Page 1

Do-more H2 Series PLC Hardware User Manual

Manual Number: H2-DM-M

H2-DM1E

IN 12-24

VDC

0

1

2

3

D2-08ND3

12-24

OUT

A

4

0

5

1

2

6

3

B

7

F2-16TD1P

10.2-26.4

VDC 0.25A

CLASS2

A

0V

0

4

1

5

2

6

3

7

24V

0V

0

4

1

5

2

6

3

7

B

VDC

4

5

6

7

IN 12-24

VDC

0

1

2

3

D2-08ND3

4

5

6

7

Page 2

~ WARNING ~

Thank you for purchasing automation equipment from Automationdirect.com®, doing business as,

AutomationDirect. We want your new automation equipment to operate safely. Anyone who installs or

uses this equipment should read this publication (and any other relevant publications) before installing or

operating the equipment.

To minimize the risk of potential safety problems, you should follow all applicable local and national codes

that regulate the installation and operation of your equipment. These codes vary from area to area and

usually change with time. It is your responsibility to determine which codes should be followed, and to

verify that the equipment, installation, and operation is in compliance with the latest revision of these

codes.

At a minimum, you should follow all applicable sections of the National Fire Code, National Electrical

Code, and the codes of the National Electrical Manufacturer’s Association (NEMA). There may be local

regulatory or government offices that can also help determine which codes and standards are necessary for

safe installation and operation.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable codes

and standards. We do not guarantee the products described in this publication are suitable for your particular

application, nor do we assume any responsibility for your product design, installation, or operation.

Our products are not fault-tolerant and are not designed, manufactured or intended for use or resale as

on-line control equipment in hazardous environments requiring fail-safe performance, such as in the

operation of nuclear facilities, aircraft navigation or communication systems, air traffic control, direct life

support machines, or weapons systems, in which the failure of the product could lead directly to death,

personal injury, or severe physical or environmental damage (“High Risk Activities”). AutomationDirect

specifically disclaims any expressed or implied warranty of fitness for High Risk Activities.

For additional warranty and safety information, see the Terms and Conditions section of our catalog. If

you have any questions concerning the installation or operation of this equipment, or if you need

additional information, please call us at 1-770-844-4200.

This publication is based on information that was available at the time it was printed. At

AutomationDirect we constantly strive to improve our products and services, so we reserve the right to

make changes to the products and/or publications at any time without notice and without any obligation.

This publication may also discuss features that may not be available in certain revisions of the product.

Trademarks

This publication may contain references to products produced and/or offered by other companies. The

product and company names may be trademarked and are the sole property of their respective owners.

AutomationDirect disclaims any proprietary interest in the marks and names of others.

Copyright 2019, Automationdirect.com® Incorporated

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior, written

consent of Automationdirect.com® Incorporated. AutomationDirect retains the exclusive rights to all

information included in this document.

All Rights Reserved

Page 3

~ ADVERTENCIA ~

Gracias por comprar equipo de automatización de Automationdirect.com®. Deseamos que su nuevo equipo

de automatización opere de manera segura. Cualquier persona que instale o use este equipo debe leer esta

publicación (y cualquier otra publicación pertinente) antes de instalar u operar el equipo.

Para reducir al mínimo el riesgo debido a problemas de seguridad, debe seguir todos los códigos de seguridad

locales o nacionales aplicables que regulan la instalación y operación de su equipo. Estos códigos varian de

área en área y usualmente cambian con el tiempo. Es su responsabilidad determinar cuales códigos deben ser

seguidos y verificar que el equipo, instalación y operación estén en cumplimiento con la revisión mas reciente

de estos códigos.

Como mínimo, debe seguir las secciones aplicables del Código Nacional de Incendio, Código Nacional Eléctrico,

y los códigos de (NEMA) la Asociación Nacional de Fabricantes Eléctricos de USA. Puede haber oficinas de

normas locales o del gobierno que pueden ayudar a determinar cuales códigos y normas son necesarios para una

instalación y operación segura.

Si no se siguen todos los códigos y normas aplicables, puede resultar en daños al equipo o lesiones serias a

personas. No garantizamos los productos descritos en esta publicación para ser adecuados para su aplicación

en particular, ni asumimos ninguna responsabilidad por el diseño de su producto, la instalación u operación.

Nuestros productos no son tolerantes a fallas y no han sido diseñados, fabricados o intencionados para uso

o reventa como equipo de control en línea en ambientes peligrosos que requieren una ejecución sin fallas,

tales como operación en instalaciones nucleares, sistemas de navegación aérea, o de comunicación, control de

tráfico aéreo, máquinas de soporte de vida o sistemas de armamentos en las cuales la falla del producto puede

resultar directamente en muerte, heridas personales, o daños físicos o ambientales severos (“Actividades de Alto

Riesgo”). Automationdirect.com específicamente rechaza cualquier garantía ya sea expresada o implicada

para actividades de alto riesgo.

Para información adicional acerca de garantía e información de seguridad, vea la sección de Términos y

Condiciones de nuestro catálogo. Si tiene alguna pregunta sobre instalación u operación de este equipo, o si

necesita información adicional, por favor llámenos al número 1-770-844-4200 en Estados Unidos.

Esta publicación está basada en la información disponible al momento de impresión. En Automationdirect.

com nos esforzamos constantemente para mejorar nuestros productos y servicios, así que nos reservamos el

derecho de hacer cambios al producto y/o a las publicaciones en cualquier momento sin notificación y sin

ninguna obligación. Esta publicación también puede discutir características que no estén disponibles en ciertas

revisiones del producto.

Marcas Registradas

Esta publicación puede contener referencias a productos producidos y/u ofrecidos por otras compañías. Los nombres de las compañías

y productos pueden tener marcas registradas y son propiedad única de sus respectivos dueños. Automationdirect.com, renuncia

cualquier interés propietario en las marcas y nombres de otros.

PROPIEDAD LITERARIA 2019, AUTOMATIONDIRECT.COM® INCORPORATED

No se permite copiar, reproducir, o transmitir de ninguna forma ninguna parte de este manual sin previo consentimiento por escrito

de Automationdirect.com® Incorprated. Automationdirect.com retiene los derechos exclusivos a toda la información incluida en

este documento. Los usuarios de este equipo pueden copiar este documento solamente para instalar, configurar y mantener el equipo

correspondiente. También las instituciones de enseñanza pueden usar este manual para propósitos educativos.

Todos los derechos reservados

Page 4

~ AVERTISSEMENT ~

Nous vous remercions d’avoir acheté l’équipement d’automatisation de Automationdirect.com®, en faisant des

affaires comme, AutomationDirect. Nous tenons à ce que votre nouvel équipement d’automatisation fonctionne en

toute sécurité. Toute personne qui installe ou utilise cet équipement doit lire la présente publication (et toutes les

autres publications pertinentes) avant de l’installer ou de l’utiliser.

Afin de réduire au minimum le risque d’éventuels problèmes de sécurité, vous devez respecter tous les codes locaux

et nationaux applicables régissant l’installation et le fonctionnement de votre équipement. Ces codes diffèrent d’une

région à l’autre et, habituellement, évoluent au fil du temps. Il vous incombe de déterminer les codes à respecter et de

vous assurer que l’équipement, l’installation et le fonctionnement sont conformes aux exigences de la version la plus

récente de ces codes.

Vous devez, à tout le moins, respecter toutes les sections applicables du Code national de prévention des incendies,

du Code national de l’électricité et des codes de la National Electrical Manufacturer’s Association (NEMA). Des

organismes de réglementation ou des services gouvernementaux locaux peuvent également vous aider à déterminer les

codes ainsi que les normes à respecter pour assurer une installation et un fonctionnement sûrs.

L’omission de respecter la totalité des codes et des normes applicables peut entraîner des dommages à l’équipement

ou causer de graves blessures au personnel. Nous ne garantissons pas que les produits décrits dans cette publication

conviennent à votre application particulière et nous n’assumons aucune responsabilité à l’égard de la conception, de

l’installation ou du fonctionnement de votre produit.

Nos produits ne sont pas insensibles aux défaillances et ne sont ni conçus ni fabriqués pour l’utilisation ou la revente en

tant qu’équipement de commande en ligne dans des environnements dangereux nécessitant une sécurité absolue, par

exemple, l’exploitation d’installations nucléaires, les systèmes de navigation aérienne ou de communication, le contrôle

de la circulation aérienne, les équipements de survie ou les systèmes d’armes, pour lesquels la défaillance du produit

peut provoquer la mort, des blessures corporelles ou de graves dommages matériels ou environnementaux («activités à

risque élevé»). La société AutomationDirect nie toute garantie expresse ou implicite d’aptitude à l’emploi en ce qui a

trait aux activités à risque élevé.

Pour des renseignements additionnels touchant la garantie et la sécurité, veuillez consulter la section Modalités et

conditions de notre documentation. Si vous avez des questions au sujet de l’installation ou du fonctionnement de

cet équipement, ou encore si vous avez besoin de renseignements supplémentaires, n’hésitez pas à nous téléphoner au

1-770-844-4200.

Cette publication s’appuie sur l’information qui était disponible au moment de l’impression. À la société

AutomationDirect, nous nous efforçons constamment d’améliorer nos produits et services. C’est pourquoi nous nous

réservons le droit d’apporter des modifications aux produits ou aux publications en tout temps, sans préavis ni quelque

obligation que ce soit. La présente publication peut aussi porter sur des caractéristiques susceptibles de ne pas être

offertes dans certaines versions révisées du produit.

Marques de commerce

La présente publication peut contenir des références à des produits fabriqués ou offerts par d’autres entreprises. Les

désignations des produits et des entreprises peuvent être des marques de commerce et appartiennent exclusivement à

leurs propriétaires respectifs. AutomationDirect nie tout intérêt dans les autres marques et désignations.

Copyright 2019, Automationdirect.com® Incorporated

Nulle partie de ce manuel ne doit être copiée, reproduite ou transmise de quelque façon que ce soit sans le consentement

préalable écrit de la société Automationdirect.com® Incorporated. AutomationDirect conserve les droits exclusifs à

l’égard de tous les renseignements contenus dans le présent document.

Tous droits réservés

Page 5

Notes:

Page 6

Do-more H2 Series PLC User Manual

Please include the Manual Number and the Manual Issue, both shown below,

when communicating with Technical Support regarding this publication.

Manual Number:

Issue:

Issue Date:

H2-DM-M

1st Edition, Revision I

02/21

Publication History

Issue Date Description of Changes

1st Edition 9/12 Original

Revision A 9/12 Minor corrections made throughout manual

Revision B 02/13

Revision C 08/13

Revision D 3/17 General Update of Manual

Revision E 12/17 H2-CTRIO discontinued, added notes.

Revision F 06/18 Corrected 2’s complement data format selection.

Revision G 10/18 Updated EU Directives appendix

Revision H 01/19 Updated F2-8AD4DA-2 output resolution

Revision I

02/21 Added note on H2-SERIO-4 internal biasing.

