Page 1

RHINO Installation Instructions for PSS0524-100 Power Supply

READ INSTRUCTIONS BEFORE INSTALLING OR OPERATING THIS DEVICE. KEEP FOR FUTURE REFERENCE.

1. Safety instructions

• To ensure sufficient convection cooling, always maintain a safety distance of M 20 mm (0.79 in) from all

ventilated surfaces while the device is in operation.

• The device is not recommended to be placed on low thermal conductive surface, for example, plastics.

• Note that the enclosure of the device can become very hot depending on the ambient temperature and load

of the power supply. Do not touch the device while it is in operation or immediately after power is turned OFF.

Risk of burning.

• Do not touch the terminals while power is being supplied. Risk of electric shock.

• Prevent any foreign metal, particles or conductors from entering the device through the openings during installation. It can cause electric shock, safety hazard, fire, and/or product failure.

• Warning: When connecting the device, secure GND connection before connecting L and N. When

disconnecting the device, remove the L and N connections before removing the GND connection.

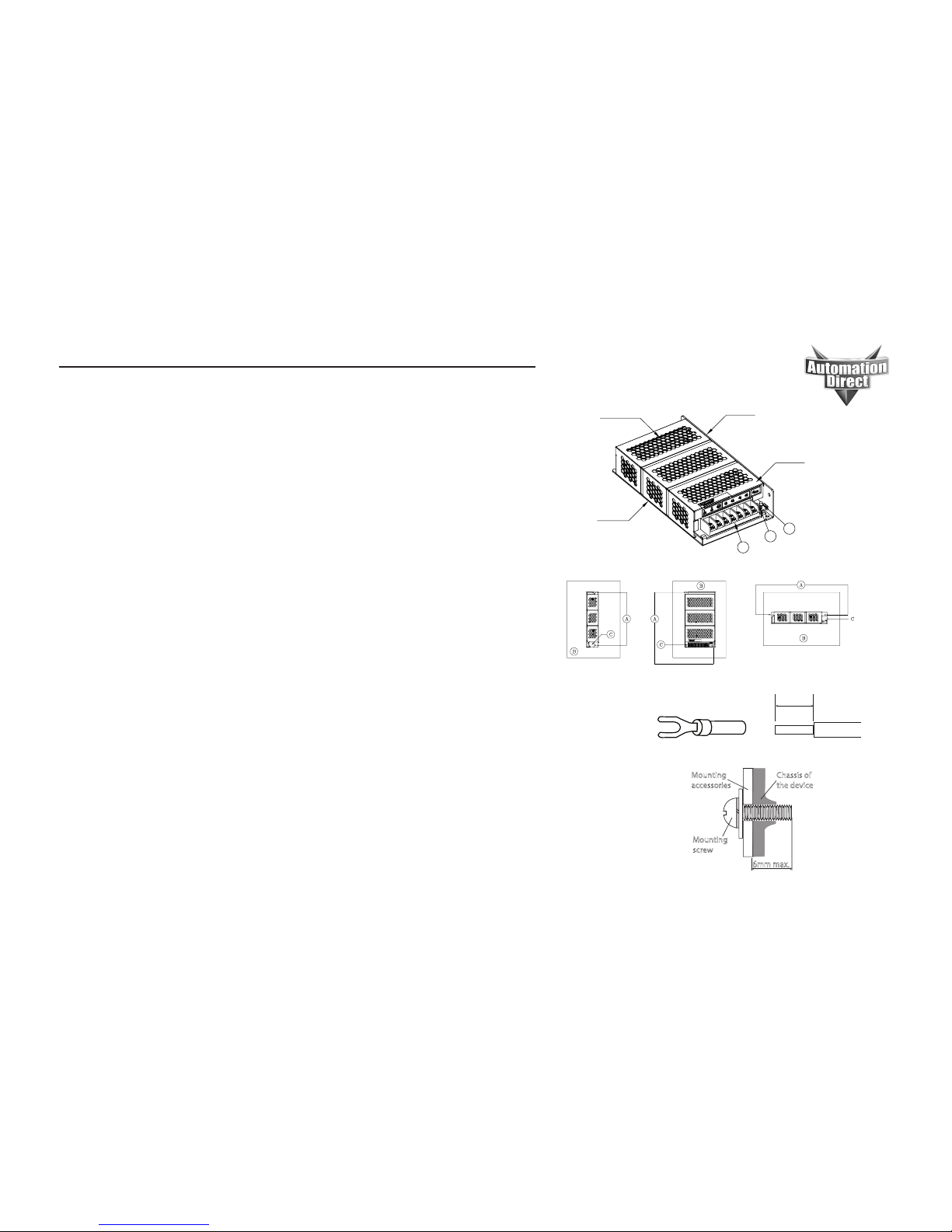

2. Device description (Fig. 1)

(1) Input & Output terminal block connector (V1: 24VDC, V2: 5VDC)

(2) DC voltage adjustment potentiometer for V1: 24VDC

(3) DC OK indicatorLED (green)

3. Connection (Fig. 1)

The terminal block connector allows easy and fast wiring.

