Page 1

Manual Number: P1AM-USER-M

Page 2

~ WARNING ~

Thank you for purchasing automation equipment from Automationdirect.com®, doing business as,

AutomationDirect. We want your new automation equipment to operate safely. Anyone who installs or

uses this equipment should read this publication (and any other relevant publications) before installing or

operating the equipment.

To minimize the risk of potential safety problems, you should follow all applicable local and national

codes that regulate the installation and operation of your equipment. These codes vary from area to area

and usually change with time. It is your responsibility to determine which codes should be followed, and

to verify that the equipment, installation, and operation is in compliance with the latest revision of these

codes.

At a minimum, you should follow all applicable sections of the National Fire Code, National Electrical

Code, and the codes of the National Electrical Manufacturer’s Association (NEMA). There may be local

regulatory or government offices that can also help determine which codes and standards are necessary for

safe installation and operation.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable

codes and standards. We do not guarantee the products described in this publication are suitable for

your particular application, nor do we assume any responsibility for your product design, installation, or

operation.

Our products are not fault-tolerant and are not designed, manufactured or intended for use or resale as

on-line control equipment in hazardous environments requiring fail-safe performance, such as in the

operation of nuclear facilities, aircraft navigation or communication systems, air traffic control, direct life

support machines, or weapons systems, in which the failure of the product could lead directly to death,

personal injury, or severe physical or environmental damage (“High Risk Activities”). AutomationDirect

specifically disclaims any expressed or implied warranty of fitness for High Risk Activities.

For additional warranty and safety information, see the Terms and Conditions section of our catalog.

If you have any questions concerning the installation or operation of this equipment, or if you need

additional information, please call us at 770-844-4200.

This publication is based on information that was available at the time it was printed. At

AutomationDirect we constantly strive to improve our products and services, so we reserve the right to

make changes to the products and/or publications at any time without notice and without any obligation.

This publication may also discuss features that may not be available in certain revisions of the product.

Trademarks

This publication may contain references to products produced and/or offered by other companies. The

product and company names may be trademarked and are the sole property of their respective owners.

AutomationDirect disclaims any proprietary interest in the marks and names of others.

Copyright© 2020, Automationdirect.com® Incorporated

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior, written

consent of Automationdirect.com® Incorporated. AutomationDirect retains the exclusive rights to all

information included in this document.

All Rights Reserved

Page 3

~ ADVERTENCIA ~

Gracias por comprar equipo de automatización de Automationdirect.com®. Deseamos que su nuevo equipo

de automatización opere de manera segura. Cualquier persona que instale o use este equipo debe leer esta

publicación (y cualquier otra publicación pertinente) antes de instalar u operar el equipo.

Para reducir al mínimo el riesgo debido a problemas de seguridad, debe seguir todos los códigos de seguridad

locales o nacionales aplicables que regulan la instalación y operación de su equipo. Estos códigos varian de

área en área y usualmente cambian con el tiempo. Es su responsabilidad determinar cuales códigos deben ser

seguidos y verificar que el equipo, instalación y operación estén en cumplimiento con la revisión mas reciente

de estos códigos.

Como mínimo, debe seguir las secciones aplicables del Código Nacional de Incendio, Código Nacional Eléctrico,

y los códigos de (NEMA) la Asociación Nacional de Fabricantes Eléctricos de USA. Puede haber oficinas de

normas locales o del gobierno que pueden ayudar a determinar cuales códigos y normas son necesarios para una

instalación y operación segura.

Si no se siguen todos los códigos y normas aplicables, puede resultar en daños al equipo o lesiones serias a

personas. No garantizamos los productos descritos en esta publicación para ser adecuados para su aplicación

en particular, ni asumimos ninguna responsabilidad por el diseño de su producto, la instalación u operación.

Nuestros productos no son tolerantes a fallas y no han sido diseñados, fabricados o intencionados para uso

o reventa como equipo de control en línea en ambientes peligrosos que requieren una ejecución sin fallas,

tales como operación en instalaciones nucleares, sistemas de navegación aérea, o de comunicación, control de

tráfico aéreo, máquinas de soporte de vida o sistemas de armamentos en las cuales la falla del producto puede

resultar directamente en muerte, heridas personales, o daños físicos o ambientales severos (“Actividades de Alto

Riesgo”). Automationdirect.com específicamente rechaza cualquier garantía ya sea expresada o implicada

para actividades de alto riesgo.

Para información adicional acerca de garantía e información de seguridad, vea la sección de Términos

y Condiciones de nuestro catálogo. Si tiene alguna pregunta sobre instalación u operación de este equipo, o

si necesita información adicional, por favor llámenos al número 770-844-4200 en Estados Unidos.

Esta publicación está basada en la información disponible al momento de impresión. En Automationdirect.

com nos esforzamos constantemente para mejorar nuestros productos y servicios, así que nos reservamos el

derecho de hacer cambios al producto y/o a las publicaciones en cualquier momento sin notificación y sin

ninguna obligación. Esta publicación también puede discutir características que no estén disponibles en ciertas

revisiones del producto.

Marcas Registradas

Esta publicación puede contener referencias a productos producidos y/u ofrecidos por otras compañías. Los nombres de las

compañías y productos pueden tener marcas registradas y son propiedad única de sus respectivos dueños. Automationdirect.com,

renuncia cualquier interés propietario en las marcas y nombres de otros.

PROPIEDAD LITERARIA

No se permite copiar, reproducir, o transmitir de ninguna forma ninguna parte de este manual sin previo consentimiento por escrito

de Automationdirect.com

este documento. Los usuarios de este equipo pueden copiar este documento solamente para instalar, configurar y mantener el equipo

correspondiente. También las instituciones de enseñanza pueden usar este manual para propósitos educativos.

®

Incorprated. Automationdirect.com retiene los derechos exclusivos a toda la información incluida en

©

2020, AUTOMATIONDIRECT.COM® INCORPORATED

Todos los derechos reservados

Page 4

~ AVERTISSEMENT ~

Nous vous remercions d’avoir acheté l’équipement d’automatisation de Automationdirect.com®, en faisant des

affaires comme, AutomationDirect. Nous tenons à ce que votre nouvel équipement d’automatisation fonctionne en

toute sécurité. Toute personne qui installe ou utilise cet équipement doit lire la présente publication (et toutes les

autres publications pertinentes) avant de l’installer ou de l’utiliser.

Afin de réduire au minimum le risque d’éventuels problèmes de sécurité, vous devez respecter tous les codes locaux

et nationaux applicables régissant l’installation et le fonctionnement de votre équipement. Ces codes diffèrent d’une

région à l’autre et, habituellement, évoluent au fil du temps. Il vous incombe de déterminer les codes à respecter et

de vous assurer que l’équipement, l’installation et le fonctionnement sont conformes aux exigences de la version la

plus récente de ces codes.

Vous devez, à tout le moins, respecter toutes les sections applicables du Code national de prévention des incendies,

du Code national de l’électricité et des codes de la National Electrical Manufacturer’s Association (NEMA). Des

organismes de réglementation ou des services gouvernementaux locaux peuvent également vous aider à déterminer

les codes ainsi que les normes à respecter pour assurer une installation et un fonctionnement sûrs.

L’omission de respecter la totalité des codes et des normes applicables peut entraîner des dommages à l’équipement

ou causer de graves blessures au personnel. Nous ne garantissons pas que les produits décrits dans cette publication

conviennent à votre application particulière et nous n’assumons aucune responsabilité à l’égard de la conception, de

l’installation ou du fonctionnement de votre produit.

Nos produits ne sont pas insensibles aux défaillances et ne sont ni conçus ni fabriqués pour l’utilisation ou la revente

en tant qu’équipement de commande en ligne dans des environnements dangereux nécessitant une sécurité absolue,

par exemple, l’exploitation d’installations nucléaires, les systèmes de navigation aérienne ou de communication, le

contrôle de la circulation aérienne, les équipements de survie ou les systèmes d’armes, pour lesquels la défaillance du

produit peut provoquer la mort, des blessures corporelles ou de graves dommages matériels ou environnementaux

(«activités à risque élevé»). La société AutomationDirect nie toute garantie expresse ou implicite d’aptitude à

l’emploi en ce qui a trait aux activités à risque élevé.

Pour des renseignements additionnels touchant la garantie et la sécurité, veuillez consulter la section Modalités et

conditions de notre documentation. Si vous avez des questions au sujet de l’installation ou du fonctionnement de cet

équipement, ou encore si vous avez besoin de renseignements supplémentaires, n’hésitez pas à nous téléphoner au

770-844-4200.

Cette publication s’appuie sur l’information qui était disponible au moment de l’impression. À la société

AutomationDirect, nous nous efforçons constamment d’améliorer nos produits et services. C’est pourquoi nous

nous réservons le droit d’apporter des modifications aux produits ou aux publications en tout temps, sans préavis ni

quelque obligation que ce soit. La présente publication peut aussi porter sur des caractéristiques susceptibles de ne

pas être offertes dans certaines versions révisées du produit.

Marques de commerce

La présente publication peut contenir des références à des produits fabriqués ou offerts par d’autres entreprises. Les

désignations des produits et des entreprises peuvent être des marques de commerce et appartiennent exclusivement à

leurs propriétaires respectifs. AutomationDirect nie tout intérêt dans les autres marques et désignations.

Copyright© 2019, Automationdirect.com® Incorporated

Nulle partie de ce manuel ne doit être copiée, reproduite ou transmise de quelque façon que ce soit sans le

consentement préalable écrit de la société Automationdirect.com® Incorporated. AutomationDirect conserve les

droits exclusifs à l’égard de tous les renseignements contenus dans le présent document.

Tous droits réservés

Page 5

ProductivityOpen User Manual

Please include the Manual Number and the Manual Issue, both shown below,

when communicating with Technical Support regarding this publication.

Manual Number: P1AM-USER-M

Issue: 1st Edition, Rev. A

Issue Date: 02/2020

Publication History

Issue Date Description of Changes

1st Edition 01/2020 Original

1st Ed. Rev. A 02/2020 Added Appendix A - Networks Security material.

Page 6

Table of ConTenTs

Chapter 1 - Getting Started

Introduction .............................................................................................................. 1–2

Intended Use of This Product ..................................................................................1–2

Purpose of this Manual ..........................................................................................1–3

Important Online Resources .....................................................................................1–3

Conventions Used ...................................................................................................... 1–4

Key Topics for Each Chapter ..................................................................................... 1–4

Install Programming Software .................................................................................. 1–5

Mounting Hardware .................................................................................................. 1–8

Power the System ...................................................................................................... 1–9

Chapter 2 - Specifications

Overview ................................................................................................................... 2–2

Right Side Expansion - Productivity1000 Input/output Modules ............................... 2–2

Left Side Expansion - Arduino MKR-compatible Shields ........................................... 2–2

P1AM-100 Arduino Compatible CPU ........................................................................ 2–3

P1AM-100 Module Faceplate Layout ........................................................................ 2–4

P1AM-100 MicroB USB Programming Port ............................................................... 2–5

microSD Slot ............................................................................................................ 2–6

P1AM-100 CPU Headers ...........................................................................................2–7

Powering Your ProductivityOpen System ..................................................................2–8

AutomationDirect Shields .........................................................................................2–9

Ethernet Communications Shield .............................................................................2–9

Header Pin Breakout Module .................................................................................. 2–11

I/O Modules Overview ............................................................................................2–13

Page 7

Table of Contents

Chapter 3 - Installation and Wiring

Safety Guidelines ....................................................................................................... 3–3

Plan for Safety .......................................................................................................... 3–3

Three Levels of Protection ........................................................................................3–4

Orderly System Shutdown ........................................................................................3–4

System Power Disconnect ........................................................................................3–4

Emergency Stop Circuits ..........................................................................................3–5

Introduction to the ProductivityOpen Mechanical Design ...................................... 3–6

Typical P1AM-100 ....................................................................................................3–6

Dimensions and Installation ...................................................................................... 3–7

Basic Dimensions .......................................................................................................3–9

Mounting Guidelines ............................................................................................... 3–12

Enclosures ..............................................................................................................3–12

Mounting Position ..................................................................................................3–12

Using Mounting Rails .............................................................................................3–12

Mounting Clearances .............................................................................................3–13

Temperature Considerations ................................................................................... 3–13

Power Considerations ............................................................................................. 3–13

Grounding .............................................................................................................3–14

Agency Approvals ...................................................................................................3–14

DIN Rail Mounting P1AM-100 System ....................................................................3–15

Surface Mounting P1AM-100 System ..................................................................... 3–15

Installing the I/O Modules ...................................................................................... 3–16

Wiring Guidelines ....................................................................................................3–17

Power Supply Wiring .............................................................................................. 3–17

Grounding .............................................................................................................3–17

Fuse Protection .......................................................................................................3–18

I/O Module Wiring Options ....................................................................................3–19

Hand Wiring System ............................................................................................... 3–19

ZIPLink Wiring System ...........................................................................................3–20

Terminal Block With Pigtail Cable ........................................................................... 3–20

Input and Output Modules ZIPLink Selections .......................................................3–21

Analog Modules ZIPLink Selections ........................................................................ 3–22

ii

Hardware User Manual, 1st Ed. Rev. A

Page 8

Table of Contents

Removable Terminal Blocks (Optional) ................................................................... 3–23

P1-10RTB and P1-10RTB-1 .....................................................................................3–23

P2-RTB and P2-RTB-1 .............................................................................................3–23

Terminal Block Installation ...................................................................................... 3–24

Terminal Block Removal .......................................................................................... 3–25

Planning the I/O Wiring Routes .............................................................................. 3–25

System Wiring Strategies ........................................................................................3–26

CPU Isolation Boundaries .......................................................................................3–26

Sinking/Sourcing Concepts ....................................................................................3–27

I/O “Common Terminal” Concepts ........................................................................ 3–28

DC Input Wiring Methods ...................................................................................... 3–29

DC Output Wiring Methods ................................................................................... 3–29

Relay Outputs - Wiring Methods ............................................................................3–31

Relay Outputs – Transient Suppression for Inductive Loads in a Control System ..... 3–32

Appendix A - Security Considerations for Controls Networks

Security Considerations for Controls Networks .......................................................A–2

Hardware User Manual, 1st Ed. Rev. A

iii

Page 9

Chapter

Chapter

Chapter

GettinG Started

1

1

1

In This Chapter...

Introduction .............................................................................................................. 1–2

Intended Use of This Product ..................................................................................1–2

Purpose of this Manual ..........................................................................................1–3

Important Online Resources .....................................................................................1–3

Conventions Used ...................................................................................................... 1–4

Key Topics for Each Chapter ..................................................................................... 1–4

Install Programming Software .................................................................................. 1–5

Mounting Hardware .................................................................................................. 1–8

Power the System ...................................................................................................... 1–9

Page 10

Chapter 1: Getting Started

Introduction

Intended Use of This Product

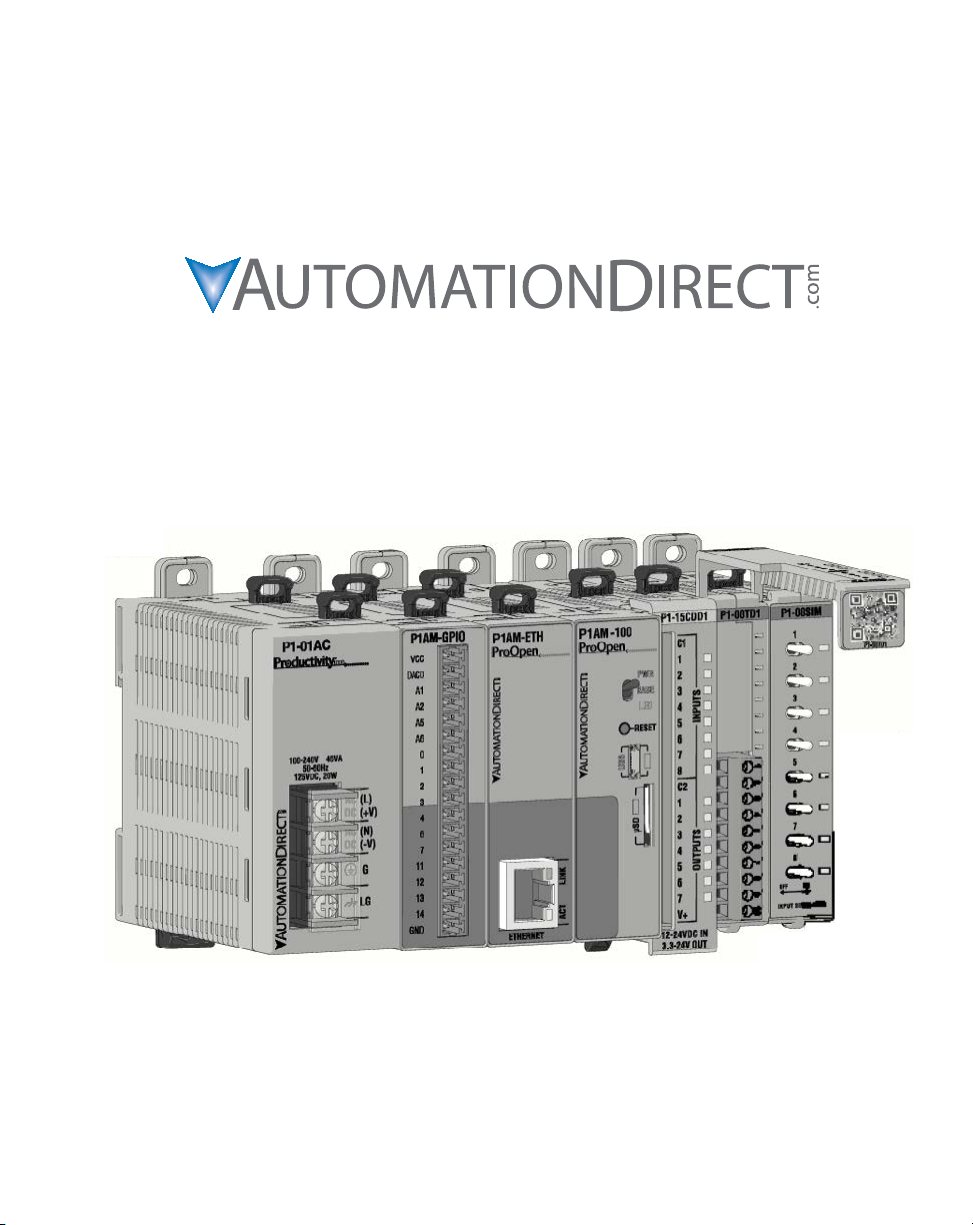

The PIAM-100 is a small computer with on-board I/O based on the “Open-Source Arduino

platform”. This product can be used to solve various control and automation tasks using

customized programs.

The user community website of PIAM-100 (http://go2adc.com/p1am) is where you will find

various demo programs and libraries that will allow you to jump right into programming and

design.

Follow all applicable safety parameters when connecting to external I/O sensors and devices.

Any use other than described in this manual is not permitted, as this may expose the user to

possible harm and/or damage to the device or connected equipment.

The P1AM-100 must not be altered or modified. The safety instructions as well as the

maximum permissible ambient conditions and operating parameters are given in Chapter 2

“Technical Specifications”.

The instruction manual is meant to be read thoroughly while being mindful of safe and

proper operation. It contains important information on mounting, operating and handling

the P1AM-100.

CAUTION: The P1AM CPU Base Controller uses pins A3 and A4 so any shield that uses these same pins

will have a conflict. The MKR RGB shield is one that has this conflict.

1–2

Hardware User Manual, 1st Ed. Rev. A

Page 11

Chapter 1: Getting Started

Purpose of this Manual

Thank you for purchasing the AutomationDirect ProductivityOpen Arduino compatible

Controller. This user manual provides information that will help you install, set up, program,

troubleshoot, and maintain your ProductivityOpen project.

The manual includes information that is critical to the safety of the personnel who will install

and use the controller and to the machinery, processes, and equipment controlled by the

P1AM-100.

