Page 1

D0–DCM Data

Communications

Module

Manual Number D0–DCM–M

Page 2

WARNING

Thank you for purchasing automation equipment from Automationdirect.com™, doing business as,

AutomationDirect. We want your new DirectLOGIC™ automation equipment to operate safely. Anyone who installs

or uses this equipment should read this publication (and any other relevant publications) before installing or operating

the equipment.

To minimize the risk of potential safety problems, you should follow all applicable local and national codes that regulate

the installation and operation of your equipment. These codes vary from area to area and usually change with time. It is

your responsibility to determine which codes should be followed, and to verify that the equipment, installation, and

operation are in compliance with the latest revision of these codes.

At a minimum, you should follow all applicable sections of the National Fire Code, National Electrical Code, and the

codes of the National Electrical Manufacturer’s Association (NEMA). There may be local regulatory or government

offices that can also help determine which codes and standards are necessary for safe installation and operation.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable codes and

standards. We do not guarantee the products described in this publication are suitable for your particular application,

nor do we assume any responsibility for your product design, installation, or operation.

Our products are not fault–tolerant and are not designed, manufactured or intended for use or resale as on–line control

equipment in hazardous environments requiring fail–safe performance, such as in the operation of nuclear facilities,

aircraft navigation or communication systems, air traffic control, direct life support machines, or weapons systems, in

which the failure of the product could lead directly to death, personal injury, or severe physical or environmental

damage (”High Risk Activities”). AutomationDirect specifically disclaims any expressed or implied warranty of fitness

for High Risk Activities.

For additional warranty and safety information, see the Terms and Conditions section of our Desk Reference. If you

have any questions concerning the installation or operation of this equipment, or if you need additional information,

please call us at 770–844–4200.

This publication is based on information that was available at the time it was printed. At AutomationDirect we

constantly strive to improve our products and services, so we reserve the right to make changes to the products and/or

publications at any time without notice and without any obligation. This publication may also discuss features that may

not be available in certain revisions of the product.

Trademarks

This publication may contain references to products produced and/or offered by other companies. The product and

company names may be trademarked and are the sole property of their respective owners. AutomationDirect

disclaims any proprietary interest in the marks and names of others.

Copyright 2005, Automationdirect.com™ Incorporated

All Rights Reserved

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior, written consent of

Automationdirect.com™ Incorporated. AutomationDirect retains the exclusive rights to all information included in

this document.

Page 3

AVERTISSEMENT

Nous vous remercions d’avoir acheté l’équipement d’automatisation de Automationdirect.comE, en faisant des affaires

comme, AutomationDirect. Nous tenons à ce que votre nouvel équipement d’automatisation DirectLOGIC™ fonctionne

en toute sécurité. Toute personne qui installe ou utilise cet équipement doit lire la présente publication (et toutes les autres

publications pertinentes) avant de l’installer ou de l’utiliser.

Afin de réduire au minimum le risque d’éventuels problèmes de sécurité, vous devez respecter tous les codes locaux et

nationaux applicables régissant l’installation et le fonctionnement de votre équipement. Ces codes diffèrent d’une région à

l’autre et, habituellement, évoluent au fil du temps. Il vous incombe de déterminer les codes à respecter et de vous assurer

que l’équipement, l’installation et le fonctionnement sont conformes aux exigences de la version la plus récente de ces

codes.

Vous devez, à tout le moins, respecter toutes les sections applicables du Code national de prévention des incendies, du

Code national de l’électricité et des codes de la National Electrical Manufacturer’s Association (NEMA). Des organismes de

réglementation ou des services gouvernementaux locaux peuvent également vous aider à déterminer les codes ainsi que

les normes à respecter pour assurer une installation et un fonctionnement sûrs.

L’omission de respecter la totalité des codes et des normes applicables peut entraîner des dommages à l’équipement ou

causer de graves blessures au personnel. Nous ne garantissons pas que les produits décrits dans cette publication

conviennent à votre application particulière et nous n’assumons aucune responsabilité à l’égard de la conception, de

l’installation ou du fonctionnement de votre produit.

Nos produits ne sont pas insensibles aux défaillances et ne sont ni conçus ni fabriqués pour l’utilisation ou la revente en tant

qu’équipement de commande en ligne dans des environnements dangereux nécessitant une sécurité absolue, par

exemple, l’exploitation d’installations nucléaires, les systèmes de navigation aérienne ou de communication, le contrôle de

la circulation aérienne, les équipements de survie ou les systèmes d’armes, pour lesquels la défaillance du produit peut

provoquer la mort, des blessures corporelles ou de graves dommages matériels ou environnementaux (”activités à risque

élevé”). La société AutomationDirect nie toute garantie expresse ou implicite d’aptitude à l’emploi en ce qui a trait aux

activités à risque élevé.

Pour des renseignements additionnels touchant la garantie et la sécurité, veuillez consulter la section Modalités et

conditions de notre documentation. Si vous avez des questions au sujet de l’installation ou du fonctionnement de cet

équipement, ou encore si vous avez besoin de renseignements supplémentaires, n’hésitez pas à nous téléphoner au

770–844–4200.

Cette publication s’appuie sur l’information qui était disponible au moment de l’impression. À la société AutomationDirect,

nous nous efforçons constamment d’améliorer nos produits et services. C’est pourquoi nous nous réservons le droit

d’apporter des modifications aux produits ou aux publications en tout temps, sans préavis ni quelque obligation que ce soit.

La présente publication peut aussi porter sur des caractéristiques susceptibles de ne pas être offertes dans certaines

versions révisées du produit.

Marques de commerce

La présente publication peut contenir des références à des produits fabriqués ou offerts par d’autres entreprises. Les

désignations des produits et des entreprises peuvent être des marques de commerce et appartiennent exclusivement à

leurs propriétaires respectifs. AutomationDirectE nie tout intérêt dans les autres marques et désignations.

Copyright 2005, Automationdirect.comE Incorporated

Tous droits réservés

Nulle partie de ce manuel ne doit être copiée, reproduite ou transmise de quelque façon que ce soit sans le consentement

préalable écrit de la société Automationdirect.comE Incorporated. AutomationDirect conserve les droits exclusifs à

l’égard de tous les renseignements contenus dans le présent document.

Page 4

1

Manual Revisions

If you contact us in reference to this manual, please remember to include the revision number.

Title: DL05/06 Data Communications Module

Manual Number: D0–DCM–M

Issue Date Description of Changes

Original 8/05 Original Issue

Page 5

1

Table of Contents

Chapter 1: Introduction

Manual Overview 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Purpose of this Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplemental Manuals 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Who Should Read this Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Support 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions Used 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Key Topics for Each Chapter 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D0–DCM Hardware Features 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applications 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

As a DirectNET Interface 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

As an Extra Communication Port 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

As a MODBUS RTU

Chapter 2: Installation, Network Cabling and Module

Specifications

Inserting the D0–DCM into the PLC 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D0–DCM Module Installation 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Building the Communication Cable 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Consideration 1: Physical Configuration 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Consideration 2: Electrical Specification RS232 or RS422/485 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Consideration 3: Cable Schematics 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Consideration 4: Cable Specifications 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Consideration 5: Installation Guidelines 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagrams 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D0–DCM Port 1 RS–232 Network 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D0–DCM Port 2 RS–232 Network 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D0–DCM Port 2 RS–485 Network 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D0–DCM Port 2 RS–422 Network 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Specifications 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Port 1 Specifications 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Port 2 Specifications 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Indicators 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

r

Network Interface 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3: D0–DCM Module Configuration Registers

DCM Port Configuration Registers 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Configuration Registers 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comm Port Default Configuration Parameters 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A: Port 1 – Transmit Mode, Protocol 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B: Port 1 – Station Address, Baud Rate, Parity 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C: Port 2 – RTS On/Off delay, Transmit Mode, Protocol, Comm Time–out, RS–485 Mode 3–6. . . .

D: Port 2 – Station Address, Baud Rate, Data Bit, Stop Bit, Parity 3–8. . . . . . . . . . . . . . . . . . . . . . . .

E: Port 2 – Character Time–out 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F: Port 1 and 2 Setup and Completion Code 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G: Port 1 and 2 Reset Time–out 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

ii

Table of Contents

DL05 Port Setup Examples 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Port 1 Example: Slave Mode Only 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Port 2 Example: Slave Mode 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Port 2 Example: DirectNet Master 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Port 2 Example: MODBUS RTU Master 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DL06 Port Setup Examples 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Port 1 Example: Slave Mode Only 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Port 2 Example:Slave Mode 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Port 2 Example: DirectNet Master 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Port 2 Example: MODBUS RTU Master 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4: RLL Programming for Communications

PLC-to-PLC Communications 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How RLL is Used for Communications 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Instructions 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read (RX) and Write (WX) Instructions 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Building the Read (RX) or Write (WX) Routine 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Second LD Instruction 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The LDA Instruction 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read (RX) Instruction 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Write (WX) Instruction 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing the Different Memory Types 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit Memory 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Word Memory and Aliases 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DL05 CPU 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DirectSOFT32 is Flexible 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DL06 CPU 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Relays for Communications 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program with One Read Instruction 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program for the Master PLC 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program for the Slave PLC 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program for the Master PLC 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program for the Slave PLC 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example Program with One Write Instruction 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program for the Master PLC 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program for the Slave PLC 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program for the Master PLC 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program for the Slave PLC 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integrating Multiple Read and Write Instructions 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interlocking Relays 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First RX/WX Instruction 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Second RX/WX Instruction 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Third RX/WX Instruction 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Returning to the First RX/WX Instruction 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shift Register 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Store If Equal 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First RX/WX Instruction 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Second RX/WX Instruction 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Third RX/WX Instruction 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Table of Contents

Chapter 5: D0–DCM Using MODBUSr RTU

Network Slave Operation 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODBUS Function Codes Supported 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determining the MODBUS Address 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

If Your Host Software or Master Requires the Data Type and Address 5–3. . . . . . . . . . . . . . . . . . . . .

Example 1: V2100 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 2: Y20 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 3: T10 Current Value 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 4: C54 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

If the Host Software or Master Requires an Address ONLY 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 1: V2100 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 2: Y20 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 3: C54 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Master Operation 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODBUS Function Codes Supported 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Memory Supported for Master Operation 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 1: Calculating Word PLC Address 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 2: Calculating Discrete Input PLC Address 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Building the Read (RX) or Write (WX) Routine 5–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 1: Identify DCM Slot Location and Slave 5–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 2: Load Number of Bytes to Transfer 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 3: Specify Master Memory Area 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 4: Specify Slave Memory Area 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications from a Ladder Program 5–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiple Read and Write Interlocks 5–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 8

Page 9

Introduction

In This Chapter. . . .

— Manual Overview

— D0–DCM Hardware Features

— D0–DCM Applications

1

1

Page 10

1–2

Introduction

Manual Overview

The Purpose of

this Manual

Introduction

Supplemental

Manuals

This manual is designed to allow you to setup

and install your DL05/06 Data

Communications Module (D0–DCM). This is

the only manual you will need if you are using

the D0–DCM as an extra general purpose

communication port for your DL05/06 PLC

system. If you plan on using the D0–DCM as a

network master or slave for a

DirectNET/MODBUS RTU network, this

manual covers the basic steps for setting up

the D0–DCM and the RX/WX instructions

needed in your RLL program.

