Page 1

HX-ECOM Manual

Manual Number: HX-ECOM-M

Page 2

Notes

Page 3

~ WARNING ~

Thank you for purchasing automation equipment from AutomationDirect.com®, doing business as,

AutomationDirect. We want your new automation equipment to operate safely. Anyone who installs or

uses this equipment should read this publication (and any other relevant publications) before installing or

operating the equipment.

To minimize the risk of potential safety problems, you should follow all applicable local and national

codes that regulate the installation and operation of your equipment. These codes vary from area to area

and usually change with time. It is your responsibility to determine which codes should be followed, and

to verify that the equipment, installation, and operation is in compliance with the latest revision of these

codes.

At a minimum, you should follow all applicable sections of the National Fire Code, National Electrical

Code, and the codes of the National Electrical Manufacturer’s Association (NEMA). There may be local

regulatory or government offices that can also help determine which codes and standards are necessary for

safe installation and operation.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable

codes and standards. We do not guarantee the products described in this publication are suitable for

your particular application, nor do we assume any responsibility for your product design, installation, or

operation.

Our products are not fault-tolerant and are not designed, manufactured or intended for use or resale as

on-line control equipment in hazardous environments requiring fail-safe performance, such as in the

operation of nuclear facilities, aircraft navigation or communication systems, air traffic control, direct life

support machines, or weapons systems, in which the failure of the product could lead directly to death,

personal injury, or severe physical or environmental damage (“High Risk Activities”). AutomationDirect

specifically disclaims any expressed or implied warranty of fitness for High Risk Activities.

For additional warranty and safety information, see the Terms and Conditions section of our catalog.

If you have any questions concerning the installation or operation of this equipment, or if you need

additional information, please call us at 770-844-4200.

This publication is based on information that was available at the time it was printed. At

AutomationDirect we constantly strive to improve our products and services, so we reserve the right to

make changes to the products and/or publications at any time without notice and without any obligation.

This publication may also discuss features that may not be available in certain revisions of the product.

Trademarks

This publication may contain references to products produced and/or offered by other companies. The

product and company names may be trademarked and are the sole property of their respective owners.

AutomationDirect disclaims any proprietary interest in the marks and names of others.

Copyright 2020, AutomationDirect.com Incorporated

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior, written

consent of AutomationDirect.com Incorporated. AutomationDirect retains the exclusive rights to all

information included in this document.

All Rights Reserved

Page 4

~ ADVERTENCIA ~

Gracias por comprar equipo de automatización de Automationdirect.com®. Deseamos que su nuevo equipo

de automatización opere de manera segura. Cualquier persona que instale o use este equipo debe leer esta

publicación (y cualquier otra publicación pertinente) antes de instalar u operar el equipo.

Para reducir al mínimo el riesgo debido a problemas de seguridad, debe seguir todos los códigos de seguridad

locales o nacionales aplicables que regulan la instalación y operación de su equipo. Estos códigos varian de

área en área y usualmente cambian con el tiempo. Es su responsabilidad determinar cuales códigos deben ser

seguidos y verificar que el equipo, instalación y operación estén en cumplimiento con la revisión mas reciente

de estos códigos.

Como mínimo, debe seguir las secciones aplicables del Código Nacional de Incendio, Código Nacional Eléctrico,

y los códigos de (NEMA) la Asociación Nacional de Fabricantes Eléctricos de USA. Puede haber oficinas de

normas locales o del gobierno que pueden ayudar a determinar cuales códigos y normas son necesarios para una

instalación y operación segura.

Si no se siguen todos los códigos y normas aplicables, puede resultar en daños al equipo o lesiones serias a

personas. No garantizamos los productos descritos en esta publicación para ser adecuados para su aplicación

en particular, ni asumimos ninguna responsabilidad por el diseño de su producto, la instalación u operación.

Nuestros productos no son tolerantes a fallas y no han sido diseñados, fabricados o intencionados para uso

o reventa como equipo de control en línea en ambientes peligrosos que requieren una ejecución sin fallas,

tales como operación en instalaciones nucleares, sistemas de navegación aérea, o de comunicación, control de

tráfico aéreo, máquinas de soporte de vida o sistemas de armamentos en las cuales la falla del producto puede

resultar directamente en muerte, heridas personales, o daños físicos o ambientales severos (“Actividades de Alto

Riesgo”). Automationdirect.com específicamente rechaza cualquier garantía ya sea expresada o implicada

para actividades de alto riesgo.

Para información adicional acerca de garantía e información de seguridad, vea la sección de Términos

y Condiciones de nuestro catálogo. Si tiene alguna pregunta sobre instalación u operación de este equipo, o

si necesita información adicional, por favor llámenos al número 770-844-4200 en Estados Unidos.

Esta publicación está basada en la información disponible al momento de impresión. En Automationdirect.

com nos esforzamos constantemente para mejorar nuestros productos y servicios, así que nos reservamos el

derecho de hacer cambios al producto y/o a las publicaciones en cualquier momento sin notificación y sin

ninguna obligación. Esta publicación también puede discutir características que no estén disponibles en ciertas

revisiones del producto.

Marcas Registradas

Esta publicación puede contener referencias a productos producidos y/u ofrecidos por otras compañías. Los nombres de las

compañías y productos pueden tener marcas registradas y son propiedad única de sus respectivos dueños. Automationdirect.com,

renuncia cualquier interés propietario en las marcas y nombres de otros.

PROPIEDAD LITERARIA 2020, AUTOMATIONDIRECT.COM® INCORPORATED

No se permite copiar, reproducir, o transmitir de ninguna forma ninguna parte de este manual sin previo consentimiento por escrito

de Automationdirect.com

este documento. Los usuarios de este equipo pueden copiar este documento solamente para instalar, configurar y mantener el equipo

correspondiente. También las instituciones de enseñanza pueden usar este manual para propósitos educativos.

®

Incorprated. Automationdirect.com retiene los derechos exclusivos a toda la información incluida en

Todos los derechos reservados

Page 5

~ AVERTISSEMENT ~

Nous vous remercions d’avoir acheté l’équipement d’automatisation de Automationdirect.comMC, en faisant des

affaires comme, AutomationDirect. Nous tenons à ce que votre nouvel équipement d’automatisation fonctionne en

toute sécurité. Toute personne qui installe ou utilise cet équipement doit lire la présente publication (et toutes les

autres publications pertinentes) avant de l’installer ou de l’utiliser.

Afin de réduire au minimum le risque d’éventuels problèmes de sécurité, vous devez respecter tous les codes locaux

et nationaux applicables régissant l’installation et le fonctionnement de votre équipement. Ces codes diffèrent d’une

région à l’autre et, habituellement, évoluent au fil du temps. Il vous incombe de déterminer les codes à respecter et

de vous assurer que l’équipement, l’installation et le fonctionnement sont conformes aux exigences de la version la

plus récente de ces codes.

Vous devez, à tout le moins, respecter toutes les sections applicables du Code national de prévention des incendies,

du Code national de l’électricité et des codes de la National Electrical Manufacturer’s Association (NEMA). Des

organismes de réglementation ou des services gouvernementaux locaux peuvent également vous aider à déterminer

les codes ainsi que les normes à respecter pour assurer une installation et un fonctionnement sûrs.

L’omission de respecter la totalité des codes et des normes applicables peut entraîner des dommages à l’équipement

ou causer de graves blessures au personnel. Nous ne garantissons pas que les produits décrits dans cette publication

conviennent à votre application particulière et nous n’assumons aucune responsabilité à l’égard de la conception, de

l’installation ou du fonctionnement de votre produit.

Nos produits ne sont pas insensibles aux défaillances et ne sont ni conçus ni fabriqués pour l’utilisation ou la revente

en tant qu’équipement de commande en ligne dans des environnements dangereux nécessitant une sécurité absolue,

par exemple, l’exploitation d’installations nucléaires, les systèmes de navigation aérienne ou de communication, le

contrôle de la circulation aérienne, les équipements de survie ou les systèmes d’armes, pour lesquels la défaillance du

produit peut provoquer la mort, des blessures corporelles ou de graves dommages matériels ou environnementaux

(«activités à risque élevé»). La société AutomationDirect nie toute garantie expresse ou implicite d’aptitude à

l’emploi en ce qui a trait aux activités à risque élevé.

Pour des renseignements additionnels touchant la garantie et la sécurité, veuillez consulter la section Modalités et

conditions de notre documentation. Si vous avez des questions au sujet de l’installation ou du fonctionnement de cet

équipement, ou encore si vous avez besoin de renseignements supplémentaires, n’hésitez pas à nous téléphoner au

770-844-4200.

Cette publication s’appuie sur l’information qui était disponible au moment de l’impression. À la société

AutomationDirect, nous nous efforçons constamment d’améliorer nos produits et services. C’est pourquoi nous

nous réservons le droit d’apporter des modifications aux produits ou aux publications en tout temps, sans préavis ni

quelque obligation que ce soit. La présente publication peut aussi porter sur des caractéristiques susceptibles de ne

pas être offertes dans certaines versions révisées du produit.

Marques de commerce

La présente publication peut contenir des références à des produits fabriqués ou offerts par d’autres entreprises. Les

désignations des produits et des entreprises peuvent être des marques de commerce et appartiennent exclusivement à

leurs propriétaires respectifs. AutomationDirect nie tout intérêt dans les autres marques et désignations.

Copyright 2020, Automationdirect.com Incorporated

Nulle partie de ce manuel ne doit être copiée, reproduite ou transmise de quelque façon que ce soit sans le

consentement préalable écrit de la société Automationdirect.com Incorporated. AutomationDirect conserve les

droits exclusifs à l’égard de tous les renseignements contenus dans le présent document.

Tous droits réservés

Page 6

Manual Revisions

Please include the Manual Number and the Manual Issue, both shown below, when

communicating with Technical Support regarding this publication.

Manual Number: HX-ECOM-M

Issue: 3rd Edition Rev. E

Issue Date: 02/20

Issue Date Description of Changes

Original 4/98 Original Issue

Added DL250-1 and DL260 references

1st Edition, Rev A 8/02

2nd Edition 6/03 Added H0-ECOM module, changed manual part number

2nd Edition, Rev A 6/03 Corrected Special Purpose Communication Relays

3rd Edition 11/04 Added H2-ECOM100 module Updates for NetEdit3

3rd Edition, Rev A 04/05 Added H0-ECOM100 module

3rd Edition, Rev B 04/06 Added H4-ECOM100 module

3rd Edition, Rev C 06/11

3rd Edition, Rev D 12/18 General update of manual. Added references to D2-262 and D4-454 CPUs.

3rd Edition, Rev E 02/20 Added Appendix C for network security considerations.

Removed DL250 references and made minor changes

(Note: DL250 has the same functionality as the DL250-1 except for local

expansion capability.)

Updated manual and made change to Module ID DIP switch and corrected

tables in Chapter 5.

Page 7

Table of ConTenTs

Chapter 1 - Introduction

Introduction ............................................................................................................... 1–2

The Purpose of this Manual ...................................................................................... 1–2

Other Reference Materials ........................................................................................1–2

Who Should Read this Manual .................................................................................1–2

Quality Technical Support ........................................................................................ 1–3

Conventions Used ...................................................................................................... 1–3

Key Topics for Each Chapter ..................................................................................... 1–3

ECOM Module Introduction ..................................................................................... 1–4

ECOM Communication Possibilities .......................................................................... 1–4

Your Network PC ......................................................................................................1–5

Frequently Asked Questions ...................................................................................... 1–6

Chapter 2 - Setup and Installation

ECOM Network Identifiers ........................................................................................2–2

Module ID ................................................................................................................ 2–3

Name ....................................................................................................................... 2–3

Example: ................................................................................................................. 2–4

Ethernet (MAC) Address ........................................................................................... 2–4

Using Multiple Network Identifies ............................................................................2–4

Setting the Module ID with the DIP Switch ............................................................. 2–5

H0 / H2 Series ECOM DIP Switch ............................................................................. 2–6

H4 Series ECOM DIP Switch ..................................................................................... 2–7

Inserting the ECOM Module in the PLC Base ...........................................................2–8

H0 Series ECOM Module Installation ........................................................................ 2–8

DL205 Slot Choices ................................................................................................. 2–8

H2 Series ECOM Module .......................................................................................... 2–9

DL405 Slot Choices ................................................................................................ 2–10

H4 Series ECOM ..................................................................................................... 2–11

Page 8

Table of Contents

ECOM Network Layouts ..........................................................................................2–11

Network Cabling ......................................................................................................2–13

ECOM Supports Two Standards .............................................................................2–13

10/100BaseT Networks .........................................................................................2–13

10/100BaseT Connections ...................................................................................... 2–14

UTP Cable .. .......................................................................................................... 2–14

10BaseFL Connections ............................................................................................2–14

Fiber Optic Cable ...................................................................................................2–14

Fiber Optic Module ST Connector .......................................................................... 2–14

Maximum Cable Length .......................................................................................... 2–15

10/100BaseT Distance Limitations .......................................................................... 2–15

10BaseFL Distance Limitations ................................................................................ 2–15

Maximum Number of ECOM Modules on the Network ........................................2–16

Chapter 3 - Configuring ECOMs Using NetEdit3

NetEdit3 Software .....................................................................................................3–2

Installing NetEdit3 .................................................................................................... 3–2

Launching NetEdit3 ..................................................................................................3–3

The NetEdit3 Screen.................................................................................................3–3

Adding Network Protocol Support to the NetEdit3 PC ............................................ 3–4

Using NetEdit3 ......................................................................................................... 3–5

Ethernet Communication Protocol ...........................................................................3–5

Ethernet Address ......................................................................................................3–6

Module Type, IP Address and ID ..............................................................................3–6

Module Info> General Information ........................................................................... 3–7

Module Info> Ethernet Stats ..................................................................................... 3–7

ECOM Settings ......................................................................................................... 3–7

ECOM Settings> Configuration> General .................................................................3–8

