Page 1

Digital Panel Meter

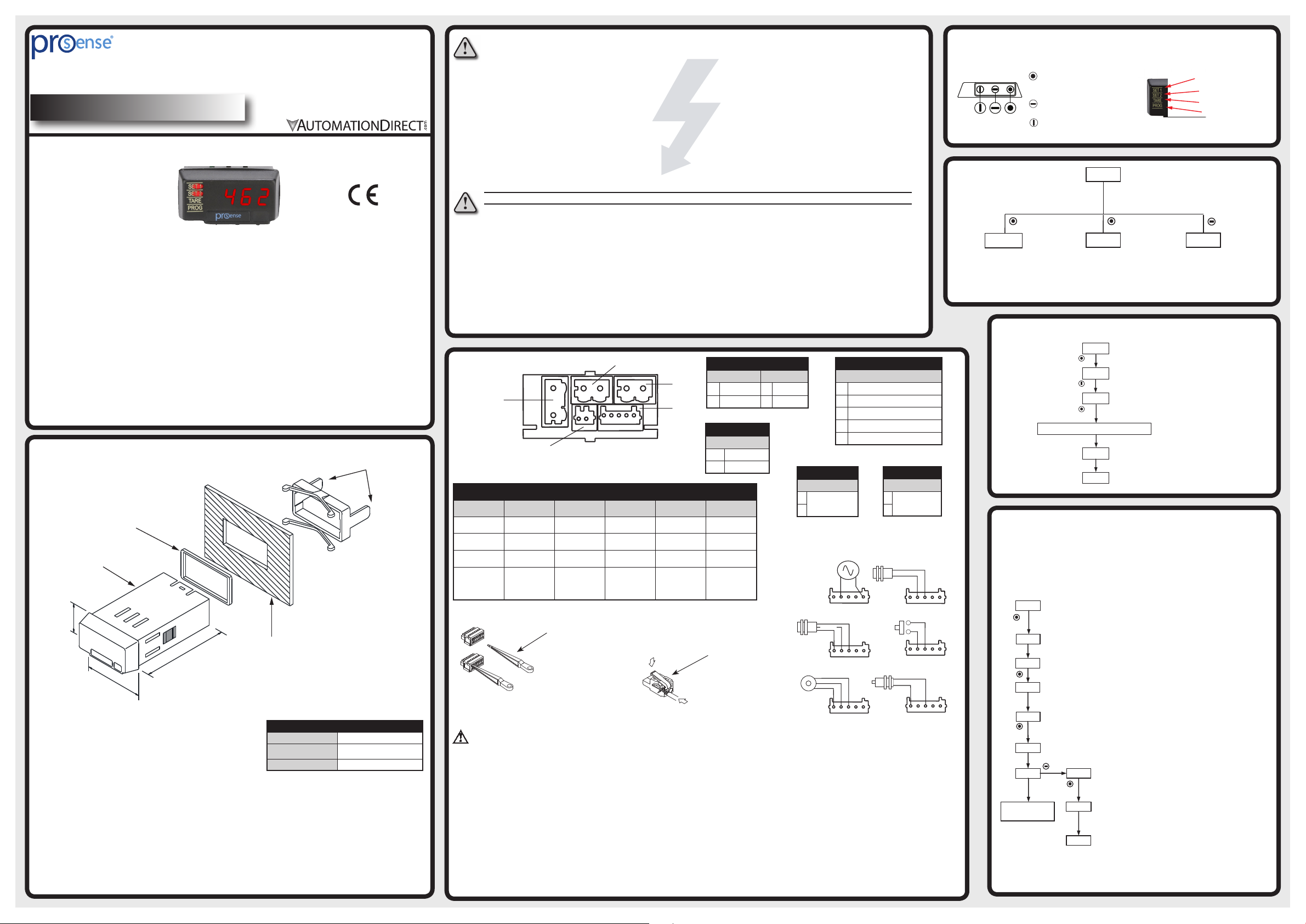

CN4

(1

DPM1-P Series

Quick Start Guide

3505 HUTCHINSON ROAD

Models:

DPM1-P-A2R-H

DPM1-P-A2R-L

This Quick Start Guide provides basic information for configuring the ProSense DPM1-P series digital

panel meters. For more specific information and advanced configuration instructions please visit

www.AutomationDirect.com and download the free instruction manual for the DPM1-P series.