The manual also includes important information about power and signal wiring, mounting the

CPU and modules, and configuring the system.

Important Online Resources

Access to ADC Community based help for your ProductivityOpen projects is available from

our website: http://go2adc.com/p1am.

You will need libraries and other files available from our GitHub page at

https://github.com/facts-engineering/P1AM

The P1AM libraries and Board Support Package and other support files are located on Github.

A variety of other useful information about the Productivity1000 I/O modules, as well as code

for example tasks and more is available at https://facts-engineering.github.io.

The P1AM-100 may be programmed by Arduino IDE which may be downloaded from

https://www.arduino.cc/en/Main/Software. A graphical programming tool customized for

P1AM-100 based on ArduBlock (ProductivityBlocks® )is accessible from the Tools menu in the

Arduino IDE.

In addition, the Productivity1000 series power supplies and I/O modules, which work with the

P1AM-100, include an installation insert.

Use a QR symbol reader or click on graphic icon to see an overview video.

Hardware User Manual, 1st Ed. Rev. A

1–3

Page 12

Chapter 1: Getting Started

Conventions Used

NOTE: When you see the “note pad” icon in the left-hand margin, the paragraph to its immediate right will be

a special note. Notes represent information that may make your work quicker or more efficient. The word

NOTE in boldface will mark the beginning of the text.

When you see the “exclamation point” icon in the left-hand margin, the paragraph to its immediate right

will be a warning. This information could prevent injury, loss of property, or even death in extreme

cases. Any warning in this manual should be regarded as critical information that should be read in its

entirety. The word WARNING in boldface will mark the beginning of the text.

Key Topics for Each Chapter

The beginning of each chapter will list the key

topics that can be found in that chapter.

1–4

Hardware User Manual, 1st Ed. Rev. A

Page 13

Install Programming Software

NOTE: An active Internet connection is required to download the Arduino IDE and access the libraries and

board driver.

The P1AM-100 CPU may be programmed with the Arduino IDE. ProductivityBlocks® is

an optional graphical environment used with the IDE that AutomationDirect has adapted to

make Productivity1000 I/O modules conveniently accessible as blocks.

1. Download the latest version of the Arduino IDE software

from https://www.arduino.cc/en/Main/Software.

2. Library Install:

a. In the Arduino IDE go to “Sketch -> Include Library -> Manage Libraries…”

b. Leave the Type and Topic filters as “All” and type “P1AM” in the “Filter your search…” box

c. Click on the P1AM by FACTS Engineering that appears

d. Click the Install button

e. Close the Library Manager window

f. Confirm the installation by checking for “File -> Examples -> P1AM-100”. Several categories

of examples should be present.

Productivity

Blocks

CC

Chapter 1: Getting Started

Hardware User Manual, 1st Ed. Rev. A

1–5

Page 14

Chapter 1: Getting Started

3. Arduino Board Support Package Install:

a. Go to “File->Preferences” and paste the following link into the “Additional Boards Manager

URLs” field.

NOTE: Make sure you right click on the link and choose “Copy Link”.

i. https://raw.githubusercontent.com/facts-engineering/facts-engineering.github.io/master/

package_productivity-P1AM-boardmanagermodule_index.json

b. Go to “Tools -> Boards -> Board Manager”. Type P1AM into the search box at the top.

Mouse over the result and click install. The install may take several minutes to complete.

c. If you are on a version of Windows before Windows 10 this is mandatory. For Windows

10 users, this may be run if you want the board to appear as P1AM-100 in device

manager.

i. Download the “driver install” file from this link:

https://github.com/facts-engineering/P1AMCore/raw/master/drivers.zip.

ii. Extract the file

iii. Run the “P1AM-100_install.bat” file to complete the driver installation.

d. If you are having trouble installing the BSP due to network issues such as firewall

restrictions, you can use the “Arduino SAMD Boards” (specifically the MKRZERO) as

an alternative. These are present in the board manager automatically.

4. Testing installation

a. Attach the modules and/or shields you wish to use. REMEMBER modules/shields must not

be connected or disconnected while power is applied - either 24V or USB.

b. Plug the micro USB cable into the P1AM-100 and computer

i. If using P1000 I/O modules power the system with 24V

c. Go to “Tools -> Board:” and select “P1AM-100” from the dropdown that appears.

d. Go to “Tools -> Port” and select the “P1AM-100” device that you have plugged in.

e. Go to File -> Examples -> P1AM-100->Basic->PrintModules to open the Print Modules

example. Note that the PrintModules example is intended for a system with Productivity1000

modules connected and powered.

f. Click the right facing arrow button under “Edit” to upload the code to the board.

g. Go to “Tools -> Serial Monitor” and check to see that the name of module(s) you have in the

base is printing to the terminal.

1–6

Hardware User Manual, 1st Ed. Rev. A

Page 15

Productivity

Blocks

Chapter 1: Getting Started

5. Next Steps

a. Start with the “Basic” category of the P1AM-100 Library examples to become familiar with

the API.

b. Once you are comfortable with the basic examples you can move on to more complex

routines included in the P1AM-100 examples.

6. Install ProductivityBlocks

a. Run the ProductivityBlocks Installer.

b. ProductivityBlocks will be installed in the Documents -> ProductivityBlocks folder. The

ProductivityBlocks programming environment is accessible from the Tools menu in the

Arduino IDE.

c. Example ProductivityBlocks programs are also included in this folder.

®

Hardware User Manual, 1st Ed. Rev. A

1–7

Page 16

Chapter 1: Getting Started

Mounting Hardware

Install Shields on the left side of the P1AM CPU and P1 I/O Modules on the right side of the

P1AM CPU.

The ProductivityOpen Shields and Productivity1000 Input/Output modules are DIN rail

mountable and designed to snap together to simplify connection. A system may include

communications, inputs and outputs. See Chapter 3 of this manual and Chapters 4 and 5 of

the Productivity1000 manual for more detailed hardware installation information.

!WARNING! Do not add or remove modules with field power applied!

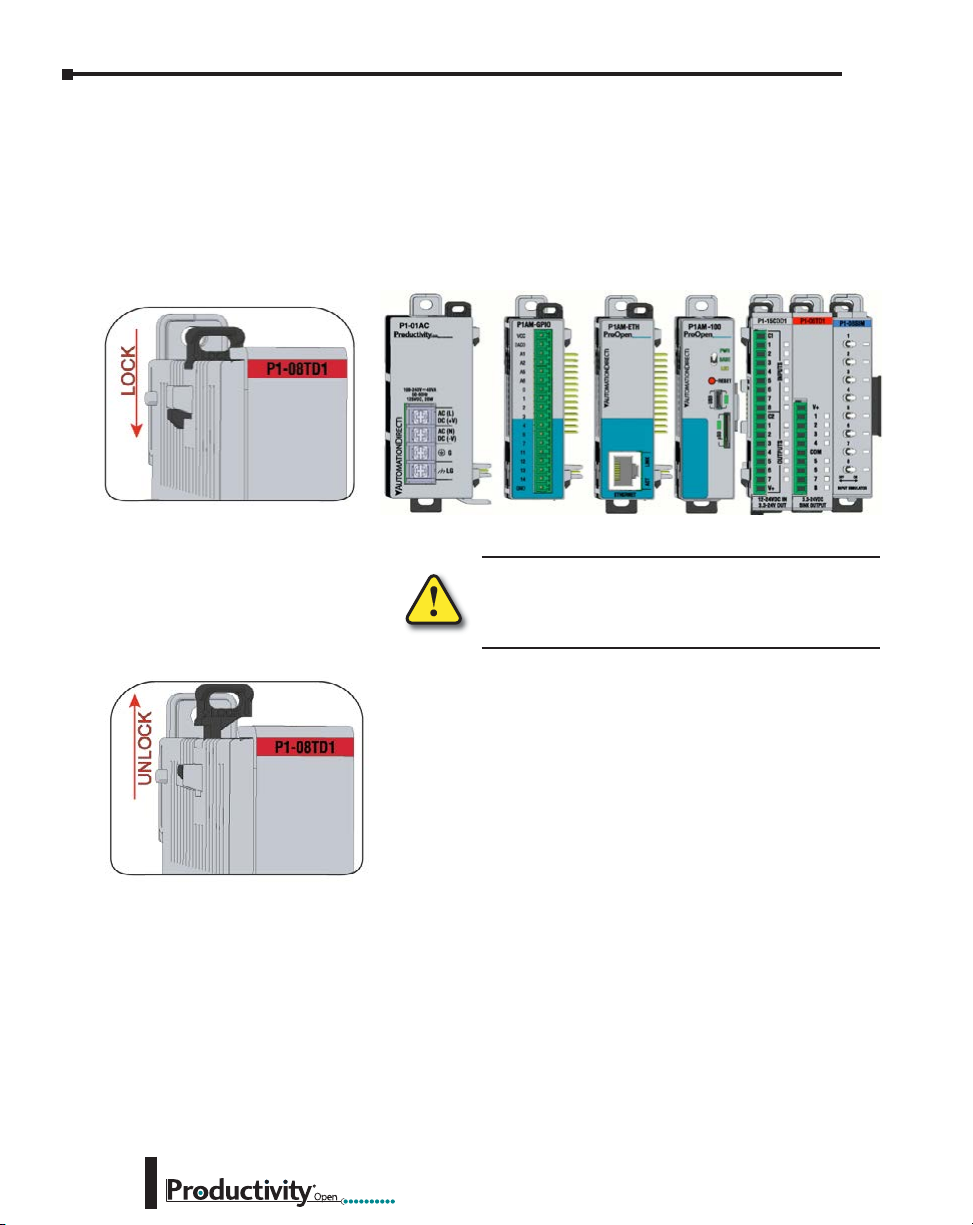

Step One:

With latch in “locked” position,

align connectors on the side of

each module and stack by pressing

together. An audible click indicates

lock is engaged.

Step Two:

Attach field wiring using the removable

terminal block or ZIPLink wiring system.

Step Three:

To unstack modules, pull locking latch up

into the unlocked position and then pull

modules apart.

CAUTION: Ensure all latches

are secured after modules

are connected.

1–8

Hardware User Manual, 1st Ed. Rev. A

Page 17

Power the System

NOTE: Ensure all modules are connected to the system before power is applied. Do not assemble or

disassemble the system while power is applied.

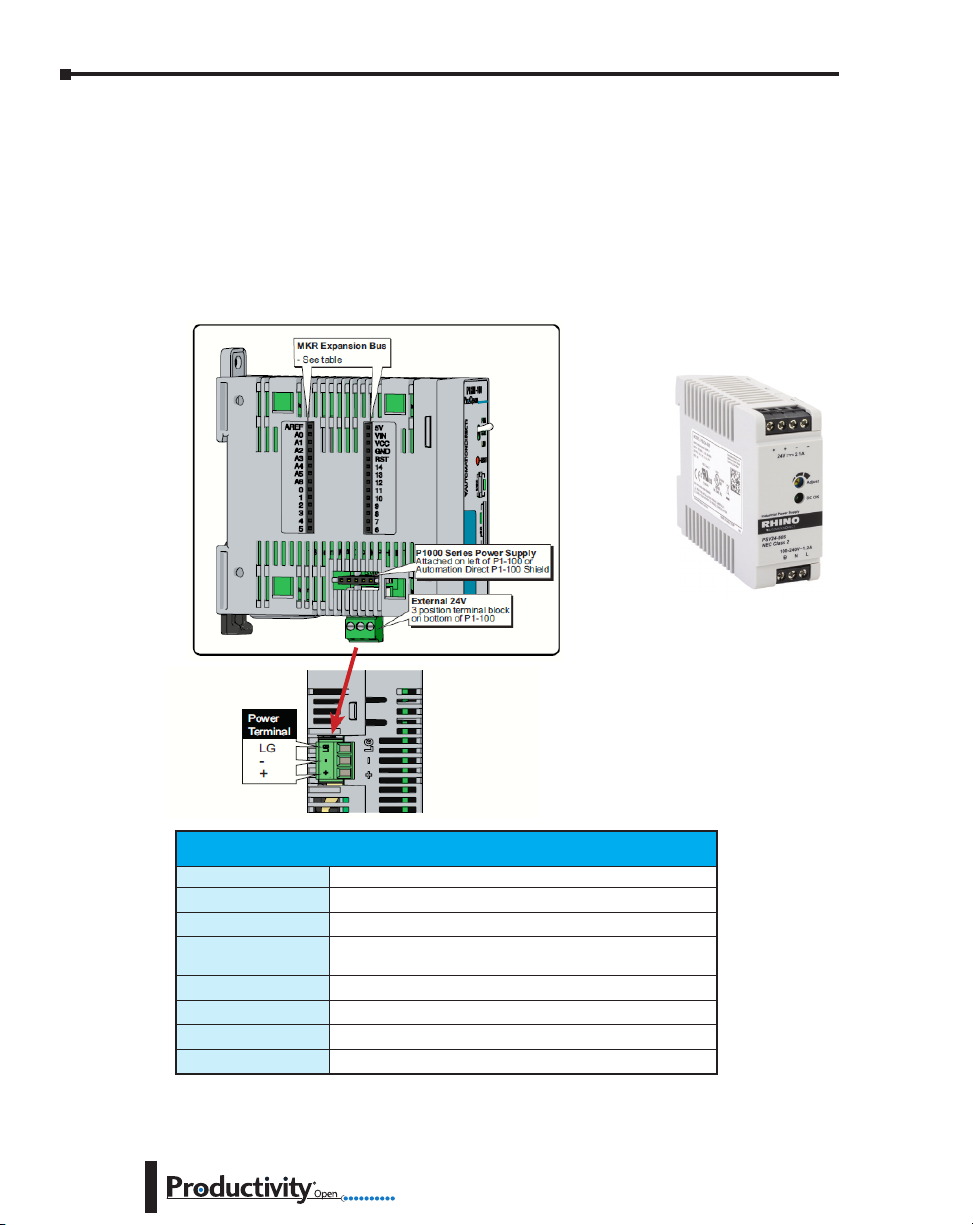

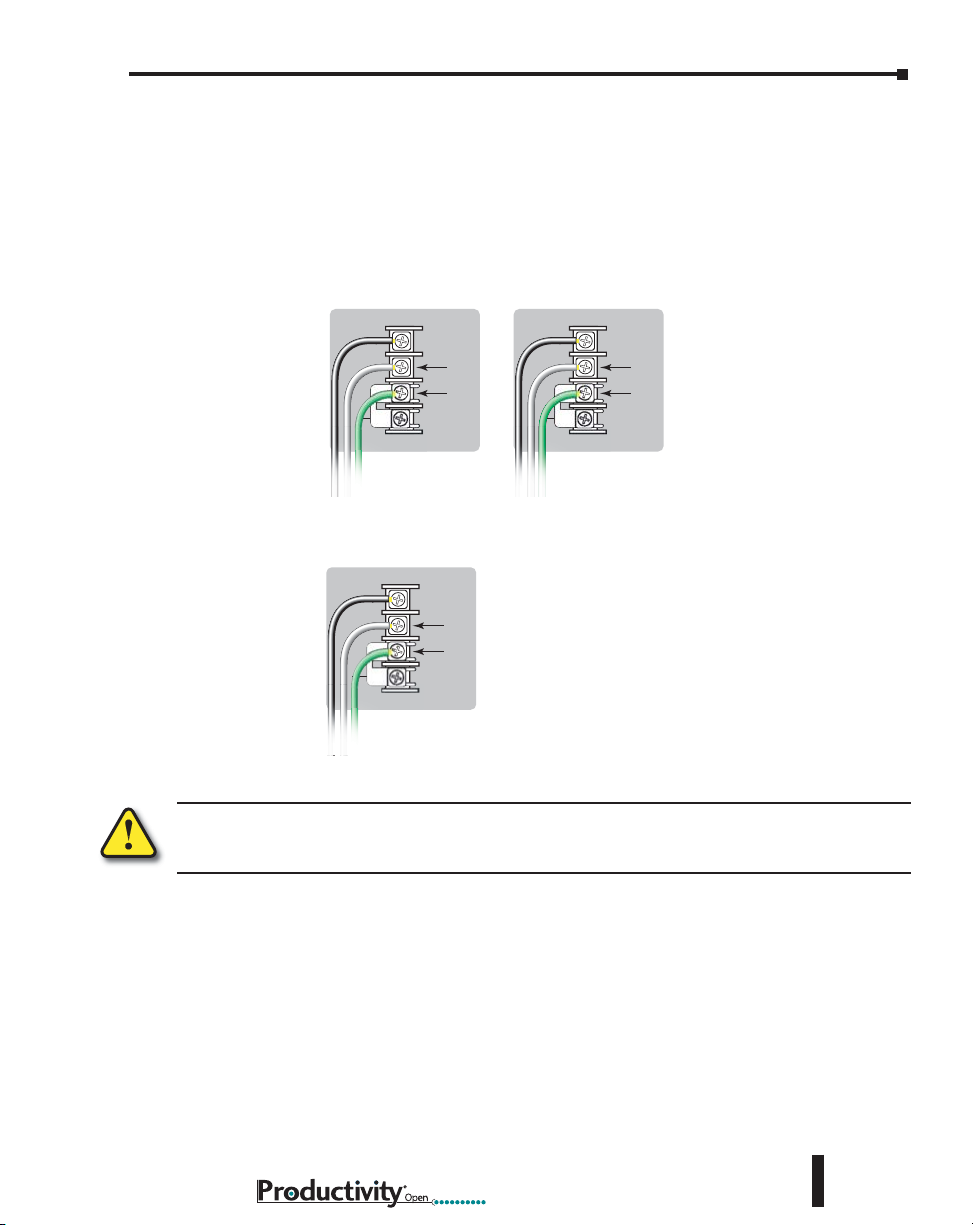

Productivity1000 Power Supplies:

1. Connect one of the Productivity1000 power supplies to P1AM-100. Should you choose

Arduino MKR compatible shields instead of or in addition to the ProductivityOpen shields,

the Productivity1000 power supplies cannot be used. In this case an alternative power supply

is required (See below for information on connecting an external power supply).

P1000 24VDC input power supplies:

• P1-01AC: AC Input 85–132 / 170–264 VAC, 16W

(power for P1AM-100 and up to 8 modules)

• P1-02AC: AC Input 85–132 / 170–264 VAC, 26W

(power for P1AM-100 and up to 15 modules)

• P1-01DC: DC Input 12–24 VDC, 16W

(power for P1AM-100 and up to 8 modules)

Chapter 1: Getting Started

P1-01AC

100-240V 48VA

125VDC, 20W

®

50-60Hz

P1-01AC

AC (L)

DC (+V)

AC (N)

DC (-V)

LG

P1-02AC

™

100-240V 74VA

50-60Hz

125VDC, 33W

AC (L)

DC (+V)

AC (N)

DC (-V)

G

G

LG

P1-02AC

P1-01DC

12-24V 21W

P1-01DC

™

+V

-V

G

LG

CAUTION: Ensure that only one power supply source is connected to the Arduino system. When a

Productivity1000 power supply is connected immediately to the left of the CPU module, the bottom Power

Connector must be removed before connecting P1-01AC Power Supply. This precludes connection of two

separate power supplies. If an AutomationDirect shield is connected between a Productivity1000 power

supply and the CPU module care must be taken to ensure an external power supply is not connected to the

bottom terminals.

Hardware User Manual, 1st Ed. Rev. A

1–9

Page 18

Chapter 1: Getting Started

2. OR using an alternative 24VDC external power source connect directly to P1AM-100 Optional

Power Connector terminals. This option allows for the use of Input/Output modules from the

Productivity1000 family as well as all Arduino MKR compatible shields.

• The LG and minus terminals on the external power supply connection are internally

shorted.

• Use separate 24VDC supplies, one for the P1AM-100 and another for inductive loads to

keep the P1AM-100 supply power clean and free of voltage spikes caused by switching

inductive loads.

