Page 1

Hardware User Manual

®

EA9-USER-M

Page 2

Page 3

~ WARNING ~

Thank you for purchasing automation equipment from Automationdirect.com®, doing business as,

AutomationDirect. We want your new automation equipment to operate safely. Anyone who installs or

uses this equipment should read this publication (and any other relevant publications) before installing or

operating the equipment.

To minimize the risk of potential safety problems, you should follow all applicable local and national

codes that regulate the installation and operation of your equipment. These codes vary from area to area

and usually change with time. It is your responsibility to determine which codes should be followed, and

to verify that the equipment, installation, and operation is in compliance with the latest revision of these

codes.

At a minimum, you should follow all applicable sections of the National Fire Code, National Electrical

Code, and the codes of the National Electrical Manufacturer’s Association (NEMA). There may be local

regulatory or government offices that can also help determine which codes and standards are necessary for

safe installation and operation.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable

codes and standards. We do not guarantee the products described in this publication are suitable for

your particular application, nor do we assume any responsibility for your product design, installation, or

operation.

Our products are not fault-tolerant and are not designed, manufactured or intended for use or resale as

on-line control equipment in hazardous environments requiring fail-safe performance, such as in the

operation of nuclear facilities, aircraft navigation or communication systems, air traffic control, direct life

support machines, or weapons systems, in which the failure of the product could lead directly to death,

personal injury, or severe physical or environmental damage (“High Risk Activities”). AutomationDirect

specifically disclaims any expressed or implied warranty of fitness for High Risk Activities.

For additional warranty and safety information, see the Terms and Conditions section of our catalog.

If you have any questions concerning the installation or operation of this equipment, or if you need

additional information, please call us at 770-844-4200.

This publication is based on information that was available at the time it was printed. At

AutomationDirect we constantly strive to improve our products and services, so we reserve the right to

make changes to the products and/or publications at any time without notice and without any obligation.

This publication may also discuss features that may not be available in certain revisions of the product.

Trademarks

This publication may contain references to products produced and/or offered by other companies. The

product and company names may be trademarked and are the sole property of their respective owners.

AutomationDirect disclaims any proprietary interest in the marks and names of others.

Copyright 2020, Automationdirect.com® Incorporated

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior, written

consent of Automationdirect.com® Incorporated. AutomationDirect retains the exclusive rights to all

information included in this document.

All Rights Reserved

Page 4

~ ADVERTENCIA ~

Gracias por comprar equipo de automatización de Automationdirect.com®. Deseamos que su nuevo equipo de

automatización opere de manera segura. Cualquier persona que instale o use este equipo debe leer esta publicación

(y cualquier otra publicación pertinente) antes de instalar u operar el equipo.

Para reducir al mínimo el riesgo debido a problemas de seguridad, debe seguir todos los códigos de seguridad

locales o nacionales aplicables que regulan la instalación y operación de su equipo. Estos códigos varian de área

en área y usualmente cambian con el tiempo. Es su responsabilidad determinar cuales códigos deben ser seguidos

y verificar que el equipo, instalación y operación estén en cumplimiento con la revisión mas reciente de estos

códigos.

Como mínimo, debe seguir las secciones aplicables del Código Nacional de Incendio, Código Nacional Eléctrico,

y los códigos de (NEMA) la Asociación Nacional de Fabricantes Eléctricos de USA. Puede haber oficinas de

normas locales o del gobierno que pueden ayudar a determinar cuales códigos y normas son necesarios para una

instalación y operación segura.

Si no se siguen todos los códigos y normas aplicables, puede resultar en daños al equipo o lesiones serias a personas.

No garantizamos los productos descritos en esta publicación para ser adecuados para su aplicación en particular, ni

asumimos ninguna responsabilidad por el diseño de su producto, la instalación u operación.

Nuestros productos no son tolerantes a fallas y no han sido diseñados, fabricados o intencionados para uso o

reventa como equipo de control en línea en ambientes peligrosos que requieren una ejecución sin fallas, tales

como operación en instalaciones nucleares, sistemas de navegación aérea, o de comunicación, control de

tráfico aéreo, máquinas de soporte de vida o sistemas de armamentos en las cuales la falla del producto puede

resultar directamente en muerte, heridas personales, o daños físicos o ambientales severos (“Actividades de Alto

Riesgo”). Automationdirect.com específicamente rechaza cualquier garantía ya sea expresada o implicada para

actividades de alto riesgo. Para

información adicional acerca de garantía e información de seguridad, vea la sección de Términos y Condiciones de

nuestro catálogo. Si tiene alguna pregunta sobre instalación u operación de este equipo, o si necesita información

adicional, por favor llámenos al número 770-844-4200 en Estados Unidos. Esta publicación está basada en la

información disponible al momento de impresión. En Automationdirect.com nos esforzamos constantemente

para mejorar nuestros productos y servicios, así que nos reservamos el derecho de hacer cambios al producto y/o

a las publicaciones en cualquier momento sin notificación y sin ninguna obligación. Esta publicación también

puede discutir características que no estén disponibles en ciertas revisiones del producto.

Esta publicación puede contener referencias a productos producidos y/u ofrecidos por otras compañías. Los nombres de las compañías y

Marcas Registradas

productos pueden tener marcas registradas y son propiedad única de sus respectivos dueños. Automationdirect.com, renuncia cualquier

interés propietario en las marcas y nombres de otros.

PROPIEDAD LITERARIA 2020, AUTOMATIONDIRECT.COM® INCORPORATED

No se permite copiar, reproducir, o transmitir de ninguna forma ninguna parte de este manual sin previo consentimiento por escrito

de Automationdirect.com

este documento. Los usuarios de este equipo pueden copiar este documento solamente para instalar, configurar y mantener el equipo

correspondiente. También las instituciones de enseñanza pueden usar este manual para propósitos educativos.

®

Incorprated. Automationdirect.com retiene los derechos exclusivos a toda la información incluida en

Todos los derechos reservados

Page 5

~ AVERTISSEMENT ~

Nous vous remercions d’avoir acheté l’équipement d’automatisation de Automationdirect.com®, en faisant des affaires

comme, AutomationDirect. Nous tenons à ce que votre nouvel équipement d’automatisation fonctionne en toute

sécurité. Toute personne qui installe ou utilise cet équipement doit lire la présente publication (et toutes les autres

publications pertinentes) avant de l’installer ou de l’utiliser.

Afin de réduire au minimum le risque d’éventuels problèmes de sécurité, vous devez respecter tous les codes locaux

et nationaux applicables régissant l’installation et le fonctionnement de votre équipement. Ces codes diffèrent d’une

région à l’autre et, habituellement, évoluent au fil du temps. Il vous incombe de déterminer les codes à respecter et de

vous assurer que l’équipement, l’installation et le fonctionnement sont conformes aux exigences de la version la plus

récente de ces codes.

Vous devez, à tout le moins, respecter toutes les sections applicables du Code national de prévention des incendies,

du Code national de l’électricité et des codes de la National Electrical Manufacturer’s Association (NEMA). Des

organismes de réglementation ou des services gouvernementaux locaux peuvent également vous aider à déterminer les

codes ainsi que les normes à respecter pour assurer une installation et un fonctionnement sûrs.

L’omission de respecter la totalité des codes et des normes applicables peut entraîner des dommages à l’équipement

ou causer de graves blessures au personnel. Nous ne garantissons pas que les produits décrits dans cette publication

conviennent à votre application particulière et nous n’assumons aucune responsabilité à l’égard de la conception, de

l’installation ou du fonctionnement de votre produit.

Nos produits ne sont pas insensibles aux défaillances et ne sont ni conçus ni fabriqués pour l’utilisation ou la revente en

tant qu’équipement de commande en ligne dans des environnements dangereux nécessitant une sécurité absolue, par

exemple, l’exploitation d’installations nucléaires, les systèmes de navigation aérienne ou de communication, le contrôle

de la circulation aérienne, les équipements de survie ou les systèmes d’armes, pour lesquels la défaillance du produit

peut provoquer la mort, des blessures corporelles ou de graves dommages matériels ou environnementaux («activités à

risque élevé»). La société AutomationDirect nie toute garantie expresse ou implicite d’aptitude à l’emploi en ce qui a

trait aux activités à risque élevé.

Pour des renseignements additionnels touchant la garantie et la sécurité, veuillez consulter la section Modalités et

conditions de notre documentation. Si vous avez des questions au sujet de l’installation ou du fonctionnement de cet

équipement, ou encore si vous avez besoin de renseignements supplémentaires, n’hésitez pas à nous téléphoner au

770-844-4200.

Cette publication s’appuie sur l’information qui était disponible au moment de l’impression. À la société

AutomationDirect, nous nous efforçons constamment d’améliorer nos produits et services. C’est pourquoi nous nous

réservons le droit d’apporter des modifications aux produits ou aux publications en tout temps, sans préavis ni quelque

obligation que ce soit. La présente publication peut aussi porter sur des caractéristiques susceptibles de ne pas être

offertes dans certaines versions révisées du produit.

Marques de commerce

La présente publication peut contenir des références à des produits fabriqués ou offerts par d’autres entreprises. Les

désignations des produits et des entreprises peuvent être des marques de commerce et appartiennent exclusivement à

leurs propriétaires respectifs. AutomationDirect nie tout intérêt dans les autres marques et désignations.

Copyright 2020, Automationdirect.com® Incorporated

Nulle partie de ce manuel ne doit être copiée, reproduite ou transmise de quelque façon que ce soit sans le

consentement préalable écrit de la société Automationdirect.com® Incorporated. AutomationDirect conserve les

droits exclusifs à l’égard de tous les renseignements contenus dans le présent document.

Tous droits réservés

Page 6

Page 7

®

HARDWARE USER MANUAL

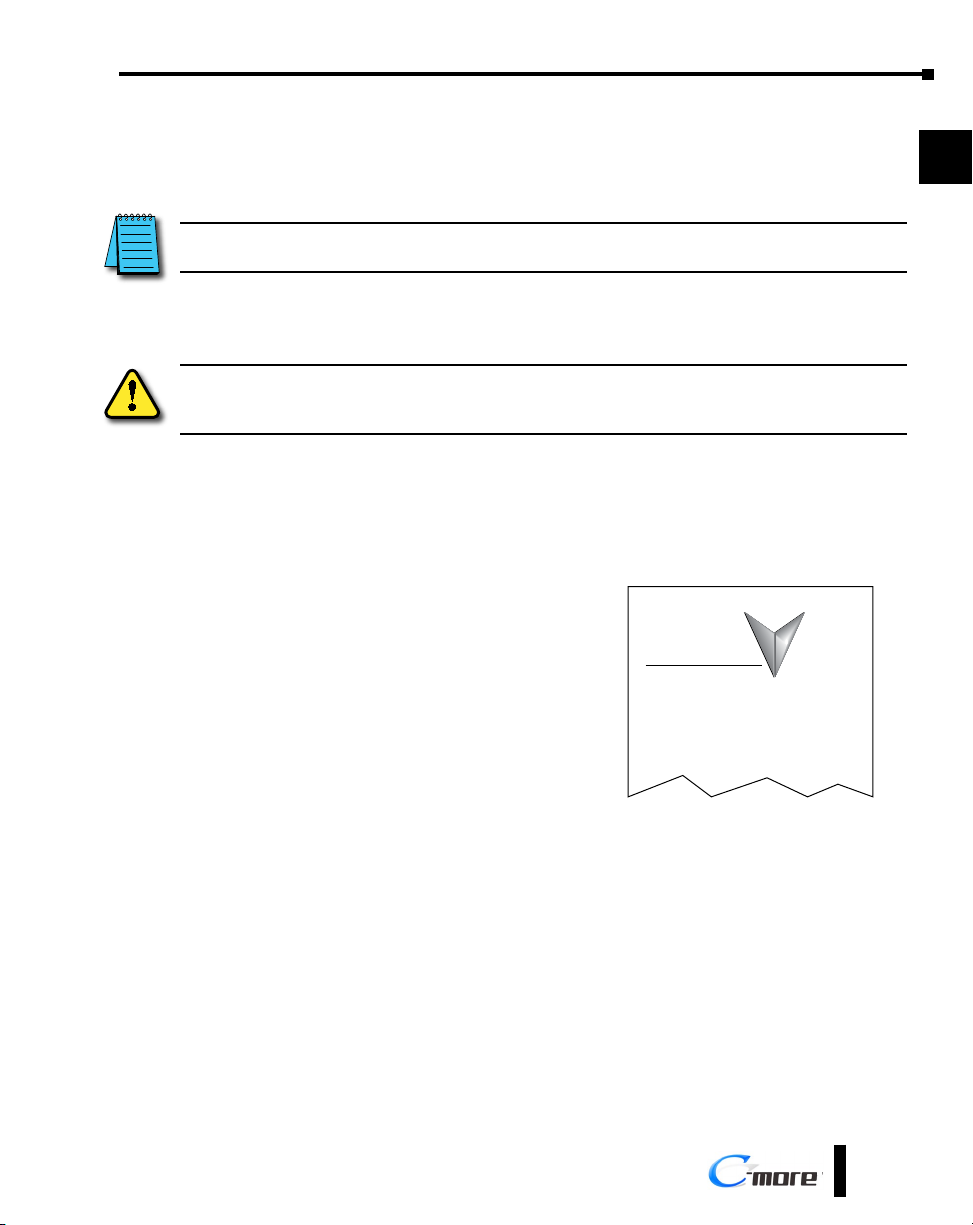

Please include the Manual Number and the Manual Issue, both shown below,

when communicating with Technical Support regarding this publication.