Features

• 48 x 24mm 1/32 DIN

• 4 digit (0 to 9999) red LED display

• Selectable decimal point

• Frequency/Tachometer/Rate/PWM Modes

- AC voltage

- Magnetic sensor

- NAMUR sensor

- NPN/PNP sensor

- TTL/24V encoder

- Switched contact

• AC or DC powered

• Sensor excitation voltage

• (2) Form A SPST normally open relays

Activation on increasing or decreasing input

signal

Hysteresis or time delay operation

• 0/4-20mA analog output

• Total or selective configuration lock out

• Minimum and maximum value memory

• Display brightness adjustment

Dimensions and Mounting

Sealing gasket

DPM1 Meter

24mm

Panel mounting surface

100mm

48mm

To install the instrument, prepare a 45mm x 22mm panel

cut-out and slide the unit inwards making sure to place the

sealing gasket between the front side panel and the front

bezel.

While holding the unit in place, put the fixing clip around

Dimensions

Panel Cutout

Case Material

CUMMING, GA 30040-5860

Fixing clip

Installation

48 x 24 x 100mm (1/32 DIN)

45 x 22mm

(Max. panel thickness 7mm)

Polycarbonate UL 94 V-0

WARNING: To minimize the risk of potential safety problems, you should follow all applicable local

and national codes that regulate the installation and operation of your equipment. These codes vary

from area to area and it is your responsibility to determine which codes should be followed, and to

verify that the equipment, installation, and operation are in compliance with the latest revision of

these codes.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable

codes and standards. We do not guarantee the products described in this publication are suitable for

your particular application, nor do we assume any responsibility for your product design, installation,

or operation.

If you have any questions concerning the installation or operation of this equipment, or if you need

additional information, please call us at 1-800-633-0405 or 770-844-4200.

This publication is based on information that was available at the time it was printed. At

Automationdirect.com® we constantly strive to improve our products and services, so we reserve the

right to make changes to the products and/or publications at any time without notice and without

obligation. This publication may also discuss features that may not be available in certain revisions of

the product.

WARNING! Electric shock danger

1. Keep away from high-voltage and high-frequency environment during the installation to prevent interference.

Avoid using the device in environments which contain: (a) dust or corrosive gas; (b) high humidity or high

radiation; (c) shock or vibration

2. Make sure the input power is switched off when installing or uninstalling the DPM1 to prevent harm to

personnel or equipment.

3. Before switching on the input power, check the signal connection, e.g. the input voltage and polarity. Voltage

that is too high may cause damage to the DPM1.

4. Front cover should be cleaned only with a soft cloth soaked in neutral soap product. DO NOT USE

SOLVENTS.

5. Outputs remain active in Programming Mode.

Wiring

Terminals

CN1

1

2

11122 2

125 34

CN5

CN2

CN3

Note: For additional wiring information download complete

manual from www.AutomationDirect.com

Terminals

Connector CN1 CN2 CN3 CN4 CN5

Wire cross section

Strip length 8 to 9mm 5 to 6mm 5 to 6mm 8 to 9mm 8 to 9mm

Manufacturer

Cage clamp

connection

0.08 to 2.5mm²

(28 to 12 AWG)

Wago 231202/026-000

Insertion tool or

screwdriver with

0.5 mm x 3.0 mm

blade

CN2 and CN3 Terminals

0.08 to 0.5mm²

(28 to 20 AWG)

Wago 733-105 Wago 733-102

Insertion tool or

screwdriver with

0.3 mm x 1.8 mm

blade

Insertion Tool (included with meter)

Insert wires into the

proper terminal while

using the insertion tool

to open the clip inside

the connector. Release

the insertion tool to fix

wire to the terminal.

0.08 to 0.5mm²

(28 to 20 AWG)

Insertion tool or

screwdriver with

0.3 mm x 1.8 mm

blade

0.08 to 2.5mm²

(28 to 12 AWG)

Wago 231102/026-000

Insertion tool or

screwdriver with

0.5 mm x 3.0 mm

blade

CN1, CN4 and CN5

Terminals

AC Supply DC Supply

1 Line 1 -VDC

2 Neutral 2 +VDC

Analog Output

1 -0/4-20mA

2 +0/4-20mA

0.08 to 2.5mm²

(28 to 12 AWG)

Wago 231302/026-000

Insertion tool or

screwdriver with

0.5 mm x 3.0 mm

blade

Insertion Tool (included with meter)

Insert wires into the

proper terminal while

using the insertion tool

to open the clip inside

the connector. Release

the insertion tool to fix

wire to the terminal.