RHINO Power Supply

P/N PSV24-50s

Example of Alternative

24VDC Power Supply

1–10

Terminal Block Specications

Part Number

Number of positions

Pitch

Wire Range

Conductors

Screw Driver Width

Screw Size

Screw Torque

*Recommended screw driver P/N: TW-SD-MSL-2

PCON-KIT

3 screw terminals

3.5 mm

28–16 AWG (0.324 to 3.31 mm²) Solid / Stranded conductor

1/4 in (6–7 mm) Strip Length

Use copper conductors, 75°C or equivalent

1/8 in (3.175 mm) Maximum

M2

1.7 lb·in (0.4 N·m)

Hardware User Manual, 1st Ed. Rev. A

Page 19

Chapter 1: Getting Started

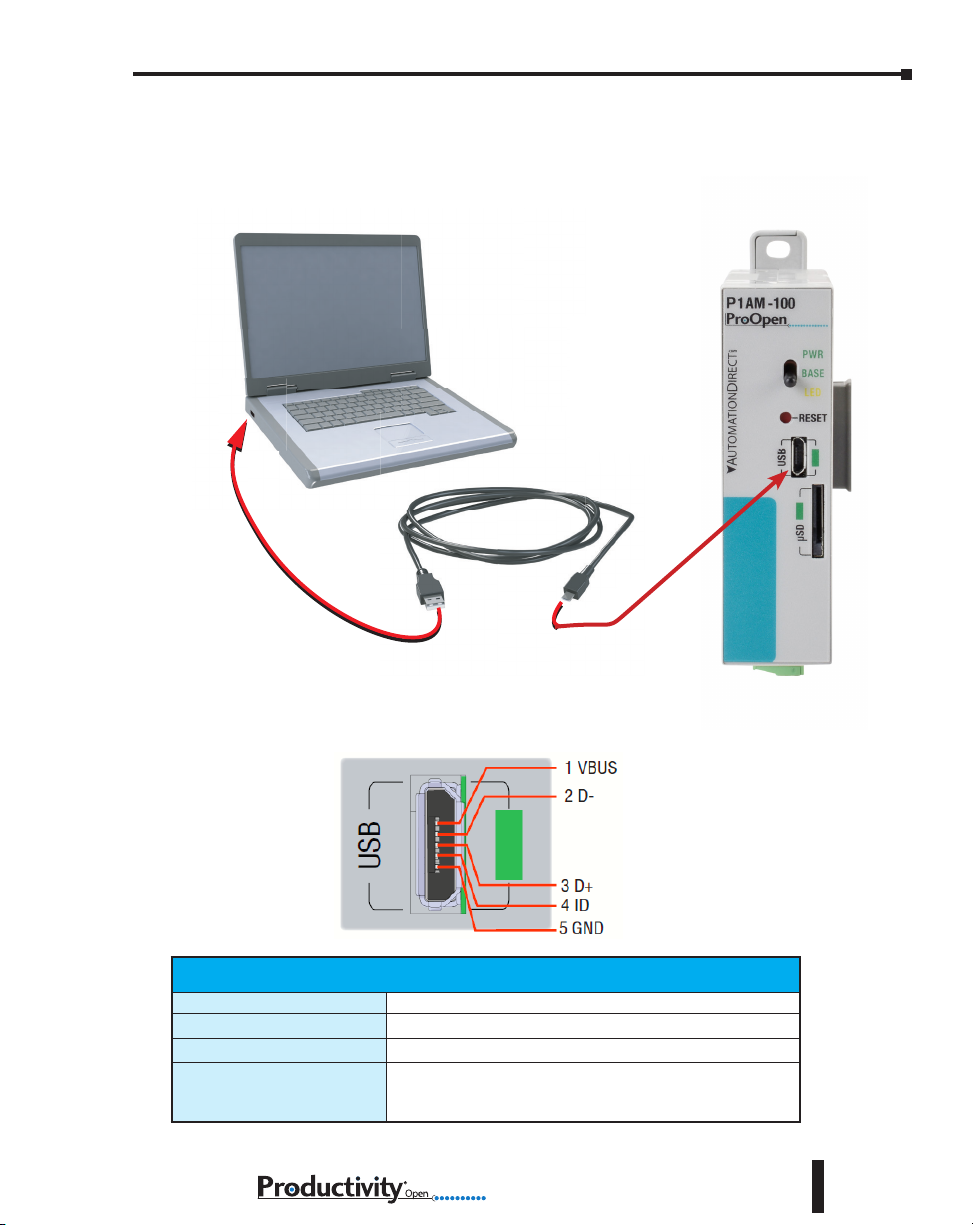

3. OR using USB input power, connect to the microB USB port on the face of the P1AM-100.

USB power is intended for programming and will not power Productivity1000 Input /output

modules.

Micro USB Type B Input Specications

Port Name

Description

Port Status LED

Cables

Micro USB

Standard Micro USB input for programming and monitoring

Green LED is illuminated when a power cable is plugged in.

USB Type A to Micro USB Type B:

6ft cable part # USB-CBL-AMICB6

15ft cable part # USB-CBL-AMICB15

Hardware User Manual, 1st Ed. Rev. A

1–11

Page 20

Chapter

Chapter

Chapter

SpecificationS

2

2

2

In This Chapter...

Overview ................................................................................................................... 2–2

Right Side Expansion - Productivity1000 Input/output Modules ............................... 2–2

Left Side Expansion - Arduino MKR-compatible Shields ........................................... 2–2

P1AM-100 Arduino Compatible CPU ........................................................................ 2–3

P1AM-100 Module Faceplate Layout ........................................................................ 2–4

P1AM-100 MicroB USB Programming Port ............................................................... 2–5

microSD Slot ............................................................................................................ 2–6

P1AM-100 CPU Headers ...........................................................................................2–7

Powering Your ProductivityOpen System ..................................................................2–8

AutomationDirect Shields .........................................................................................2–9

Ethernet Communications Shield .............................................................................2–9

Header Pin Breakout Module .................................................................................. 2–11

I/O Modules Overview ............................................................................................2–13

Page 21

Chapter 2: Specifications

Overview

The ProductivityOpen system is intended to provide a robust selection of components for a

compact and expandable design with a simple-to-use philosophy.

Right Side Expansion - Productivity1000 Input/output Modules

The P1AM-100 can be expanded with the addition of easily connected I/O modules and does

not require a mounting base. I/O modules are connected via an expansion port on the right

side of the P1AM-100 case. A variety of I/O modules are available from the Productivity1000

series for flexible and optimal system configuration. Refer to the Productivity1000 user manual

for detailed descriptions (https://cdn.automationdirect.com/static/manuals/p1userm/

p1userm.html).

Left Side Expansion - Arduino MKR-compatible Shields

The left side of the case allows expansion with most* Arduino MKR compatible shields.

A selection of shields to support P1AM-100 in housings to conveniently connect to the

P1AM-100 specifically are available from AutomationDirect. See detailed descriptions

following.

* NOTE: The P1AM CPU Base Controller uses pins A3 and A4 so any shield that uses these same pins will

have a conflict. The MKR RGB shield is one that has this conflict.

2–2

Hardware User Manual, 1st Ed. Rev. A

Page 22

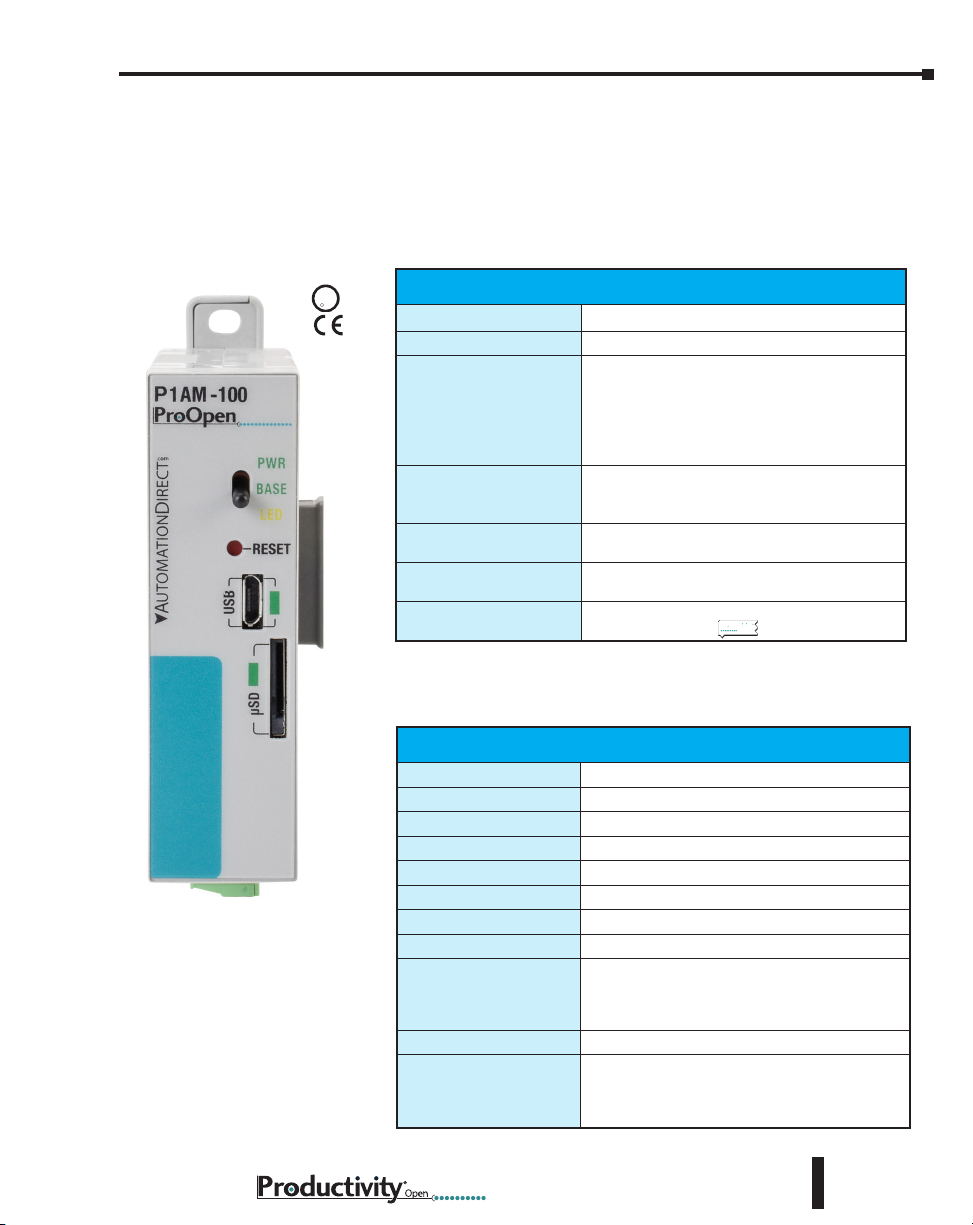

P1AM-100 Arduino Compatible CPU

U

L

C

US

The P1AM-100 is an Arduino-compatible CPU. It uses the Atmel SAMD21G18 microcontroller and can be programmed using Arduino IDE or ProductivityBlocks®. It interfaces

with all Productivity1000 Series I/O modules connected to the right side of the P1AM-100

and most Arduino MKR form factor shields connected to the left side. The specifications are

listed in the tables below.

Chapter 2: Specifications

P1AM-100

R

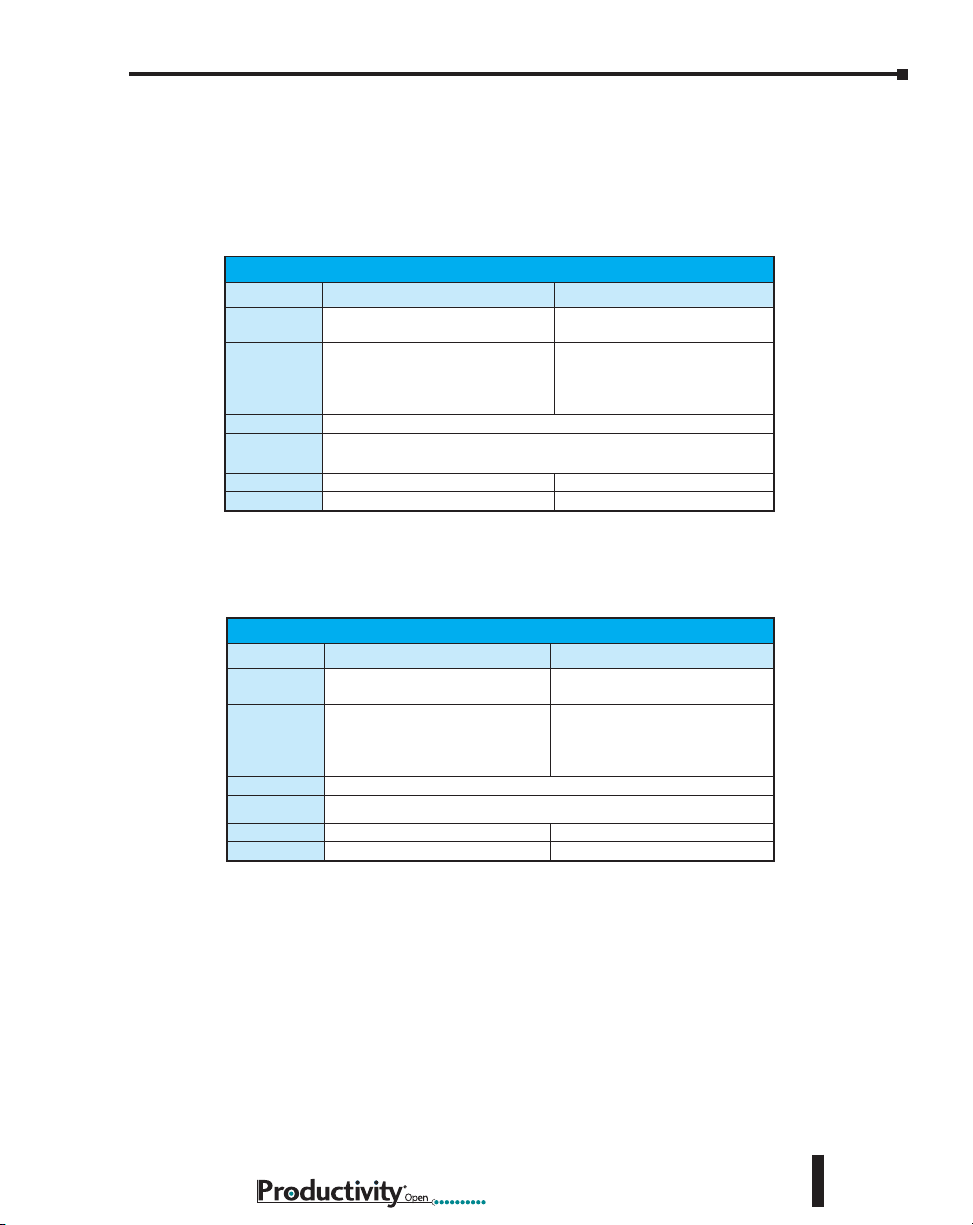

User Specications

User Memory

Memory Type

Base Controller and I/O

Power Requirement

Recommended Fuse

(External)

Peripherals

Hardware Limits of System

Programming

¹ If you do not use a Productivity1000 power supply, like the P1-01AC, then use a power supply that has

transformer isolation. Use different 24VDC supplies for the CPU and inductive loads to keep the CPU power

clean and free of voltage spikes caused by switching solenoids, motors and relay coils.

² See MKR Expansion Bus table and notes for shield power budget restrictions.

1

256kB Flash with 10kB used for bootloader

Flash: 256kB, SRAM: 32kB

24VDC ±2%

Plan 0.5 W for the SAMD chip and base controller

Plan 1.25 W per P1000 I/O module

Plan 9W for max. header power draw (which

provides max. 4.25 W power to left side connected

shields).

Edison S5061-R, Time Delay, 1A Fuse

For 9–15 modules: Edison S5062-R, Time Delay,

2A Fuse

MicroB USB, Arduino MKR-compatible, microSD

card slot, User controlled LED

15 Productivity1000 I/O Modules; Arduino MKR

2

shields

Programmed in C/C++ with the Arduino IDE or

ProductivityBlocks

®

Productivity

Blocks

General Specications

Operating Temperature

Storage Temperature

Humidity

Environmental Air

Vibration

Shock

Heat Dissipation

Enclosure Type

Module Location

Weight

Agency Approvals

0° to 60°C (32° to 140°F)

-20° to 70°C (-4° to 158°F)

5 to 95% (non-condensing)

No corrosive gases permitted

IEC60068-2-6 (Test Fc)

IEC60068-2-27 (Test Ea)

4000mW

Open Equipment

Productivity1000 I/O modules connect on the right

side of module. Productivity1000 power supply,

P1AM Shields and MKR Shields connect on the left

side on the module.

76g (2.8 oz)

UL 61010-1 and UL 61010-2-201 File E139594,

Canada & USA

CE (EN 61131-2 EMC, EN 61010-1 and EN 610102-201 Safety)

Hardware User Manual, 1st Ed. Rev. A

2–3

Page 23

Chapter 2: Specifications

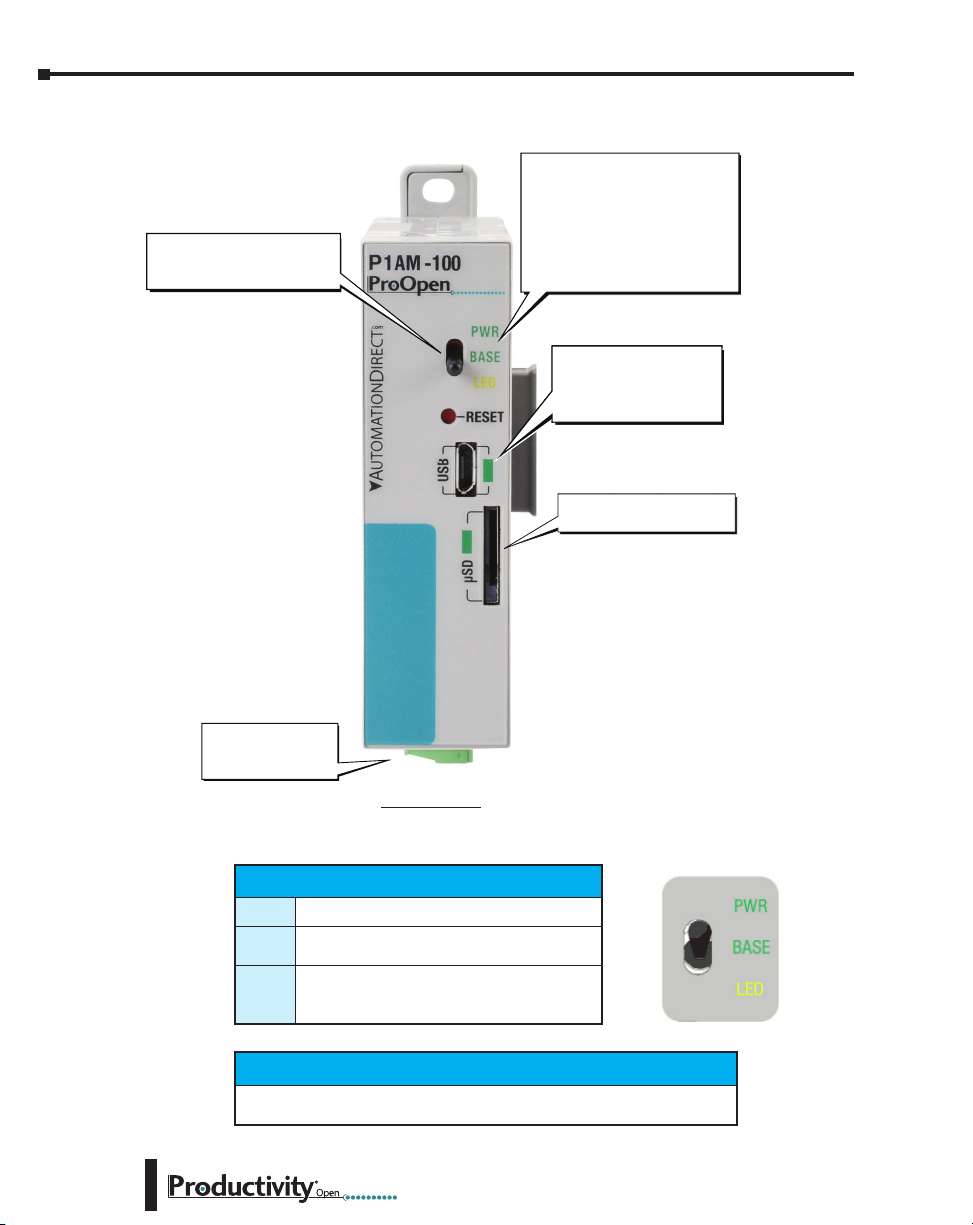

P1AM-100 Module Faceplate Layout

Toggle Switch

- Tied to SWITCH_BUILTIN

or Digital Pin 31

CPU Status Indicators

- PWR LED indicates

power applied

- BASE LED indicates when

base controller is powered

and initialized

- LED controlled by writing to

LED_BUILTIN or Digital Pin 32

Power Option for the

Power Option for the

Power Option for the

Arduino and shields

Arduino and shields

Arduino and shields

- Programming

- Programming

- Programming

- Online monitoring

- Online monitoring

- Online monitoring

microSD Port

- removable flash memory

2–4

External Power

- 24VDC on bottom

connector

P1AM-100

CPU Status Indicators

PWR

BASE

LED

Green LED is illuminated when power is ON

Green LED is illuminated when P1AM I/O

controller is powered and has been initialized

Yellow LED is illuminated when commanded

by user program. LED can be referred to as

LED_BUILTIN or Pin 32.