Added H2-ERM100 module data

Minor corrections made throughout manual

Added Ethernet Expansion I/O section

Minor corrections made throughout manual

Page 7

Table of ConTenTs

Chapter 1 - Getting Started

Introduction ............................................................................................................... 1–2

Purpose of this Manual .............................................................................................1–2

Purpose of this Chapter ............................................................................................ 1–2

Online Help Files and Other Documentation ............................................................ 1–2

Technical Support..................................................................................................... 1–2

Conventions Used ...................................................................................................... 1–3

Key Topics for Each Chapter ..................................................................................... 1–3

Before You Begin ....................................................................................................... 1–4

Do-more! PLC System Components .........................................................................1–5

Do-more! Designer Software System Requirements .................................................. 1–5

Step 1: Install Do-more Designer Software .............................................................. 1–6

Step 2: Launch Do-more! Designer Software ........................................................... 1–9

Step 3: Install Hardware .......................................................................................... 1–11

Step 4: Apply Power to the Do-more! PLC ............................................................. 1–12

Step 5: Establish Communication ...........................................................................1–13

Step 6: Verify Hardware Configuration ..................................................................1–19

Step 7: Create a Ladder Logic Program ..................................................................1–23

Rung #1 ................................................................................................................. 1–23

Rung #2 ................................................................................................................. 1–26

Step 8: Save a Project .............................................................................................. 1–28

Step 9: Write Project to the Do-more PLC .............................................................1–28

Step 10: Testing Project Using Data View .............................................................. 1–29

Accessing the Help File ............................................................................................ 1–31

Page 8

Table of Contents

Chapter 2 - Do-more! H2 Series PLC Overview

Do-more H2 Series PLC Overview ............................................................................. 2–2

Do-more/DL205 System Compatibility ..................................................................... 2–3

Communications ...................................................................................................... 2–4

Chapter 3 - Specifications: CPU Modules

CPU Specifications ..................................................................................................... 3–2

CPU General Specifications ....................................................................................... 3–2

Communications Ports Specifications ....................................................................... 3–4

Port 1 Specifications (USB) .......................................................................................3–4

Port 2 Specifications (Serial) .....................................................................................3–4

Port 3 Specifications (Ethernet) ................................................................................3–5

Ethernet Expansion I/O ............................................................................................. 3–6

Status Indicators ........................................................................................................ 3–8

Mode Switch Functions ............................................................................................. 3–8

DIP Switch Specifications ..........................................................................................3–9

Battery Replacement ...............................................................................................3–12

Chapter 4 - Specifications: Base Units

Base Unit Overview ...................................................................................................4–2

Choosing a Base Type ..............................................................................................4–2

AC Powered Base Units .............................................................................................4–3

24VDC Powered Base Units .......................................................................................4–4

125VDC Powered Base Units .....................................................................................4–5

Power Budget ............................................................................................................ 4–6

Power Budget Example ............................................................................................4–6

Power Requirements .................................................................................................4–7

Chapter 5 - Specifications: Discrete I/O Modules

Discrete I/O Modules Overview ................................................................................ 5–3

Discrete Input Modules ............................................................................................5–3

Discrete Output Modules .........................................................................................5–4

Discrete Input/Output Module ................................................................................. 5–4

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

ii

Page 9

Table of Contents

D2-08ND3, DC Input .................................................................................................5–5

D2-16ND3-2, DC Input .............................................................................................. 5–6

D2–32ND3, DC Input ................................................................................................. 5–7

D2–32ND3–2, DC Input ............................................................................................. 5–8

D2–08NA-1, AC Input ................................................................................................5–9

D2-08NA-2, AC Input ............................................................................................... 5–10

D2-16NA, AC Input .................................................................................................. 5–11

D2-04TD1, DC Output ............................................................................................. 5–12

D2–08TD1, DC Output ............................................................................................5–13

D2–08TD2, DC Output ............................................................................................5–14

D2–16TD1–2, DC Output ......................................................................................... 5–15

D2–16TD2–2, DC Output ......................................................................................... 5–16

F2–16TD1P, DC Output With Fault Protection ......................................................5–17

F2–16TD2P, DC Output with Fault Protection ........................................................ 5–19

D2–32TD1, DC Output ............................................................................................5–21

D2–32TD2, DC Output ............................................................................................5–22

F2–08TA, AC Output ................................................................................................5–23

D2–08TA, AC Output ..............................................................................................5–24

D2–12TA, AC Output ...............................................................................................5–25

D2–04TRS, Relay Output .........................................................................................5–26

D2–08TR, Relay Output ...........................................................................................5–27

F2–08TR, Relay Output ............................................................................................ 5–28

F2–08TRS, Relay Output ..........................................................................................5–29

D2–12TR, Relay Output ...........................................................................................5–30

D2–08CDR, 4 pt. DC Input / 4pt. Relay Output .....................................................5–31

Chapter 6 - Specifications: Analog I/O Modules

Analog I/O Modules Overview ..................................................................................6–3

Analog Input Modules .............................................................................................. 6–3

Analog Output Modules ........................................................................................... 6–4

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

iii

Page 10

Table of Contents

Analog Input/Output Module ...................................................................................6–4

How to Access the Analog I/O Modules ...................................................................6–5

F2-04AD-1(L) Analog Input ....................................................................................... 6–7

Setting the Module Jumpers ..................................................................................... 6–8

F2-04AD-1(L) Addressing .........................................................................................6–9

F2-04AD-2(L), Analog Input .................................................................................... 6–10

Setting the Module Jumpers ................................................................................... 6–11

F2-04AD-2(L) Addressing .......................................................................................6–12

F2-08AD-1, Analog Input ......................................................................................... 6–13

Setting the Module Jumpers ................................................................................... 6–14

F2-08AD-1 Addressing ............................................................................................6–15

F2-08AD-2, Analog Input ......................................................................................... 6–16

Setting the Module Jumpers ................................................................................... 6–17

F2-08AD-2 Addressing ............................................................................................6–18

F2-04RTD ..................................................................................................................6–19

Setting the Module Jumpers ................................................................................... 6–20

F2-04RTD Addressing ............................................................................................. 6–22

F2-04THM ................................................................................................................6–23

Setting the Module Jumpers ................................................................................... 6–25

F2-02DA-1(L), Analog Output .................................................................................6–29

F2-02DA-2(L), Analog Output .................................................................................6–31

Unipolar Ranges ..................................................................................................... 6–34

Bipolar Ranges ........................................................................................................6–34

F2-02DAS-1, Analog Output .................................................................................... 6–35

F2-02DAS-2, Analog Output .................................................................................... 6–37

Setting the Module Jumpers ................................................................................... 6–38

F2–08DA–1, Analog Output .....................................................................................6–40

F2-08DA-2, Analog Output ...................................................................................... 6–42

Setting the Module Jumpers ................................................................................... 6–43

F2–4AD2DA, Analog Input/Output ......................................................................... 6–45

Input ...................................................................................................................... 6–47

Output ................................................................................................................... 6–47

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

iv

Page 11

Table of Contents

F2-8AD4DA-1 Analog Input/Output .......................................................................6–48

Input ...................................................................................................................... 6–51

Output ................................................................................................................... 6–51

Input Configuration Using Do-more Designer Version 1.1 or Newer ......................6–52

Input Resolution Selection (WYn+4) .......................................................................6–53

Input Track and Hold Selection (WYn+6) ............................................................... 6–54

F2-8AD4DA-2 Analog Input/Output .......................................................................6–55

Input ...................................................................................................................... 6–58

Output ................................................................................................................... 6–58

Input Configuration Using Do-more Designer Version 1.1 or Newer ......................6–59

Input Resolution Selection (WYn+4) .......................................................................6–60

Input and Output Range Selection (WYn+5) ..........................................................6–61

Input Track and Hold Selection (WYn+6) ................................................................ 6–62

Chapter 7 - Specifications: Specialty Modules

Specialty Modules Overview .....................................................................................7–3

Specialty Modules ....................................................................................................7–3

H2-CTRIO(2) ..............................................................................................................7–5

H2-CTRIO(2) Overview .............................................................................................7–5

H2-CTRIO(2) Specifications ......................................................................................7–7

H2-CTRIO(2) LED Indicators ..................................................................................... 7–8

H2-CTRIO(2) Jumper Setup ...................................................................................... 7–9

H2-CTRIO ................................................................................................................. 7–9

H2-CTRIO2 ............................................................................................................... 7–9

Wiring Information ................................................................................................. 7–10

PNP Field Device (source) ....................................................................................... 7–10

NPN Field Device (sink) .......................................................................................... 7–10

H2-CTRIO(2) Input Wiring Examples ......................................................................7–11

TTL Quadrature Encoder Field Wiring ..................................................................... 7–11

TTL Input Wiring Example ...................................................................................... 7–11

Quadrature Encoder Wiring Example ....................................................................7–12

NPN Open Collector Device ................................................................................... 7–12

PNP Open Collector Device ....................................................................................7–12

H2-CTRIO(2) Output Wiring Examples ...................................................................7–13

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

v

Page 12

Table of Contents

H2-ECOM100 .......................................................................................................... 7–14

H2-ECOM100 Overview ......................................................................................... 7–14

H2-ECOM100 Specifications ...................................................................................7–14

H2-ECOM100 LED Indicators .................................................................................7–15

H2-ECOM100 Network Identifiers .......................................................................... 7–15

H2-ECOM100 Network Layouts .............................................................................7–18

H2-ECOM100 Network Cabling ............................................................................. 7–19

H2-ERM(100)/ H2-EBC100* ..................................................................................... 7–22

H2-ERM(100) Overview ..........................................................................................7–22

H2-ERM(100) Specifications ...................................................................................7–22

H2-ERM(100) LED Indicators .................................................................................. 7–23

H2-EBC100 Overview ............................................................................................. 7–23

H2-EBC100 Specifications .......................................................................................7–23

H2-EBC100 LED Indicators .....................................................................................7–24

H2-ERM(100)/H2-EBC100 Network Identifiers ........................................................ 7–24

H2-ERM(100)/H2-EBC100 Network Layouts ........................................................... 7–27

H2-ERM(100)/H2-EBC100 Network Cabling ........................................................... 7–28

H2-SERIO(-4) ............................................................................................................ 7–30

H2-SERIO(-4) Overview ..........................................................................................7–30

H2-SERIO(-4) Specifications .................................................................................... 7–32

H2-SERIO(-4) Wiring: RS-232 .................................................................................. 7–32

H2-SERIO-4 Wiring: RS-422/485 ............................................................................. 7–33

F2-08SIM, Input Simulator ......................................................................................7–34

F2-08SIM Specifications .........................................................................................7–34

Chapter 8 - Installation and Wiring

Safety Guidelines ....................................................................................................... 8–3

Plan for Safety .......................................................................................................... 8–3

Three Levels of Protection ........................................................................................8–4

Emergency Stops ......................................................................................................8–4

Emergency Power Disconnect ..................................................................................8–5

Orderly System Shutdown ........................................................................................8–5

Class 1, Division 2, Approval ....................................................................................8–5

