Page 1

Barcode Scanners Communication

To AutomationDirect PLCs via RS232

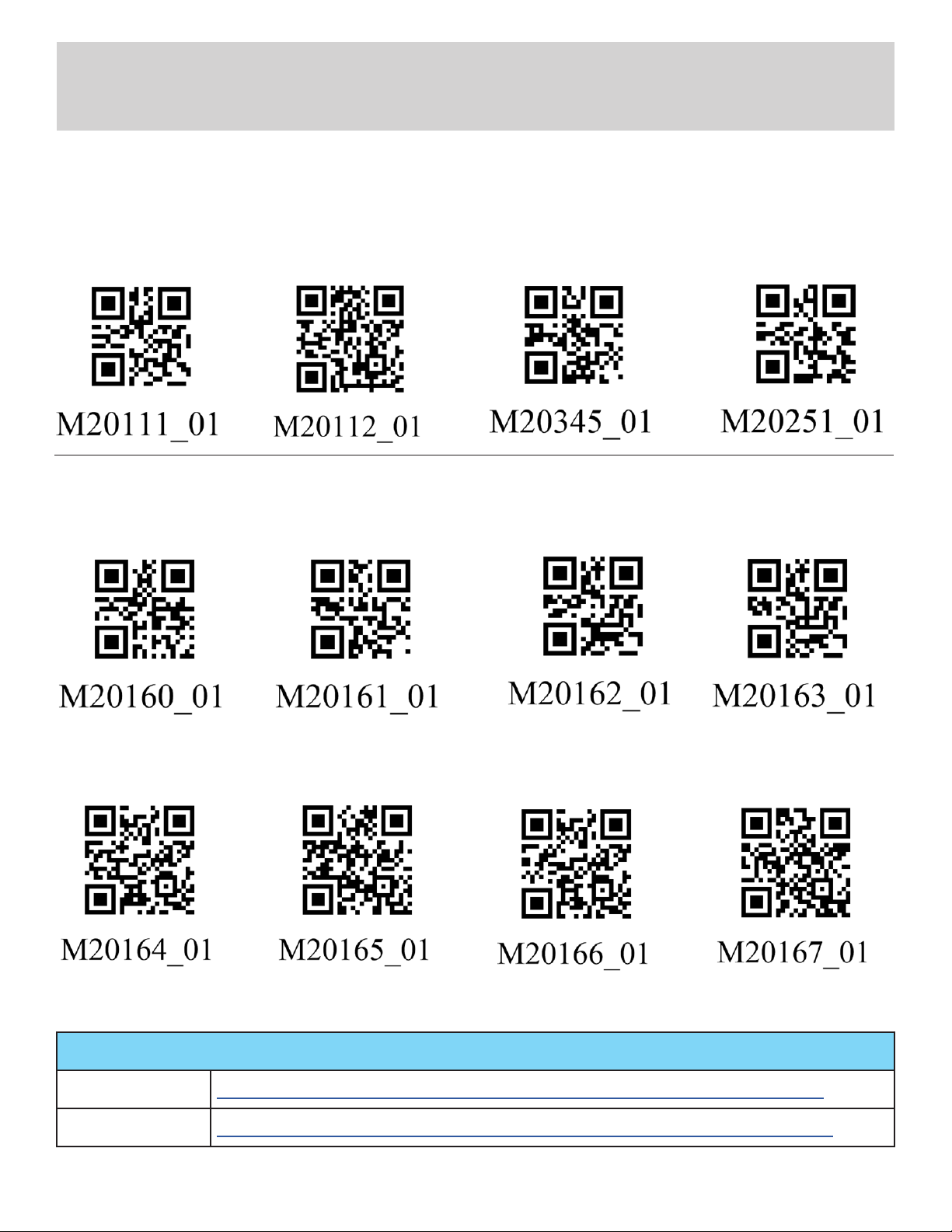

To allow the Code barcode readers to communicate to the AutomationDirect PLCs, you must rst set

up the scanner. With the scanner powered up, scan the column of code that correlates with the reader’s part number.

User will need to select the baud rate, number of data bits, parity, and stop bits and set up RS232

connection through the selected PLC software.

USB Connections (CRA-500-C298, CRA-C508-C298)

RS232 Connections (CRA-501-C298, CRA-C502-C298)

5VDC

TX

RX

0VDC

DB9 to RJ12 (CRA-519-C298)

Code Handheld Scanner Supplemental Programming Manual - 1

Page 2

CR950/CR1100 Configuration Codes

Conguration changes will take effect immediately and be saved to memory

Reset and Reboot

Note: When a Factory Reset is performed, a Reboot will be necessary.