If you plan on using a PC as the network master, it may be helpful to read the

DirectNET manual first. In either case, the DirectNET manual can be useful

because it provides detailed descriptions of network configurations, various cable

connections, etc.

Depending on which products you have purchased, there may be other manuals that

are necessary or helpful for your application. These are some suggested manuals:

User Manuals

• DirectNET Network Guide part number DA–DNET–M

• DirectSoft32 Programming Software part number PC–DSOFT32–M

Who Should Read

this Manual

Installation and

Safety Guidelines

Technical Support

If you plan to use your D0–DCM to communicate with another PLC, you will need the

appropriate user manual for the other PLC.

If you plan to use your D0–DCM module as an interface to HMI or PC Control

software or to an Operator Interface panel, you will need to refer to the

documentation for that product.

If you need an additional communications port for your DL05/06 PLC and you

understand the basics of installing and programming PLCs, this is the right manual

for you. This manual gives you the information you need to set up an active port on

the D0–DCM module.

We strive to make our manuals the best in the industry and rely on your feedback in

reaching our goal. If you cannot find the solution to your particular application, or, if

for any reason you need additional technical assistance, please call us at

770–844–4200.

Our technical support team is glad to work with you in answering your questions.

They are available weekdays from 9:00 a.m. to 6:00 p.m. Eastern Time. We also

encourage you to visit our website where you can find technical and nontechnical

information about our products and our company.

www.automationdirect.com

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 11

Conventions Used

1–3

Introduction

Key Topics for

Each Chapter

The “light bulb” icon in the left-hand margin indicates a tip or shortcut.

The “note pad” icon in the left–hand margin indicates a special note.

The “exclamation mark” icon in the left-hand margin indicates a warning or caution.

These are very important because the information may help you prevent serious

personal injury or equipment damage.

The beginning of each chapter will list the

key topics that can be found in that

chapter.

1

Introduction Installation and

DL05/06 Data Communications Module, 1st Edition, 08/05

Safety Guidelines

Page 12

1–4

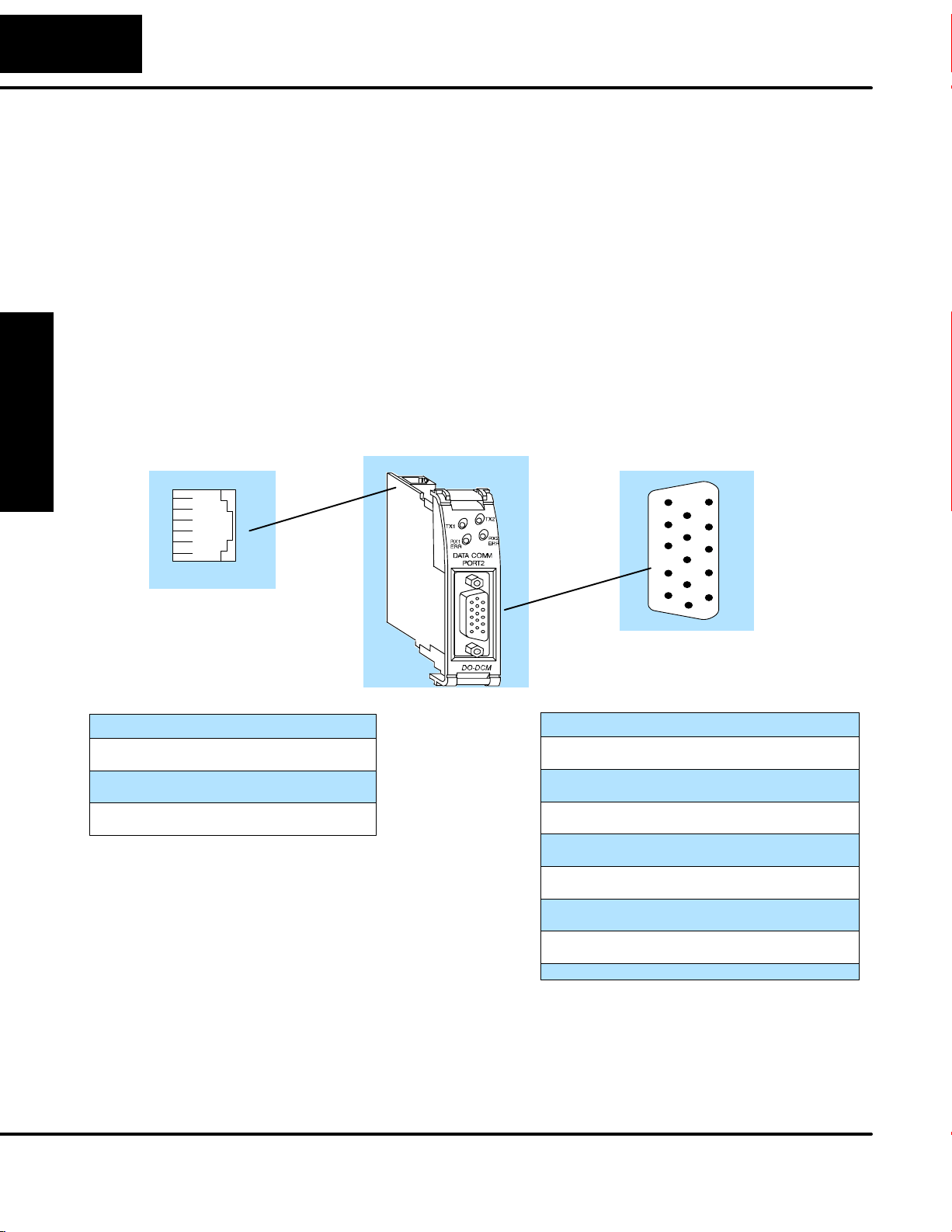

D0–DCM Hardware Features

Introduction

Introduction

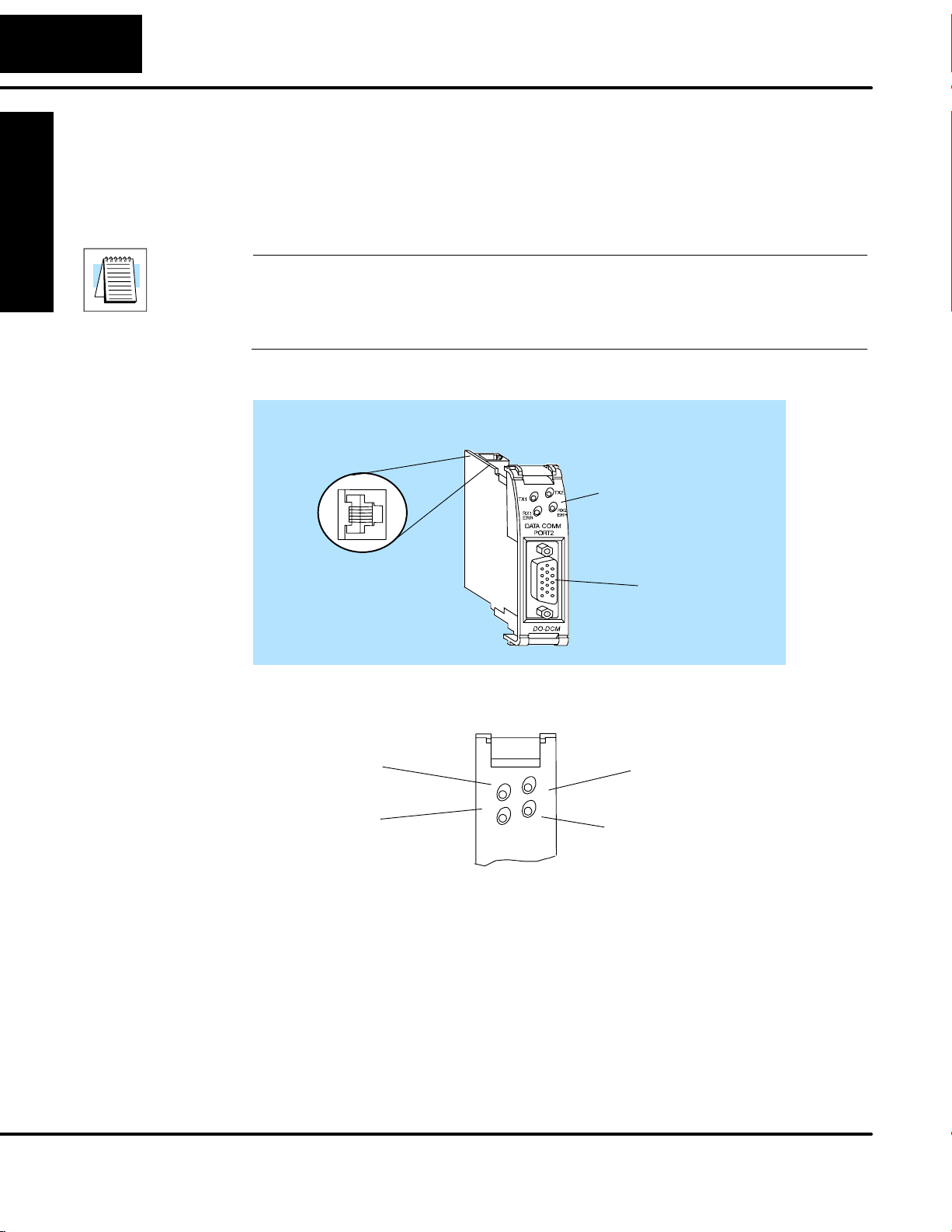

The following diagram shows the D0–DCM hardware components. The

communication parameters are configured using DirectSOFT32. There are no DIP

switches to set on this module.

The D0–DCM requires ladder logic programming to configure its communication

parameters, unless the default settings are acceptable for the application. If the

D0–DCM is to be used as a network master, you must use ladder logic code to

configure this parameter.