Manual Number: EA9-USER-M

Issue: 1st Edition Revision N

Issue Date: 07/20

Publication History

Issue Date Description of Changes

First Edition 03/14 Original

1st Ed. Rev. A 10/14 Minor Revisions

1st Ed. Rev. B 01/15 Revised PLC communication and drivers, minor revisions

1st Ed. Rev. C 03/16 Added Recovery Tool and No System Found to Troubleshooting, minor revisions

1st Ed. Rev. D 12/16 Added EA9-T7CL(-R). Added Appendix C, minor revisions

1st Ed. Rev. E 11/17 Added EA9-T10WCL and EA9-T15CL-R. Minor revisions

1st Ed. Rev. F 02/18 Revised Memory Device Formatting table

1st Ed. Rev. G 08/18 Corrected DH485-CBL description

1st Ed. Rev. H 08/19 Added Micro-800 series. Minor revisions

1st Ed. Rev. J 09/19 Minor Revisions

1st Ed. Rev. K 01/20 Added S7-1500

1st Ed. Rev. L 04/20 Minor Revisions

1st Ed. Rev. M 06/20 Revised Appendix C

1st Ed. Rev. N 07/20 Revised Hazardous location information

Page 8

Page 9

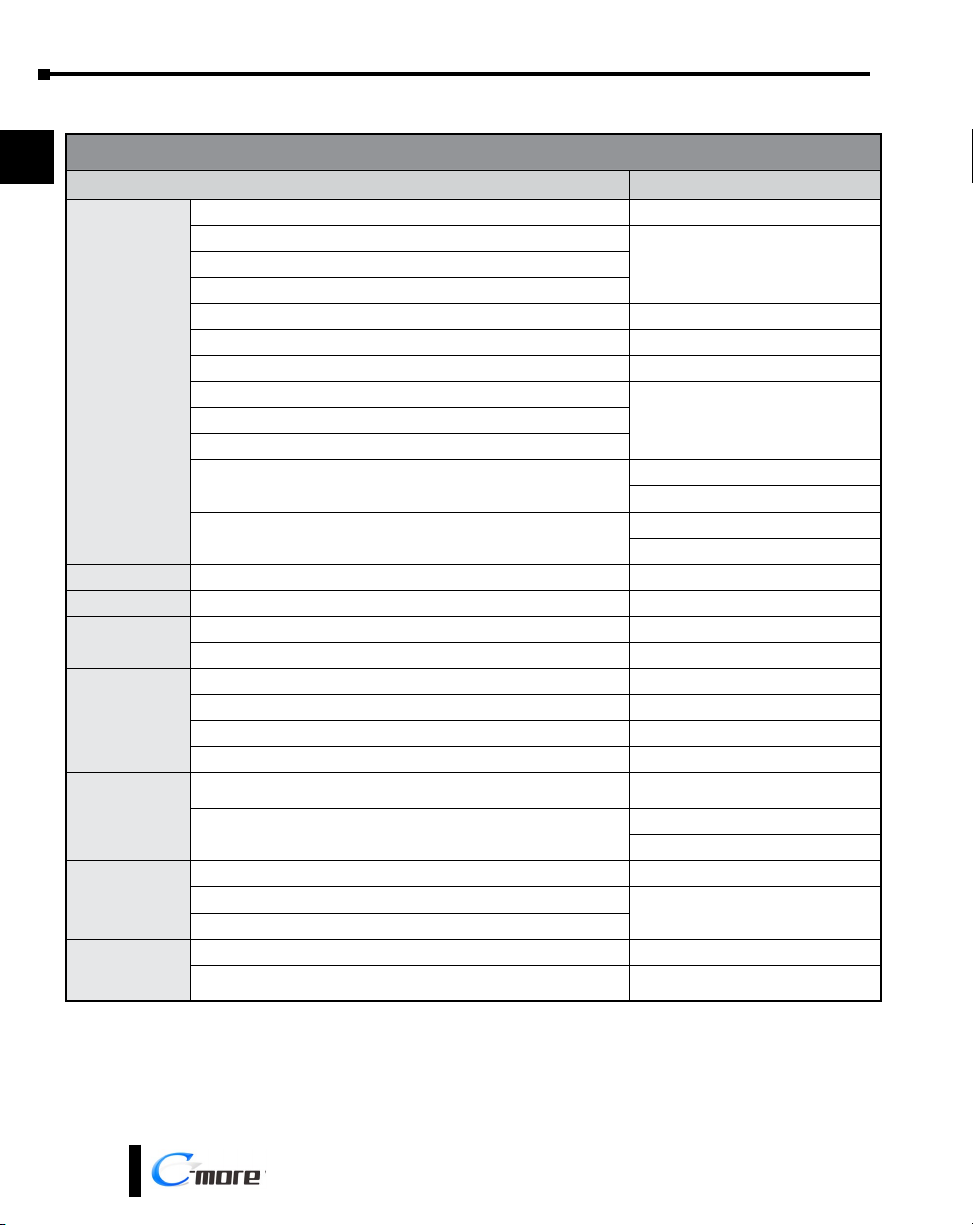

Table of ConTenTs

Chapter 1: Getting Started

Introduction ...................................................................................................................1-2

The Purpose of this Manual ������������������������������������������������������������������������������������������1-2

Supplemental Manuals �������������������������������������������������������������������������������������������������1-2

Technical Support ��������������������������������������������������������������������������������������������������������1-2

Conventions Used ..........................................................................................................1-3

Key Topics for Each Chapter �����������������������������������������������������������������������������������������1-3

Product Overview ..........................................................................................................1-4

Quick Start Steps ...........................................................................................................1-5

Step 1 – Unpack and Inspect ����������������������������������������������������������������������������������������1-5

Step 2 – Install Optional Hardware Accessories �������������������������������������������������������������1-6

Step 3 – Become Familiar with Available Communication Ports ������������������������������������1-7

Step 4 – Install the Programming Software and Develop a Project �������������������������������1-8

Step 5 – Connect Touch Panel to Computer ����������������������������������������������������������������1-9

Step 6 – Provide Power to the Touch Panel ����������������������������������������������������������������1-10

Step 7 – Access the Touch Panel Setup Screens����������������������������������������������������������1-12

Step 8 – Choose Touch Panel to Device Cables ����������������������������������������������������������1-13

Step 9 – Connect Touch Panel to PLC ������������������������������������������������������������������������1-16

Chapter 2: Specifications

Available Models ............................................................................................................2-4

Model Specifications .....................................................................................................2-5

Specifications common to all models ���������������������������������������������������������������������������2-6

6-inch Models ��������������������������������������������������������������������������������������������������������������2-7

7-inch Models ��������������������������������������������������������������������������������������������������������������2-8

8-inch and 10-inch Models ������������������������������������������������������������������������������������������2-9

12-inch and 15-inch Models ��������������������������������������������������������������������������������������2-10

Page 10

Table of Contents

EA9-T6CL-R, EA9-T6CL ............................................................................................... 2-11

Dimensions, Inches [mm] ����������������������������������������������������������������������������������������� 2-11

Ports and Memory Expansion ����������������������������������������������������������������������������������� 2-12

EA9-T7CL-R, EA9-T7CL ............................................................................................... 2-13

Dimensions, Inches [mm] ����������������������������������������������������������������������������������������� 2-13

Ports and Memory Expansion ����������������������������������������������������������������������������������� 2-14

EA9-T8CL .................................................................................................................... 2-15

Dimensions, Inches [mm] ����������������������������������������������������������������������������������������� 2-15

Ports and Memory Expansion ����������������������������������������������������������������������������������� 2-16

EA9-T10CL .................................................................................................................. 2-17

Dimensions, Inches [mm] ����������������������������������������������������������������������������������������� 2-17

EA9-T10WCL .............................................................................................................. 2-18

Dimensions, Inches [mm] ����������������������������������������������������������������������������������������� 2-18

Ports and Memory Expansion ����������������������������������������������������������������������������������� 2-19

EA9-T12CL .................................................................................................................. 2-20

Dimensions, Inches [mm] ����������������������������������������������������������������������������������������� 2-20

Ports and Memory Expansion ����������������������������������������������������������������������������������� 2-21

EA9-T15CL-R, EA9-T15CL ........................................................................................... 2-22

Dimensions, Inches [mm] ����������������������������������������������������������������������������������������� 2-22

Ports and Memory Expansion ����������������������������������������������������������������������������������� 2-23

Mounting Clearances ................................................................................................ 2-25

EA9-T15CL-R, EA9-T15CL Derating �������������������������������������������������������������������������� 2-26

Communications Ports .............................................................................................. 2-27

Handling External Memory Devices .......................................................................... 2-30

Writing to External Memory Devices ������������������������������������������������������������������������ 2-30

Memory Device Formatting �������������������������������������������������������������������������������������� 2-30

Minimizing Data Errors ��������������������������������������������������������������������������������������������� 2-31

Monitoring Available Memory ��������������������������������������������������������������������������������� 2-31

File Name Limitations ����������������������������������������������������������������������������������������������� 2-32

Power Loss Retention ����������������������������������������������������������������������������������������������� 2-32

Chemical Compatibility ............................................................................................. 2-32

®

ii

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 11

Table of Contents

Chapter 3: Accessories

Accessories Overview ................................................................................................... 3-2

AC/DC Power Adapter ................................................................................................ 3-3

AC/DC Power Adapter Dimensions ���������������������������������������������������������������������������� 3-5

AC/DC Power Adapter Installation ������������������������������������������������������������������������������ 3-6

EA-ECOM Ethernet Communication Module .............................................................. 3-7

D-SUB 15-pin to Terminal Block Adapters .................................................................. 3-8

Non-glare Screen Covers ............................................................................................. 3-9

Clear Screen Overlay Installation ������������������������������������������������������������������������������ 3-10

SD Card ...................................................................................................................... 3-11

USB FLASH Drive ....................................................................................................... 3-11

Chapter 4: Installation and Wiring

Safety Guidelines ......................................................................................................... 4-2

Introduction ................................................................................................................. 4-3

UL Requirements ......................................................................................................... 4-4

EA9-T6CL-R, EA9-T6CL, EA9-T7CL-R and EA9-T7CL

Cutout Dimensions ...................................................................................................... 4-5