Factory Reset Reboot Reader

1A

Baud Rate

RS232 Interface

2A

1200 Baud Rate

Reset to RS232

1B

Factory Defaults

RS232 Interface

2B

2400 Baud Rate

1C 1D

2C 2D

RS232 Interface

4800 Baud Rate

Enable RS232

Serial Mode

(Default)

RS232 Interface

9600 Baud Rate

RS232 Interface

3A

19200 Baud Rate

Additional conguration codes can be found in the conguration guides as follows:

CR950 https://www.automationdirect.com/pn/doc/manual/CR950-K301-C298

CR1100 https://www.automationdirect.com/pn/doc/manual/CR1100-K201-C298

Code Handheld Scanner Supplemental Programming Manual - 2

RS232 Interface

3B

38400 Baud Rate

3C 3D

RS232 Interface

57600 Baud Rate

RS232 Interface

115200 Baud Rate

(Default)

Page 3

CR950/CR1100 Configuration Codes (continued)

Conguration changes will take effect immediately and be saved to memory

Data Bits

RS232 Interface

4A

7 Data Bits

Parity

RS232 Interface

5A

Even Parity

RS232 Interface

4B

8 Data Bits

(Default)

RS232 Interface

5B

No Parity

Stop Bit

RS232 Interface

4C

1 Stop Bit

(Default)

RS232 Interface

5C

Odd Parity

RS232 Interface

4D

2 Stop Bit

Sufx

Sufx Carriage

6A

Return

(RS232 Mode Only)

Additional conguration codes can be found in the conguration guides as follows:

CR950 https://www.automationdirect.com/pn/doc/manual/CR950-K301-C298

CR1100 https://www.automationdirect.com/pn/doc/manual/CR1100-K201-C298

Code Handheld Scanner Supplemental Programming Manual - 3

Sufx Carriage Return

6B

Line Feed

(RS232 Mode Only)

(Default)

Sufx Line Feed

6C

(RS232 Mode Only)

Erase Sufx Data

6C

Page 4

CR6022 Series Configuration Codes

Conguration changes will take effect immediately and be saved to memory

Reset and Reboot

Reset to RS232

7A

Factory Defaults

Baud Rate

RS232 Interface

8A

1200 Baud Rate

Reset to USB

7B

Factory Defaults

RS232 Interface

8B

2400 Baud Rate

Reboot Reader

7C

RS232 Interface

8C

4800 Baud Rate

Note: When a

Factory Reset is

performed, a Reboot

will be necessary.

RS232 Interface

8D

9600 Baud Rate

RS232 Interface

9A

19200 Baud Rate

Additional conguration codes can be found in the conguration guide as follows:

CR6022 https://www.automationdirect.com/pn/doc/manual/CR6022-C500-C298

Code Handheld Scanner Supplemental Programming Manual - 4

RS232 Interface

9B

38400 Baud Rate

RS232 Interface

9C

57600 Baud Rate

RS232 Interface

9D

115200 Baud Rate

(Default)

Page 5

CR6022 Series Configuration Codes (continued)

Conguration changes will take effect immediately and be saved to memory

Data Bits

RS232 Interface

10A

7 Data Bits

Parity

RS232 Interface

11A

Even Parity

RS232 Interface

10B

8 Data Bits

(Default)

11B

RS232 Interface

Odd Parity

Stop Bit

RS232 Interface

10C

11C

Stop Bit 1

(Default)

RS232 Interface

No Parity

(Default)

RS232 Interface

10D

Stop Bit 2

Sufx

Sufx Carriage Return

12A

(RS232 Mode Only)

Additional conguration codes can be found in the conguration guide as follows:

CR6022 https://www.automationdirect.com/pn/doc/manual/CR6022-C500-C298

12B

Code Handheld Scanner Supplemental Programming Manual - 5

Sufx Carriage Return

Line Feed

(RS232 Mode Only)

Sufx Line Feed

12C

(RS232 Mode Only)

Erase Sufx Data

12D

(Default)