CN3

CN1

CN2

Signal Input

1 10 - 600 VAC

2 Not used

3 + Input pulses

4 Common

5 + Excitation (5, 8, 12V) @ 60mA

CN4

Relay 2

1

2

1

2

Relay 1

N.O. Contact

Input Wiring Diagrams

10-600V AC Input

CN2

5 4 3 2 1

NPN / PNP / PWM sensors

+ Pulses (Out)

Common

+ Exc.

CN2

5 4 3 2 1

TTL/24V DC Encoder input

+ Pulses (Out)

Common

+ Exc.

CN2

5 4 3 2 1

CN2

CN2

+ Pulses (Out)

+ Exc.

CN2

CN5

N.O. Contact

Magnetic sensor

5 4 3 2 1

Switched contact

5 4 3 2 1

NAMUR sensor

5 4 3 2 1

Warning: If this instrument is not installed and used in accordance with these instructions, the protection

provided by it against hazards may be impaired. To meet the requirements of EN 610101-1 standard, where the

unit is permanently connected to main supply, it is obligatory to install a circuit breaking device that is easily

reachable by the operator and clearly marked as the disconnecting device.

Programming Keys

(Bottom View)

ENTER: Enters configuration

and validates data and

parameters.

(Bottom View)

SHIFT: Selects mode or shifts

blinking digit in configuration.

UP: Increases value of blinking

digit in configuration mode.

Main Menu

<3s >3s

Pro

Enters configuration

menu (non-locked

out parameters)

) If all parameters are locked out, display shows dAtA.

1

.

Return to Factory Configuration

<3s ec

>3s ec

Total Configuration Lock-out

Note: For selective lock-out configuration download complete manual

from www.AutomationDirect.com

Run Mode

8888

>3sec

CodE

Enter code (default code is 0000). If code is forgotten,

8888

CHAn

perform Return to Factory Configuration to again

have access to parameters lock-out configuration.

Previous Settings will be lost.

Change code? No for this example.

no

Select YES for complete lock out of ALL parameters. When locked

out parameter values can be viewed but not changed (dAtA Mode

ALL

instead of Pro Programming Mode)

YES no

8888

Enters lock

out menu.

Indicators

Relay 1 activation

Run Mode

Displays value according to all configured

parameters.

Run Mode

Programming Mode

If parameter lock out has been enabled, dAtA

will be displayed instread of Pro

Enter code 74

Save value

Run Mode

Displays detected maximum and minimum

values. Value RESET can be done by

pressing at least 3s (then new maximum or

Relay 2 activation

Not used

Programming

mode

Hi-Lo CodE

minimum value is displayed).

<3s

the case and slide it until it reaches the panel at the rear side.

Press slightly to fasten the clips to the latching slots on the

case and get the unit fully assembled and close fitted to

achieve a good seal.

To remove the instrument from the panel, pull the rear

fixing clips latching tabs outwards until they are disengaged,

then slide the fixing clips back over the case.

To guarantee electromagnetic compatibility, the following guidelines should be followed:

• Power supply wires should be separately routed from

signal wires and never ran in the same conduit.

• Use shielded cable for signal wiring.

• Cable cross-section must be ≥0.25mm²

Before connecting signal wires, signal type and input range should be verified to be within the proper limits. Do not

Refer to manual

for options

Stor

8888

Save values

Run Mode

connect more than one input signal to the meter simultaneously.

Page 2

Model DPM1-P-A2R-H Example Application :

10-600VAC input, 0.0 to 100.0 Hz display, relay 1 set to activate on a decrease to a display value of 20.0 after a 5 sec. delay, relay 2 set to activate on a increase

to a display value of 80.0 after a 5 sec. delay, analog output of 4-20mA over a display range of 0.0 to 100.0.

Note: For additional configuration information download complete manual from www.AutomationDirect.com

Run Mode

8888

< 3 sec.

Stor

8888

Pro

InP

1

Save values

Run Mode

Pro: Programming Mode. If total parameter lock out has been

enabled, dAtA will be displayed instead of Pro.

ModE

Select 1 for

10-600 VAC

input

FrEC

dCP

Frequency value

Decimal place

1 0.1 0.01

Select 0.1 for

this example

SEt

Relay Configuration Menu

Refer to “Relay Setpoints”

menu to enter or change relay

setpoints.

Relay 1 configuration

CnF

Relay 1 changes state at

dLy

SP1.U setpoint after time

delay

Enter delay time of

88

5 seconds for this example

Lo

Hi

Relay 1 activates on a decreasing

display to setpoint. Select Lo for

this example.

