Page 1

DURApulse GS20 AC Drive Quick-Start Guide

R/L1

S/L2

T/L3*

R/L1

S/L2

T/L3*

U/T1

V/T2

W/T3

3

~

R1C

R1

R1C and R1 are the relay output terminals.

Input: one-phase / three-phase* power

DC reactor (optional)

Brake resistor (optional)

Jumper

Motor

Circuit Breaker or Fuse

MC

ON

MC

OFF

It is recommended that

you install a protective

circuit at R1C – R1 to

protect the drive from

damage.

When a fault occurs, the MC contactor

switches to OFF to shut off the drive input

power and protect the power system.

MC

DO

DCM

Multi-function output

frequency terminals

30 VDC / 30 mA 33 kHz

DO2

DOC

DO1

Multi-function output

terminal 48 VDC / 50 mA

Multi-function output

terminal 48 VDC / 50 mA

Multi-function output

common terminal (photocoupler)

USB Port

Communication card/

DC 24V external power supply card

Option Slot

250 VAC / 3 A (N.O.)

250 VAC / 3 A (N.C.)

R1O

R1C

R1

250 VAC / 1.2 A (N.O)

Multi-function relay output terminals

Estimate at COS (0.4)

Modbus RS-485

8

1

S

G

+

S

G

N

D

Control terminals

Shielded leads & Cable

Main circuit terminals

NOT

E

DI1/FWD

DI2/REV

DI3

DI4

DI5

DI6

DI7

DCM

+

24V

+

24V

Default

FWD/STOP

REV/STOP

Multi-step speed 1

Multi-step speed 2

Multi-step speed 3

Multi-step speed 4

N/A

Digital Signal Common

*DI7 can input 33 kHz pulses.

*Do NOT apply the mains voltage directly to

external terminals.

Default:

NPN (SINK) Mode (internal power)

Please refer to the wiring of NPN mode and PNP mode.

STO1

+24 V

STO2

ESTOP

+24 VDC

Safety PLC

NOT

E

SCM

*

1

It is a short circuiting jumper installed between

+24 V, S1 and S2 short when GS20 leaves the factory.

Remove this short circuiting jumper before using the

safety function while wiring.

*

1:

*

2:

The +24 V is for STO only, and cannot be used for any

other purpose.

2

*

AI1

ACM

+

10V

3

2

1

0 – 10 VDC

AI2

0 – 10 VDC

+

10 VDC / 20 mA

-10 VDC – 10 VDC

0 – 20 mA / 4

–

20 mA

Analog Signal common

Analog Multi-function output

terminal 0 – 10 VDC /

0 – 20 mA / 4 – 20 mA

Analog Signal common

+

5KΩ

P

N

P

NPN

P

N

P

N

P

N

0

-

1

0

V

AFM

–

0

-

1

0

V

AO1

0

–

20 mA

0

–

10 V

0

-

2

0

m

A

4

-

2

0

m

A

ACI

0 – 20 mA

4 – 20 mA

0

-

2

0

m

A

4

-

2

0

m

A

AI2

0

–

20 mA

4

–

20 mA

0

–

AO1

GS20 AC Drives Installation Instructions

Sensorless Vector Control Variable Frequency Micro-drive

• Please read this instruction sheet thoroughly before installation and retain for later

reference.

• To ensure the safety of operators and equipment, only qualified personnel familiar

with AC drives should install, wire, program, and operate the GS20 drive. Always read this instruction sheet

thoroughly before using the GS20 drive, especially the WARNING, DANGER and CAUTION notes. If you have any

questions, please contact AutomationDirect.

PLEASE READ PRIOR TO INSTALLATION FOR SAFETY

• The ground terminal of the GS20 drive must be grounded correctly. The grounding method

must comply with the laws of the country where the GS20 drive is to be installed.

• After power has been turned off, the capacitors in the GS20 drive may retain a charge for

several minutes. To prevent personal injury, visually verify that the “CHARGE” LED has

turned off. Then measure to confirm that the DC bus voltage level between terminals (+1)

and (-) is less than 25VDC before touching any terminals. (Capacitor discharge will take at

least 5 minutes for most GS20 models)

• The CMOS ICs on the internal circuit boards of the GS20 drive are sensitive to static

electricity. Please DO NOT touch the circuit boards with your bare hands before taking

DANGER

WARNING

CAUTION

anti-static measures. Never disassemble the internal components or circuits.

• If wiring changes must be made, turn off power to the GS20 drive before making those

changes. Allow the internal DC bus capacitors in the GS20 drive sufficient time to discharge

prior to making changes in power or control wiring. Failure to do so may result in short

circuit and fire. To ensure personal safety, allow DC bus voltage to discharge to a safe level

before making wiring changes to the GS20 drive.

• DO NOT install the GS20 drive in locations subject to high temperature, direct sunlight, or

flammable materials.

• Never apply power to the output terminals U/T1, V/T2, W/T3 of the GS20 drive. If a fault

occurs during operation of the GS20 drive, refer to the fault code descriptions and corrective

actions to reset the fault before attempting to operate the GS20 drive.

• DO NOT use Hi-pot test for internal components. The semi-conductors in the GS20 drive are

easily damaged by high voltage.

• Long motor lead lengths may result in reflective wave due to impedance mismatch between

the motor cable and the motor. Reflective wave may damage the insulation of the motor.

To avoid the possibility of reflective wave damage, use an inverter-rated motor with an

insulation rating of 1600 volts. A load reactor installed between the GS20 drive and motor

will help to mitigate reflective wave.

• Nominal supply voltage to the GS20 drive should be less than or equal to 120/240/480 volts

AC depending on GS20 model.

• Nominal supply current capacity should be less than or equal to 100kA for all GS20 models.

• The GS20 drive must be installed in a clean, well-ventilated and dry location, free from

corrosive gases or liquids.

• The GS20 drive must be stored within an ambient temperature range from –40°C to +85°C,

and relative humidity range of 0% to 90% without condensation.

• Do not apply AC power to the GS20 drive with the front cover removed. Following a fault of

the GS20 drive, wait 5 seconds before pressing the RESET key.

• To improve power factor, install a line reactor ahead of the GS20 drive. Do not install power

correction capacitors in the main AC supply circuit to the GS20 drive to prevent drive faults

due to over-current.

Wiring Diagrams

RFI Jumper Removal

If the power distribution system supplying the GS20 AC drive is a floating (IT) or an

asymmetric ground system (including most 120V inputs), the RFI jumper must be

removed.

Removing the RFI jumper uncouples the internal RFI capacitor (filter capacitor)

between the GS20 drive frame and circuitry to avoid damaging those circuits and

(according to IEC 61800-3) to reduce ground leakage current.

GS20 Frame A through F

Note: Remove Clip

Main Wiring (Power Circuit)

For main (power) wiring terminal specifications, Please refer to “Specifications for Wiring Terminals –

Main-Circuit Terminals” (page 2).

GS20 all Frames

*(Note that 1-phase drives do not have a T/L3 terminal)

GS20 Control Terminal Wiring

FWD (DI1)

REV (DI2)

DI7

FWD (DI1)

REV (DI2)

DI7

DCM

Minimum Wiring

• AC input power to R/L1, S/L2, T/L3 (for single-phase input, use two of the terminals) (For applicability of 1-phase

input power, please refer to Chapter 1 of the DURApulse GS20 AC Drives User Manual at AutomationDirect.com.)

• Ground from the power supply

• Drive power to the motor (U, V, W on T1, T2, T3) (For use with 3-phase motors only!)

• Ground to the motor

• STO1 and STO2 (both must be wired through appropriate N.C. safety-rated contacts to DCM or the

factory-installed jumpers must be left in place)

With this minimal wiring, the drive can be operated via the keypad to test the motor and drive installation.

See the “Parameter Set Up” (page 4) section to configure the drive for keypad operation.

Recommended Safety Wiring

We strongly recommend that customers use the STO safety feature.

The Safe Torque Off (STO) function turns off the power supplied to the motor through the hardware, so

that the motor cannot produce torque. This method of removing power from the motor is considered an

emergency stop, also known as “coast to stop.”

