Page 1

CTRIO

High-Speed Counter

Module

Manual Number: HX-CTRIO-M

Page 2

~ WARNING ~

Thank you for purchasing automation equipment from Automationdirect.com®, doing business as,

AutomationDirect. We want your new automation equipment to operate safely. Anyone who installs or

uses this equipment should read this publication (and any other relevant publications) before installing or

operating the equipment.

To minimize the risk of potential safety problems, you should follow all applicable local and national

codes that regulate the installation and operation of your equipment. These codes vary from area to area

and usually change with time. It is your responsibility to determine which codes should be followed, and

to verify that the equipment, installation, and operation is in compliance with the latest revision of these

codes.

At a minimum, you should follow all applicable sections of the National Fire Code, National Electrical

Code, and the codes of the National Electrical Manufacturer’s Association (NEMA). There may be local

regulatory or government offices that can also help determine which codes and standards are necessary for

safe installation and operation.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable

codes and standards. We do not guarantee the products described in this publication are suitable for

your particular application, nor do we assume any responsibility for your product design, installation, or

operation.

Our products are not fault-tolerant and are not designed, manufactured or intended for use or resale as

on-line control equipment in hazardous environments requiring fail-safe performance, such as in the

operation of nuclear facilities, aircraft navigation or communication systems, air traffic control, direct life

support machines, or weapons systems, in which the failure of the product could lead directly to death,

personal injury, or severe physical or environmental damage (“High Risk Activities”). AutomationDirect

specifically disclaims any expressed or implied warranty of fitness for High Risk Activities.

For additional warranty and safety information, see the Terms and Conditions section of our catalog.

If you have any questions concerning the installation or operation of this equipment, or if you need

additional information, please call us at 770-844-4200.

This publication is based on information that was available at the time it was printed. At

AutomationDirect we constantly strive to improve our products and services, so we reserve the right to

make changes to the products and/or publications at any time without notice and without any obligation.

This publication may also discuss features that may not be available in certain revisions of the product.

Trademarks

This publication may contain references to products produced and/or offered by other companies. The

product and company names may be trademarked and are the sole property of their respective owners.

AutomationDirect disclaims any proprietary interest in the marks and names of others.

Copyright 2021, Automationdirect.com® Incorporated

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior, written

consent of Automationdirect.com® Incorporated. AutomationDirect retains the exclusive rights to all

information included in this document.

All Rights Reserved

Page 3

~ ADVERTENCIA ~

Gracias por comprar equipo de automatización de Automationdirect.com®. Deseamos que su nuevo equipo

de automatización opere de manera segura. Cualquier persona que instale o use este equipo debe leer esta

publicación (y cualquier otra publicación pertinente) antes de instalar u operar el equipo.

Para reducir al mínimo el riesgo debido a problemas de seguridad, debe seguir todos los códigos de seguridad

locales o nacionales aplicables que regulan la instalación y operación de su equipo. Estos códigos varian de

área en área y usualmente cambian con el tiempo. Es su responsabilidad determinar cuales códigos deben ser

seguidos y verificar que el equipo, instalación y operación estén en cumplimiento con la revisión mas reciente

de estos códigos.

Como mínimo, debe seguir las secciones aplicables del Código Nacional de Incendio, Código Nacional Eléctrico,

y los códigos de (NEMA) la Asociación Nacional de Fabricantes Eléctricos de USA. Puede haber oficinas de

normas locales o del gobierno que pueden ayudar a determinar cuales códigos y normas son necesarios para una

instalación y operación segura.

Si no se siguen todos los códigos y normas aplicables, puede resultar en daños al equipo o lesiones serias a

personas. No garantizamos los productos descritos en esta publicación para ser adecuados para su aplicación

en particular, ni asumimos ninguna responsabilidad por el diseño de su producto, la instalación u operación.

Nuestros productos no son tolerantes a fallas y no han sido diseñados, fabricados o intencionados para uso

o reventa como equipo de control en línea en ambientes peligrosos que requieren una ejecución sin fallas,

tales como operación en instalaciones nucleares, sistemas de navegación aérea, o de comunicación, control de

tráfico aéreo, máquinas de soporte de vida o sistemas de armamentos en las cuales la falla del producto puede

resultar directamente en muerte, heridas personales, o daños físicos o ambientales severos (“Actividades de Alto

Riesgo”). Automationdirect.com específicamente rechaza cualquier garantía ya sea expresada o implicada

para actividades de alto riesgo.

Para información adicional acerca de garantía e información de seguridad, vea la sección de Términos

y Condiciones de nuestro catálogo. Si tiene alguna pregunta sobre instalación u operación de este equipo, o

si necesita información adicional, por favor llámenos al número 770-844-4200 en Estados Unidos.

Esta publicación está basada en la información disponible al momento de impresión. En Automationdirect.

com nos esforzamos constantemente para mejorar nuestros productos y servicios, así que nos reservamos el

derecho de hacer cambios al producto y/o a las publicaciones en cualquier momento sin notificación y sin

ninguna obligación. Esta publicación también puede discutir características que no estén disponibles en ciertas

revisiones del producto.

Marcas Registradas

Esta publicación puede contener referencias a productos producidos y/u ofrecidos por otras compañías. Los nombres de las

compañías y productos pueden tener marcas registradas y son propiedad única de sus respectivos dueños. Automationdirect.com,

renuncia cualquier interés propietario en las marcas y nombres de otros.

PROPIEDAD LITERARIA 2021, AUTOMATIONDIRECT.COM® INCORPORATED

No se permite copiar, reproducir, o transmitir de ninguna forma ninguna parte de este manual sin previo consentimiento por escrito

de Automationdirect.com

este documento. Los usuarios de este equipo pueden copiar este documento solamente para instalar, configurar y mantener el equipo

correspondiente. También las instituciones de enseñanza pueden usar este manual para propósitos educativos.

®

Incorprated. Automationdirect.com retiene los derechos exclusivos a toda la información incluida en

Todos los derechos reservados

Page 4

~ AVERTISSEMENT ~

Nous vous remercions d’avoir acheté l’équipement d’automatisation de Automationdirect.com®, en faisant des

affaires comme, AutomationDirect. Nous tenons à ce que votre nouvel équipement d’automatisation fonctionne en

toute sécurité. Toute personne qui installe ou utilise cet équipement doit lire la présente publication (et toutes les

autres publications pertinentes) avant de l’installer ou de l’utiliser.

Afin de réduire au minimum le risque d’éventuels problèmes de sécurité, vous devez respecter tous les codes locaux

et nationaux applicables régissant l’installation et le fonctionnement de votre équipement. Ces codes diffèrent d’une

région à l’autre et, habituellement, évoluent au fil du temps. Il vous incombe de déterminer les codes à respecter et

de vous assurer que l’équipement, l’installation et le fonctionnement sont conformes aux exigences de la version la

plus récente de ces codes.

Vous devez, à tout le moins, respecter toutes les sections applicables du Code national de prévention des incendies,

du Code national de l’électricité et des codes de la National Electrical Manufacturer’s Association (NEMA). Des

organismes de réglementation ou des services gouvernementaux locaux peuvent également vous aider à déterminer

les codes ainsi que les normes à respecter pour assurer une installation et un fonctionnement sûrs.

L’omission de respecter la totalité des codes et des normes applicables peut entraîner des dommages à l’équipement

ou causer de graves blessures au personnel. Nous ne garantissons pas que les produits décrits dans cette publication

conviennent à votre application particulière et nous n’assumons aucune responsabilité à l’égard de la conception, de

l’installation ou du fonctionnement de votre produit.

Nos produits ne sont pas insensibles aux défaillances et ne sont ni conçus ni fabriqués pour l’utilisation ou la revente

en tant qu’équipement de commande en ligne dans des environnements dangereux nécessitant une sécurité absolue,

par exemple, l’exploitation d’installations nucléaires, les systèmes de navigation aérienne ou de communication, le

contrôle de la circulation aérienne, les équipements de survie ou les systèmes d’armes, pour lesquels la défaillance du

produit peut provoquer la mort, des blessures corporelles ou de graves dommages matériels ou environnementaux

(«activités à risque élevé»). La société AutomationDirect nie toute garantie expresse ou implicite d’aptitude à

l’emploi en ce qui a trait aux activités à risque élevé.

Pour des renseignements additionnels touchant la garantie et la sécurité, veuillez consulter la section Modalités et

conditions de notre documentation. Si vous avez des questions au sujet de l’installation ou du fonctionnement de cet

équipement, ou encore si vous avez besoin de renseignements supplémentaires, n’hésitez pas à nous téléphoner au

770-844-4200.

Cette publication s’appuie sur l’information qui était disponible au moment de l’impression. À la société

AutomationDirect, nous nous efforçons constamment d’améliorer nos produits et services. C’est pourquoi nous

nous réservons le droit d’apporter des modifications aux produits ou aux publications en tout temps, sans préavis ni

quelque obligation que ce soit. La présente publication peut aussi porter sur des caractéristiques susceptibles de ne

pas être offertes dans certaines versions révisées du produit.

Marques de commerce

La présente publication peut contenir des références à des produits fabriqués ou offerts par d’autres entreprises. Les

désignations des produits et des entreprises peuvent être des marques de commerce et appartiennent exclusivement à

leurs propriétaires respectifs. AutomationDirect nie tout intérêt dans les autres marques et désignations.

Copyright 2021, Automationdirect.com® Incorporated

Nulle partie de ce manuel ne doit être copiée, reproduite ou transmise de quelque façon que ce soit sans le

consentement préalable écrit de la société Automationdirect.com® Incorporated. AutomationDirect conserve les

droits exclusifs à l’égard de tous les renseignements contenus dans le présent document.

Tous droits réservés

Page 5

CTRIO HIgH-Speed COunTeR uSeR Manual

Please include the Manual Number and the Manual Issue, both shown below,

when communicating with Technical Support regarding this publication.

Manual Number: HX-CTRIO-M

Issue: 3rd Edition, Rev. E

Issue Date: 03/21

Publication History

Issue Date Description of Changes

First Edition 9/01 Original

Rev. A 10/01 Corrections

Rev. B 8/02 Corrections

Second Edition 2/03 Added T1H-CTRIO and H4-CTRIO. Updated for CTRIO/Workbench version 2.

Rev. A Added H0-CTRIO and flowcharts.

Rev. B 10/03 Corrections

Rev. C 03/11 Made corrections and updated manual.

Updated manual with new H0-CTRIO2 and H2-CTRIO2 information.

Rev. D 2/13

Rev. E 09/13

Third Edition 06/16 Completely reworked and reorganized manual.

Added Do-more PLC series data and examples.

Updated CTRIO Workbench section with new pulse profiles available.

Made minor corrections throughout manual.

Added Do-more structure table to Chapter 6.

Added Appendix A, Appendix B and Appendix C which contain flowcharts for various

instructions

Made minor corrections throughout manual.

Rev. A 11/18 Revised and added material to Appendix B.

Rev. B 6/19 Revised and added material to Chapter 9, pp 28-34.

Rev. C 10/19 Revised and added material to Chapter 1, pp 9, Chapter 2, pp 5.

Rev. D 08/20 T1H-PBC module retired; added notes to Ch1, Ch3, and Ch7 accordingly.

Rev. E 08/20 Revised ladder program B-14, B-15, B-16.

Page 6

Table of ConTenTs

Chapter 1 - Introduction to the CTRIO & CTRIO2 Modules

Introduction ............................................................................................................... 1–2

Conventions Used ...................................................................................................... 1–3

CTRIO and CTRIO2 Module Overview ...................................................................... 1–4

Support Systems for the CTRIO(2) Modules ............................................................1–6

CTRIO(2) Specifications ............................................................................................. 1–7

H0-CTRIO(2) LED Indicators .................................................................................... 1–10

H2-CTRIO(2) LED Indicators .................................................................................... 1–11

H4-CTRIO LED Indicators .........................................................................................1–12

T1H-CTRIO LED Indicators.......................................................................................1–13

Overview, How it Works as Part of the Control System .........................................1–14

CTRIO(2) Module Work Flow Diagram ...................................................................1–17

Chapter 2 - Getting Started, Basics and Examples

Overview .................................................................................................................... 2-2

Basic Motion Functions, Summary of Examples ....................................................... 2-2

Detailed Example: Configure and Test a Quadrature Input ................................... 2-7

Detailed Example: Configure and Test a Pulse Output w/Trapezoidal Profile ..... 2-16

Flow Chart Example: Configure and Test a Pulse Output w/Trapezoidal Profile 2-27

Chapter 3 - Installation and Field Wiring

Installing the H0-CTRIO(2) Module .......................................................................... 3-2

Setting H0-CTRIO(2) Jumpers ................................................................................... 3-3

Page 7

Table of Contents

H0- CTRIO(2) Quadrature Encoder Wiring Example ................................................ 3-5

H0-CTRIO(2) TTL Quadrature Encoder Field Wiring ............................................... 3-6

H0- CTRIO(2) TTL Input Wiring ................................................................................ 3-7

H0- CTRIO(2) Output Wiring Schematic ................................................................... 3-8

H0-CTRIO(2) Stepper/Servo Drive Wiring Example ................................................. 3-9

Solid State Input Device Wiring to the H0-CTRIO(2) Module ............................... 3-10

Installing the H2-CTRIO(2) Module ........................................................................ 3-11

Setting H2-CTRIO(2) Jumpers ................................................................................. 3-12

Wiring the H2-CTRIO(2) Module ............................................................................ 3-13

H2- CTRIO(2) Quadrature Encoder Wiring Example .............................................. 3-14

H2-CTRIO(2) TTL Quadrature Encoder Field Wiring .............................................. 3-15

H2-CTRIO(2) TTL Input Wiring ............................................................................... 3-16

H2- CTRIO(2) Output Wiring Schematic ................................................................. 3-17

H2-CTRIO(2) Stepper/Servo Drive Wiring Example ............................................... 3-18

Solid State Input Device Wiring to the H2-CTRIO(2) Module ............................... 3-19

Installing the H4-CTRIO ........................................................................................... 3-20

Wiring the H4-CTRIO Module ................................................................................. 3-21

H4-CTRIO Quadrature Encoder Wiring Example .................................................... 3-22

H4-CTRIO TTL Quadrature Encoder Field Wiring ................................................... 3-23

H4-CTRIO TTL Input Wiring .................................................................................... 3-24

H4-CTRIO Output Wiring Schematic ....................................................................... 3-25

H4-CTRIO Stepper/Servo Drive Wiring Example .................................................... 3-26

Solid State Input Device Wiring to the H4-CTRIO Module .................................... 3-27