Toggle Switch Specications

Switch can be read using the “digitalRead” function. Switch can be referred to as

“SWITCH_BUILTIN” or Pin 31.

Hardware User Manual, 1st Ed. Rev. A

Page 24

Chapter 2: Specifications

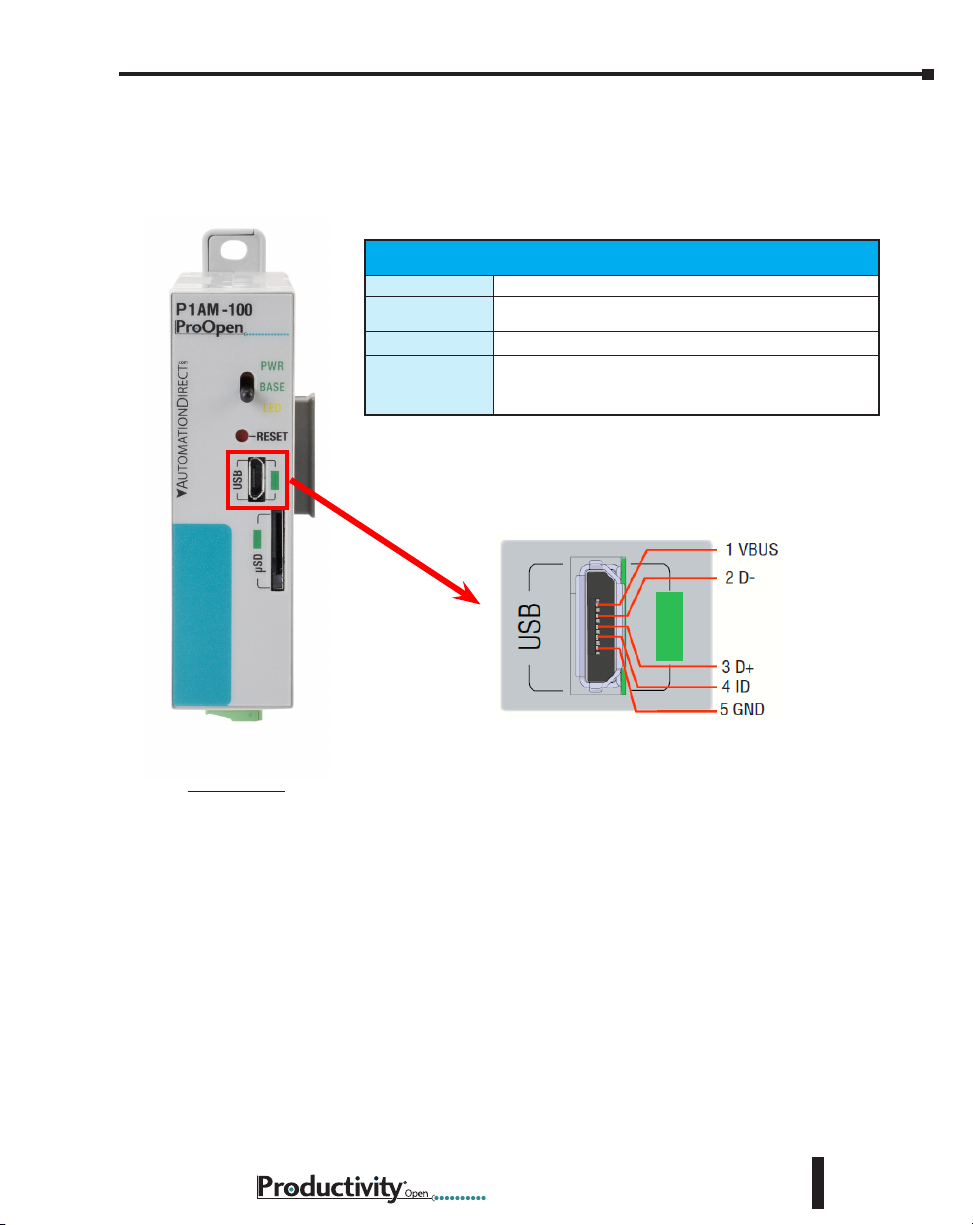

P1AM-100 MicroB USB Programming Port

The P1AM-100 controller has one built-in communication port; used exclusively for connecting

to a PC running the Arduino IDE programming software. Following are the specifications and

pin-out diagram.

Micro USB Type B Specications

Port Name

Description

Port Status LED

Cables

MicroB USB

Standard MicroB USB input for programming, monitoring,

and a power option

Green LED is illuminated when a power cable is plugged in.

USB Type A to Micro USB Type B:

6ft cable part # USB-CBL-AMICB6

15ft cable part # USB-CBL-AMICB15

P1AM-100

Hardware User Manual, 1st Ed. Rev. A

2–5

Page 25

Chapter 2: Specifications

PinSD

1

2

3

4

5

6

7

8

DAT2

CD/DAT3

CMD

VDD

CLK

VSS

DAT0

DAT1

microSD Slot

Retentive memory for data logging, parameter storage, etc. (Card not included with unit).

microSD Specications

Port Name

Description

Maximum Card

Capacity

Transfer Rate

(ADATA microSDHC

Class 4 memory card)

Port Status LED

microSD

Standard microSD socket for data logging

32GB

Mbps Minimum Typical Maximum

Read 14.3 14.4 14.6

Write 4.8 4.9 5.1

Green LED is illuminated when card is inserted and detected

1

8

Pin SD

1

DAT2

2

CD/DAT3

3

CMD

4

VDD

5

CLK

6

VSS

7

DAT0

8

DAT1

2–6

Hardware User Manual, 1st Ed. Rev. A

Page 26

Chapter 2: Specifications

P1AM-100 CPU Headers

Following are the specifications and pin-out diagram for the Arduino MKR-compatible

expansion bus available for Left Side Expansion Arduino MKR-compatible shields.

MKR Expansion Bus Pins

GPIO A0–A6, 0–14

Analog Input Pins A0–A6

P1AM-100

Analog Output

Pins

PWM Pins 0–8, 10, A3, A4

Interrupt Pins 0, 1, 4–8, A1, A2

5V 5V supply output

Vin 5V regulated supply

VCC 3.3 V supply output

GND Ground

RST Reset

AREF

Critical Notes:

Pins A3, A4, and 8–10 are used for the base

controller.

Do not exceed 46mA combined from pins 0, 1,

and 4–10.

Do not exceed 3.3 V on any I/O pin.

Do not exceed 7mA on any I/O pin.

Do not apply power to 5V or VCC

A0

Analog Input Reference

Hardware User Manual, 1st Ed. Rev. A

2–7

Page 27

Chapter 2: Specifications

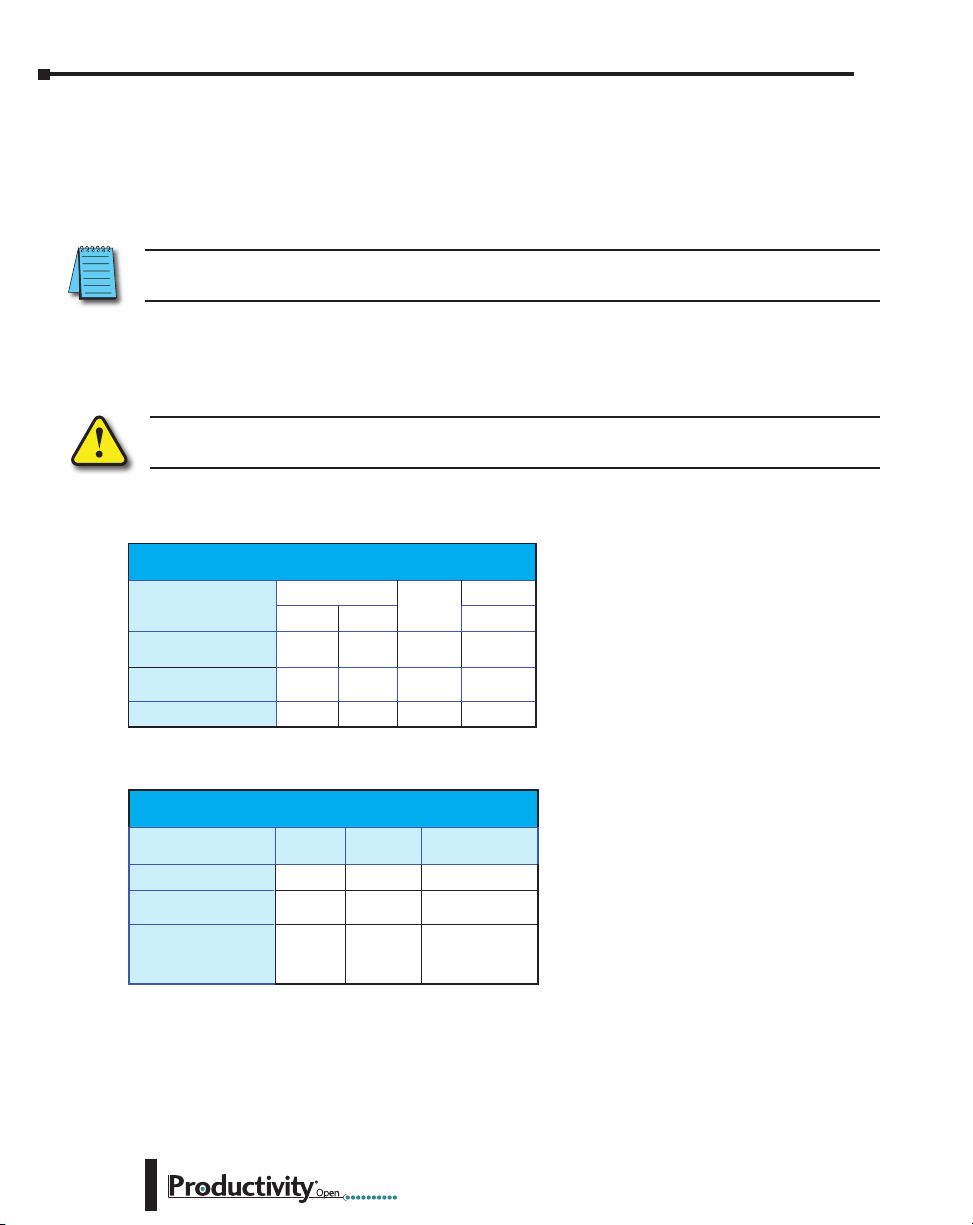

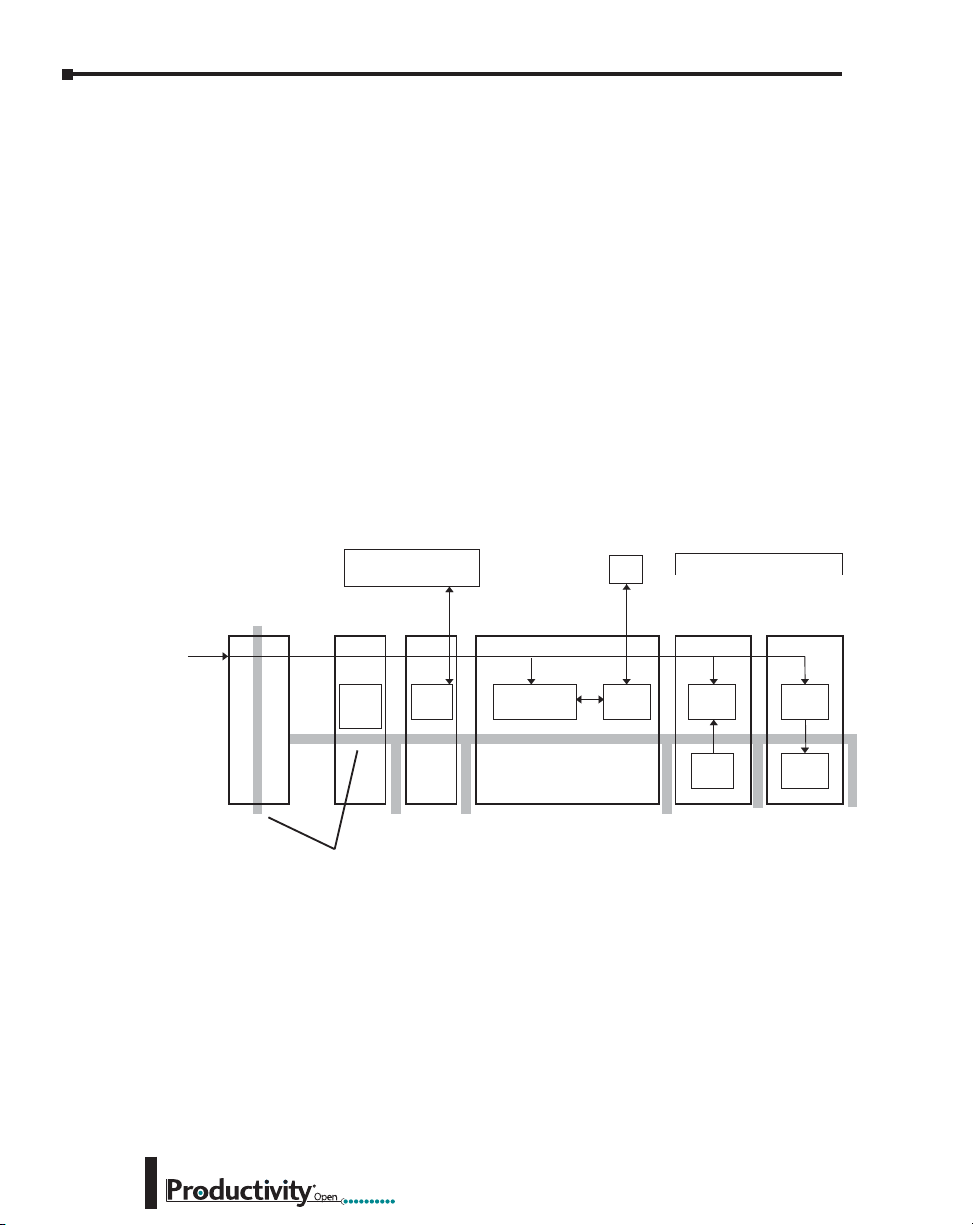

Powering Your ProductivityOpen System

It is important to understand that the Productivity1000 I/O modules on the right side will be

powered either by the Productivity1000 power supply connected to the left of the CPU OR

by an external 24VDC power supply connected to the terminals at the bottom of the CPU

module. The ProductivityOpen shields sold by AutomationDirect will also be powered by

either of these sources.

NOTE: Only one of these 24VDC sources shall be connected.

Third party shields on the left side shall be powered in the field according to the manufacturer

specs.

The USB programming cable will power the CPU and shields connected on the left side of

the CPU.

CAUTION! Shields and I/O modules must not be connected or disconnected when power is applied.

Power Supply Options

LSX Shields

USB Power Cable

(5VDC)

ADC P1-01AC or

P1-02AC

AUX 24Vin

Open ADC ADC I/O

ø ø ø

ø ø ø

ø ø ø ø

CPU

RSX

2–8

MKR Header Power Limitations

Power Source 5V 3.3 V

USB 330mA 500mA 1.65 W

VIN (Pin Header) 600mA 1A 3.3 W

P1000 Series Supply

OR External 24V

850mA 1.28 A 4.25 W

Max. Combined

Power

Hardware User Manual, 1st Ed. Rev. A

Page 28

AutomationDirect Shields

Ethernet Communications Shield

The P1AM-ETH is a housed Arduino Compatible Ethernet Shield based on the Wiznet W5500

Ethernet Controller. It interfaces to the left side of the P1AM-100 CPU and most Arduino MKR

form factor shields.

Ethernet Features

• Supports Hardwired TCP Protocols:

TCP, UDP, ICMP, IPV4, ARP, IGMP, PPPOE

• Supports 8 independent sockets simultaneously

• Supports Power Down Mode

• Supports Wake on LAN over UDP

• Supports High Speed Serial Peripheral Interface (SPI MODE 0, 3)

• Internal 32K bytes of Memory for TX/RX Buffers

• 10BaseT / 100BaseTX Ethernet PHY embedded

• Supports Auto Negotiation (Full and Half Duplex,

10 and 100-based)

• Does Not Support IP Fragmentation

• 3.3 V operation with 5V I/O signal tolerance

• LED outputs (Full / Half duplex, Link, Speed, Active)

Chapter 2: Specifications

!WARNING!

Do not add or remove

modules with field power

applied!

General Specications

Operating Temperature

Storage Temperature

Humidity

Environmental Air

Vibration

Shock

Heat Dissipation

Enclosure Type

Power Budget

Recommended Library

Module Location

Weight

Agency Approvals

0° to 60°C (32° to 140°F)

-20° to 70°C (-4° to 158°F)

5 to 95% (non-condensing)

No corrosive gases permitted

IEC60068-2-6 (Test Fc)

IEC60068-2-27 (Test Ea)

750mW

Open Equipment

150mA/5V

Arduino Ethernet

Connects to the left side of the P1AM-100 CPU.

20g (0.8 oz.)

UL 61010-1 and

UL 61010-2-201 File E139594, Canada & USA

CE

Hardware User Manual, 1st Ed. Rev. A

2–9

Page 29

Chapter 2: Specifications

AutomationDirect Shields, cont’d

Header Pins Used for

Ethernet Shield

Pins Used Function

5

ETH SS

8

MOSI

SCK

MISO

SPI pins are shared

with other devices on

SPI bus

9

10

P1AM-ETH

MKR Expansion Bus Pins

GPIO A0–A6, 0–14

Analog Input Pins A0–A6

Analog Output

Pins

PWM Pins 0–8, 10, A3, A4

Interrupt Pins 0, 1, 4–8, A1, A2

5V 5V supply output

Vin 5V regulated supply

VCC 3.3 V supply output

GND Ground

RST Reset

AREF

Critical Notes:

Pins A3, A4, and 8–10 are used for the base controller.

Do not exceed 46mA combined from pins 0, 1, and 4–10.

Do not exceed 3.3 V on any I/O pin.

Do not exceed 7mA on any I/O pin.