EA9-T8CL and EA9-T10WCL Cutout Dimensions ........................................................ 4-6

EA9-T12CL Cutout Dimensions ................................................................................... 4-8

EA9-T15CL-R and EA9-T15CL Cutout Dimensions ...................................................... 4-9

Mounting Clearances ................................................................................................ 4-10

EA9-T15CL-R, EA9-T15CL Derating �������������������������������������������������������������������������� 4-11

Wiring Guidelines ...................................................................................................... 4-12

Agency Approvals ����������������������������������������������������������������������������������������������������� 4-12

Providing Power to the Touch Panel ������������������������������������������������������������������������ 4-13

C-more LED Status Indicators ����������������������������������������������������������������������������������� 4-14

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

®

iii

Page 12

Table of Contents

Chapter 5: System Setup Screens

Introduction ................................................................................................................. 5-2

Accessing the System Setup Screens (no project loaded) ......................................... 5-3

Accessing the System Setup Screens (with project loaded) ...................................... 5-4

System Setup Screens – Enable Password in Software .............................................. 5-6

System Setup Screens Flowchart .............................................................................. 5-12

Main Menu................................................................................................................. 5-13

Information Menu ..................................................................................................... 5-14

Setting Menu ............................................................................................................. 5-18

Test Menu .................................................................................................................. 5-25

Memory Menu ........................................................................................................... 5-34

Chapter 6: PLC Communications

Introduction ................................................................................................................. 6-2

DirectLOGIC PLCs Password Protection...................................................................... 6-2

PLC Protocols ������������������������������������������������������������������������������������������������������������� 6-3

PLC Communication Cables & Wiring Diagrams ........................................................ 6-5

AutomationDirect PLCs RS-232C Serial ����������������������������������������������������������������������� 6-7

AutomationDirect PLCs RS-422A/RS-485A ���������������������������������������������������������������� 6-10

DirectLOGIC Universal Isolated Network Adapter, p/n FA-ISOCON: ������������������������ 6-16

DirectLOGIC Universal Converter, p/n F2-UNICON: ������������������������������������������������ 6-17

RS-422A/RS-485A Multi-Drop Wiring Diagram Examples ����������������������������������������� 6-18

Allen-Bradley ������������������������������������������������������������������������������������������������������������ 6-22

GE ���������������������������������������������������������������������������������������������������������������������������� 6-27

GE VersaMax Micro �������������������������������������������������������������������������������������������������� 6-27

Mitsubishi����������������������������������������������������������������������������������������������������������������� 6-28

Omron ��������������������������������������������������������������������������������������������������������������������� 6-30

Modicon Modbus RS-232 ����������������������������������������������������������������������������������������� 6-31

Modicon Micro Series����������������������������������������������������������������������������������������������� 6-31

Modicon Modbus with RJ45 ������������������������������������������������������������������������������������� 6-31

Siemens �������������������������������������������������������������������������������������������������������������������� 6-32

®

iv

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 13

Table of Contents

Chapter 7: Maintenance

Project Backup ����������������������������������������������������������������������������������������������������������� 7-2

Check Operating Environment ����������������������������������������������������������������������������������� 7-2

Check Operating Voltage ������������������������������������������������������������������������������������������� 7-2

Check Status Indicators ���������������������������������������������������������������������������������������������� 7-2

Check Physical Conditions ������������������������������������������������������������������������������������������ 7-3

Run Tests under System Setup Screens ����������������������������������������������������������������������� 7-3

Check Memory Usage ������������������������������������������������������������������������������������������������ 7-4

Check/Adjust Display Brightness ��������������������������������������������������������������������������������� 7-4

Check Error Log �������������������������������������������������������������������������������������������������������� 7-4

Adjust Touch Panel ����������������������������������������������������������������������������������������������������� 7-4

Cleaning the Display Screen ��������������������������������������������������������������������������������������� 7-5

Check Project Functionality ���������������������������������������������������������������������������������������� 7-6

Checks from C-more Programming Software ������������������������������������������������������������� 7-6

Notes: ........................................................................................................................... 7-7

Chapter 8: Troubleshooting

Common Problems ���������������������������������������������������������������������������������������������������� 8-2

Troubleshooting Flow Chart ��������������������������������������������������������������������������������������� 8-3

Touch Panel does not Power up ��������������������������������������������������������������������������������� 8-4

Display is Blank ���������������������������������������������������������������������������������������������������������� 8-5

Display is Dim ������������������������������������������������������������������������������������������������������������ 8-6

No User Program ������������������������������������������������������������������������������������������������������� 8-7

Firmware Recovery Tool ��������������������������������������������������������������������������������������������� 8-8

No System Found ������������������������������������������������������������������������������������������������������� 8-9

No Communications between Panel and PC (Personal Computer) via USB �������������� 8-10

USB Driver Troubleshooting ������������������������������������������������������������������������������������� 8-12

No Communications between Panel and PC (Personal Computer) via Ethernet ������� 8-14

No Communications between Panel and PLC ���������������������������������������������������������� 8-18

IP Address in System Setup Screens displays 0�0�0�0 ������������������������������������������������ 8-21

Difficulty Connecting to the Panel over the Internet (Web server and Remote Access

features) ������������������������������������������������������������������������������������������������������������������� 8-22

PLC Protocol Error Codes ����������������������������������������������������������������������������������������� 8-23

Touch Panel Runtime Errors ������������������������������������������������������������������������������������� 8-24

Panel Constantly Displays “Initializing” when Powering up �������������������������������������� 8-25

Data not Logging Problems ������������������������������������������������������������������������������������� 8-25

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

®

v

Page 14

Table of Contents

Electrical Noise Problems ������������������������������������������������������������������������������������������ 8-26

Chapter 9: Replacement Parts

Replacement Parts Overview ...................................................................................... 9-2

Panel Mounting Clip Replacements – EA9-BRK .......................................................... 9-3

Logo Label Replacement Insert - EA9-LBL .................................................................. 9-4

3-wire Communications Terminal Block – EA9-3TB .................................................... 9-5

DC Panel Power Connector Replacement – EA-DC-CON ........................................... 9-5

AC Power Adapter Connector Replacement– EA-AC-CON ......................................... 9-6

Panel Gasket Replacements – EA9-xx-GSK ................................................................. 9-7

Gasket Replacement Installation Instructions: ........................................................... 9-7

Appendix A: Panel and PLC Error Code Tables

Introduction .................................................................................................................A-2

C-more Touch Panel Error Code Table .......................................................................A-3

DirectLOGIC – Panel Error Code PLC-499 Explanation ..............................................A-5

DirectLOGIC K-Sequence Protocol – PLC Error Code Table .......................................A-5

DirectLOGIC DirectNET Protocol – PLC Error Codes .................................................. A-5

Modbus Protocols Error Code P499 Explanation .......................................................A-6

AutomationDirect CLICK ��������������������������������������������������������������������������������������������A-6

AutomationDirect DirectLOGIC - Modbus (Koyo) �������������������������������������������������������A-6

Modicon Modbus RTU �����������������������������������������������������������������������������������������������A-6

Entivity Modbus RTU �������������������������������������������������������������������������������������������������� A-6

DirectLOGIC ECOM Protocol – PLC Error Codes ........................................................A-6

Productivity Error Code P499 ......................................................................................A-7

AutomationDirect Do-More Error Codes ....................................................................A-8

Allen-Bradley – Panel Error Code PLC-499 Explanation .............................................A-9

Allen-Bradley DF1 & DH485 Protocols – PLC Error Code Tables .............................A-10

Allen-Bradley EtherNet/IP Protocol –

Panel Error Code PLC-496, 497 and 498 Explanation ..............................................A-12

®

vi

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 15

Table of Contents

Allen-Bradley – EtherNet/IP Protocol – PLC Error Code Tables ControlLogix,

CompactLogix, & FlexLogix .......................................................................................A-13

Allen-Bradley – Micro800 Serial and EtherNet/IP Tag Based PLC Error Code Tables

...................................................................................................................................A-17

Allen-Bradley – EtherNet/IP Protocol – PLC Error Code Tables ...............................A-21

Generic EtherNet IP Protocol – PLC Error Codes .....................................................A-26

GE 90-30 – Panel Error Code PLC-499 Explanation ..................................................A-27

GE 90-30 SNPX Protocol – PLC Error Code Tables ...................................................A-28

Mitsubishi FX Protocol – PLC Error Codes ................................................................A-37

Omron – Panel Error Code PLC-499 Explanation .....................................................A-37

Omron Host Link Protocol – PLC Error Code Table .................................................A-38

Omron FINS Protocol – PLC Error Code Table .........................................................A-39

Omron – Panel Error Code P495 Explanation ..........................................................A-42

Omron CS/CJ FINS Ethernet Protocol – PLC Error Code Table ................................A-43

Siemens – Panel Error Code P499 Explanation.........................................................A-44

Siemens PPI Protocol – PLC Error Code Table ..........................................................A-45

Siemens ISO over TCP Protocol – PLC Error Code Table .........................................A-46

Appendix B: Touch Panel Runtime Errors

Introduction ................................................................................................................. B-2

Runtime Errors ............................................................................................................. B-3

Log File Naming ��������������������������������������������������������������������������������������������������������� B-4

Appendix C: Security Considerations for Control Systems Networks

Security Considerations for Control Systems Networks.............................................C-2

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

®

vii

Page 16

Page 17

Chapter

Chapter

Chapter

GettinG Started

1

1

1

In This Chapter...

Introduction ...................................................................................................................1-2

The Purpose of this Manual ������������������������������������������������������������������������������������������1-2

Supplemental Manuals �������������������������������������������������������������������������������������������������1-2

Technical Support ��������������������������������������������������������������������������������������������������������1-2

Conventions Used ..........................................................................................................1-3

Key Topics for Each Chapter �����������������������������������������������������������������������������������������1-3

Product Overview ..........................................................................................................1-4

Quick Start Steps ...........................................................................................................1-5

Step 1 – Unpack and Inspect ����������������������������������������������������������������������������������������1-5

Step 2 – Install Optional Hardware Accessories �������������������������������������������������������������1-6

Step 3 – Become Familiar with Available Communication Ports ������������������������������������1-7

Step 4 – Install the Programming Software and Develop a Project �������������������������������1-8

Step 5 – Connect Touch Panel to Computer ����������������������������������������������������������������1-9

Step 6 – Provide Power to the Touch Panel ����������������������������������������������������������������1-10

Step 7 – Access the Touch Panel Setup Screens����������������������������������������������������������1-12

Step 8 – Choose Touch Panel to Device Cables ����������������������������������������������������������1-13

Step 9 – Connect Touch Panel to PLC ������������������������������������������������������������������������1-16

Page 18

Chapter 1 - Getting Started

Introduction

1

2

3

4

5

6

7

8

9

10

11

12

13

14

The Purpose of this Manual

Thank you for purchasing our C-more® Touch Panel family of products. This manual

describes AutomationDirect.com’s C-more Touch Panels, their specifications, included

components, available accessories and provides you with important information for

installation, connectivity and setup. The manual shows you how install, wire and use the

products. It also helps you understand how to interface the panels to other devices in a

control system.

This user manual contains important information for personnel who will install the touch

panels and accessories, and for the personnel who will be programming the panel. If you

understand control systems that make use of operating interfaces such as the C-more touch

panels, our user manuals will provide all the information you need to get, and keep your

system up and running.

Supplemental Manuals

If you are familiar with industrial control type devices, you may be able to get up and running

with just the aide of the Quick Start Guide that is included with each touch panel. You can

also refer to the On-line help that is available in the C-more programming software for more

information about programming the panel.