To use this feature, disconnect the appropriate factory-installed jumpers and wire a safety relay, safety PLC, or

E-Stop pushbutton as shown. See Main Wiring (Power Circuit) (page 1) for wiring the GS20.

GS20_QSP 1st Edition, Rev B 01/29/2021

DCM

FWD (DI1)

REV (DI2)

DI7

DCM

FWD (DI1)

REV (DI2)

DI7

DCM

DURApulse GS20 AC Drive Quick-Start Guide – 1st Ed, Rev B 01/29/2021

Page 1

Page 2

DURApulse GS20 AC Drive Quick-Start Guide

P02.00 External Terminal Control Circuits

Setting value: 1

Two-wire operation control

FWD / STOP

REV / STOP

Setting value: 2

Two-wire operation control

RUN / STOP

FWD / REV

FWD/DI1

REV/DI2

DCM

FWD/DI1

REV/DI2

DCM

FWD/DI1

Setting value: 3

Three-wire operation control

DI3

REV/DI2

DCM

Specifications for Wiring Terminals – Control Circuit

GS20-xxxx All Models; All Frame Sizes

Terminal Wire Gauge Torque

Control

Relay

24–18 AWG

[0.21–0.82 mm2]

24–16 AWG

[0.21–1.31 mm2]

GS20(X)

GS20(X)

GS20(X)

n/a (spring terminals)

5kg·cm

[4.3 lb·in]

Recommended models or dimensions for ferrule terminals

Wire Gauge Manufacturer Model Name A (MAX) B (MAX) D (MAX) W (MAX)

0.25 mm2

[24 AWG]

0.34 mm2

[22 AWG]

0.5 mm2

[20 AWG]

PHOENIX

CONTACT

PHOENIX

CONTACT

PHOENIX

CONTACT

Z+F V30AE000006 14 8 2.6 1.15

AI 0,25- 8 YE 12.5 8 2.6 1.1

AI 0,34- 8 TQ 12.5 8 3.3 1.3

AI 0,5 - 8 WH 14 8 3.5 1.4

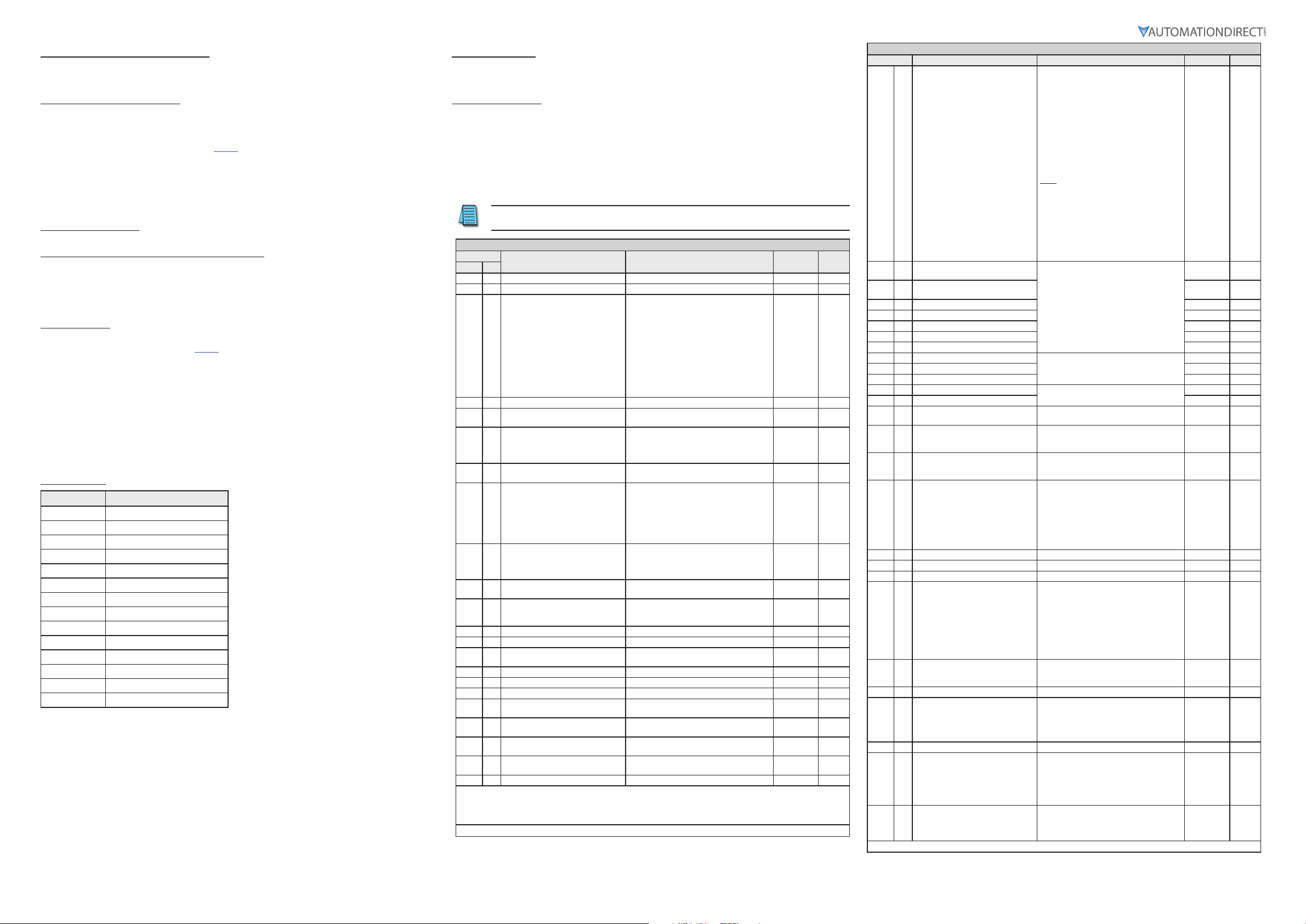

Specifications for Wiring Terminals – Main-Circuit Terminals

Notes:

• If you install at Ta 45°C above environment, please use copper wire with a 600V voltage rating and

temperature resistance of 90°C or higher.

• For UL compliant installation, you must:

1) Use 75°C temperature resistant copper wire or better. Do not reduce wire gauge when using higher

temperature wire.

2) Use the specific ring lug part listed in the table below.

3) Use crimp tool KST2000D-1322 or IZUMI 5N18 for 22–8 AWG wire, or

IZUMI 9H-60 for 6–4 AWG wire.

Specifications for Wiring Terminals – Main-Circuit Terminals (continued)

Drive Models

GS21-11P0

GS21-22P0

GS21-23P0

GS23-23P0

GS23-25P0

Frame C

GS23-43P0

GS23-45P0

GS23-53P0

GS23-55P0

GS23-27P5

GS23-47P5

GS23-4010

Frame D

GS23-57P5

GS23-5010

Max Wire

Gauge

8AWG

[8.4 mm2]

8AWG

[8.4 mm2]

Min Wire

Gauge

10AWG

[5.3 mm2]

8AWG

[8.4 mm2]

12AWG

[3,3 mm2]

10AWG

[5.3 mm2]

14AWG

[2.1 mm2]

12AWG

[3,3 mm2]

8AWG

[8.4 mm2]

10AWG

[5.3 mm2]

Ring

Lug P/N

RNBS

5-4

RNBS

8-4

RNBS

5-4

RNBS

2-4

RNBS

5-4

RNBS 8-4

RNBS 5-4

Screw

M4

M4

Torque

(±10%)

20 kg-cm

[17,4 lb-in.]

[1.96 N·m]

20 kg-cm

[17,4 lb-in.]