Do not apply power to 5V or VCC

A0

Analog Input Reference

2–10

Hardware User Manual, 1st Ed. Rev. A

Page 30

AutomationDirect Shields, cont’d

Header Pin Breakout Module

The P1AM-GPIO is a housed Arduino MKR form factor shield that brings a subset of the MKR

header pins out to the front 18 position terminal block. These pins include basic overvoltage,

undervoltage, and overcurrent protection. It connects to the left side of the P1AM-100 CPU

and most Arduino MKR form factor shields.

General Specications

Operating Temperature

Storage Temperature

Humidity

Environmental Air

Vibration

Shock

Heat Dissipation

Enclosure Type

Module Location

Weight

Agency Approvals

Chapter 2: Specifications

0° to 60°C (32° to 140°F)

-20° to 70°C (-4° to 158°F)

5 to 95% (non-condensing)

No corrosive gases permitted

IEC60068-2-6 (Test Fc)

IEC60068-2-27 (Test Ea)

475mW

Open Equipment

Connects to the left side of the P1AM-100 CPU.

56g (2.0 oz.)

UL 61010-1 and

UL 61010-2-201 File E139594, Canada & USA

CE

!WARNING!

Do not add or remove

modules with field power

applied!

Terminal block connector sold separately.

Recommended connector options P2-RTB or

P2-RTB-1.

Hardware User Manual, 1st Ed. Rev. A

2–11

Page 31

Chapter 2: Specifications

AutomationDirect Shields, cont’d

P1AM-GPIO

MKR Expansion Bus Pins

GPIO A0–A6, 0–14

Analog Input Pins A0–A6

Analog Output

Pins

PWM Pins 0–8, 10, A3, A4

Interrupt Pins 0, 1, 4–8, A1, A2

5V 5V supply output

Vin 5V regulated supply

VCC 3.3 V supply output

GND Ground

RST Reset

AREF

Critical Notes:

Pins A3, A4, and 8–10 are used for the base

controller.

Do not exceed 46mA combined from pins 0,

1, and 4–10.

Do not exceed 3.3 V on any I/O pin.

Do not exceed 7mA on any I/O pin.

Do not apply power to 5V or VCC

A0

Analog Input Reference

Terminal Block Pins

Pin Functions

VCC 3.3 V supply output

DAC0*

A1 GPIO, Analog input, Interrupt

A2 GPIO, Analog input, Interrupt

A5 GPIO, Analog input

A6 GPIO, Analog input

0 GPIO, PWM, Interrupt

1 GPIO, PWM, Interrupt

2 GPIO, PWM

3 GPIO, PWM

4 GPIO, PWM, Interrupt

6 GPIO, PWM, Interrupt

7 GPIO, PWM, Interrupt

11 GPIO, SDA

12 GPIO, SCL

13 GPIO, RX

14 GPIO, TX

GND Ground

*There is no ESD, overvoltage, or overcurrent protection on the DAC0 pin.

GPIO, Analog input,

Analog output

2–12

Hardware User Manual, 1st Ed. Rev. A

Page 32

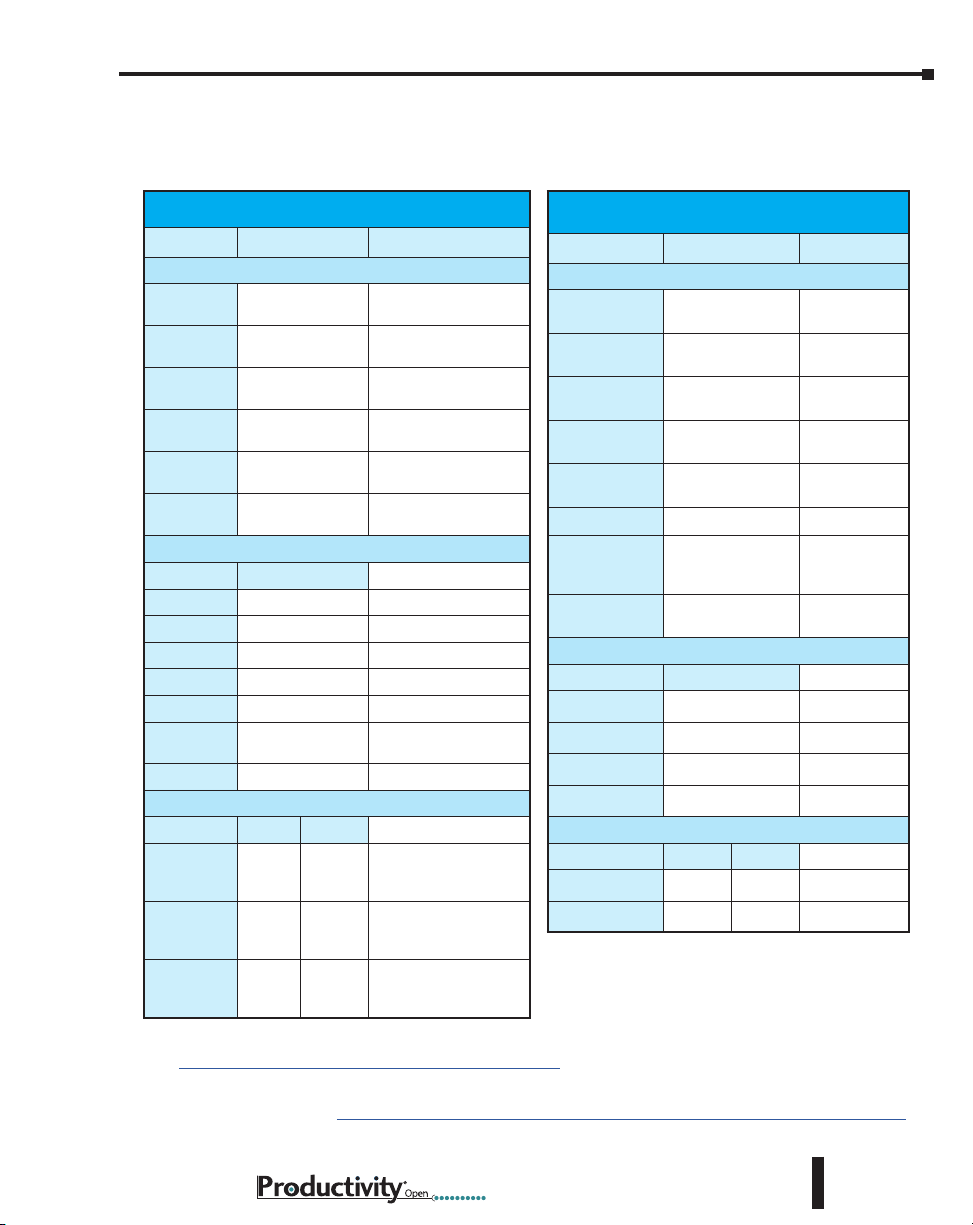

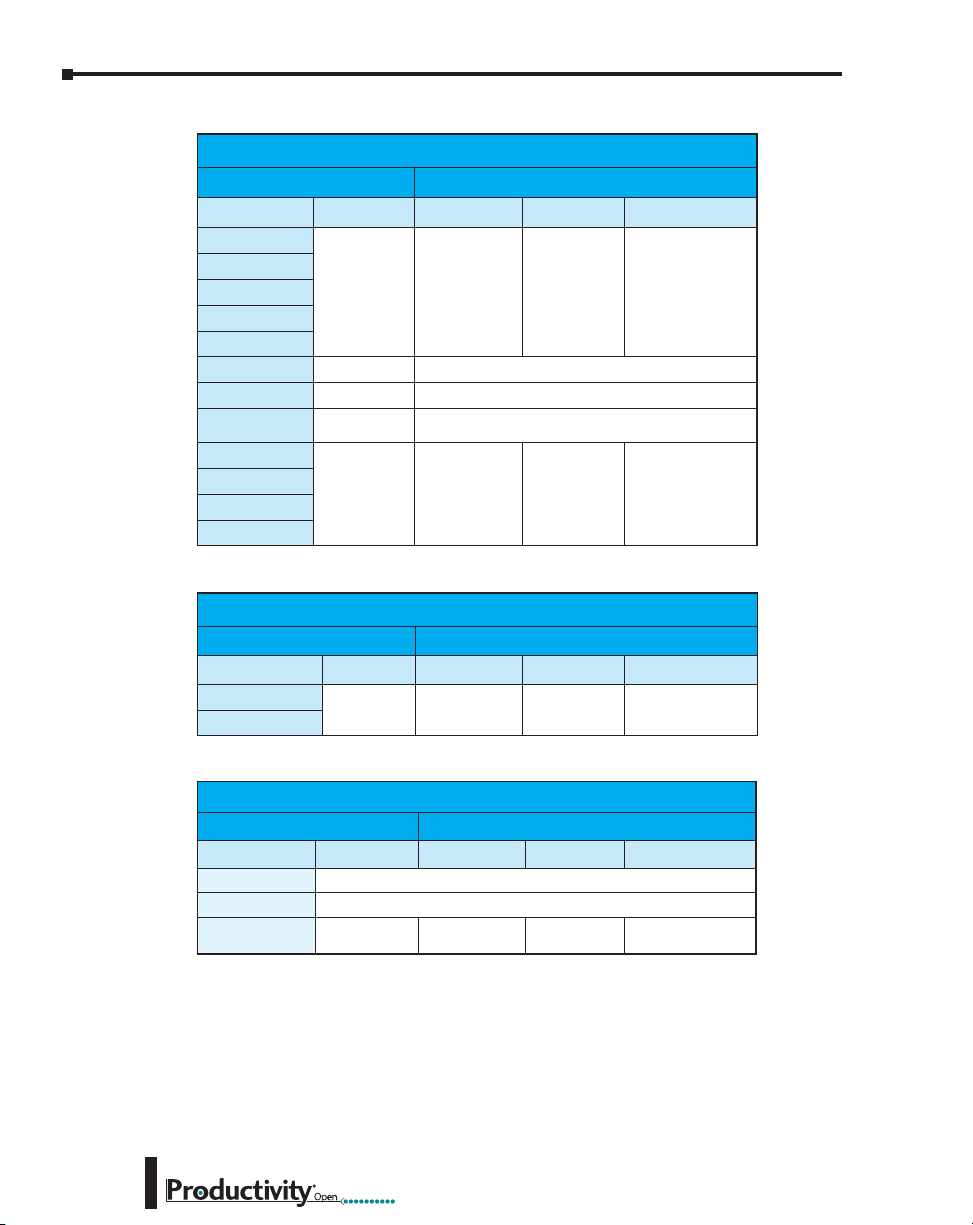

I/O Modules Overview

A variety of discrete and analog I/O modules from our Productivity1000 line are available

for use with the P1AM-100.

Chapter 2: Specifications

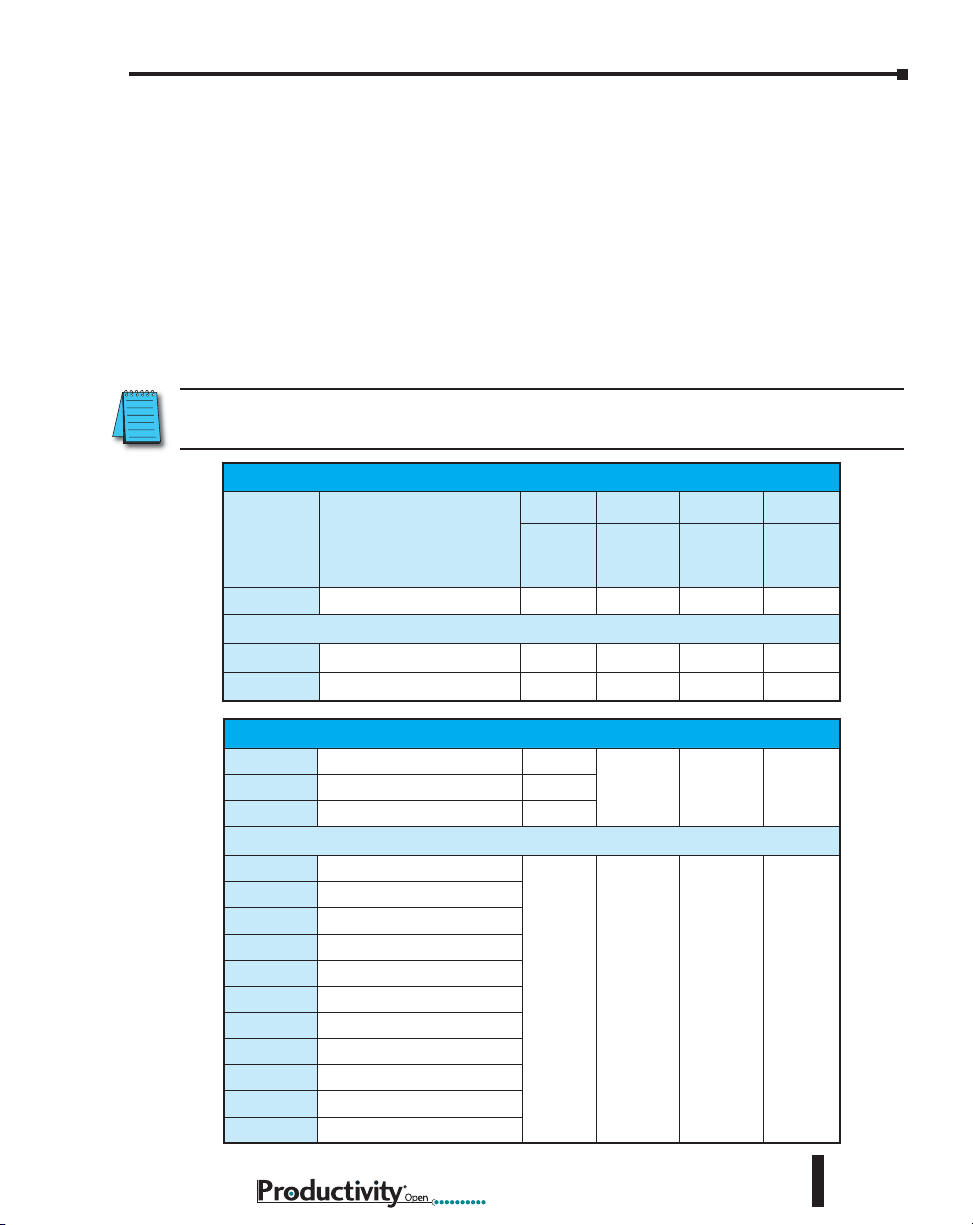

Productivity1000 Modules

Part Number Number of Inputs Description

Input Modules

P1-08SIM

P1-08ND3

P1-16ND3

P1-08NE3

P1-16NE3

P1-08NA

Output Modules

Number of Outputs

P1-08TD1

P1-08TD2

P1-15TD1

P1-15TD2

P1-08TA

P1-08TRS

P1-16TR

Input/Output Modules

Inputs Outputs

P1-15CDD1

P1-15CDD2

P1-16CDR

8 7

8 7

8 8

8

8

16

8

16

8

8 Sinking DC Output

8

15 Sinking DC Output

15

8

8

16

Input Simulator

Module

Sinking/Sourcing

12–24 VDC Input

Sinking/Sourcing

12–24 VDC Input

Sinking/Sourcing

24V AC/DC

Sinking/Sourcing

24V AC/DC

AC Isolated

100–240 VAC

Sourcing DC Output

Sourcing DC Output

AC Output

Isolated Relay

Output

Relay Output

Input: Sinking/

Sourcing; Output:

Sinking

Input: Sinking/

Sourcing; Output:

Sourcing

Input: Sinking/

Sourcing; Output:

Relay

Productivity1000 Modules

Part Number Number of Inputs Description

Input Modules

P1-04AD

P1-04ADL-1

P1-04ADL-2

P1-08ADL-1

P1-08ADL-2

P1-04RTD

P1-04THM

P1-04NTC

Output Modules

Number of Outputs

P1-04DAL-1

P1-04DAL-2

P1-08DAL-1

P1-08DAL-2

Input/Output Modules

P1-4ADL2DAL-1

P1-4ADL2DAL-2

4

4

4

8

8

4 RTD Input

4

4

4

4

8

8

Inputs Outputs

4 2

4 2

Analog Input

(Current)

Analog Input

(Current)

Analog Input

(Voltage)

Analog Input

(Current)

Analog Input

(Voltage)

Analog

Thermocouple

Input

Analog Thermistor

Input

Analog Output

(Current)

Analog Output

(Voltage)

Analog Output

(Current)

Analog Output

(Voltage)

Analog Input/Analog

Output (Current)

Analog Input/Analog

Output (Voltage)

Details on connecting to the Productivity1000 modules can be found at

https://github.com/facts-engineering/P1AM/wiki.

The Productivity1000 User Manual contains electrical and installation details. It is available for

FREE download at: https://cdn.automationdirect.com/static/manuals/p1userm/p1userm.html

Hardware User Manual, 1st Ed. Rev. A

2–13

Page 33

Chapter

Chapter

Chapter

InstallatIon and

IrIng

W

3

3

3

In This Chapter...

Safety Guidelines ....................................................................................................... 3–3

Plan for Safety .......................................................................................................... 3–3

Three Levels of Protection ........................................................................................3–4

Orderly System Shutdown ........................................................................................3–4

System Power Disconnect ........................................................................................3–4

Emergency Stop Circuits ..........................................................................................3–5

Introduction to the ProductivityOpen Mechanical Design ...................................... 3–6

Typical P1AM-100 ....................................................................................................3–6

Dimensions and Installation ...................................................................................... 3–7

Basic Dimensions .......................................................................................................3–9

Mounting Guidelines ............................................................................................... 3–12

Enclosures ..............................................................................................................3–12

Mounting Position ..................................................................................................3–12

Using Mounting Rails .............................................................................................3–12

Mounting Clearances .............................................................................................3–13

Temperature Considerations ................................................................................... 3–13

Power Considerations ............................................................................................. 3–13

Grounding .............................................................................................................3–14

Agency Approvals ...................................................................................................3–14

DIN Rail Mounting P1AM-100 System ....................................................................3–15

Surface Mounting P1AM-100 System ..................................................................... 3–15

Installing the I/O Modules ...................................................................................... 3–16

Wiring Guidelines ....................................................................................................3–17

Power Supply Wiring .............................................................................................. 3–17

Grounding .............................................................................................................3–17

Fuse Protection .......................................................................................................3–18

Page 34

Table of Contents

I/O Module Wiring Options ....................................................................................3–19

Hand Wiring System ............................................................................................... 3–19

ZIPLink Wiring System ...........................................................................................3–20

Terminal Block With Pigtail Cable ........................................................................... 3–20

Input and Output Modules ZIPLink Selections .......................................................3–21

Analog Modules ZIPLink Selections ........................................................................ 3–22

Removable Terminal Blocks (Optional) ................................................................... 3–23

P1-10RTB and P1-10RTB-1 .....................................................................................3–23

P2-RTB and P2-RTB-1 .............................................................................................3–23

Terminal Block Installation ...................................................................................... 3–24

Terminal Block Removal .......................................................................................... 3–25

Planning the I/O Wiring Routes .............................................................................. 3–25