ECOM Settings> Configuration> Advanced .............................................................. 3–9

ECOM Settings> Configuration> Peer to Peer .........................................................3–10

ECOM Settings> Utils>Test CPU Access .................................................................. 3–12

ECOM Settings> Firmware .....................................................................................3–12

FileMenu> Live Update ........................................................................................... 3–13

F / B / C Columns ..................................................................................................3–13

ii

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 9

Table of Contents

Chapter 4 - RLL Programming for Communications

PLC-to-PLC Communications .....................................................................................4–2

How RLL is Used for Communications ...................................................................... 4–2

Network Instructions ................................................................................................. 4–3

Read (RX) and Write (WX) Instructions ..................................................................... 4–3

Building the Read (RX) and Write (WX) Routine .......................................................4–3

The First LD Instruction ............................................................................................4–3

The Second LD Instruction .......................................................................................4–4

The LDA Instruction .................................................................................................4–4

Read (WX) Instruction ..............................................................................................4–5

Write (WX) Instruction..............................................................................................4–5

Addressing the Different Memory ........................................................................... 4–6

Bit Memory ............................................................................................................. 4–6

Word Memory and Aliases ........................................................................................ 4–6

DirectSOFT is Flexible ..............................................................................................4–7

DL05 CPU ................................................................................................................4–7

DL06 CPU ................................................................................................................4–7

D2-240 CPU ............................................................................................................. 4–8

D2-250-1 CPU ..........................................................................................................4–8

D2-260/D2-262 CPU ................................................................................................ 4–9

D4-430 CPU ............................................................................................................. 4–9

D4-440 CPU ........................................................................................................... 4–10

D4-450/D4-454 CPU .............................................................................................. 4–10

Special Relays for Communications ........................................................................4–11

Program with One Read Instruction ....................................................................... 4–13

Program for the Initiating PLC ................................................................................ 4–13

Program for the Responding PLC ...........................................................................4–13

Example Program with One Write Instruction .......................................................4–15

Program for the Initiating PLC ................................................................................ 4–15

Program for the Responding PLC ...........................................................................4–15

Integrating Multiple Read and Write Instructions .................................................4–17

Interlocking Relays ..................................................................................................4–17

First RX/WX Instruction ..........................................................................................4–18

Ethernet Communications Modules, 3rd Edition, Rev. E

iii

Page 10

Table of Contents

Second RX/WX Instruction .....................................................................................4–19

Third RX/WX Instruction ........................................................................................4–19

Shift Register .......................................................................................................... 4–20

Store If Equal .......................................................................................................... 4–20

First RX/WX Instruction ..........................................................................................4–21

Second RX/WX Instruction .....................................................................................4–21

Third RX/WX Instruction ........................................................................................4–21

Chapter 5 - Modbus TCP for H0/H2/H4-ECOM100

Modbus TCP .............................................................................................................. 5-2

Client / Server Model ............................................................................................... 5-2

Protocol Description ................................................................................................. 5-2

Supported Modbu Function Codes ........................................................................... 5-4

Network Server (Slave) Operation ............................................................................ 5-5

Modbus Function Codes Supported ......................................................................... 5-5

Determining the Modbus Address ............................................................................ 5-5

If Your Host Software or Client Requires the Data Type and Address ........................ 5-6

Example 1: V2100 .................................................................................................. 5-11

Example 2: Y20 ...................................................................................................... 5-11

Example 3: T10 Current Value ................................................................................ 5-11

Example 4: C54 ...................................................................................................... 5-12

If the Host Software or Client Requires an Address ONLY ....................................... 5-12

Example 1: V2100 .................................................................................................. 5-14

Example 2: Y20 ...................................................................................................... 5-14

Example 3: C54 ...................................................................................................... 5-14

Network Client (Master) Operation ....................................................................... 5-15

PLC Memory Supported for Client Operation ......................................................... 5-17

Example 1: Calculating Word PLC Address ............................................................. 5-18

Example 2: Calculating Discrete Input PLC Address ................................................ 5-18

Building the Read (RX) or Write (WX) Routine ........................................................ 5-19

Step 1: Identify ECOM Slot Location and Server Node # ........................................ 5-19

Step 2: Load Number of Bytes to Transfer .............................................................. 5-20

Step 3: Specify Master Memory Area...................................................................... 5-20

Step 4: Specify Slave Memory Area ........................................................................ 5-20

Communications from a Ladder Program ............................................................... 5-21

iv

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 11

Table of Contents

Multiple Read and Write Interlocks ......................................................................... 5-21

ECOM100 IBOX .................................................................................................... 5-22

Modbus TCP Setup ................................................................................................ 5-24

Example Modbus TCP Program .............................................................................. 5-26

Troubleshooting: .................................................................................................... 5-26

H0/H2/H4 -ECOM100 System Memory .................................................................. 5-30

Chapter 6 - H0/H2/H4-ECOM100 DHCP & HTML Configuration

H0/H2/H4 -ECOM100 DHCP ..................................................................................... 6-2

DHCP Issues ............................................................................................................. 6-2

Disabling DHCP and Assigning a Static IP Address ................................................... 6-2

Using HTML Configuration ....................................................................................... 6-3

Connecting to the H0/H2/H4 -ECOM100 ................................................................ 6-3

H0/H2/H4-ECOM100 Client Peer to Peer Configuration ........................................... 6-5

Chapter 7 - Maintenance and Troubleshooting

Isolating a Communication Problem ........................................................................ 7-2

Diagnostic Tools and Techniques ............................................................................. 7-2

Troubleshooting Chart .............................................................................................. 7-2

ECOM Module Diagnostic LEDs ................................................................................ 7-4

H0 Series Indicators .................................................................................................. 7-4

OK Indicator ............................................................................................................. 7-4

LINK Indicator .......................................................................................................... 7-4

ACT Indicator ........................................................................................................... 7-4

ERR Indicator ............................................................................................................ 7-4

100MBIT Indicator ................................................................................................... 7-4

Network Server (Slave) Operation ............................................................................ 7-5

H24-ECOM-(F) Indicators ......................................................................................... 7-5

LINKGD Indicator ..................................................................................................... 7-5

ACT Indicator ........................................................................................................... 7-5

ERROR Indicator ....................................................................................................... 7-5

H2/H4-ECOM100 Indicators ..................................................................................... 7-6

STATUS ..................................................................................................................... 7-6

LINKGD Indicator ..................................................................................................... 7-6

Ethernet Communications Modules, 3rd Edition, Rev. E

v

Page 12

Table of Contents

ACTIVE Indicator ...................................................................................................... 7-6

ERROR Indicator ....................................................................................................... 7-6

100MBIT Indicator ................................................................................................... 7-6

Using NetEdit3 for Troubleshooting ......................................................................... 7-7

Select a Module ....................................................................................................... 7-7

Module Information ................................................................................................. 7-7

Change Protocol ...................................................................................................... 7-8

Ethernet Stats ........................................................................................................... 7-8

RX/WX Settings ........................................................................................................ 7-9

Record the Module Settings ..................................................................................... 7-9

Replacing the ECOM Module .................................................................................. 7-10

Diagnosing Network Cable Problems ..................................................................... 7-11

Appendix A - General Specifications

General Specifications ............................................................................................... A-2

ECOM Specifications ............................................................................................... A-2

Ethernet Standards .................................................................................................... A-4

Appendix B - Peerlink Specifications

Peerlink Function for ECOM100 ............................................................................... B-2

Peerlink Data-Sharing Network ................................................................................ B-3

Configuration ........................................................................................................... B-4

Parameters: .............................................................................................................. B-5

DL05 ........................................................................................................................ B-6

DL06 ........................................................................................................................ B-7

DL205 ...................................................................................................................... B-8

DL405 ...................................................................................................................... B-9

Do-more ................................................................................................................ B-10

Block Summary ...................................................................................................... B-11

Appendix C - Security Considerations for Control Systems

Networks

Security Considerations for Control Systems Networks ......................................... C-2

vi

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 13

Chapter

Chapter

Chapter

IntroductIon

1

1

1

In This Chapter...

Introduction ............................................................................................................... 1–2

Conventions Used ...................................................................................................... 1–3

Frequently Asked Questions ...................................................................................... 1–6

Page 14

Chapter 1: Introduction

Introduction

The Purpose of this Manual

This manual describes how to use the Ethernet

Communication (ECOM) Modules. You will find

information about:

• Setting up the ECOM module

• Network layouts

• PC-to-PLC communications

• PLC-to-PLC communications

• RLL programming examples

• Maintenance and troubleshooting

Other Reference Materials

Other DirectLOGIC manuals may be useful for your application.

User Manuals:

• DL05 User Manual (ADC p/n D0-USER-M)

• DL06 User Manual (ADC p/n D0-06USER-M)

• DL205 User Manual (ADC p/n D2-USER-M)

• DL405 User Manual (ADC p/n D4-USER-M)

• D4-454 User Manual (ADC p/n D4-454-M)

• DirectSOFT User Manual (ADC p/n PC-DSOFT6-M, for version 6)

• KEPDirect for PLCs (with part number DA-KEPPLC-M)

1–2

Who Should Read this Manual

If you need a high-speed communications link between your DirectLOGIC PLC and PCs or

other DirectLOGIC PLCs and you understand the basics of installing and programming PLCs,

this is the right manual for you. This manual gives you the information you need to set up and

install a communication link to an ECOM module.

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 15

Quality Technical Support

Getting Started

CHAPTER

1

In This Chapter...

.................................................................1-2

...........................................................................1-4Specifications

General Information

We strive to make our manuals the best in the industry. We rely on your feedback to let

us know if we are reaching our goal. If you cannot find the solution to your particular

application, or, if for any reason you need technical assistance, please call us at:

770–844–4200

Our technical support group will work with you to answer your questions. They are available

Monday through Friday from 9:00 A.M. to 6:00 P.M. Eastern Time. We also encourage you

to visit our web site where you can find technical and non-technical information about our

products and our company.

http://www.automationdirect.com

If you have a comment, question or suggestion about any of our products, services, or

manuals, please fill out and return the Suggestions card that was included with this manual.

Conventions Used

When the “notepad” icon is in the left–hand margin, the paragraph to its immediate right

will be a special note. The word NOTE in boldface will mark the beginning of the text.

When the “exclamation mark” icon is in the left–hand margin, the paragraph to its immediate

right will be a warning. This information could prevent injury, loss of property, or even death

(in extreme cases). The word WARNING in boldface will mark the beginning of the text

which will also be in boldface..

Chapter 1: Introduction

Key Topics for Each Chapter

The beginning of each chapter will list the key topics that can be

found in that chapter.

Ethernet Communications Modules, 3rd Edition, Rev. E

1–3

Page 16

Chapter 1: Introduction

ECOM Module Introduction

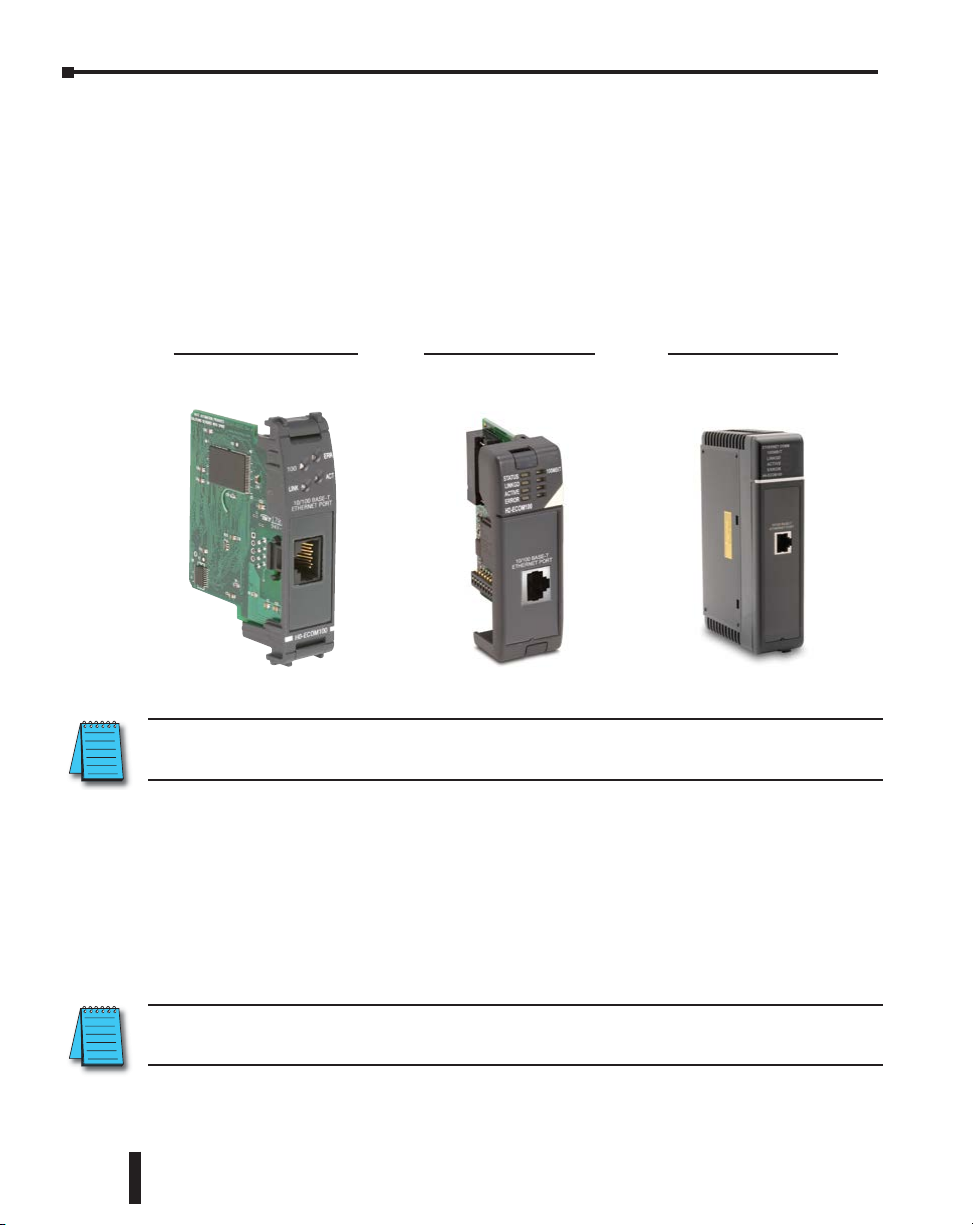

Several Ethernet Communication (ECOM) modules are currently available for use with

DL05/06, DL205 and DL405 PLC systems. The ECOM modules are shown below. These

modules provide a low-cost, high-speed Ethernet link for PLC systems. The modules are easy

to set up and install on 10/100BaseT (twisted pair, copper wire) or 10BaseFL (fiber optic)

Ethernet networks.