CnF

Relay 2 configuration

Relay 2 changes state at SP2.U

dLy

setpoint after time delay

Enter delay time of

88

5 seconds for this example

Relay 2 activates on an

increasing display to setpoint.

Select Hi for this example.

A.out

tyPE

0-20

Analog output menu

Analog out signal

selection

4-20

Lo

8888

Hi

8888

Select 4-20 for

this example

Enter display

value of 0.0 for

4mA output for

this example

Enter display

value of 100.0

for 20mA

output for this

example

10-600 VAC Input Wiring

Relay Setpoints

Run Mode

<3 sec.

Programming Mode

.

Relay 1 setpoint

Enter setpoint of 20.0 for

this example

Relay 2 setpoint

.

Enter setpoint of 80.0 for

this example

Save values

Run Mode

Relay Output wiring

1

2

1

2

RELAY 1

Terminals CN4

SPST- Normally Open

RELAY 2

Terminals CN5

SPST- Normally Open

Note: For additional wiring information download complete manual from www.AutomationDirect.com

CN2

5 4 3 2 1

Technical Specifications

12kHz (tachometer rpm or rate modes)

85-265VAC 50/60Hz or 100-300VDC

21-53VAC 50/60Hz or 10.5-70VDC

Signal Input

AC Voltage Input

Magnetic Sensor Input

NAMUR Sensor Input

NPN/PNP/PWM Sensors Input

TTL/24V Encoder Input

Switched Contact Input

Accuracy at 23ºC ±5ºC

Power Supply and Fuses

Power Consumption

Stabilized Excitations

Display

Relays

Analog Output (0/4-20mA)

Environmental Conditions

Environmental Air

Agency Approvals

Maximum Frequency

Minimum Frequency (all modes) 0.01Hz

Range 10 to 600 VAC

Sensitivity

R

C

I

ON

I

OFF

R

C

Logic level “0” < 2.4 VDC

Logic level “1” > 2.6 VDC

Logic level “0” < 2.4 VDC

Logic level “1” > 2.6 VDC

V

C

R

C

F

C

Maximum error ± (0.01% of reading +1digit)

Temperature coefficient 50ppm / ºC

Warm-up time 5 minutes

DPM1-P-A2R-H

DPM1-P-A2R-L

5V@60mA ; 8V@60mA and 12V@60mA (Menu selectable)

Range 0 to 9999

Type 4-digit 8mm (0.31”), red

Decimal point Configurable

LEDs 4, for functions and outputs

Display refresh rate 4 times per second

Input overrange indication “OuE” or “0” flashing

Display overrange indication “OuE”

Relays, maximum and minimum value refresh 10 times per second

2 Relays (Form A) SPST normally open 5A @ 250VAC / 30VDC

Resolution 5.5µA

Accuracy ±(0.3% of reading +40µA)

EMI Max. influence ±0.25mA

Temperature coefficient 3µA/ºC

Maximum load ≤500Ω

Operating temperature -10ºC to +60ºC (14ºF to 140ºF)

Storage temperature -25ºC to +85ºC (-13ºF to 185ºF)

Relative humidity (non-condensing) <95% @ 40ºC (104ºF)

Maximum altitude 2000m

Frontal protection degree IP65

(Recommended fusing, 0.2A/250V, 5mm x 20mm glass miniature or DIN

(Recommended fusing, 1A/250V, 5mm x 20mm glass miniature or DIN

5W

No corrosive gases permitted

CE

Additional Help and Support

• For additional information on this product download the complete manual from www.

AutomationDirect.com

• For additional technical support and questions, call our Technical Support team @

1-800-633-0405 or 770-844-4200

• Scan or click the QR link for configuration and programming videos for the ProSense

DPM Series Panel Meters

9999Hz (frequency mode)

100Hz (duty/PWM mode)

Vin min. ≥ 30mV for f ≤ 60Hz

Vin min. > 300mV for f ≥ 6kHz

1.5kΩ

< 1mA DC

> 3mA DC

3.9kΩ (NPN) ; 1.5kΩ (PNP)

5V (internal)

3.9kΩ

20Hz

(Ton, Toff > 25ms)

41661 equivalent)

41661 equivalent)

Copyright 2020, Automationdirect.com Incorporated/All Rights Reserved Worldwide

Quick Start Guide: DPM1-P-A2R-H, DPM1-P-A2R-L

Loading...

Loading...