Technical Support

We strive to make our manuals the best in the industry. We rely on your feedback to let

us know if we are reaching our goal. If you cannot find the solution to your particular

application, or, if for any reason you need technical assistance, please call us at:

770–844–4200

Our technical support group will work with you to answer your questions. They are available

Monday through Friday from 9:00 A.M. to 6:00 P.M. Eastern Time. We also encourage you

to visit our web site where you can find technical and non-technical information about our

products and our company.

http://c-more.automationdirect.com

A

B

C

D

1-2

®

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 19

Conventions Used

Chapter 1 - Getting Started

1

When you see the “notepad” icon in the left-hand margin, the paragraph to its immediate right will be a special note.

The word NOTE: in boldface will mark the beginning of the text.

When you see the “exclamation mark” icon in the left-hand margin, the paragraph to its immediate

right will be a warning. This information could prevent injury, loss of property, or even death (in

extreme cases). The word Warning: in boldface will mark the beginning of the text.

Key Topics for Each Chapter

The beginning of each chapter will list the key topics

that can be found in that chapter.

Getting Started

In This Chapter...

General Information

.................................................................1-2

...........................................................................1-4Specifications

CHAPTER

2

3

4

5

6

7

8

9

1

10

11

12

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

13

14

A

B

C

D

®

1-3

Page 20

Chapter 1 - Getting Started

Product Overview

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Some of the features designed into the product to provide excellent hardware and software are

listed below.

• Analog touch screen (no touch cell boundaries). The touchscreen is designed to respond to a single

touch. If it is touched at multiple points at the same time, an unexpected object may be activated.

• Plenty of memory and methods to get data in/out of the panel

• Overlapping active devices on the touch screen

• 65,536 colors for enhanced graphics

• Screen resolutions up to 1024 X 768 pixel

• HDMI Video Output on 12-inch and 15-inch models.

• Built-in FTP client/server, E-mail client, and Web server

• Audio output port - stereo, requires amplifier and speaker(s) (full feature units only)

• User configurable LED on the front of the panel

• Built-in project simulation; test on PC while developing

• Ethernet 10/100Base-T communications (not available on EA9-T6CL-R)

• 15 pin serial port with RS-232, RS422/485

• 3-wire terminal block RS-485 port and RJ12 RS-232 port (full feature units only)

• Programming via USB or Ethernet (Ethernet not available on EA9-T6CL-R)

• Optional AC/DC power adapter (EA-AC)

• Animation of bitmaps and objects

• Thousands of built-in symbols and Windows fonts

• PID face plate, trending, alarming and a recipe database

• Event Manager to trigger actions based on assigned state changes, schedules, PLC tag names, etc.

setup in a database environment. The event can also trigger a sound byte, initiate a screen capture,

send a data file (FTP), send an E-mail, etc.

• Trend Data logging

• Internet Remote Access

• Customizable label on the front of the panel

A

B

C

D

1-4

®

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 21

Quick Start Steps

Chapter 1 - Getting Started

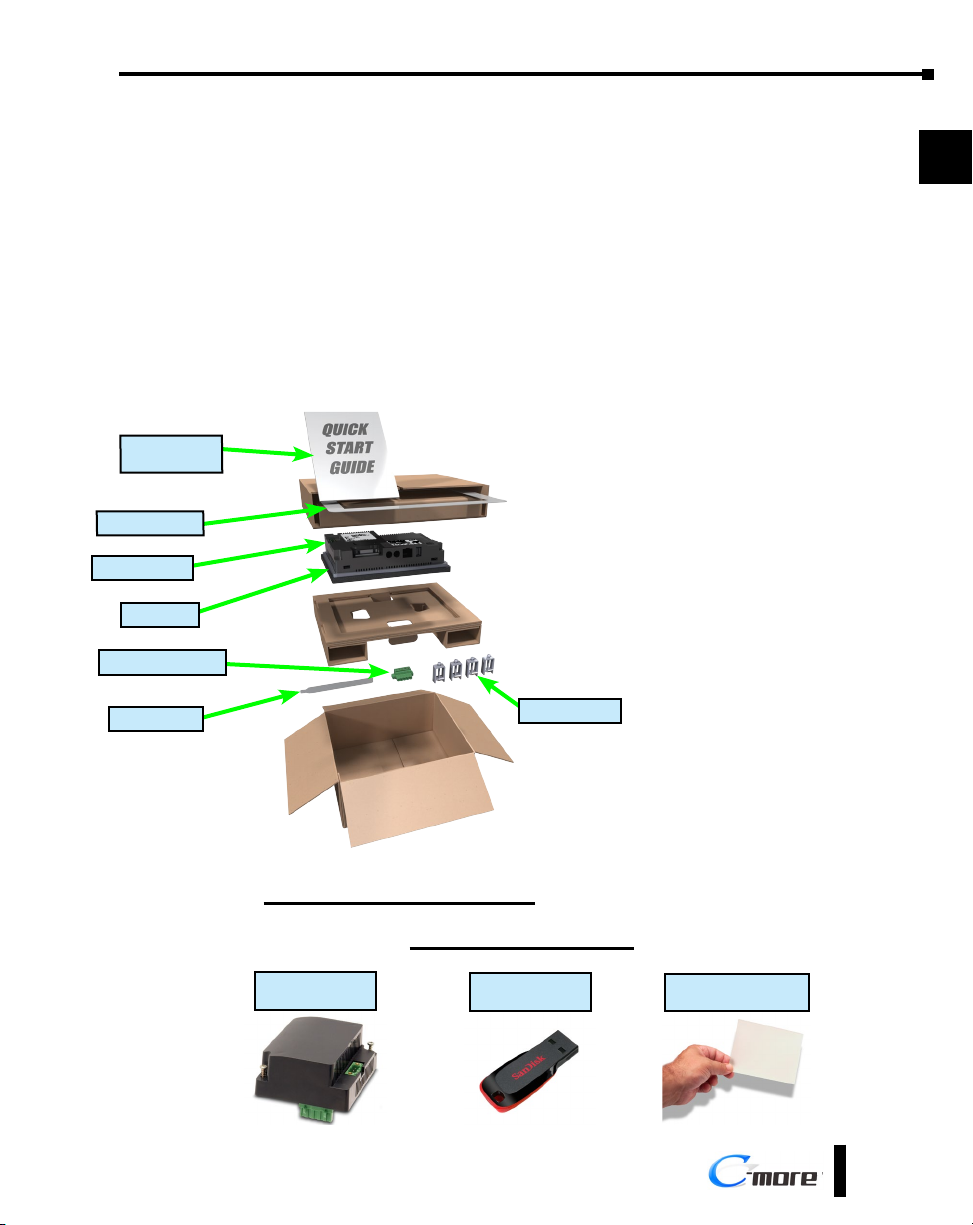

Step 1 – Unpack and Inspect

a.) Unpack the C-more Touch Panel from its shipping carton. Included in the carton are the

following:

• C-more Touch Panel

• cutout template

• mounting clips

• DC power connector

• gasket

• logo label

• Quick Start Guide

Quick Start

Guide

Cutout Template*

C-more Panel

Gasket

DC power connector

Logo Label*

Mounting Clips

b.) Unpack any accessories that have

been ordered, such as: AC/DC

Power Adapter, programming cable,

communications cable, etc.

c.) Inspect all equipment for

completeness. If anything is missing

or damaged, immediately call

the AutomationDirect® returns

department @ 1-800-633-0405.

1

2

3

4

5

6

7

8

9

10

11

*Not included with EA9-T7CL-R and EA9-T7CL.