LEDs on the face of each module give vital information about the status of the module and the

communication link. The 10/100BaseT modules use standard RJ45 modular connectors, and

the 10BaseFL modules use ST style bayonet connectors.

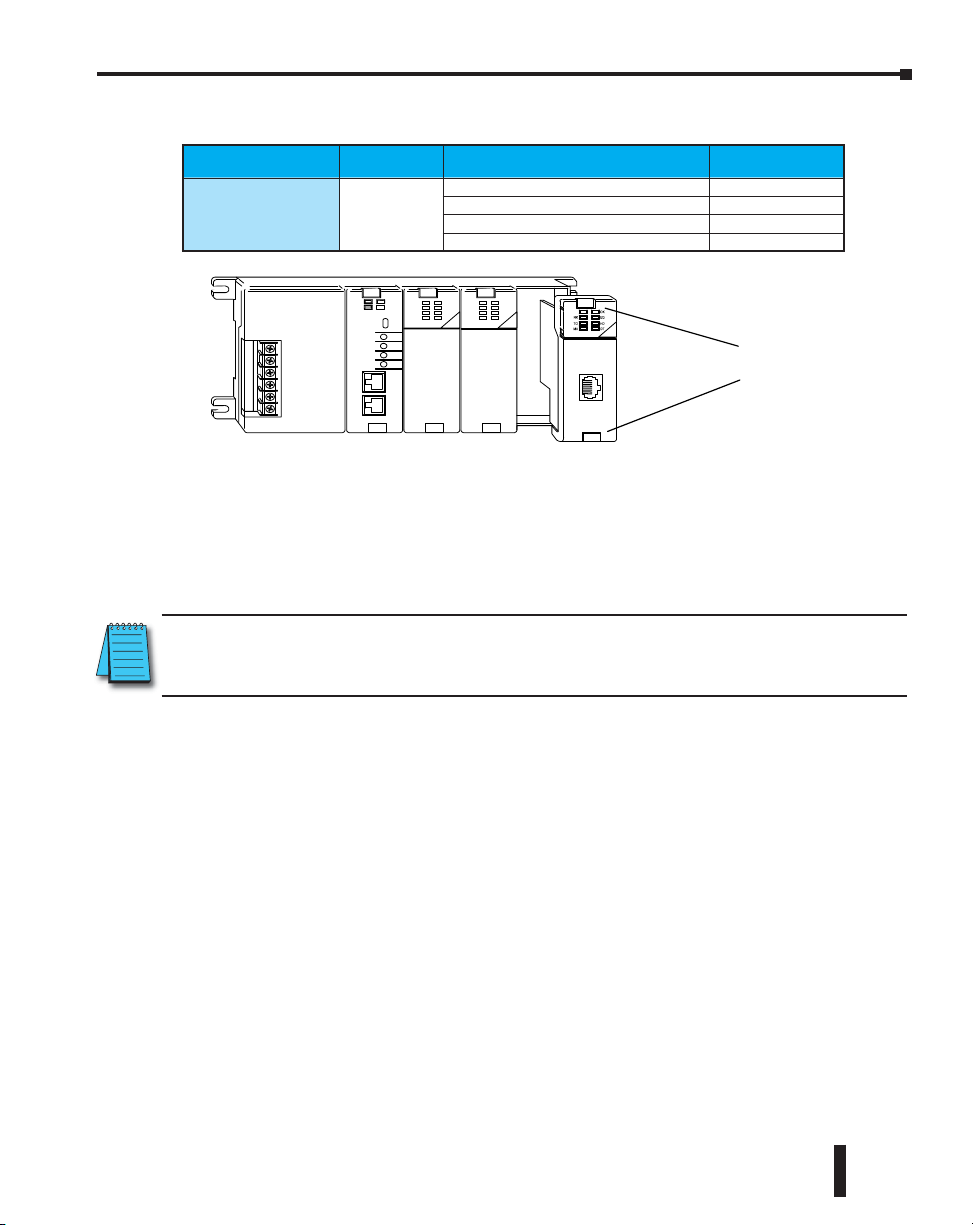

DL05/06 ECOM Modules

H0-ECOM

H0-ECOM100

H0-ECOM100

NOTE: If you are using a D0-06LCD in your DL06 PLC, the date code for the display unit must be 032A_ or

later to be compatible with the H0 series ECOM modules.

DL205 ECOM Modules

H2-ECOM

H2-ECOM100

H2-ECOM-F

H2-ECOM100

DL405 ECOM Modules

H4-ECOM

H4-ECOM100

H4-ECOM-F

H4-ECOM100

ECOM Communication Possibilities

You can use the ECOM modules to share data between two or more DirectLOGIC PLCs

or between DirectLOGIC PLCs and personal computers. The H0/H2/H4 -ECOM100

additionally allows client/server communications with other Ethernet devices using the

MODBUS TCP protocol. Communication between PLCs/MODBUS TCP devices is

accomplished by using the Read/Write (RX/WX) instructions which are available in the

DirectSOFT Programming Software Users Manual. Chapters 4 and 5 explain the use of the

RX/WX instructions.

1–4

NOTE: Please review intelligent instructions (IBox) in Chapter 5 of the user manual for the PLC you are

using, which simplify this and other functions.

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 17

Chapter 1: Introduction

You can also use a personal computer running DirectSOFT Programming Software to program

your PLCs over the Ethernet network. It is just like programming through the programming

port on the CPU, but with the convenience of doing it from a single location.

Use DirectSOFT programming software to program the complete DirectLOGIC family of PLCs

(the DL105 and DL305 series are the only PLCs that cannot be programmed over Ethernet).

Chapter 2 will indicate the CPUs which can be used with the ECOM modules.

NOTE: We recommend using a dedicated network for your PLC control applications. For more information

see Chapter 2, Setup and Installation

Your Network PC

PCs running our KEPDirect for PLCs software can establish Ethernet links for exchanging

information with DirectLOGIC 05/06/205/405 PLCs.

You can use a personal computer equipped with a 10/100BaseT or 10BaseFL network adapter

card and NetEdit3 software to configure the ECOM module over the network. You can also use

NetEdit3 for troubleshooting certain communication problems. The NetEdit3 utility is available

for download at http://www.automationdirect.com.

Ethernet Communications Modules, 3rd Edition, Rev. E

1–5

Page 18

Chapter 1: Introduction

Frequently Asked Questions

.Q How can I speed up my ECOM communications?

.A Try shortening the scan time of the PLC (the PLC allows

only one ECOM transaction per scan).

.Q What causes “Task code error response” with extended E353 error?

.A Error is from the PLC and means “timeout in the background communications”.

Error is due to a backplane communication problem (ECOM, DCM, etc.).

.Q Can an ECOM be configured to talk through a gateway?

.A Yes. You configure the gateway to reroute traffic to

and from the ECOM via port 7070 (hex).

.Q When using a DL205 with an ECOM, is there a way to turn on the PLC

outputs from a computer using a non- Windows operating system?

.A Host Engineering has what is called an Ethernet SDK (software developers

kit) which can normally be downloaded (free) from their website. However,

this will be useless for your system, but to accommodate your operating

system, you can fill out a form located on the Host Engineering website

and request the source code for the Ethernet SDK. This is necessary

so that Host Engineering will know who is using their source code.

The source code can then be recompiled to work on your system.

With the SDK recompiled for your system, you can use CCM (i.e.

DirectNET) protocol to turn on PLC outputs by simply knowing

the memory types and ranges as required for syntax.

The request form and details about the SDK can be found on the Host

Engineering homepage (www.hosteng.com). Once there, click on “EBC/

ECOM/EDRV” under “S/W Developer Kits” in the left- hand column.

.Q What is the fastest way to get data from PLC to PLC?

.A Install ECOM in both PLCs and use the RX/WX commands is the quickest

way to do this. It is much faster that using serial communication.

.Q Can the ECOM do a broadcast message to multiple slave devices?

.A No.

.Q Can the MAC address be changed?

.A The MAC address is burned into ROM on the module and is set just before it

leaves the factory. There is no logical way for any protocol to change this address.

Host Engineering’s range for Ethernet (MAC) addresses is 00.E0.62.xx.xx.xx.

1–6

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 19

Chapter

Chapter

Chapter

Setup and InStallatIon

2

2

1

In This Chapter...

ECOM Network Identifiers ........................................................................................2–2

Setting the Module ID with the DIP Switch ............................................................. 2–5

Inserting the ECOM Module in the PLC Base ...........................................................2–7

ECOM Network Layouts ..........................................................................................2–10

Network Cabling ......................................................................................................2–12

Maximum Cable Length .......................................................................................... 2–14

Maximum Number of ECOM Modules on the Network ........................................2–15

Page 20

Chapter 2: Setup and Installation

ECOM Network Identifiers

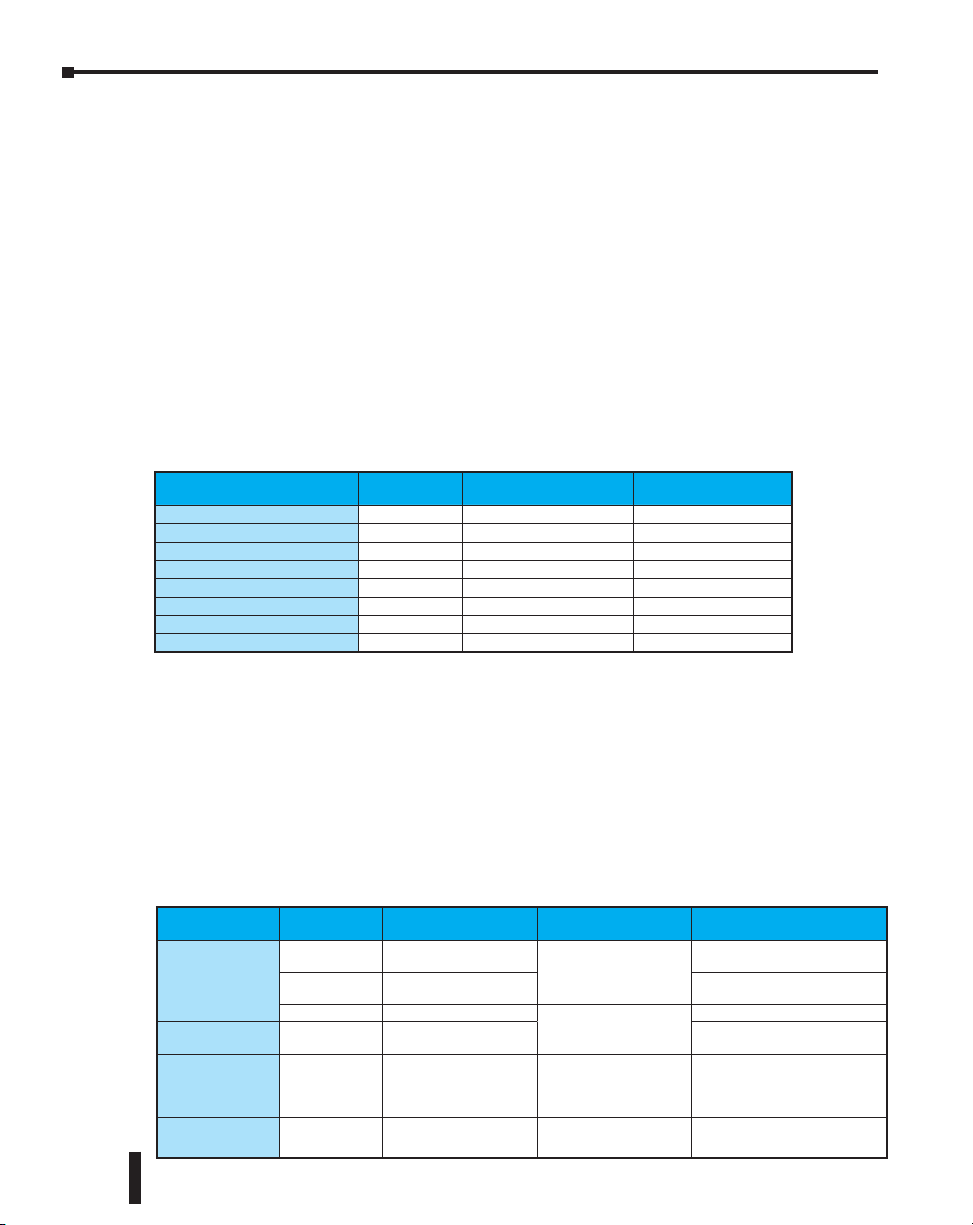

This section describes network identifiers that can be assigned to the ECOM module. Each

module must be assigned at least one unique identifier to make it possible for PCs or other

ECOMs to recognize it on the network. Four methods of identifying the ECOM module give

it the flexibility to fit most networking schemes.