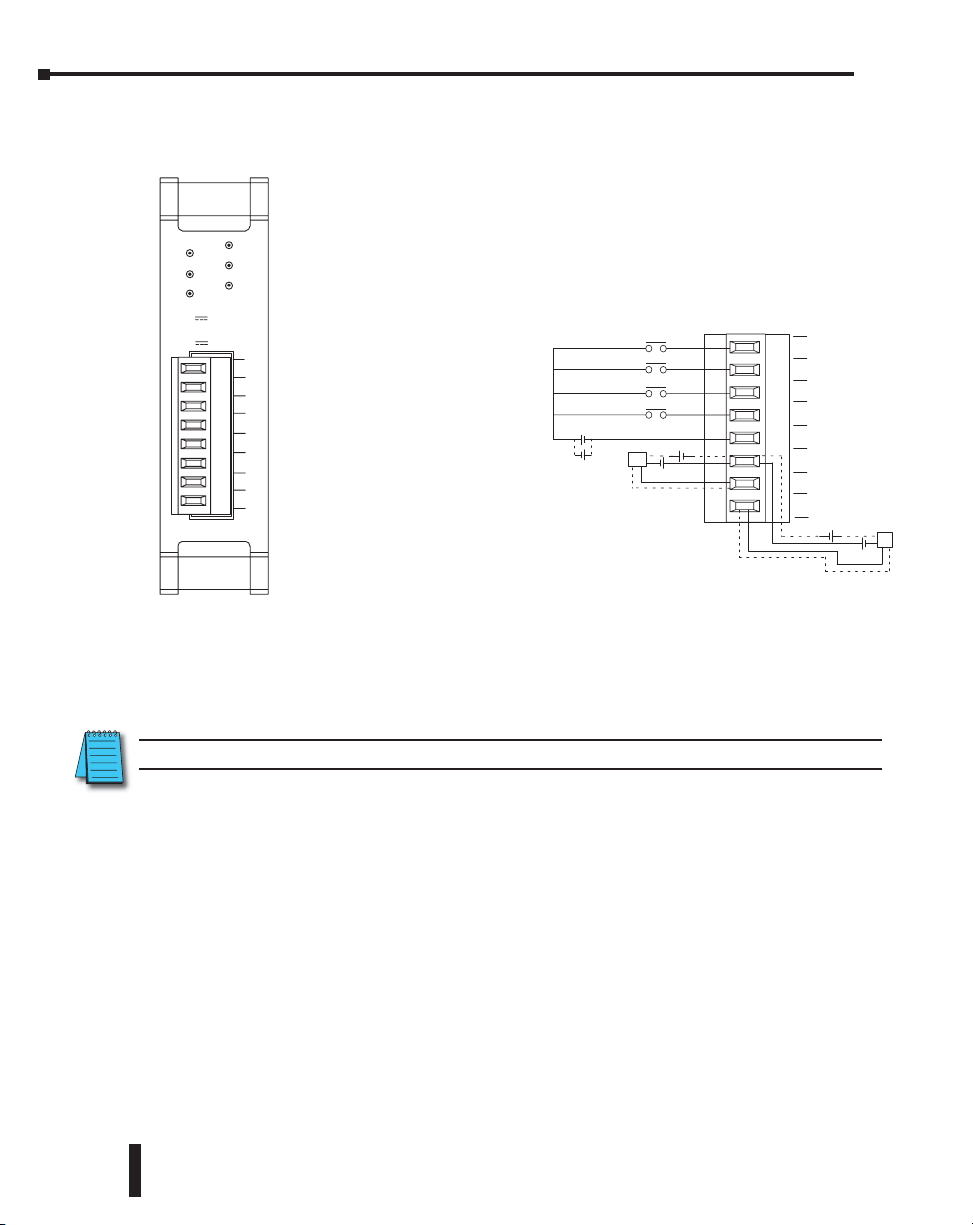

Installing the T1H-CTRIO ......................................................................................... 3-28

Wiring the T1H-CTRIO Module ............................................................................... 3-29

T1H-CTRIO Quadrature Encoder Wiring Example .................................................. 3-31

T1H-CTRIO TTL Quadrature Encoder Field Wiring ................................................. 3-32

T1H-CTRIO TTL Input Wiring .................................................................................. 3-33

T1H-CTRIO Output Wiring Schematic..................................................................... 3-34

Counter I/O User Manual, 3rd Ed., Rev. E

ii

Page 8

Table of Contents

T1H-CTRIO Stepper/Servo Drive Wiring Example .................................................. 3-35

Solid State Input Device Wiring to T1H-CTRIO Module ........................................ 3-36

Chapter 4 - CTRIO Workbench, Overview

Configuring a CTRIO Module for Do-more CPUs ..................................................... 4–2

What is CTRIO Workbench? ......................................................................................4–2

Getting Started with CTRIO Workbench ..................................................................4–3

Module Modes of Operation .....................................................................................4–6

Chapter 5 - CTRIO Workbench, Configuring Inputs

Configure I/O Dialog Overview ................................................................................5–2

Input Function Selections .......................................................................................... 5–3

Counter Function ....................................................................................................... 5–4

Pulse Catch ................................................................................................................5–6

Edge Timer ................................................................................................................. 5–7

Dual Edge Timer ........................................................................................................5–8

Reset FN1 and Reset FN2 (Hard Resets for Counters Only) ..................................5–10

Soft Resets ..............................................................................................................5–10

Capture FN1 ............................................................................................................. 5–11

Inhibit FN1 ............................................................................................................... 5–11

Limit Out .................................................................................................................. 5–11

Introduction to the Scaling Wizard ........................................................................5–12

Chapter 6 - CTRIO Workbench Configuring Outputs

Configure I/O Dialog Overview ................................................................................6–2

Output Function Selections ....................................................................................... 6–3

Raw Output ................................................................................................................ 6–4

Discrete Outputs ........................................................................................................ 6–5

Pulse Outputs ...........................................................................................................6–11

Counter I/O User Manual, 3rd Ed., Rev. E

iii

Page 9

Table of Contents

Chapter 7 - CTRIO Workbench, I/O Map

I/O Map Dialog .......................................................................................................... 7–2

Chapter 8 - CTRIO Workbench, Monitor I/O

Using the Monitor I/O Dialog ................................................................................... 8–2

Monitor I/O Error Codes ........................................................................................... 8–7

Chapter 9 - Output Functions

Runtime Changes to CTRIO Configured Preset Tables (DL PLCs) ........................... 9–3

Pulse Output Profiles (DL PLCs) ................................................................................ 9–6

Trapezoid Profile........................................................................................................ 9–7

S-Curve Profile ........................................................................................................... 9–8

Symmetrical S-Curve Profile ...................................................................................... 9–9

Home Search Profile ................................................................................................ 9–10

Free Form Profile .....................................................................................................9–13

Pulse Output Status/Control Bits and Command Codes (DL PLCs) ......................9–14

DirectLOGIC Programming Examples Overview ....................................................9–20

Trapezoid with Limits Profile ..................................................................................9–21

Trapezoid with Limits (CTRIO2) Profile ..................................................................9–22

Pulse Output Status/Control Bits and Command Codes (DL PLCs) ......................9–25

Trapezoid Plus (CTRIO2) Profile ..............................................................................9–29

Pulse Output Status/Control Bits and Command Codes (DL PLCs) ......................9–31

Load and Run a Trapezoid Plus Profile .................................................................9–34

Dynamic Positioning Plus and Dynamic Positioning Profiles .................................9–35

Dynamic Positioning Plus (CTRIO2) Profile ............................................................ 9–36

Pulse Output Status/Control Bits and Command Codes (DL PLCs) ......................9–37

Dynamic Velocity Profile ..........................................................................................9–43

Pulse Output Status/Control Bits and Command Codes (DL PLCs) ......................9–44

Velocity Mode .........................................................................................................9–49

Pulse Output Status/Control Bits and Command Codes (DL PLCs) ......................9–50

Counter I/O User Manual, 3rd Ed., Rev. E

iv

Page 10

Table of Contents

Run to Limit Mode .................................................................................................9–55

Pulse Output Status/Control Bits and Command Codes (DL PLCs) ......................9–56

Run to Position Mode .............................................................................................9–62

Pulse Output Status/Control Bits and Command Codes (DL PLCs) ......................9–63

Run to Position Mode with DirectSOFT IBox Instructions ..................................... 9–68

Raw Output .............................................................................................................. 9–70

Pulse Output Status/Control Bits and Command Codes (DL PLCs) ......................9–71

Chapter 10 - Input Functions

Input Memory Mapping for Counter Data Transfer ..............................................10–2

Input Memory Map for Scaled Counter Data .......................................................10–5

Input Memory Map for Capture Count Data Transfers .........................................10–9

Input Memory Map for Edge Timer and Dual Edge Timer .................................. 10–12

Input Memory Map for Pulse Catch Data Transfers .............................................10–25

Chapter 11 - Runtime Table Functions

Introduction to Runtime Table Functions ............................................................... 11–2

Preset Tables and Programmable Limit Switch (PLS) Tables ................................. 11–4

Load Preset Table .................................................................................................... 11–4

Load Table ................................................................................................................ 11–8

Clear Preset Table ................................................................................................. 11–11

Create Preset Table (Initialize Table) .................................................................... 11–14

Add Entry to Preset Table .....................................................................................11–17

CTRIO2 - DirectLOGIC Using IBoxes Flowcharts...................................................11–18

CTRIO2 - DirectLOGIC PLC Flowcharts .................................................................11–19

Edit Preset Table Entry .......................................................................................... 11–20

Edit Preset Table Entry and Reload ....................................................................... 11–23

Write File to ROM .................................................................................................. 11–26

Create Preset Table on Reset (Initialize Table on Reset) .....................................11–29

Update Level (Edit Level Response) ...................................................................... 11–32

Counter I/O User Manual, 3rd Ed., Rev. E

v

Page 11

Table of Contents

Appendix A - Memory Mapping

Input Memory Map for Data Transfers from CTRIO(2) to DL CPUs ........................ A-2

Output Memory Map for Data Transfers from DL CPUs to CTRIO(2) ..................... A-4

Addressing Conventions (with V-memory Examples for DirectLOGIC PLCs) .......... A-7

Input Function Status/Control Bits and Parameters ................................................ A-8

Appendix B - System Functions

System Functions ....................................................................................................... B-2

Write All Registers (IBoxes) ....................................................................................... B-3

Write All Registers (DL-PLC)...................................................................................... B-4

Write One Register (IBoxes) ...................................................................................... B-5

Write One Register (DL-PLC) .................................................................................... B-6

Read All Registers (IBoxes) ........................................................................................ B-7

Read All Registers (DL-PLC) ...................................................................................... B-8

Read One Register (IBoxes) ...................................................................................... B-9

Read One Register (DL-PLC) ................................................................................... B-10

Read Error Code (IBoxes) ........................................................................................ B-11

Read Error Code (DL-PLC) ....................................................................................... B-12

System Functions Examples Overview .................................................................... B-13

Single Channel Simulating Retentive Quad Counter ............................................ B-14

Dual Channel Simulating Retentive Quad Counters .............................................. B-17

Reading CTRIO Internal Registers ........................................................................... B-20

Counter I/O User Manual, 3rd Ed., Rev. E

vi

Page 12

IntroductIon to the

ctrIo & ctrIo2

Chapter

Chapter

Chapter

Modules

In This Chapter...

Introduction ............................................................................................................... 1–2

Conventions Used ...................................................................................................... 1–3

CTRIO and CTRIO2 Module Overview ...................................................................... 1–4

Support Systems for the CTRIO(2) Modules ............................................................1–6

CTRIO(2) Specifications ............................................................................................. 1–7

CH0-CTRIO(2) LED Indicators .................................................................................1–10

H2-CTRIO(2) LED Indicators .................................................................................... 1–11

H4-CTRIO LED Indicators .........................................................................................1–12

T1H-CTRIO LED Indicators.......................................................................................1–13

Overview, How it Works as Part of the Control System .........................................1–14

CTRIO(2) Module Work Flow Diagram ...................................................................1–17

1

1

1

Page 13

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

Introduction

The Purpose of this Manual

This manual is intended as a help for the user to install, program, and maintain the CTRIO(2)

module in their system. This manual contains important information for personnel who

will install the CTRIO(2) high-speed counter module as well as for the PLC programmer.

This manual will provide all the information needed for the novice and seasoned automation

professional alike to start and keep your system up and running.

Online Help Files and Other Documentation

Regardless of the platform you are using, the programming software needed for the CTRIO(2)

modules is available as a download from our website.

http://www.aboutplcs.com/

Each programming software includes searchable online help topics covering all aspects of the

software, instruction set, module setup, and communications.

Technical Support

We strive to make our manuals the best in the industry. We rely on your feedback to let us

know if we are reaching our goal. If you cannot find the solution to your particular application,

or, if for any reason you need technical assistance, please call us at:

1-770–844–4200

Our technical support group will work with you to answer your questions. They are available

Monday through Friday from 9:00 A.M. to 6:00 P.M. Eastern Time. We also encourage you

to visit our web site where you can find information about our company and specific technical

information about a wide array of our products, www.automationdirect.com.

1–2

Counter I/O User Manual, 3rd Ed., Rev. E

Page 14

Conventions Used

DL

DL

Win

NOTE: When you see the “note pad” icon in the left-hand margin, the paragraph to its immediate right will be

a special note. Notes represent information that may make your work quicker or more efficient. The word

NOTE in boldface will mark the beginning of the text.

WARNING! When you see the “exclamation point” icon in the left-hand margin, the paragraph to its

immediate right will be a warning. This information could prevent injury, loss of property, or even

death in extreme cases. Any warning in this manual should be regarded as critical information that

should be read in its entirety. The word WARNING in boldface will mark the beginning of the text.

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

Key Topics for Each Chapter

The beginning of each chapter will list the key topics that

can be found in that chapter.

Getting Started!

In This Chapter...

.............................................................................1-2

Introduction

About Getting Started!

Supplemental Manuals and Other Help

.............................................................................1-2

Technical Support

....................................................................1-3Conventions Used

CHAPTER

....................................................................1-2Purpose of this Manual

......................................................................1-2

............................................1-2

Icons

CTRIO(2) modules are available for several hardware platforms, including DL05/06,

DL205, DL405 and Terminator. Among these four hardware platforms, there are a variety

of CPUs that can occupy the CPU slot, including, Do-more, DirectLOGIC or WinPLC.

There are also several communication interface modules that could occupy the

CPU slot, including EBCs, Modbus, DeviceNet or Profibus.

Throughout this manual, a set of icons (on right) is used to designate which

hardware platform a topic applies to, based on what module is in the CPU slot.

Icon Legend:

Do-more icon- Topic is applicable when CTRIO(2) is used with a Do-more CPU or

DM

in a slave on a Do-more CPU’s Ethernet I/O network.

DirectLOGIC icon- Topic is applicable when CTRIO(2) is used with a DirectLOGIC

DL

CPU.

WinPLC icon- Topic is applicable when CTRIO(2) is used with a WinPLC CPU.

Win

Network Interface icon- Topic is applicable when CTRIO(2) is used with any of the

NI

network interfaces: EBC (see Do-more icon instead if EBC is a slave on Do-more

Ethernet I/O network) DeviceNet, Profibus or Modbus.

1

DM

DL

Win

NI

Counter I/O User Manual, 3rd Ed., Rev. E.