4. Mounting (Fig. 2)

A. Mounting holes for power supply assembly onto the mounting surface. Power supply shall be mounted on

minimum 2 mounting holes using M3 x 0.5 screw minimum 5 mm (0.19 in) length.

B. This surface belongs to customer’s system or panel where the power supply is mounted.

C. Connector:

Use flexible (stranded wire) or solid wire 22–12 AWG. The torque at the connector shall not

exceed 1.3 Nm (11.3 in-lb). The insulation stripping length should not exceed 0.28 in or 7 mm.

Fork terminal recommended for stranded wire. Refer to figure 3.

5. Installation of Mounting Accessories (Fig. 4)

• Only use M3 screw m 6 mm through the base mounting holes. This is to keep a safety distance between the

screw and internal compontents.

• Refer to Figure 4: Recommended mounting tightening torque: 0.4 to 0.8 Nm (3.5 to 7 in-lb).

FOR TECHNICAL ASSISTANCE CALL 770-844-4200

1

2

3

Top surface

Side surface

Ventilated surface

Base surface

Figure 1 - Device Descriptions

Figure 2 - Mounting

7mm

[0.28in]

Figure 3 - Wire Type

AutomationDirect

P/N V70GK004003 (22-18AWG)

V70GK004008 (16-14AWG)

V70GK004003 (12AWG)

or equivalent

Mounting

accessories

Chassis of

the device

Mounting

screw

6mm max.

Figure 4 - Mounting Screw

Side Mounting (Vertical) Base Mounting (Vertical) Side Mounting (Horizontal)