The four ECOM identifiers are:

• Module ID

• Name

• IP (Internet Protocol) Address

• Ethernet (MAC) Address

The first three are user-selectable. The last one is set at the factory. Each of the identifiers is

discussed in this chapter. If you have more than a few ECOMs on your network, consider

making a chart or spreadsheet of network IDs, as shown below:

Ethernet (MAC) Address Module ID Name IP Address

00 E0 62 20 01 20

00 E0 62 20 01 58

00 E0 62 20 01 8D

00 E0 62 20 01 94

00 E0 62 20 01 DE

00 E0 62 20 01 F1

00 E0 62 20 01 FB

00 E0 62 20 01 F0

The decision about which type of identifier to use is an important one. Much of the decision

depends on the requirements of your particular application. PC-to-PLC communications are

generally better accommodated with one type of identifier while PLC-to-PLC communications

require a different type. Ease of maintenance and troubleshooting also must be considered

before deciding which type to use.

The identifiers are used to link your PC to your PLC or one PLC to another PLC. The flexible

design of the module allows you to use different identifiers for different links to the same

module. This is particularly important if you require both PC-to-PLC and PLC-to-PLC

communications on the same network.

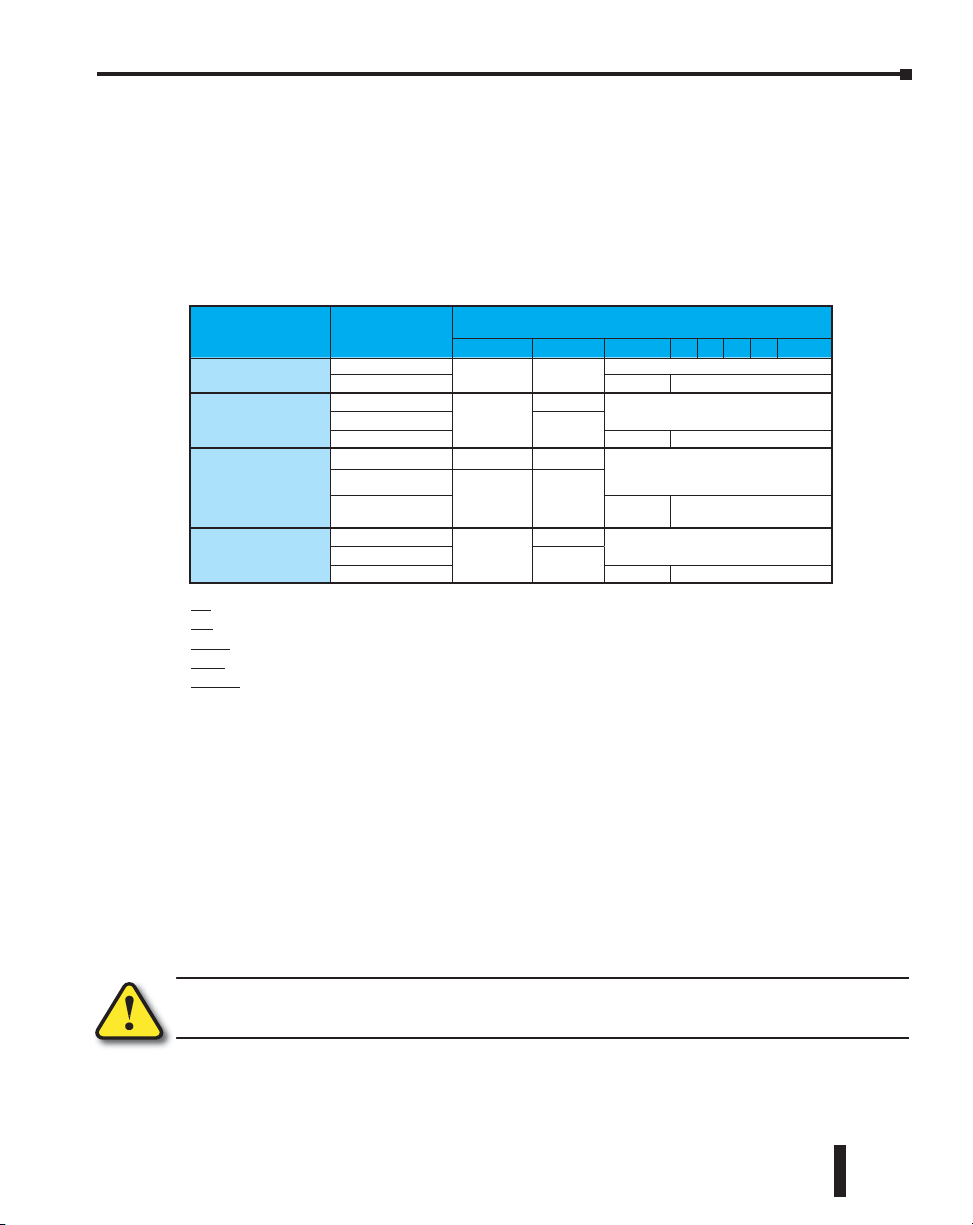

The following table summarizes Network Identifiers and their uses:

17 BldgThree 192.168.100.001

61 192.168.100.003

33 192.168.100.004

3 PumpStationTwo 192.168.100.005

8 Effluent 255.255.255.255

2 PumpStationOne 192.168.100.002

1 Control Room 255.255.255.255

5 Mixer 192.168.100.006

2–2

How to Set Format Communication Restrictions/Notes

Module ID

Name

IP Address

Ethernet (MAC)

Address

DIP Switch Number 1–63

NetEdit3 Number 1–90

NetEdit3 Number 1–999,999,999

NetEdit3

NetEdit3

Set at Factory 12 Hex digits PC to PLC only Factory assigned, for IPX

32 Alphanumeric

Characters

4 Three-digit Numbers,

xxx.xxx.xxx.xxx

(See page 2-4)

PLC to PLC or

PC to PLC

PC to PLC only

PC to PLC; (PLC to PLC

- Client/Server using

TCP/IP or Modbus TCP

protocol)

Ethernet Communications Modules, 3rd Edition, Rev. E

Disables Module ID in

NetEdit3

DIP switch must be set

to “0”

>90 (Not for PLC to PLC)

HMI software may have

restrictions

See you network

administrator for IP address;

(refer to pages 3-10 to 3-11,

chapters 5 & 6)

Page 21

Chapter 2: Setup and Installation

Module ID

A Module ID is required for PLC-to-PLC communications, and it can be set either of two

ways. You can assign the Module ID:

• Using the DIP switches on the module.

• Using the configuration tools in NetEdit3

• HTML Configuration (after IP address is assigned to module using

NetEdit3; described in Chapter 5; H0/H2/H4- ECOM100 only)

Use the DIP switch if you want the ability to install or change modules without using a PC to

set the Module ID. Set the module’s DIP switch, insert the module in the base, and connect the

network cable. Your Module ID is set on powerup, and your ECOM is ready to communicate

on the network. We step through setting the DIP switch on pages 2-5 and 2-6.

8 7 6 5 4 3 2 1

ON

7 6 5 4 3 2 1 0

Name

If you prefer to be able to set or change all Module IDs on your network from a single PC, use

the tools in NetEdit3, discussed in chapter 3.

A Name makes it easy to recognize the PLC by its function. An example of a Name is

“PumpStationOne.” The Name can be up to 32 alphanumeric characters in length. A Name

can be assigned using NetEdit3.

Pump Station One

PUMP STATION ONE

NOTE: Some HMI software products will not accept Names with numbers as the first character, spaces or

certain other non-alphanumeric ASCII characters. Also, your HMI product may not accept Names longer

than 16 characters. Consult your HMI product documentation about its naming conventions

Ethernet Communications Modules, 3rd Edition, Rev. E

2–3

Page 22

Chapter 2: Setup and Installation

An IP Address can be assigned to the ECOM module if your network requires one. Usually, the

IP Address is required in cases where PLCs are sharing the same network with PCs, and some of

the PCs are carrying out functions unrelated to PLC control. Normally, a network administrator

will assign an IP Address to each device on the network. If you have a separate dedicated

network for your PLCs, you can use the Module ID or a Name for each communication link.

You must use an IP Address, if you are using the UDP/IP or MODBUS TCP protocol.

Use NetEdit3 to assign an IP address to the ECOM (refer to chapter 3).

The module ships from the factory with an IP Address of 0.0.0.0. This is not a usable IP

Address for normal communications. It only serves as a default setting which can be changed

using NetEdit3. Valid settings are 1 through 254. You do not have to change the default IP

Address unless you are using the IP Address to link to your ECOM module. The default setting

does not cause conflicts with other network communications.

If you change the default IP Address for linking to other network devices, you must change all

four “0” fields. If any field contains the number 255 and other fields have been changed, the

module will not be recognized on the network.

Example:

Client (PC/ECOM) Subnet Mask: 255.255.0.0

Valid Client (PC/ECOM) IP Address: 192.168.50.2

Valid Server ECOM IP Address: 192.168.55.5

Valid Server ECOM IP Address: 192.168.70.15

1–254 Valid settings for Bold number

fields (Do not duplicate).

2–4

WARNING: It is extremely important not to have duplicate IP Addresses on your network. If you are

using the IP Address to link the ECOM to any network devices (PCs or PLCs), the ECOM must have a

unique number.

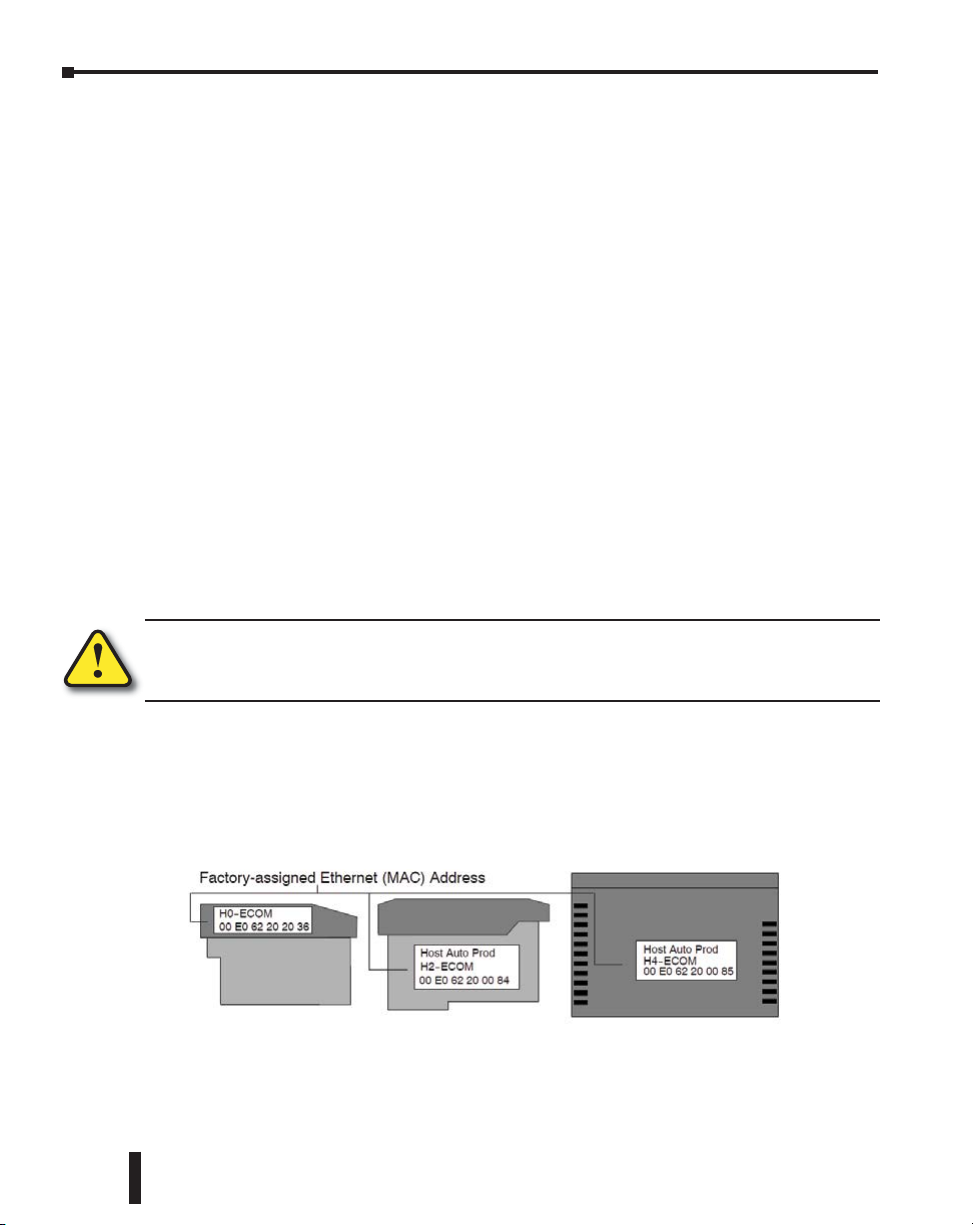

Ethernet (MAC) Address

A unique Ethernet (MAC) Address is assigned to each module at the factory and will not

change. It is printed on a label attached to each ECOM module. The Ethernet (MAC) Address

is recognized by NetEdit3. The Ethernet (MAC) Address is a twelve digit number with no

deliberate relationship to your network or functional areas of your plant. It does not usually

serve as a convenient and easily remembered identifier for your ECOM.

Using Multiple Network Identifies

You can use the IP Address to satisfy network requirements, a Name for PCs running HMI

software and the Module ID for PLCs to share data among themselves. Using one type of

identifier does not limit your use of the other identifier types.