[1.96 N·m]

Ring Lug Dimensions (mm)

Dimension Value Min/Max

A 17.8 Max

B 5.0 Max

C 6.1 Min

D 7.2 Max

d2 4.3 Min

E 13.0 Min

F 5.5 Min

W 8.0 Max

t 1.2 Max

Dimension Value Min/Max

A 17.8 Max

B 5.0 Max

C 6.1 Min

D 7.2 Max

d2 4.3 Min

E 13.0 Min

F 5.5 Min

W 8.0 Max

t 1.2 Max

PNP

AI2

DI6

4-20mA

0-20mA

SG+

AO1

DI7

SG-

NPN

SGND

DO1

+24V

DO2

+24V

DOC

USB

DATAMATRIX

24P

32637012

SLOT 1

RELAY

R1

R1C

R1O

RS485

Port

DO

DCM

DCM

4-20mA

0-20mA

AI2

+24V

Safety function

+10V

REV

FWD

0-10V

STO1

DI3

STO2

ACM

DI4

0-10V

AO1

SCM

AI1

DI5

Wiring Precautions

1) The factory default condition is +24 V/ S1/ S2 shorted by jumper, as shown in the block 1 of the figure above.

Refer to the wiring chapter of the User Manual for more details.

2) The +24 V power supply for safety function is only for STO use and cannot be used for other purposes.

3) The RELAY terminal uses the PCB terminal block:

• Tighten the wiring with a 3.5 mm width and 0.6 mm thickness slotted screwdriver.

• The ideal length of stripped wire at the connection side is 6–7 mm.

• When wiring bare wires, make sure they are perfectly arranged to go through the wiring holes.

4) The control circuit terminal uses a spring clamp terminal block:

• Tighten the wiring with a 2.5 mm width and 0.4 mm thickness slotted screwdriver.

• The ideal length of stripped wire at the connection side is 9 mm.

Drive Models

GS21-10P2

GS21-20P2

GS23-20P2

GS23-20P5

GS21-10P5

GS21-20P5

Frame A

GS23-40P5

GS23-21P0

GS23-41P0

GS23-51P0

GS23-22P0

GS23-42P0

Frame B

GS23-52P0

GS21-21P0

Max Wire

Gauge

14AWG

[2.1 mm2]

12AWG

[3,3 mm2]

Min Wire

Gauge

16AWG

[1.3 mm2]

18AWG

[0.82 mm2]

14AWG

[2.1 mm2]

18AWG

[0.82 mm2]

16AWG

[1.3 mm2]

18AWG

[0.82 mm2]

14AWG

[2.1 mm2]

Ring

Lug P/N

RNBS

2-3.7

RNBS

1-3.7

RNBS

2-3.7

RNBS

1-3.7

RNBS

2-3.7

RNBS

1-3.7

RNBS

2-4

Screw

M3.5

M4

Torque

(±10%)

9 kg-cm

[7,8 lb-in.]

[0.88 N·m]

15 kg-cm

[13,0 lb-in.]

[1.47 N·m]

Ring Lug Dimensions (mm)

Dimension Value Min/Max

A 9.8 Max

B 3.2 Max

C 4.8 Min

D 4.1 Max

d2 3.7 Min

E 13.0 Min

F 4.2 Min

W 6.6 Max

t 0.8 Max

Dimension Value Min/Max

A 12.1 Max

B 3.6 Max

C 6.1 Min

D 5.6 Max

d2 4.3 Min

E 13.0 Min

F 4.5 Min

W 7.2 Max

t 1 Max

GS23-2010

GS23-2015*

Frame E

GS23-4015

6AWG

[13.3 mm2]

4AWG

[21.2 mm2]

6AWG

[13.3 mm2]

6AWG

[13.3 mm2]

4AWG

[21.2 mm2]

8AWG

[8.4 mm2]

RNBS

14-5

RNBS

22-5

RNBS 8-5

M5

25 kg-cm

[21,7 lb-in.]

[2.45 N·m]

GS23-4020

GS23-2020

GS23-4025

Frame F

2AWG

[33.6 mm2]

GS23-4030

* The GS23-2015 drive must be wired with a ring terminal of the specified dimensions.

2AWG

[33.6 mm2]

6AWG

[13.3 mm2]

4AWG

[21.2 mm2]

RNBS

38-6

RNBS

14-6

RNBS

22-6

M6

40 kg-cm

[34,7 lb-in.]

[3.92 N·m]

Dimension Value Min/Max

A 27.1 Max

B 6.1 Max

C 10.5 Min

D 11.5 Max

d2 5.3 Min

E 13.0 Min

F 6.5 Min

W 12.2 Max

t 1.7 Max

Dimension Value Min/Max

A 35.0 Max

B 9.0 Max

C 13.3 Min

D 14.0 Max

d2 6.2 Min

E 13.0 Min

F 19.5 Min

W 18.0 Max

t 1.8 Max

GS20_QSP 1st Edition, Rev B 01/29/2021

DURApulse GS20 AC Drive Quick-Start Guide – 1st Ed, Rev B 01/29/2021

Page 2

Page 3

DURApulse GS20 AC Drive Quick-Start Guide

R

F

P

P

P

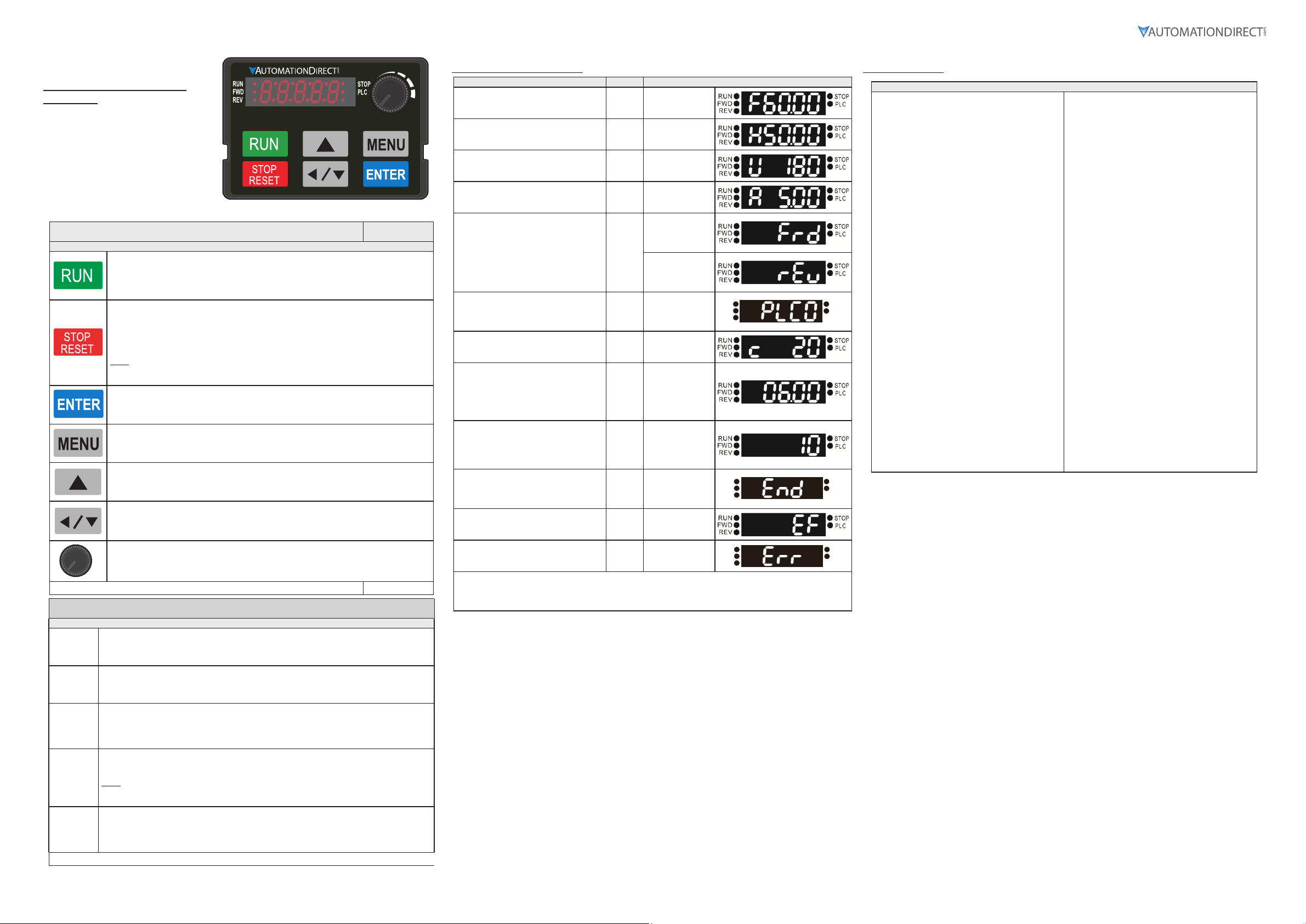

Digital Keypad Functions and

Indications

Description of the functions of the keys and

indicators of the GS20 AC Drive Keypad.

