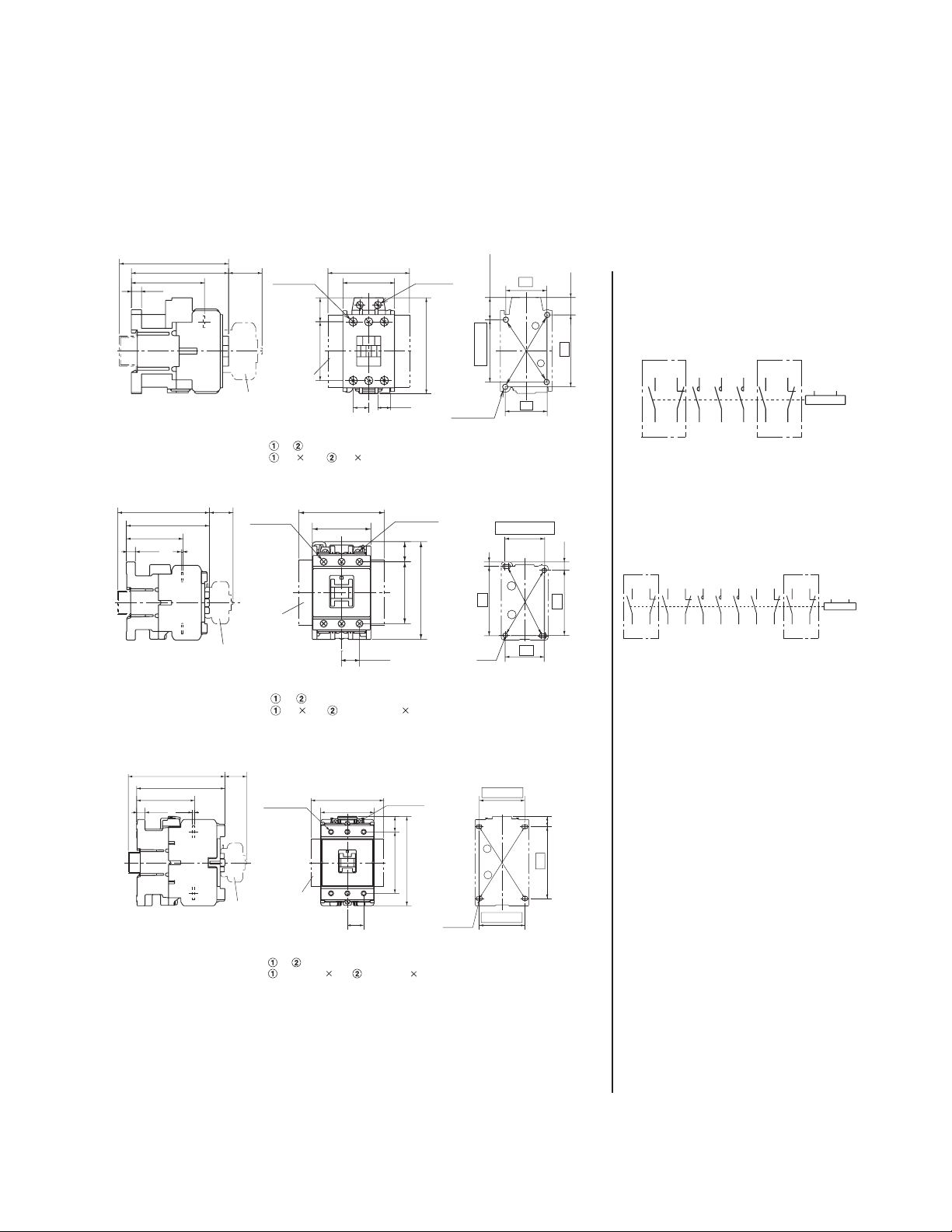

SC-E6-xxx

SC-E02G,

35 60 : 35 (48 to) 52

SC-E5-xxx

*

*

Front mounting aux. contact block

1-800-633-0405

Fuji Duo Series SC-E Contactors

Dimensions (mm)

Contactors

For the latest prices, please check AutomationDirect.com.