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

vi

Page 13

Table of Contents

Mounting Guidelines ................................................................................................. 8–6

Base Dimensions ......................................................................................................8–6

Panel Mounting and Layout ..................................................................................... 8–7

Enclosures ................................................................................................................8–8

Environmental Specifications .................................................................................... 8–9

Marine Use ............................................................................................................... 8–9

Agency Approvals ....................................................................................................8–9

24VDC Power Bases .................................................................................................8–9

Installing Bases for Do-more ................................................................................... 8–10

Mounting the Base ................................................................................................. 8–10

Using Mounting Rails .............................................................................................8–10

Installing Components in the Base ......................................................................... 8–11

Base Wiring Guidelines ............................................................................................ 8–12

Base Wiring ............................................................................................................8–12

I/O Modules Position and Wiring ...........................................................................8–13

Slot Numbering......................................................................................................8–13

Module Placement Restrictions ............................................................................... 8–13

Wiring the Different Module Connectors ................................................................ 8–14

I/O Wiring Checklist ...............................................................................................8–15

ZIPLink Wiring System ............................................................................................. 8–16

I/O Wiring Strategies ..............................................................................................8–18

PLC Isolation Boundaries ........................................................................................8–18

Powering I/O Circuits with the Auxiliary Supply .....................................................8–19

Powering I/O Circuits Using Separate Supplies ....................................................... 8–20

Sinking / Sourcing Concepts ..................................................................................8–21

I/O “Common” Terminal Concepts ........................................................................ 8–22

Connecting DC I/O to “Solid State” Field Devices .................................................. 8–23

Solid State Input Sensors ........................................................................................ 8–23

Solid State Output Loads ........................................................................................8–23

Relay Output Guidelines ......................................................................................... 8–25

Relay Outputs – Transient Suppression for Inductive Loads in a Control System ..... 8–26

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

vii

Page 14

Table of Contents

Appendix A - Do-more Product Weight Table

Do-more Product Weight Table ................................................................................ A-2

Appendix B - European Union Directives (CE)

European Union (EU) Directives ............................................................................... B-2

Member Countries ................................................................................................... B-2

Applicable Directives ................................................................................................ B-2

Compliance .............................................................................................................. B-2

General Safety .......................................................................................................... B-3

Other Sources of Information ................................................................................... B-4

Basic EMC Installation Guidelines ............................................................................. B-5

Enclosures ................................................................................................................ B-5

Electrostatic Discharge (ESD) .................................................................................... B-5

AC Mains Filters ....................................................................................................... B-6

Suppression and Fusing ............................................................................................ B-6

Internal Enclosure Grounding ................................................................................... B-6

Equipotential Grounding .......................................................................................... B-7

Communications and Shielded Cables ..................................................................... B-7

Analog and RS232 Cables ........................................................................................ B-8

Multi-drop Cables .................................................................................................... B-8

Shielded Cables within Enclosures ............................................................................ B-8

Analog Modules and RF Interference ........................................................................ B-9

Network Isolation ..................................................................................................... B-9

DC Powered Versions ............................................................................................... B-9

Items Specific to the Do-more H2 Series PLC ......................................................... B-10

viii

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 15

Chapter

Chapter

Chapter

GettinG Started

1

1

1

In This Chapter...

Introduction ............................................................................................................... 1–2

Purpose of this Manual .............................................................................................1–2

Purpose of this Chapter ............................................................................................ 1–2

Online Help Files and Other Documentation ............................................................ 1–2

Technical Support..................................................................................................... 1–2

Conventions Used ...................................................................................................... 1–3

Key Topics for Each Chapter ..................................................................................... 1–3

Before You Begin ....................................................................................................... 1–4

Do-more! PLC System Components .........................................................................1–5

Do-more! Designer Software System Requirements .................................................. 1–5

Step 1: Install Do-more Designer Software .............................................................. 1–6

Step 2: Launch Do-more! Designer Software ........................................................... 1–9

Step 3: Install Hardware .......................................................................................... 1–11

Step 4: Apply Power to the Do-more! PLC ............................................................. 1–12

Step 5: Establish Communication ...........................................................................1–13

Step 6: Verify Hardware Configuration ..................................................................1–19

Step 7: Create a Ladder Logic Program ..................................................................1–23

Rung #1 ................................................................................................................. 1–23

Rung #2 ................................................................................................................. 1–26

Step 8: Save a Project .............................................................................................. 1–28

Step 9: Write Project to the Do-more PLC .............................................................1–28

Step 10: Testing Project Using Data View .............................................................. 1–29

Accessing the Help File ............................................................................................ 1–31

Page 16

Chapter 1: Getting Started

Introduction

Purpose of this Manual

Thank you for purchasing from our Do-more PLC family of products. This manual shows

you how to install, set up, program, troubleshoot and maintain your Do-more PLC. For

installation personnel, this manual contains information on power and signal wiring,

mounting details and configuration procedures.

This manual can be very helpful as a quick reference guide for those who are experienced in

PLCs. For those who may be new to PLCs or our products, reading this manual will give you an

understanding of the variety of features available with the Do-more PLC.

Purpose of this Chapter

This chapter will guide you through the basic set up of a Do-more H2 Series PLC. It contains

step by step instructions on installing the programming software, installing and configuring your

hardware, applying power to the PLC, establishing a communications link, and creating, saving

and writing a project to the CPU. Once these steps are completed, your Do-more PLC will be

running a ladder logic project that you have programmed.

Online Help Files and Other Documentation

Do-more Designer, the Do-more PLC programming software, is available for free download from

our website at:

http://www.automationdirect.com

The software includes searchable online help topics covering all aspects of the software, instruction

set, module set up and communication.

1–2

Technical Support

We strive to make our manuals the best in the industry. We rely on your feedback to

let us know if we are reaching our goal. If you cannot find the solution to your particular

application, or, if for any reason you need technical assistance, please call us at:

770-844-4200

Our technical support group will work with you to answer your questions. They are available

Monday through Friday from 9:00 A.M. to 6:00 P.M. Eastern Time. We also encourage you to

visit our web site where you can find technical and non-technical information about our products

and our company.

http://www.automationdirect.com

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 17

Conventions Used

When you see the “note pad” icon in the left-hand margin, the paragraph to its immediate right will be a

special note. Notes represent information that may make your work quicker or more efficient. The word

NOTE: in boldface will mark the beginning of the text.

When you see the “exclamation point” icon in the left-hand margin, the paragraph to its immediate right

will be a warning. This information could prevent injury, loss of property, or even death in extreme

cases. Any warning in this manual should be regarded as critical information that should be read in its

entirety. The word WARNING in boldface will mark the beginning of the text.

Chapter 1: Getting Started

Key Topics for Each Chapter

The beginning of each chapter will list the key topics

that can be found in that chapter.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Getting Started!

In This Chapter...

.............................................................................1-2

Introduction

About Getting Started!

Supplemental Manuals and Other Help

Technical Support

....................................................................1-2Purpose of this Manual

......................................................................1-2

.............................................................................1-2

....................................................................1-3Conventions Used