NOTE: Drive default is AUTO mode. There is

no indication from the keypad of the mode.

Local mode can be set with I/O configuration

or GS4-KPD only.

Descriptions of Keypad Functions (continued)

Descriptions of Keypad Functions

RUN Key

• Valid only when the source of operation command is from the keypad.

• RUN can be pressed even when drive is in process of stopping.

• When in “LOCAL” mode, RUN is valid only when the source of operation command is from

the keypad (drive default is Auto mode, Local mode can be set with I/O or GS4-KPD only).

STOP/RESET Key

This key has the highest processing priority in any situation.

• When the drive receives a STOP command, whether or not the drive is in operation or stop

status, the drive will execute a "STOP" command.

• The RESET key can be used to reset the drive after a fault occurs. For those faults that can't

be reset by the RESET key, see the fault records after pressing MENU key for details.

N OTE: The ability to STOP the drive from the keypad is effective ONLY if the drive is configured

to RUN and/or STOP from the keypad. Keypad STOP can be disabled by parameter 00.32,

Digital Keypad STOP Function.

ENTER Key

Press ENTER to go to the next menu level or accept parameter entry. If it is the last level, then

press ENTER to execute the command.

MENU Key

Press MENU to return to the Main Menu or cycle through the available menu options.

Direction: Up

Press to make the value set on the current menu/parameter higher.

Direction: Left/Down

• Press to make the value set on the current menu/parameter lower.

• In the menu/text selection mode, the arrows are used for item selection. Long press the

MENU key to use the left direction function.

Frequency Setting Dial (Potentiometer)

The dial can be set as the main frequency input. Set Parameter 00-20 or 00-30 to equal

‘7-Digital Keypad Dial’.

Continued on next page.

Descriptions of LED Functions (continued)

Descriptions of LED Functions

Steady ON: Drive is running.

RUN

Blinking: Drive is stopping or in base block.

Steady OFF: Drive is not running.

Keypad Navigation Example

Instruction Press Key Display Will Show

First menu to display after power up. n/a

Press MENU once from startup. MENU

Press MENU twice from startup. MENU

Press MENU three times from startup. MENU

Press MENU four times from startup.

Displays Frd if the drive is currently

configured for Forward operation. Press

the UP or DOWN key to change to Reverse.

Press ENTER to confirm the change.

Press MENU five times from startup.

Displays the current PLC setting. Press the

UP or DOWN arrow keys to change the

PLC setting, then press ENTER to confirm.

Enable the counter by setting parameter

00.04 to 1. See the user manual for full

instructions on using the counter.

After selecting the desired menu option,

press ENTER to bring up the parameter

number (Format XX.YY). Use the UP

and DOWN arrow keys to change the

parameter number as needed, then press

ENTER to adjust the parameter value.

From the parameter number screen, press

ENTER to bring up the current value of

the selected parameter. Use the UP and

DOWN arrows to adjust the value. Press

ENTER again to confirm the choice.

Once a desired parameter value has been

set using the UP and DOWN arrow keys,

press ENTER to save the choice and display

End message.

Displays when an external fault is detected. n/a

Displays when data is not accepted or the

value exceeded

Scroll sequentially through the rest of the parameters in the “Basic Configuration” Quick-Start group, and set those

parameters as needed for your application.

After changing all of the applicable parameters, press “MENU” key to return to the Menu screen, and then press

“ESC” key to return to the home screen.

DOWN

DOWN

ENTER,

DOWN,

ENTER,

DOWN

Displays the

present frequency

setting of the drive

Displays the actual

output frequency

of the drive

Displays user

defined output

Displays output

current

Displays the

Forward command

if configured for

MENU,

Forward operation.

UP/

Displays the

ENTER

Reverse command

if configured for

Reverse operation.

MENU,

Displays the

UP/

current PLC

setting.

ENTER

Displays the

MENU

counter value

UP/

Displays the

parameter number

ENTER

Displays the value

UP/

of the selected

parameter

End message.

Displays when data

ENTER

has been accepted

and stored

External fault

message

n/a Error message.

UN

WD

R EV

R UN

FWD

R EV

R UN

FWD

R EV

GS20 Fault Codes

STO

PL C

STO

PL C

STO

PL C

0: No Error

1: Overcurrent during Accel (ocA)

2: Overcurrent during Decel (ocd)

3: Overcurrent during constant speed (ocn)

4: Ground Fault (GFF)

6: Overcurrent during Stop (ocS)

7: Overvoltage during Accel (ovA)

8: Overvoltage during Decel (ovd)

9: Overvoltage during constant speed (ovn)

10: Overvoltage during Stop (ovS)

11: Low voltage during Accel (LvA)

12: Low voltage during Decel (Lvd)

13: Low voltage during constant speed (Lvn)

14: Low voltage during Stop (LvS)

15: Input phase loss (OrP)

16: IGBT Overheat 1 (oH1)

18: Thermister 1 open (tH1o)

21: Drive over-load (oL)

22: Electronics thermal relay protection 1 (EoL1)

23: Electronics thermal relay protection 2 (EoL2)

24: Motor Overheat-PTC (oH3)

26: Over Torque 1 (ot1)

27: Over Torque 2 (ot2)

28: Under current (uc)

31: Memory read-out error (cF2)

33: U phase current sensor detection error (cd1)

34: V phase current sensor detection error (cd2)

35: W phase current sensor detection error (cd3)

36: Clamp current detection error (Hd0)

37: Over-current detection error (Hd1)

40: Auto tuning error (AuE)

41: PID Feedback loss (AFE)

42: PG feedback error (PGF1)

43: PG feedback loss (PGF2)

44: PRG feedback stall (PGF3)

45: PG slip error (PGF4)

48: Analog current input loss (ACE)

49: External Fault input (EF)

50: Emergency Stop (EF1)

51: External Base Block (bb)

52: Password Error (Pcod)

Fault Codes

54: Communication Error (CE1)

55: Communication Error (CE2)

56: Communication Error (CE3)

57: Communication Error (CE4)

58: PC Communication Time Out (CE10)

61: Y-Delta connection Error (ydc)

62: Decel Energy Backup Error (dEb)

63: Slip Error (oSL)

72: Channel 1 (S1~DCM) safety loop error (STL1)

76: Safety Torque Off (STO)

77: Channel 2 (S2~DCM) safety loop error (STL2)

78: Internal loop error (STL3)

79: U Phase over current before run (Aoc)

80: V Phase over current before run (boc)

81: W Phase over current before run (coc)

82: U Phase output phase loss (oPL1)

83: V Phase output phase loss (oPL2)

84: W Phase output phase loss (oPL3)

87: Drive over load in low frequency (oL3)

89: Initial rotor position detection error (roPd)

121: Internal communication error (CP20)

123: Internal communication error (CP22)

124: Internal communication error (CP30)

126: Internal communication error (CP32)

127: Software version error (CP33)

128: Over-torque 3 (ot3)

129: Over-torque 4 (ot4)

134: Electronics thermal relay 3 protection (EoL3)

135: Electronics thermal relay 4 protection (EoL4)

140: GFF detected when power on (Hd6)

141: GFF occurs before run (b4GFF)

142: Auto tuning error 1 (DC test stage) (AUE1)

143: Auto tuning error 2 (High frequency test stage)

(AUE2)

144: Auto tuning error 3 (Rotary test stage) (AUE3)

Steady ON: Drive is operating in Forward mode.

FWD

REV

STOP

PLC

GS20_QSP 1st Edition, Rev B 01/29/2021

Blinking: Drive is changing direction.

Steady OFF: Drive is operating in Reverse mode.

Steady ON: Drive is operating in Reverse mode.

Blinking: Drive is changing direction.

Steady OFF: Drive is operating in Forward mode.

Steady ON: Drive is stopped or in the process of stopping.