132

77

32.7

4

Weight: 2.0 kg

Mass: 2.0kg

1

Side mounting aux. contact block

2

138

77

4

38.8

Mass: 2.6kg

Weight: 2.6 kg

Main

terminal

Auxiliary

terminal

M3.5

Main

terminal

Auxiliary

terminal

M3.5

(111)

88

32

(123)

100

*

32

Coil terminal

1

M3.5

13.5

Coil terminal

M3.5

1

*

129

155

143 13.5

169

Panel drilling

70

Mounting hole

2-M4

75

Panel drilling

(80 to)90

Mounting hole

2-M5

110

SC-E7-xxx

140

76.8

38.8

Weight: 2.9 kg

Mass: 2.9kg

118 (Rail height 15)

8.5

Weight: 0.59 kg

Mass: 0.59kg

Main

terminal

Auxiliary

terminal

M3.5

E03G, E04G, E05G-xxx

2

*

108

88

(28)

2

*

Coil terminal

M3.5

1

(138)

*

115

14.5

146

175

35

Main

terminal

M4

49 20

1

*

Use the two mounting holes on a diagonal line

or to mount contactor

13

(68)

43

1

*

10.5

Coil terminal

M3.5

80

18.5(to 20.5)

(48 to)52

Mounting hole

2-M4

Panel drilling

(80 to)90

Mounting hole

2-M5

Panel drilling

34

1

2

35

110

14.5

60

www.automationdirect.com

Motor Controls

39

Page 13

SC-E1G, E2G, E2SG-xxx

*

*

Front mounting aux. contact block

SC-E3G, E4G-xxx

SC-E3G, E4G-xxx

67

112

54 62 72 84

1-800-633-0405

Fuji Duo Series SC-E Contactors

Dimensions (mm)

Contactors

For the latest prices, please check AutomationDirect.com.

2

130 (Rail height 15)

121.5

91

10.5

Weight: 0.79 kg

Mass: 0.79kg

1

Side mounting aux. contact block

2

140 (Rail height 15)

10.5 2.5 67

Weight: 1.4 kg

Mass: 1.4kg

2

130

91.5

*

(28)

Main

terminal

1

*

2

*

(28)

2

*

Main

terminal

2

*

1

*

Side mounting aux. contact block

2

*

Front mounting aux. contact block

1

*

(79)

54

Use the two mounting holes on a diagonal line

or to mount contactor

16.5

Coil terminal

M3.5

18.5

90

57

Mounting hole

2-M4

Panel drilling

45(38 to 46)

5

2

80

1

45

9.5

75

Panel drilling

Coil terminal

1

(91)

*

M3.5

19.5

77

112

1

*

20.5

Use the two mounting holes on a diagonal line

or to mount contactor

Mounting hole

2-M4

(54 to)60

2

1

(55 to)60

13

90

Dimensions-mm

Auxiliary contact blocks - front mounting

SZ-A22T, A20T, A11T for SC-E02 (G)-xxx to E4 (G)-xxx

M3.5

11

Approx

3

525

SZ-A20T , A11T

Type

SC-E02, E03, E04, E05-xxx

SC-E1, E2, E2S-xxx

SC-E3, E4-xxx

SC-E02G, E03G, E04G, E05(G)-xxx

SC-E1G, E2G, E2SG-xxx

7.7

10

43

7.7

M3.5

28

49

10

24

A22T Mass: 36g

Weight: 36 g

Weight: 20 g

Mass: 20g

Wiring diagrams

SZ-A22T, A20T, A11T

53 63

Contactor with aux. contact block

AC

Approx

3

49

28

A

43

54

67

43

54

B

80

90

112

80

90

C

109

124

139

136

149.5

A

B

B

2NO

54 64

53 61

1NO+1NC

54 62

53 61 71 83

2NO+2NC

www.automationdirect.com

Motor Controls

40

Page 14

1 N.O. + 1 N.C.

SZ-AS1T for SC-E02(G)-xxx to E4(G)-xxx

SZ-AS2T for SC-E5 to E7-xxx

115

1-800-633-0405

Fuji Duo Series SC-E Contactors

For the latest prices, please check AutomationDirect.com.

Dimensions (mm)

Auxiliary contact blocks - side mounting

Contactor with aux. contact block

C

M3.5

43

28

59.5

45

Weight: 28 g

Mass: 28g

7.7

12 7.5

Type

SC-E02, E03, E04, E05-xxx

SC-E1, E2, E2S-xxx

SC-E3, E4-xxx

SC-E02G, E03G, E04G, E05(G)-xxx

SC-E1G, E2G, E2SG-xxx

SC-E3G, E4G-xxx

Contactor with aux. contact block

M3.5

C

67

78

91

67

78

91

Wiring diagrams

Mounted on right side

A

12 12D

B

A

B

C

81

54

67

108

121.5

130

A

D

D

43

54

67

43

54

67

12

80

90

112

80

90

112

12

71 83

72 84

Mounted on left side

53 61

54 62

1 N.O. + 1 N.C.

Mounted on right side

71 83

72 84

28

47

64.5

47.5

Weight: 40 g

Mass: 40g

7.7

12

7

Type

SC-E5-xxx

SC-E6-xxx

SC-E7-xxx

A

112

124

139

B

155

169

175

B

C

132

138

140

D

88

100

Mounted on left side

53 61

54 62

www.automationdirect.com

Motor Controls

41

Page 15

1-800-633-0405

Fuji Duo Series SC-E Contactors

For the latest prices, please check AutomationDirect.com.