1–3

Page 15

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

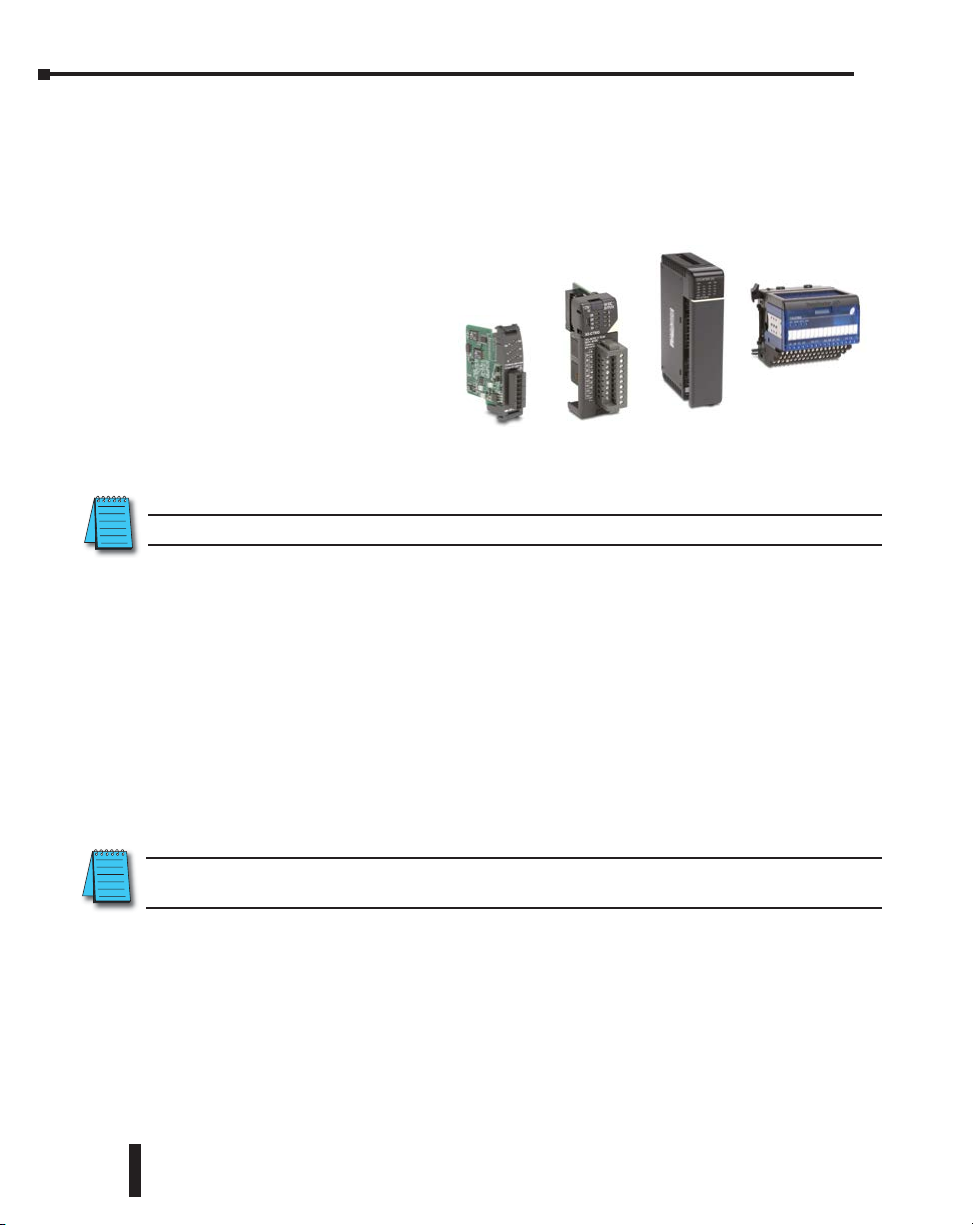

CTRIO and CTRIO2 Module Overview

A CTRIO(2) module is a programmable motion co-processor capable of accepting a variety

of encoder or discrete sensor inputs, accepting commands from the CPU, natively executing

simple control algorithms, and generating a variety of pulse-type motion control signals or

discrete actuator outputs. A CTRIO can be used for a wide variety of basic motion tasks.

Most commonly, a CTRIO module is

used to:

• Track an encoder

• Calculate rate from an encoder

• Execute homing routines

• Generate simple motion profiles

• Send pulse train control signals

to a stepper or servo amplifier

• Precisely fire a discrete output based on the position read from an encoder

NOTE: The T1H-CTRIO(2) is only supported by the T1H-EBC, T1H-EBC100 and T1H-PBC (Retired 08/20).

H0-CTRIO(2)

Available Functions

The various functions available in a CTRIO(2) module are enumerated in the following text.

There are however, limitations and dependencies to keep in mind.

• An H0-CTRIO(2) module has 4 input points on its single channel. The H2-CTRIO(2)

modules have 8 input points split between two channels. Although each channel of a

CTRIO(2) module has four input points, a channel may have only two counters/quad

counters defined. The counter/quad counter inputs appear as Function 1 and Function 2

in CTRIO Workbench.

• Some functions rely on another function being enabled. For example, scaling

cannot be selected until other inputs have been configured as a counter

or quad counter. The dependencies are enforced by CTRIO Workbench

software to ensure that an invalid configuration cannot be created.

H2-CTRIO(2)

H4-CTRIO

T1H-CTRIO(2)

1–4

If a function cannot be found in CTRIO Workbench, try enabling the function(s) on which it might

depend.

Inputs:

Input types accepted:

• Quadrature encoder with AB or ABZ

• Counter (tachometer)

• Discrete (photo eye, limit switch, Z pulse, etc.)

Counter I/O User Manual, 3rd Ed., Rev. E

Page 16

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

Functions available for discrete inputs:

• Pulse catch (high-speed discrete input with programmable filter)

• Timing: edge timer (period), dual edge timer (time difference of two inputs)

• Reset counts (Z input from encoder)

• Capture counts (copy counts of one of the counter inputs to a register)

• Inhibit counting (freeze one of the counter inputs)

• Limit for pulse output functions (CTRIO2, home switch on an axis)

Scaling of timing functions or encoder inputs:

• Rate scaling (allows the CTRIO(2) to provide encoder

data to the PLC in engineering units)

• Position scaling (allows the CTRIO(2) to provide encoder

data to the PLC in engineering units)

Outputs:

Assign the output points:

• Stepper control: Step/Direction or CW/CCW

• Discrete

Pulse profiles for stepper outputs to follow:

• Dynamic Position Plus, Trapezoid Plus, Trapezoid with Limits (homing)

(CTRIO2 only and CTRIO, Workbench v2.2.0 or later required)

• Trapezoid, S-curve, Symmetrical S-curve, Dynamic Position, Dynamic Velocity

• Home Search, Free Form

Associate output functions with inputs

• Programmable Limit Switch or ‘PLS’ (CTRIO2 only and

CTRIO Workbench v2.2.0 or later required)

• Preset tables.

Unsuitable Applications

There are some applications the CTRIO(2) specifications appear to support that are not

feasible. Common applications a CTRIO(2) cannot readily handle are listed below. If in

doubt regarding your application, please contact Automationdirect Tech Support for assistance.

Closed loop control: CTRIO2 modules are capable of very basic closed loop control. However, they

do not have full functionality expected of a typical dedicated closed loop controller. Most notably,

position or velocity errors are not reported and there is no built-in error alarming.

• CTRIO modules do not support any closed loop control. Trying to use the CPU to

close the control loop will produce unacceptable results due to excessive latency.

Counter I/O User Manual, 3rd Ed., Rev. E.

1–5

Page 17

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

Coordinated motion: Some CTRIO(2) modules have enough outputs to control multiple axes,

but there is no internal mechanism to coordinate them. Axes can move simultaneously, but

not with coordination.

Follower: CTRIO(2) modules cannot support follower applications natively. Trying to use

the CPU to close the control loop will produce unacceptable results due to excessive latency.

Precise registration: There is no means for precisely timing the start of a motion profile. Motion

profiles are initiated by the controller in the base, so scan time latency of the controller is

always a factor.

Absolute encoders: A CTRIO(2) module cannot read an absolute encoder.

Mechanical contacts as counter or encoder inputs: Reliable readings are not possible using

mechanical contacts. The bounce of mechanical contacts will cause the CTRIO(2) to see

more edges than intended.

Direct connection to TTL, line driver or differential encoders: A CTRIO(2) module cannot

accept these low voltage inputs directly. These signals need to be level shifted as shown in

Chapter 3: Installation and Field Wiring.

Support Systems for the CTRIO(2) Modules

The CTRIO(2) modules are compatible with several CPU-slot interfaces. Consideration

must be given to the firmware versions of the CPU-slot interfaces to assure their compatibility

with the CTRIO(2) (See Chapter 3 for CPU/CTRIO compatibility listings). Multiple

CTRIO(2) modules can reside in the same base provided that the backplane power budget is

adequate.

1–6

Support Systems for the H0-CTRIO(2):

• DirectLOGIC 05/06 PLC systems

Support Systems for the H2-CTRIO(2):

• DirectLOGIC 205 PLC systems (D2-240, D2-250-1, D2-260, D2-262)

• DL205 WinPLC systems (H2-WPLCx-xx)

• PC-based control strategies using the H2-EBC(100) interface module

• Hx-ERM networks using the H2-EBC(100) interface module

• Profibus systems using the H2-PBC slave interface module

• Do-more PLC systems (H2-DM1, H2-DM1E); See Do-more Designer help file.

• Do-more PLC Ethernet I/O network using H2-EBC100;

See Do-more Designer help file.

Counter I/O User Manual, 3rd Ed., Rev. E

Page 18

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

Support Systems for the H4-CTRIO:

• DirectLOGIC 405 PLC systems (D4-450 OR D4-454 only)

• PC-based control strategies using the H4-EBC interface module

• Hx-ERM networks using the H4-EBC interface module

Support Systems for the T1H-CTRIO:

• PC-based control strategies using the T1H-EBC interface module

• Profibus systems using the T1H-PBC slave interface module (Discontinued 08/2020)