Blinking: Drive is in standby (run but does not output).

Steady OFF: Drive is not currently executing an operational (STOP) command.

N OTE: The ability to STOP the drive from the keypad is effective ONLY if the drive is configured to

RUN and/or STOP from the keypad. Keypad STOP can be disabled by parameter 00.32, Digital

Keypad STOP Function.

Steady ON: PLC STOP (PLC 2) initiated.

Blinking: PLC Run (PLC1) inititated.

Steady OFF: No PLC functions implemented (PLC 0).

Continued on next page.

DURApulse GS20 AC Drive Quick-Start Guide – 1st Ed, Rev B 01/29/2021

Page 3

Page 4

DURApulse GS20 AC Drive Quick-Start Guide

Introduction – How To Get Started

Automationdirect.com would like to thank you for your purchase of the Durapulse GS20 AC drive. The GS20

drive is a state-of-the-art, full-featured AC drive. The Quick-Start Guide below will introduce you to many of

the GS20 drive features and help you configure the GS20 drive in a minimum amount of time.

STO (Safe Torque Off) / Emergency Stop

The GS20 drive offers Safe Torque Off (STO) functionality, instead of a standard Emergency Stop circuit. STO

provides the ability to immediately turn off the output of the GS20 drive in the event of an emergency, without

the need for an emergency stop contactor between the drive and motor.

Please see the Control-Circuit Wiring diagrams (page 1) for how to wire the STO circuit. From the factory,

the GS20 STO terminals are jumpered and the STO circuitry of the drive is bypassed. STO is recommended for

personnel safety.

After wiring the drive (but before applying power), the first thing you should do is press the E-stop button (or

otherwise break the safety circuit) and verify that the circuit between the STO1/STO2 terminals and the STO

+24V terminal is not connected. If these circuits are open, the STO feature will stop all power from going to the

motor and there will be no danger of unexpected movement when you power up the drive.

Powering Up the GS20 Drive

Apply AC line power to the GS20 drive, but don’t engage the safety circuit yet (keep the E-stop PB pushed in).

Starting, Stopping, and Controlling the Speed of the GS20 Drive

Out of the box GS20 drives are set to use the keypad buttons to RUN and STOP the drive and vary the drive

speed. The drive can also be configured to run from potentiometers, external pushbuttons, Ethernet

communication, etc.

Do not attempt to run the motor yet. Certain parameters (especially the motor protection parameters) must

be set first.

Configure the Drive

The tables below list those parameters typically used in most applications. You can navigate to any of these

parameters through the keypad. (Refer to page 3 for information and instructions for using the Digital

Keypad.)

All applications need to configure the parameters in the “Quick Configuration” table. At minimum, you MUST

configure these motor parameters before operating the drive:

• 01.02 Motor1 Max Output Voltage (this will typically be either 230V or 460V)

• 05.01 Motor1 Rated Amps (depends on the motor)

• 01.01 Motor1 Max Output Frequency (this will typically be 50Hz or 60Hz)

The main configuration parameters required to get your drive up and running are included in this guide.

For more advanced configuration options, please see the User Manual. Your application will dictate which

parameters need to be configured. It is NOT necessary to configure every parameter listed in the tables in the

User Manual, use only those you need.

Parameter Groups

Group Number Group Category

00 Drive Config

01 Basic Config

02 Digital I/O Config

03 Analog I/O Config

04 Multi-Step Speed Config

05 Motor Config

06 Protection Config

07 Special Parameters

08 PID Config

09 Communications Config

10 Speed Control Config

11 Advanced Config

13 Macro Config

14 Protection (2) Config

After configuring the minimum settings, you can now engage the safety circuit. The RUN and STOP/RESET

buttons should Start and Stop the drive. To adjust the output frequency, press the MENU button until the

frequency screen appears. Use the Up and Down arrow buttons to adjust the frequency, the press ENTER to

confirm. Press ENTER again to return to the main menu.

Parameter Set Up

DURApulse GS20 AC Drives offer parameter setup from the keypad for some of the most common drives

applications. Choose parameters from the table below, then set the applicable parameters for that

application as shown.

To Configure Parameters:

From the power up screen:

1) Press MENU until you see H 0.00 (this is the actual drive frequency) and press ENTER.

2) Use the UP/DWN arrows to select the parameter group you want and press ENTER.

3) Use the UP/DWN arrows to select the parameter number you want within that group and press ENTER.

4) Change the value of the parameter using the UP/DWN arrows and press ENTER.

5) Press MENU to exit back to the main menu.

6) Repeat as needed until all required parameters are configured.

Please refer to the user manual if you need more detailed information about the

parameters.

DURApulse GS20 Parameter Settings – Quick Configuration*

Parameter

Group #

* Assumes default V/Hz mode with no feedback. To change control modes see complete parameter listing in User manual.

** Reboot drive after resetting defaults.

Note: Drive default is Auto mode and cannot be changed from the keypad. For Local/Hand, use Discrete input configuration

settings (P02.00–P02.07) and P00.29–P00.31.

Description Range Default User

00 00 GS20 Model ID Read Only n/a

00 01 Displays AC drive rated current Displays value based on model n/a

00 02 Restore to default**

00 06 Firmware Version Read Only n/a

00 10 Control Mode

00 11 Speed Control Mode

00 16 Load Selection

00 20 Frequency Command Source (Auto)

00 21 Operation Command Source (Auto)

00 22 Stop Method

00 23 Motor Direction Control

01 00 Motor 1 Max Frequency 0.00-599.00 Hz 60

01 01 Motor 1 Base Frequency 0.00-599.00 Hz 60

01 02 Motor 1 Rated Voltage

01 09 Startup Frequency 0.00-599.0 Hz 0.5

01 10 Output Frequency Upper Limit 0.00-599.0 Hz 599.0

01 11 Output Frequency Lower Limit 0.00-5.99.0 Hz 0.00

01 12 Acceleration Time 1

01 13 Deceleration Time 1

01 20 Jog Acceleration Time

01 21 Jog Deceleration Time

01 22 Jog Frequency 0.00-599.0 Hz 0.5

0=No function

1=Parameter write protect

2=Reset to GS2 mode (1 of 2)

5=Reset kWH display to 0

6=Reset PLC

7=Reserved

8=Keypad doesn’t respond

9=Reset 50Hz defaults

10=Reset 60Hz defaults

11=Reset 50Hz defaults (keep user config)

12=Reset 60Hz defaults (keep user config)

20=Reset to GS2 mode (2 of 2)

0=Speed mode

2=Torque mode

0=VF (IM V/F control)

1=VFPG (IM V/F control + Encoder)

2=SVC (Parameter 05.33 set as IM or PM)

5=FOC (Field Oriented Control)

0=VT

1=CT

0=Digital keypad

1=Communication RS-485 input

2=External analog input (refer to parm 03.00)

3=External UP/DOWN terminal

4=Pulse input without direction command

(refer to parm 10.16 without direction)

7=Digital keypad dial

0=Digital keypad

1=External terminals

2=Communication RS-485 input

5=Communication card

0=Ramp to stop

1=Coast to stop

0=Enable forward/reverse

1=Disable reverse

2=Disable forward

110V/230V: 0.0~255.0

460V: 0.0~510.0V

P01.45=0: 0.00-600.00 sec

P01.45=1: 0.00-6000.00 sec

P01.45=0: 0.00-600.00 sec

P01.45=1: 0.00-6000.00 sec

P01.45=0: 0.00-600.00 sec

P01.45=1: 0.00-6000.00 sec

P01.45=0: 0.00-600.00 sec

P01.45=1: 0.00-6000.00 sec

0

0

0

1

0

0

0

0

220.0

440.0

10.00

10.00

10.00

10.00

10.00

10.00

10.00

10.00

(table continued next page)

DURApulse GS20 Parameter Settings – Quick Configuration (continued)

Parameter Description Settings Default User

02 00 2-wire / 3-wire Control

Multi-function Input Command 1

02 01

(FWD/DI1)

Multi-function Input Command 2

02 02

(REV/DI2)