D0–DCM

Port 1: RS–232

Communication Port

Status Indicators

(shown below)

Installation and

Safety Guidelines

Port 2:

RS232/422/485

Communication Port

Status Indicators

TX1: Port 1

Transmitting Data

(Green)

RX1: Port 1

Receiving Data (Green);

Error (Red)

TX1

RX1

ERR

DATA COMM

PORT2

TX2

RX2

ERR

TX2: Port 2

Transmitting data

(Green)

RX2: Port 2

Receiving Data (Green);

Error (Red)

The D0–DCM Data Communications Module is a general purpose communications

interface that c an b e u sed i n a D L05/06 P LC s ystem. T he m odule c an g o in any o ption

slot. This module is primarily used for several reasons:

• As an extra general purpose communications port to connect to a personal

computer or operator interface

• As a network master or slave interface to a DirectNET network (port 2);

port 1 functions as a DirectNET slave only

• As a network master or slave interface to a MODBUS

port 1 functions as a MODBUS

R

RTU slave only

R

RTU network (port 2);

• As a K–sequence slave (both ports)

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 13

Applications

As a DirectNET

Interface

1–5

Introduction

Introduction Installation and

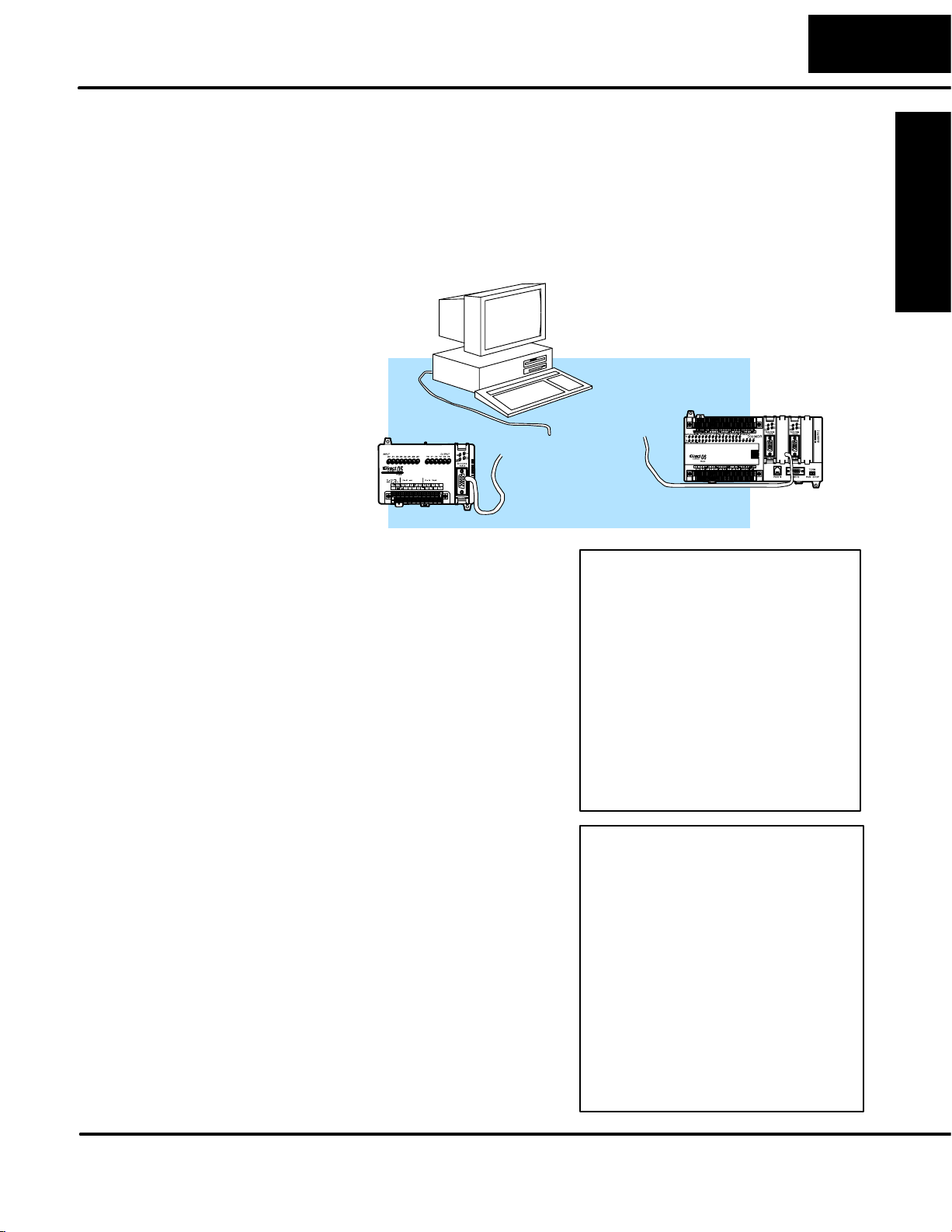

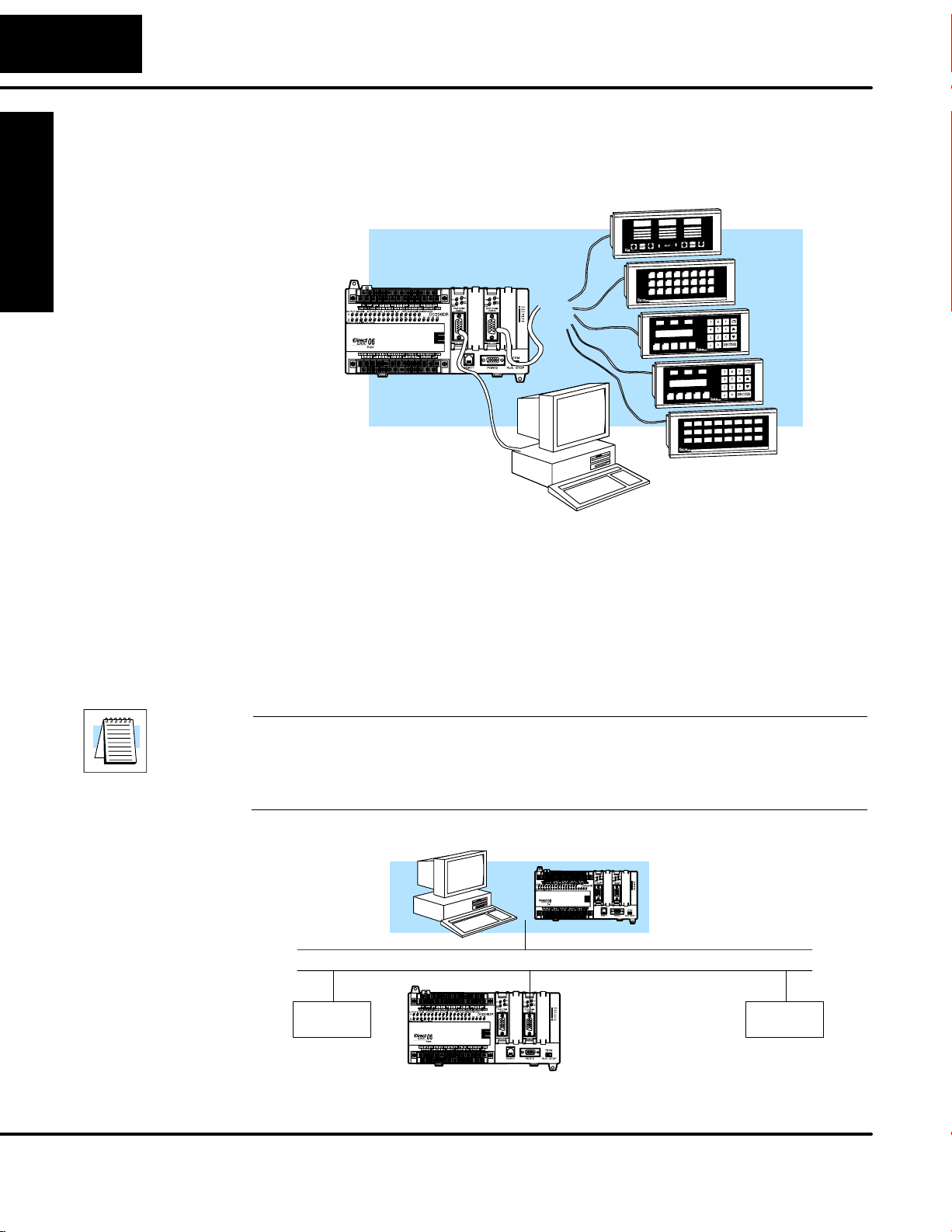

The D0–DCM can be used as a network interface for applications that require data to

be shared between PLCs, or between PLCs and an intelligent device (such as a host

computer). The D0–DCM can be configured as either a master or slave station and

allows you to upload or download virtually any type of system data including

Timer/Counter data, I/O information, and V-memory information.

DirectNET Master

Issues requests to slave

stations

PC or D0–DCM

master can

communicate with

DirectNET Slaves

Using a D0–DCM as a network Master

The D0–DCM can be used with a DL05 or

DL06 CPU to serve as a network master . A

master is the network station that initiates

requests for data from other stations on the

network). You simply use special RLL

instructions (RX and W X) inside o f your R LL

program to initiate the data exchange. The

D0–DCM takes communication requests

issued by the PLC program i nstructions and

automatically converts these requests into

network commands that read data from or

write data to another network station.

DirectNET Slaves

Slaves respond to the master’s request

Possible Slaves

S DL05/DL06 CPU (either port)

S DL05/DL06 CPU w/D0–DCM

S D2–240/250–1/260 CPU (either

port)

S D2–240/250–1/260 w/ D2–DCM

S D3–330/330P w/ DCU

S D3–340/350 (either port)

S D4–430/440 (bottom port)

S D4–450 (phone jack or bottom port)

S Any DL405 CPU w/ D4–DCM

Safety Guidelines

Using a D0–DCM as a network Slave

The D0–DCM can also be used with a

DL05 or DL06 CPU to serve as a network

slave station. In this case, the D0–DCM

“listens” to the network for any messages

that contain the D0–DCM’s address. The

D0–DCM deciphers the network

commands, carries out the request to read

or write data, and sends confirmation

and/or information to the master station.

DL05/06 Data Communications Module, 1st Edition, 08/05

Possible Masters

S DL05/06 CPU (port 2)

S DL05/06 CPU w/ D0–DCM

S 250–1/260 CPU (bottom port)

S D2–240/250–1/260 CPU

w/ D2–DCM

S D3–340/350 CPU (bottom

port)

S Any DL405 CPU w/ D4–DCM

S D4–450 CPU (bottom port)

S Host computer w/KEPDirect

for PLCs

Page 14

1–6

Introduction

As an Extra

Communication

Port

Introduction

As a MODBUSRTU

Network Interface

The D0–DCM ports are similiar to the ports on the DL05 and DL06 CPUs. In general,

if you can connect a device to the CPU ports, then you can also connect the same

device to the D0–DCM. These devices can be a variety of things, such as operator

interfaces or personal computers.

Quickly add extra

communication ports*

* Number of option modules is

limited by the DL06 available

power budget.

The D0–DCM can be used as a master or slave interface to connect your DL05/06

system to a M ODBUS RTU network. P ort 1 c an o nly s erve a s a MODBUS R TU s lave.

Port 2 can serve a s a M ODBUS R TU master o r slave. This m anual does not describe

the MODBUS protocol. We recommend that you reference the Gould MODBUS

Protocol Reference Guide (P1-MBUS-300 Rev. B) for details on the protocol. There

may be more recent editions of this manual, so check with your MODBUS supplier

before ordering the documentation.

Installation and

Safety Guidelines

DL05/06 Data Communications Module, 1st Edition, 08/05

For information about the MODBUS protocol see the Group Schneider Web site at:

www.schneiderautomation.com. At the main menu, select Support/Services,

Modbus, Modbus Technical Manuals, PI–MBUS–300 Modbus Protocol Reference

Guide or search for PIMBUS300.

MODBUS® Master

MODBUS Network using RTU Protocol

Network

Slave

DL06 Slave with

D0–DCM

As a slave station....

responding to network reĆ

quests

Network

Slave

Page 15

Installation, Network

Cabling and Module

Specifications

In This Chapter. . . .