Shipping Carton Contents

Optional Accessories

AC Power Adapter

EA-AC

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

USB Pen Drive

USB-FLASH

Protective Screen Cover

EA-x-COV2

12

13

14

A

B

C

D

®

1-5

Page 22

Chapter 1 - Getting Started

Step 2 – Install Optional Hardware Accessories

1

2

3

4

5

6

7

8

9

10

11

12

AC / DC Power Adapter

C-more Touch Panel

EA-AC

EA-COMCON-3A

DSUB Port Adapter

EA-x-COV2

Screen Protector

EA-ECOM

Expansion Module

EA-SD-CARD

SD Card

USB-FLASH

USB Pen Drive

13

14

A

B

C

D

1-6

®

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 23

Chapter 1 - Getting Started

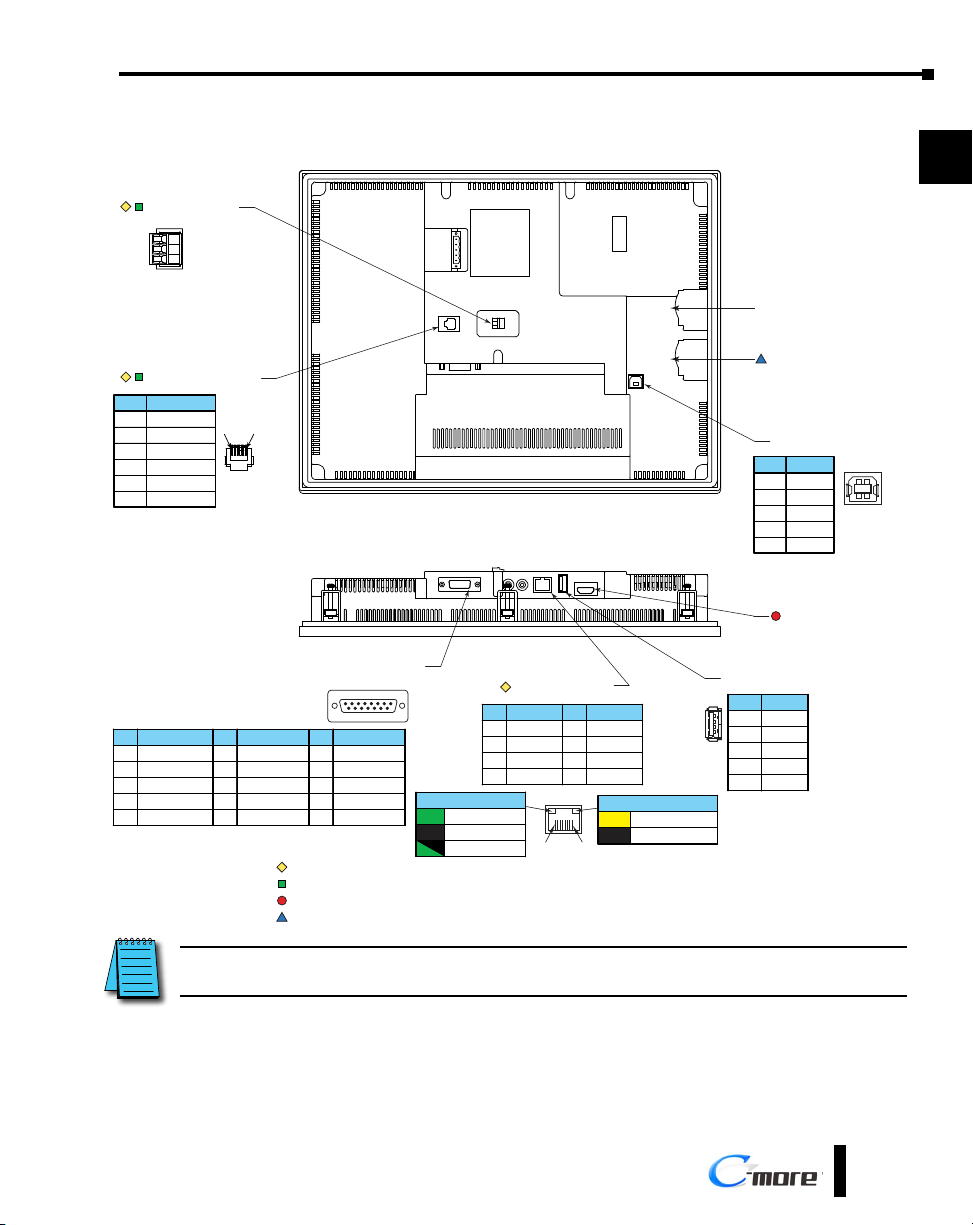

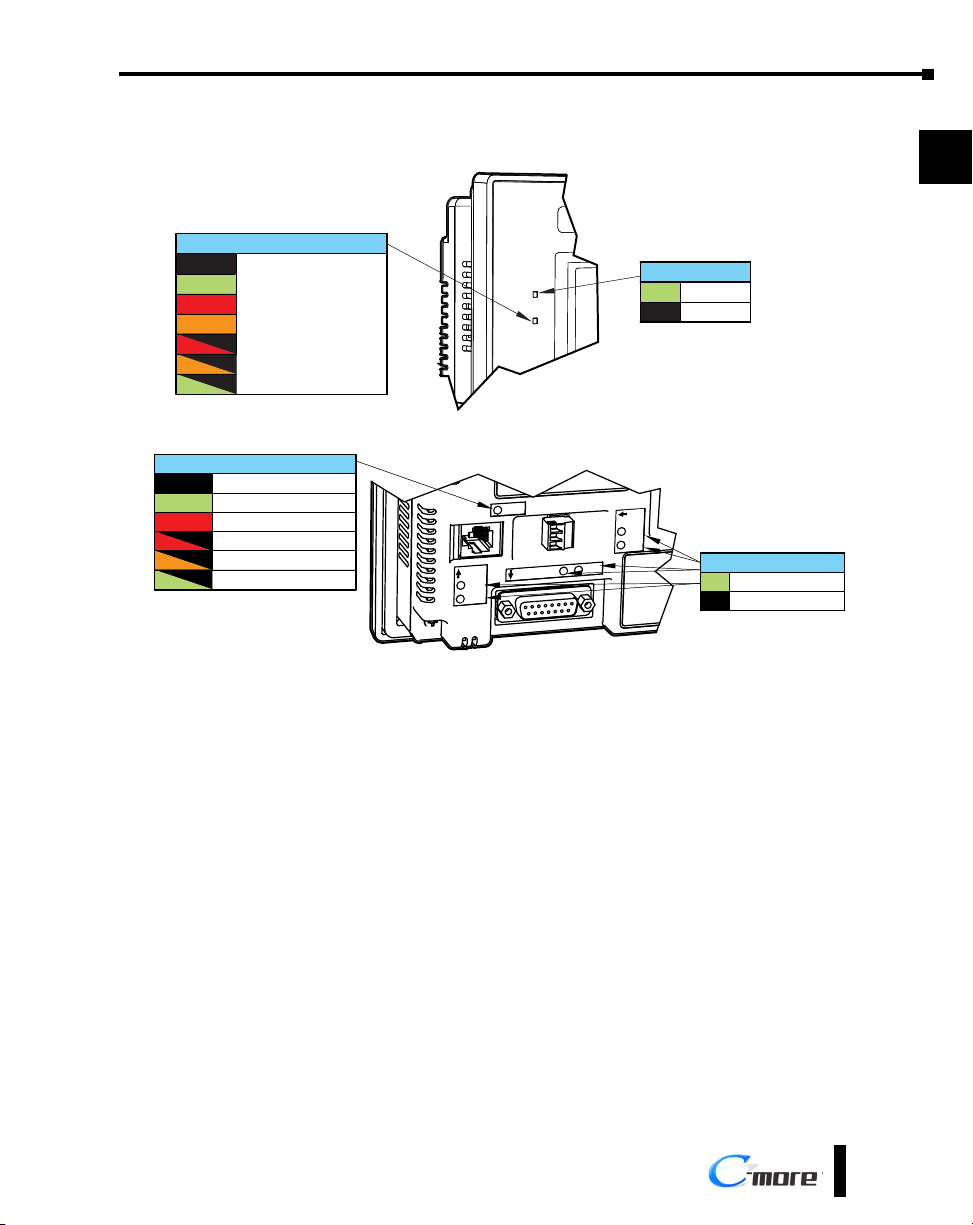

Step 3 – Become Familiar with Available Communication Ports

Port 2

Serial Communication

RS-485

+

–

Logic Ground

Port 3

RJ12 Serial Communication

1 0V

2

3

4

N.C.

RXD

TXD

N.C.5

0V6

RS-232C

1 6

Pin Signal

SD Card Slot 1

SD Card Slot 2

USB Port - Type B

Programming

Pin Signal

1 N.C.

D–

2

D+

3

GND

4

ShieldShell

1

2

3

4

5

6

1

2

3

4

7

8

Port 1

Pin Signal

1 Frame GND

TXD (232C)

2

RXD (232C)

3

Do Not Connect

4

5 Logic GND

PLC Serial Communications

RS-232C / RS-485

8 1

Pin Signal Pin Signal

6 LE (for DH485)

CTS (232C)

7

RTS (232C)

8

RXD+ (422/485)

9

10 RXD– (422/485)

15 9

11 TXD+ (422/485)

TXD– (422/485)

12

Term. Resistor

13

N.C.

14

15 N.C.

Note: Device is not available on Base Feature touch panel EA9-T6CL-R

Note: Device is not available on Base Feature touch panels EA9-T7CL-R and EA9-T15CL-R

Note: Device is only available on touch panels EA9-T12CL and EA9-T15CL.

Note: Device is only available on touch panels EA9-T12CL, EA9-T15CL and EA9-T15CL-R.

Pin Signal

Link Status LED (Green)

On Ethernet Linked

No Ethernet Comm.Off

Blinking

Comm. Activity

Green

Ethernet 10/100 Base-T

PLC Communications,

Programming/Download

1 TD+

TD–

2

RD+

3

do not use

4

1 8

Pin Signal

5 do not use

RD–

6

N.C.

7

N.C.

8

Network Speed LED (Yellow)

On 100M

10MOff

USB Port - Type A

USB Device Options

Pin Signal

4

1 Vbus

3

21

2

3

4

NOTE: See Chapter 2: Specifications and Chapter 6: PLC Communications for additional details on the available

communication ports, protocols and cables.

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

HDMI Port Video Out

D–

D+

GND

ShieldSHELL

9

10

11

12

13

14

A

B

C

D

®

1-7

Page 24

Chapter 1 - Getting Started

Step 4 – Install the Programming Software and Develop a Project

Download the latest version of the C-more Programming Software, p/n EA9-PGMSW,

1

2

3

4

5

6

7

8

from the Automationdirect website. Alternately, if the C-more Programming Software CD is

available, you may install from the software CD. Refer to the AutomationDirect website for

current minimum system requirements for installation.

For software download installation, follow the screen prompts to download and install the

C-more Programming Software.

For CD installation, insert the supplied CD into the PC’s CD drive and navigate to the CD

drive location on the PC. Double-click on EA_Setup.exe and follow the instructions. If you

need assistance during the software installation, call the AutomationDirect Technical Support

team @ 770-844-4200.

NOTES: Regarding Ethernet access to a C-more panel.

If you intend to take advantage of the methods of remote access to the panel, including the web server, PC remote

access, FTP, iOS or Android app, you need to consider the security exposure in order to minimize the risks to your

process and your C-more panel.

Security measures may include password protection, changing the ports exposed on your network, including a VPN

in your network, and other methods. Security should always be carefully evaluated for each installation. Refer to

Appendix C - Security Considerations for Control Systems Networks.

9

10

11

12

13

14

A

B

C

D

1-8

®

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 25

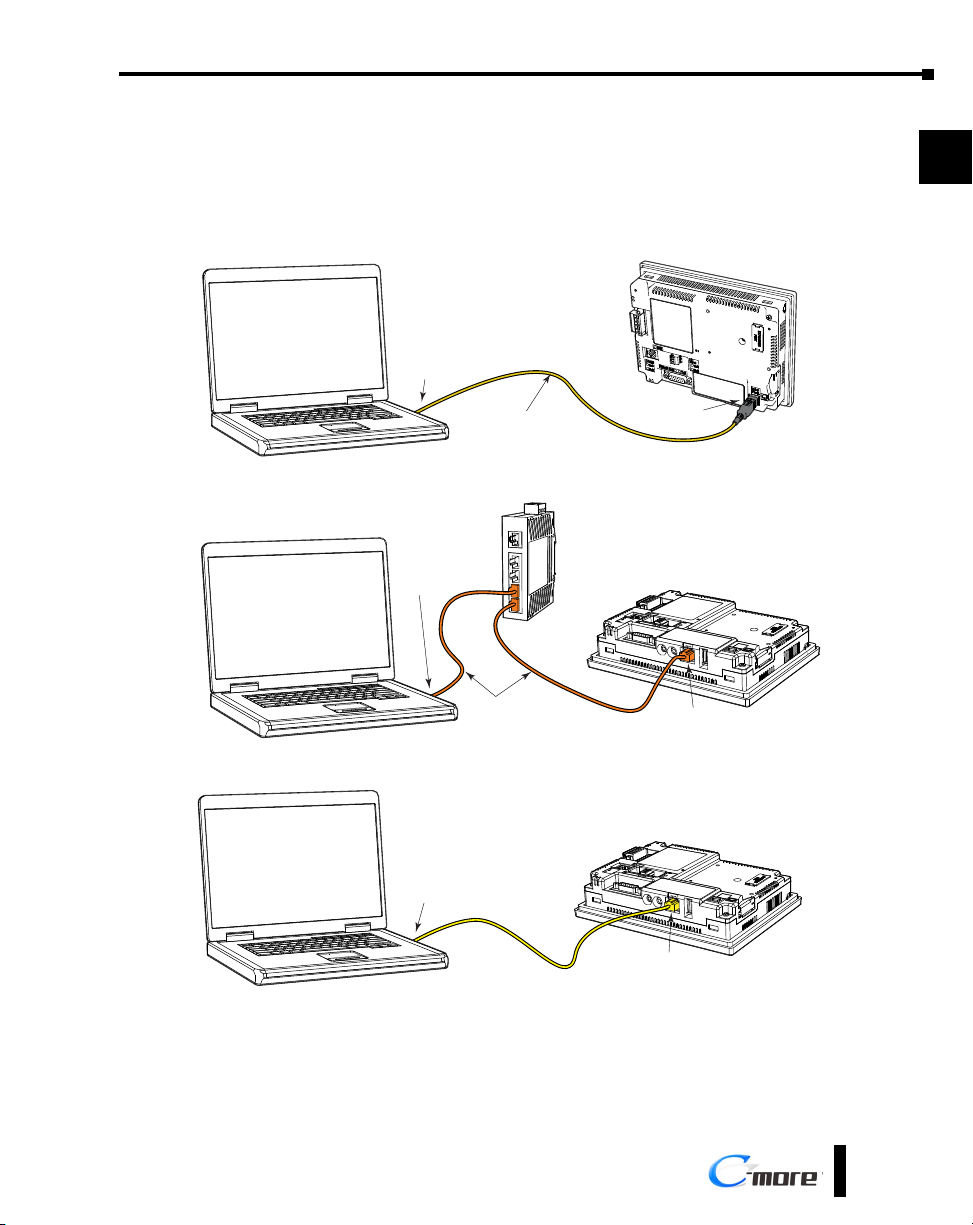

Step 5 – Connect Touch Panel to Computer

• Connect a USB Programming Cable, such as p/n USB-CBL-AB15, from a USB type A port on the

PC to the USB type B programming port on the C-more touch panel

• or connect the C-more touch panel and PC together either directly or via an Ethernet switch, and

CAT5 Ethernet cables (full feature panels only)

PC

USB

Port

USB-CBL-ABxx

USB Cable

Chapter 1 - Getting Started

C-more

Touch Panel

USB

Port

1

2

3

4

5

6

PC

PC

Ethernet

Port

Ethernet

Port

Ethernet CAT5

Cable

Ethernet CAT5

Cable

Stride™

Ethernet Switch

10/100 Base-T

(such as SE2-SW5U)

