Page 1

RHINO Installation Instructions for PSD24-240-L Power Supply

-25

-20

-15

-10-50510152025303540455055606570

Surrounding Air Temperature

-13-4514233241505968778695

104

113

122

131

140

149

158

READ INSTRUCTIONS BEFORE INSTALLING OR OPERATING THIS DEVICE. KEEP FOR FUTURE REFERENCE.

(2)

(3)

(11)

(1)

(4)

(5)

(6)

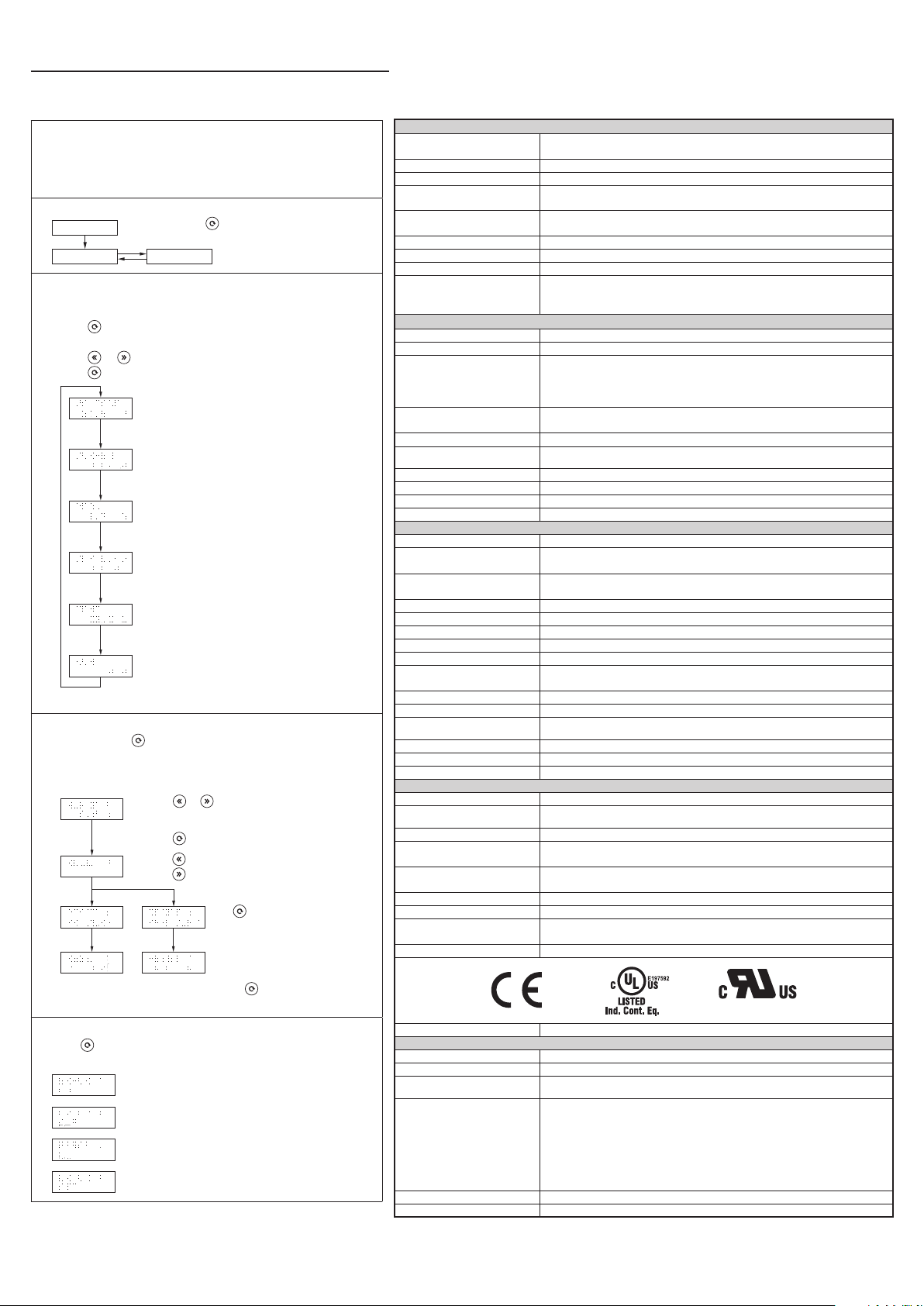

Figure 1

2

1

3

1

Figure 2 Figure 3

Normal mode OFF ON Closed

During Power Boost OFF ON Closed

Overload (V

Output short circuit Flashing OFF Open

Temperature shut down Flashing OFF Open

No input power OFF OFF Open

< 90%) Flashing OFF Open

out

Overload LED DC OK LED DC OK Contact

Figure 4

7mm

[0.28in]