Page 6

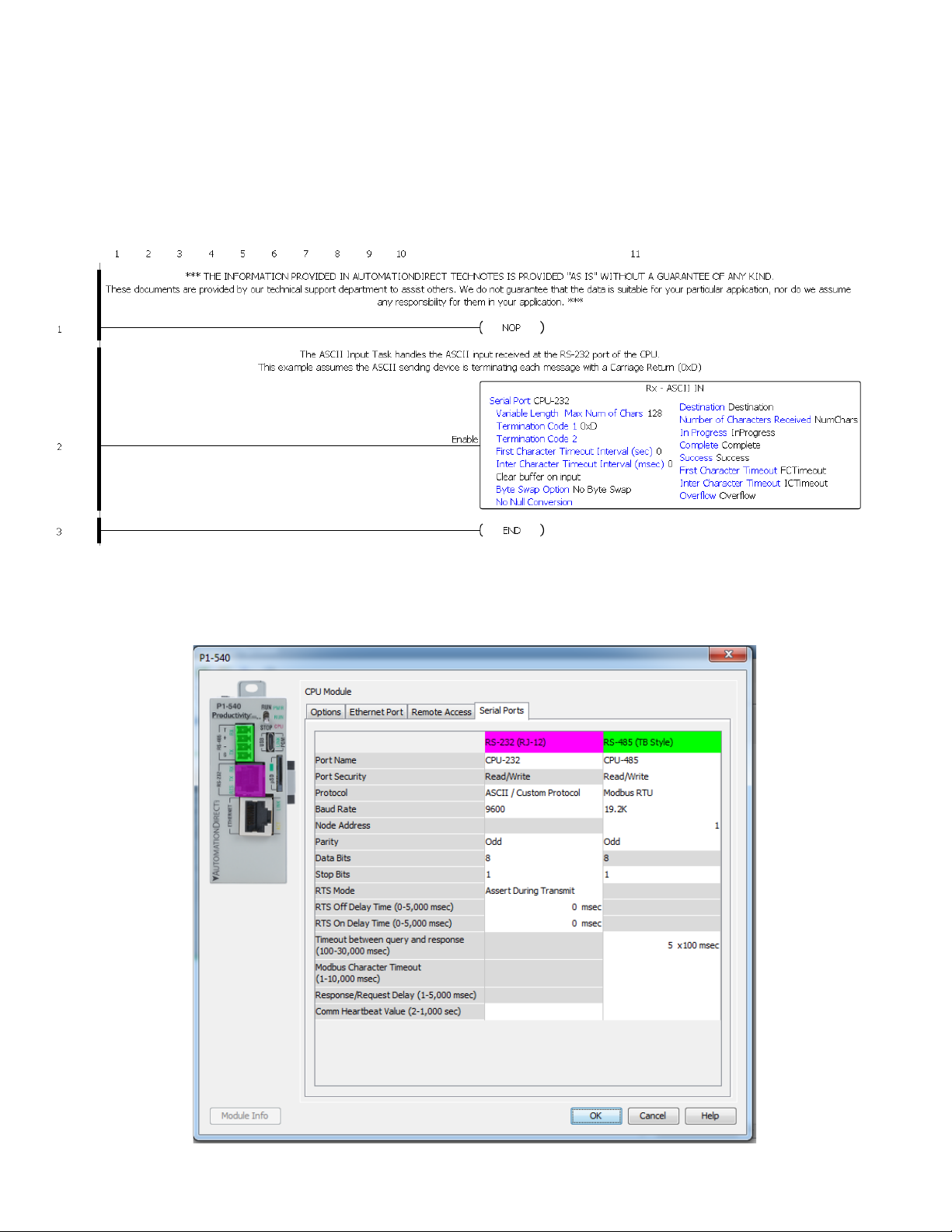

Productivity PLC Example

The Productivity PLC ASCII Input Task handles the ASCII input received at the RS-232 port of the

CPU. This example assumes the ASCII sending device is terminating each message with a carriage

return (0xD)

The Serial Port needs to be set up. This example assumes Baud Rate = 9600, Parity = Odd,

Data Bits = 8, and Stop Bits = 1, but any conguration can work.

Code Handheld Scanner Supplemental Programming Manual - 6

Page 7

CLICK Example

The CLICK programming example is a three-step process that (1) receives the data from the scanner

and (2) places that data in holding register before (3) moving it to the nal register.

Main Program

The EnableReceive bit is triggered automatically with the First Scan and during the

"CycleReceiveEnable" subroutine. Therefore, after each successful read of the incoming ASCII string,

the EnableReceive bit will be reset and set again, allowing the RECEIVE instruction to be re-enabled

for the next incoming string.

In order to keep shorter strings from inheriting residual characters from previous strings of a longer

length, TXT130 through TXT257 (128 bytes) are temporary holding registers for the incoming ASCII

string and will be cleared once the data has been moved from TXT130 (128 bytes) to TXT1 (128

bytes.)

Code Handheld Scanner Supplemental Programming Manual - 7

Page 8

CLICK Example (continued)

Subroutine Programs

"FirstScan" – This subroutine is called upon rst scan (SC2). It initializes (clears) registers and SETS

the “EnableReceive” bit that enables the RECEIVE instruction. The RECEIVE instruction is located in

the main program.