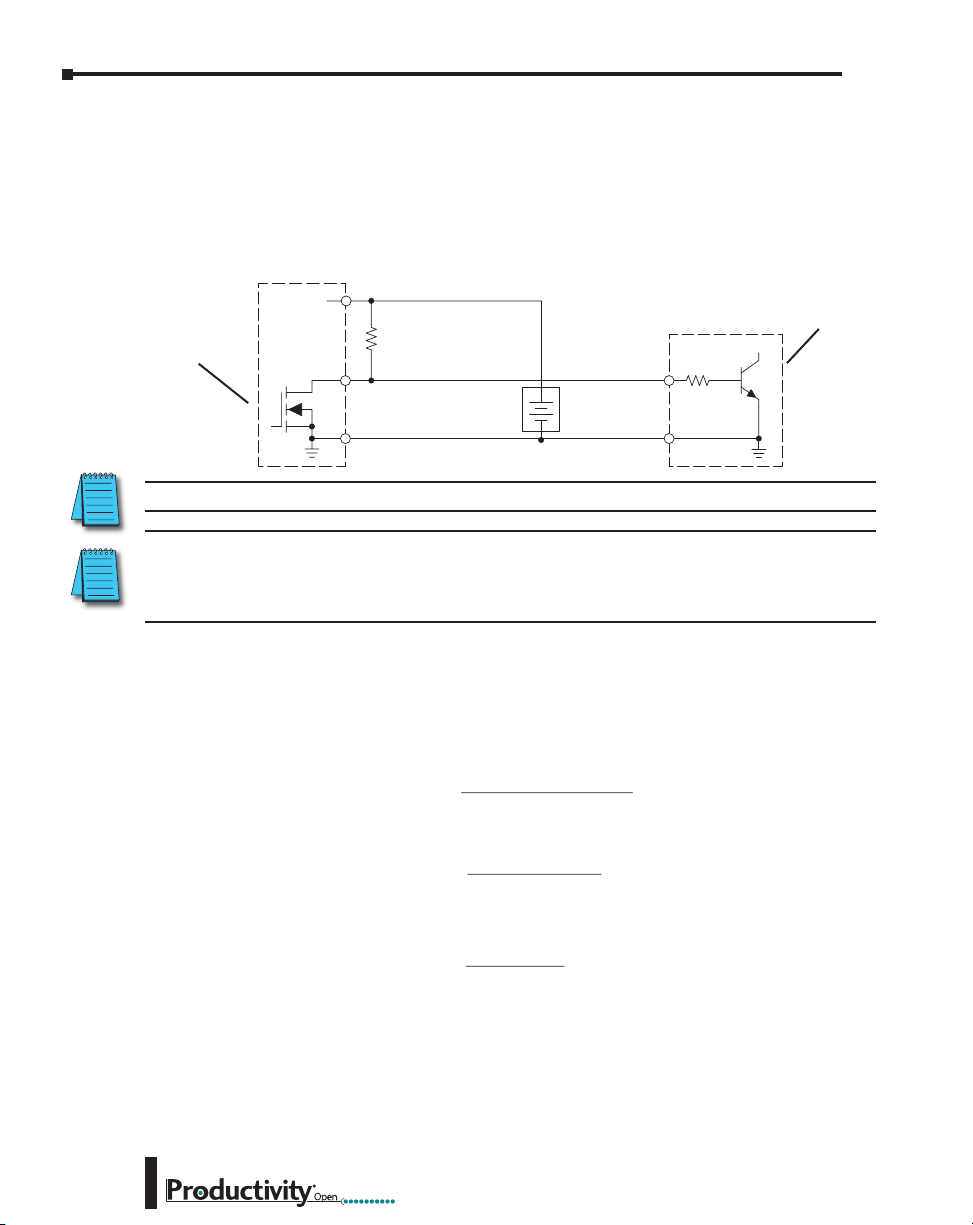

System Wiring Strategies ........................................................................................3–26

CPU Isolation Boundaries .......................................................................................3–26

Sinking/Sourcing Concepts ....................................................................................3–27

I/O “Common Terminal” Concepts ........................................................................ 3–28

DC Input Wiring Methods ...................................................................................... 3–29

DC Output Wiring Methods ................................................................................... 3–29

Relay Outputs - Wiring Methods ............................................................................3–31

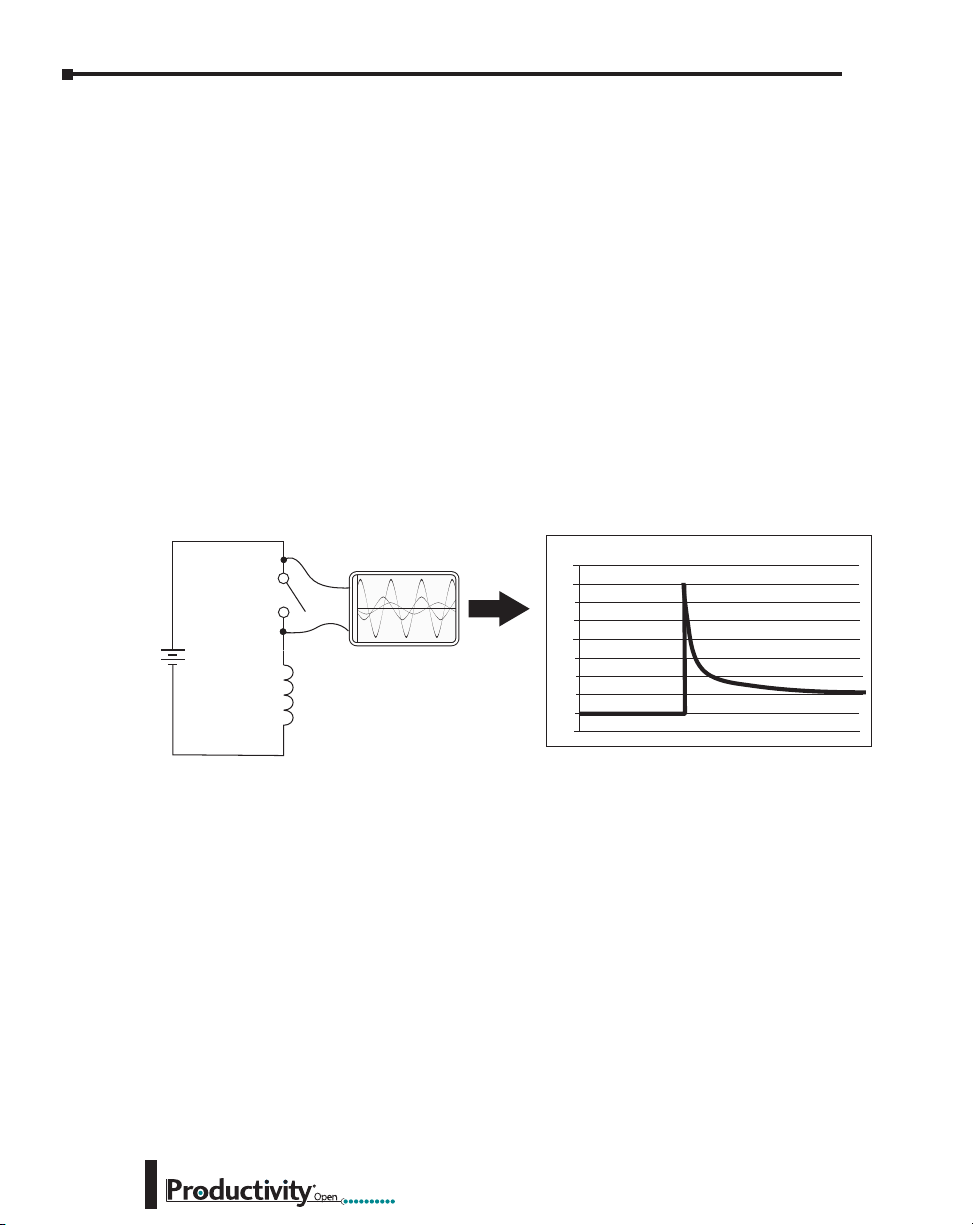

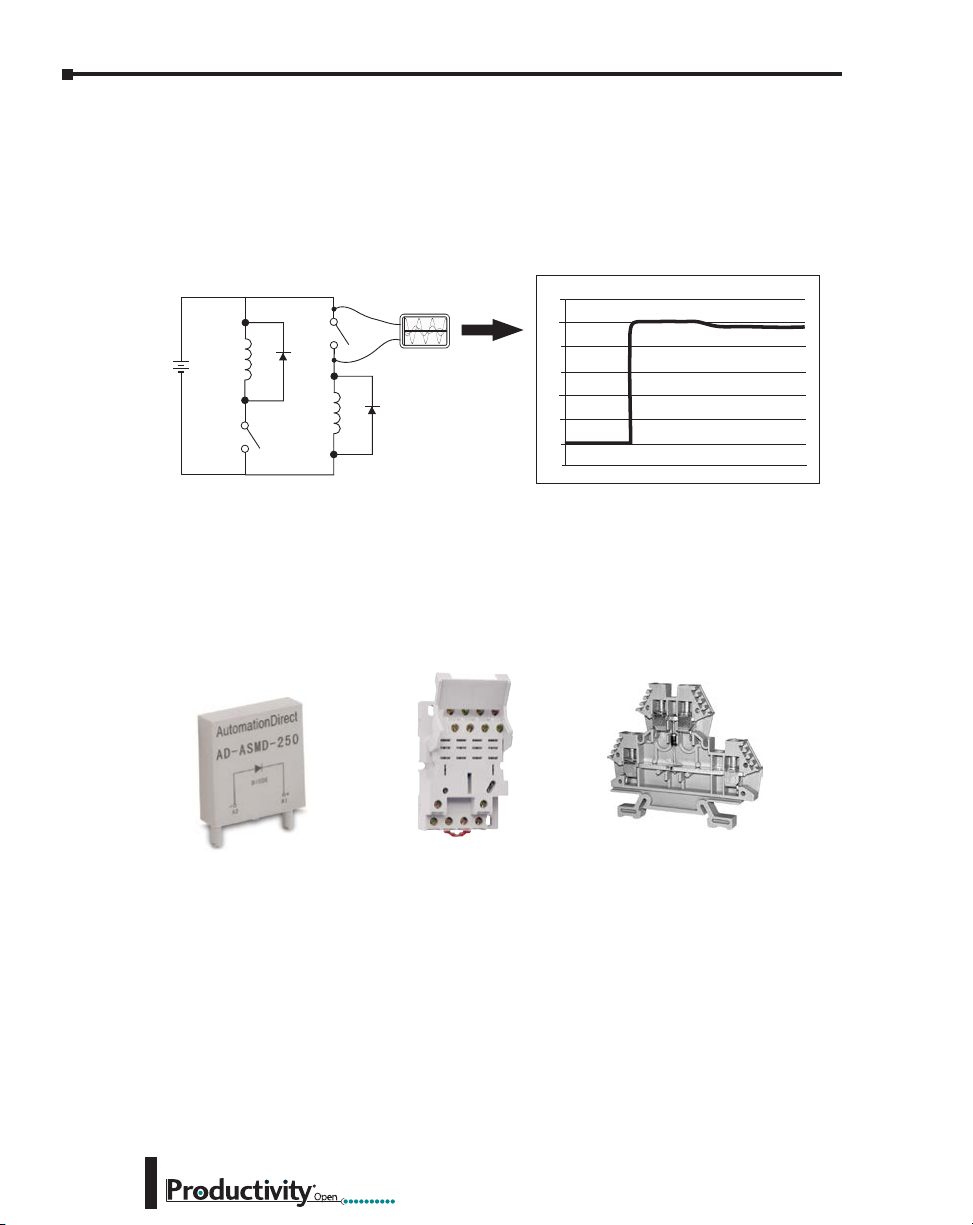

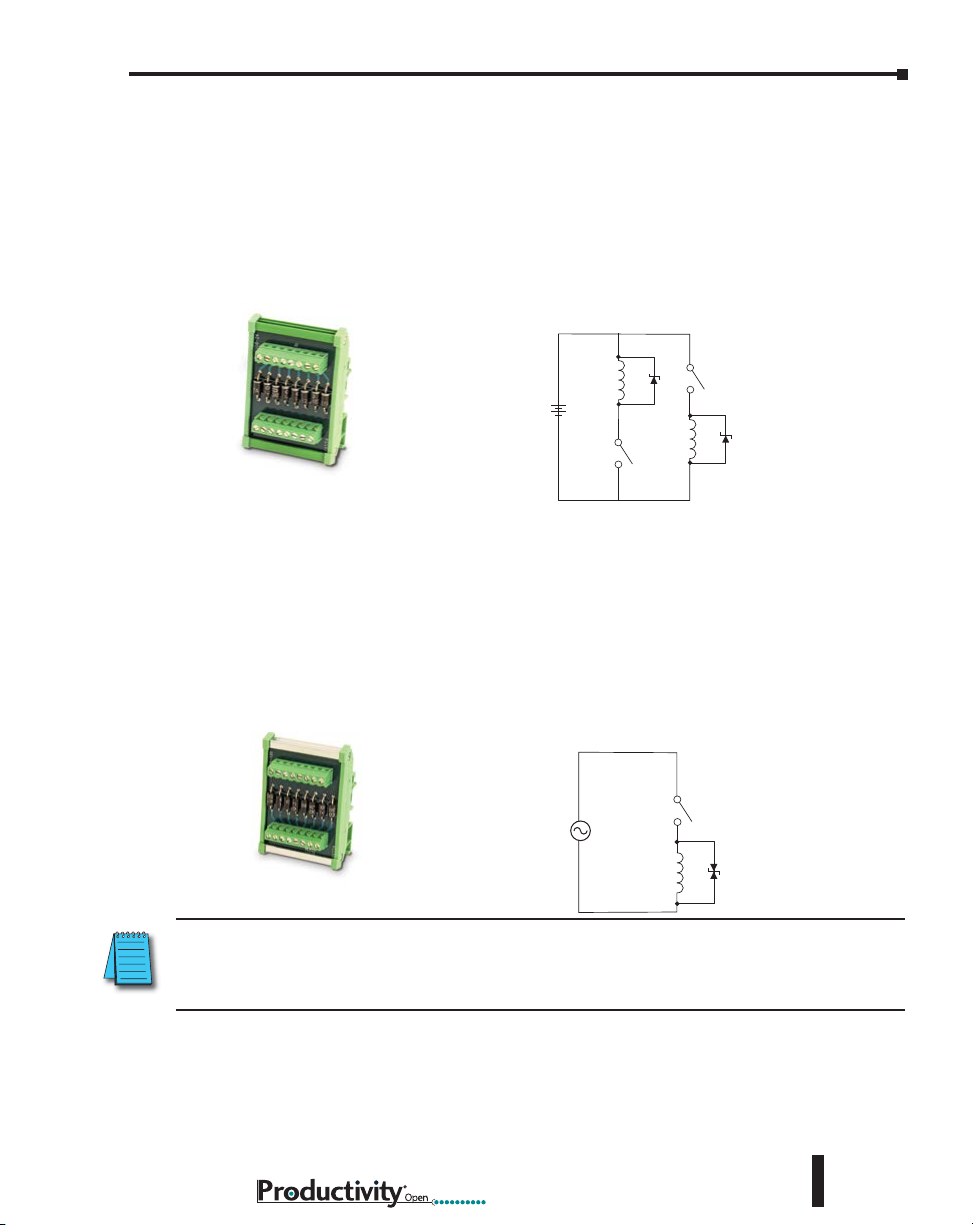

Relay Outputs – Transient Suppression for Inductive Loads in a Control System ..... 3–32

3–2

Hardware User Manual, 1st Ed. Rev. A

Page 35

Safety Guidelines

NOTE: Products with CE marks perform their required functions safely and adhere to relevant standards

as specified by CE directives provided they are used according to their intended purpose and that the

instructions in this manual are adhered to. The protection provided by the equipment may be impaired if

this equipment is used in a manner not specified in this manual. A listing of our international affiliates is

available on our Web site at http://www.automationdirect.com.

WARNING: Providing a safe operating environment for personnel and equipment is your responsibility

and should be your primary goal during system planning and installation. Automation systems can

fail and may result in situations that can cause serious injury to personnel or damage to equipment.

Do not rely on the automation system alone to provide a safe operating environment. You should

use external electromechanical devices, such as relays or limit switches, that are independent of the

P1AM-100 application to provide protection for any part of the system that may cause personal injury

or damage. Every automation application is different, so there may be special requirements for your

particular application. Make sure you follow all national, state, and local government requirements for

the proper installation and use of your equipment.

Plan for Safety

The best way to provide a safe operating environment is to make personnel and equipment

safety part of the planning process. You should examine every aspect of the system to determine

which areas are critical to operator or machine safety. If you are not familiar with controller

type system installation practices, or your company does not have established installation

guidelines, you should obtain additional information from the following sources.

• NEMA — The National Electrical Manufacturers Association, located in Washington,

D.C., publishes many different documents that discuss standards for industrial control

systems. You can order these publications directly from NEMA. Some of these include:

ICS 1, General Standards for Industrial Control and Systems

ICS 3, Industrial Systems

ICS 6, Enclosures for Industrial Control Systems

• NEC — The National Electrical Code provides regulations concerning the installation

and use of various types of electrical equipment. Copies of the NEC Handbook can

often be obtained from your local electrical equipment distributor or your local library.

• Local and State Agencies — many local governments and state governments have

additional requirements above and beyond those described in the NEC Handbook.

Check with your local Electrical Inspector or Fire Marshall office for information.

Chapter 3: Installation and Wiring

Hardware User Manual, 1st Ed. Rev. A

3–3

Page 36

Chapter 3: Installation and Wiring

Arm

Three Levels of Protection

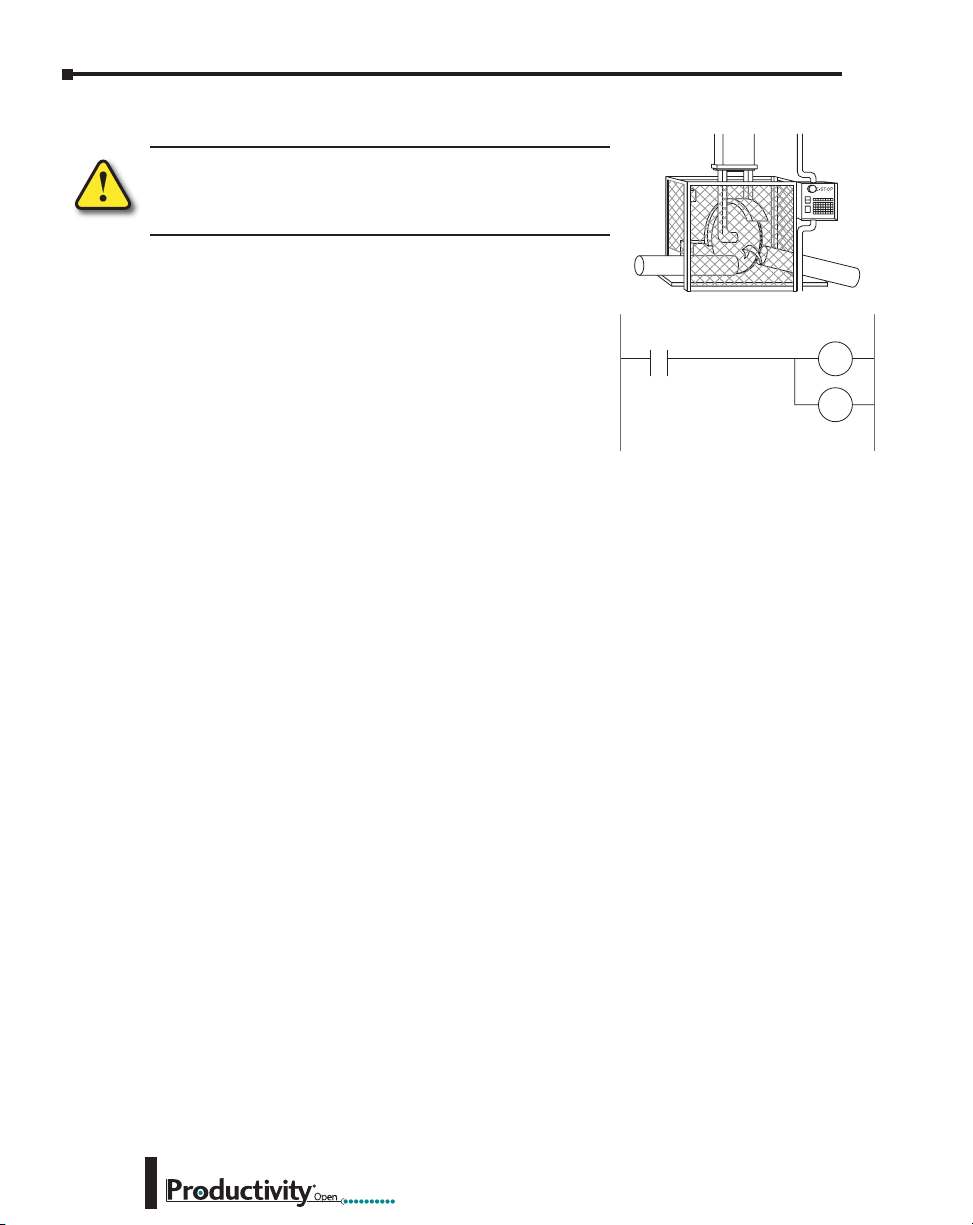

WARNING: The control program must not be the only form of

protection for any problems that may result in a risk of personal

injury or equipment damage.