Page 2

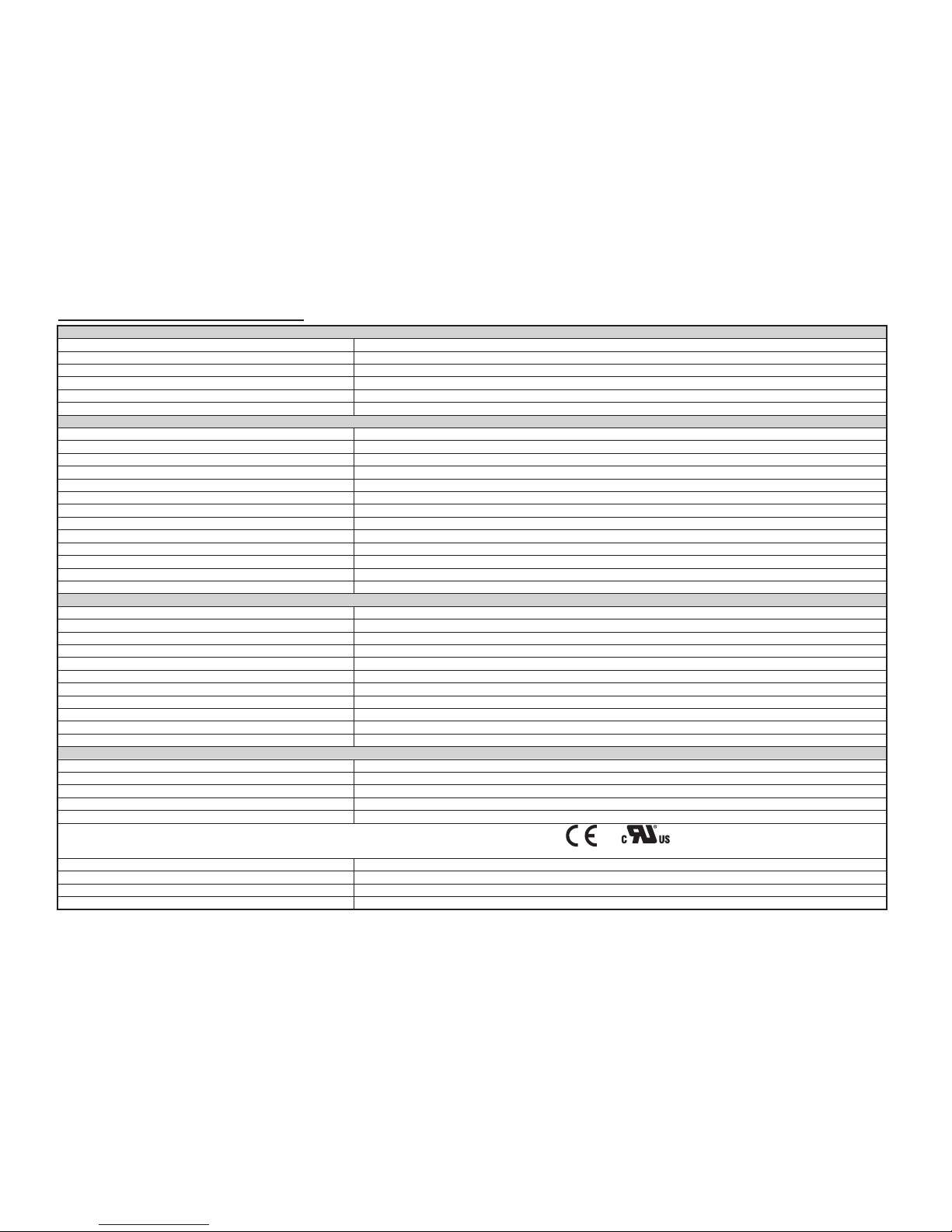

Technical Data For PSS0524-100

All parameters are specified at 25°C (77°F)

* Operating to 70 °C (158°F) possible with a linear derating to half power from 50°C to 70°C (122°F to 158°F)

Input (AC)

Nominal input voltage 100-240 VAC / 125-250 VDC

Voltage range 85-264 VAC (DC input range 125-375 VDC)

Frequency 47-63 Hz (0 Hz @ DC input)

Nominal current 2.0A max. @ 115 VAC, 1.1A max. @ 230 VAC

Inrush current limitation. I2t (+25 °C) typ. < 50A @ 115 VAC, < 100A @ 230 VAC

Leakage current < 1 mA @ 240 VAC

Output (DC)

Nominal output voltage / adjustment range V1: 24 VDC / 22.8-26.4 VDC; V2: 5 VDC / fixed

Output Voltage Tolerance V1: +/- 2% (initial setpoint tolerance from factory); V2: fixed

Output power* 100W

Output current V1: 0.3-4.0 Amp; V2: 0.8-7.0 Amp (each output can work within the current range, but ensure that the total output power does not exceed 100W)

PARD (ripple and noise) (20MHz) V1: <200mVpp; V2: <80mVpp (each measured with AC coupling mode, and in parallel with 0.1uF ceramic capacitor and 47uF electrolytic capacitor.)

Start-up time <1000ms@100% load and typical line input

Hold-up time > 15ms @ 115VAC, >80ms @ 230VAC with 100% load

Rise time V1: <30ms; V2: <20ms @100% load

Dynamic response (overshoot and undershoot O/P voltage) +/-5%@V1: 0-100% rated load and V2: 60%rated load and vice versa (Slew rate: 0.1A/uS)

Start-up with capacitive loads V1: 4000uF max

Efficiency > 84% @ 115 VAC & > 86% @ 230 VAC

Line regulation < 0.5% typical (@ 85-264VAC input)

Load regulation <1% typical (@85 to 264 VAC input, V1: 20-100% rated load and V2: 60% rated load and vice versa)

General Data

Type of housing Aluminum

Dimensions (L x W x H) 178 mm x 97 mm x 38 mm (7.0 in x 3.82 in x 1.50 in)

Weight 0.52 kg (1.15 lb)

MTBF > 700,000 hrs.

Connection method Screw connection

Noise Sound pressure level (SPL) < 40 dBA

Cooling Convection

Terminal input/output M3.5 x 7 Pins (Rated 300V/15A)

Wire size / torque 0.82-2.08 mm² (AWG 18-14) / 1.3 Nm (11.3 in-lb)

Shock test (non-operating) IEC60068-2-27, 30G (300m/S²) for a duration of 18ms 3 times per direction, 18 times in total

Vibration (non-operating) IEC60068-2-6, 10Hz to 150Hz @ 50m/S² (5G peak); 20 min per axis for all X, Y, Z direction

Safety / Environmental

EMC / Emissions FCC Title 47, Class B/EN55032;CISPR32, Class B

Immunity IEC61000-4-2; IEC61000-4-3; IEC61000-4-4; IEC61000-4-5; IEC61006-4-6; IEC61006-4-8; IEC61006-4-11; IEC61006-4-12

Voltage dips IEC61000-4-11 100% dip; 1 cycle (20ms); self recoverable

Galvanic isolation Input to Output : 3KVAC, Input to Ground : 1.5KVAC, Output to Ground : 0.5KVAC

Approvals UR/cUR recognized to UL60950-1 and CSA C22.2 No. 60950-1 (file no. E198298); CB test certificate and report to IEC60950-1, CE (EMC and Low Voltage directive)

E198298

RoHS Compliant Yes

Operating temperature -10 °C to +70 °C* (14°F to 158°F)

Storage temperature -25 °C to +85 °C (-13°F to 185°F)

Humidity < 95 % RH non-condensing

Loading...

Loading...