Code Handheld Scanner Supplemental Programming Manual - 8

Page 9

CLICK Example (continued)

"ASCII_RxSuccess" – This subroutine is called after success of the RECEIVE instruction below.

Move ASCII data from the 128 bytes of temporary registers (TXT130-257) to TXT1-128.

Fill the 128 bytes of temporary registers (TXT130-257) with the null from TXT129.

The RECEIVE instruction needs to see a transition from OFF to ON in order to be re-enabled. So

RESET the "Success" bit and the "EnableReceive" bit, and SET the "Cycle" bit that will trigger a

subroutine to SET the "EnableReceive" bit once again.

Move the "Port2 Data Length" from the system data register, SD50, to user register "CharReceived."

Code Handheld Scanner Supplemental Programming Manual - 9

Page 10

CLICK Example (continued)

"CycleReceiveEnable" – After the "ASCII_RxSuccess" subroutine, the "EnableReceive" bit is

RESET. The "CycleReceiveEnable" subroutine SETS the bit once again, allowing the OFF to ON

transition the RECEIVE instruction requires to execute again.

"ErrorHandling" – This subroutine is placed here for the user to write code to handle any errors

encountered from the RECEIVE instruction (First Character Timeout, Character Interval Timeout, and

Overow.)

Below are the bits that are used in the code shown above:

Code Handheld Scanner Supplemental Programming Manual - 10

Page 11

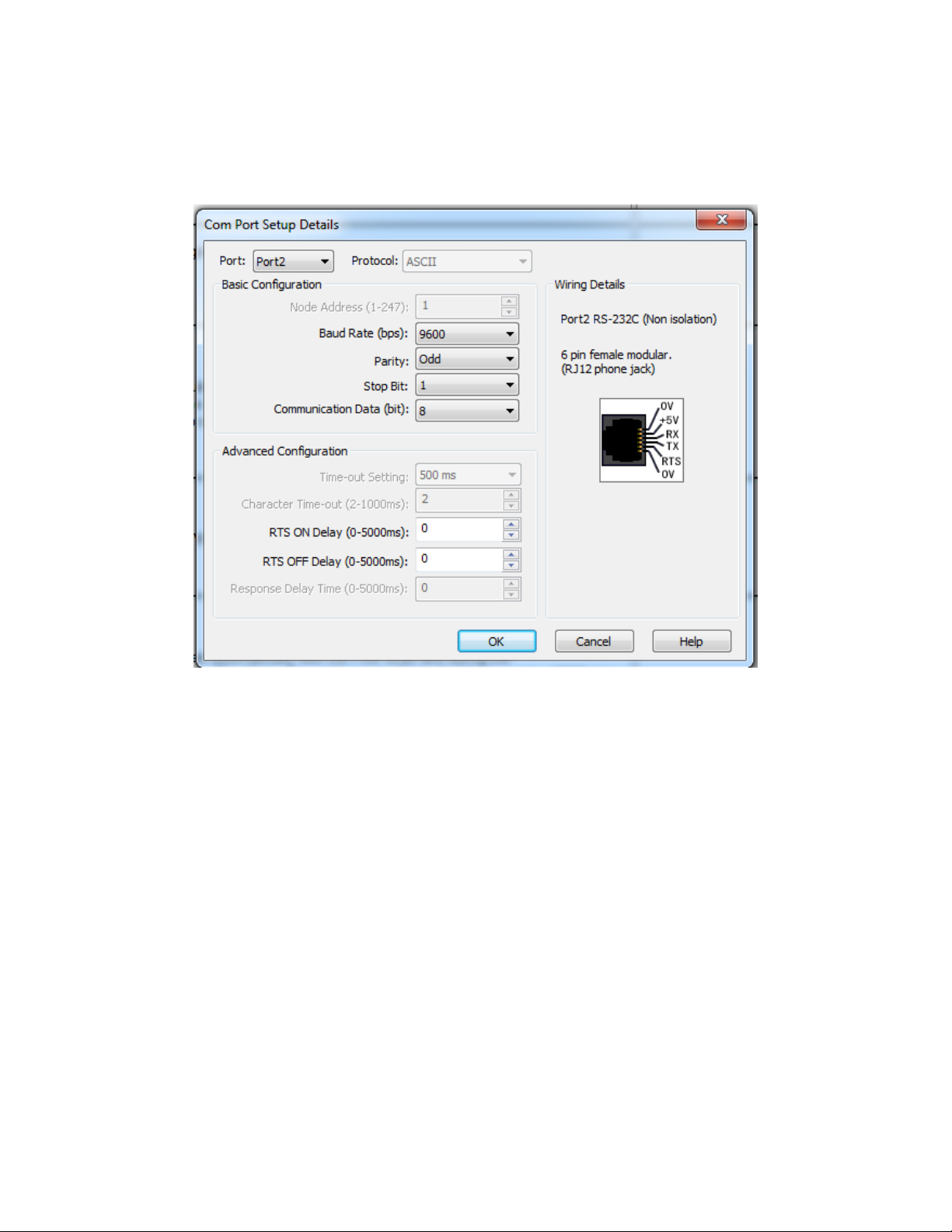

CLICK Example (continued)