The publications mentioned provide many ideas and

requirements for system safety. At a minimum, you should

follow these regulations. Also, you should use the following

techniques, which provide three levels of system control.

1. Orderly system shutdown sequence in

the P1AM-100 control program.

2. Mechanical disconnect for output module power.

3. Emergency stop switch for

disconnecting system power.

Orderly System Shutdown

The first level of fault detection is ideally the P1AM-100 control program, which can identify

machine problems. Certain shutdown sequences should be performed. These types of

problems are usually things such as jammed parts, etc., that do not pose a risk of personal

injury or equipment damage.

System Power Disconnect

You should also use electromechanical devices, such as master control relays and/or limit

switches, to prevent accidental equipment startup at an unexpected time. These devices should

be installed in a manner that will prevent any machine operations from occurring.

For example, if the machine in the illustration has a jammed part, the P1AM-100 control

program can turn off the saw blade and retract the arbor. If the operator must open the guard

to remove the part, you should also include a bypass switch that disconnects all system power

any time the guard is opened.

Jam

Detect

Turn off

Saw

RST

RST

Retract

3–4

Hardware User Manual, 1st Ed. Rev. A

Page 37

Chapter 3: Installation and Wiring

1

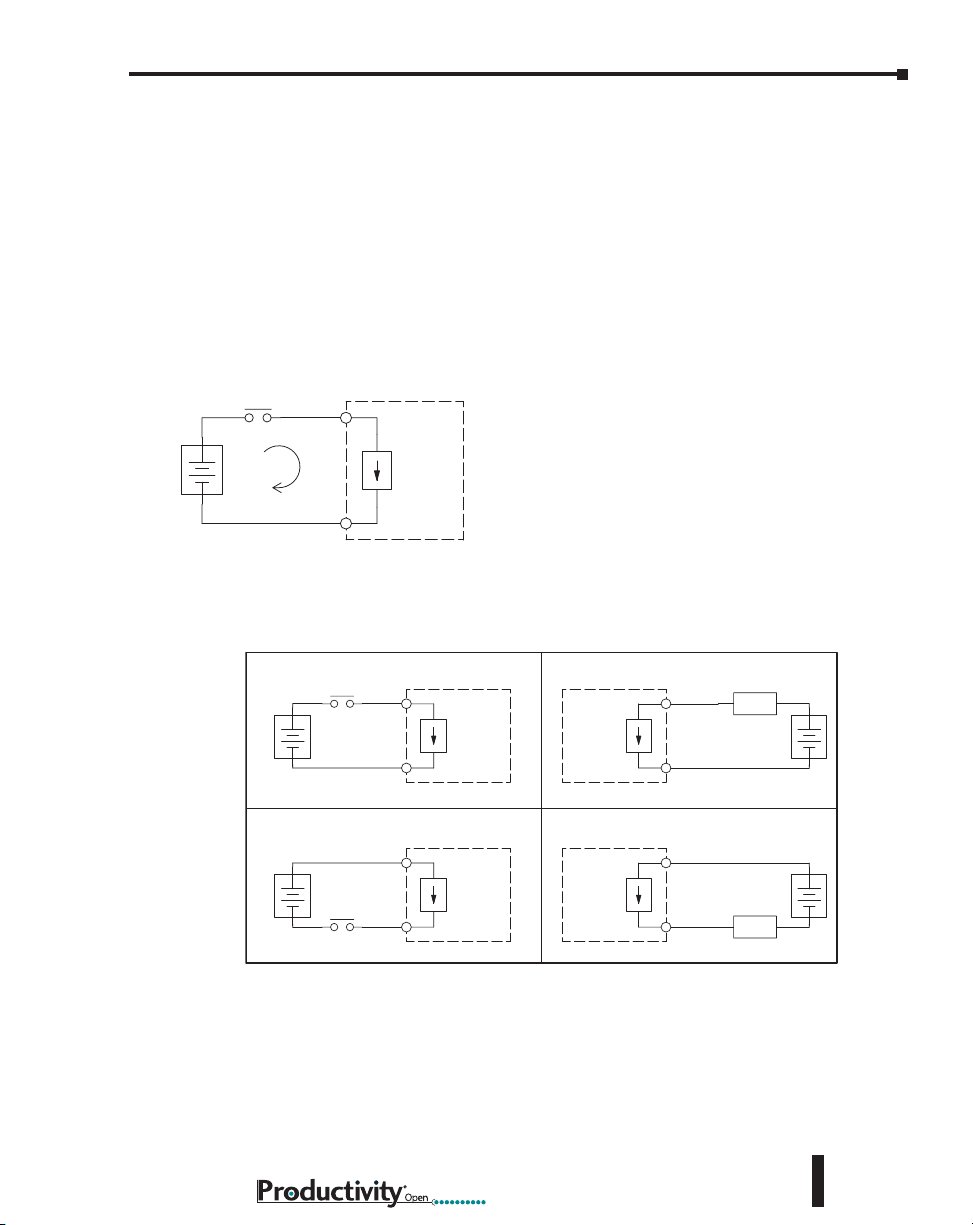

Emergency Stop Circuits

Emergency stop (E-Stop) circuits are a critical part of automation safety. For each machine

controlled by a P1AM-100, provide an emergency stop device that is wired outside the P1AM100 and easily accessed by the machine operator.

E-Stop devices are commonly wired through a master control relay (MCR) or a safety control

relay (SCR) that will remove power from the P1AM-100 I/O system in an emergency.

MCRs and SCRs provide a convenient means for removing power from the I/O system

during an emergency situation. By de-energizing an MCR (or SCR) coil, power to the input

(optional) and output devices is removed. This event occurs when any emergency stop switch

opens. However, the P1AM-100 continues to receive power and operate even though all its

inputs and outputs are disabled.

The MCR circuit could be extended by placing a P1AM-100 fault relay (closed during normal

P1AM-100 operation) in series with any other emergency stop conditions. This would cause

the MCR circuit to drop the P1AM-100 I/O power in case of a P1AM-100 failure (memory

error, I/O communications error, etc.).

EMERGENCY

STOP

Guard

Limit

Switch

L1 N

L

Use E-Stop and Master Control Relay

se E-Stop and Maste

E-Stop Power On

E-Stopower On

MCR

MCR

MCR

CR1

Limit

Switch

Master

Control

Relay (MCR)

CR1

Saw Arbor

WARNING: For some applications, field device power may still be present on the terminal block even

though the P1AM-100 is turned off. To minimize the risk of electrical shock, remove all field device

power before you expose or remove P1AM-100 wiring.

Hardware User Manual, 1st Ed. Rev. A

3–5

Page 38

Chapter 3: Installation and Wiring

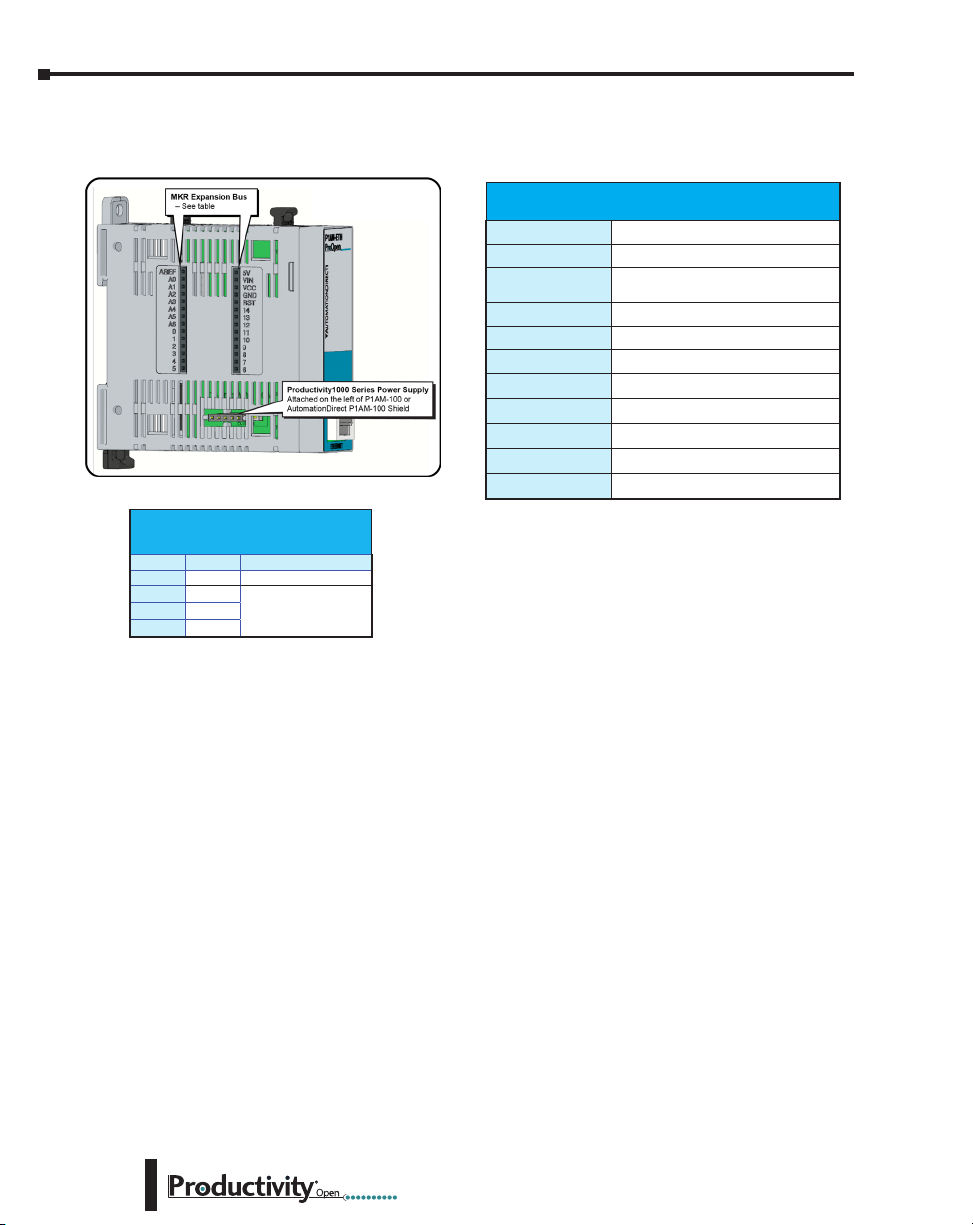

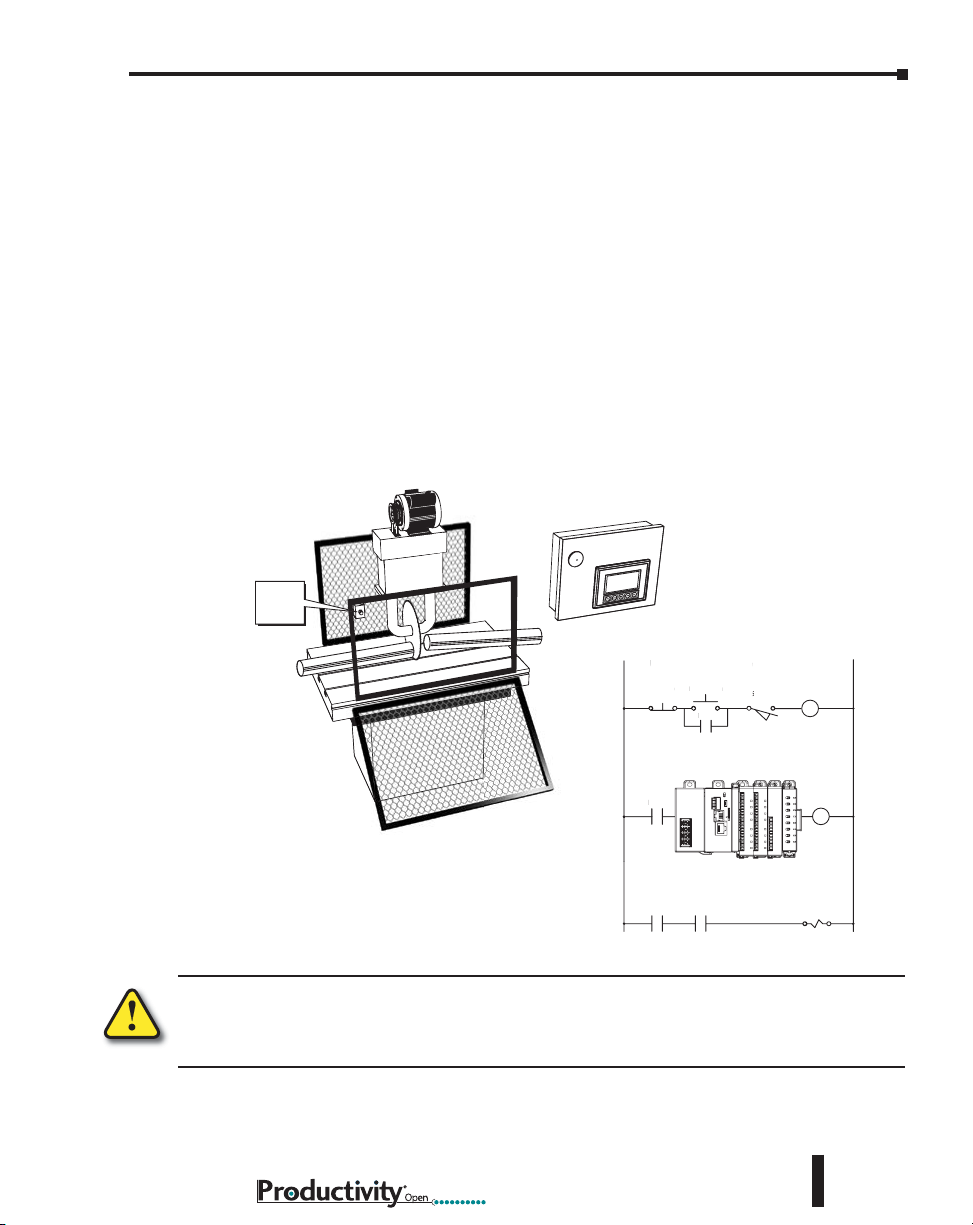

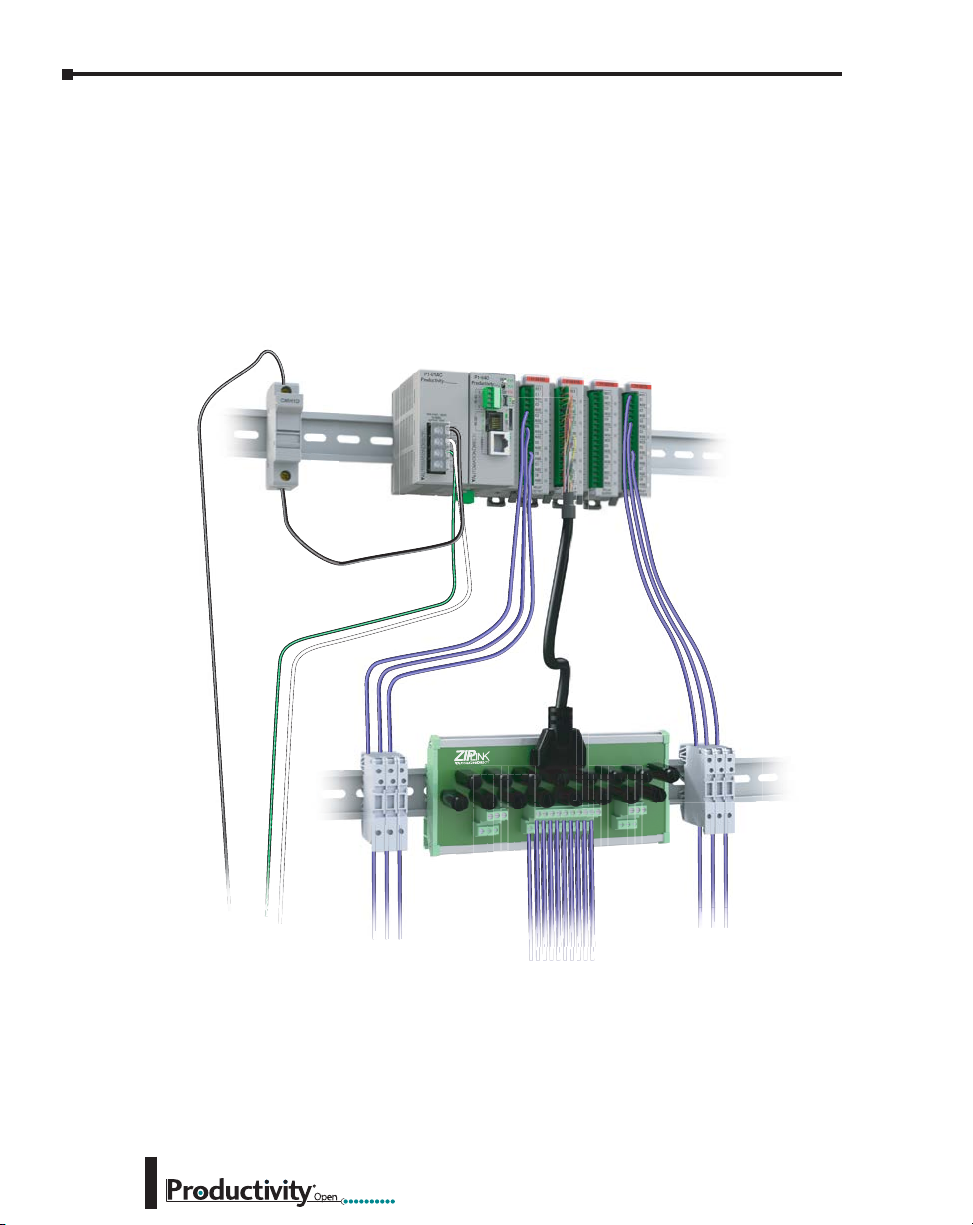

Introduction to the ProductivityOpen Mechanical Design

The ProductivityOpen is a modular system built by adding Productivity1000 Input/output

modules and Arduino MKR-compatible shields to a P1AM-100 Arduino-compatible CPU.

The I/O modules are connected directly to the right side of the P1AM-100 and to each other

in a continuous stack up to 15 modules.

Power budget does need to be considered - 8 or fewer modules can use the P1-01AC,

exceeding 8 modules uses P1-02AC. No backplane or base is required. Each module

connection extends the backbone communication bus.

Connect Arduino-MKR shields to the left side of the P1AM-100 CPU. The combinations on

the left side are limited only by the general purpose IO pins that must be dedicated to each

shield.

Typical P1AM-100

P1-08SIM

P1-08TD1

P1-15CDD1

C1

1

2

3

4

5

6

7

8

C2

1

2

3

4

5

6

7

V+

12-24VDC IN

3.3-24V OUT

INPUTSOUTPUTS

3.3-24VDC

SINK OUTPUT

COM

V+

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

OFF ON

INPUT SIMULATOR

P1-01AC

Power Supply

or Alternate

3–6

P1AM-PROTO

(Customizable

Shield Kit)

P1AM-GPIO

P1-15CDD1

Combo Module

P1AM-ETH

P1AM-100

Hardware User Manual, 1st Ed. Rev. A

P1-08TD1 Output

Module

P1-08SIM

Input Module

Page 39

Dimensions and Installation

Before installing the P1AM-100 you will need to know the dimensions of the components

considered. The tables and diagrams on the following pages provide basic dimensions to use

in defining your enclosure specifications. Remember to leave room for expansion module

insertion and/or replacement and for potential expansion. If you are using other components

in your system, refer to the appropriate manual to determine how those units can affect

mounting dimensions.