— Inserting the D0–DCM into the PLC

— Building the Communication Cable

— Wiring Diagrams

— Module Specifications

1

2

Page 16

2–2

Installation and Setup

Inserting the D0–DCM into the PLC

D0–DCM Module

Installation

and Setup

Installation

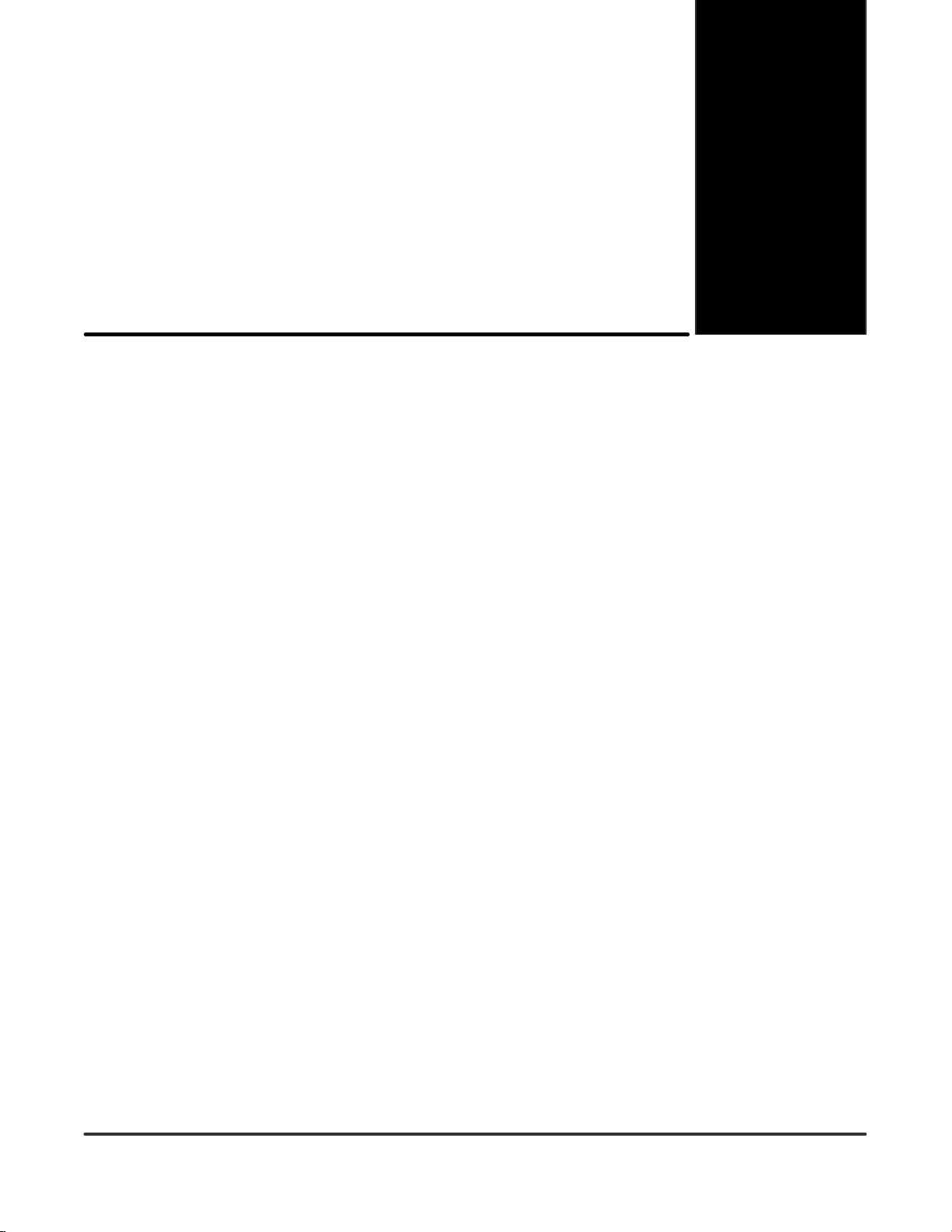

Remove the front protective option slot cover by squeezing the pinch tabs and lifting

the cover off. Remove the top option slot cover using small flat–head screwdriver or

similiar device. Be sure PLC power is off when installing the D0–DCM module.

DL05

Front View

Pinch Tabs to

remove front

slot cover

0V

C0 C2 Y16Y14Y13Y11Y6Y4Y3Y1

C1 C3Y0 Y15Y12Y10 Y17Y7Y5Y2

2.0AOUTPUT: 6–240V

N.C.

40VA50–60HzPWR: 100–240V

D0–06DR

PWR

RUN

CPU

TX1

RX1

TX2

RX2

LGG

)

AC(N)24V

AC(L

50 – 60Hz2.0A,6 – 27V

Y

0 1 2 3 4 5 6 7 10 11 12 13 14 15 16 17 20 21 22 23

X

INPUT: 12 – 24V3 – 15mA

DL06

Front View

C0 C4C2X1 X3 X4 X6 X11X13X14 X16 X21 X23N.C.

C1 C3X2 X5 X7 X10 X12 X15X17 X20 X22X0 N.C.

PORT1 RUN STOP

PORT2

TERM

Remove top

slot cover with

small flat–head

screwdriver

Installation and

Safety Guidelines

DL06

Top View

Insert the module into the open slot in the DL05 or into any one of the four slots in the

DL06. Locate the module so the printed information is oriented in the same direction

as the markings on the PLC. Be careful to align the female connector on the printed

circuit board of the module with the male connector on the PLC mother board. Press

the module into the slot until the front of the module is flush with the front of the PLC.

Check the DL06 power budget to be sure that it remains within the power supply

limits before installing more modules.

NOTE: The DL05 CPU’s communication feature for the D0–DCM requires

DirectSOFT32 Version 3.0c (or later) and firmware version 5.00 (or later). The DL06

requires DirectSOFT32 version V4.0, build 16 (or later) and firmware version 1.90 (or

later). See our website for more information: www.automationdirect.com.

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 17

Installation and Setup

Building the Communication Cable

There are several considerations that help determine the type of cable needed for

your D0–DCM application. The next few pages discuss these considerations in

detail.

Consideration 1:

Physical

Configuration

The D0–DCM can be used in either a point-to-point or multi-drop configuration. A

point-to-point connection only has two stations, a master and a slave. Use the

point-to-point configuration to connect a personal computer, an operator interface,

or an intelligent device to a single D0–DCM. You must also use this configuration

when you want to connect a DirectNET master station to a single DirectNET slave

station.

Use the multi-drop configuration to connect one master to two or more slaves (90

slave maximum).

Point to Point – RS–232C

PC or OI

Master

2–3

Installation

and Setup

D0–DCM Slave

DL06 Master

Multi-drop – RS–422/485

DirectNET or

MODBUS

RTU

Masters

or

or

DL05 Slave

DirectNET Slaves

Safety Guidelines

Installation and

D0–DCM

Data Communications Module, 1st Edition, 08/05

Page 18

2–4

Installation and Setup

Consideration 2:

Electrical

Specification

RS232C or

RS422/485

Consideration 3:

Cable Schematics

and Setup

Installation

Port 1

6

5

4

3

2

1

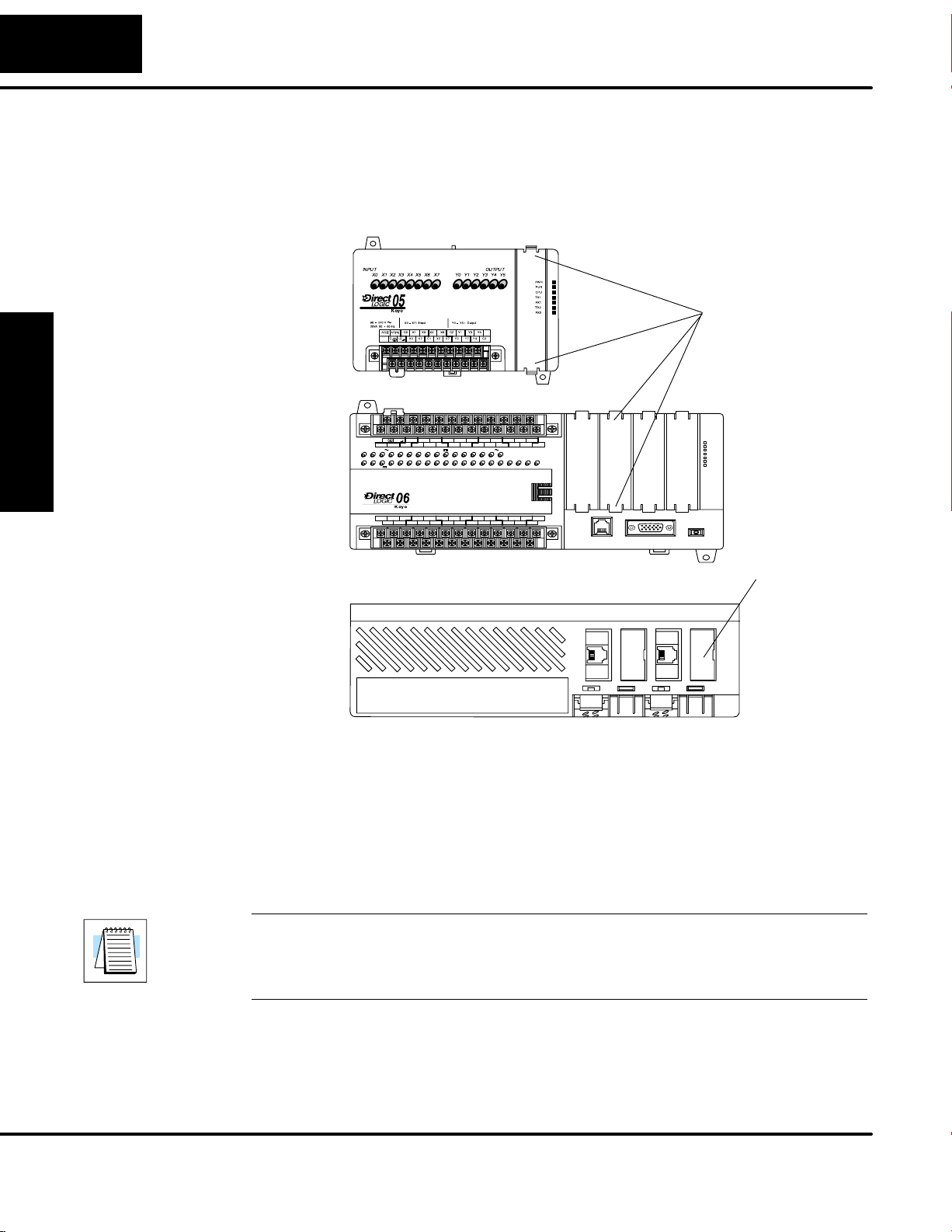

The D0–DCM can support RS–232 (ports 1 and 2) or RS–422/485 (port 2)

communication. Your application and configuration choice will help determine which

electrical specification is best for you. If you are using multi-drop, you must use RS–422

or RS–485. If you are using point-to-point, you may have a choice between RS–232C

and RS–422/485.

You can use RS–232 if the cable length is less than 50 feet and if the cable will not be

subjected to induced electrical noise that is commonly found near welders, large motors,

or other devices that create large magnetic fields.

You must use RS–422/485 for all other applications. RS–422/485 allows longer cable

distances (up to 3300 feet) and provides higher noise immunity.

Although the network configuration and electrical specification are important, the type of

devices being connected to the D0–DCM are just as important. The exact cable

schematic needed really depends on a combination of all three things.