• Hx-ERM networks using the T1H-EBC interface module

• Do-more PLC Ethernet I/O network using T1H-EBC100

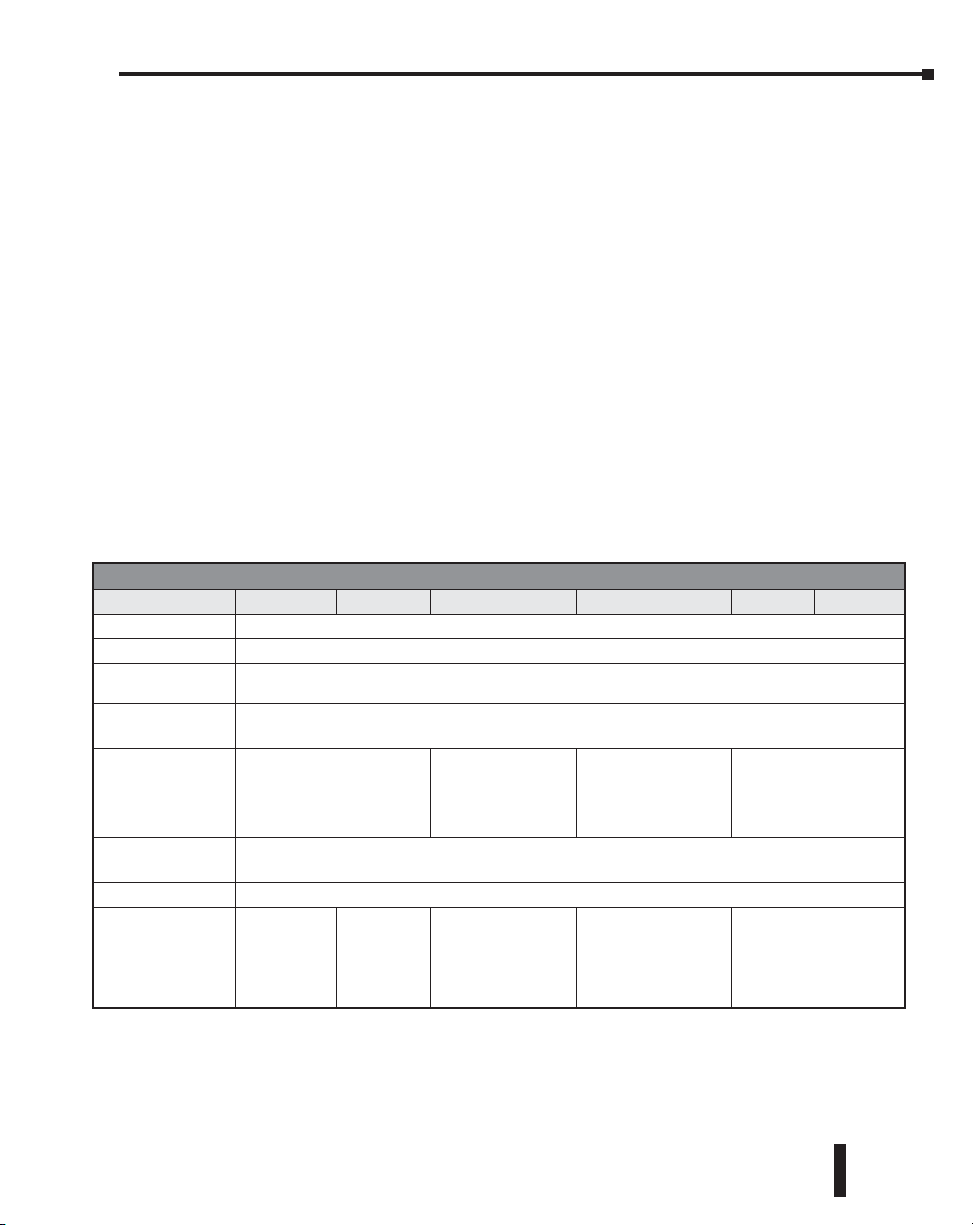

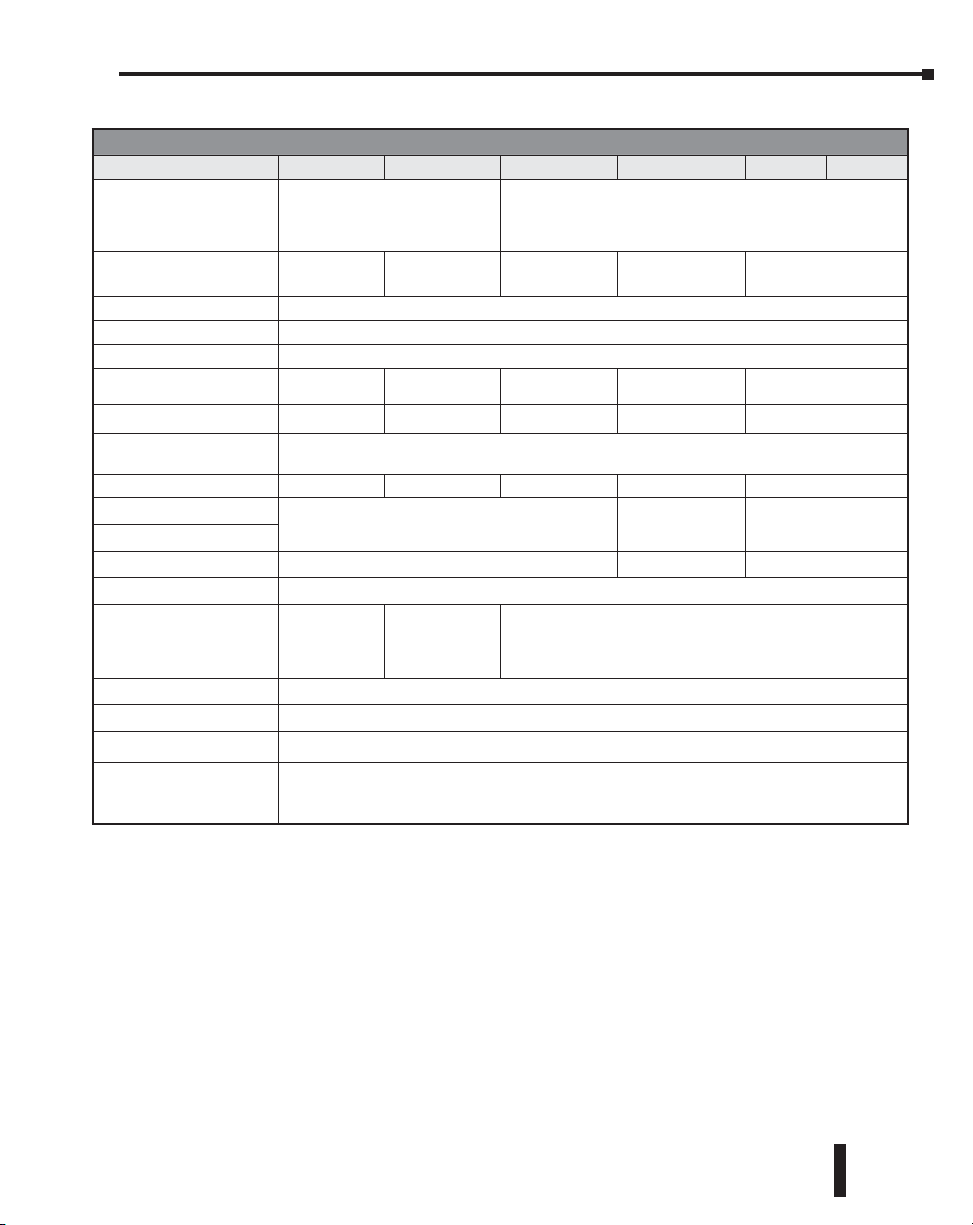

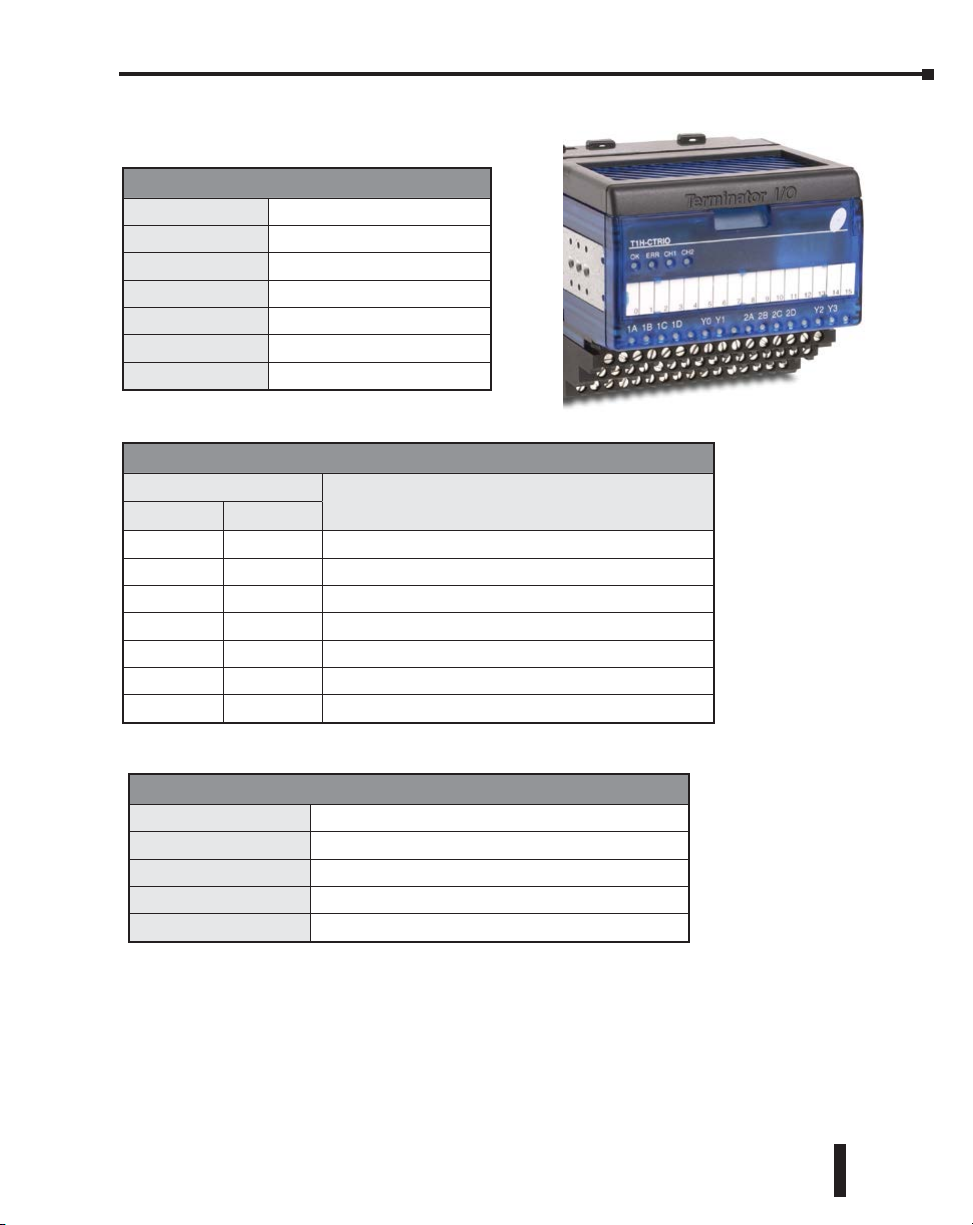

CTRIO(2) Specifications

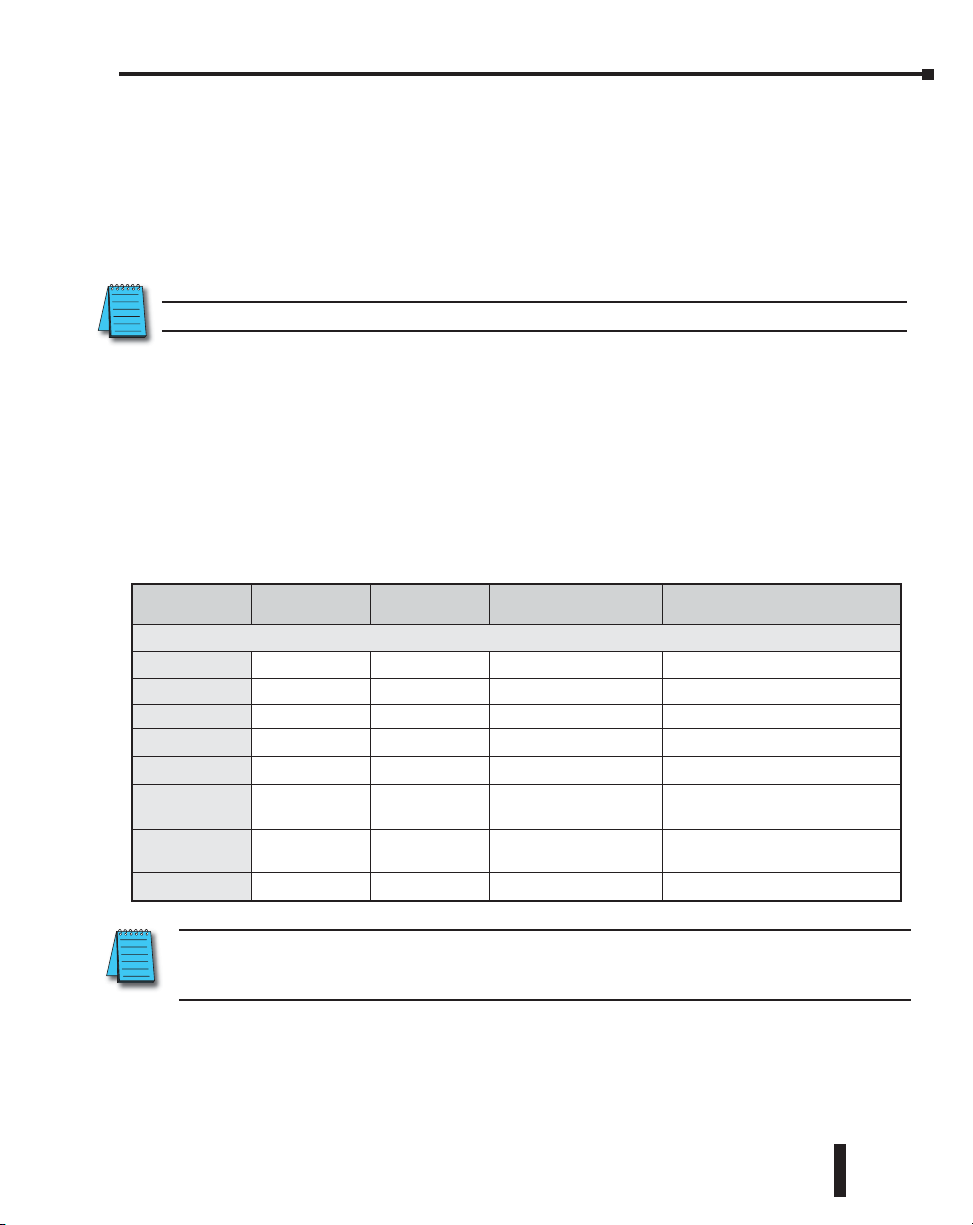

The tables following show general and specific information associated with CTRIO modules.

Module

Module Type

Modules Per Base

I/O Points Used

Field Wiring

Connector

Internal Power

Consumption

Operating

Environment

Manufacturer

Isolation

H0-CTRIO H0-CTRIO2 H2-CTRIO H2-CTRIO2 H4-CTRIO T1H-CTRIO

None, I/O map directly in PLC memory (V-memory for DirectLOGIC PLCs and Data structures for Do-more

250mA at +5V from Base

Power Supply

(All I/O in ON State at Max

Voltage/Current)

32°F to 140°F (0°C to 60°C), Humidity (non-condensing) 5% to 95%

2500V I/O to

Logic, 1000V

among Input

Channels and

All Outputs

1500V I/O to

Logic, 1000V

among Input

Channels and

All Outputs

General

Intelligent

Limited only by power consumption

PLCs) or PC control access

Standard removable terminal block

400mA Max at +5V

from Base Power

Supply

(All I/O in ON State at

Max Voltage/Current)

Host Automation Products, LLC

2500V I/O to Logic,

1000V among Input

Channels and All

Outputs

275mA Max at +5V

from Base Power

(All I/O in ON State at

Max Voltage/Current)

1500V I/O to Logic,

1000V among Input

Channels and All

Supply

Outputs

400mA Max at +5V from

Base Power Supply

(All I/O in ON State at Max

Voltage/Current)

2500V I/O to Logic, 1000V

among Input Channels and

All Outputs

Counter I/O User Manual, 3rd Ed., Rev. E.

1–7

Page 19

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

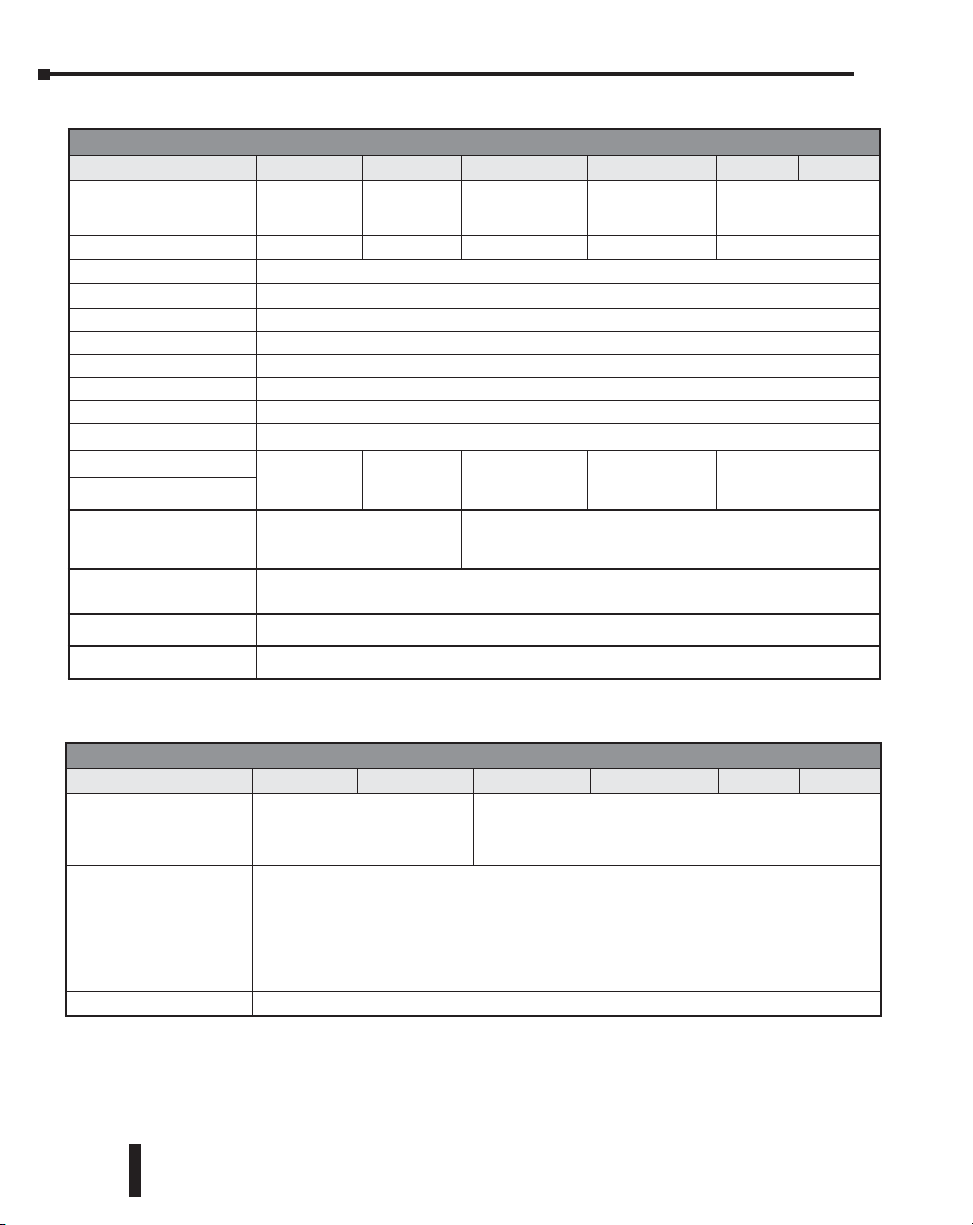

CTRIO(2) Specifications, cont’d

CTRIO(2) Input Specifications

Module

Inputs

Minimum Pulse Width

Input Voltage Range

Maximum Voltage

Input Voltage Protection

Rated Input Current

Minimum ON Voltage

Maximum OFF Voltage

Minimum ON Current

Maximum OFF Current

OFF to ON Response

ON to OFF Response

Counter/Timer

Resource Options

Timer Range/ Resolution

Counter Range

H0-CTRIO H0-CTRIO2 H2-CTRIO H2-CTRIO2 H4-CTRIO T1H-CTRIO

4 pts. sink/

source

100kHz Max

5 µsec 0.5 µsec 5 µsec 0.5 µsec 5 µsec

Less than 3

µsec

2, (2 per single 4 input

channel); supports 1

quadrature counter max.