CHAPTER

1

............................................1-2

1–3

Page 18

Chapter 1: Getting Started

R

/

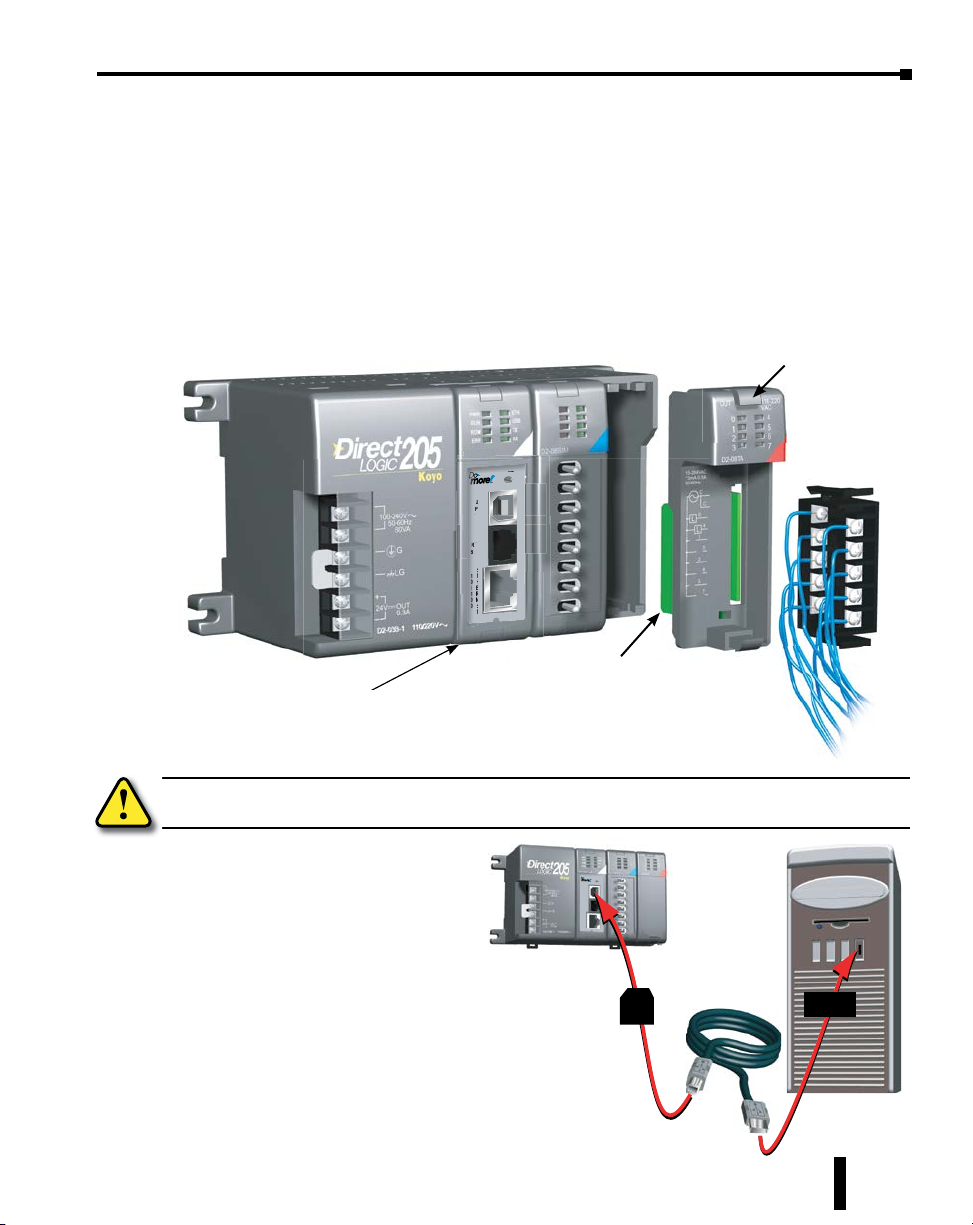

Before You Begin

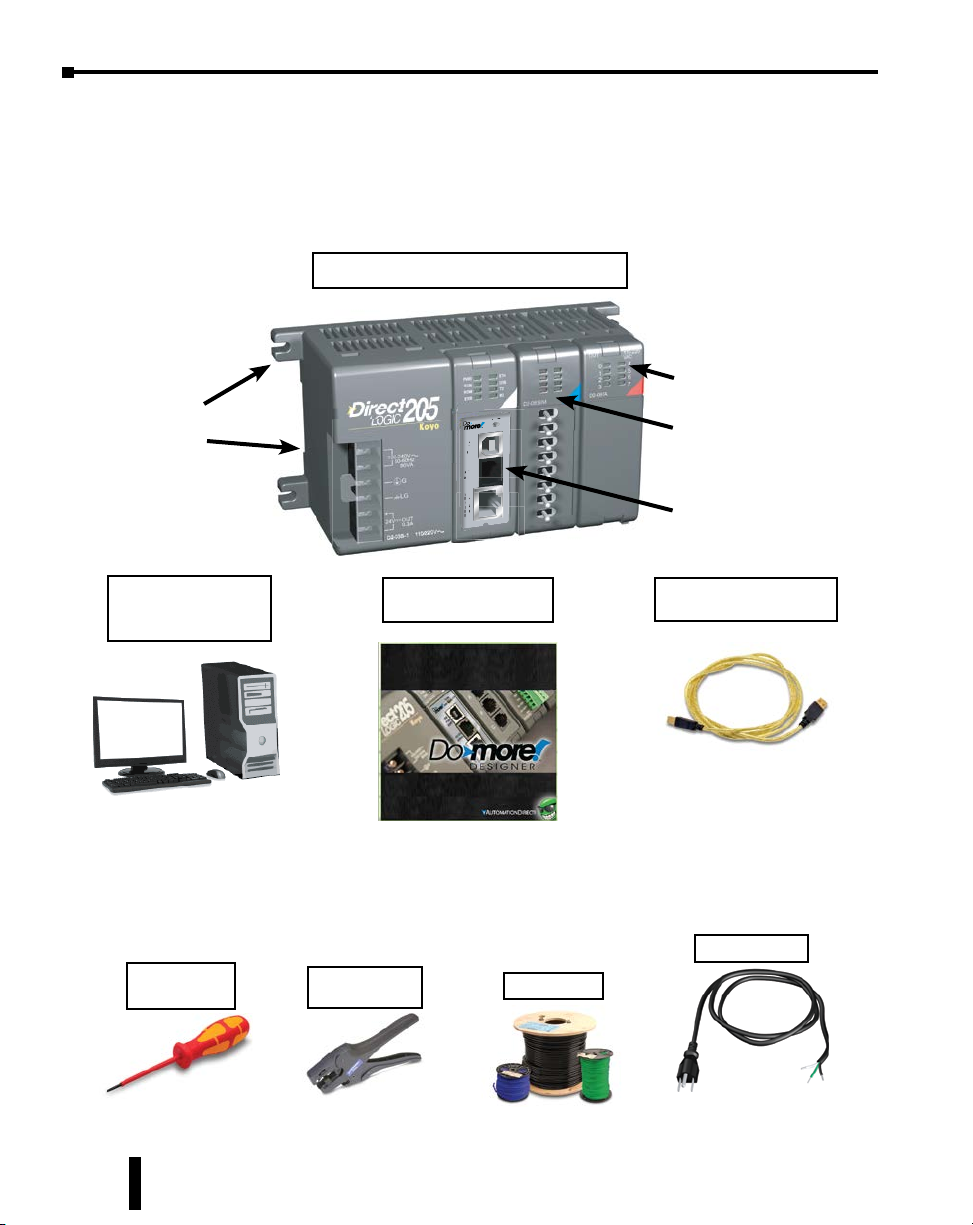

It is recommended that the following items be available to make this short step-by-step

introduction to the Do-more PLC go smoothly.

D2-03B-1 Base

with 110/220 VAC

Power Supply

Example Do-more PLC

H2-DM1E

H2-DM1E

TERM

STOP

RUN

USB

PGM

PORT

RS-232

SERIAL

E

T

1

H

0

E

/

R

1

N

0

E

0

T

D2-08TA Output Module

F2-08SIM Module

Do-more! CPU Module

PC Running

Windows XP, Vista,

Windows 7, Windows 8

Not available from

Automationdirect.com.

Screwdriver

TW-SD-VSL-1

Programming Software

Download software from

our webste at: http://www.

automationdirect.com

Wire Strippers

DN-WS

Do-more! Designer

Hookup Wire

USB-A to USB-B

Programming Cable

You can also use an Ethernet

or Serial (D2-DSCBL) cable

for programming, but we

recommend using a USB cable;

just plug it in and it works.

AC Power Cord

Not available from

Automationdirect.com.

1–4

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 19

Chapter 1: Getting Started

Do-more! PLC System Components

The Do-more H2 Series CPU modules were designed to stand in place of the DL205 series PLC.

As a result, this CPU easily integrates with DL205 PLC family components. The following is a

summary of the major parts of a Do-more H2 Series PLC.

CPU

H2-DM1/H2-DM1E

Bases

The Do-more H2 Series CPU module can be placed into any DL205 PLC family base. The four base

sizes available are 3, 4, 6 and 9 slot. All bases include a built-in power supply and can be purchased for

use with AC or DC sources. The Do-more H2 Series PLC supports local and Ethernet remote

I/O configurations only.

NOTE: The Do-more H2 Series PLC does not support local expansion I/O.

I/O Modules

The DL205 PLC family has some of the most powerful I/O modules in the industry. A complete

range of discrete modules which support 24VDC, 110/220 VAC and up to 10A relay outputs

(subject to derating) are offered. The analog modules provide 12 and 16 bit resolution and several

selections of input and output signal ranges (including bipolar). Several specialty modules are also

available.

Do-more! Designer Software System Requirements

The Do-more! Designer Windows-based programming software works with Windows® XP

(Home or Professional, 32-bit), Vista (Home, Basic, Premium, 32 or 64-bit), Windows 7

(Home, Professional, Ultimate, 32 or 64-bit), Windows 8 & 10 (Home, Professional, Enterprise

32 or 64-bit; Windows 8 RT edition is NOT supported).

Please check the following requirements when choosing your PC configuration:

• Minimum PC to PLC Connectivity, at least one of the following:

- USB Port: connects to the CPU with USB-A connector (USB-A to USB-B cable)

- RS-232 Serial Port: connects to the CPU with RJ-12 connector (RJ-12 to DB9 or RJ-12

to USB-B serial converter cable)

- Ethernet Port: connects to the CPU (H2-DM1E) with RJ-45 10Base-T or 100Base-T

(Cat5 Patch Cable)

• Hard Disk: 100MB free disk space

• Video Display: 1024x768, 256 colors resolution (1280x720, true color recommended)

• Windows XP, 32-bit:

- 800MHz, single core CPU (2GHz, multi-core or hyper-threaded recommended)

- 512MB RAM (2GB recommended)

• Vista, Windows 7 or Windows 8 & 10, 32 or 64-bit:

- 1GHz, single core CPU (2GHz, multi-core recommended)

- 1GB RAM (3GB recommended)

NOTE: The PC/Laptop/Ethernet Switch connector at the “opposite end” of the PLC connector will dictate

what kind of cable you need.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

1–5

Page 20

Chapter 1: Getting Started

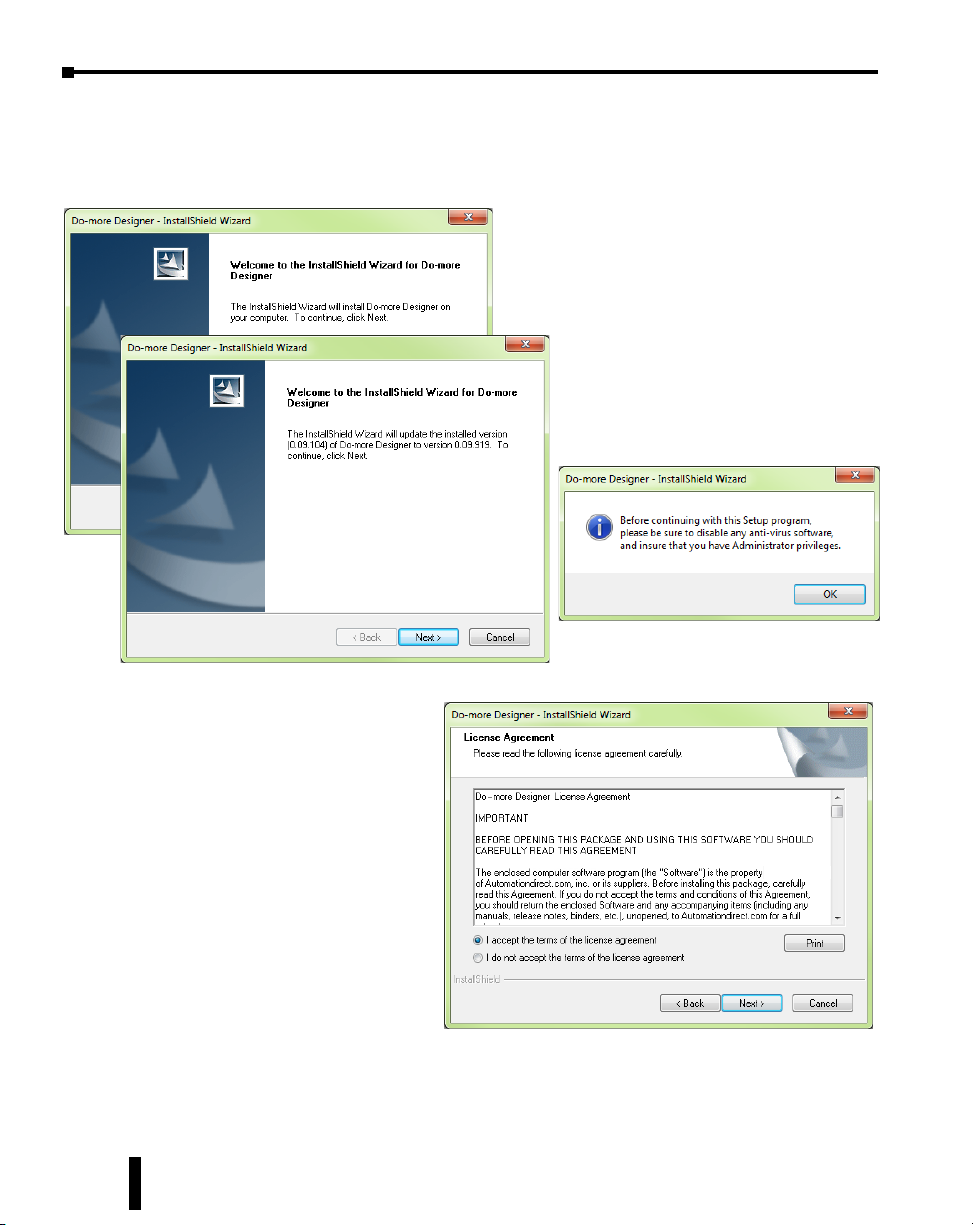

Step 1: Install Do-more Designer Software

Download the Do-more Designer programming software (DM-PGMSW) from our website

at http://automationdirect.com and launch the install procedure.