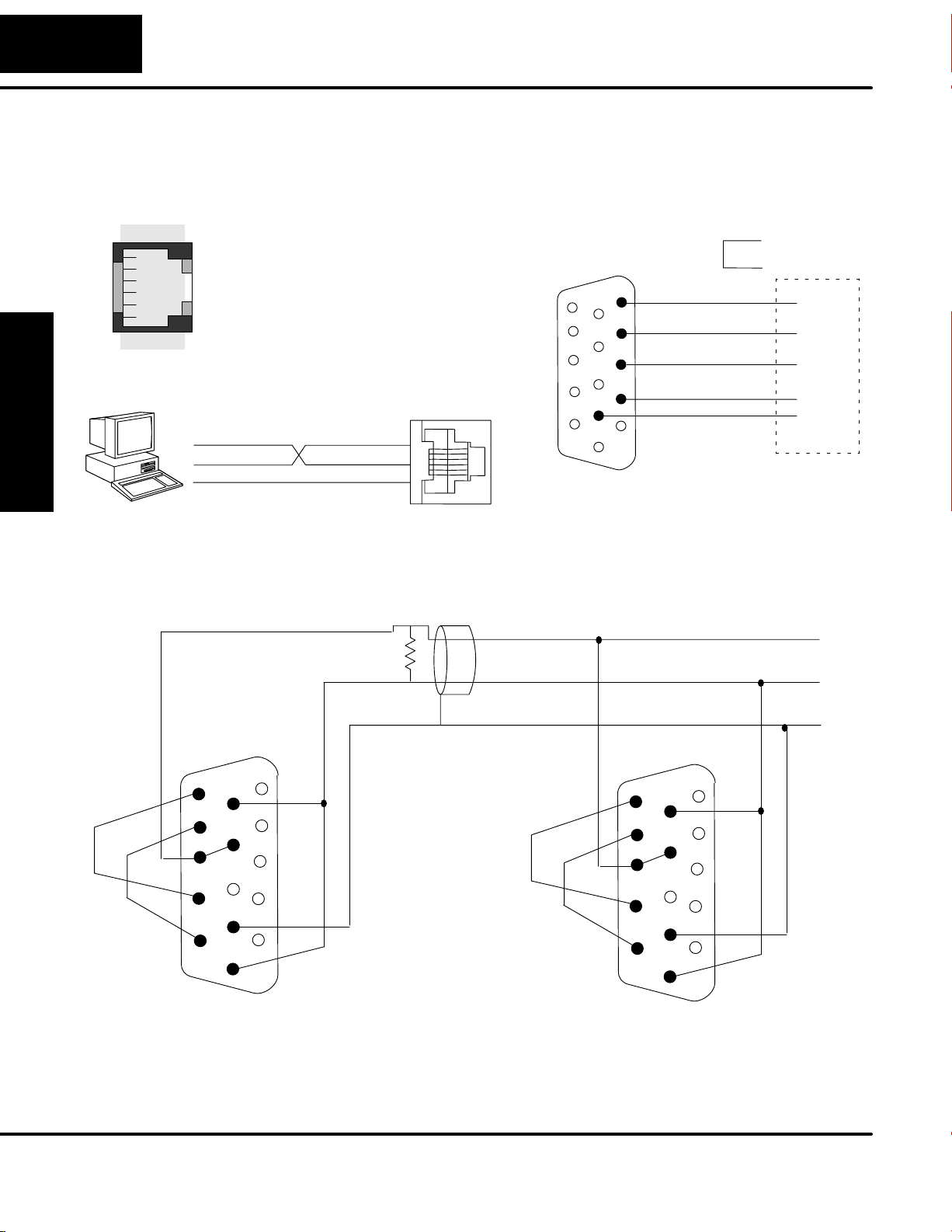

The following diagram shows the port pinouts for the D0–DCM.

D0–DCM Pinouts

Port 2

15

5

10

Port 1 Pin Descriptions

10V

25V

3 RXD Receive Data (RS–232)

4 TXD Transmit Data (RS–232)

5 RTS Request to Send

60V

Installation and

Safety Guidelines

RJ12 Phone Jack

Connector

11

6

1

15-pin Female

HD Connector

Port 2 Pin Descriptions

1 5V 5 VDC

2 TXD2 Transmit Data (RS–232)

3 RXD2 Receive Data (RS–232)

4 RTS2 Ready to Send (RS–232C

5 CTS2 Clear to Send (RS–232)

6 RXD2– Receive Data – (RS–422/485)

7 0V Logic Ground

8 0V Logic Ground

9 TXD2+ Transmit Data + (RS–422/485)

10 TXD2 – Transmit Data – (RS–422/485)

11 RTS2 + Request to Send + (RS–422/485)

12 RTS2 – Request to Send – (RS–422/485

13 RXD2 + Receive Data + (RS–422/485)

14 CTS2 + Clear to Send + (RS422/485)

15 CTS2 – Clear to Send – (RS–422/485)

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 19

Installation and Setup

2–5

Consideration 4:

Cable Specifications

Consideration 5:

Installation

Guidelines

Although many types of cables may work for your application, we recommend you

use a cable that is constructed to offer a high degree of noise immunity . The following

specifications are to be used as a guideline.

Structure Shielded, twisted-pair. . . . . . . . . . . . . . . . . . . . . . .

(RS232 only uses two wires and a ground)

Conductor size 24 AWG or larger. . . . . . . . . . . . . . . . . .

Insulation Polyethylene. . . . . . . . . . . . . . . . . . . . . . .

Shield Copper braid or aluminum foil. . . . . . . . . . . . . . . . . . . . . . . . . .

Impedance 100W @ 1MHz. . . . . . . . . . . . . . . . . . . . . .

Capacitance 60pf / meter or less. . . . . . . . . . . . . . . . . . . .

Y our company may have guidelines for cable installation. If so, you must check those

before you begin the installation. Here are some general things to consider.

• Don’t run cable next to larger motors, high current switches, or

transformers. This may cause noise problems.

• Route the cable through an approved cable housing to minimize the risk

of accidental cable damage. Check local and national codes to choose

the correct method for your application.

• Consider redundant cabling if the application data is critical. This allows

you to quickly reconnect all stations while the primary cable is being

repaired.

Installation

and Setup

Cable Shield Grounding — It is important to ground the cable shield to minimize

the possibility of noise. The preferred method is to connect one end of the cable

shield to the connector housing. If noise problems are still present and you have a

good earth ground for the cabinet, you must connect one end of the shield to the

cabinet earth ground. Don’t ground both ends of the shield because this will create

induced noise on the cable.

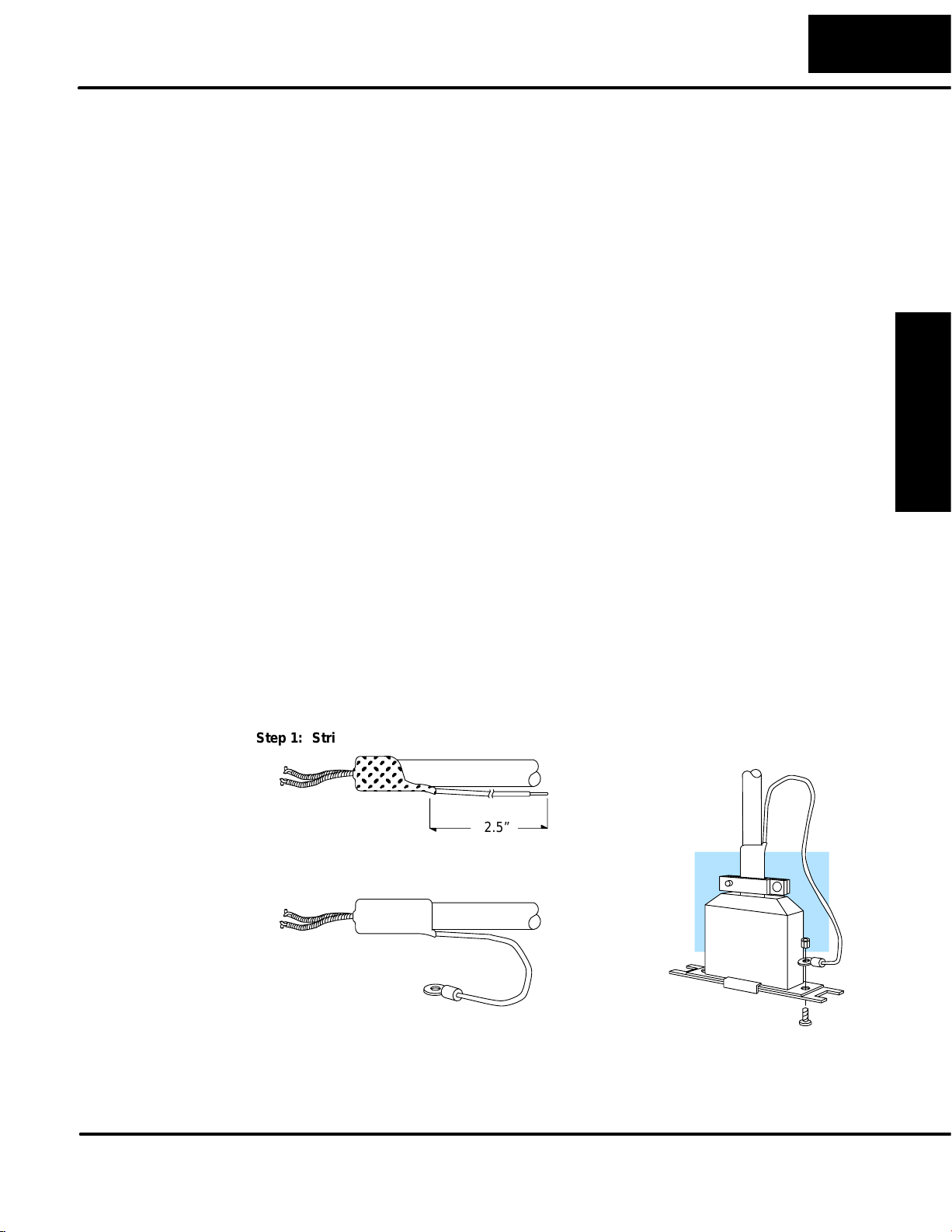

Step 1: Strip back about 2.5” of the shield.

2.5”

Step 2: Crimp a ring connector onto the shield.

Step 3: Secure the shield to

the connector shell.