1X, 2X, or 4X Quadrature, Up or Down Counter, Edge Timer, Dual Edge Timer, Input Pulse Catch,

Reset, Inhibit, Capture

4 pts. sink/

source 250kHz

Max

5.0 mA (9VDC required to guarantee ON state)

Less than 0.5

µsec

4.2 billion (32 bits); 1 µsec (70 minutes)

W2.1 billion (32 bits or 31 bits + sign bit)

8 pts. sink/source

100kHz Max

9-30 VDC

30VDC

Zener Clamped at 33VDC

8mA typical, 12mA maximum

9.0 VDC

2.0 VDC

2.0 mA

Less than 3 µsec Less than 0.5 µsec Less than 3 µsec

4, (2 per each 4 input channel group); supports 2 quadrature

8 pts. sink/source

250kHz Max

counters max.

8 pts. sink/source

100kHz Max

Module

Pulse output / Discrete

outputs

Resource Options

Target Position Range

Counter I/O User Manual, 3rd Ed., Rev. E

1–8

CTRIO(2) Output Resources

H0-CTRIO H0-CTRIO2 H2-CTRIO H2-CTRIO2 H4-CTRIO T1H-CTRIO

Pulse outputs: 1 channel (2

outputs per single channel)

Discrete outputs: 2 pts.

Pulse Outputs: pulse/direction or cw/ccw; Profiles:Trapezoid, S-Curve, Symmetrical S-Curve,

Dynamic Positioning, Dynamic Velocity, Home Search, Free Form, Dynamic Positioning Plus (CTRIO2

only),Trapezoid Plus (CTRIO2 only), Trapezoid w/Limits (CTRIO2 only), Velocity Mode, Run to Limit

Mode, Run to Position Mode

Discrete Outputs: configurable for set, reset, pulse on, pulse off, toggle, reset count functions

(assigned to respond to Timer/Count input functions).

Raw Mode: Direct access to discrete outputs from user application program

W2.1 billion (32 bits or 31 bits + sign bit)

Pulse outputs: 2 channels (2 outputs per each channel)

Discrete outputs: 4 pts.

Page 20

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

CTRIO(2) Specifications, cont’d

CTRIO(2) Output Specifications

Module

Outputs

Pulse Output Control

Range

Voltage Range

Maximum Voltage

Output clamp voltage

Maximum load current

Maximum load voltage

Maximum leakage

current

Inrush current

OFF to ON response

ON to OFF Response

ON state V drop

External power supply

Overcurrent protection

Thermal shutdown

Overtemperature reset

Duty cycle range

Configurable Presets

a) single

b) multiple

H0-CTRIO H0-CTRIO2 H2-CTRIO H2-CTRIO2 H4-CTRIO T1H-CTRIO

2 pts, isolated, either both current

sourcing or both current sinking

FET Outputs: open drain and

source with floating gate drive

20Hz to 25kHz 20Hz to 250kHz 20Hz to 25kHz 20Hz to 250kHz 20Hz to 25kHz

1.0A

36VDC 33VDC 36VDC 36VDC 36VDC

5A for 20ms 1A for 10ms 5A for 20ms 2A for 10ms 5A for 20ms

15A max

a) Each output can be assigned one preset, or

b) Each output can be assigned one table of presets, one table can contain max. 128 presets,

max. predefined tables = 255

0.5 A at 23°C

0.33 A at 60°C

Less than 3 µsec Less than 1 µsec Less than 3 µsec

m 0.3 V m 0.45 V m 0.3 V

For loop power only, not required for internal module function*

15A max;

Self resetting

overcurrent

protection

1% to 99% in 1% increments (default = 50%)

4 pts, independently isolated, current sourcing or sinking

FET Outputs: open drain and source with floating gate drive

5VDC – 36VDC

36VDC

60VDC

1.0 A

100µA

Tjunction = 150°C

Tjunction = 130°C

1.0 A at 23°C,

0.5 A at 60°C

15A max

1.0 A

Counter I/O User Manual, 3rd Ed., Rev. E.

1–9

Page 21

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

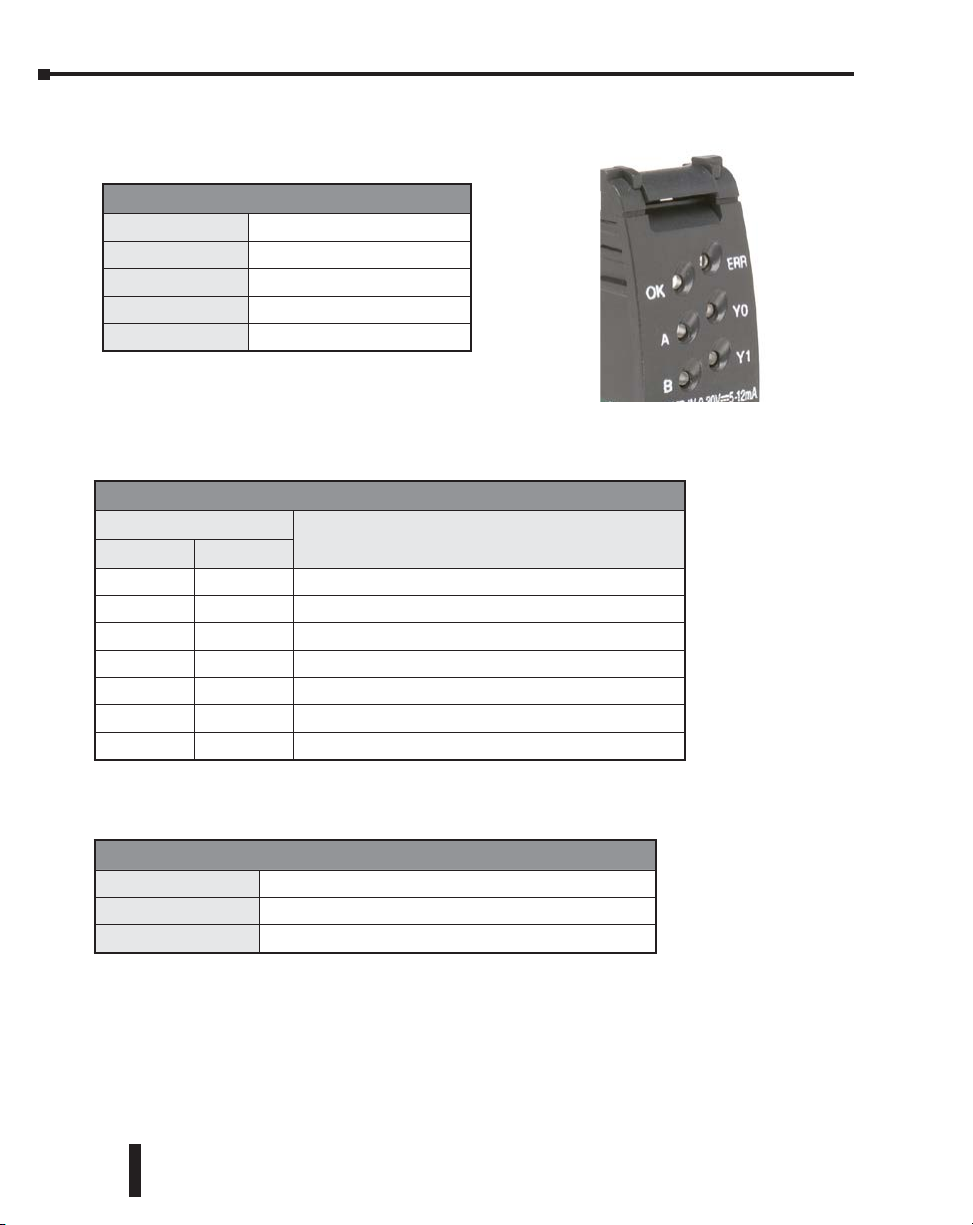

H0-CTRIO(2) LED Indicators

H0-CTRIO(2) LED Descriptions

OK

ERR

A

B

Y0 - Y1

LED Status

OK ERR

ON OFF RUN Mode

ON ON Hardware Failure

Blinking Blinking Boot Mode - Used for Field OS Upgrades

Blinking OFF Program Mode

OFF Blinking Module Self-diagnostic Failure

OFF ON Module Error Due to Watchdog Timeout

OFF OFF No Power to Module

Module OK

User Program Error

Ch1 F1 Resource State

Ch1 F2 Resource State

Output Status

H0-CTRIO(2) LED Diagnostics

Status Description

1–10

H0-CTRIO(2) LED Run Diagnostics Definitions

A

B

Y0–Y1

Blinks when Channel 1 Function 1 is counting or timing

Blinks when Channel 1 Function 2 is counting or timing

Follow actual output state; ON = output is passing current

Counter I/O User Manual, 3rd Ed., Rev. E

Page 22

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

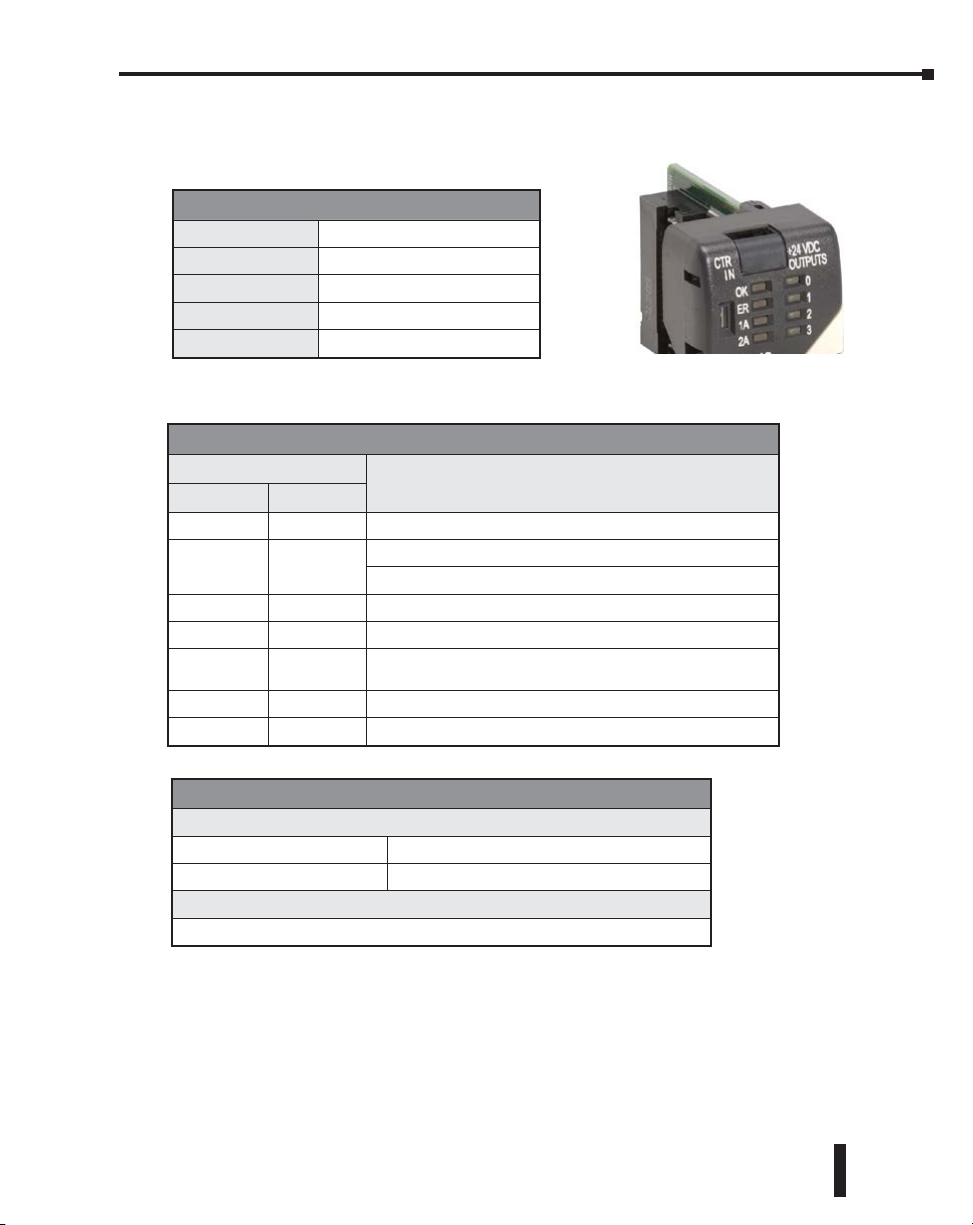

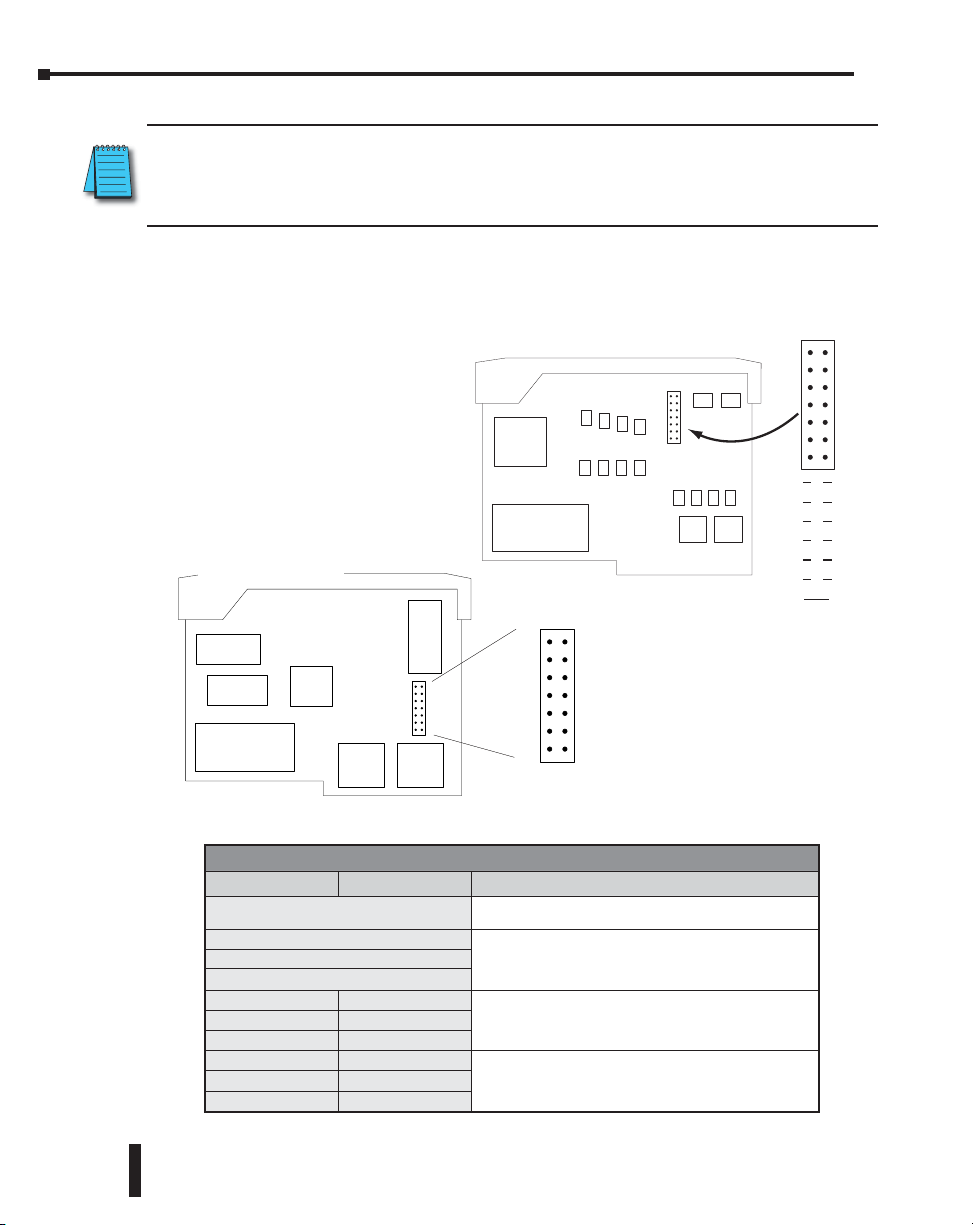

H2-CTRIO(2) LED Indicators

H2-CTRIO(2) LED Descriptions

OK

ER

1A

2A

0–3

LED Status

OK ER

ON OFF RUN Mode

ON ON

Blinking Blinking Boot Mode - Used for Field OS Upgrades

Blinking OFF Program Mode

Module OK

User Program Error

Channel 1 Status

Channel 2 Status

Output Status

H2-CTRIO(2) LED Diagnostics

Hardware Failure (H2-CTRIO)

Not Used (H2-CTRIO2)

Status Description

OFF Blinking Module Self-diagnostic Failure (Blinks may be coded by counts)

OFF ON Module Error Due to Watchdog Timeout

OFF OFF No Power to Module

H2-CTRIO(2) LED Diagnostics Definitions

1A /2A

Blinking 7 times per second Input is Configured as Counter and is Changing

Following State of Input Input is not Configured as Counter

0–3

Follow actual output state; ON = output is passing current

Counter I/O User Manual, 3rd Ed., Rev. E.