1

Figure 5

TN-S

L N PE

TN-C

L

N

PE

L N PE

L

PEN

++

TT

L N PE

Figure 6

110

100

90

80

70

60

50

40

30

20

Percentage of Max Load (%)

10

0

Power Derating Curve for PSU

Surrounding Air Temperature

Vertical Mounting Horizontal Mounting

Figure 7

(8)

(10)

(9)

1. Safety instructions

• An easily accessible disconnecting device shall be provided to disconnect the unit from the mains supply for

servicing.

• Switch main power off before connecting or disconnecting the device. Risk of explosion!

(7)

• If the unit is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

• To guarantee sufficient convection cooling, please refer to the following instructions to ensure sufficient clearance

around the device.

Vertical Mounting: 40 mm [1.57 in] above and 20 mm [0.79 in] below the device as well as a lateral distance of

5 mm [0.20 in] to other units. In case the adjacent device is a heat source, the lateral distance will be 15 mm [0.59 in].

Horizontal Mounting: 40 mm [1.57 in] above and below the device as well as a lateral distance of 20 mm [0.79 in] to

other units.

• The external enclosure where the unit will be installed shall meet the requirements for mechanical, electrical and

fire enclosure.

• Note that the enclosure of the device can become very hot depending on the ambient temperature and load of the

power supply. Risk of burns!

• The main power must be turned off before connecting or disconnecting wires to the terminals!

• Do not introduce any objects into the unit!

• Dangerous voltage present for at least 5 minutes after disconnecting all sources of power.

• The power supplies are built in units and must be installed in a cabinet or room (condensation free environment

2

3

and indoor location) that is relatively free of conductive contaminants.

• CAUTION: “For use in a controlled environment”.

2. Device description (Fig. 1)

(1) Input terminal block connector

(2) Output terminal block connector

(3) Alarm signal terminal block connector

(4) DC voltage adjustment potentiometer

(5) DC OK LED (green)

(7) LCD display

(8) Back key

(9) Forward key

(10) Mode key

(11) 35mm DIN rail mounting (DIN rail sold separately)

(6) Overload LED (red)

3. Mounting and dismounting (Fig. 2, Fig. 3)

The power supply unit can be mounted on 35 mm DIN rails in accordance with EN60715. For Vertical Mounting, the

device should be installed with input terminal block on the bottom. For Horizontal Mounting, the device should be

installed with input terminal block on the left side.

Each device is delivered ready to install.

1. Tilt the unit slightly upwards and put it onto the DIN rail. Snap on the DIN rail as shown in Fig. 2.

2. Push downwards until stopped.

3. Press against the bottom front side for locking.

4. Shake the unit slightly to ensure that it is secured.

5. To uninstall, pull or slide down the latch as shown in Fig. 3. Then, slide the PSU in the opposite direction, release

the latch and pull out the PSU from the rail.

4. Connection

The terminal block connectors allow easy and fast wiring.

You can use flexible (stranded wire) or solid cables with the following cross sections:

Table 1

Refer to Fig. 1:

Standard / Solid Torque

(mm²) (AWG) (Nm) (lb in)

(1) 0.82-8.4 18-8 0.91 8.1

(2) 1.3-3.3 16-12 0.61 5.4

2

(3) 0.52-1.3 (solid cable) 20-16 (solid cable) - -

To secure reliable and shock proof connections, the stripping length should be 7 mm [0.28 in] (see Fig. 5 (1)). Please

ensure that wires are fully inserted into the connecting terminals as shown in Fig. 5 (2). All wire strands must be

fully inserted into the terminals with the screws securely fastened in order to ensure safety and maximum contact.

In accordance to EN 60950 / UL 60950, flexible wires require ferrules.

Use appropriate copper wire that is designed to sustain operating temperature of :

1. At least 60°C / 75°C (140°F / 167°F) for USA.

2. At least 90°C (194°F) for Canada and IEC/EN61010-1, IEC/EN61010-2-201.

4.1. Input connection (Fig. 1, Fig. 6)

L N PE

iT

L

N

+

L

N

+

For AC input connections, use L, N and PE connections on the input terminal connector (see Fig. 1 (1)) to establish

the 100-240 VAC connection. Fig. 6 shows the connection to the various network types.