The basic dimensions for the modules are listed in the tables. The width varies depending on

the type of module. P1AM-100 is designed to be mounted on standard 35mm DIN rail, or it

may be surface mounted. Make sure you have followed the installation guidelines for proper

spacing.

NOTE: Dimensional drawings for the P1AM-100, power supplies, and all modules are available on the

AutomationDirect.com site.

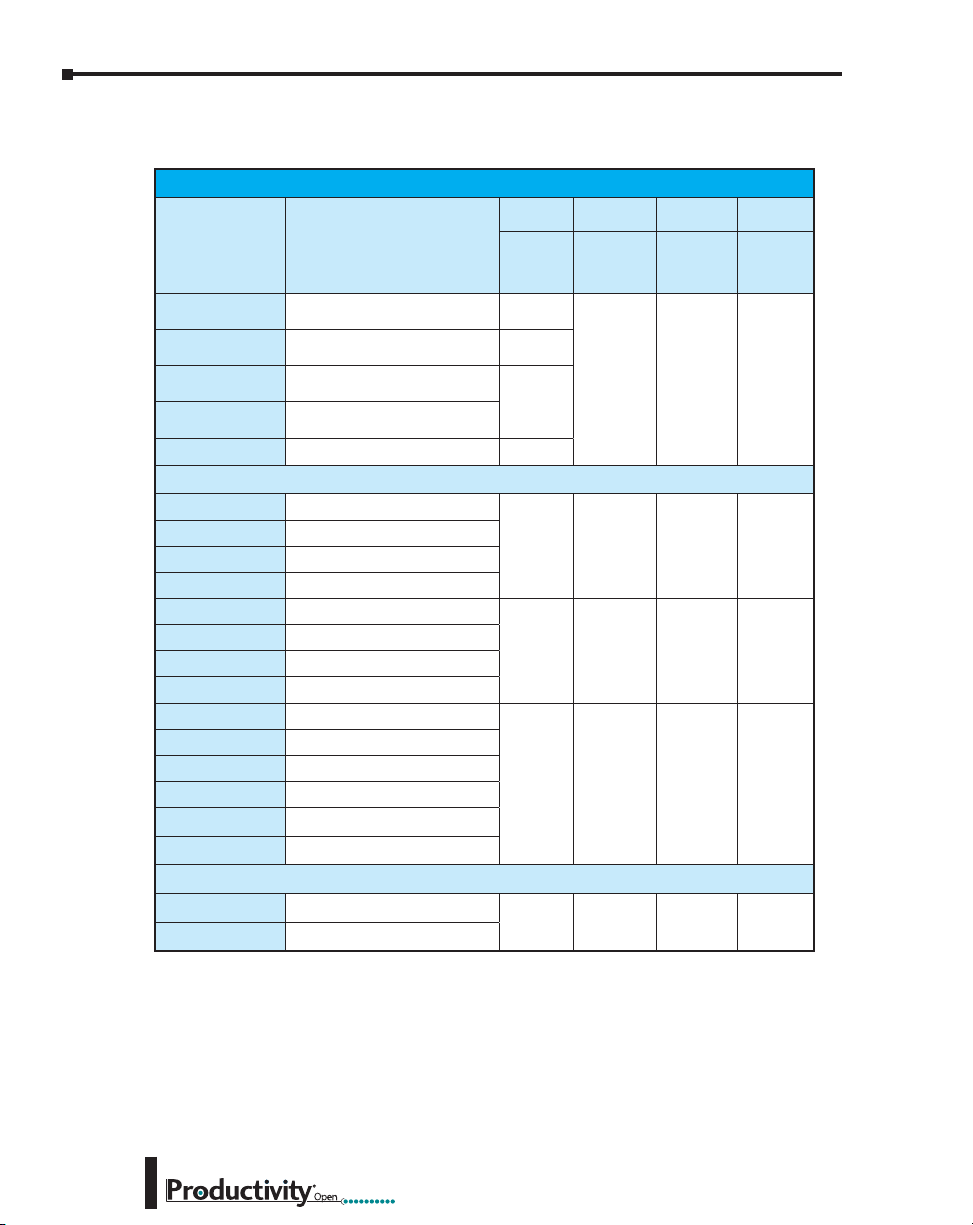

Productivity Open Component Dimensions

Module

P1AM-100

P1AM-GPIO

P1AM-ETH

Description

Controller 23.1 [0.91] 77.0 [3.03] 92.8 [3.65] 91.3 [3.59]

Left Side Communication Shields (LSX)

General Purpose I/O

Ethernet Communication

Chapter 3: Installation and Wiring

A B C D

Height

w/Tabs

mm [in]

Depth

mm [in]

Width

mm [in]

23.1 [0.91] 77.0 [3.03] 92.8 [3.65] 86.7 [3.41]

23.1 [0.91] 77.0 [3.03] 92.8 [3.65] 89.7 [3.53]

Height

Faceplate

mm [in]

P1-01AC

P1-02AC

P1-01DC

P1-08SIM

P1-08ND3

P1-16ND3

P1-08NE3

P1-16NE3

P1-08NA

P1-08TD1

P1-08TD2

P1-15TD1

P1-15TD2

P1-08TA

Productivity1000 Component Dimensions

AC/DC Power Supply 35.0 [1.38]

AC Power Supply 52.2 [2.06]

DC Power Supply 35.0 [1.38]

Discrete Expansion Modules (Right Side)

Simulator Input

Sinking/Sourcing 12–24 VDC Input

Sinking/Sourcing 12–24 VDC Input

Sinking/Sourcing 12–24 VDC Input

Sinking/Sourcing 12–24 VDC Input

AC Isolated 100–240 VAC

Sinking Output

Sourcing Output

Sinking Output

Sourcing Output

AC Output

17.2 [0.68] 77.0 [3.03] 93.6 [3.69] 86.6 [3.41]

Hardware User Manual, 1st Ed. Rev. A

77.0 [3.03] 92.8 [3.65] 98.3 [3.87]

3–7

Page 40

Chapter 3: Installation and Wiring

Dimensions and Installation (continued)

ProductivityOpen Component Dimensions

A B C D

Module Description

P1-08TRS

Isolated Relay Output 17.2 [0.68]

Width

mm [in]

Height

Faceplate

mm [in]

mm [in]

Height

w/Tabs

Depth

mm [in]

P1-16TR

P1-15CDD1

P1-15CDD2

P1-16CDR

P1-04RTD

P1-04THM

P1-04NTC

P1-04AD

P1-04ADL-1

P1-04ADL-2

P1-04DAL-1

P1-04DAL-2

P1-08ADL-1

P1-08ADL-2

P1-08DAL-1

P1-08DAL-2

P1-4ADL2DAL-1

P1-4ADL2DAL-2

P1-02HSC

P1-04PWM

Relay Output 26.3 [1.03]

Input: Sinking/Sourcing;

Output: Sinking

Input: Sinking/Sourcing;

Output: Sourcing

Discrete Relay Combo Module 26.3 [1.03]

Analog Expansion Modules

Dierential RTD

Analog Thermocouple Input

Analog Thermistor Input

Analog Input (Current)

Analog Input (Current)

Analog Input (Voltage)

Analog Output (Current)

Analog Output (Voltage)

Analog Input (Current)

Analog Input (Voltage)

Analog Output (Current)

Analog Output (Voltage)

Analog Input/Analog Output (Current)

Analog Input/Analog Output (Voltage)

Specialty Expansion Modules

High-Speed Input (Current)

Pulse Width Modulation Input (Voltage)

77.0 [3.03] 93.6 [3.69] 86.6 [3.41]

17.2 [0.68]

17.2 [0.68] 77.0 [3.03] 93.6 [3.69] 81.6 [3.21]

17.2 [0.68] 77.0 [3.03] 93.6 [3.69] 81.9 [3.22]

17.2 [0.68] 77.0 [3.03] 93.6 [3.69] 81.6 [3.21]

17.2 [0.68] 77.0 [3.03] 93.6 [3.69] 81.6 [3.21]

3–8

Hardware User Manual, 1st Ed. Rev. A

Page 41

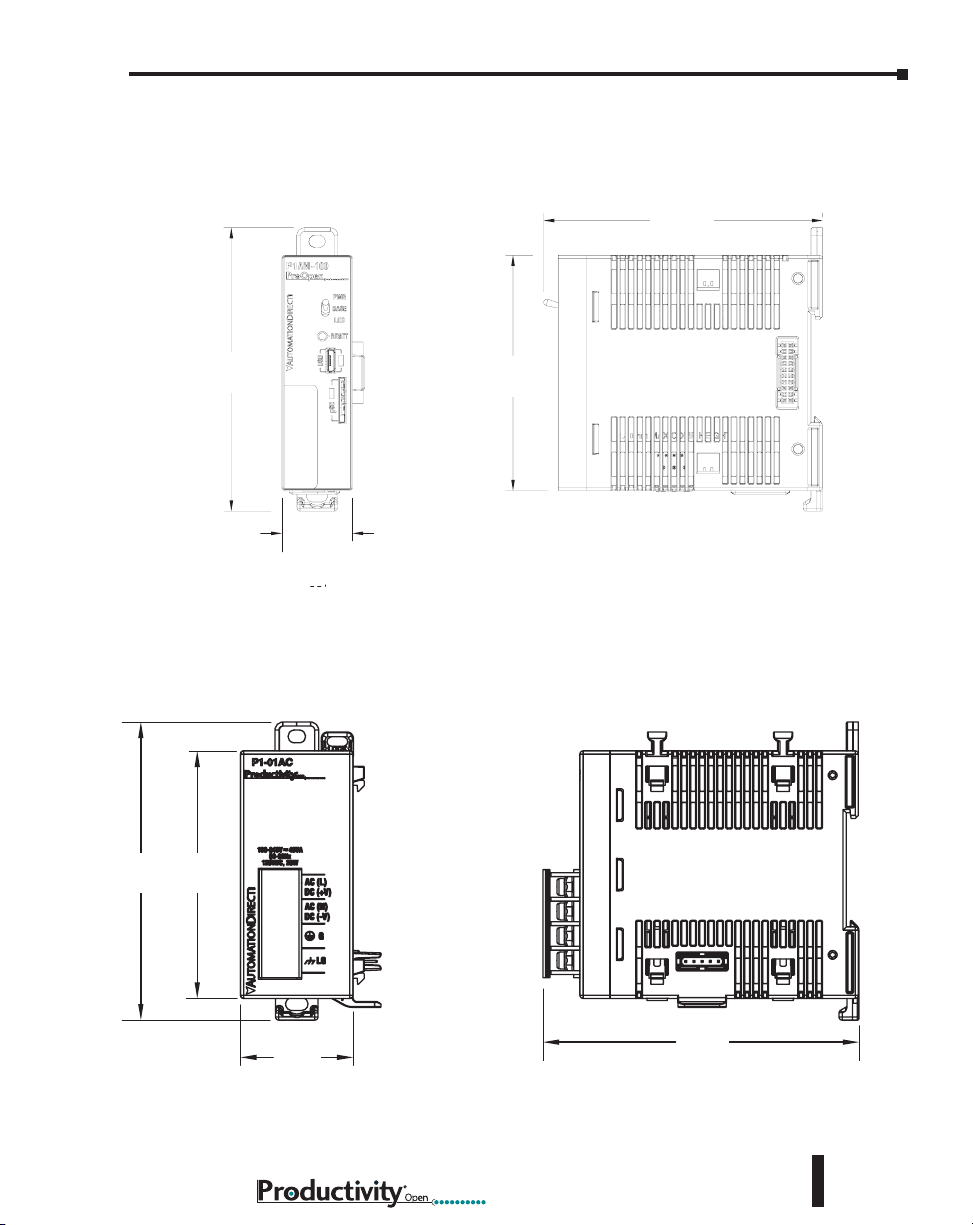

Basic Dimensions

P1AM-100

Chapter 3: Installation and Wiring

Units: mm [inches]

D

C

A

P1-01AC, P1-02AC and P1-01DC

C

B

B

A

Hardware User Manual, 1st Ed. Rev. A

D

3–9

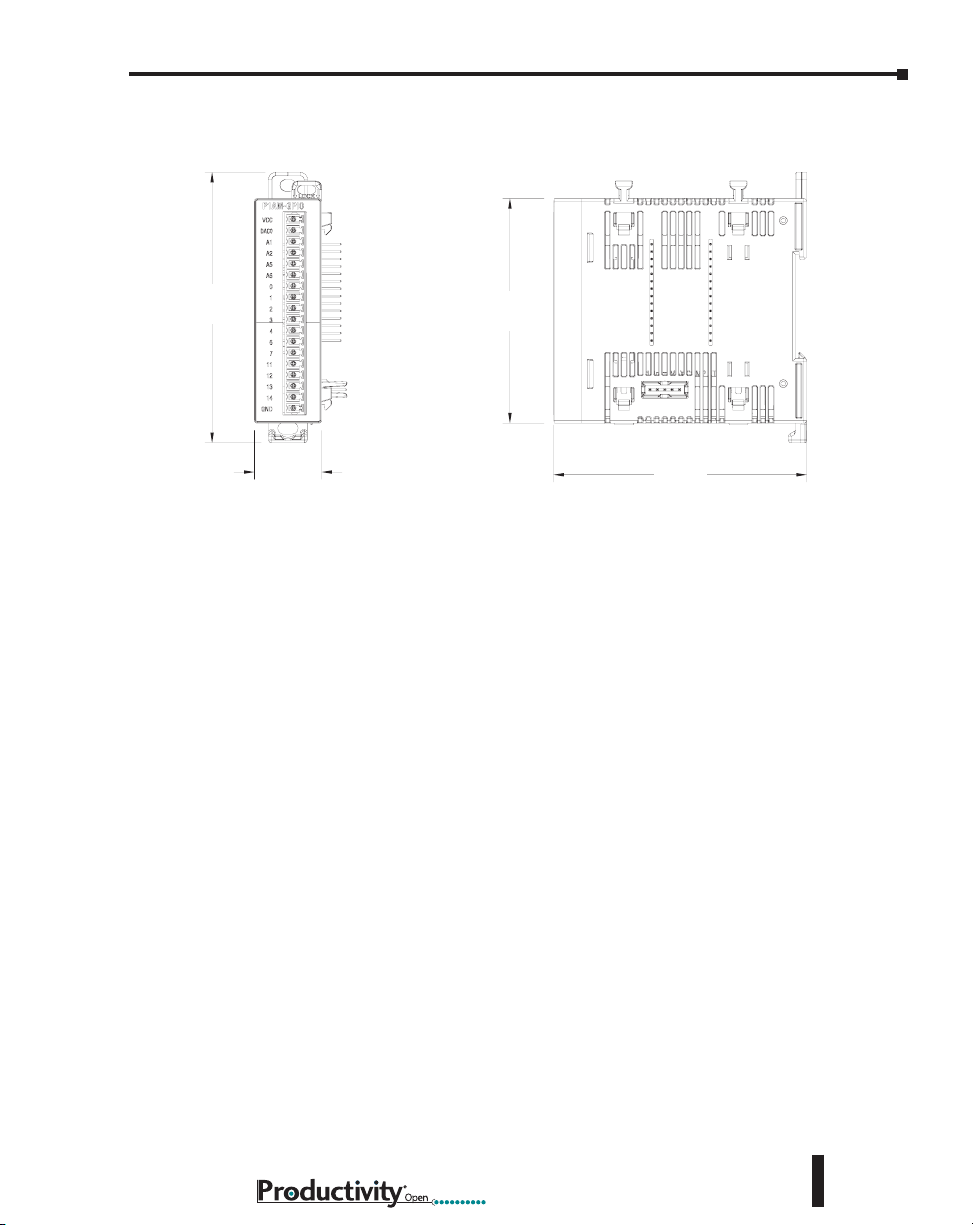

Page 42

Chapter 3: Installation and Wiring

Basic Dimensions (continued)

Productivity1000 I/O Modules

P1AM-ETH

C

C

A

B

D

B

3–10

A

Hardware User Manual, 1st Ed. Rev. A

D

Units: mm [inches]

Page 43

P1AM-GPIO Module

Chapter 3: Installation and Wiring

C

A

B

D

Units: mm [inches]

Hardware User Manual, 1st Ed. Rev. A

3–11

Page 44

Chapter 3: Installation and Wiring

Airflow

2ʺ

g

Mounting Guidelines

Enclosures

Your selection of a proper enclosure is important to ensure safe and proper operation of your

P1AM-100. Applications for the P1AM-100 vary and may require additional hardware

considerations. The minimum considerations for enclosures include:

• Conformance to electrical standards

• Protection from the elements in an industrial environment

• Common ground reference

• Maintenance of specified ambient temperature

• Access to the equipment

• Security or restricted access

• Sufficient space for proper installation and

maintenance of the equipment

Mounting Position

Mount the P1AM-100 and expansion modules horizontally, as shown in the illustration on the

following page, to provide proper ventilation. Do not mount vertically, upside down, or on a

flat horizontal surface.

NOTE: Add 2ʺ to mountin

depth when using ZIPLink

cable.

Using Mounting Rails

The ProductivityOpen modules can be secured within an enclosure or cabinet using mounting

rails. Use rails that conform to DIN EN standard 50022. We offer a complete line of DIN rail,

DINnectors and DIN rail mounted apparatus. The rails are approximately 35mm high, with a

depth of 7.5 mm. If you mount the module(s) on a DIN rail, consider using end brackets on

each side of the base. The end brackets keep the module(s) from sliding horizontally along the

rail, thus minimizing the possibility of accidentally pulling the wiring loose.

3–12

End Bracket (Part No. DN-EB35)

DIN Rail (Part No. DN-R35S1)

Hardware User Manual, 1st Ed. Rev. A

DIN Rail

Dimensions

7.5 mm

35 mm

Page 45

Chapter 3: Installation and Wiring

Mounting Clearances

Provide a minimum clearance of 2 inches (50mm) on all sides of the assembled system. Allow

extra clearance for door mounted operator panels, push buttons, lights and other items. There

should be a minimum of 3 inches (76mm) vertical clearance between the module(s) and any

wire duct, and a minimum of 7.2 inches (183mm) vertical distance from chassis to chassis in a

multiple unit installation.

The clearances required for P1AM-100 are represented in the graphic below of a similar PLC

system when mounted in an enclosure.

2”

50mm

min

7.2”

3”

min

3”

76mm

min

183mm

min

76mm

2”

50mm

min

Temperature Considerations

The P1AM-100 enclosure should be installed in an environment which is within the specified

equipment operating temperature. If the environment temperature deviates above or below the

specification, measures such as cooling or heating the enclosure should be taken to maintain

the specification.

Power Considerations

When the P1AM-100 is powered by a Productivity power supply (P1-01AC, P1-02AC or

P1-01DC), EMF/RFI line filters are not required to meet the requirements of the CE EMC

Directive.

Hardware User Manual, 1st Ed. Rev. A

3–13

Page 46

Chapter 3: Installation and Wiring

In addition to the panel layout guidelines, other specifications can affect the installation of a

CPU system. Always consider the following:

• Environmental Specifications

• Power Requirements

• Agency Approvals

• Enclosure Selection and Component Dimensions

Grounding

A sound common ground reference (earth ground) is essential for proper operation of the

P1AM-100. One side of all control circuits and power circuits along with the ground lead

must be properly connected to earth ground (earthing) either by connecting to the incoming

power system ground or by installing a ground rod in close proximity to the enclosure. There

must be a single-point ground (i.e. copper bus bar) for all devices in the enclosure that require

an earth ground.

Panel

Ground Braid

Copper Lugs

Panel or

Single Point