1–11

Page 23

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

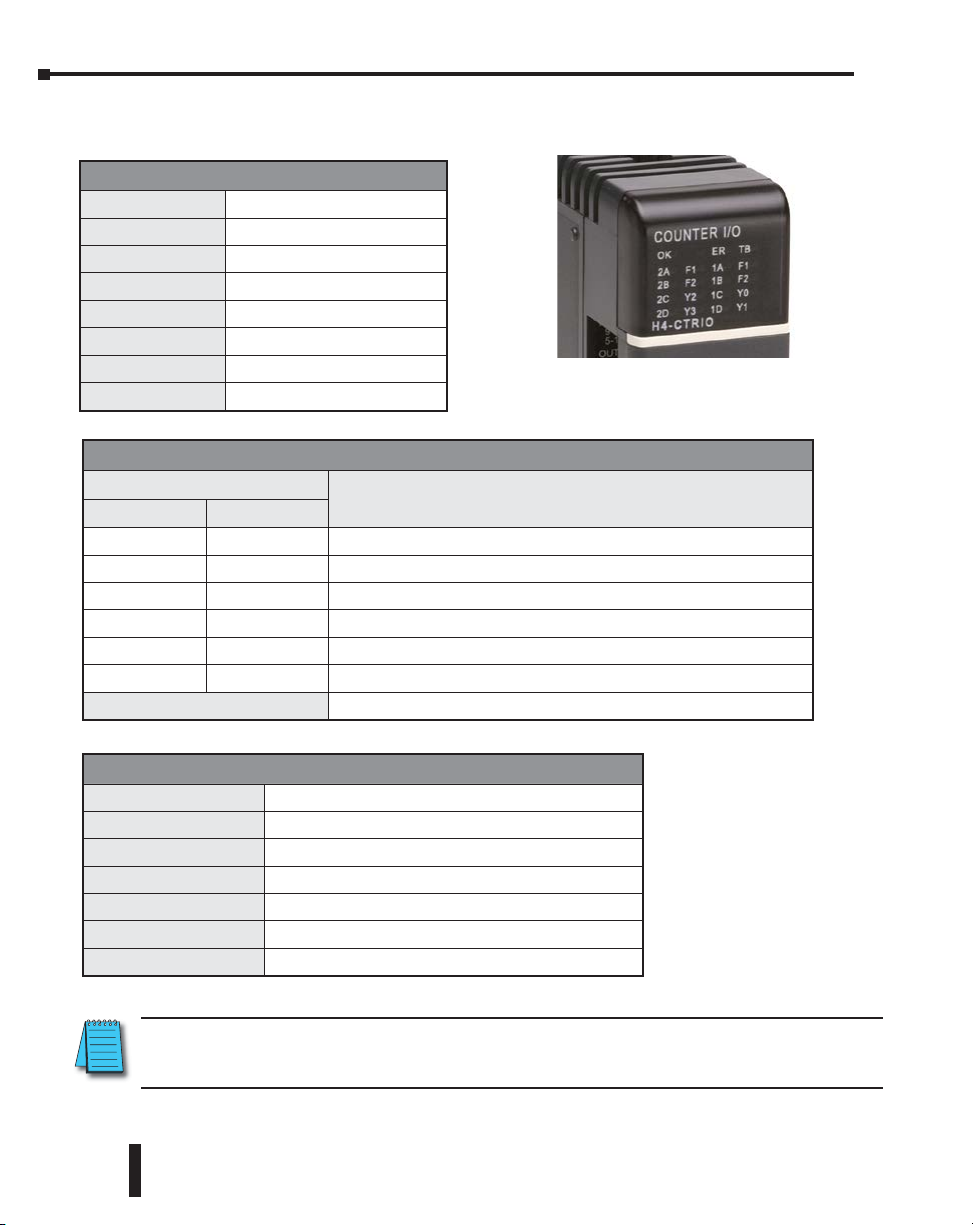

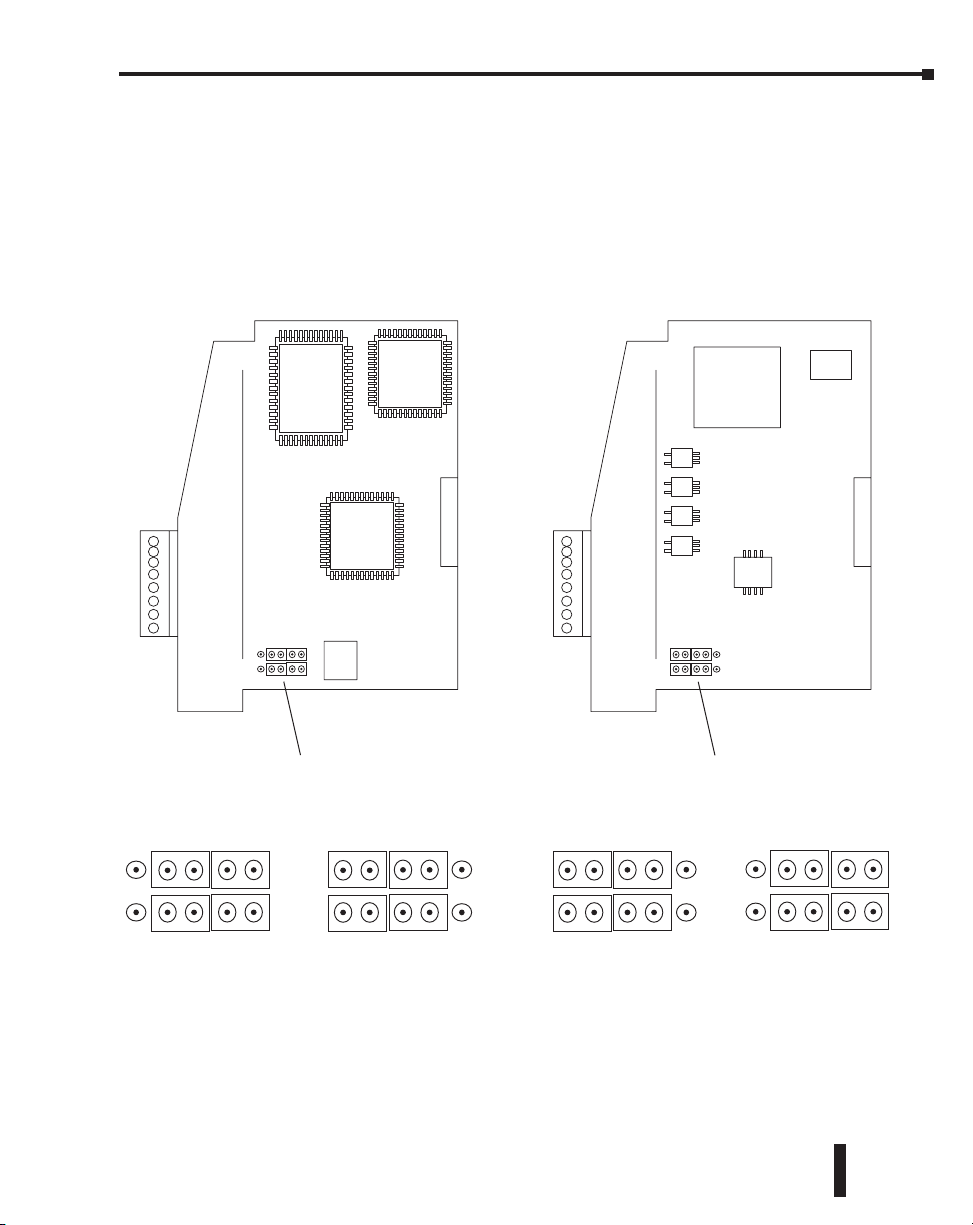

H4-CTRIO LED Indicators

H4-CTRIO LED Descriptions

OK

ER

TB

1A–1D

2A–2D

(Ch1) F1–F2

(Ch2) F1–F2

Y0–Y3

LED Status

OK ER

ON OFF RUN Mode

Blinking Blinking Boot Mode - Used for Field OS Upgrades

Blinking OFF Program Mode

OFF Blinking Module Self-diagnostic Failure

OFF ON Module Error Due to Watchdog Timeout

OFF OFF No Power to Module

Module OK

User Program Error

Removed Terminal Block

Ch1A - Ch1D Input Status

Ch2A - Ch2D Input Status

Ch1 Resource State

Ch2 Resource State

Output Status

TB

H4-CTRIO LED Diagnostics

Status Description

User Terminal Block is not Properly Installed

1–12

H4-CTRIO LED Diagnostics Definition

1A–1D

2A–2D

(Ch1) F1

(Ch1) F2

(Ch2) F1

(Ch2) F2

Y0–Y3

NOTE: Due to the multiplexed design of the DL405 LED matrix, OFF state LEDs may appear to blink ON

slightly. This is to be expected and does not necessarily indicate a transient condition of the function

corresponding to the LED.

Follow actual input state / Ch1

Follow actual input state / Ch2

Blinks when Channel 1 Function 1 is counting or timing

Blinks when Channel 1 Function 2 is counting or timing

Blinks when Channel 2 Function 1 is counting or timing

Blinks when Channel 2 Function 2 is counting or timing

Follow actual output state; ON = output is passing current

Counter I/O User Manual, 3rd Ed., Rev. E

Page 24

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

T1H-CTRIO LED Indicators

T1H-CTRIO LED Descriptions

OK

ERR

CH1

CH2

1A–1D

2A–2D

Y0–Y3

LED Status

OK ER

ON OFF RUN Mode

ON ON Hardware Failure

Blinking Blinking Boot Mode - Used for Field OS Upgrades

Blinking OFF Program Mode

OFF Blinking Module Self-diagnostic Failure

OFF ON Module Error Due to Watchdog Timeout

OFF OFF No Power to Module

Module OK

User Program Error

Channel 1 Status

Channel 2 Status

Channel 1 A-D Input Status

Channel 2 A-D Input Status

Output Status

T1H-CTRIO LED Diagnostics

Status Description

CH1

CH2

1A–1D

2A–2D

Y0–Y3

T1H-CTRIO LED Diagnostics Definitions

Blinks when Channel 1 Function 1 is counting or timing

Blinks when Channel 2 Function 1 is counting or timing

Follow actual input state / Ch1

Follow actual input state / Ch2

Follow actual output state; ON = output is passing current

Counter I/O User Manual, 3rd Ed., Rev. E.

1–13

Page 25

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

Overview, How it Works as Part of the Control System

Basic Operation

A CTRIO(2) is an intelligent co-processor module. It has to be configured using CTRIO

Workbench before it can do anything. It has its own scan time and can be in either program

or run mode.

Being an Intelligent Module means that the CTRIO(2) controls its own writes to and reads

from CPU memory. The CPU does not directly write to or read from the CTRIO(2). The

CTRIO(2) will write to and read from the addresses designated in I/O Map. Understanding this

relationship is helpful to understanding the timing (interlocking) requirements for performing

operations that require the PLC to make changes to the CTRIO(2) from ladder logic.

Understand that the CPU can only make requests to the CTRIO(2) by turning on specific bits

and placing appropriate data in its own memory. The CTRIO(2) reads the data from those

addresses in the CPU and then acts on it. The CTRIO(2) provides feedback to the CPU by

writing to other CPU memory.

NOTE: A CTRIO(2) is an Intelligent Module. It directly writes to and reads from CPU memory. The CPU

cannot directly write to or read from CTRIO(2) memory. The CTRIO(2) writes to and reads from the

addresses designated in I/O Map.

After being configured by CTRIO Workbench, a CTRIO(2) module is ready to be placed in

run mode. Basic input functions of the CTRIO(2) run automatically, such as reporting counts

on an input channel. Output functions are initiated by the controller (the PLC CPU). The

controller uses Command Codes to control the output functions of the CTRIO(2), such as

executing a pulse profile on an output, or loading or editing a preset table. IBox instructions

are macros that use Command Codes. Command Codes and the instructions on their use are

found later in this manual.