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 23

Chapter 2: Setup and Installation

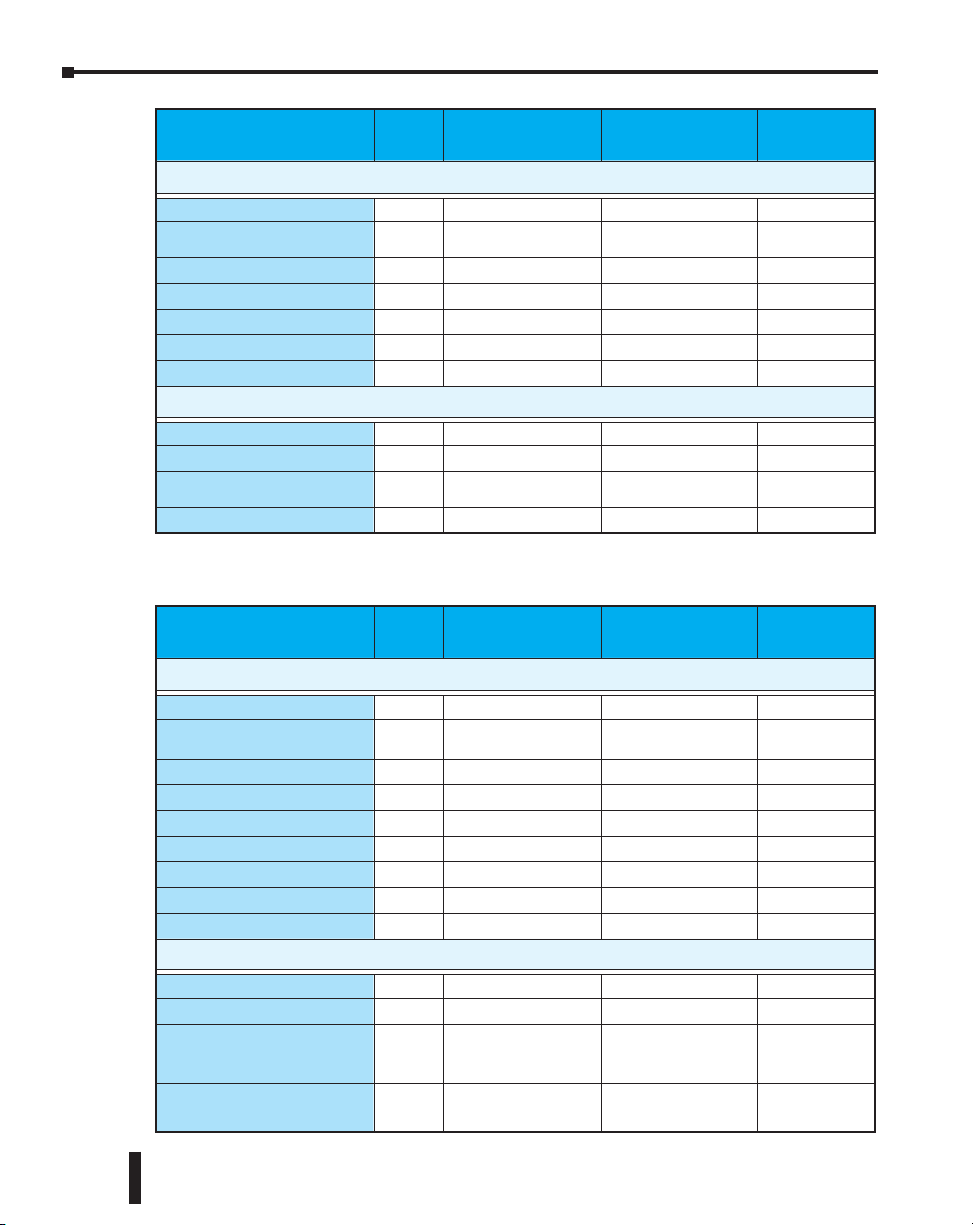

Setting the Module ID with the DIP Switch

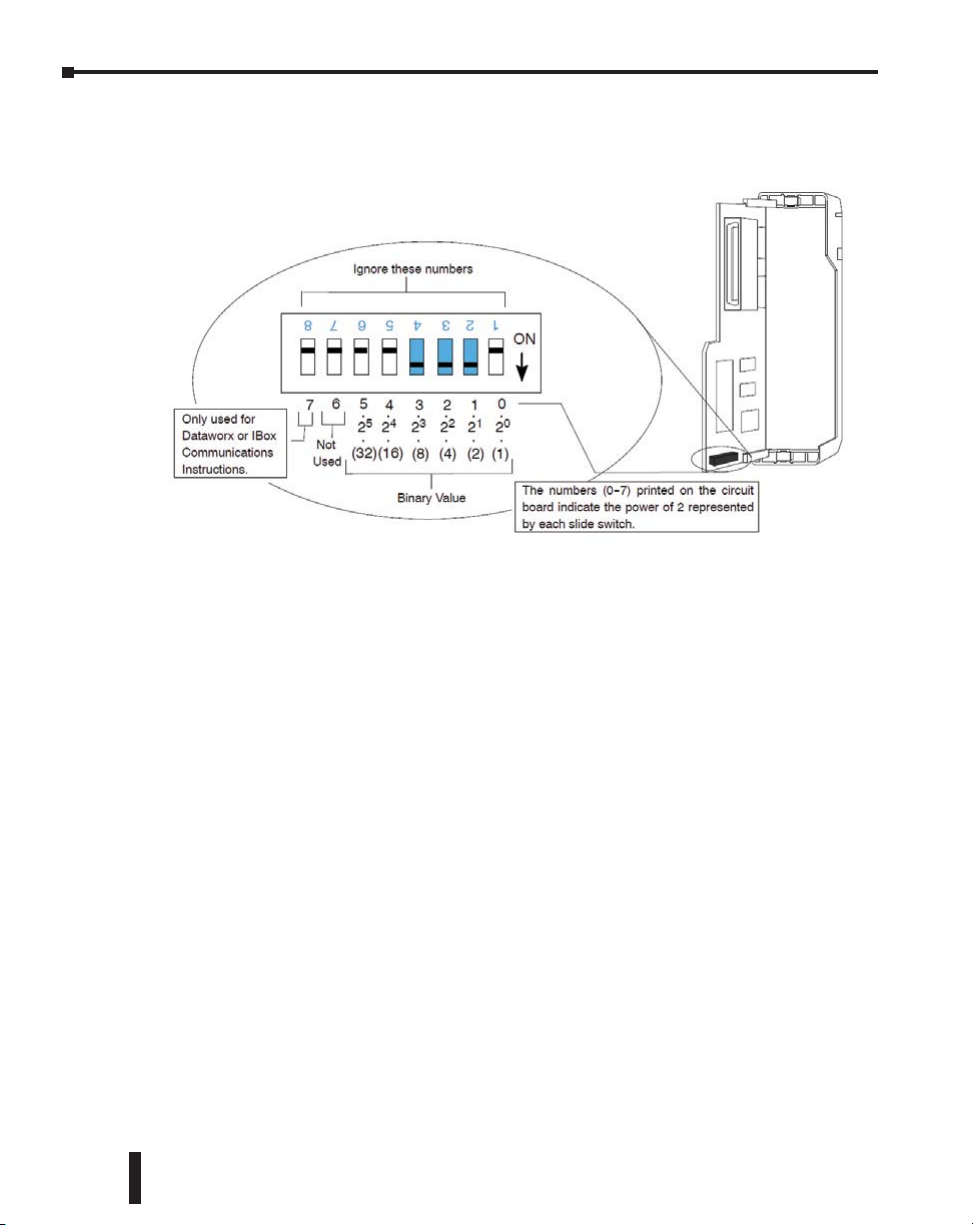

The ECOM’s DIP switches contain eight individual slide switches, but not all of these are

active. The individual slide switches are labeled 1 through 8 on the body of the DIP switch

(upside down in the following figures).

You will find that the printed circuit board is labeled 0 (zero) through 7. We use the labeling

on the printed circuit board in describing how to set the switch. The table below shows the

meaning of each dipswitch based on the version of the module being used.

Module Type

H0-ECOM

H0-ECOM100

H2-ECOM

H2-ECOM-F

H4-ECOM

H4-ECOM-F

H2-ECOM100

H4-ECOM100

RBE (Report by Exception) - Dipswitch must be ON for this function.

IBox (Intelligent Boxes) - Dipswitch must be ON for the ECxxxxx IBoxes to Function.

Recover - Dipswitch used to reset IP settings back to factory default on power-up in case device is lot on network.

Protect - Dipswitch must be ON to write protect firmware and network, node, peer-to-peer, SMTP (email) configurations.

Module ID - Bit-weighted for manual setting of this parameter.

Release

Version

v1.0.354

v1.0.364 Protect Module ID

v4.0.49

v4.0.167

v4.0.320 Protect Module ID

v1.0.7

v1.0.147

v1.0.227 Protect Module ID

v4.0.877

v4.0.1237

v4.0.1735 Protect Module ID

7 6 5 4 3 2 1 0

RBE

RBE/IBox

RBE

RBE/IBox

Recover

Recover

Dipswitch

Module ID

Module ID

Module ID

Module ID

The dipswitch numbers on the printed circuit board indicate the power of 2 represented by

each slide switch. For example, switch 0 represents 20 (or 1), switch 1 is 21 (or 2), switch 2 is 22

(or 4), and so on. The following figures show the binary value of each switch in parentheses ( ).

You can use the DIP switch on the ECOM module to set the Module ID to a number from

1 to 63. Each module on a given network must be assigned a unique Module ID if the Module

ID is to be used for communications. Do not use Module ID “0” for communications.

If the DIP switch is set to a number greater than 0, the software tools are disabled from setting

the Module ID. The software tools will only allow changes to the Module ID if the DIP switch

setting is 0 (zero, all switches OFF). The DIP switch settings are read at powerup. You can use

the software tools to set the Name and IP Address even if you use the DIP switch for setting

the Module ID.

WARNING: Using duplicate Module IDs on a single network will cause unreliable PLC-to-PLC

communications.

Ethernet Communications Modules, 3rd Edition, Rev. E

2–5

Page 24

Chapter 2: Setup and Installation

H0 / H2 Series ECOM DIP Switch

If using the ECOM/ECOM100 module with Dataworx software, or the ECOM100 with

IBox Communication instructions, then dipswitch 7 must be set to ON.

The Module ID equals the sum of the binary values of the slide switches set in the ON position.

For example, if you set slide switches 1, 2, and 3 to the ON position, the Module ID will be

14. This is found by adding 8+4+2=14. The maximum value you can set on the DIP switch

is 32+16+8+4+2+1=63. This is achieved by setting switches 0 through 5 to the ON position.

2–6

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 25

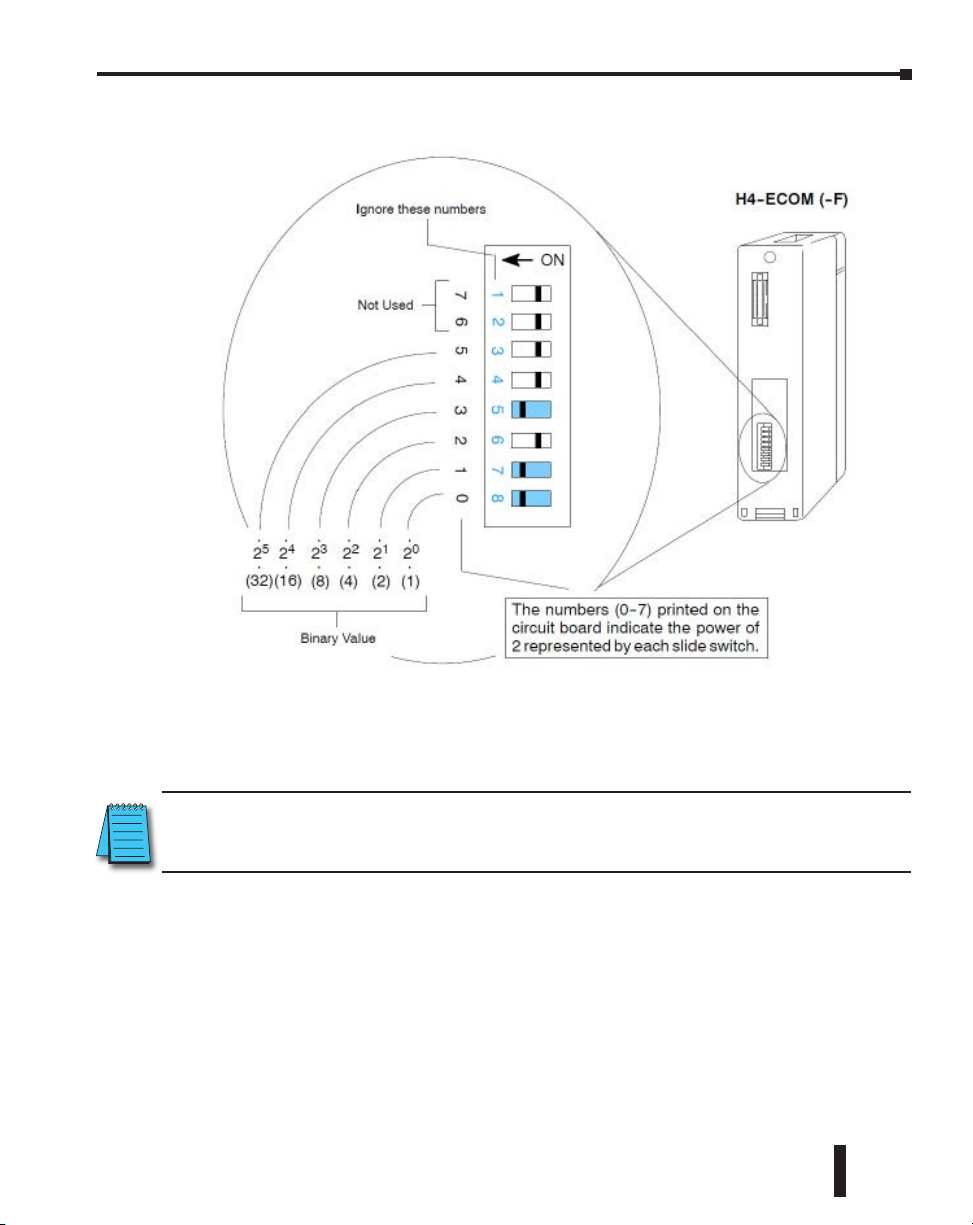

H4 Series ECOM DIP Switch

Chapter 2: Setup and Installation

The Module ID equals the sum of the binary values of the slide switch set in the ON position.