Safety Guidelines

Installation and

Data Communications Module, 1st Edition, 08/05

Page 20

2–6

Installation and Setup

Wiring Diagrams

D0–DCM Port 1

RS–232 Network

Modular Connector

and Setup

Installation

123456

6-pin Female

TXD

RXD

0V

D0–DCM Port 2

RS–485 Network

TXD+ / RXD+

TXD 4

RXD 3

0V 1

Termination

Resistor

D0–DCM

PORT 1

D0–DCM Port 2

RS–232 Network

TXD+ / RXD+

15

OR

Loop

Back

5

CTS

10

RTS

4

RXD

3

TXD

2

7

11

Signal GND

1

6

RTS

RTS

CTS

TXD

RXD

GND

TXD+ / RXD+

CTS–

CTS+

Installation and

Safety Guidelines

RTS–

RTS+

15

RXD+

11

10

TXD+

7

TXD– / RXD–

Signal GND

Connect shield

5

TXD–

0V

1

RXD–

6

to signal ground

Cable: Use Belden

9841 or equivalent

CTS–

CTS+

RTS–

RTS+

TXD– / RXD–

15

10

TXD+

RXD+

7

11

6

5

TXD–

0V

1

RXD–

TXD– / RXD–

Signal GND

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 21

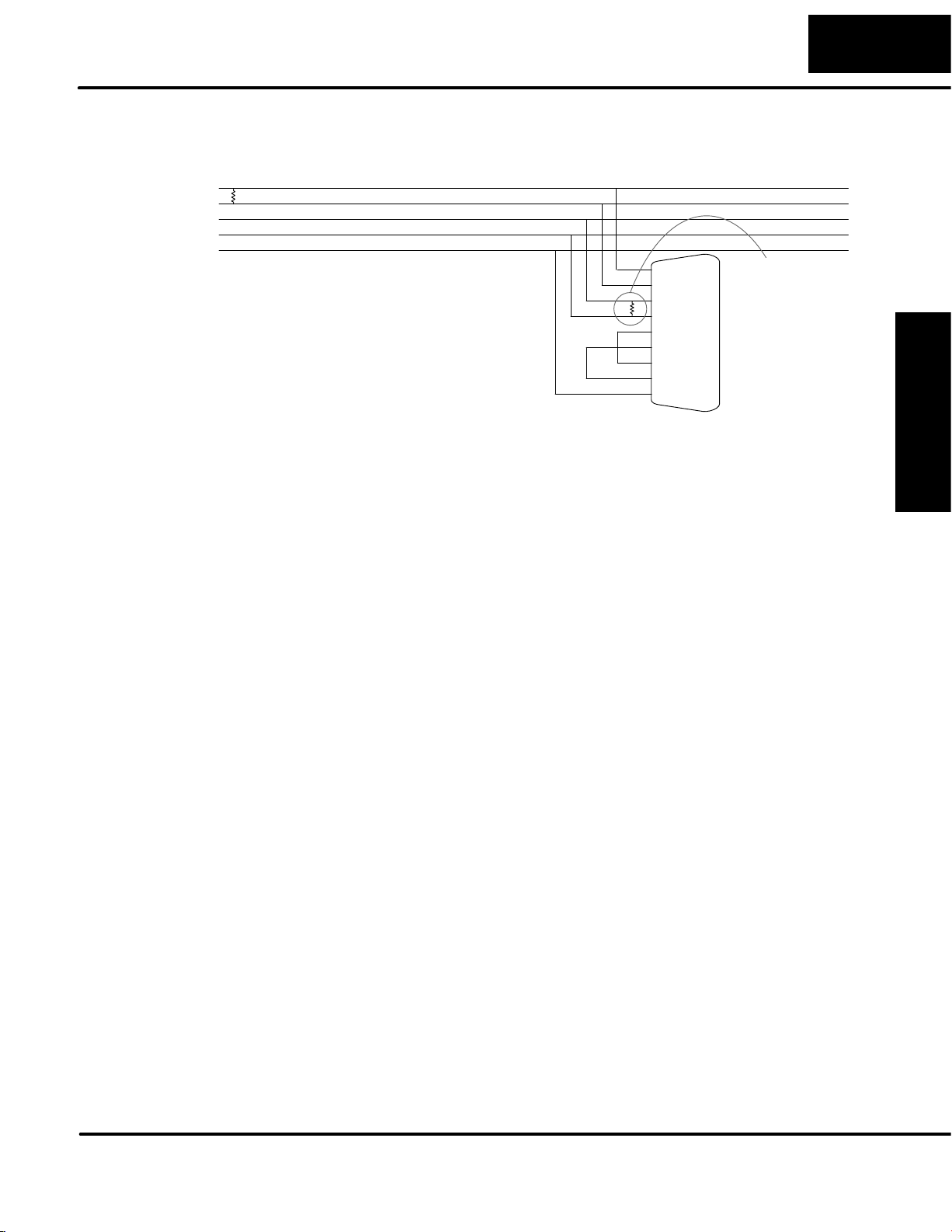

D0–DCM Port 2

RS–422 Network

Installation and Setup

RXD+

RXD–

TXD+

TXD–

Signal GND

PC/PLC Master

Cable: Use Belden

9729 or equivalent

9 TXD+

10 TXD–

13 RXD+

6 RXD–

11 RTS+

12 RTS–

14 CTS+

15 CTS–

70V

Termination

Resistor on

last slave only

PORT 2

(D0–DCM)

RS–422 Slave

RS–422/485 Multi-drop Termination Resistors — It is important you add

termination resistors at each end of the RS422/485 line. This helps reduce data

errors during data transmission. You must select resistors that match the cable

impedance. For example, a typical 22 AWG solid conductor cable with 4.5 twists per

foot has a typical impedance of about 120 ohm.

There are two ways to actually connect the resistors.

• Line-to-Line — this method balances the receive data lines (IN+ and

IN–) and requires one resistor at each end of the line. (The cable

diagrams we’ve provided show this method, but you can use either).

• Line-to-Ground — this method also balances the receive data lines, but

common mode noise rejection is improved significantly. This method

requires two resistors at each end of the line. Also, since there are two

resistors, the sum total of both resistors must match the cable

impedance.

2–7

Installation

and Setup

Data Communications Module, 1st Edition, 08/05

Safety Guidelines

Installation and

Page 22

2–8

Module Specifications

General

Specifications

and Setup

Installation

Installation and Setup

Power Budget Requirement 250mA @ 5 VDC

(not including external 5VDC consumption)

Maximum Number of Modules DL05: 1; DL06: 4

Operating Temperature 32° F to 131° F (0° to 55° C)

Storage Temperature –4° F to 158° F (–20° to 80° C)

Operating Humidity 5 to 95% (non-condensing)

Air Composition No corrosive gases permitted

Vibration MIL STD 810C, Method 514.2

Shock MIL STD 810C, Method 516.2

Voltage Isolation 1000 VAC, 1 minute duration

Insulation Resistance 10M ohms at 500 VDC

Port 1

Specifications

Installation and

Safety Guidelines

Noise Immunity NEMA ICS3–304, UL, CE, (FCC Class A)

Class 1, Division 2 (C1D2)

Weight 1.75 oz. (50g)

Connector 6–pin female modular (RJ12)

Communications RS–232

Protocol

(auto–dectection)

DirectNET slave

K-sequence slave

MODBUS® RTU slave

Station Number 0 – 247

Communication Data 8 data bits, 1 start bit, 1 stop bit (fixed)

Parity Bit None, Odd

Baud Rates 9600, 19200, 38400, 57600, 115200 bps

Transmit Mode ASCII, Hex

Maximum Distance RS–232: 50ft (15 meters)

Port 1

6

5

4

3

2

1

Port 1 Pin Descriptions

10V

25V

3 RXD Receive Data (RS–232)

4 TXD Transmit Data (RS–232)

5 RTS Request to Send

60V

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 23

Port 2

Specifications

Installation and Setup

Connector

15–pin female high–density D–shell

Communications RS–232

RS–422/485

Protocol

(auto–dectection)

DirectNET master/slave

K-Sequence slave

MODBUS® RTU master/slave

Non–sequence (ASCII IN/OUT)

Station Number 0 – 247

Communication Data 8/7 data bits, 1 start bit, 1/2 stop bits

Parity Bit None, Odd, Even

Baud Rates 300, 600, 1200, 4800, 9600, 19200, 38400,

57600, 115200 bps

Transmit Mode ASCII, Hex

Communications Time–out Base time x (1–50)

2–9

Installation

and Setup

Status Indicators

Response Delay Time 0/2/5/10/20/50/100/500ms

Character Time–out 0–9999ms

Maximum Distance RS232 – 15 m

RS422/485 – 1000m

Port 2

15

11

5

10

1

6

Port 2 Pin Descriptions

1 5V 5 VDC

2 TXD2 Transmit Data (RS–232)

3 RXD2 Receive Data (RS–232)

4 RTS2 Ready to Send (RS–232)

5 CTS2 Clear to Send (RS–232)

6 RXD2– Receive Data – (RS–422/485)

7 0V Logic Ground

8 0V Logic Ground

9 TXD2+ Transmit Data + (RS–422/485)

10 TXD2 – Transmit Data – (RS–422/485)

11 RTS2 + Request to Send + (RS–422/485)

12 RTS2 – Request to Send – (RS–422/485

13 RXD2 + Receive Data + (RS–422/485)

14 CTS2 + Clear to Send + (RS422/485)

15 CTS2 – Clear to Send – (RS–422/485)

Indicator State Definition

TX1 (Green) ON Port 1 transmitting data

Safety Guidelines

Installation and

RX1 (Green)

ERR (Red)

ON

ON

Port 1 receiving data

Port 1 Timeout, NAK or Exception

Response

TX2 (Green) ON Port 2 transmitting data

RX2 (Green)

ERR (Red)

ON

ON

Port 2 receiving data

Port 2 Timeout, NAK or Exception

Response

Data Communications Module, 1st Edition, 08/05

Page 24

Page 25

D0–DCM Module

Configuration

Registers

In This Chapter. . . .

— DCM Port Configuration Registers

— DL05 Ladder Logic Port Setup Examples

— DL06 Ladder Logic Port Setup Examples

3

Page 26

3–2

D0–DCM Setup

DCM Port Configuration Registers

Module

Configuration

Registers

DCM Port

Configuration

The table below lists the special V-memory locations used by the DL05 and DL06

PLCs for the D0–DCM module. The following pages define each registers function.

Module Configuration

Parameters

Port 1–Transmit Mode

A

(ASCII/Hex), Protocol

Port 1–Station Address,

B

Baud Rate , Parity

Port 2–RTS On/Off Delay,

Transmit Mode (ASCII/

C

Hex), Protocol, Comm

Time–out, RS–485 Mode

Select

Port 2–Station Address,

D

Baud Rate, Data Bit , Stop

Bit , Parity

Port 2–Character Time–

E

out

Port1/Port 2 – Setup

F

Completion Code

Port 1/Port 2–

G

Reset Time–out

Word

Offset

+0000 V7700 V700 V710 V720 V730

+0001 V7701 V701 V711 V721 V731

+0002 V7702 V702 V712 V722 V732

+0003 V7703 V703 V713 V723 V733

+0006 V7706 V706 V716 V726 V736

+0007 V7707 V707 V717 V727 V737

DL05 and DL06 Option Slot

DL05

V7730 V7730 V7731 V7732 V7733

DL06

Slot 1

DL06

Slot 2

DL06

Slot 3

DL06

Slot 4

Comm Port

Default

Configuration

Parameters

Installation and

Safety Guidelines

On power up, the DCM will write the necessary data to the V–memory configuration

registers to result with the following default port communications parameters. If you

need to change any of the default settings, you must use ladder logic code to update

the appropriate configuration register.

Default Settings

Parameter Port 1 Port 2

Baud Rate 9600bps 19200bps

Parity Odd

Protocol K–Sequence/DirectNet/MODBUS

(auto–detect)

Station Address 1

Data Bits 8 (fixed) 8

Stop Bits 1 (fixed) 1

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 27

3–3

D0–DCM Setup

Protocol Selection:

Communications Port for DirectSOFT32 Programming: If you plan to program the CPU

through the D0–DCM, then you can use either DirectNET protocol or our proprietary

K-sequence protocol.