1–14

Counter I/O User Manual, 3rd Ed., Rev. E

Page 26

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

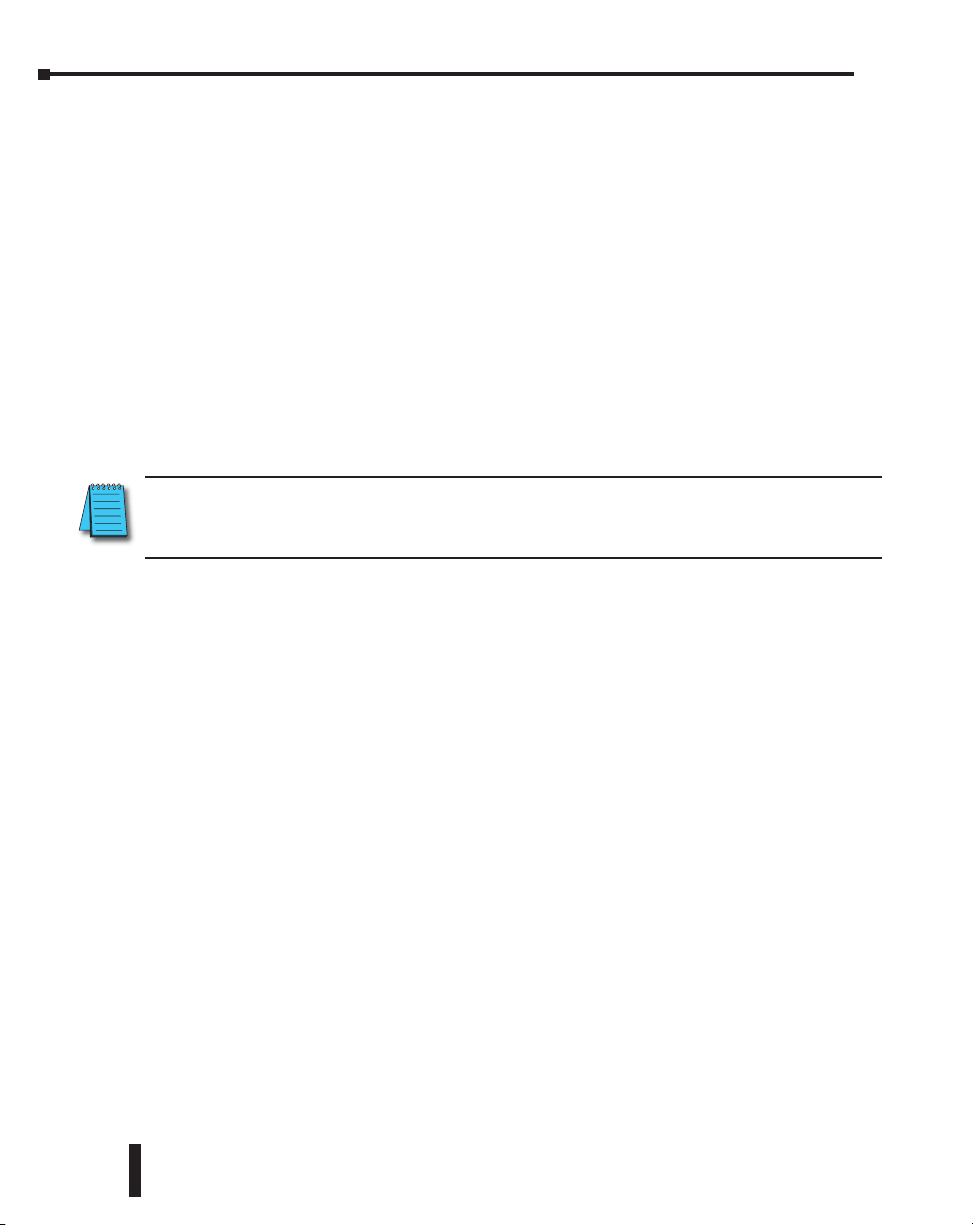

CTRIO Workbench

CTRIO Workbench is the utility used to configure the many functions available for a

CTRIO(2) module.

CTRIO Workbench communicates with a CTRIO(2) module through the base controller to

configure the CTRIO(2). The configuration is stored in the CTRIO(2) and also stored in a

file on your computer. Configuring the CTRIO(2) is a separate process from programming

the base controller.

The CTRIO Workbench

configuration contains these basic

parameters:

• Assignments of the input and

output points

• Scaling of inputs (optional)

• Preset Table setup (optional)

• Programmable Limit Switch setup

(CTRIO(2), optional)

• Mapping to CPU memory

NOTE: The CTRIO(2) must be configured in program mode, and the memory must be mapped prior to

program execution.

Counter I/O User Manual, 3rd Ed., Rev. E.

1–15

Page 27

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

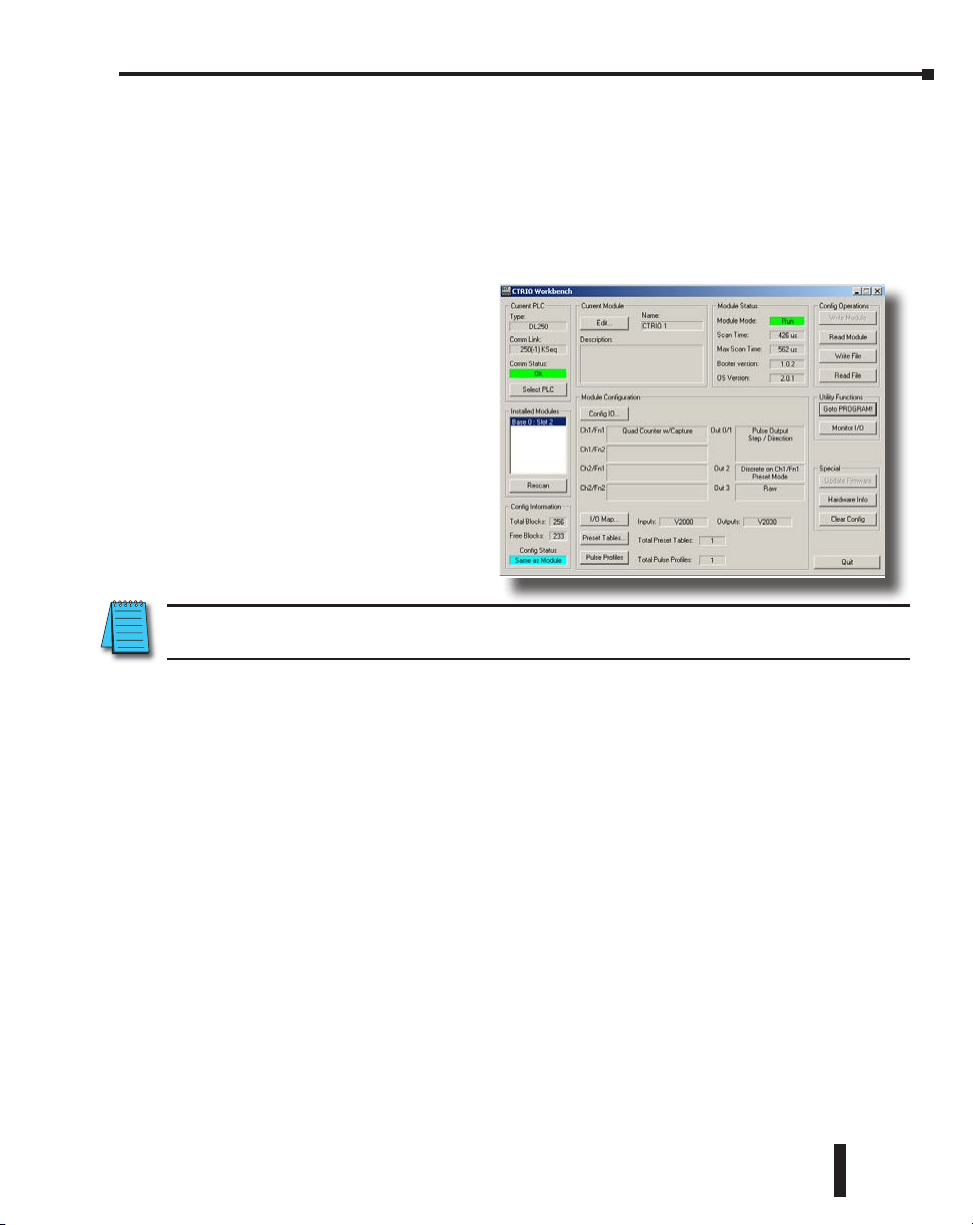

Command Codes

Command Codes are the instructions available to the CPU to tell the CTRIO what to do. A list

of the Command Codes with a brief description of their function are shown in the table below.

Command Code and Parameter Definitions

Command

Load Table from ROM 10

Load Table from ROM 10

Load Table from ROM 10

Velocity Mode 20

Run to Limit Mode 21

Run to Position Mode 22

* A value of 0 will generate a duty cycle of 50%

Code

(Hex/BCD)

Those fields separated by an “&” indicate a code with different definitions for each byte

(high byte and low byte). For example, to enter the Pulse Output to Limit command, set the

high byte of the Word Parameter 2 to the edge you wish to terminate the output pulses (see

definition following), and set the low byte to the desired duty cycle.

In order to process a command, first the program must load the Command Code and required

DWord, Word, and bit parameters. Then the program should turn ON the Process Command

bit and look for the CTRIO(2) module to acknowledge the command with the Command

Complete bit. Finally, the program should reset the Process Command bit and set the Enable

Output bit when appropriate. If the Command Error bit is received, the CTRIO(2) module

was unable to process the command due to an illegal value in either the Command Code or

parameter files.

DWord and Word values for pulse outputs are unsigned integers (Parameter 3 on some profiles

can be signed).

Word Parameter 1

(decimal)

Trapezoid or S-curve

Symmetrical S-Curve

Home Search

File Number

Dynamic Positioning

File Number

Dynamic Velocity

File Number

Run Frequency

(CTRIO: 20Hz - 25KHz

CTRIO2: 20Hz - 64KHz)

Run Frequency

(CTRIO: 20Hz - 25KHz

CTRIO2: 20Hz - 64KHz)

Run Frequency

(CTRIO: 20Hz - 25KHz

CTRIO2: 20Hz - 64KHz)

Word Parameter 2 DWord Parameter 3

- -

- Target Position (decimal)

- Target Velocity (decimal)

Duty Cycle (0 to 99)*

(decimal)

Edge &

Duty Cycle (0 to 99)*

(Hex/BCD)

Compare Function &

Duty Cycle (0 to 99)*

(Hex/BCD)

Number of Pulses (BCD/Hex)

-

Desired Input Function Value

(decimal)

1–16

Counter I/O User Manual, 3rd Ed., Rev. E

Page 28

Chapter 1: Introduction to the CTRIO & CTRIO2 Modules

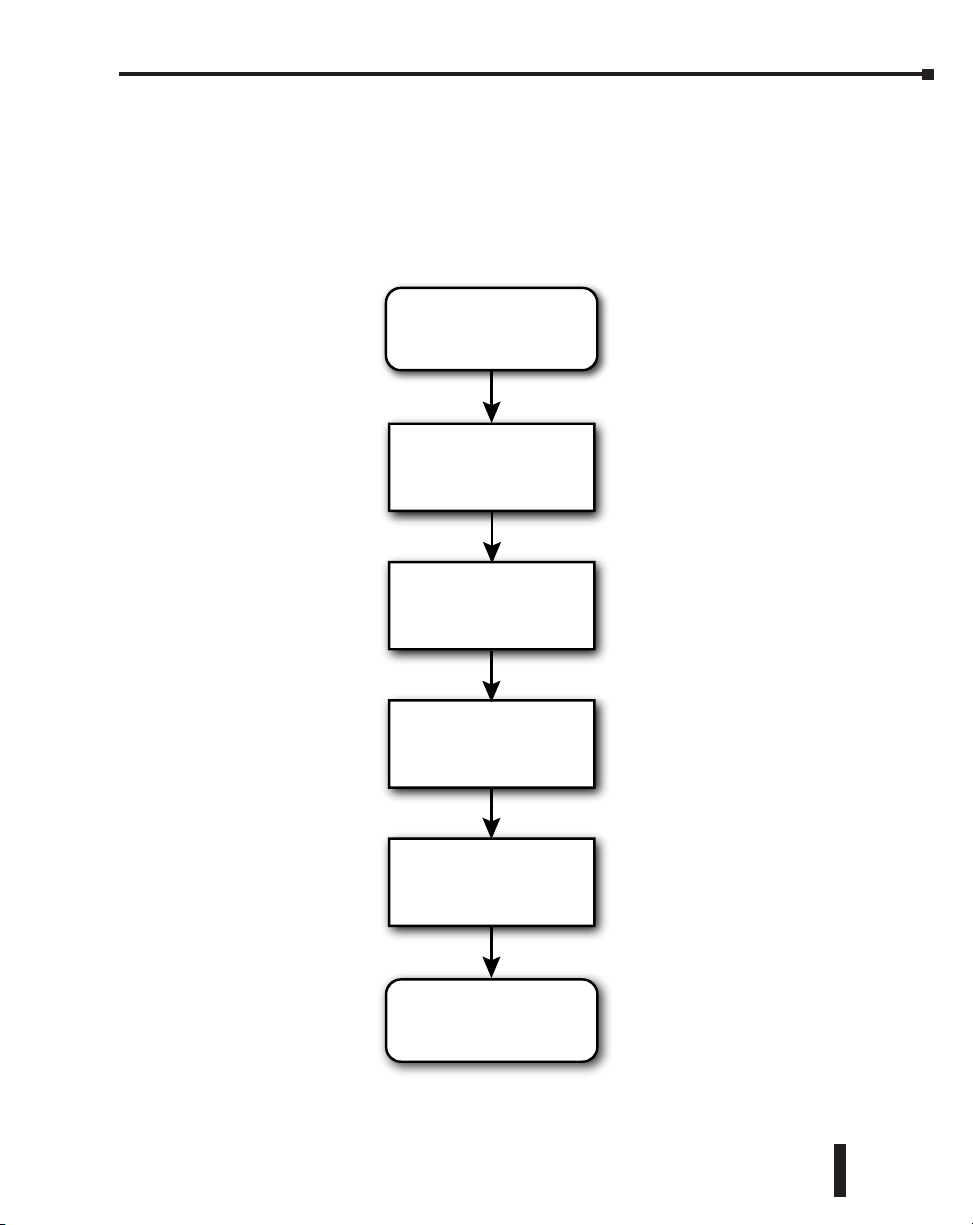

CTRIO(2) Module Work Flow Diagram

The following workflow diagram shows the steps needed, with their associated chapters in this

manual, to install and setup a CTRIO(2) module into your system.

DirectLOGIC, WinPLC or EBC

Install CTRIO

Chapter 3

Configure CTRIO using

CTRIO Workbench

Chapter 4, 5 & 6

Testing Wiring using

CTRIO Workbench’s

Monitor I/O Dialog

Chapter 7, 8 & 9

Map Memory

in Controller

Chapter 10, Appx A

Runtime Table Functions

Chapter 11

System Functions

Appendix B

Counter I/O User Manual, 3rd Ed., Rev. E.

1–17

Page 29

Chapter

Chapter

GettinG Started,

BaSicS and exampleS

In This Chapter...

Overview .................................................................................................................... 2-2

Basic Motion Functions, Summary of Examples ....................................................... 2-2

Detailed Example: Configure and Test a Quadrature Input ................................... 2-7

Detailed Example: Configure and Test a Pulse Output w/Trapezoidal Profile ..... 2-16

Flow Chart Example: Configure and Test a Pulse Output w/Trapezoidal Profile 2-27

Chapter

2

2

2

Page 30

Chapter 2: Getting Started

Overview

This chapter is intended for the newcomer and includes brief descriptions of how to implement

some common motion control solutions using CTRIO(2). The descriptions should give the

newcomer a good understanding of what basic steps are required to implement the function.

With this general understanding, specifics on each step can be sought out later in the manual.

Later in the chapter, two detailed examples walk the user through what is required to implement

two of the most common functions, reading a quadrature encoder and generating a trapezoidal

profile.

Basic Motion Functions, Summary of Examples

Get Position Using an Encoder

To read the position of an encoder, follow these basic steps in CTRIO Workbench:

1: Config I/O - Configure the appropriate inputs to recognize the encoder.

2: Optionally set up position scaling if desired.

3: Use I/O Map to map the CTRIO(2) to the controller’s memory and print the I/O Map

Report.

4: Download the configuration to the CTRIO(2) module and put the CTRIO(2) in Run.

5: Finally, go online with the controller to check that the encoder counts are appearing in

the mapped address.

2-2

Get Rate Using an Encoder

To read the rate of an encoder, follow these basic steps in CTRIO Workbench:

1: Select Config I/O under Module Configuration to Configure the appropriate inputs to

recognize the encoder.

2: Set scaling to rate - Scaling Wizard ruler button:

3: Choose the conversion parameters.

4: Use the Rate Scaling Calculator to verify the chosen settings.

5: Use I/O Map to map the CTRIO(2) to the controller’s memory and print the I/O Map

Report.

6: Download the configuration to the CTRIO(2) module and put the CTRIO(2) in Run.

7: Go online with the controller to check that encoder rate is appearing in the mapped

address.