For DC input connections, connect L pin to + from DC source and connect N pin to − from DC source.

The unit is protected with internal fuse (not replaceable) at L pin and it has been tested and approved on 20A (UL)

and 16A (IEC) branch circuits without additional protection device. An external protection device is only required

if the supplying branch has an ampacity greater than above. Thus, if an external protective device is necessary, or,

utilized, a minimum value of 6A B- or 4A C- characteristic breaker should be used.

The internal fuse must not be replaced by the user.

4.2. Output Connection (Fig. 1 (2))

Use the “+” and “-” screw connections to establish the 24 VDC connection. The output provides 24 VDC. The output

voltage can be adjusted from 24 to 28 VDC on the potentiometer. The green LED DC OK displays correct function of

the output (Fig. 1 (5)). The device has a short circuit and overload protection and an overvoltage protection limited

to 35 VDC.

4.3. Output characteristic curve

The device functions normal under operating line and load conditions. In the event of an over load (IO > 150%) the

output voltage will start to droop and bounce until over load has been removed.

4.4. Indicators and relay contacts (Fig. 4)

4.5. Thermal behavior (Fig. 7)

(oC)

(oF)

If the output capacity is beyond what is recommended in Fig. 7, the device will run into thermal protection by

switching off i.e. device will go in bouncing mode and will recover when ambient temperature is lowered or load is

reduced as far as necessary to keep device in working condition.

FOR TECHNICAL ASSISTANCE CALL 770-844-4200

Page 2

Technical Data For PSD24-240-L

■

What is the “Lifetime Expectancy Function”?

The lifetime expectancy function indicates an approximate period

of life left for the power supply unit, based on deterioration of the

electrolytic capacitor. It does not predict failures caused by other

reasons.

■

Mode Change

Power ON

Display Mode Setting Mode

■

Display Mode

Press and hold (mode key) for 5 seconds or more to

change the mode.

By default, the power supply unit is set to auto display mode and will

show the status in the following sequence below.

• Press (mode key) to freeze the current indicated status on the

LCD display.

• Press or (back or forward key) to move between each status.

• Press (mode key) to return to auto display mode.

Output voltage

Values will show up to 2 decimal places (accuracy of output

voltage indication is ±2%).

Output current

Values will show up to 2 decimal places (accuracy of output

current indication is ±5%).*

Peak hold current

Values will show up to 2 decimal places (accuracy of peak

hold current indication is ±5%).* The minimum signal width

required for hold current is 20 ms.

Lifetime expectancy

Values will show up to 1 decimal place. The lifetime

expectancy is calculated by the amount of deterioration of

the electrolytic capacitor according to the running hours and

inside ambient temperature.

Ambient temperature

This is ambient temperature inside the power supply unit.

Monitored readings will be displayed about 30 seconds after it

is turned on. Values will show up to 1 decimal place.

KWH

Values will show up to 1 decimal place. The KWH is calculated

based on the running hours and output power.

*If Io < 5%, accuracy is ±10%.

■

Setting Mode

• Press and hold (mode key) for 5 seconds or more to change from

“Display Mode” to “Setting Mode”.

• The power supply unit will show the items in the following sequence

below.

• Press or (back or forward key) to increase or

decrease the alarm setting.

Factory setting is 10.0 years and minimum setting is 0.5 years.

• Press (mode key) to go to “Reset”.

• Press (back key) to reset peak hold current.

• Press (forward key) to reset KWH.

Press (mode key) to confirm and clear

peak hold current or KWH value.

Input (AC)

Nominal input voltage / frequency

Voltage range 85-276 VAC (DC input range 88-375 VDC)

Frequency 47-63Hz

Nominal current

Inrush current limitation

(+25°C, cold start)

Mains buffering at nominal load (typ.) 27 ms typ. @ 120 VAC, 28 ms typ. @ 230 VAC

Turn-on time < 650 ms @ 120 VAC, > 340 ms @ 230 VAC

Internal fuse T 6.3 A / 500 VAC or 400 VDC min.