Computer or Operator Interface: If you’re using the D0–DCM to connect a computer or

operator interface, check your documentation to see which protocol the PC or OI is using.

MODBUS® RTU: The D0–DCM can serve as a MODBUS® slave (port1 and 2) or as a

MODBUSmaster (port 2 only).

Communication Timeout:

developing your own DirectNET programs. By disabling the timeout, you can send one

DirectNET component without any communication timeout problems. If you have this

timeout disabled and a communication error does occur, you must restart communications

by sending a retry or an End of Transmission (EOT) command. If you want to know more, see

the DirectNET manual for details.

Transmit Mode:

fastest communication possible, use HEX mode, which is the default. The difference is in the way

the data is represented. The same data is twice as long in ASCII format, so if there’s more data, it

takes longer to transfer. If you have a device on the network that requires ASCII mode, then

configure the DCM for ASCII mode, otherwise, use HEX mode.

Baud Rate:

115.2Kbps. All stations must have the same baud rate before the communications will

operate correctly. Usually, you should use the highest baud rate possible unless noise

problems appear. If noise problems appear, try reducing the baud rates.

Parity:

RTS Delay Times:

waits to send the data after it has raised the RTS signal line. This is normally set to 0, and is

typically only adjusted if you are using the D0–DCM with a radio modem. If you are using the

D0–DCM with a radio modem, check your modem documentation to help you choose the

proper setting. Also, if you’re considering the use of a modem, check out Appendix D. It may

be of some help. RTS Off Delay – the delay time specifies the amount of time the D0–DCM

will wait to reset the RTS line after sending the data.

Address Selection

have a unique address. If you’re using the D0–DCM as a master, make sure you select

address 0. For example, a RLL communications program, the DirectSOFT32 Programming

Software, and our KEPDirect for PLCs all use the decimal equivalent of the HEX address. It’s

easy to convert from hex to decimal.

Choose between none, even and odd parity for error checking.

Select between ASCII and HEX modes of data representation. If you want the

There are several baud rate selections available ranging from 300bps to

On Delay – The delay time specifies the amount of time the D0–DCM

: The addresses do not have to be consecutive, but each station must

Communication Timeout Disable is normally used only if you’re

Configuration

DCM Port

Safety Guidelines

Installation and

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 28

3–4

D0–DCM Setup

A: Port 1 –

Transmit Mode,

Protocol

DCM Port

Configuration

Use word +0000 to set Port 1:

• K–Sequence slave, DirectNET slave or MODBUS RTU slave protocol

(or auto–detect for all three protocols)

• HEX or ASCII transmit mode

word +0000

1

5

MSB LSB

Protocol

Transmit Mode

Set all unused bits to zero.

Port 1: Transmit Mode

Mode Bit 3

HEX Mode 0

ASCII Mode 1

Port 1: Protocol

Protocol Bit 7–4

(Hex)

K–Sequence 8 1 0 0 0

DirectNet 4 0 1 0 0

MODBUS RTU 2 0 0 1 0

K–Seq / D–Net

/MODBUS RTU

E 1 1 1 0

Bit 7 Bit 6 Bit 5 Bit 4

07654321

Installation and

Safety Guidelines

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 29

D0–DCM Setup

3–5

B: Port 1 –

Station Address,

Baud Rate,

Parity

Use word +0001 to set Port 1:

• Station address ranges from 0–247 (00–F7 Hex)

• Baud rates ranging from 9.6K to 115.2K bps

• Odd or No parity

word +0001

1514131

MSB

Parity

Set all unused bits to zero.

Address Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

00 0 0 0 0 0 0 0 0

01 0 0 0 0 0 0 0 1

02 0 0 0 0 0 0 1 0

– – – – –

F6 1 1 1 1 0 1 1 0

F7 1 1 1 1 0 1 1 1

111

0

2

987654321

Baud

Rate

Station

Address

0

LSB

Port 1: Station Address

Configuration

DCM Port

Port 1: Baud Rate

Baud Rate Bit 10 Bit 9 Bit 8

9.6 K bps 0 0 0

19.K bps 0 0 1

38.4K bps 0 1 0

57.6K bps 0 1 1

115.2K bps 1 0 0

Port 1: Parity

Parity Bit 14

No Parity 0

Odd Parity 1

DL05/06 Data Communications Module, 1st Edition, 08/05

Safety Guidelines

Installation and

Page 30

3–6

D0–DCM Setup

C: Port 2 –

RTS On/Off delay,

Transmit Mode,

Protocol,

Comm Time–out,

RS–485 Mode

Use word +0002 to set Port 2:

• K–Sequence slave, DirectNET slave or MODBUS RTU slave protocol

(or auto–detect for all three protocols)

• HEX or ASCII transmit mode

• RTS On and Off delay times

• Communication Time–out

• Echo Suppression

word +0002

1514131

MSB

RTS on

delay

111

0

2

Echo

Suppression

987654321

Comm

Time–out

Protocol

Transmit

Mode

0

LSB

RTS off

delay

Set all unused bits to zero.

DCM Port

Configuration

Installation and

Safety Guidelines

Port 2: RTS Off Delay

Time (ms) Bit 2 Bit 1 Bit 0

0 0 0 0

2 0 0 1

5 0 1 0

10 0 1 1

20 1 0 0

50 1 0 1

100 1 1 0

500 1 1 1

Base Time–out for K–Seq/D–Net = 800ms

Base Time–out for MODBUS = 500ms

Port 2: Transmit Mode

Mode Bit 3

HEX Mode 0

ASCII Mode 1

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 31

Port 2: Protocol

Protocol Bit 7–4

(Hex)

K–Sequence 8 1 0 0 0

DirectNet 4 0 1 0 0

MODBUS RTU 2 0 0 1 0

Non–Sequence 1 0 0 0 1

K–Seq / D–Net

/MODBUS RTU

K–Seq, D–Net,

MODBUS RTU

Base Time x 1 0 0 0 0

Base Time x 1.2 2 0 0 1

Base Time x 1.5 5 0 1 0

Base Time x 2 10 0 1 1

Base Time x 5 20 1 0 0

Base Time x 10 50 1 0 1

Base Time x 20 100 1 1 0

Base Time x 50 500 1 1 1

E 1 1 1 0

Port 2: Communication Time–out (ms)

Bit 7 Bit 6 Bit 5 Bit 4

Non–Sequence

Protocol

Bit 10 Bit 9 Bit 8

3–7

D0–DCM Setup

Configuration

DCM Port

Port 2: Echo Suppression

Mode Bit 11

RS–422/485: 4–wire

RS–232

RS–485: 2–wire 1

Port 2: RTS On Delay

Time (ms) Bit 14 Bit 13 Bit 12

0 0 0 0

2 0 0 1

5 0 1 0

10 0 1 1

20 1 0 0

50 1 0 1

100 1 1 0

500 1 1 1

0

Safety Guidelines

Installation and

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 32

3–8

D0–DCM Setup

D: Port 2 –

Station Address,

Baud Rate,

Data Bit,

Stop Bit,

Parity

DCM Port

Configuration

Use word +0003 to set Port 2:

• Station address ranges from 0–247 (00–F7 Hex)

• Baud rates ranging from 9.6K to 115.2K bps

• Data Bit Length (7 or 8 bits)

• Stop Bit Length (1 or 2 bits)

• Odd, Even or No Parity

word +0003

1514131

MSB

Parity

Stop

Bit

Address Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

00 0 0 0 0 0 0 0 0

01 0 0 0 0 0 0 0 1

02 0 0 0 0 0 0 1 0

–––––

F6 1 1 1 1 0 1 1 0

F7 1 1 1 1 0 1 1 1

111

2

Data

Bit

0

987654321

Baud

Rate

Station

Address

Set all unused bits to zero.

0

LSB

Port 2: Station Address

Installation and

Safety Guidelines

DL05/06 Data Communications Module, 1st Edition, 08/05

Port 2: Baud Rate

Baud Rate Bit 11 Bit 10 Bit 9 Bit 8

300 bps 0 0 0 0

600 bps 0 0 0 1

1200 bps 0 0 1 0

2400 bps 0 0 1 1

4800 bps 0 1 0 0

9600 bps 0 1 0 1

19.K bps 0 1 1 0

38.4K bps 0 1 1 1

57.6K bps 1 0 0 0

115.2K bps 1 0 0 1

Page 33

Port 2: Data Bit

Length Bit 12

8 Bit 0

7 Bit 1

Port 2: Stop Bit

Length Bit 13

1 Bit 0

2 Bit 1

Port 2: Parity

Parity Bit 15 Bit 14

No Parity 0 0

Odd Parity 0 1

Even Parity 1 0

3–9

D0–DCM Setup

Configuration

DCM Port

E: Port 2 –

Character

Time–out

Use word +0006 to set Port 2:

• Character Time–out (BCD)

This parameter is used when the DCM is used as a MODBUS RTU master.

word +0006

1514131

MSB

Bit 15–0 time

0 3.5 characters

1–9999 (BCD) time–out (ms)

111

0

2

Port 2: Character Time–out

987654321

Character

Time–out

(BCD)

0

LSB

Safety Guidelines

Installation and

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 34

3–10

Port 1: Bit 0 7

D0–DCM Setup

F: Port 1 and 2

Setup and

Completion Code

G: Port 1 and 2

Reset Time–out

Word +0007 is used for Port 1 and Port 2 to :

• request that the DCM recognizes changes in the port(s) communication

parameters from default or previous settings

• confirm that Port 1 and Port 2 configuration is complete

word +0007

1

5

MSB

Set all unused

bits to zero.

Loading a K0055 (BCD) into word +0007 will request that the DCM recognizes (looks for) new

or desired port communication parameters that are written to the DCM port configuration

registers. If the requested changes are valid, a 00AA (hex) will then be written to word +0007.

If the desired or new communications are invalid or out of range, an error code 00E* (Hex) will

be written to word +0007. The last digits indicate the address that has an error. For example,

error code 00E2 means that word +0002 has an error.

Use word +0024 to set Port 1 and Port 2:

• Reset Time–out in seconds

Port Configuration

Completion Code

07654321

LSB

DCM Port

Configuration

Installation and

Safety Guidelines

The communication port will reset after the specified time after the port goes from the BUSY

state to the IDLE state.

word +0024

1514131

MSB

Port 1: Bit 0–7

Port 2: Bit 15–8

111

0

2

Port 2 Reset

Time–out

(BCD)

Port Time(s) Function

987654321

Port 1 Reset

Time–out

(BCD)

Reset Time–out

0 Disable

1–99 Enable

0

LSB

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 35

DL05 Port Setup Examples

3–11

D0–DCM Setup

Port 1 Example:

(This port can

serve as slave

only)

Port 2 Example:

Slave Mode

SP0

SP0

LD

KE0

OUT

V7700

LD

K4001

OUT

V7701

LD

K55

OUT

V7707

LD

KE0

Selects auto–detect protocol mode

(K–seq, D–Net and MODBUS) and

HEX transmit mode.

Write configuration data into V7700.