Auto MDI / MDI-X

Ethernet Port

C-more

Touch Panel

Auto MDI / MDI-X

Ethernet Port

C-more

Touch Panel

7

8

9

10

11

12

13

14

A

B

C

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

D

®

1-9

Page 26

Chapter 1 - Getting Started

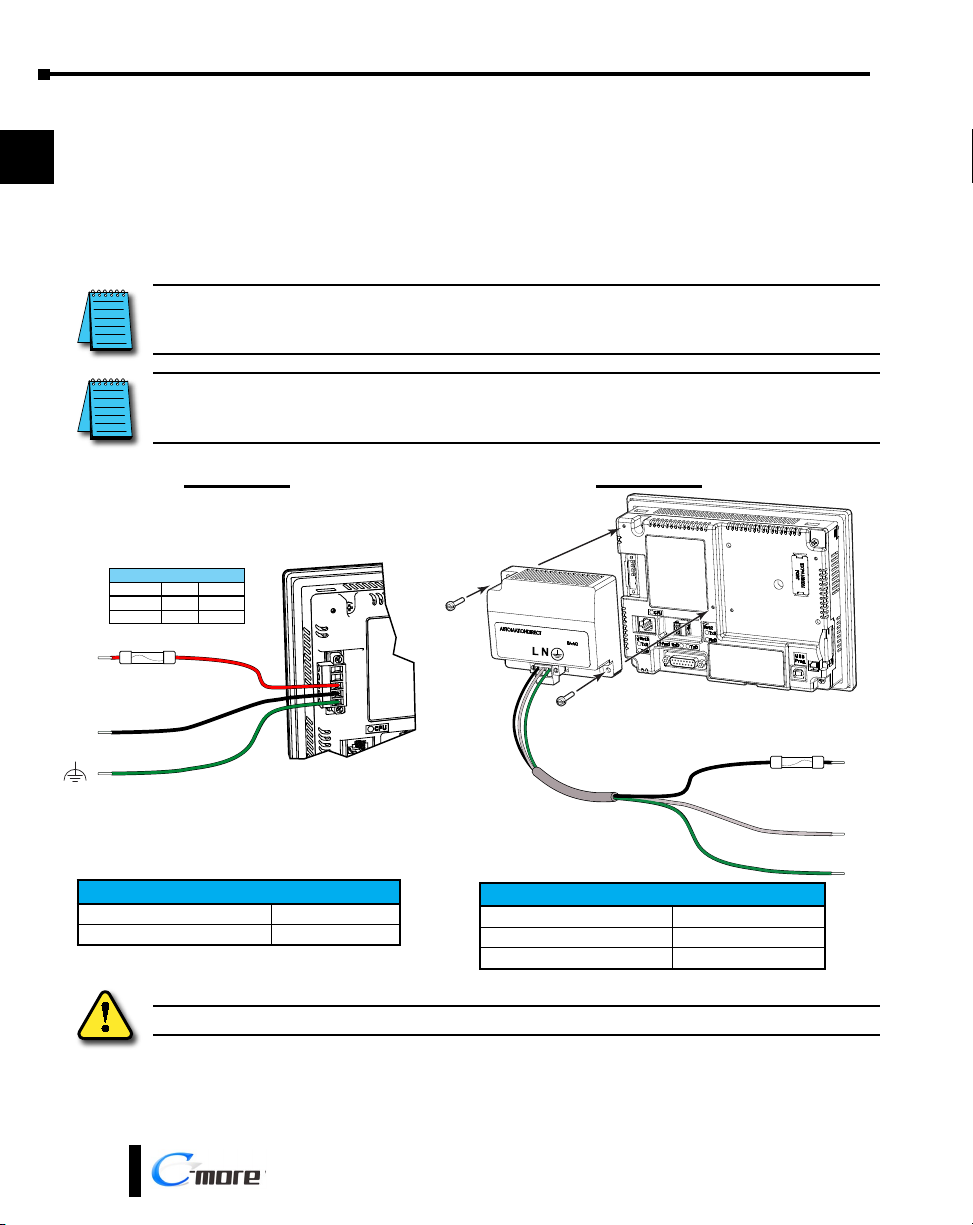

Step 6 – Provide Power to the Touch Panel

• Connect a dedicated 12-24 VDC Class 2 power supply to the DC connector on the rear of the

1

2

3

4

C-more touch panel, include wiring the ground terminal to a proper equipment ground

• or install a C-more AC/DC Power Adapter, EA-AC, to the rear of the touch panel and connect an

AC voltage source of 100-240 VAC, 50/60Hertz, to its AC connector (see note below)

• then turn on the power source and check the LED status indicators on the front and rear of the

C-more touch panel for proper indication (see next page)

NOTE: A dedicated power supply is recommended. If the power supply also feeds inductive loads such as

solenoids or relays, the transients caused by these loads can affect the operation of the panel or damage panel

components.

5

6

7

8

9

10

11

12

13

14

A

B

NOTE: The AC/DC Power Adapter, EA-AC, is for C-more touch panels only. The adapter is powered from a 100240 VAC, 50/60 Hertz power source. The adapter provides 24 VDC @ 1.5 A. Power Fault features help protect data

on an SD memory card during power failures.

DC Wiring

Recommended DC Supply Fuse

Rating ADC p/n

Panel Size

6“ – 10”

2.5 A

4.0 A

MDL2-5

MDL4

12“ & 15”

+

12-24 VDC

–

GND

Equipment

Ground

DC-CON Tightening Torque

Power connector screw torque 70.4 oz-in (0.5 Nm)

Power connector mounting torque 56 oz-in (0.4 Nm)

AC Wiring

Recommended AC Supply Fuse

3.0A time delay, ADC p/n: MDL3

100 - 240 VAC

Tightening Torque

Power supply cable torque 71 - 85 oz-in (0.5 - 0.6 Nm)

Power connector mounting torque 71 - 85 oz-in (0.5 - 0.6 Nm)

Mounting flange screw torque 57 - 71 oz-in (0.4 - 0.5 Nm)

L

50 / 60 Hz

N

G

C

D

1-10

Warning: Use 60 / 75 °C copper conductors only.

®

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 27

Step 6 – Provide Power to the Touch Panel (cont’d)

C-more LED Status Indicators

Chapter 1 - Getting Started

1

User Defined LED (Green, Orange & Red)

Off

Green

Red

Orange

Blinking

Red

Blinking

Orange

Blinking

Green

CPU Status LED (Green, Orange & Red)

Off Power Off

Normal – CPU Run StateGreen

Red Memory Error

Blinking

Watchdog Timer Error

Red

Blinking

OS Error

Orange

Blinking

Power Loss Detection

Green

User Defined

(Refer to online help

file for further details)

Front View

Port3

TxD

RxD

Rear View

CPU

Port1

RxD

TxD

Power LED (Green)

On Power On

Port2

TxD

RxD

Power OffOff

Serial TxD/RxD LED (Green)

On Comm. is active

No communicationOff

2

3

4

5

6

7

8

9

10

11

12

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

®

13

14

A

B

C

D

1-11

Page 28

Chapter 1 - Getting Started

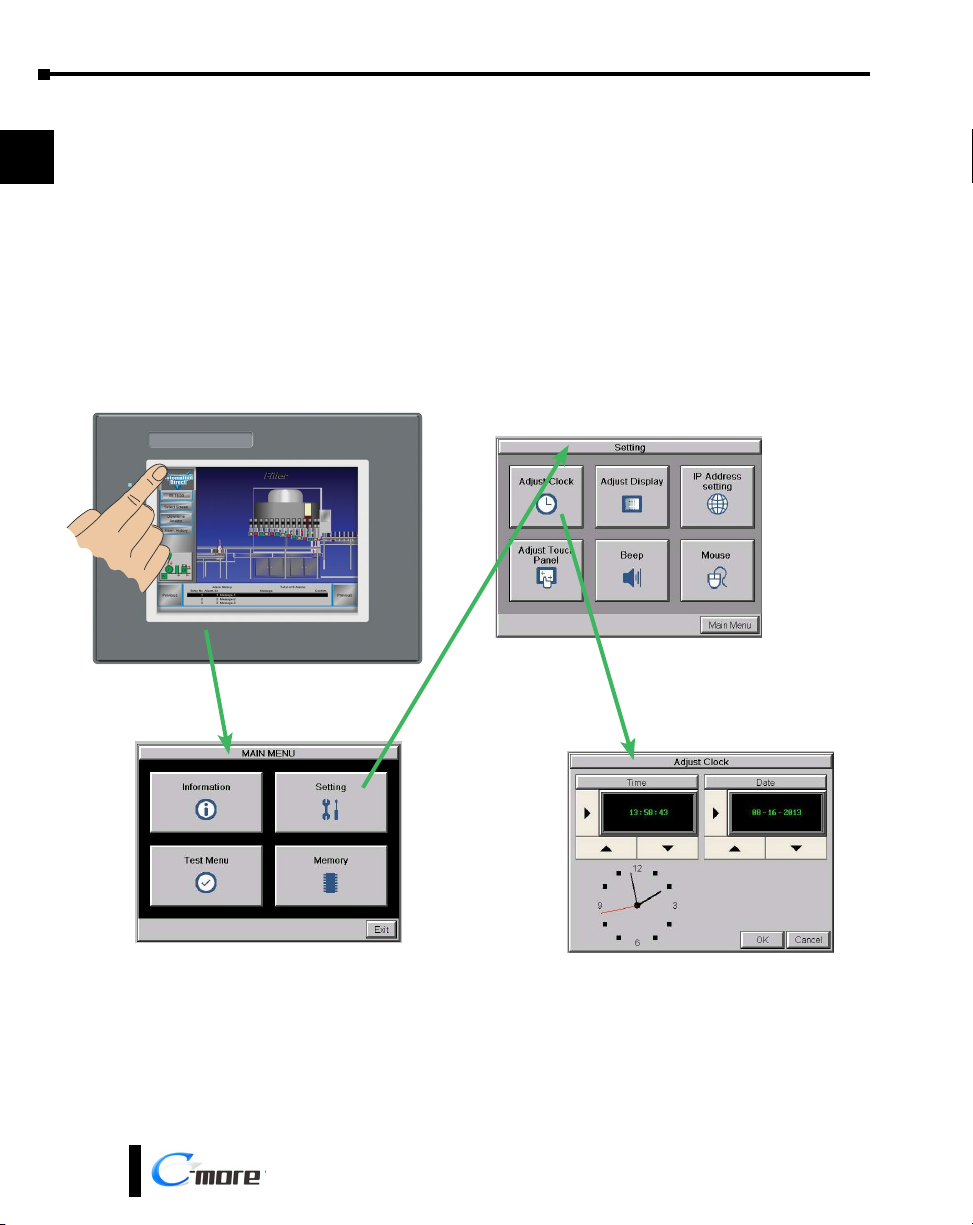

Step 7 – Access the Touch Panel Setup Screens

• Access the Main Menu of the touch panel System Setup Screens by pressing the extreme upper left

1

2

3

4

5

corner of the panel display area for three (3) seconds as shown below.

• Adjust the time and date for the panel by pressing the Setting button on the Main Menu, then press

the Adjust Clock button on the Setting screen.

• Use the right pointing arrows for the time or date display to select the unit to change. Use the up

and down arrows to increment or decrement the value for the selected unit.

• Press OK when done to accept the changes to the time and date in the touch panel or press Cancel

to exit the Adjust Clock setup screen without making any changes.

• Press the Main Menu button on the Setting screen and then the Exit button on the Main Menu

screen to return to the application screen.