02 03 Multi-function Input Command 3 (DI3) 1

02 04 Multi-function Input Command 4 (DI4) 2

02 05 Multi-function Input Command 5 (DI5) 3

02 06 Multi-function Input Command 6 (DI6) 4

02 07 Multi-function Input Command 7 (DI7) 0

02 13 Multi-function Output 1 (R1)

02 16 Multi-function Output 2 (DO1) 0

02 17 Multi-function Output 3 (DO2 0

03 00 Analog Input Selection (AI1)

03 01 Analog Input Selection (AI2) 0

03 20 Multi-function Output (AO1)

03 29 AI2 terminal input selection

00

04

to14Multi-step Speed Frequency 1–15 0.00-599.00 Hz 0.00

05 00 Motor Parameter Auto-tuning

05 01 Motor 1 Full Load Amps (FLA) 10-120% of drive rated current #.##

05 03 Motor 1 Rated RPM 0-65535 1710

05 04 Motor 1 Number of poles 2-20 4

Over-torque Detection Selection

06 06

(Motor 1)

06 07 Over-torque Detection Level (Motor 1)

06 08 Over-torque Detection Time (Motor 1) 0.1–60.0 seconds 0.1

Motor 1 Electronic Thermal Overload

06 13

Relay

06 14 Motor 1 Electronic Thermal Relay Time 30.0-600.0 60

06 55 Drive Derating Method

07 10 Restart after fault action

0=No function

1=2-wire mode 1, power on for operation

control (M1: FWD/STOP, M2: REV/STOP)

2=2-wire mode 2, power on for operation

control (M1: RUN/STOP, M2 REV/FWD)

3=3-wire, power on for operation control

(M1: RUN, M2: REV/FWD, M3: STOP)

4=2-wire mode 1, fast start up

(M1: FWD/STOP, M2: REV/STOP)

5=2-wire mode 2, fast start up

(M1: RUN/STOP, M2: REV/FWD)

6=3-wire, fast start up

(M1: RUN, M2: REV/FWD, M3: STOP)

Note:

In fast start up mode, the drive skips

detecting IGBT signal and will run

immediately. When using fast start up mode:

• Terminal output stays in ready status and

drive responds to commands immediately.

• The output terminal will have higher

voltage

• If the drive is short circuited an OC error

will display when running up

See “Multi-function Input Selections” on

page 5

See “Multi-function Output Selections” on

page 5

See “AI Multi-function Input Selections” on

page 5

See “AO1 Multi-function Output Selections”

on page 5

0=4-20 mA

1=0-10 V

2=0-20 mA

0=No function

1=Dynamic test for induction motor (IM)

2=Static test for induction motor (IM)

5=Rolling auto-tuning for PM (IPM /SPM)

6=Simple rolling auto-tuning for induction

motor (IM)

12=FOC sensorless inertia estimation

13=High frequency stall test for PM

0=No function

1=Continue operation after over-torque

detection during constant speed operation

2=Stop after over-torque detection during

constant speed operation

3=Continue operation after over-torque

detection during RUN

4=Stop after over-torque detection during

RUN

10–250%

(100% corresponds to the rated current of

the drive)

0=Inverter motor (with external forced

cooling)

1=Standard motor (motor with fan on the

shaft)

2=Disabled

0=Constant rated current and limit carrier

wave by load current and temperature

1=Constant carrier frequency and limit load

current by setting carrier wave

2=Constant rated current (same as setting 0)

but close current limit

0=Stop operation

1=Speed tracking by current speed

2=Speed tracking by minimum output

frequency

1

0

0

11

1

0

0

0

0

120

2

0

0

(table continued next page)

GS20_QSP 1st Edition, Rev B 01/29/2021

DURApulse GS20 AC Drive Quick-Start Guide – 1st Ed, Rev B 01/29/2021

Page 4

Page 5

DURApulse GS20 AC Drive Quick-Start Guide

DURApulse GS20 Parameter Settings – Quick Configuration (continued)

Parameter

Group #

Description Range Default User

07 11 Number of times of restart after fault 0–10 0

07 19 Fan cooling control

08 00 Terminal selection of PID feedback

08 01 Proportional gain (P)

08 02 Integral time (I) 0.00–100.00 sec. 1.00

08 03 Differential time (D) 0.00–1.00 sec. 0.00

08 04 Upper limit of integral control 0.0–100.0% 100.0

PID output command limit (positive

08 05

limit)

PID feedback value by communication

08 06

protocol

08 07 PID delay time 0.0–2.5 sec. 0.0

08 08 Feedback signal detection time 0.0–3600.0 sec. 0.0

08 09 Feedback signal fault treatment

08 65 PID target value source

13 00 Application Selection

0=Fan is always ON

1=Fan is OFF after the AC motor drive stops

for one minute

2=Fan is ON when the AC motor drive runs,

fan is OFF when the AC motor drive stops

3=Fan turns ON when temperature (IGBT)

reaches approximately 600°C

0=No function

1=Negative PID feedback: by analog input

(P03.00, P03.01)

2=Negative PID feedback: by single- phase

input (DI7), without direction (P10.16=5)

4=Positive PID feedback: by analog input

(P03.00, P03.01)

5=Positive PID feedback: by single- phase

input (DI7), without direction (P10.16=5)

7=Negative PID feedback: by communication

protocols

8=Positive PID feedback: by communication

protocols

0.0–1000.0 (When P08.23 bit 1=0)

0.00–100.00 (When P08.23 bit 1=1)

0.0–110.0% 100.0

-200.00–200.00% 0.00

0=Warn and continue operation

1=Fault and ramp to stop

2=Fault and coast to stop

3=Warn and operate at last frequency

0=Frequency command (P00.20, P00.30)

1=P08.66 setting

2=RS-485 communication input

3=External analog input (refer to P03.00,

P03.01)

6=Communication card

7=Digital keypad potentiometer dial (GS20

only)

00=Disabled

01=User parameter

02=Compressor

03=Fan

04=Pump

05=Conveyor

06=Machine tool

07=Packing

08=Textiles

Multi-function Input Selections

0=No function

1=Multi-step speed command 1 /

multi-step position command 1

2=Multi-step speed command 2 /

multi-step position command 2

3=Multi-step speed command 3 /

multi-step position command 3

4=Multi-step speed command 4 /

multi-step position command 4

5=Reset

6=JOG [by external control or GS4-KPD

(optional)]

7=Acceleration / deceleration speed

inhibit

8=1st and 2nd acceleration /

deceleration time selection

9=3rd and 4th acceleration /

deceleration time selection

10=External Fault (EF) Input (P07.20)

11=Base Block (B.B.) input from external

source

12=Output stop

13=Cancel the setting of auto-

acceleration / auto-deceleration

time

15=Rotating speed command from AI1

16=Rotating speed command from AI2

18=Force to stop (P07.20)

19=Digital up command

20=Digital down command

21=PID function disabled

22=Clear the counter

23=Input the counter value (DI6)

24=FWD JOG command

25=REV JOG command

26=TQC / Field Oriented Control (FOC)

mode selection

27=ASR1 / ASR2 selection

28=Emergency stop (EF1)

29=Signal confirmation for

Y-connection

30=Signal confirmation for

δ-connection

31=High torque bias (P11.30)

32=Middle torque bias (P11.31)

33=Low torque bias (P11.32)

38=Disable writing EEPROM function

39=Torque command direction

40=Force coasting to stop

41=HAND switch

42=AUTO switch

48=Mechanical gear ratio switch

49=Enable drive

50=Slave dEb action to execute

51=Selection for PLC mode bit 0

52=Selection for PLC mode bit 1

56=Local / Remote selection

58=Enable fire mode (with RUN

command)

59=Enable fire mode (without RUN

command)

70=Force auxiliary frequency return to 0

71=Disable PID function, force PID

output return to 0

72=Disable PID function, retain the

output value before disabled

73=Force PID integral gain return to 0,

disable integral

74=Reverse PID feedback

81=Simple positioning zero point

position signal input

82=OOB loading balance detection

83=Multi-motor (IM) selection bit 0

84=Multi-motor (IM) selection bit 1

1.00

Multi-function Output Selections

0=No function

1=Indication during RUN

2=Operation speed reached

3=Desired frequency reached 1 (P02.22)