The first screen that opens is the Welcome

screen seen here. If there are previous versions of

this software already installed, this screen will

detail the version number of the software being

replaced and the one being installed, click Next

to continue.

An alert window will appear requesting

that all anti-virus software be disabled

and also reminding the user that

Administrative restrictions may exist.

1–6

The License Agreement window

will be displayed next. Read over

the agreement, select “I accept the

terms of the license agreement” and

click the Next button to continue.

There is also the option to print the

license agreement if desired. The

print function will print the license

agreement to a pdf file and save it

in the location you choose.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 21

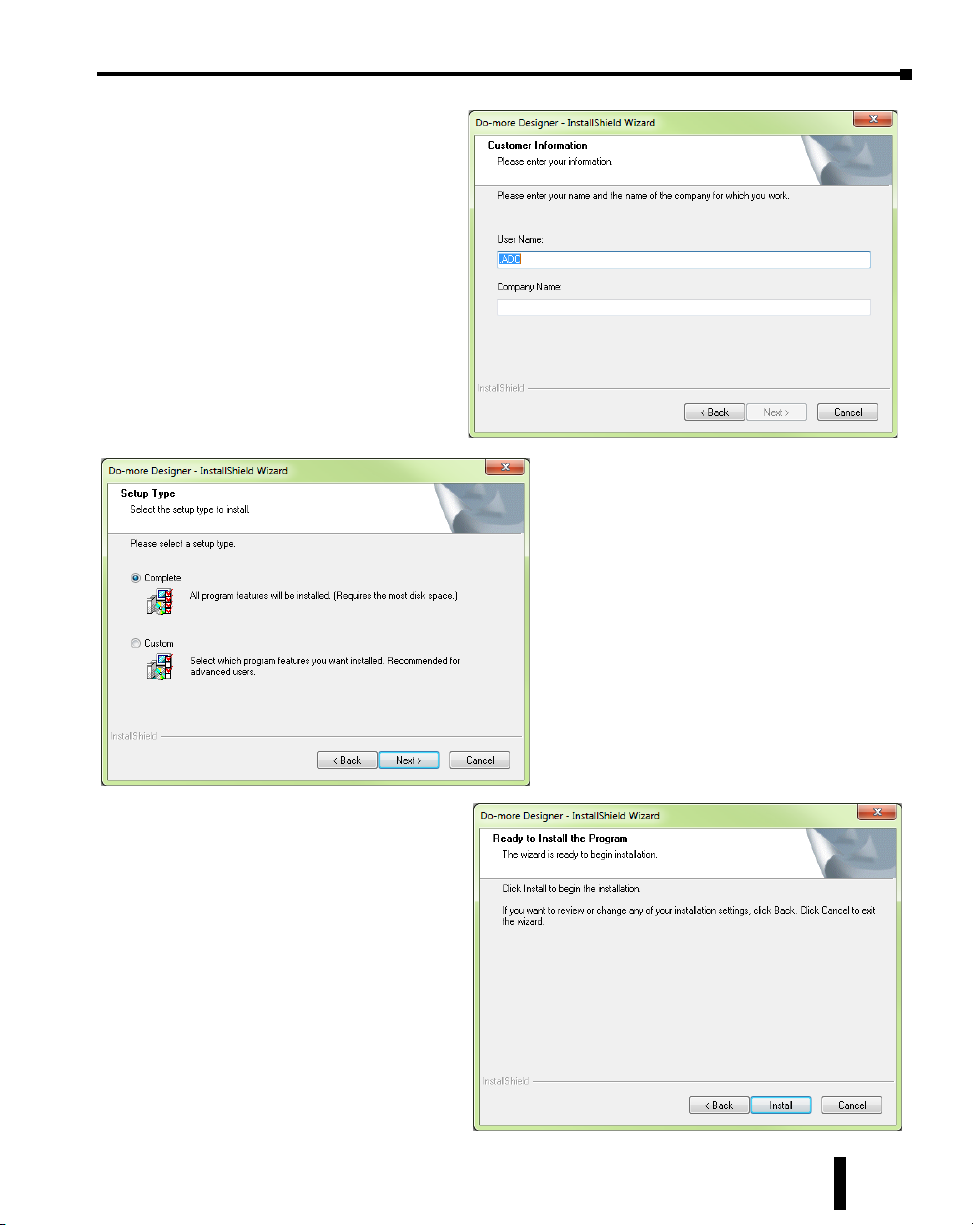

Now the software will ask a little

about you. Please fill in the

information requested on the

Customer Information screen and

click Next to continue.

At this stage, the software will ask

which type of install you would like

to perform. The Select Type

window seen below gives two

options for installation type:

Complete and Custom.

Chapter 1: Getting Started

Custom installation allows you to choose which

program features to install, whereas Complete

installation installs all of the program features

available. The Complete installation is selected

by default and is recommended for first-time

users.

Select the installation type desired and click the

Next button to continue.

The next screen to appear is the

Ready to Install the Program

window. This window is an alert

window, cautioning you that the

program is about to be installed. If

there are any changes that need to

be made to the install settings do

them now before continuing.

To review or change any of the

previous installation selections, click

the Back button to return to the

appropriate window and make the

change. If no changes are necessary

click the Install button to begin the

installation.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

1–7

Page 22

Chapter 1: Getting Started

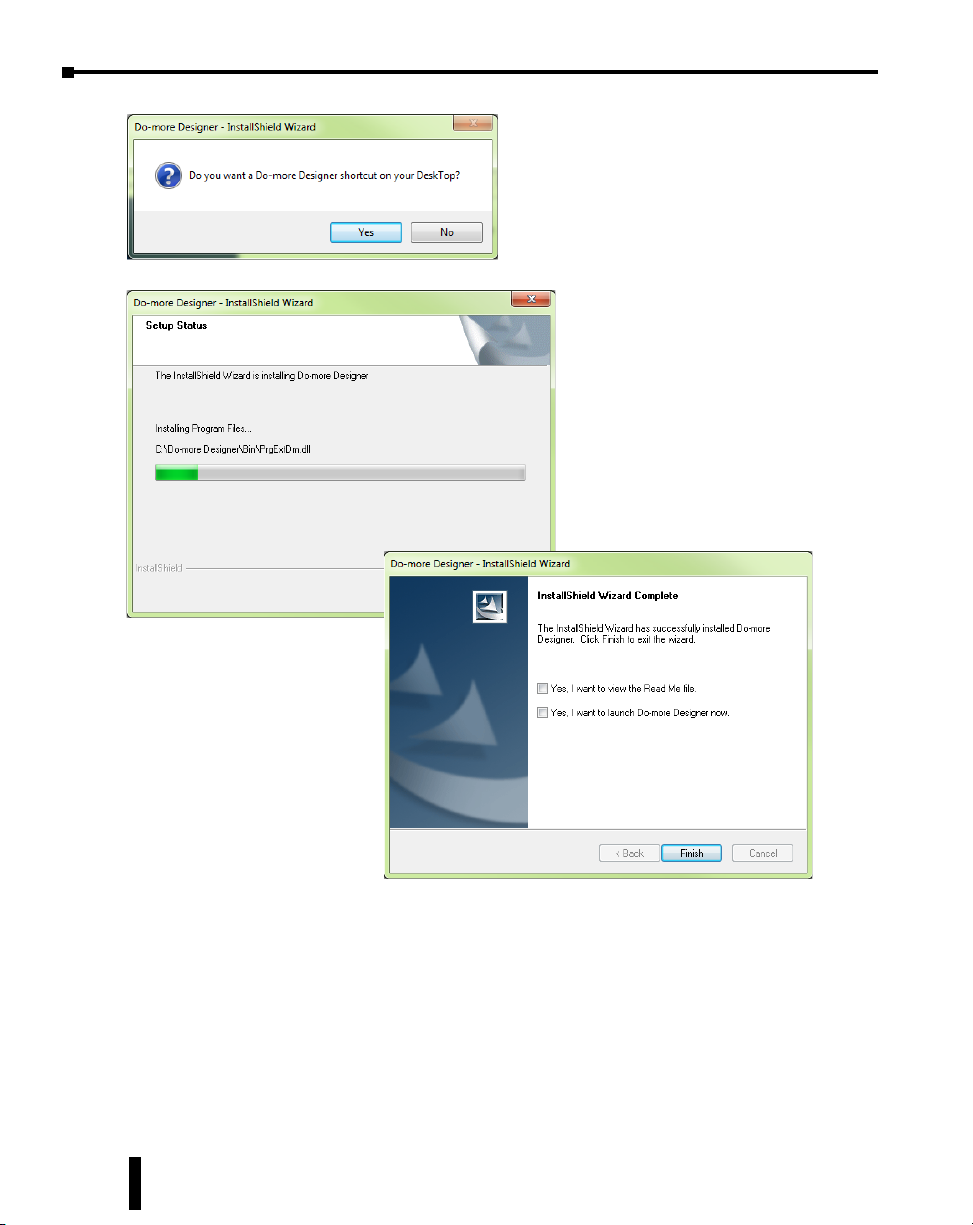

The popup shown here will allow you to choose

whether or not to install a shortcut for the

software on your PC’s desktop. Click Yes or No

to continue with the installation.

The software will now install the

needed files and folders with the Setup

Status window detailing the status of

the installation.

Once the installation has been

successfully completed, the window

below will open. Your software is now

installed and ready to use. The

installation wizard can now be closed

by clicking the Finish button at the

bottom of the window.

1–8

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 23

Chapter 1: Getting Started

Step 2: Launch Do-more! Designer Software

After installing Do-more! Designer, launch the software by double clicking the

desktop DM icon.

You can also launch the software from the PC’s Start

menu or All Programs menu. If the software link is

not embedded in the Start menu, use

the path: Start > All Programs > Domore > Designer x.x > Do-more

Designer x.x to launch the software.