For example, if you set slide switches 0, 1, and 3 to the ON position, the Module ID will be

11. This is found by adding 8+2+1=11. The maximum value you can set on the DIP switch

is 32+16+8+4+2+1=63. This is achieved by setting switches 0 through 5 to the ON position.

NOTE: When all the switches are set to OFF (Module ID = 0), the Module ID can be set using the software

utilities in NetEdit and DirectSOFT. Do not use Module ID “0” for normal communications. It is okay to

leave the Module ID set at zero if you are using the Name or IP Address for communications

Ethernet Communications Modules, 3rd Edition, Rev. E

2–7

Page 26

Chapter 2: Setup and Installation

Setup and

Installation

2--7

Setup and Installation

Setup and

Installation

Installation and

Safety Guidelines

2--7

Setup and Installation

Pinch Tabs

C0 C4C2X1 X3 X4 X6 X11X13X14 X16 X21X23N.C.

C1 C3X2 X5 X7 X10 X12 X15X17 X20X22X 0 N.C.

AC(N)24V

0V

N.C.

C1 C3Y0 Y15Y12Y10 Y17Y7Y5Y2

C0 C2 Y16Y14Y13Y 11Y6Y4Y3Y1

LGG

AC(L

)

2.0AOUTPUT:6--240V

50 --60Hz2.0A,6 -- 27V

INPUT:12 -- 24V3 --15mA

Y

X

40VA50--60HzPWR: 100--240V

0 1 2 3 4 5 6 7 10 11 12 13 14 15 16 17 20 2122 23

PORT1 RUN STOP

PWR

RUN

CPU

TX1

RX1

TX2

RX2

D0--06DR

PORT2

TERM

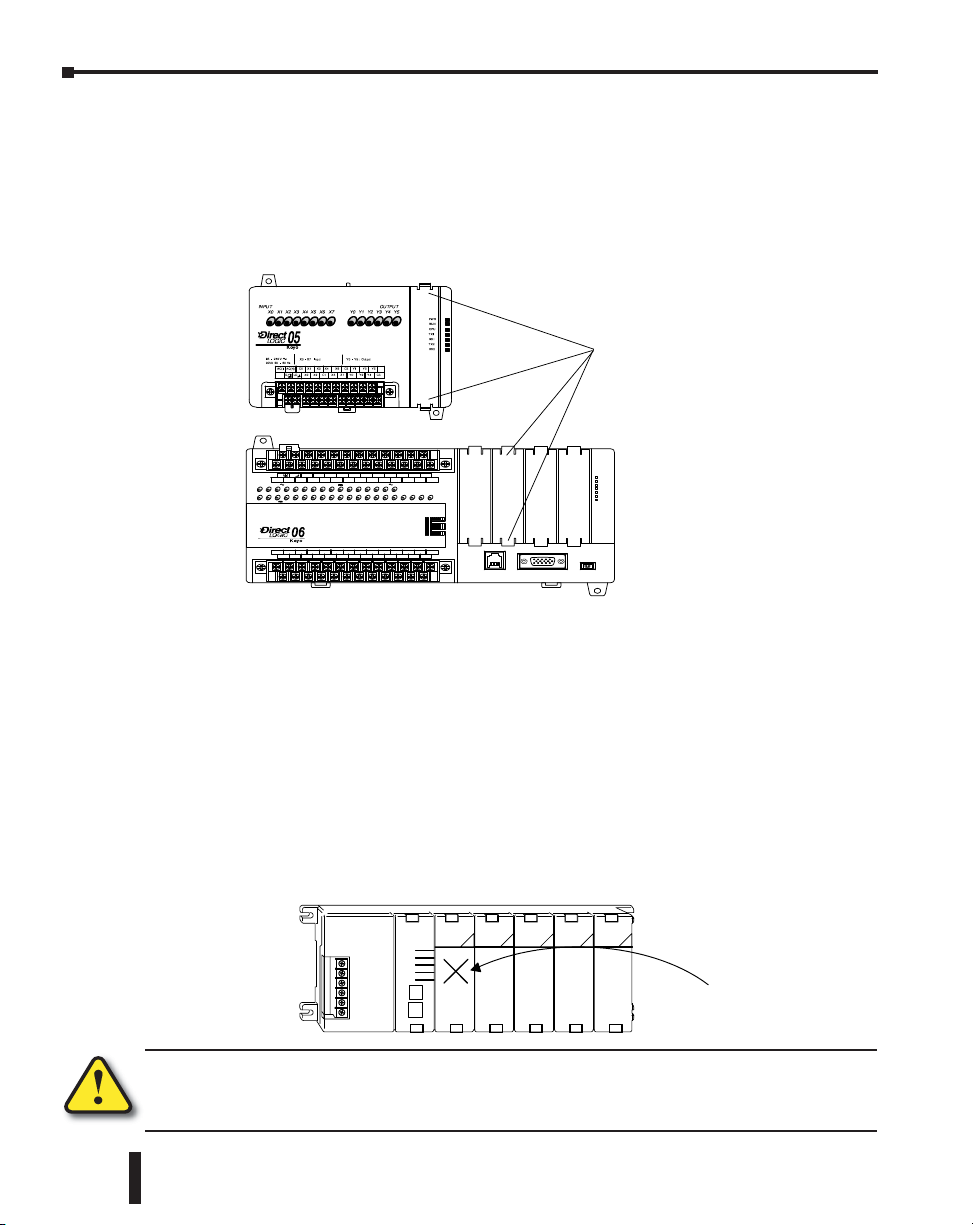

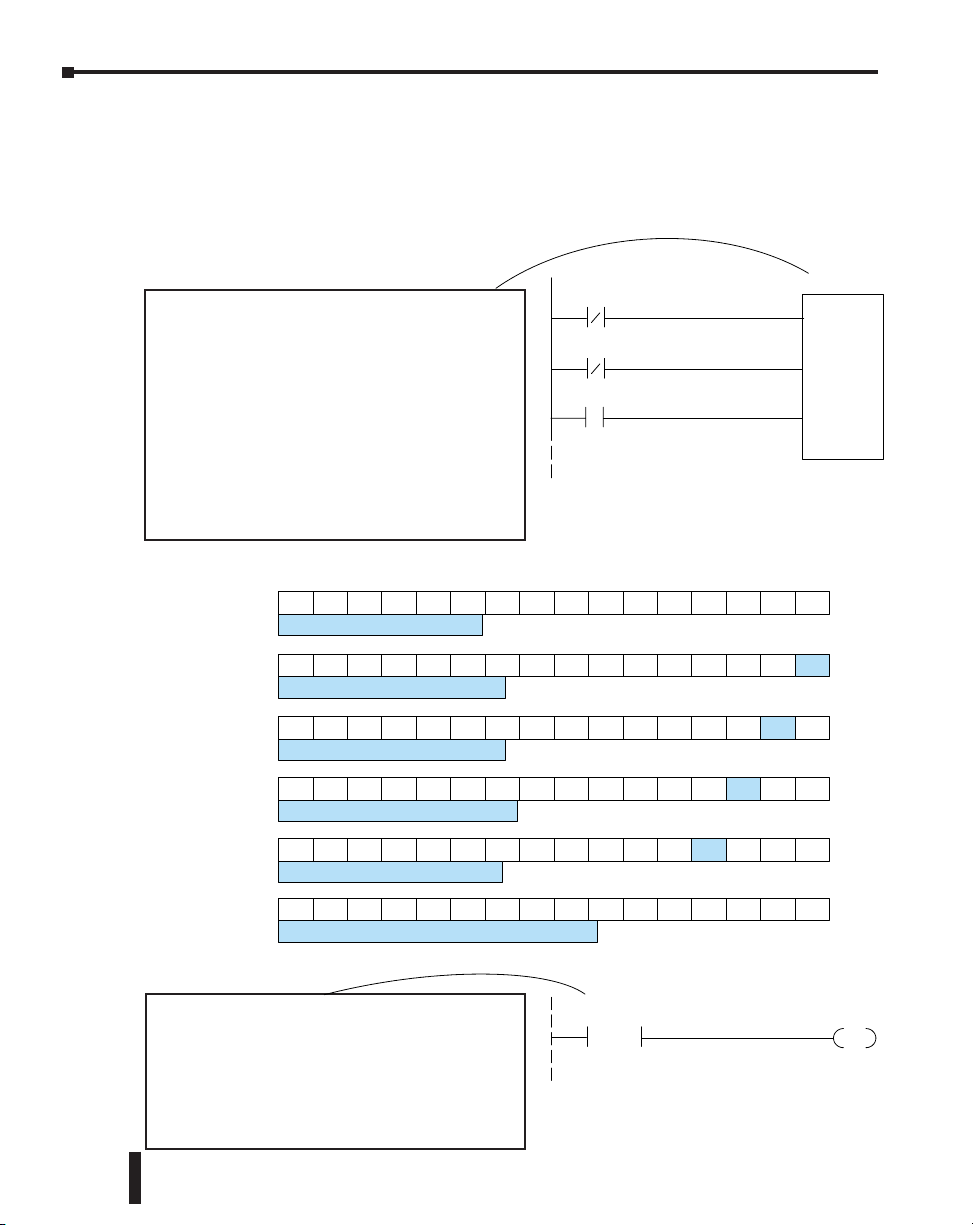

Inserting the ECOM Module in the PLC Base

H0 Series ECOM Module Installation

Before installing the option module in the DL05 option slot or any of the DL06 option slots,

set the Module ID dip switch (if your application requires this) on the H0 Series ECOM

module. Verify power to the PLC is turned off. The next step is to remove the protective option

slot cover. Remove the cover by squeezing the pinch tabs and lifting the cover off

Pinch Tabs

DL205 Slot Choices

C1 C3Y0 Y15Y12Y10 Y17Y7Y5Y2

LGG

0V

)

C0 C2 Y16Y14Y13Y11Y6Y4Y3Y1

AC(N)24V

AC(L

Y

0 1 2 3 4 5 6 7 10 11 12 13 14 15 16 17 20 21 22 23

X

INPUT:12 --24V3-- 15mA

C0 C4C2X1 X3 X4 X6 X11X13X14 X16 X21X23 N.C.

Now, insert the module into the open slot on the DL05 or into any one of the four slots in the

2.0AOUTPUT:6 --240V

50 -- 60Hz2.0A,6 -- 27V

C1 C3X2 X5 X7 X10 X12 X15X17X20 X22X 0 N.C.

N.C.

40VA50--60HzPWR: 100--240V

D0--06DR

PORT1 RUN STOP

PORT2

DL06. Locate the module so the printed information is oriented in the same direction as the

markings on the PLC. Be careful to align the female connector on the printed circuit board of

the module with the male connector on the PLC mother board. Press the module into the slot

until the front of the module is flush with the front of the PLC. Check the DL06 power budget

to be sure that it remains within the power supply limits before installing more modules.

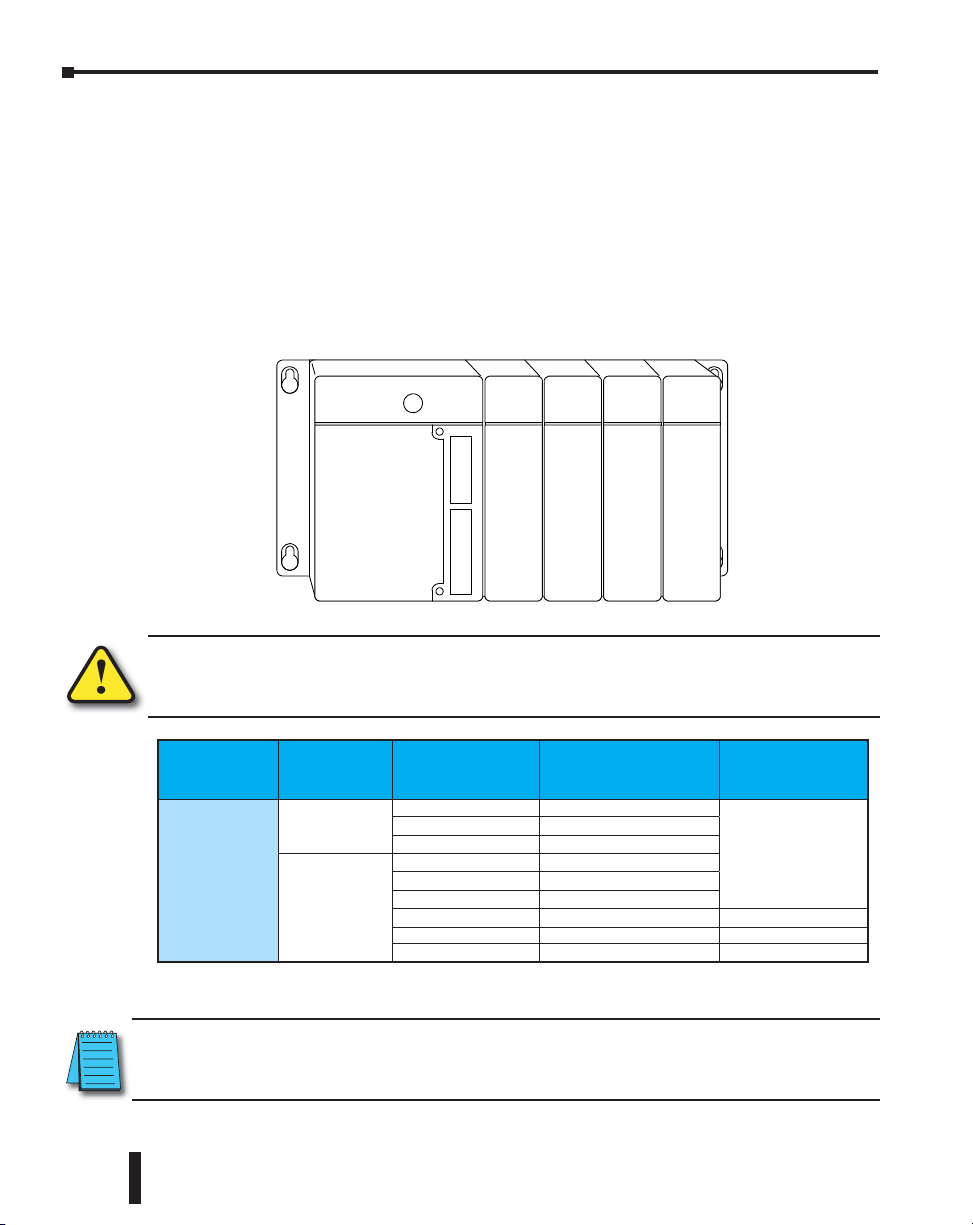

The DL205 system supports placement of the ECOM module in the CPU-base only, not in

local expansion bases or remote I/O bases. The number of usable slots depends on how many

slots your base has. The module does not work in slot 0 of the DL205 series PLCs, the slot

next to the CPU. The D2-240, D2-250-1, D2-260 and D2-262 CPUs support the ECOM

modules. The D2-230 CPU does not support the ECOM modules.