6

7

8

9

10

11

12

13

14

A

B

C

D

®

1-12

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 29

Chapter 1 - Getting Started

Step 8 – Choose Touch Panel to Device Cables

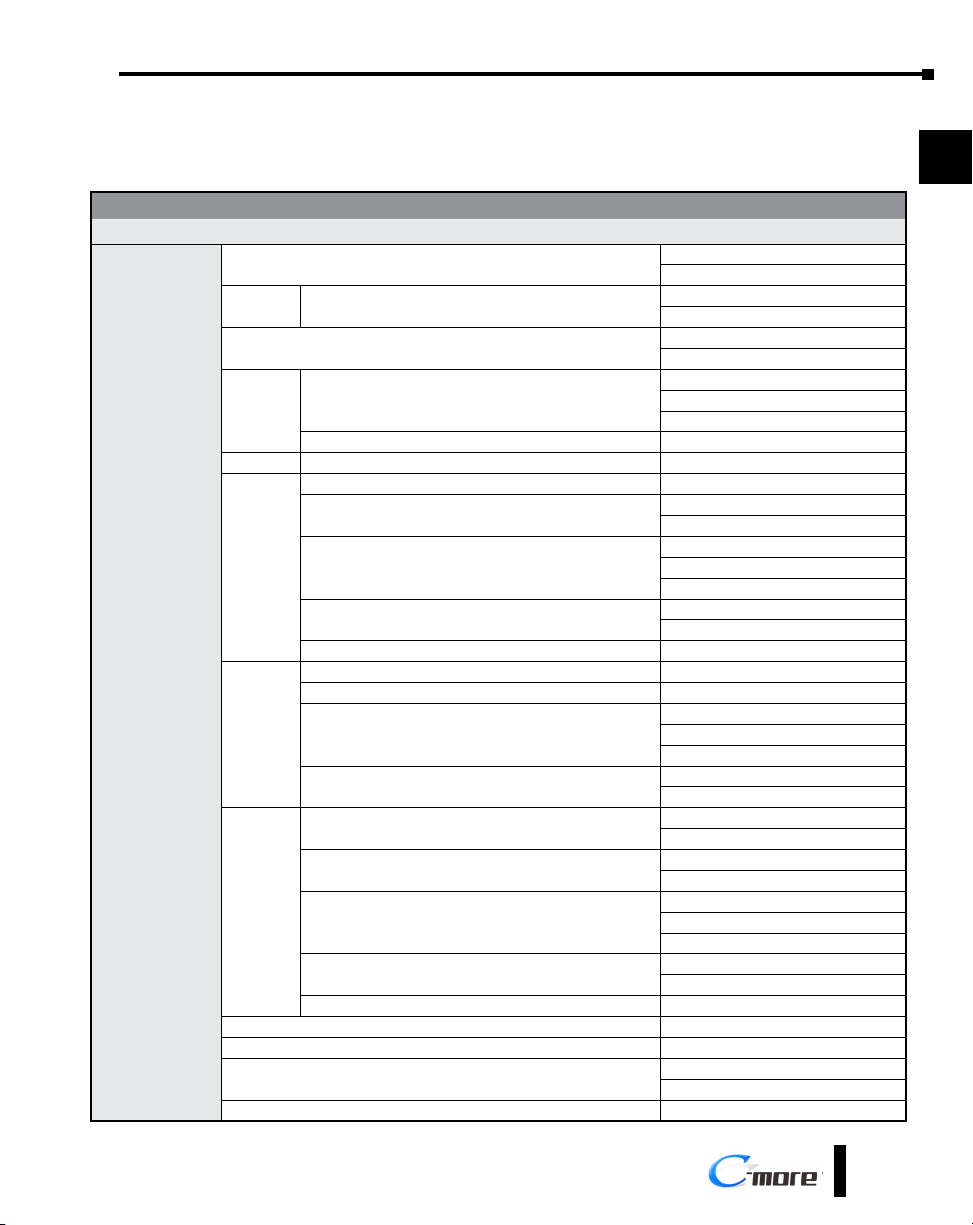

The table below shows the PLCs, controllers and protocols supported by the EA9-RHMI.

Ensure your controller and protocol are supported.

1

PLC Protocol Table

Model Protocols

Productivity Serial

Productivity Ethernet

Do-more Serial

Do-more Ethernet

Modbus (CLICK addressing)

Modbus TCP (CLICK addressing)

K-Sequence

Direct NET

Modbus (Koyo addressing)

K-Sequence

Direct NET

K-Sequence

Direct NET

Modbus (Koyo addressing)

Direct NET

Modbus (Koyo addressing)

K-Sequence

Direct NET

Modbus (Koyo addressing)

Direct NET

Modbus (Koyo addressing)

K-Sequence

Direct NET

K-Sequence

Direct NET

K-Sequence

Direct NET

Modbus (Koyo addressing)

Direct NET

Modbus (Koyo addressing)

GS Drives Serial

GS Drives TCP/IP (GS-EDRV)

AutomationDirect

Productivity Series

Do-more

(BRX)

CLICK

DL05/DL06

DL105 all K-Sequence

DL205

DL305

DL405

H2-WinPLC (Think & Do) Live V5.2 or later and Studio any version Think & Do Modbus RTU (serial port)

H2-WinPLC (Think & Do) Live V5.5.1 or later and Studio V7.2.1 or later Think & Do Modbus TCP/IP (Ethernet port)

GS Drives

SOLO Temperature Controllers (models with serial communications) SOLO Temperature Controller

all

all

H0-ECOM/H0-ECOM100 Direct LOGIC Ethernet

D2-230 K-Sequence

D2-240

D2-250/D2-250-1/D2-260/D2-262

D2-240/D2-250-1/D2-260

Using DCM

H2-ECOM/H2-ECOM100 Direct LOGIC Ethernet

D3-330/330P (Requires the use of a Data Communications Unit) Direct NET

D3-340 Direct NET

D3-350

D3-350 DCM

D4-430

D4-440

D4-450/D4-454

All with DCM

H4-ECOM/H4-ECOM100 Direct LOGIC Ethernet

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

®

1-13

Page 30

Chapter 1 - Getting Started

Step 8 – Choose Touch Panel to Device Cables (cont’d)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

PLC Protocol Table (cont’d)

Model Protocols

MicroLogix 1000, 1100, 1200, 1400, 1500, SLC 5-01/02/03 DH485/AIC/AIC+

MicroLogix 1000, 1100, 1200, 1400 and 1500

DF1 Half Duplex; DF1 Full DuplexSLC 5-03/04/05

ControlLogix™, CompactLogix™, FlexLogix™

PLC-5 DF1 Full Duplex

ControlLogix, CompactLogix, FlexLogix - Tag Based DF1 Half Duplex; DF1 Full Duplex

Allen-Bradley

Modbus RTU

Modbus TCP/IP

GE

Mitsubishi

Modicon

Omron

Siemens

ControlLogix, CompactLogix, FlexLogix - Generic I/O Messaging EtherNet/IP Server

ControlLogix, CompactLogix, FlexLogix - Tag Based

EtherNet/IP ClientMicroLogix 1100, 1400 and SLC 5/05, via native Ethernet port

MicroLogix 1000, 1100, 1200, 1400, 1500, SLC 5-03/04/05, all via ENI adapter

Micro 800 Series

Micro 800 Series - Tag Based

Modbus RTU devices Modbus RTU

Modbus TCP/IP devices Modbus TCP/IP

90/30, 90/70, Micro 90, VersaMax Micro SNPX

90/30, Rx3i SRTP Ethernet

FX Series FX Direct

Q02, Q02H, Q06H, Q12H, Q25H Q CPU

Q, QnA Serial QnA Serial

Q, QnA Ethernet QnA Ethernet

984 CPU, Quantum 113 CPU, AEG Modicon Micro Series 110 CPU: 311-xx, 411-xx,

512-xx, 612-xx

Other devices using Modicon Modbus addressing

C200 Adapter, C500 Host Link

CJ1/CS1 Serial

CJ1/CS1 Ethernet

S7-200 CPU, RS-485 Serial PPI

S7-200 CPU, S7-300 CPU, S7-400, S7-1200, S7-1500 CPU

Ethernet

Modbus RTU

Modbus TCP

DF1 Full Duplex

EtherNet/IP Client

Modbus RTU

Modbus RTU

TUModbus TCP/IP

FINS

Ethernet ISO over TCP

C

D

1-14

®

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 31

Chapter 1 - Getting Started

Step 8 – Choose Touch Panel to Device Cables (cont’d)

Available cables to connect from PLC to C-more serial Port 1

To use Serial communication through Port 1 of a C-more panel, consult the chart below for

the proper cable. See Chapter 6: PLC Communications for wiring diagrams of additional user

contructed cables.

Purchased Cable

Description

AutomationDirect Productivity Series, Do-more, CLICK,

Direct LOGIC PLC RJ-12 port, DL05, DL06, DL105,

DL205, D3-350, D4-450 & H2-WINPLC (RS-232C)

Cable

Part Number

EA-2CBL

1

2

3

4

Direct LOGIC (VGA Style) 15-pin port

DL06, D2-250 (250-1), D2-260 (RS-232C)

Direct LOGIC PLC RJ-11 port, D3-340 (RS-232C)

Direct LOGIC DL405 PLC 15-pin D-sub port,

DL405 (RS-232C)

Direct LOGIC PLC 25-pin D-sub port, DL405, D3-350,

DL305 DCU and all DCM’s (RS-232C)

Allen-Bradley MicroLogix 1000, 1100, 1200, 1400,

1500 (RS-232C)

Allen-Bradley SLC 5-03/04/05, ControlLogix,

CompactLogix, FlexLogix DF1 port (RS-232C)

Allen-Bradley PLC-5 DF1 port (RS-232C)

Allen-Bradley SLC 5-01/02/03, PLC5

DH485 port

GE 90/30, 90/70, Micro 90, VersaMax Micro

15-pin D-sub port (RS-422A)

MITSUBISHI FX Series 25-pin port (RS-422A)

MITSUBISHI FX Series 8-pin mini-DIN (RS-422A)

OMRON Host Link (C200 Adapter, C500) (RS-232C)

NOTE: The above list of pre-made communications cables may be purchased. See Chapter 6: PLC

Communications for wiring diagrams of additional user constructed cables. Chapter 6 also includes wiring diagrams

for the pre-made cables.

EA-2CBL

EA-2CBL-1

EA-3CBL

EA-4CBL-1

EA-4CBL-2

EA-MLOGIX-CBL

EA-SLC-232-CBL

EA-PLC5-232-CBL

EA-DH485-CBL

EA-90-30-CBL

EA-MITSU-CBL

EA-MITSU-CBL-1

EA-OMRON-CBL

EA-2CBL-1

5

6

7

8

9

10

11

12

13

14

A

Pre-made cable

examples

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

B

C

D

®

1-15

Page 32

Chapter 1 - Getting Started

Step 9 – Connect Touch Panel to PLC

• Connect the serial communications cable between the C-more touch panel and the PLC

1

2

• or connect the C-more touch panel and PLC together either directly or via an Ethernet switch, and

CAT5 Ethernet cables (full feature panels only)

For further information on setting up communications between a C-more panel and a PLC, see the

C-more programming help file topic CM129: Creating a New Project.

3

4

5

6

Serial

DL-06 PLC

C-more

Touch Panel

7

8

9

10

11

12

13

14

A

B

C

D

Port 2

Ethernet via Switch

H0-ECOM/H0-ECOM100

Ethernet Module

DL06 PLC

Ethernet

H0-ECOM/H0-ECOMM100

Ethernet Module

DL06 PLC

EA-2CBL-1

Stride™

Ethernet Switch

10/100 Base-T

(such as SE2-SW5U)

Ethernet CAT5

Cable

Ethernet CAT5

Cable

Port 1

C-more

Touch Panel

Auto MDI / MDI-X

Ethernet Port

C-more

Touch Panel

Auto MDI / MDI-X

Ethernet Port

1-16

®

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 33

Chapter

Chapter

Chapter

SpecificationS

2

2

2

In This Chapter...