The Do-more! Designer Software will

start up and display the Start Page

shown below. This page consists

of a Launchpad with quick links to

existing projects, software applications

and communications links. There

is also a section containing shortcuts

to important help file topics and

the Do-more! Designer simulator

application.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

1–9

Page 24

Chapter 1: Getting Started

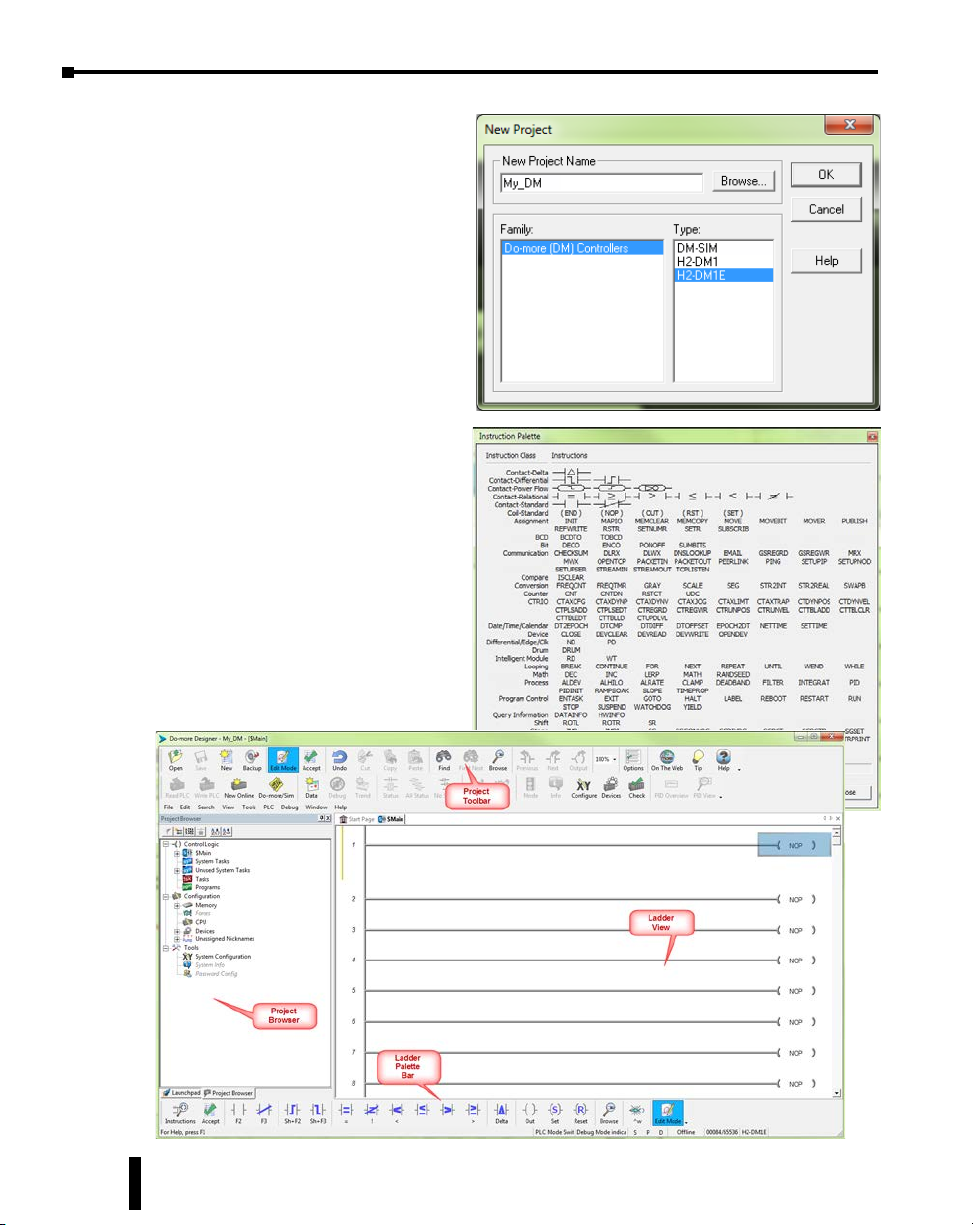

To begin a new project offline select

New from the toolbar on the Start

Page. The New Project window seen

here will open.

Name the new project and select the

type of controller it is intended for. You

can use the Browse button to choose a

different location to store the project or

use the default location. Click OK after

your selections have been made to

continue. The Main programming

window and Instruction Palette shown

below will open.

The Instruction Palette lists all of the

instructions available for use in your

program. A brief explanation of

each instruction is provided once the

instruction is highlighted and a more

detailed explanation is available in the

help file.

The Main programming window is

divided into menus and toolbars for

quick access to configurations,

instructions and other needed items

used during project development.

1–10

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 25

Step 3: Install Hardware

O

/

/

The “Installation and Wiring” chapter of this manual contains detailed information for the

installation of components in your Do-more! PLC system. The following summary explains

the basic steps for installing modules in a base.

First slide the module retaining clips to the out position and align the PC board(s) of the

module with the grooves on the top and bottom of the base. Push the module straight into the

base until it is firmly seated in the backplane connector. Once the module is inserted into the

base, push in the retaining clips to firmly secure the module to the base.

H2-DM1E

USB

PGM

PORT

RS-232

SERIAL

E

T

1

H

0

E

/

R

1

N

0

E

0

T

Chapter 1: Getting Started

Push the retaining clips in to

secure the module to the base

TERM

STOP

RUN

Align module PC board to slots

CPU must be positioned in the

in base and slide in

first slot of the base

WARNING: Minimize the risk of electrical shock, personal injury, or equipment damage. Always

disconnect the system power before installing or removing any system component.

Once all of the modules have been

installed in the base, connect the USB

cable. Use a standard USB cable with

Type A and Type B connectors.

H2-DM1E

TERM

RUN

STOP

USB

PGM

PORT

RS-232

SERIAL

E

1

T

0

H

/

E

1

R

0

N

0

E

T

(Ethernet and Serial connections are

also available, but are not shown for

this example.)

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Type

B

Type A

1–11

Page 26

Chapter 1: Getting Started

1 10/220 V AC Base T erminal Strip

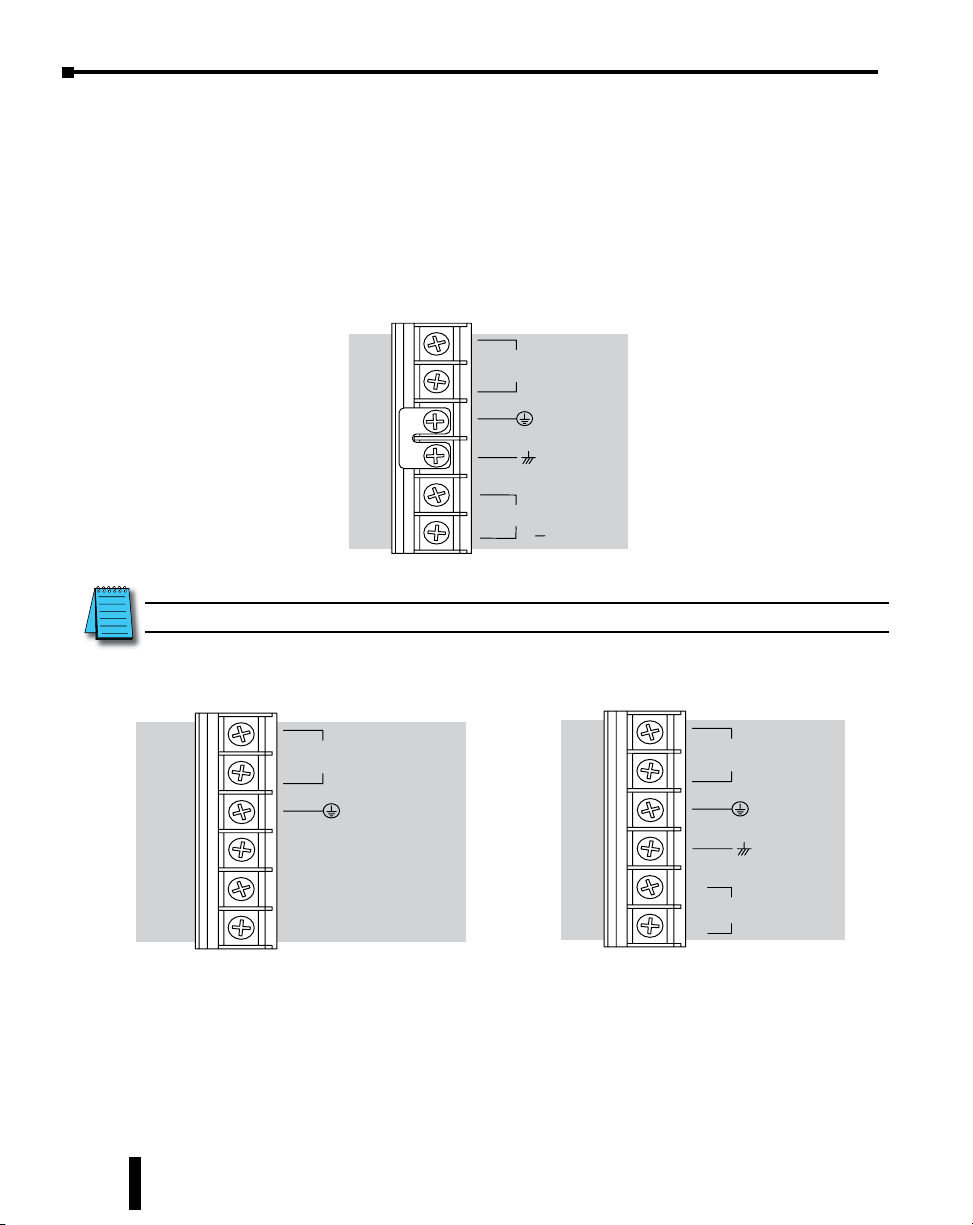

Step 4: Apply Power to the Do-more! PLC

Power is supplied to the Do-more! PLC through the backplane of the base from the power

supply. The following diagrams show the terminal connections located on the power supplies

of the DL205 bases. The base terminals can accept up to 16AWG. You may be able to use

larger wiring depending on the type of wire used, but 16AWG is the recommended size. Do not

over-tighten the connector screws; the recommended torque value is 7.81 lb·in (0.882 N·m).

100 – 240 VAC

G

LG

+

24 VDC OUT,

NOTE: You can connect either a 115VAC or 220VAC supply to the AC terminals.