CPU

205

PWR

RUN

CPU

TX1

RX1

TX2

RX2

TERM

2–8

Slot 0 Slot 1 Slot 2 Slot 3 Slot 4

No!

WARNING: Your system can be damaged if you install or remove system components before disconnecting

the system power. To minimize the risk of equipment damage, electrical shock, or personal injury,

always disconnect the system power before installing or removing any system

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 27

Chapter 2: Setup and Installation

H2 Series ECOM Module

Module Type CPU CPU - Base Usuable Slots

H2-ECOM

H2-ECOM100

H2-ECOM-F

D2-240 D2-03B-1, D2-03BDC1-1, D2-03BDC-2 1

D2-250-1 D2-04B-1, D2-04BDC1-1, D2-04BDC-2 1, 2

D2-260 D2-06B-1, D2-06BDC1-1, D2-06BDC-1 1, 2, 3, 4

D2-262 D2-09B-1, D2-09BDC1-1, D2-09BDC-1 1, 2, 3, 4, 5, 6, 7

205

Retaining Clips

Before installing the module, verify power to the PLC is turned off. To install the ECOM

module, line up the module’s printed circuit board with the grooves in the base and push

the module until it is flush with face of the DL205 base power supply. If you feel more than

moderate resistance when you push the module into the base, the circuit board may not be

aligned with the grooves in the base. When the module is firmly seated in the slot, depress the

top and bottom retaining clips to lock the module in place.

NOTE: When adding modules to your PLC always confirm that your power budget will accommodate the

added module. See the User Manual for your PLC for more information about calculating the power budget.

See Appendix A for the power consumption of the ECOM modules.

Ethernet Communications Modules, 3rd Edition, Rev. E

2–9

Page 28

Chapter 2: Setup and Installation

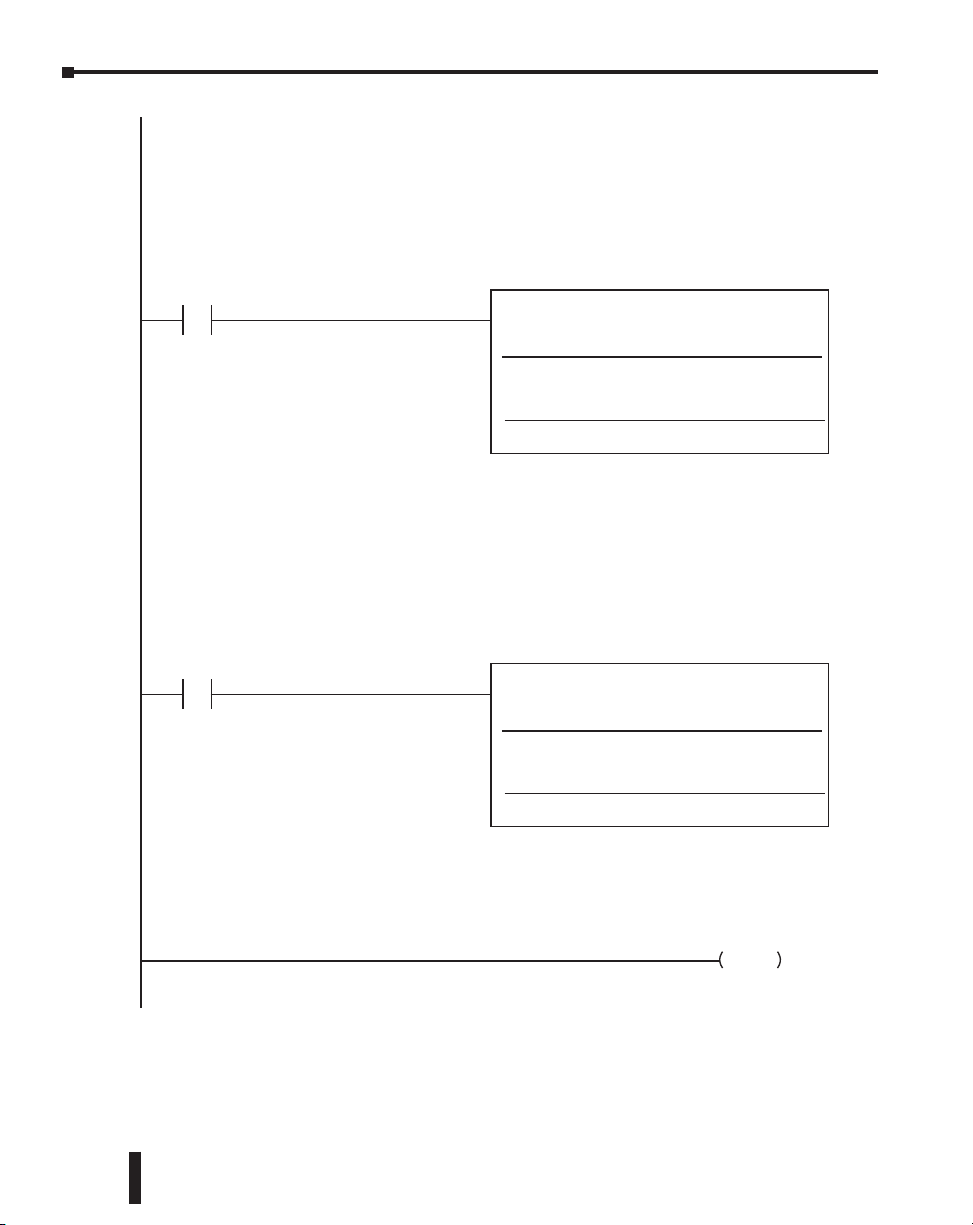

DL405 Slot Choices

For PLC systems with D4-430 and D4-440 CPUs, the ECOM modules can reside in any I/O

slot but only in the CPU-base. The D4-450 and D4-454 CPUs allows the installation of the

ECOM module in the CPU-base or in local expansion bases. However, it is still recommended

the ECOM be installed on the CPU base.

If the ECOM module is used in a local expansion base, all bases in the system must be the “-1”

type bases. The valid part numbers for these bases are D4-04B-1, D4-06B-1, and D4-08B-1.

The “-1” on the end of the part number indicates that the base supports specialty modules

including the ECOM. The “-1” bases can be connected as local expansion bases or remote

bases. They are not the same thing. Remote bases do not support the ECOM modules.

405

CPU

Slot 0 Slot 1 Slot 2

Slot 3

2–10

WARNING: Your system can be damaged if you install or remove system components before disconnecting

the system power. To minimize the risk of equipment damage, electrical shock, or personal injury,

always disconnect the system power before installing or removing any system component.

Module Type CPU Base

D4-04B, D4-04B-1 0, 1, 2, 3

D4-430/D4-440

H2-ECOM

H2-ECOM100

H2-ECOM-F

* You must use the “- 1” base for the CPU-base and all local expansion bases.

NOTE: Before installing the ECOM module, confirm that your power budget will accommodate the added

module. See the DL205 or DL405 User Manual for your PLC for more information about calculating the

power budget. See Appendix A for the power consumption of the ECOM modules.

D4-450/D4-454

D4-06B, D4-06B-1 0, 1, 2, 3, 4, 5

D4-08B, D4-08B-1 0, 1, 2, 3, 4, 5, 6, 7

D4-04B 0, 1, 2, 3

D4-06B 0, 1, 2, 3, 4, 5

D4-08B 0, 1, 2, 3, 4, 5, 6, 7

D4-04B 0, 1, 2, 3 0, 1, 2, 3*

D4-06B 0, 1, 2, 3, 4, 5 0, 1, 2, 3, 4, 5*

D4-08B 0, 1, 2, 3, 4, 5, 6, 7 0, 1, 2, 3, 4, 5, 6, 7*

Available

CPU-Base Slots

Available

Expansion Base

Slots

N/A

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 29

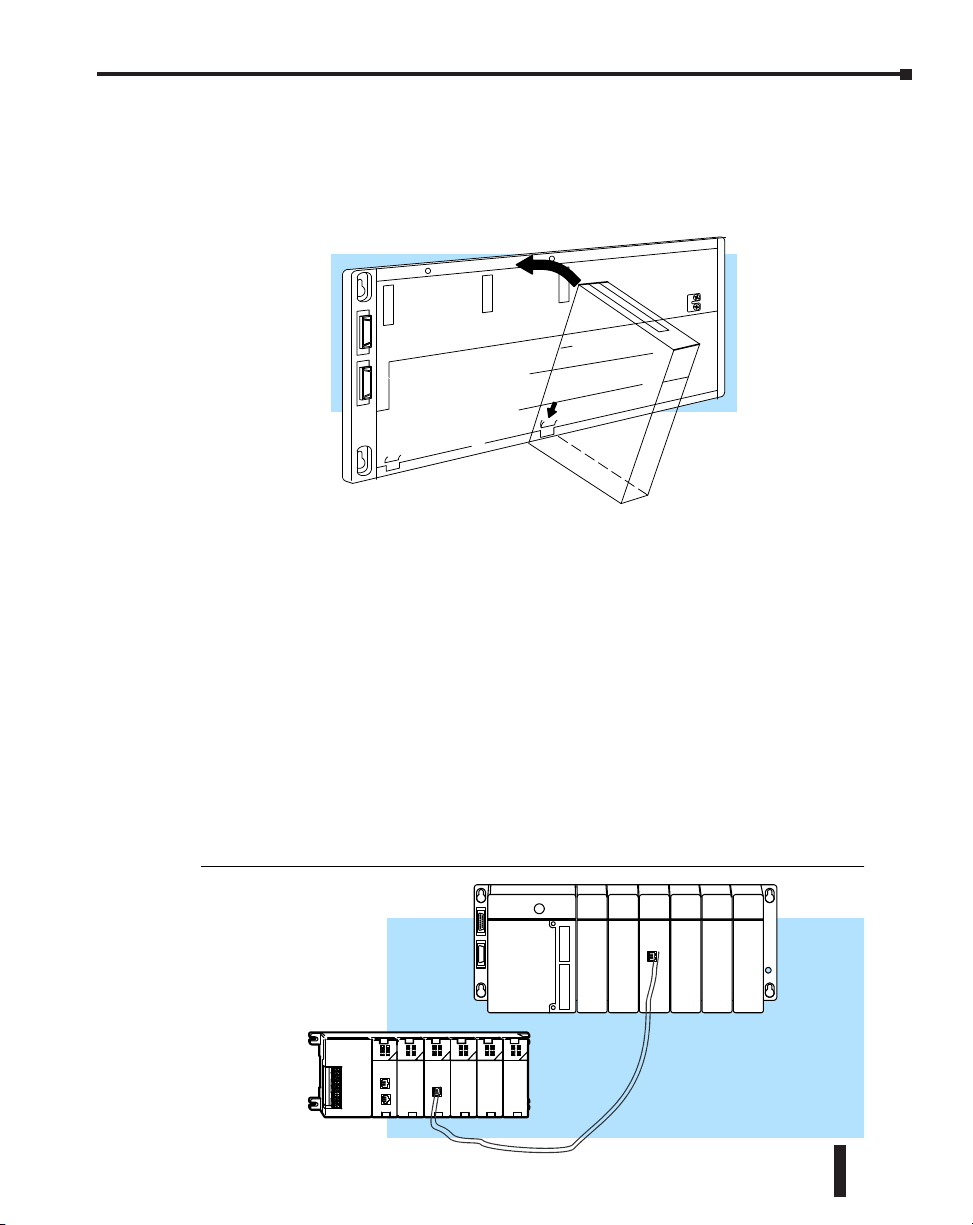

H4 Series ECOM

Before installing the ECOM module, verify power to the PLC is turned off. To insert the

ECOM module in a DL405 base, place the bottom tab of the module into Module Installation

the notch at the bottom of the base. Pivot the module toward the base as shown below. Ensure

that each module is tightly seated and secured with the captive screw at the top of the module.

DL405 Base

Disconnect power before installing module!