Dimensions (mm)

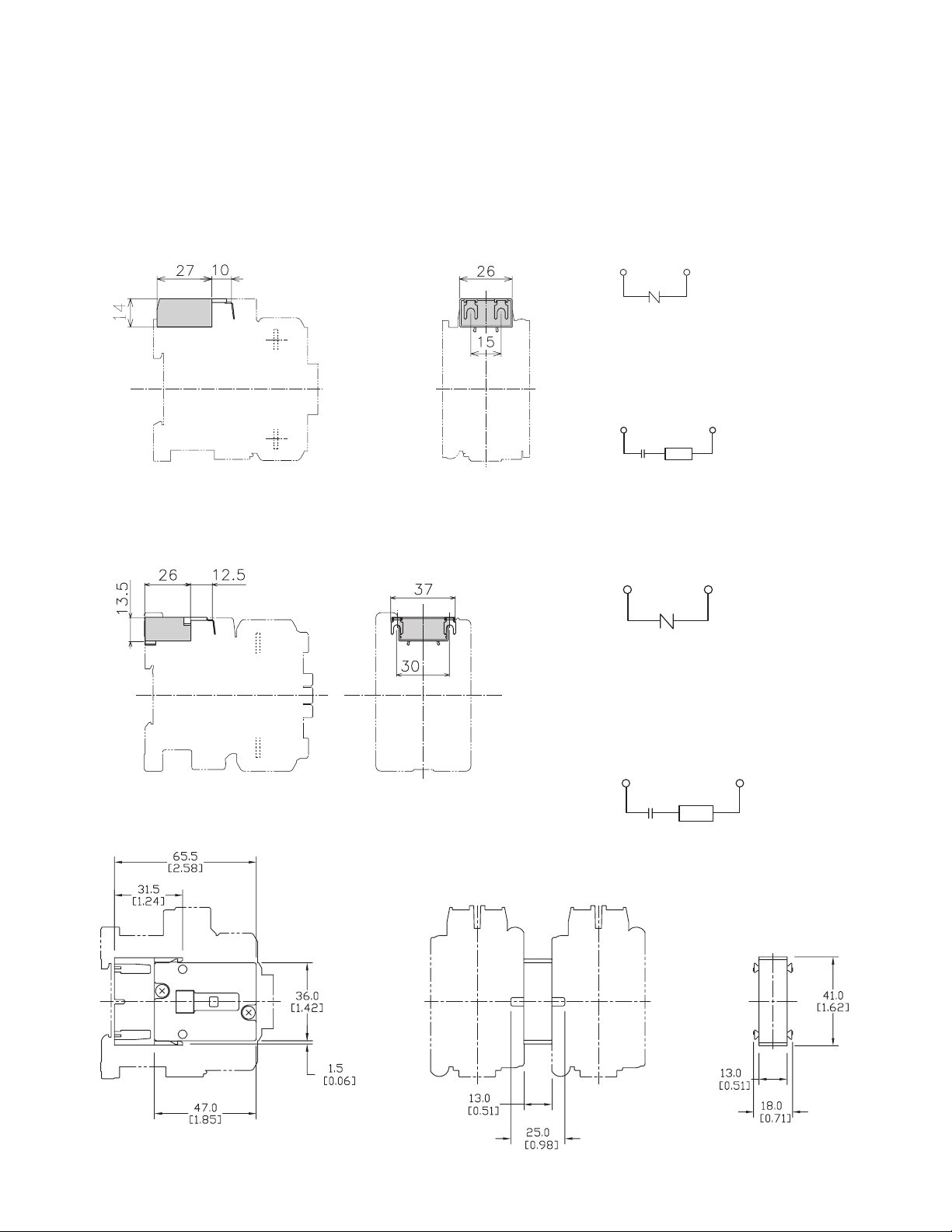

Coil surge suppression units

SZ-Z1, Z2, Z4, Z5

Weight: 14 g

SZ-Z31, Z32, Z34, Z35, Z36, Z36, Z37

Wiring diagrams

SC-E02 to E05-xxx + SZ-Z1, Z2

(Built-in varistor)

SC-E02 to E05-xxx + SZ-Z4, Z5

(Built-in capacitor/resistor)

C

R

SC-E1 to E4-xxx + SZ-Z31, Z32

(Built-in varistor)

Weight: 15 g

SC-E1 to E4-xxx + SZ-Z34, Z35

(Built-in capacitor/resistor)

SC-E1G to E4G-xxx + SZ-Z36, Z37

(Built-in capacitor/resistor)

C

R

SZ-RM

www.automationdirect.com

Motor Controls

42

Loading...

Loading...