Selects station address 1, baud rate

of 9600bps and odd parity.

Write configuration data into V7701.

K55 is the port setup completion

code that must be used to request

that the CPU recognizes the

new/desired port parameters

Write configuration data into V7707.

Selects auto–detect protocol mode (K–seq,

D–Net and MODBUS), HEX transmit mode,

RTS On/Off delay times are set to zero and

RS–422/485 (4–wire) / RS–232

Configuration

DCM Port

OUT

V7702

Write configuration data into V7702.

Selects station address 1, baud rate

LD

K4601

OUT

V7703

of 19200bps, odd parity, 8–bit data

length and 1 stop bit.

Write configuration data into V7703.

K55 is the port setup completion

LD

K55

code that must be used to request

that the CPU recognizes the

new/desired port parameters

OUT

V7707

Write configuration data into V7707.

DL05/06 Data Communications Module, 1st Edition, 08/05

Safety Guidelines

Installation and

Page 36

3–12

D0–DCM Setup

Port 2 Example:

DirectNet Master

Port 2 Example:

MODBUS RTU

Master

DCM Port

Configuration

SP0

SP0

LD

K40

OUT

V7702

LD

K4601

OUT

V7703

LD

K55

OUT

V7707

LD

K20

Selects DirectNet protocol, HEX transmit

mode, RTS On/Off delay times are set to

zero and RS–422/485 (4–wire) / RS–232

Write configuration data into V7702.

Selects station address 1, baud rate

of 19200bps, odd parity, 8–bit data

length and 1 stop bit.

Write configuration data into V7703.

K55 is the port setup completion

code that must be used to request

that the CPU recognizes the

new/desired port parameters

Write configuration data into V7707.

Selects MODBUS protocol, HEX transmit

mode, RTS On/Off delay times are set to

zero and RS–422/485 (4–wire) / RS–232

Installation and

Safety Guidelines

OUT

V7702

LD

K4601

OUT

V7703

LD

K0

OUT

V7706

LD

K55

OUT

V7707

Write configuration data into V7702.

Selects station address 1, baud rate

of 19200bps, odd parity, 8–bit data

length and 1 stop bit.

Write configuration data into V7703.

Selects 3.5 characters length

time–out.

Write configuration data into V7706.

K55 is the port setup completion

code that must be used to request

that the CPU recognizes the

new/desired port parameters

Write configuration data into V7707.

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 37

DL06 Port Setup Examples

The following examples assumes the D0–DCM is installed in slot 1.

3–13

D0–DCM Setup

Port 1 Example:

Slave Mode Only

Port 2 Example:

Slave Mode

SP0

SP0

LD

KE0

OUT

V700

LD

K4001

OUT

V701

LD

K55

OUT

V707

LD

KE0

OUT

V702

Selects auto–detect protocol mode

(K–seq, D–Net and MODBUS) and

HEX transmit mode.

Write configuration data into V700 (based

on module slot location).

Selects station address 1, baud rate

of 9600bps and odd parity.

Write configuration data into V701 (based

on module slot location).

K55 is the port setup completion

code that must be used to request

that the CPU recognizes the

new/desired port parameters

Write configuration data into V707 (based

on module slot location).

Selects auto–detect protocol mode (K–seq,

D–Net and MODBUS), HEX transmit mode,

RTS On/Off delay times are set to zero and

RS–422/485 (4–wire) / RS–232

Write configuration data into V702 (based

on module slot location).

Configuration

DCM Port

Safety Guidelines

Installation and

Selects station address 1, baud rate

LD

K4601

OUT

V703

of 19200bps, odd parity, 8–bit data

length and 1 stop bit.

Write configuration data into V703 (based

on module slot location).

K55 is the port setup completion

LD

K55

code that must be used to request

that the CPU recognizes the

new/desired port parameters

OUT

V707

Write configuration data into V707 (based

on module slot location).

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 38

3–14

D0–DCM Setup

Port 2 Example:

DirectNet Master

Port 2 Example:

MODBUS RTU

Master

DCM Port

Configuration

SP0

SP0

LD

K40

OUT

V702

LD

K4601

OUT

V703

LD

K55

OUT

V707

LD

K20

OUT

V702

Selects DirectNet protocol, HEX transmit

mode, RTS On/Off delay times are set to

zero and RS–422/485 (4–wire) / RS–232

Write configuration data into V702 (based

on module slot location).

Selects station address 1, baud rate

of 19200bps, odd parity, 8–bit data

length and 1 stop bit.

Write configuration data into V703 (based

on module slot location).

K55 is the port setup completion

code that must be used to request

that the CPU recognizes the

new/desired port parameters

Write configuration data into V707 (based

on module slot location).

Selects MODBUS protocol, HEX transmit

mode, RTS On/Off delay times are set to

zero and RS–422/485 (4–wire) / RS–232C

Write configuration data into V702 (based

on module slot location).

Installation and

Safety Guidelines

DL05/06 Data Communications Module, 1st Edition, 08/05

LD

K4601

OUT

V703

LD

K0

OUT

V706

LD

K55

OUT

V707

Selects station address 1, baud rate

of 19200bps, odd parity, 8–bit data

length and 1 stop bit.

Write configuration data into V703 (based

on module slot location).

Selects 3.5 characters length

time–out.

Write configuration data into V706 (based

on module slot location).

K55 is the port setup completion

code that must be used to request

that the CPU recognizes the

new/desired port parameters

Write configuration data into V707 (based

on module slot location).

Page 39

RLL Programming for

Communications

In This Chapter. . . .

— PLC-to-PLC Communications

— How RLL is Used for Communications

— Network Instructions

1

4

— Addressing the Different Memory Types

— Special Relays for Communications

— Example Program with One Read Instruction

— Example Program with One Write Instruction

— Integrating Multiple Read and Write Instructions

Page 40

4–2

PLC-to-PLC Communications

Getting Started

How RLL is Used for Communications

RLL Programming for Communications

This chapter steps you through the development of a Relay Ladder Logic (RLL)

program to enable one PLC to communicate with another PLC. For the experienced

programmer of DirectLOGIC PLCs, the communication programs presented in this

chapter will be simple to follow . If you have never programmed a DirectLOGIC PLC,

you may want to refer to the DirectSOFT32 Programming Software User Manual

and the User Manual for your PLC for additional information.

NOTE: The programs described in this chapter are not used for communication

between a PC and a PLC. For PC-to-PLC communications, please see the product

documentation for the PC software you are using.

DirectSOFT32 Programming Software provides Read and Write instructions

(RX/WX) for PLC-to-PLC communication over a network. The Read and Write

instructions are part of the ladder logic program running in the CPU of the initiating,

or master, PLC. These instructions tell the initiating CPU to send a message over the

serial network to a responding, or slave, PLC. The initiating PLC’s Read or Write

communication finds its destination by the slave address of the responding PLC.

Guidelines

User Application

RLL Programming

for Communications

Master DCM

O

O

U

CPU CPU

T

P

U

T

Slave 1

I

N

P

U

T

O

I

U

N

T

P

P

U

U

T

T

O

U

Slave 2

T

P

U

T

W

r

R

e

a

d

I

U

N

i

t

e

T

P

P

U

U

T

T

Slave 3

CPUCPU

NOTE: When all slave’s addresses are set to 0 (zero), the master D0–DCM can write

data to all slaves at the same time using the WX instruction. This is referred to as

“broadcast mode”. If this mode is used, the master DCM cannot use the RX

instruction to read data from individual slaves.

I

N

P

U

T

I

N

P

U

T

O

U

T

P

U

T

O

E

U

C

O

M

T

P

U

T

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 41

Network Instructions

4–3

RLL Programming for Communications

Read (RX) and

Write (WX)

Instructions

Building the

Read (RX) or

Write (WX)

Routine

The Read (RX) and Write (WX) instructions are used by the master PLC to Read a

block of data from another PLC or Write a block of data to another PLC. To perform

their functions, the RX and WX boxes must be preceded in the ladder logic program

by two Load instructions and one Load Address instruction.

The Load and Load Address instructions load communication parameters into the

accumulator and the first and second level of the accumulator stack. The RX or

WX instruction takes these parameters from the stack and the accumulator and

prepares the data to be sent over the network. If you need to know more about the

function of the accumulator and the accumulator stack, refer to the User Manual for

your PLC.

For network communications, you build

the Read (RX) or Write (WX) instructions

into a routine which requires the four

instructions you see to the right. The

function of each of these instructions is

explained below or on the next page. They

LD

A aaa

LD

A aaa

must be used in the sequence shown.

LDA

O aaa

RX or WX

A aaa

User Application

Guidelines

The First LD

Instruction

The first Load (LD) instruction accepts either a constant or a variable. Use a “K” to

designate the number as a constant. Use a “V” if you are entering the address of a

register. The contents of that register perform the same function as the constant

shown below . For example, you could use V2000 in place of K0114. If the contents of

V2000 is the number “114,” the function would be the same. Using a variable allows

changing parameters while the program is running. It is recommended, however, t o

use a constant when possible.

DCM Slot Number

Master PLC

Upper Byte

K

1140

Lower Byte

SlaveMaster DCM

Slave Address # (Hex)

Slave Device on Network

LD

K114

for Communications

RLL Programming

DL05/06 Data Communications Module, 1st Edition, 08/05

Page 42

4–4

RLL Programming for Communications

The Second LD

Instruction

Getting Started

The LDA

Instruction

Guidelines

User Application

RLL Programming

for Communications

The second Load (LD) instruction

determines the length of the data block to

be transmitted during the Read or Write

communication. This instruction will also

accept two data types. Use a “K” to

designate the number as a constant. Use a

“V” if you are entering the address of a

register.

For Word Memory data, you must use a

multiple of two bytes between 2 and 128.

For Bit Memory data, you can use any

multiple of one byte between 1 and 128.

For more information about addressing

Word and Bit Memory, see page 4-6.

PLC Memory

The Load Address (LDA) instruction

specifies the V-memory address of the

beginning memory register in the master

PLC. The data block to be transmitted will

begin at this address and extend the

number of bytes specified in the preceding

LD instruction. The leading “O” indicates

this is an octal number. Simply substitute

the letter “O” for the “V” in the V-memory

designation. For example, V40600

becomes O40600.

Read instructions copy the data block from

the slave PLC memory into the master PLC

memory.

Write instructions copy the data block from

the master PLC memory into the slave PLC

memory.

LD

K114

LD

K8

4 words = 8 bytes

LD

K114

LD

K8

LDA

O40600

Master PLC

DL05/06 Data Communications Module, 1st Edition, 08/05

V40577

V40600

V40601

V40602

V40603

V40604

Page 43

RLL Programming for Communications

s

e

4–5

Read (RX)

Instruction

The Read (RX) instruction specifies the

memory location to be read from the slave

PLC.

A block of data is read that begins at the

specified memory location and extends the

number of bytes specified in the second LD

instruction.

In this example, the eight byte block of data

beginning at C100 and ending at C177 in

the slave PLC is read (copied) into the

master PLC’s memory beginning at

V40600.

ad

e

R

Master PLC

V40577

V40600

V40601

V40602

V40603

V40604

byte

word 4 words = 8 bytes

byte

Slave PLC

bit

LD

LD

LDA

RX