Leakage current

TN/TT-system / IT-system: < 0.29 mA / 0.82 mA @ 110 VAC, 50Hz

TN/TT-system / IT-system: < 0.38 mA / 1.02 mA @ 132 VAC, 50Hz

TN/TT-system / IT-system: < 0.74 mA / 2.25 mA @ 264 VAC, 50Hz

100-240 VAC / 50-60Hz; or

110-300 VDC (for ITE only)

< 2.65 A @ 100 VAC, < 1.22 A @ 230 VAC

< 2.37 A @ 110 VDC, < 0.85 A @ 300 VDC

6 A typ. @ 120 VAC, 7 A typ. @ 230 VAC

Output (DC)

Nominal output voltage U

Adjustment range of the voltage 24-28 VDC

Nominal current

Derating

Startup with capacitive loads 10,000 µF typ.

Max. power dissipation idling / nominal

load approx.

Efficiency 92.6% typ. @ 120 VAC, 93.5% typ. @ 230 VAC

PARD (20MHz) at 100% load < 50 mVpp

Max. relay contact rating 30V (SELV) / 1 A resistive load

Parallel operation PSB60-REM20S / PSB60-REM40S

N

> 60°C [140°F] (2.5% / °C) in Vertical

> 50°C [122°F] (2.5% / °C) in Horizontal

General Data

Type of housing Aluminum

Signals

MTBF

Dimensions (L x W x H) 124 mm x 60 mm x 139 mm [4.88 in x 2.36 in x 5.47 in]

Weight 1.02 kg [2.25 lb]

Connection method Screw connection

Wire size / torque See Table 1

Stripping length 7 mm [0.28 in]

Operating temperature

(surrounding air temperature)

Storage temperature -40°C to +85°C [-40°F to 185°F]

Humidity at +25°C, no condensation 5 to 95% RH

Vibration (non-operating)

Shock (non-operating, in all directions) 30G (300m/S²) in all directions according to IEC60068-2-27

Pollution degree 2

Altitude (operating) 5000m

10 to 500Hz @ 30m/S² (3G peak); displacement of 0.35mm; 60 min. per axis for all X, Y, Z directions

> 1,268,000 hrs. as per Telcordia SR-332

(I/P: 100 VAC; O/P: 24V, 10 A; Ta: 25°C)

-25°C to +70°C [-13°F to 158°F] (Refer to Fig. 7)

Certification and Standards

Electrical equipment of machines IEC60204-1 (over voltage category III)

Electronic equipment for use in electrical

power installations

Safety entry low voltage PELV (EN 60204-1), SELV (EN 60950-1)

Electrical safety (of information

technology equipment)

Industrial control equipment

CE In conformance with EMC directive 2014/30/EU and low voltage directive 2014/35/EU

Component power supply for general use EN61204-3

Immunity

Emission EN55032, EN55011, EN61000-3-2 Class A, EN61000-3-3, EN61000-6-3

UL/C-UL recognized to UL60950-1 and CSA C22.2 No. 60950-1 (File No. E198298),

CB scheme to IEC 60950-1, IEC 61010-1, IEC 61010-2-201

UL/C-UL listed to UL508 and CSA C22.2 No. 107.1-01 (File No. E197592),

CSA to CSA C22.2 No. 107.1-01 (File No. 249074)

(EN61000-4-2, 3, 4, 5, 6, 8, 11, 12)

24 VDC

10 A (Vout = 24 VDC)

8.57 A (Vout = 28 VDC)

15 A (for 5 s, Vout = 24 VDC)

13.5 A (for 5 s, Vout = 28 VDC)

6.1W / 16.7W

Green LED DC OK

Red LED Overload

in acc. with IEC60068-2-6

IEC/EN 62477-1 / IEC62103

EN 55024, EN 61000-6-2

Note: To return to auto display mode, press and hold (mode key) for 5 seconds or

more.

■

Failure Mode Display

Press (mode key) to clear error messages and return to auto display

mode.

When overvoltage protection occurs (Auto-recovery)

When overload/overcurrent protection occurs (Auto-recovery)

When short circuit protection occurs (Auto-recovery)

When over temperature protection occurs (Auto-recovery)

Rev. 00, 07/2020

E198298

RoHS Compliant Yes

Safety and Protection

Transient surge voltage protection VARISTOR

Current limitation at short-circuits approx. Isurge = 150 % of Pomax typically (continuous current)

Surge voltage protection against internal

surge voltages

Isolation voltage:

Input / Output

Input / PE

Input / DC OK*

Output / PE

Output / DC OK

DC OK / PE

Protection degree IP20

Safety class Class I with GND connection

*Recommend connecting DC OK pins to output pins.

Yes

3.00 kVAC

2.00 kVAC

3.00 kVAC

1.50 kVAC

0.50 kVAC

1.50 kVAC

Loading...

Loading...