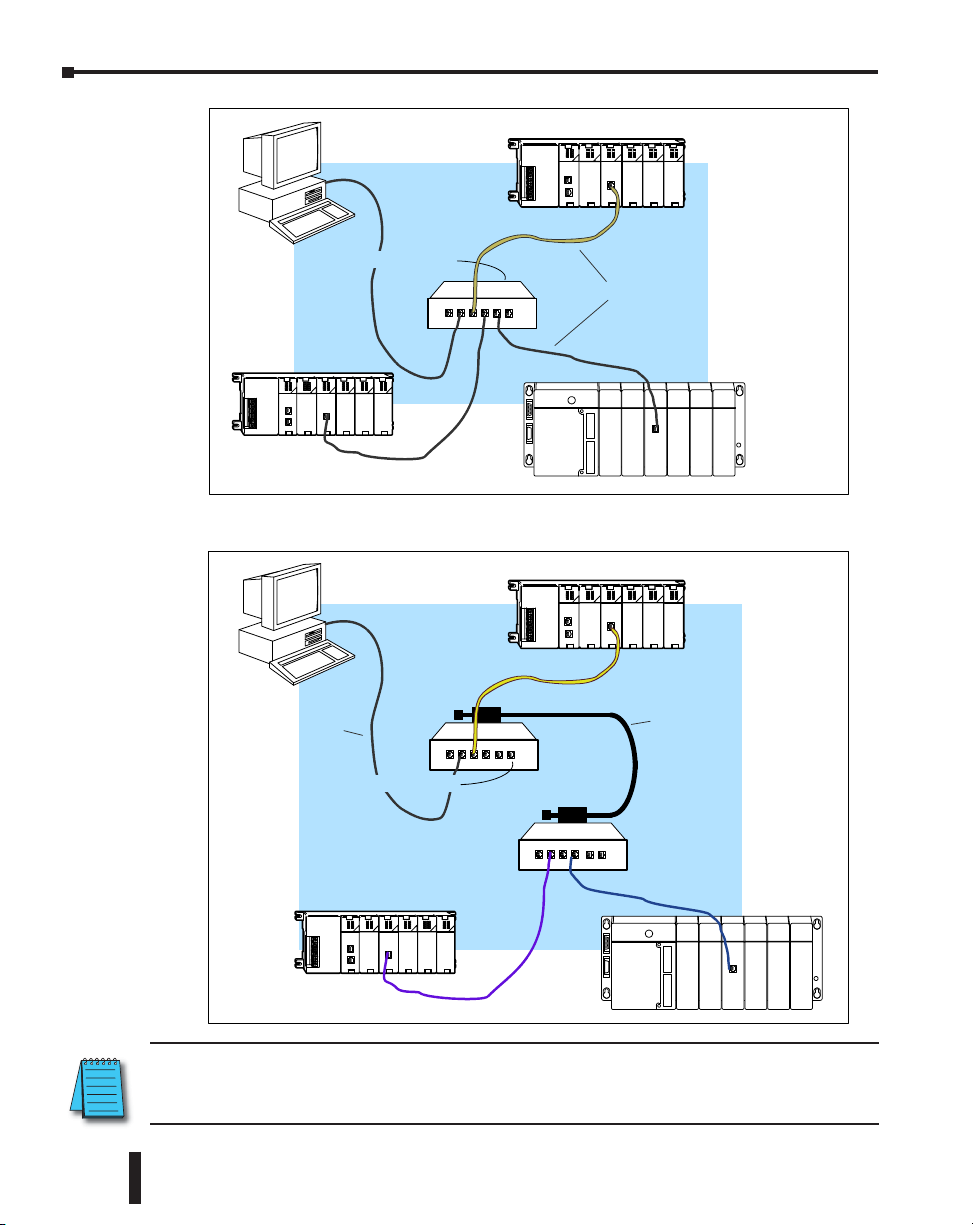

ECOM Network Layouts

The ECOM Ethernet network is a peer-to-peer network. Using Read (RX) or Write (WX)

instructions, any PLC on the network can initiate communications with any other PLC on the

network. A PC running our KEPDirect for PLCs software can also initiate communications

with any ECOM that is on the same network, but a PLC cannot initiate communication with

the PC. A PLC cannot literally broadcast to all other PLCs at the same time, but a PLC can

sequence through communication connections with other PLCs on the network, one at a time.

The ECOM products inherently support two network layouts: point-to-point and star. The

point-to-point layout can be used to link together two PLCs or a PC and a PLC. A hub or

repeater connects multiple network capable devices into a star topology. Multiple hubs or

repeaters are used to modify the star topology so that it becomes a star-bus-star topology. See

the figures below and on the next page.

Chapter 2: Setup and Installation

Point-to-Point

Point-to-Point

Ethernet Communications Modules, 3rd Edition, Rev. E

2–11

Page 30

Chapter 2: Setup and Installation

Hub or Repeater

Star Topology

10/100BaseT

or

10BaseFL

Hubs or repeaters can connect together to make it possible to connect more devices to the

network or to extend the range of the network

10BaseT

or

10BaseFL

Hub or Repeater

Star-Bus-Star Topology

Any Backbone

10Base2

10Base5

10BaseT

100BaseT

10BaseFL

2–12

NOTE: Hubs or repeaters often designate one port for uplink to another hub. This port may not be able

to be used to connect to a PLC. If the uplink port is used to connect to another hub, it may disable the

adjacent port. Use of the uplink port may require the use of a crossover cable.

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 31

Network Cabling

ECOM Supports Two Standards

Two types of ECOMs are available. One type supports the 10/100BaseT cabling standard, and

the other supports the 10BaseFL connection standard. The 10/100BaseT standard uses twisted

pairs of copper wire conductors, and the 10BaseFL standard is for fiber optic cabling.

Chapter 2: Setup and Installation

10/100BaseT

Unshielded

Twisted-Pair

cable with RJ45

connectors

10BaseFL

62.5/125 MMF

fiber optics cable

with ST-style

connectors

10/100BaseT Networks

The cable used to connect a PLC (or PC) to a hub or repeater is called a patch (straightthrough) cable. The cable used to connect together two PLCs, or a PC and a PLC or two hubs

is a crossover cable. We recommend that you purchase cables pre-assembled with connectors for

convenient and reliable networking.

The above diagrams illustrate the standard wire positions in the RJ45 connector. We recommend

all ECOM 10/100BaseT cables to be Category 5, UTP cable.

Ethernet Communications Modules, 3rd Edition, Rev. E

2–13

Page 32

Chapter 2: Setup and Installation

Ferrule

10/100BaseT Connections

Most 10/100BaseT hubs or repeaters use a patch (straight-through) cable for connecting the

network devices (PLCs or PCs). For hub-to-hub connections a crossover type cable is commonly

required. The figures on the previous page show pin assignments and insulation color codes for

patch (straight-through) and crossover type Ethernet cables.

UTP Cable

The ECOM has an eight-pin modular port that accepts RJ45 type connectors. UTP (Unshielded

Twisted-Pair) cable is rated according to its data-carrying ability (bandwidth) and is given a

“category” number. We strongly recommend using a category 5 cable for all ECOM connections.

NOTE: See page 2-14 for 10/100BaseT cable distance limitations.

10BaseFL Connections

Each module has two bayonet ST-style connectors. The ST-style connector uses a quick

release coupling which requires a quarter turn to engage or disengage. The connectors provide

mechanical and optical alignment of fibers.

Each cable segment requires two strands of fiber: one to transmit data and one to receive data.

The ST-style connectors are used to connect the H2-ECOM-F or H4-ECOM-F module to

another H2-ECOM-F or H4-ECOM-F module or a fiber optic hub or repeater.

Fiber Optic Cable

The H2-ECOM-F and H4-ECOM-F modules accept 62.5/125 multimode fiber optic (MMF)

cable. The glass core diameter is 62.5 micrometers and the glass cladding is 125 micrometers.

The fiber optic cable is highly immune to noise and permits communications over much greater

distances than 10BaseT.

Fiber Optic Module ST Connector

Multimode Fiber Optic (MMF) Cable

Transmit

Fiber Cross-section

Sheathing

2–14

Receive

NOTE: See page 2-14 for 10BaseFL distance limitations

62.5/125 MMF cable with

bayonet ST-style connectors

Connecting Two

Transmit

Receive

Fiber Optic ECOMs

Ethernet Communications Modules, 3rd Edition, Rev. E

Core

Cladding

Transmit

Receive

Page 33

Maximum Cable Length

The maximum distance per 10/100BaseT cable segment is 100 meters or 328 feet. Repeaters

extend the distance. Each cable segment attached to a repeater can be 100 meters. Two repeaters

connected together extend the total range to 300 meters.

10/100BaseT Distance Limitations

Chapter 2: Setup and Installation

100 meters

(328 feet)

100 meters

(328 feet)

100 meters

(328 feet)

100 meters

(328 feet)

100 meters

(328 feet)

Between

Repeaters

The maximum distance per 10BaseFL cable segment is 2,000 meters or 6,560 feet. Repeaters

extend the distance. Each cable segment attached to a repeater can be 2,000 meters. Two

repeaters connected together extend the total range to 6,000 meters.

10BaseFL Distance Limitations

2,000 meters

(6,560 feet)

2,000 meters

(6,560 feet)

2,000 meters

(6,560 feet)

2,000 meters

2,000 meters

(6,560 feet)

Between

Repeaters

(6,560 feet)

Ethernet Communications Modules, 3rd Edition, Rev. E

2–15

Page 34

Chapter 2: Setup and Installation

Maximum Number of ECOM Modules on the Network

The maximum number of nodes that can be connected to a 10/100BaseT or 10BaseFL network

is a function of the topology used in constructing the network. Therefore, it is not possible to

state an absolute maximum number of nodes that would apply in all cases.

The IEEE 802.3 specification defines the maximum node limit for an Ethernet segment in

terms of the ability to detect and avoid data collisions. A “legal” network can have any number

of devices provided that they can:

• Detect all data collisions that may occur during the communication process and

• Respond to these collisions appropriately.

You must take into consideration the network limitations imposed by all cabling and network

devices. Consider the limitations imposed on your network if your network uses:

• A combination of cabling standards, such as 10/100 BaseT and 10Base2, or

• Intermediate devices, such as switches or routers.

Each ECOM module can be assigned a Module ID ranging from 1 to 999,999,999.

Theoretically, you could have this many Ethernet modules coexisting on a single network. Other

network limitations would restrict the network size before reaching this limit. For the majority

of network PLC applications there is practically no limit to the number of ECOM modules

you can access from the NetEdit3, DirectSOFT Programming Software or the KEPDirect for

PLCs software.

There is a node limit for PLC-to-PLC communications. The network Read and Write

instructions performed by the initiating (master) PLC are only capable of accessing PLCs with

Module IDs of 1 through 90. This effectively sets the maximum number of nodes available for

PLC-to-PLC communications at 90.

2–16

WARNING: We recommend against connecting Ethernet modules to the same network that serves as your

primary office network. While Ethernet networks can handle a very large number of data transmissions,

and normally handle them very quickly, heavy Ethernet traffic can adversely affect the reliability and

speed of the network.

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 35

Configuring ECoMs

Chapter

Chapter

Chapter

using nEtEdit3

In This Chapter...

NetEdit3 Software .....................................................................................................3–2

NOTE: Please reference the BRX MPU system user manual (BX-USER-M) Appendix E for an updated guide

to using the NetEdit utility. This manual can be downloaded at www.automationdirect.com. For the latest

version and information on NetEdit, please visit www.hosteng.com, under the Utilities and FAQs sections.

3

3

3

Page 36

Chapter 3: Configuring ECOMs Using NetEdit3

NetEdit3 Software

NetEdit3 is a software utility which can be used to set network identifiers (Module ID or IP

Address), perform diagnostic and troubleshooting tasks and upgrade the firmware in the ECOM

module if necessary. The H0/H2/H4 -ECOM100 requires NetEdit 3.5 or later.

Installing NetEdit3

You can install NetEdit3 on Windows98/ME/2000/XPt or Windows NT4t. NetEdit3 is

available online at www.automationdirect.com. After loading the software the following window

will appear.

Click on Install NetEdit3. A series of windows will step you through the installation process.

3–2

Click on the Essential Tools button. The following window will be displayed.

Fill in the necessary information as the installation wizard prompts through the install. In the

Setup Type window, select Typical setup. This setup type is recommended for most users. The

installation process places NetEdit3 in the C:\HAPTools directory (default).

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 37

Chapter 3: Configuring ECOMs Using NetEdit3

Launching NetEdit3

There are three methods to launch NetEdit3. The three methods are:

• using the Windows Start menu Programs>AutomationDirect Tools> NetEdit3

as shown below

• launching DirectSoft (if installed), from the programming window, select

PLC>Tools>NetEdit3

• launching DirectSoft (if installed), then select Utilities>NetEdit3

The NetEdit3 Screen

Starting NetEdit3 brings up the screen below. All NetEdit3 functions are accessed

from this screen.

Ethernet Communications Modules, 3rd Edition, Rev. E

3–3

Page 38

Chapter 3: Configuring ECOMs Using NetEdit3

Adding Network Protocol Support to the NetEdit3 PC

You may have already set up your PC with selected networking protocols for Ethernet

communications. If not, you will need to select the protocols now for communication with the

Ethernet modules. We strongly recommend that you include the IPX protocol. For Windows

2000, go from My Computer on your Windows desktop to Control Panel. Double click on

Network and Dial- up Connections, then double click on the desired Network Device to see

the installed Protocols. If IPX is not listed among the protocols already loaded, add it now by

clicking on the Install button. For Windows XP, go from Start>Settings>Control Panel. The

steps are the same as Windows 2000 from this point.

Add the TCP/IP protocol if it is necessary for your application. The TCP/IP selection will give

you support for the UDP/IP protocol. Also, add the IPX protocol if it is not already active.

3–4

NOTE: We strongly recommend you load IPX protocol on your PC for the connection from your PC to

the Ethernet modules. Use UDP/IP in your application, if required, but also add IPX to your list of active

protocols. Having IPX loaded on your PC gives you a backup for troubleshooting communication problems.

Ethernet Communications Modules, 3rd Edition, Rev. E

Page 39

Chapter 3: Configuring ECOMs Using NetEdit3

Using NetEdit3

This section steps through the features and uses of NetEdit3. We will describe the individual

segments of the NetEdit3 screen and the function of each.

NOTE: Your PC-based Control software may be capable of configuring the EBC module. If so, please refer to

the appropriate documentation for that software product to determine the best method to configure the EBC.

Depending on which software you are using, it may not be necessary to use NetEdit3.

Ethernet Communication Protocol

In the upper left corner of the NetEdit3 screen, you will find buttons labeled IPX and TCP/IP.

The ECOM module understands these protocols. Both protocols are permanently resident in

the firmware of the module.