4=Desired frequency reached 2 (P02.24)

5=Zero speed (Frequency command)

3

0

6=Zero speed including STOP

(Frequency command)

7=Over-torque 1 (P06.06–06.08)

8=Over-torque 2 (P06.09–06.11)

9=Drive is ready

10=Low voltage warning (Lv) (P06.00)

11=Malfunction indication

13=Overheat warning (P06.15)

14=Software brake signal indicator

(P07.00)

15=PID feedback error (P08.13, P08.14)

16=Slip error (oSL)

17=Count value reached, does not

return to 0 (P02.20)

18=Count value reached, return to 0

(P02.19)

19=External interrupt B.B. input (Base

Block)

20=Warning output

21=Over-voltage

22=Over-current stall prevention

23=Over-voltage stall prevention

24=Operation mode

25=Forward command

26=Reverse command

29=Output when frequency ≥ P02.34

30=Output when frequency < P02.34

31=Y-connection for the motor coil

32=δ-connection for the motor coil

33=Zero speed (actual output

frequency)

34=Zero speed including STOP (actual

output frequency)

35=Error output selection 1 (P06.23)

36=Error output selection 2 (P06.24)

37=Error output selection 3 (P06.25)

38=Error output selection 4 (P06.26)

40=Speed reached (including STOP)

42=Crane function

43=Motor speed detection

44=Low current output (use with

P06.71–06.73)

45=UVW output electromagnetic valve

switch

46=Master dEb output

51=Analog output control for RS-485

interface

52=Output control for communication

cards

53=Fire mode indication

66=SO output logic A

67=Analog input level reached

68=SO output logic B

73=Over-torque 3

74=Over-torque 4

75=Forward RUN status

76=Reverse RUN status

AI Multi-function Input Selections

0=No function

1=Frequency command

2=Torque command (torque limit under

speed mode)

3=Torque compensation command

4=PID target value

5=PID feedback signal

6=Thermistor (PTC) input value

7=Positive torque limit

8=Negative torque limit

9=Regenerative torque limit

10=Positive / negative torque limit

11=PT100 thermistor input value

12=Auxiliary frequency input

13=PID compensation value

AO1 Multi-function Output Selections

0=Output frequency (Hz)

1=Frequency command (Hz)

2=Motor speed (Hz)

0

0

3=Output current (rms)

4=Output voltage

5=DC bus voltage

6=Power factor

7=Power

OPTIONAL CONFIGURATION SETTING:

8=Output torque

9=AI1

10=AI2

12=Iq current command

13=Iq feedback value

14=Id current command

15=Id feedback value

16=Vq-axis voltage command

17=Vd-axis voltage command

18=Torque command

19=PG2 (DI7) frequency command

21=RS-485 analog output

22=Communication card analog output

23=Constant voltage output

GS2 mode is an optional setting for users who want the drive to operate in the legacy GS2 parameter

configuration. This mode changes the entire parameter structure of the drive. See the GS20 User Manual

Appendix G for more details.

Entering and Exiting “GS2” Mode

0

GS20 drives that have an equivalent GS2 model (same power and HP rating) have the option of being operated

in “GS2 Mode”. This allows you to use the new drive in exactly the same role as an older GS2 drive that needs

to be replaced, or in conjuction with existing GS2 drives.

Note that all drives will come factory standard with GS20 mode as the default setting.

Enter GS2 Mode

Note: To enter GS2 mode, parameters cannot be locked or set to read only, and the PLC must be disabled. If

any of these requirements are not met, you will be unable to set 00.02 to 20.

1) Set parameter 00.02=2, to reset to GS2 mode (1st parameter) and press ENTER.

2) Set parameter 00.02=20 to reset to GS2 mode (2nd parameter) and press ENTER.

3) Reboot the drive by cycling power.

4) Configure GS2 parameters.

Exit GS2 Mode

1) Set parameter 09.08=20 to reset to GS20 mode (parameters will reset). Press ENTER.

2) Reboot the drive by cycling power.

3) Configure GS20 parameters per the tables above and in the GS20 User Manual.

Cooling and Heat Dissipation

Airflow Rate for Cooling Power Dissipation (Watts)

Model

Number

GS21-10P2

GS21-10P5

GS21-11P0

GS21-20P2

GS21-20P5

GS21-21P0

GS21-22P0

GS21-23P0

GS23-2010

GS23-2015

GS23-2020

GS23-20P2

GS23-20P5

GS23-21P0

GS23-22P0

GS23-23P0

GS23-25P0

GS23-27P5

GS23-4010

GS23-4015

GS23-4020

GS23-4025

GS23-4030

GS23-40P5

GS23-41P0

GS23-42P0

GS23-43P0

GS23-45P0

GS23-47P5

GS23-5010

GS23-51P0

GS23-52P0

GS23-53P0

GS23-55P0

GS23-57P5

• External Flow Rate is across the heat sink.

• Internal Flow Rate is through the chassis.

• Published flow rates are the result of active

cooling using fans, factory installed in the

drive.

• Unpublished flow rates ( - ) are the result

of passive cooling in drives without factory

installed fans.

• The required airflow shown in the chart

is for installing a single GS20 drive in a

confined space.

• When installing multiple GS20 drives,

the required air volume would be the

required air volume for a single GS20 drive

multiplied by the number of GS20 drives.

Flow Rate

(cfm)

0.0 0.0

16.0 27.2 29.1 23.9 53.0

0.0 0.0

16.0 27.2

53.7 91.2

67.9 115.2 492.0 198.2 690.2

0.0 0.0

10.0 16.99 50.1 24.2 74.3

16.0 27.2

23.4 39.7

53.7 91.2

67.9 115.2

10.0 16.99

16.0 27.2

23.4 39.7

0.0 0.0 23.5 12.5 36

10.0 16.99 38.1 19 57.1

16.0 27.2

23.4 39.7 93.9 37 130.9

Flow Rate

(m3/hr)

Loss External

(Heat sink)

Internal Total

8.0 10.0 18.0

14.2 13.1 27.3

8.0 10.3 18.3

16.3 14.5 30.8

29.1 20.1 49.2

29.1 23.9 53.0

70.0 35 105

244.5 79.6 324.1

374.2 86.2 460.4

8.6 10.0 18.6

16.5 12.6 29.1

31.0 13.2 44.2

76.0 30.7 106.7

108.2 40.1 148.3

192.8 53.3 246.1

164.7 55.8 220.5

234.5 69.8 304.3

319.8 74.3 394.1

423.5 181.6 605.1

501.1 200.3 701.4

17.6 11.1 28.7

30.5 17.8 48.3

45.9 21.7 67.6

60.6 22.8 83.4

93.1 42 135.1

132.8 39.5 172.3

108.4 51 159.4

56.6 22.2 68.8

76.1 30 106.1

• When calculating power dissipation (Watt

Loss), use the Total value. Heat dissipation

shown in the chart is for installing a single

GS20 drive in a confined space.

• When installing multiple drives, the volume

of heat/power dissipation should be the

heat/power dissipated by a single GS20 drive

multiplied by the number of GS20 drives.

• Heat dissipation for each model is calculated

by rated voltage, current and default carrier

frequency.

GS20_QSP 1st Edition, Rev B 01/29/2021

DURApulse GS20 AC Drive Quick-Start Guide – 1st Ed, Rev B 01/29/2021

Page 5

Page 6

DURApulse GS20 AC Drive Quick-Start Guide

Environment for Operation, Storage, and Transportation

DO NOT expose the GS20 drive to environments that contain dust, direct sunlight, corrosive/inflammable

gases, high humidity, liquids, or high vibration. The salt in the air must be less than 0.01 mg/cm2 throughout

the year.

Installation Location IEC60364-1/IEC60664-1 Pollution degree 2, Indoor use only

Surrounding

Temperature

Rated Humidity

Air Pressure Operation/Storage: 86 to 106 kPa Transportation: 70 to 106 kPa

Pollution Level

Environment

Altitude Operation

Package

Drop

Vibration

Impact

Storage

Transportation

Operating

Non-operating 2.5 G peak, 5Hz~2kHz: 0.015” maximum displacement.