0.3A

1–12

125 VDC Base T erminal Strip 12/24 VDC Base T erminal Strip

+

10.2 – 28.8 VDC

–

G

+

1 20 – 240 VDC

–

G

LG

+

24 VDC OUT,

–

0.3A

Once all of the power wiring has been completed and verified, connect the appropriate

voltage source to the power supply and power up the controller. The Do-more PLC will

perform a self evaluation once power is applied. Refer to the “Installation and Wiring”

chapter of this manual for more power supply and input wiring information.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 27

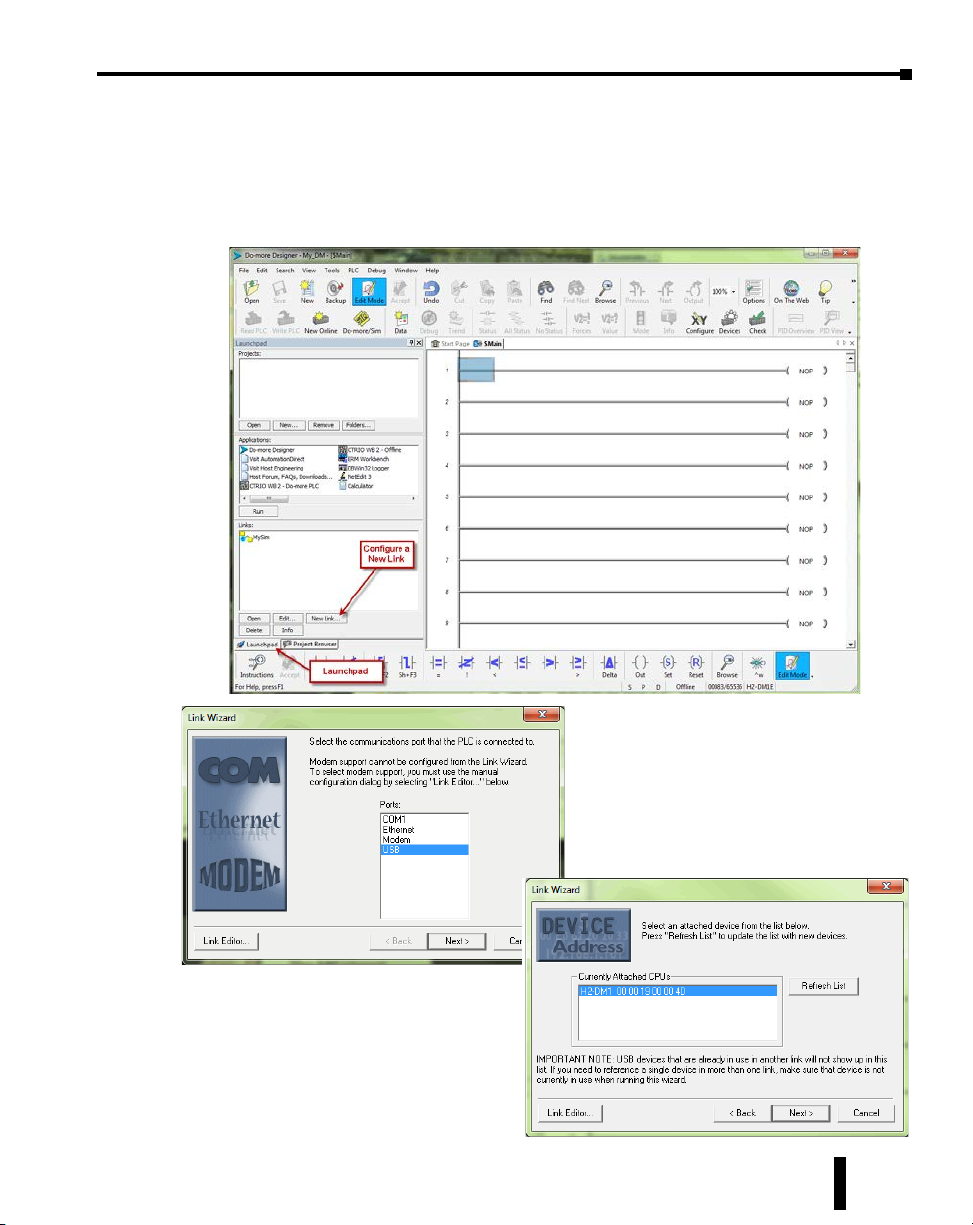

Step 5: Establish Communication

Now that the Do-more PLC is powered up, you need to establish a communications link

between the PC and the PLC. The Do-more! Designer software provides a Link Wizard to

assist you with configuring this new communications link. To open the Link Wizard, select

the New Link... button in the Links section of the Main Page’s Launchpad as shown below.

Chapter 1: Getting Started

The Link Wizard will first ask you to

choose which communications port you

will be using. In this example, we will be

using a USB connection. Select USB,

click Next and the wizard will

automatically search for available CPU’s

on that port.

Choose the CPU that you are

programming and select Next. The Domore Designer software will create a link to

that controller.

The Link Wizard will now display the

saved settings for this link as seen on

following page.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

1–13

Page 28

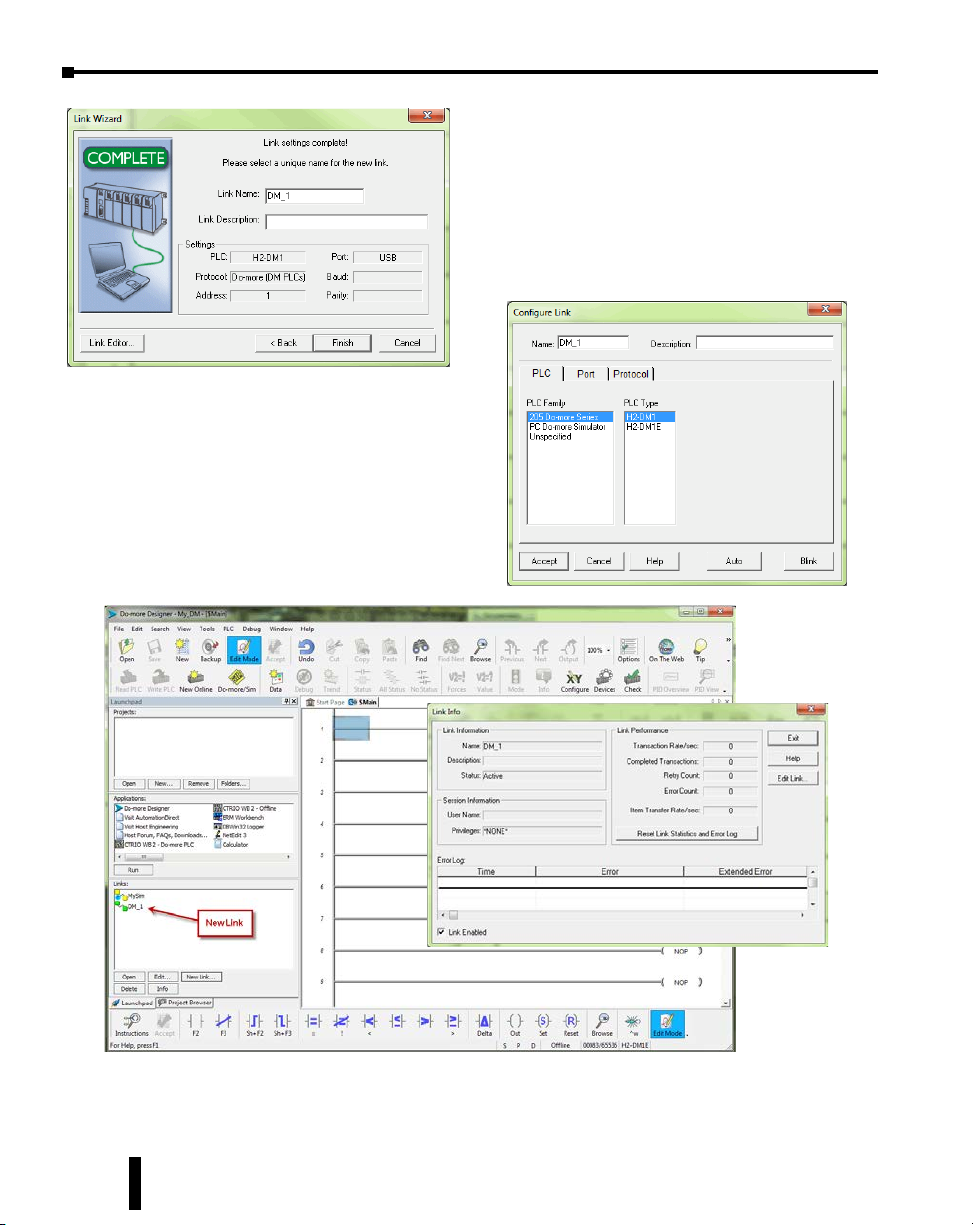

Chapter 1: Getting Started

Once you have completed configuring

your communications link, either

manually with the Link Editor or

automatically with the Link Wizard, it will

be available to select in the Links section of

the Launchpad. There you can edit, enable/

disable, delete or view statistics for that link.

A unique name is required for each link that is

created. Name the new link and, if desired, give it a

description then select Finish.

You can also manually configure each link by selecting

the Link Editor... button from the lower left corner

of the Link Wizard. The Configure Link dialog will

open, as seen below, allowing you to select PLC types,

port parameters, and protocols.

1–14

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 29

Chapter 1: Getting Started

Select the New Online button and the Online dialog box, seen below, will open. From this

dialog, you are given available communications links to choose from with options to add, edit

disable/enable, or delete links.

Choose the appropriate link, select OK

and the software will connect to the Domore PLC. If the mode selector switch on

the CPU module is not in the Term position

when connecting, the warning shown below

will appear.

You are allowed to continue if you wish or place the

mode selector switch on the CPU module in the

Term position to avoid any unintended

communication errors.

If you were connecting to the CPU module with a project created offline, you may encounter

the message window shown here.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

1–15

Page 30

Chapter 1: Getting Started

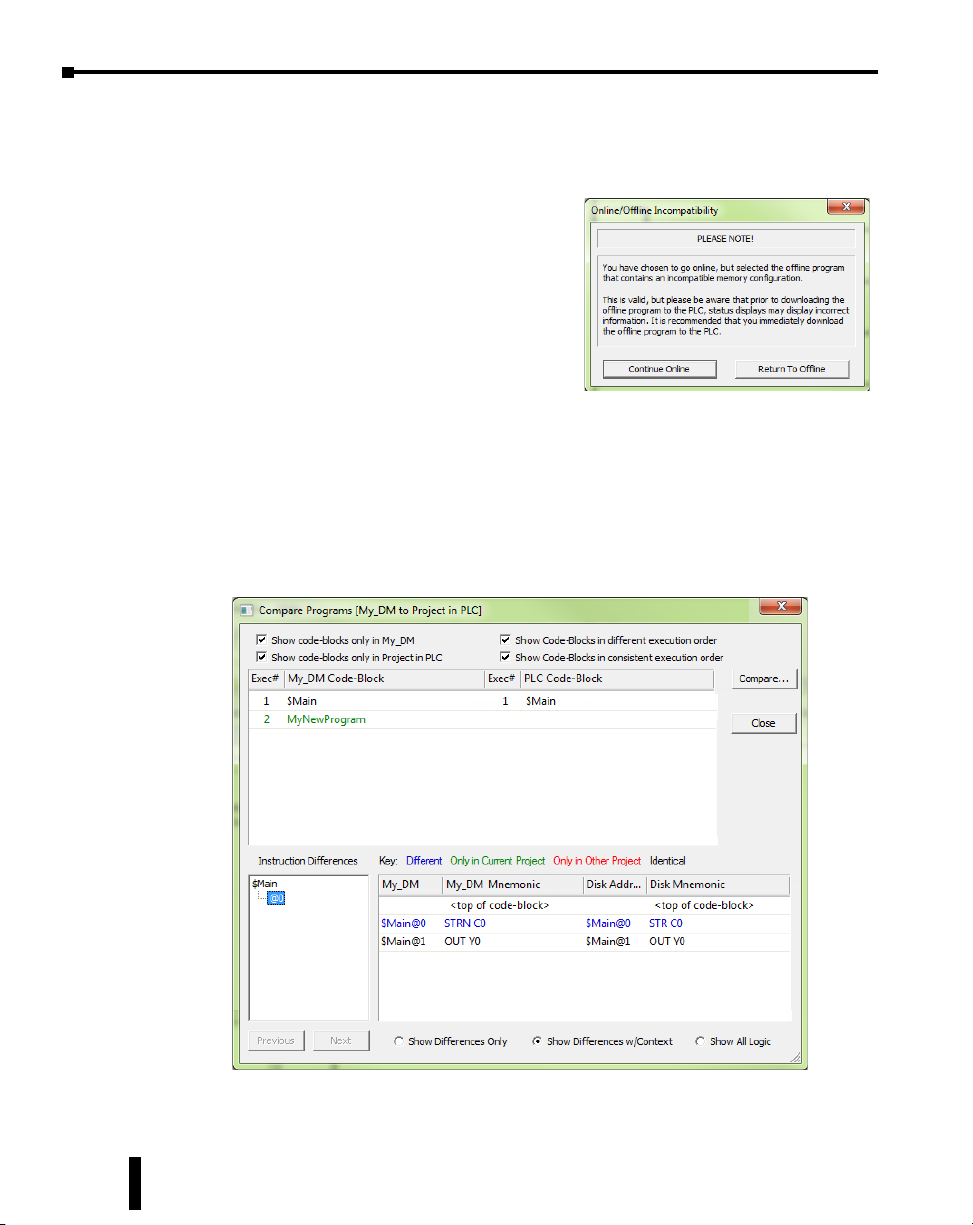

Only with the New Online option does the Do-more PLC assume that you are creating a new

project from scratch. With any other method, such as PLC > Connect, the software will compare

the project in the controller with the offline version you have open. If there are any differences,

this warning window will appear detailing the options available for continuing:

1. Go Online and view the DISK project - This option

will go online with the PLC but display the project

from disk. Status displays may show incorrect

information. If the memory configuration in the diskbased project contains elements that are incompatible

with the memory configuration currently in the

Do-more PLC the message box seen here will be

displayed.

2. Go Online and view the PLC project – The project from the PLC will be opened by Do-more!

Designer.

3. Cancel, and return to Offline – This option will cancel the connection attempt and return to the

offline project.

4. Compare Programs... – If you are unsure as to why the two projects are different, then this option

will do a comparison of the projects and detail the differences found. An example comparison is

seen below.

In this example,

the PLC

project titled

My_ DM was

with a project

stored on the

PC. The report

window shown

above illustrates

the differences

found between the

two.

compared

1–16

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 31

Chapter 1: Getting Started

According to the report, the PLC project was different in two areas. First, a new code-block was found

only in the PLC project. This new code-block is titled MyNewProgram and is highlighted in green.

The green color represents items that exist only in the Current Project (project in PLC) and not in the

Other (project in PC). Also, the comparison noted that a normally open contact (STR) was changed to

a normally closed contact (STRN) at $Main@0. This item is highlighted in blue which represents items

that are different between the PLC Project and the project in the PC.

Other colors used in the comparison are red, which notes items that exist only in the project on the

PC and not in the PLC and black which highlights items that are identical in both projects. There are

also numerous checkbox and radio button options available to help you analyze the differences between

projects.

Once you have connected to the CPU either by using the New Online option or using PLC

> Connect for offline projects, you may encounter the initialization windows shown below.

The Set PLC Clock option allows you to

set the internal, real-time clock of the PLC.

The Set PLC Clock window has

options for Timezones and Daylight

Savings Adjustments.

The Setup System Configuration

option allows you to configure the

parameters of the Do-more PLC. I/O

module configuration, CPU ports,

and I/O mapping profiles are a few

of the parameters available in the

System Configuration window. Refer

to the following section for Hardware

Configuration options.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

1–17

Page 32

Chapter 1: Getting Started

Once all parameters have been configured, the following programming window will open with

the online toolbar active.

1–18

Notice the status bar indications which show PLC type, memory usage, communication

status, PLC errors, PLC mode, etc. Hovering your mouse over the status bar will highlight

the items that are selectable. If you select one of these items, a new window will open with

real-time data and options that are available for that selection.

As an example, the System Information window seen here appears after selecting the Memory

Usage indication from the status bar.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 33

Step 6: Verify Hardware Configuration

Next, you will need to verify the hardware configuration for accuracy. The Do-more PLC

has an auto discover feature that will automatically detect the I/O modules installed in the

base. You can see the results of this search by selecting PLC > System Configuration, double

clicking the CPU link under the Configuration tab in the Project Browser, or by clicking the XY

Configure icon in the Project Toolbar.

Chapter 1: Getting Started

O n

the

left

side

o f

the

System Configuration window is an index of topics titled

Configuration Entries. Click the I/O Configuration tab and you should see an overview of

the modules that the software located, similar to the following.

From here you can verify that the software has detected all of the I/O modules that are installed.

At this point, you should also verify the base size. The Do-more PLC cannot automatically

detect the base size and if it needs to be corrected, select the DL205 Base tab in the index and

choose the appropriate size from the drop down list on that page.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

1–19

Page 34

Chapter 1: Getting Started

The Do-more PLC allows the I/O to be manually configured as well. In order to do so, you

must first set the I/O Configuration Mode to manual. Select the DL205 Local I/O Master tab

found under the I/O Configuration tab in the Configuration Entries index.

NOTE: If the manually configured I/O modules do not match the installed I/O modules, the PLC will not go

into Run Mode.

After you have set the configuration mode to Manual, select the DL205 Base tab in the

Configuration Entries index. This will take you to the following set up window.

The 205 Local I/O Master

Configuration window shown

here will appear. From here

select Manual to configure the

I/O modules that are installed

in the system yourself. It is

important to remember that

the PLC will compare what you

configure with what is installed

and they must match for the

PLC to work properly.

1–20

Notice that from this window, you can perform a Manual Base Scan. When initiated, this scan

will poll the available modules in the base connected to the PC and display the I/O found. The

results can then be altered as you choose. This window also contains the Base Size selection

which is used to select the base size that the system is using.

To manually enter your I/O modules into the configuration, right click on the slot the module

will reside in, select Add Module and then choose the module from the drop down list.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 35

Chapter 1: Getting Started

Once you have selected the module, it will appear in the slot that was chosen.

If an I/O module is manually configured but is not available for install or if at any time it has

been removed for maintenance, the I/O configuration will allow you to place that module in

an Optional state. This will allow the PLC to function properly without any hardware

mismatch errors. As previously mentioned, the Do-more PLC will not enter Run mode if the

configuration does not match the actual modules installed. With the Optional state, these errors

can be avoided.

To make a module Optional, right click on the module and select Optional from the drop down

list. The module will be labeled with the word “Optional” and the PLC will ignore it when

performing the configuration comparison.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

1–21

Page 36

Chapter 1: Getting Started

After the hardware configuration has been verified select the I/O Mappings tab in the

Configuration Entries index. This option will display the assigned addresses for the configured

modules as seen below.

1–22

These X, Y, WX and WY addresses are automatically assigned by Do-more Designer. You

have the option to manually configure these addresses by selecting Manual in the Mapping

Mode section at the bottom of the window.

The Manual Mode Instructions section, also found at the bottom of the window, details the

various color indications associated with this mode.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 37

Step 7: Create a Ladder Logic Program

To create a ladder logic program, you must first place the software in the Edit Mode. Click

the Edit Mode button found in the Project Toolbar or Ladder Palette Bar or use the shortcut

Ctrl+E.

When in Edit Mode, all of the Ladder Palette Bar’s options will become active and the cursor

in Ladder View will fill in blue. Now, you are ready to begin entering the example ladder logic

below.

Chapter 1: Getting Started

Rung #1

Place the box cursor in the NOP position on Rung #1.

If the Instruction Palette is not open, then

click Instructions from the Ladder Palette

Bar and select the TMR (Timer) or type

a “T” and select TMR from the drop down menu, then

press Enter. Once TMR is selected, a Timer dialog box

appears.

1. Set the Timer Struct to T1.

2. Enter 03 into the Preset

Constant Value for the

seconds (s) preset.

3. Click the checkmark in the

upper left corner to accept.

After clicking the checkmark,

Rung #1 should show the T1

timer (TMR) instruction with

a preset of 3.000 seconds. A user variable can be assigned

to the preset value if needed.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

1–23

Page 38

Chapter 1: Getting Started

Since a Timer is a structure it has predefined elements associated with it. Elements such as

.Acc (accumulated time), .Done (the completion bit) and .Timing (the timer is enabled and

timing). Therefore, if “T1.” is entered into any contact name the Auto-Complete feature of

Do-more Designer will display all applicable bit (boolean) selections available for that structure.

Selecting the T1.Done option as seen below, will assign this element to the contact and the

contact name will be T1.Done.

This feature works for all structures including: timers, counters, PID loops and strings. Many

system data types such as, $Main and $FirstScan, as well as user-created devices like ECOM,

CTRIO, or SERIO modules can also use this feature. See the Do-more Designer Help file for

more information on structures.

Now place the box cursor in the leftmost

column of Rung #1. Type in a meaningful

nickname, such as “T1_Start”, and press

Enter or select the Normally Open Contact

(F2) from the Ladder Palette Bar, enter

“T1_Start” for the name and click the

checkmark in the upper left corner. Either

method will open the Create Nickname

dialog seen here. Select the third option to

assign the nickname to a specified element,

type the desired memory bit for this

contact (C1) and select OK.

1–24

Rung #1 should now appear as follows:

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 39

Chapter 1: Getting Started

With the cursor in the position to the right of

contact T1_Start, you are going to begin

drawing a branch circuit. Under the Edit

drop down menu, select Wire, then select

Down. Notice the shortcuts that are available

for wire drawing. The wire that should now

appear in your ladder could have also been

drawn using the shortcut Ctrl+Down Arrow.

NOTE: There are also Delete Wire options

in the Edit drop down menu that are used

to erase any wires not needed.

Now place the cursor in the space to the left of the new line and select another normally open

contact.

Type in the nickname “T1_Manual”

and assign bit C2. Select OK to accept

and Rung #1 should now resemble the

rung seen on the following page.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

1–25

Page 40

Chapter 1: Getting Started

Rung #2

Place a normally open contact in the first position of Rung #2. This contact will be tied to the

Done bit of timer T1. Therefore, the name for this contact should be entered as “T1.Done”.

There should be no Create Nickname dialog as seen with the earlier normally open contacts.

1–26

Lastly, you will need to add an Out coil to the end of Rung #2. Place the cursor at the end of

the rung and either select Out from the Ladder Palette Bar or just type “OUT” and select the

Out instruction from the drop down menu. Next, choose which bit will be tied to this coil.

Tie this coil to the physical output Y1 by typing “Y1” and click the checkmark.

The ladder program should now look like the following. When either the T1_Start or T1_

Manual contact is energized, the timer will begin timing. When it times out, contact T1_Done

will energize and the output coil Y1 will turn on. Note that an END instruction is not required.

Do-more H2 Series PLC Hardware User Manual, 1st Edition, Rev. I - H2-DM-M

Page 41

Chapter 1: Getting Started

The yellow bar in the margin signifies logic that has not been accepted. So once you have

verified your logic, click the Accept button in the Project Toolbar or the Ladder Palette Bar to