The Com Port needs to be set up. This example assumes Baud Rate = 9600, Parity = Odd,

Data Bits = 8, and Stop Bits = 1, but any conguration can work.

Code Handheld Scanner Supplemental Programming Manual - 11

Page 12

BRX Example

Main Program

The ASCII Input program (Pgm_ASCII_Input) handles the internal serial input. On rst scan RUN this

program.

Pgm_ ASCII_Input

Upon initially running the program, CLEAR the internal serial port. This will delete any data in the Input

Queue data storage, as well as reset the .InQueue value.

IF the character count at the internal Serial buffer (IntSerial.InQueue) is greater than zero, THEN

execute the STREAMIN Instruction and populate SL0 (sInputString) element

This stage serves two purposes:

1) It allows the user to write any code required for parsing the input string and placing the parsed

content to other memory elements

2) Once the stage is complete, a jump is executed back to stage 1, allowing for a new evaluation of

the IntSerial.InQueue value.

Code Handheld Scanner Supplemental Programming Manual - 12

Continued...

Page 13

BRX Example (continued)

This stage is placed here for the user to write any required code for handling any errors encountered

during the execution of this program.

The Serial Port needs to be set up. This example assumes Baud Rate = 9600, Parity = Odd,

Data Bits = 8, and Stop Bits = 1, but any conguration can work.

Code Handheld Scanner Supplemental Programming Manual - 13

Page 14

DirectLogic Example

The ASCII input (AIN) instruction is used to receive the ASCII data through port 2 of the DL06 PLC.

This example is using the termination code 0xD. Ensure that the barcode scanner is set up to send

the termination code.

AIN instruction setup

Secondary COM port setup

Code Handheld Scanner Supplemental Programming Manual - 14

Page 15

DirectLogic Example (continued)

Components used:

• PLC: D0-06AR (using serial port 2)

• ZL-CMA15L (connected to port 2 of the D0-06AR)

• ZL-RTB-RJ12 (the RJ12 cable from the barcode reader connects here and is then wired to the ZL-

CMA15L)

Code Handheld Scanner Supplemental Programming Manual - 15

Page 16

C-more HMI Examples for CR950/CR1100 Series

Compatibility

Scanner C-more EA7* C-more EA9

CR950-K301-C298

CR1100-K201-C298

* Please note that the C-more EA7 is no longer in active production.

Yes Yes

Yes Yes

There are two ways to get the CR950/CR1100 to communicate with the C-more HMI

1. Enable Alternate Operating System (EA9 only) 2. Declare Enumeration (EA7 or EA9)

Alternate Operating System ON. Alternate Operating system OFF.

Declare Enumeration when addressed.

In all of the above examples, depending on the application, it may become necessary to add

an Enter to the sufx by scanning the following:

Sufx Enter (USB keyboard only)

Erase Sufx Data

Additional conguration codes can be found in the conguration guides as follows:

CR950 https://www.automationdirect.com/pn/doc/manual/CR950-K301-C298

CR1100 https://www.automationdirect.com/pn/doc/manual/CR1100-K201-C298

Code Handheld Scanner Supplemental Programming Manual - 16

Page 17

C-more HMI Examples for CR6022 Series

Compatibility

Scanner C-more EA7* C-more EA9

CR6022-C500-C298

* Please note that the C-more EA7 is no longer in active production.

Yes No

There are three ways to get the CR6022 to communicate with the EA7 HMI

1. Alternate Operating System ON.

Alternate Operating System OFF.

2. Declare Enumeration after the Get

Report descriptor.

3. Declare Enumeration after Set

Conguration.

In all of the above examples, depending on the application, it may become necessary to add

an Enter to the sufx by scanning the following:

Sufx Enter (USB keyboard only)

Erase Sufx Data (Default)

Additional conguration codes can be found in the conguration guide as follows:

CR6022 https://www.automationdirect.com/pn/doc/manual/CR6022-C500-C298

Code Handheld Scanner Supplemental Programming Manual - 17

Loading...

Loading...