Operating IEC/EN60068-2-27: 15G, 11ms

Non-operating 30G

Protection Level

Storage: -40°C to +85°C Transportation: -20°C to +70°C

No condensation, non-frozen

Operation: Max. 90% Storage/Transportation: Max. 95%

No condensed water

IEC60721-3

Operation:

Class 3C2; Class 3S2

No concentrate

If the GS20 drive is installed at altitudes of 0~1000m, follow normal

operation restriction. If installed at altitudes of 1000~2000m, decrease

1% of rated current or lower 0.5°C of temperature for every 100m

increase in altitude. Maximum altitude for Corner Grounded is 2000m.

Contact ADC for more information if you need to use this motor drive at

an altitude of 2000m or higher.

ISTA procedure 1A (according to weight) IEC60068-2-31

1.0mm, peak-to-peak value range from 2Hz to 13.2 Hz; 0.7G~1.0G range from

13.2Hz to 55Hz; 2.0G range from 55Hz to 512 Hz. Comply with IEC 60068-2-6.

IP40 - main unit

IP20 - wiring area (main circuit terminals and control terminals (all frame types),

and the vent near the capacitor on frame C, D, E, and F types).

Storage:

Class 2C2; Class 2S2

Transportation:

Class 1C2; Class 1S2

To prevent personal injury, please make sure that the case and wiring are installed

according to these instructions. The figures in these instructions are only for reference.

They may be slightly different from the one you have, but it will not affect your

customer rights.

These installation instructions may be revised without prior notice. The most recent

edition can be downloaded from the AutomationDirect web site at any time:

http://www.automationdirect.com/static/manuals/index.html.

Minimum Mounting Clearances

When installing your GS20 drive, please keep the following in mind:

• Prevent fiber particles, scraps of paper, shredded wood, saw dust, metal particles, etc., from adhering to the

heat sink.

• Install the AC motor drive in a metal cabinet. When installing one drive below another one, use a metal

separation between the AC motor drives to prevent mutual heating and to prevent the risk of accidental fire.

• Install the AC motor drive in Pollution Degree 2 environments only: normally only nonconductive pollution

occurs and temporary conductivity caused by condensation is expected.

← (Blue Arrow) Inflow ← (Red Arrow) Outflow

Single drive Independent installation.

Side-by-side horizontal installation:

Installation Method

Single drive installation 50 30

Side-by-side horizontal installation 50 30 30 50 60

Zero stack installation 50 30 0 40 50

A

(mm)

B

(mm)C (mm)

–

Operation Temperature

Max

(w/out derating)

50 60

(Derating)

GS20_QSP 1st Edition, Rev B 01/29/2021

Max

DURApulse GS20 AC Drive Quick-Start Guide – 1st Ed, Rev B 01/29/2021

Page 6

Page 7

DURApulse GS20 AC Drive Quick-Start Guide

FRAME_A2

FRAME_A1

FRAME_A4

GS23-20P5

GS23-40P5

GS21-10P2

GS21-20P2

GS23-20P2

FRAME_A5

GS23-21P0

FRAME_A3

GS21-10P5

GS21-20P5

MODELS BY

FRAME SIZE:

68.0

MODELS BY

FRAME SIZE:

FRAME_B2

FRAME_B1

GS21-21P0

GS23-22P0

GS23-42P0

GS23-52P0

72.0

MODELS BY

FRAME SIZE:

FRAME_C1

GS21-11P0

GS21-22P0

GS21-23P0

GS23-23P0

GS23-25P0

GS23-43P0

GS23-45P0

GS23-53P0

GS23-55P0

87.0

157.0

[6.18]

152.0

MODELS BY

FRAME SIZE:

FRAME_D1

.

GS23-27P5

GS23-47P5

GS23-4010

GS23-57P5

GS23-5010

109.0

207.0

[8.15]

Dimension Diagrams

GS20 Frame A

Units = mm [in]

GS20 Frame C

Units = mm [in]

128.0

[5.04]

[2.68]

56.0

[2.20]

118.0

[4.65]

D

3.0

[0.12]

MOUNTING HOLE

DETAIL

5.2

[0.20]

5.2

[0.20]

Models by Frame Size

Model Frame

GS21-10P2

GS21-20P2

GS23-20P2

GS23-20P5 A2 110.0 [4.33]

GS21-10P5

GS21-20P5

GS23-40P5 A4 129.0 [5.08]

GS23-21P0

GS23-41P0

GS23-51P0

A1 96.0 [3.78]

A3 125.0 [4.92]

A5 143.0 [5.63]

D

mm [in]

[3.43]

73.0

[2.87]

144.5

[5.69]

[5.98]

[0.20]

MOUNTING HOLE

DETAIL

5.5

[0.22]

5.0

5.5

[0.22]

Models by Frame Size

Model Frame

GS21-11P0

GS21-22P0

GS21-23P0

GS23-23P0

GS23-25P0

GS23-43P0

GS23-45P0

GS23-53P0

GS23-55P0

C1

GS20 Frame B

Units = mm [in]

142.0

[5.59]

[2.83]

60.0

[2.36]

130.0

[5.12]

GS20 Frame D

Units = mm [in]

D

D1

Models by Frame Size

Model Frame

GS23-22P0

GS23-42P0

GS23-52P0

GS21-21P0 B2

D D1

mm [in]

143.0

[5.63]

143.0

[5.63]

6.4

[0.25]

3.0

[0.12]

B1

[4.29]

94.0

[3.70]

193.8

[7.63]

5.2

[0.20]

154.0

[6.06]

[0.24]

5.5

[0.22]

MOUNTING HOLE

DETAIL

6.0

Models by Frame Size

Model Frame

GS23-27P5

GS23-47P5

GS23-4010

GS23-57P5

GS23-5010

D1

GS20_QSP 1st Edition, Rev B 01/29/2021

MOUNTING HOLE

DETAIL

5.2

[0.20]

5.5

[0.22]

DURApulse GS20 AC Drive Quick-Start Guide – 1st Ed, Rev B 01/29/2021

Page 7

Page 8

DURApulse GS20 AC Drive Quick-Start Guide

MODELS BY

FRAME SIZE:

FRAME_E1

GS23-2010

GS23-2015

GS23-4015

GS23-4020

MODELS BY

FRAME SIZE:

FRAME_F1

GS23-2020

GS23-4025

GS23-4030

[11.81]

[2.81]

[2.83]

[3.43]

[4.08]

[4.90]

GS20 Frame E

Units = mm [in]

250.0

[9.84]

130.0

[5.12]

115.0

[4.53]

236.8

[9.32]

185.0

[7.28]

6.0

[0.24]

5.5

[0.22]

MOUNTING HOLE

DETAIL

Models by Frame Size

Model Frame

GS23-2010

GS23-2015

GS23-4015

GS23-4020

E1

NEMA 1 Conduit Boxes

The GS20 drives can optionally be fitted to a NEMA1 conduit box, with one available box per frame size. The dimensional diagrams below show how the box will

change the dimensions of the GS20 unit.

GS20 Frame A Conduit Box

[4.02]

71.5

GS20 Frame C Conduit Box

102.1

Units = mm [in]

86.6

[3.41]

GS20 Frame B Conduit Box

87.0

[3.43]

87.7

[3.45]

72.0

GS20 Frame D Conduit Box

GS20 Frame F

Units = mm [in]

300.0

175.0

[6.89]

154.0

[6.06]

279.5

[11.00]

5.5

[0.22]

192.0

[7.56]

6.5

[0.26]

Models by Frame Size

Model Frame

GS23-2020

GS23-4025

GS23-4030

75.2

[2.06]

[2.96]

52.3

89.2

[3.51]

F1

GS20 Frame E Conduit Box

87.0

GS20 Frame F Conduit Box

58.4

[2.30]

103.7

72.6

[2.86]

88.5

[3.48]

GS20_QSP 1st Edition, Rev B 01/29/2021

8.4

[0.33]

8.4

[0.33]

MOUNTING HOLE

DETAIL

124.5

87.1

[3.43]

168.5

[6.63]

DURApulse GS20 AC Drive Quick-Start Guide – 1st Ed, Rev B 01/29/2021

90.8

[3.57]

Page 8

Loading...

Loading...