Available Models ............................................................................................................2-4

Model Specifications .....................................................................................................2-5

Specifications common to all models ���������������������������������������������������������������������������2-6

6-inch Models ��������������������������������������������������������������������������������������������������������������2-7

7-inch Models ��������������������������������������������������������������������������������������������������������������2-8

8-inch and 10-inch Models ������������������������������������������������������������������������������������������2-9

12-inch and 15-inch Models ��������������������������������������������������������������������������������������2-10

EA9-T6CL-R, EA9-T6CL .................................................................................................2-11

Dimensions, Inches [mm] �������������������������������������������������������������������������������������������2-11

Ports and Memory Expansion �������������������������������������������������������������������������������������2-12

EA9-T7CL-R, EA9-T7CL .................................................................................................2-13

Dimensions, Inches [mm] �������������������������������������������������������������������������������������������2-13

Ports and Memory Expansion �������������������������������������������������������������������������������������2-14

EA9-T8CL ......................................................................................................................2-15

Dimensions, Inches [mm] �������������������������������������������������������������������������������������������2-15

Ports and Memory Expansion �������������������������������������������������������������������������������������2-16

EA9-T10CL ....................................................................................................................2-17

Dimensions, Inches [mm] �������������������������������������������������������������������������������������������2-17

EA9-T10WCL ................................................................................................................2-18

Dimensions, Inches [mm] �������������������������������������������������������������������������������������������2-18

Ports and Memory Expansion �������������������������������������������������������������������������������������2-19

Page 34

Chapter

Chapter

Chapter

SpecificationS

2

2

2

EA9-T12CL ................................................................................................................... 2-20

Dimensions, Inches [mm] ������������������������������������������������������������������������������������������ 2-20

Ports and Memory Expansion ������������������������������������������������������������������������������������ 2-21

EA9-T15CL-R, EA9-T15CL ............................................................................................ 2-22

Dimensions, Inches [mm] ������������������������������������������������������������������������������������������ 2-22

Ports and Memory Expansion ������������������������������������������������������������������������������������ 2-23

Mounting Clearances .................................................................................................2-25

EA9-T15CL-R, EA9-T15CL Derating ���������������������������������������������������������������������������2-26

Communications Ports ...............................................................................................2-27

Handling External Memory Devices ...........................................................................2-30

Writing to External Memory Devices �������������������������������������������������������������������������2-30

Memory Device Formatting ���������������������������������������������������������������������������������������2-30

Minimizing Data Errors ���������������������������������������������������������������������������������������������� 2-31

Monitoring Available Memory ���������������������������������������������������������������������������������� 2-31

File Name Limitations ������������������������������������������������������������������������������������������������ 2-32

Power Loss Retention ������������������������������������������������������������������������������������������������2-32

Chemical Compatibility ..............................................................................................2-32

Page 35

This page intentionally left blank

Page 36

Chapter 2 - Specifications

Available Models

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

Part

Number

EA9-T6CL-R

EA9-T6CL

EA9-T7CL-R

EA9-T7CL

EA9-T8CL

EA9-T10CL

EA9-T10WCL

EA9-T12CL

EA9-T15CL-R

EA9-T15CL

The C-more® Operator Interface is the next generation of touch panel brought to you by

AutomationDirect. It has been designed to display and interchange graphical data from a

PLC by merely viewing or touching the screen.

The C-more Touch Panel is available in a variety of models to suit your application. Refer to

the following tables for a list of part numbers, descriptions and options available.

HDMI

Video

Out

Description

C-more EA9 series touch screen HMI, 6in color TFT LCD,

320 x 240 pixel, QVGA, LED backlight, supports (1) serial

and (2) USB ports and (1) memory card slot.

C-more EA9 series touch screen HMI, 6in color TFT LCD,

320 x 240 pixel, QVGA, LED backlight, supports (3) serial,

(1) Ethernet and (2) USB ports, (1) memory card slot and

(1) audio line out.

C-more EA9 series touch screen HMI, 7in color TFT

LCD, widescreen, 800 x 480 pixel, WVGA, LED backlight,

supports (1) serial, (1) Ethernet and (2) USB ports and (1)

memory card slot.

C-more EA9 series touch screen HMI, 7in color TFT

LCD, widescreen, 800 x 480 pixel, WVGA, LED backlight,

supports (3) serial, (1) Ethernet and (2) USB ports, (1)

memory card slot and (1) audio line out.

C-more EA9 series touch screen HMI, 8in color TFT LCD,

800 x 600 pixel, SVGA, LED backlight, supports (3) serial,

(1) Ethernet and (2) USB ports, (1) memory card slot and

(1) audio line out.

C-more EA9 series touch screen HMI, 10in color TFT LCD,

800 x 600 pixel, SVGA, LED backlight, supports (3) serial,

(1) Ethernet and (2) USB ports, (1) memory card slot and

(1) audio line out.

C-more EA9 series touch screen HMI, 10in color TFT LCD,

widescreen, 1024 x 600 pixel, WSVGA, LED backlight,

supports (3) serial, (1) Ethernet and (2) USB ports, (1)

memory card slot and (1) audio line out.

C-more EA9 series touch screen HMI, 12in color TFT LCD,

800 x 600 pixel, SVGA, LED backlight, supports (3) serial,

(1) Ethernet and (2) USB ports, (2) memory card slots, (1)

HDMI video out and (1) audio line out.

C-more EA9 series touch screen HMI, 15in color TFT LCD,

1024 x 768 pixel, XGA, LED backlight, supports (1) serial,

(1) Ethernet port and (2) USB ports and (2) memory card

slots.

C-more EA9 series touch screen HMI, 15in color TFT LCD,

1024 x 768 pixel, XGA, LED backlight, supports (3) serial,

(1) Ethernet and (2) USB ports, (2) memory card slots, (1)

HDMI video out and (1) audio line out.

Project

Memory

SD Card

Option

26 MB 1 slot Yes No No

26 MB 1 slot Yes Yes No

26 MB 1 slot Yes Yes No

26 MB 1 slot Yes Yes No

26 MB 1 slot Yes Yes No

26 MB 1 slot Yes Yes No

26 MB 1 slot Yes Yes No

82 MB 2 slots Yes Yes Yes

82 MB 2 slots Yes Yes No

82 MB 2 slots Yes Yes Yes

USB

Device

Ethernet

2-4

®

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 37

Model Specifications

The following specification tables are separated into these groups:

• Specifications common to all models

• 6” & 7” Reduced and Full Feature Models, EA9-T6CL-R, EA9-T6CL, EA9-T7CL-R and

EA9-T7CL

• 8” & 10” Full Feature Models, EA9-T8CL, EA9-T10CL and EA9-T10WCL

• 12” & 15” Reduced and Full Feature Models, EA9-T12CL, EA9-T15CL-R and EA9-T15CL

Chapter 2 - Specifications

1

2

3

Specification tables begin on the next page.

4

5

6

7

8

9

10

11

12

13

14

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

A

B

C

D

®

2-5

Page 38

Chapter 2 - Specifications

Specifications common to all models

1

Specification

Operating Temperature

2

Altitude

3

Storage Temperature

4

Humidity

Environment

5

6

Noise Immunity

7

Model

All Models

0 to 50 °C (32 to 122 °F); Maximum surrounding air temperature rating: 50 °C (122 °F)

IEC 60068-2-14 (Test Nb, Thermal Shock)

Up to 2000m (6562 ft)

–20 to +60 °C (–4 to +140 °F)

IEC 60068-2-1 (Test Ab, Cold)

IEC 60068-2-2 (Test Bb, Dry Heat)

IEC 60068-2-14 (Test Na, Thermal Shock)

5–95% RH (non-condensing)

For use in Pollution Degree 2 environment, no corrosive gases permitted

(EN61131-2)

EN61000-4-2 (ESD),

EN61000-4-3 (RFI)

EN61000-4-4 (FTB)

EN61000-4-5 (Serge)

EN61000-4-6 (Conducted)

EN61000-4-8 (Power frequency magnetic field immunity)

8

9

10

11

12

13

14

A

B

C

D

Withstand Voltage

Insulation Resistance

Vibration

Shock

Emission

Enclosure

Backlight Average Lifetime*

Touch Panel Type**

Supply Power

* NOTE: The backlight average lifetime is defined as the average usage time it takes before the brightness becomes

50% of the initial brightness. The lifetime of the backlight depends on the ambient temperature. The lifetime will

decrease under low or high temperature usage.

** NOTE: The Touchscreen is designed to respond to a single touch. If it is touched at multiple points at the same

time, an unexpected object may be activated.

RFI, (145MHz, 440Mhz 10W @ 10cm)

1000 VAC, 1 min. (FG to Power supply )

> 10M ohm @ 500V DC (FG to Power supply )

EN55011 Class A (Radiated RF emission)

NEMA 250 type 4/4X indoor use only

10.2-26.4VDC Class2 or SELV (Safety Extra-Low Voltage) Circuit or Limited Energy Circuit

(LEC) or use the AC/DC Power Adapter, EA-AC, to power the touch panel from a 100-240 VAC,

50/60 Hz power source. Reverse Polarity Protected

(Local Test)

Impulse 1000V @ 1µs pulse

IEC60068-2-6 (Test Fc)

IEC60068-2-27 (Test Ea)

UL50 type 4X indoor use only

IP-65 indoor use only

(When mounted correctly)

50,000 hours @ 25 °C

Four-wire analog resistive

2-6

®

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

Page 39

6-inch Models

Model

Specification

Part Number

Display Actual Size and Type

Display Viewing Area

Weight

Screen Pixel

Display Brightness

LCD Panel Dot Pitch

Color Scale

Project Memory

Number of Screens

Realtime Clock

Calendar Month / Day / Year

Serial Port 1

Serial Port 2

Serial Port 3

USB Port - Type B

USB Port - Type A

Ethernet Port

Audio Line Out

Mic In (future)

SD Card Slot

HDMI Video Out

Power Consumption

Internal Fuse

(non-replaceable)

Agency Approvals

Chapter 2 - Specifications

6” TFT color w/

base features

EA9-T6CL-R EA9-T6CL

5.7” TFT color

4.54” x 3.40”

[115.2 mm x 86.4 mm]

1.56 lb (710g) 1.59 lb (720g)

320 x 240 (QVGA)

280 nits (typ)

0.18 mm x 0.18 mm

65,536

26 MB

Up to 999 screens – limited by project memory

Realtime Clock Built into panel, backed up for 30 days at 25°C after power has been applied for

Yes - monthly deviation 60 sec at 25°C

15-pin D-sub female - RS2342C, RS-422/485

N/A 3-wire terminal block - RS-485

N/A RJ-12 modular jack - RS-232C

USB 2.0 High speed (480 Mbps) Type B - Download/Program

USB 2.0 High speed (480 Mbps) Type A - for USB device options

Bus Power – Less than 200mA at 5VDC

N/A

N/A

N/A

1 slot. Supports max 2 GB (SD,) max 32 GB (SDHC)

UL61010 (E157382), CE (EN61131-2) Class 1, Div 2, Groups A, B, C,

CUL Canadian C22.2, RoHS (2011/65/EU)

24 hours

Max cable length - 15 ft.

Max cable length - 15ft

Ethernet Port Ethernet 10/100 Base-T, auto

3.5 mm mini jack: 3-pin – requires amplifier

and speaker(s), Full Scale Output: 1.0 Vrms

3.5 mm mini jack: 2pin, Input: 100 mVrms,

N/A

16.0W

1.30A @ 12 VDC

0.66A @ 24 VDC

4A

6” TFT color w/

full features

MDI/MDI-X

Impedance: <10kOhms

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

EA9-USER-M Hardware User Manual, 1st Ed. Rev. N

®

2-7

Page 40

Chapter 2 - Specifications

7-inch Models

1

Specification

Part Number

2

Display Actual Size and Type

Display Viewing Area

3

Weight

4

Screen Pixel

Display Brightness

5

LCD Panel Dot Pitch

Color Scale

6

Project Memory

Number of Screens

7

Realtime Clock

8

Calendar Month / Day / Year

Serial Port 1

9

Serial Port 2

10

11

Serial Port 3

USB Port - Type B

USB Port - Type A

12

Ethernet Port

13

14

Audio Line Out

Mic In (future)

SD Card Slot

HDMI Video Out

A

Power Consumption

B

Internal Fuse

(non-replaceable)

C