Measure Timing Between Pulse Edges

To measure the time between edges of a pulse in CTRIO Workbench:

1: Select Config I/O under Module Configuration to configure an input as Edge Timer,

selecting the appropriate options (free-run is suggested for testing since it does not

require interaction from the controller to function).

2: Optionally, set up scaling if desired.

Counter I/O User Manual, 3rd Ed., Rev. E

Page 31

Chapter 2: Getting Started

3: Select I/O Map to map the CTRIO(2) to the controller memory and print the I/O

Map Report.4: Download the configuration to the CTRIO(2) module and put the

CTRIO(2) in Run.

5: Go online with the controller to check that pulse measurements are appearing in the

mapped address.

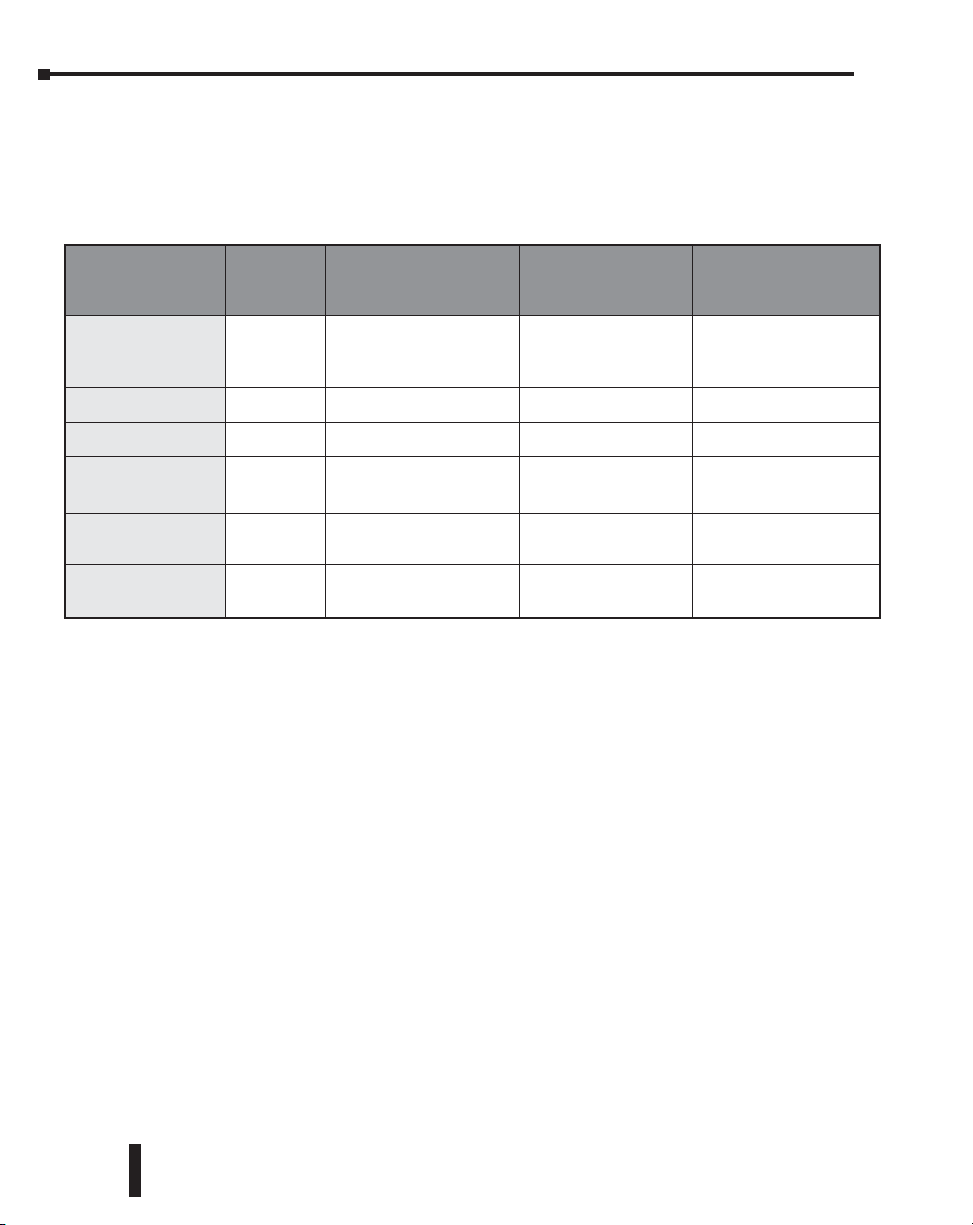

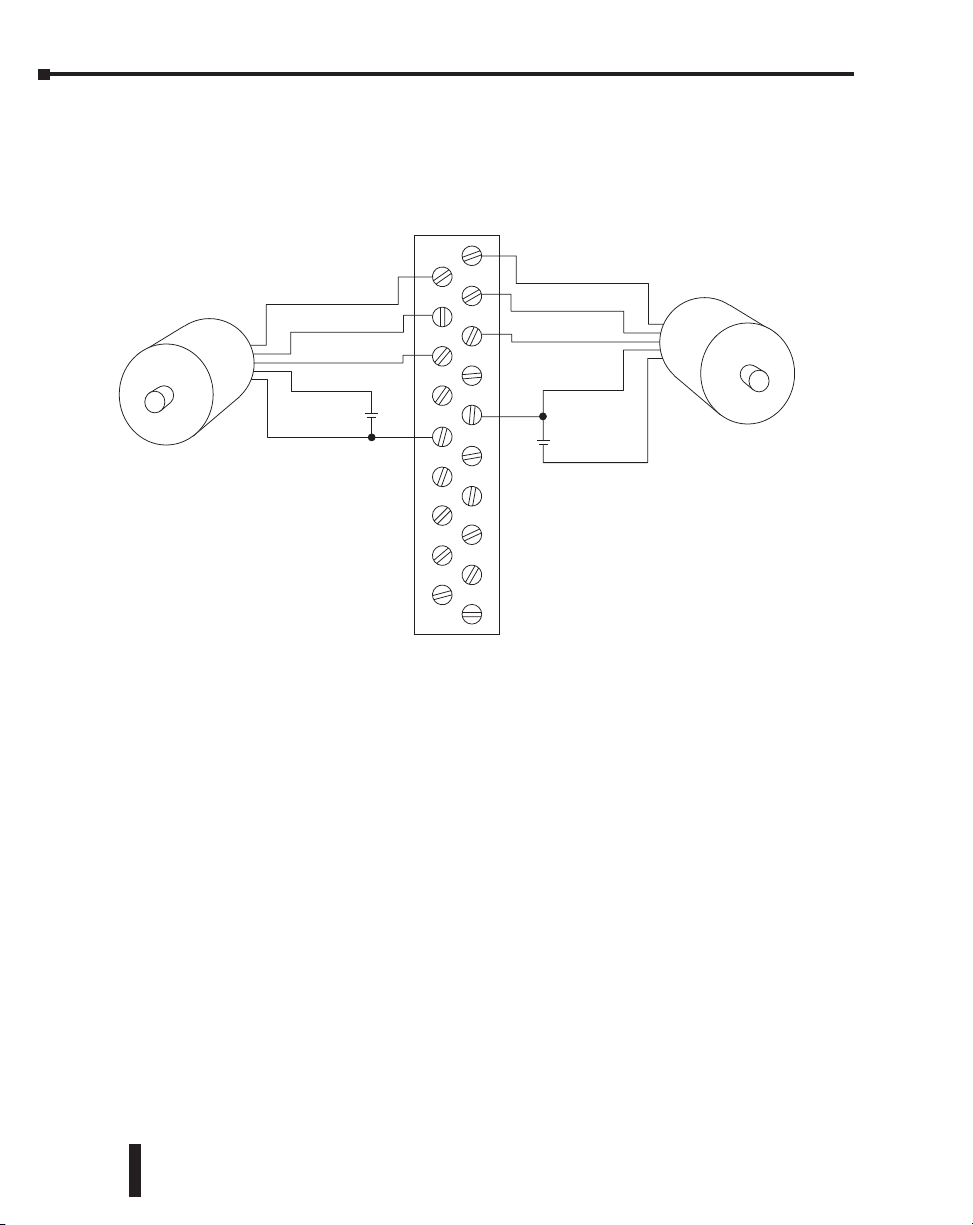

Output Position Pulses

Several options are available for generating pulses for controlling drives, steppers, servos, etc..

Some options are only available on a CTRIO2 module, as noted. Those only available on

CTRIO2 tend to be more versatile and are preferred. Shaded cells highlight the advantaged

attributes.

Options Position Source

Dynamic

Positioning Plus

Trapezoid Plus

Dynamic

Positioning

S-Curve

Symmetrical

S-Curve

Trapezoid

Free Form

From controller Ye s

From controller Ye s

From controller No

Hard-coded in

pulse prole

Hard-coded in

pulse prole

Hard-coded in

pulse prole

Hard-coded in

pulse prole

Change

target

position on

the y

No

No

No

No None 65kHz

Accel / Decel

ramps

Specify

separately

Specify

separately

One setting

for both

Specify

separately

One setting

for both

Specify

separately

Maximum

pulse rate

250kHz Yes Ye s

250kHz Yes Ye s

65kHz

65kHz

65kHz

65kHz

1

1

1

1

1

Encoder

Feedback

Possible

No No

No No

No No

No No

No No

Requires

CTRIO2

The following example uses Dynamic Positioning Plus on a CTRIO2. To use Dynamic

1

The older CTRIO outputs can only achieve 25kHz maximum. CTRIO2 outputs are limited to 65kHz when using these profiles.

Positioning Plus to send output pulses to an amplifier (without encoder feedback), follow these

basic steps in CTRIO Workbench:

1: Select Config I/O under Module Configuration to configure the outputs to provide

pulses appropriate for the amplifier.

2: Select Pulse Profiles at bottom of dialog box.

3: Optionally, give the profile a name.

4: Select Dynamic Positioning Plus and choose the Frequency Settings appropriate for

the motor and system.

5: Note the File Number assigned.

6: Use I/O Map to map the CTRIO(2) to the controller’s memory and print the I/O

Map Report.

7: Download the configuration to the CTRIO(2) module and put the CTRIO(2) in

Run.

Counter I/O User Manual, 3rd Ed., Rev. E

2-3

Page 32

Chapter 2: Getting Started

Home an Output

There are several available options for finding home on an output. If using a CTRIO2, Trapezoid

with Limits profile will nearly always be the best option. The following example uses Trapezoid

with Limits profile on a CTRIO2.

The table below shows a comparison of the available methods of homing an output with a

CTRIO(2) module. Shaded cells highlight the advantaged attributes.

To home an output with one or more limit switches, follow these basic steps in CTRIO Workbench.

Prole

Trapezoid

with Limits

Home

Search*

Run to Limit

*Home Search allows you to select 2nd limit or different speed.

Accel

and Decel

Ramps

Yes Ye s No Ye s Yes Yes Yes

No No* No Yes No Yes No

No No Ye s No No No No

1: Select Config I/O to configure the outputs to provide pulses appropriate for the chosen

amplifier.

2: Configure one or more inputs as Limit Out n where n is the output configured above.

3: Select Pulse Profiles at bottom of dialog box.

4: Select Add to create a new profile, or select an existing named profile.

5: Optionally, give the profile a name (defaults to “File 1-” upon closing dialog box).

6: Select Trapezoid profile with Limits.

7: Configure the Decel and Stop Triggers.

8: Choose the Frequency Settings appropriate for the motor and system.

9: Note the File Number assigned.

10: Use I/O Map to map the CTRIO(2) to the controller’s memory and print the I/O

Map Report.

11: Download the configuration to the CTRIO(2) module and put the CTRIO(2) in Run.

Creep to

second

limit or

position

Change

velocity

manually

on the y

Multiple

limits or

triggers

on a

single

home

search

Single

input can

act as

multiple

triggers

Prole

dened

in CTRIO

Workbench

Requires

CTRIO2

2-4

Counter I/O User Manual, 3rd Ed., Rev. E

Page 33

NOTE: The following steps are generic. Details are available in the manual.

In the controller:

1: Command the CTRIO2 to load the Trapezoid with Limits profile (by file number)

for the appropriate output.

2: Specify the direction (CW/CCW) to seek home.

3: Set the appropriate CTRIO2 Enable Output bit.

4: The controller can monitor status bits for visibility into the CTRIO’s progress.

Output PWM Pulses1

To generate PWM outputs, follow these basic steps in CTRIO Workbench.

1: Config I/O - Configure an output for Step/Direction, the step output will have the

PWM signal.

2: Use I/O Map to map the CTRIO(2) to the controller’s memory and print the I/O

Map Report.

3: Download the configuration to the CTRIO(2) module and put the CTRIO(2) in

Run.

4: In the controller - (Note: These steps are generic. Details are available in the

DirectLOGIC manual).

5: Set the command code for Velocity Mode.

6: Set Parameter 1 (Frequency).

7: Set Parameter 2 (Duty Cycle) from 1 to 99.

8: Set Parameter 3 (Number of Output Pulses) to FFFF FFFF for unlimited.

9: Set the appropriate CTRIO2 Enable Output bit to start pulses.

10: To stop pulses, reset the appropriate Enable Output bit.

11: To change the Duty Cycle, need source.

Chapter 2: Getting Started

Programmable Limit Switch or Preset Table

To control one of the CTRIO(2) outputs with a PLS or Preset Table that monitors an encoder

input, follow these basic steps in CTRIO Workbench.

1: Config I/O - Configure the appropriate inputs to recognize the encoder, noting the

Channel and Function numbers assigned.

2: Optionally set up scaling if desired.

3: Configure an output as Discrete on Ch_/Fn_, using the Channel and Function

numbers from the encoder input.

4: Discrete Tables…

Counter I/O User Manual, 3rd Ed., Rev. E

2-5

Page 34

Chapter 2: Getting Started

5: Add Preset Table or Add PLS Table

6: Optionally give the table a name.

7: Configure the table for the desired behavior.

8: Scales will be available if scaling was defined for the input.

9: Note the File Number assigned.

10: Use I/O Map to map the CTRIO(2) to the controller’s memory and print the I/O

Map Report.

11: Download the configuration to the CTRIO(2) module and put the CTRIO(2) in

Run.

NOTE: The following steps are generic. Details are available in the manual.

In the controller:

1: Command the CTRIO2 to load the Table by its file number

2: Set the appropriate CTRIO(2) Enable Output bit

3: The controller can monitor status bits for visibility into the CTRIO’s progress

1

Output Discrete On/Off from Ladder

The output points on a CTRIO(2) can be turned on and off from ladder, called Raw control.

Keep in mind that they will not react as quickly as the outputs of a standard discrete output

module since there is also the scan time of the CTRIO(2) that can add latency. To simply turn

the output of a CTRIO(2) on or off from ladder, follow these basic steps in CTRIO Workbench:

1: Config I/O - Configure any outputs to be controlled as Raw.

2: Use I/O Map to map the CTRIO(2) to the controller’s memory and print the I/O

Map Report.

3: Download the configuration to the CTRIO(2) module and put the CTRIO(2) in

Run.

NOTE: These steps are generic. Details are available later in the manual.

In the controller:

1: Set the appropriate CTRIO(2) Enable Output bit.

2: The controller can monitor status bits for visibility into the CTRIO’s progress.

1. PLS Tables are only available when using CTRIO2 hardware.

Counter I/O User Manual, 3rd Ed., Rev. E

2-6

Page 35

Chapter 2: Getting Started

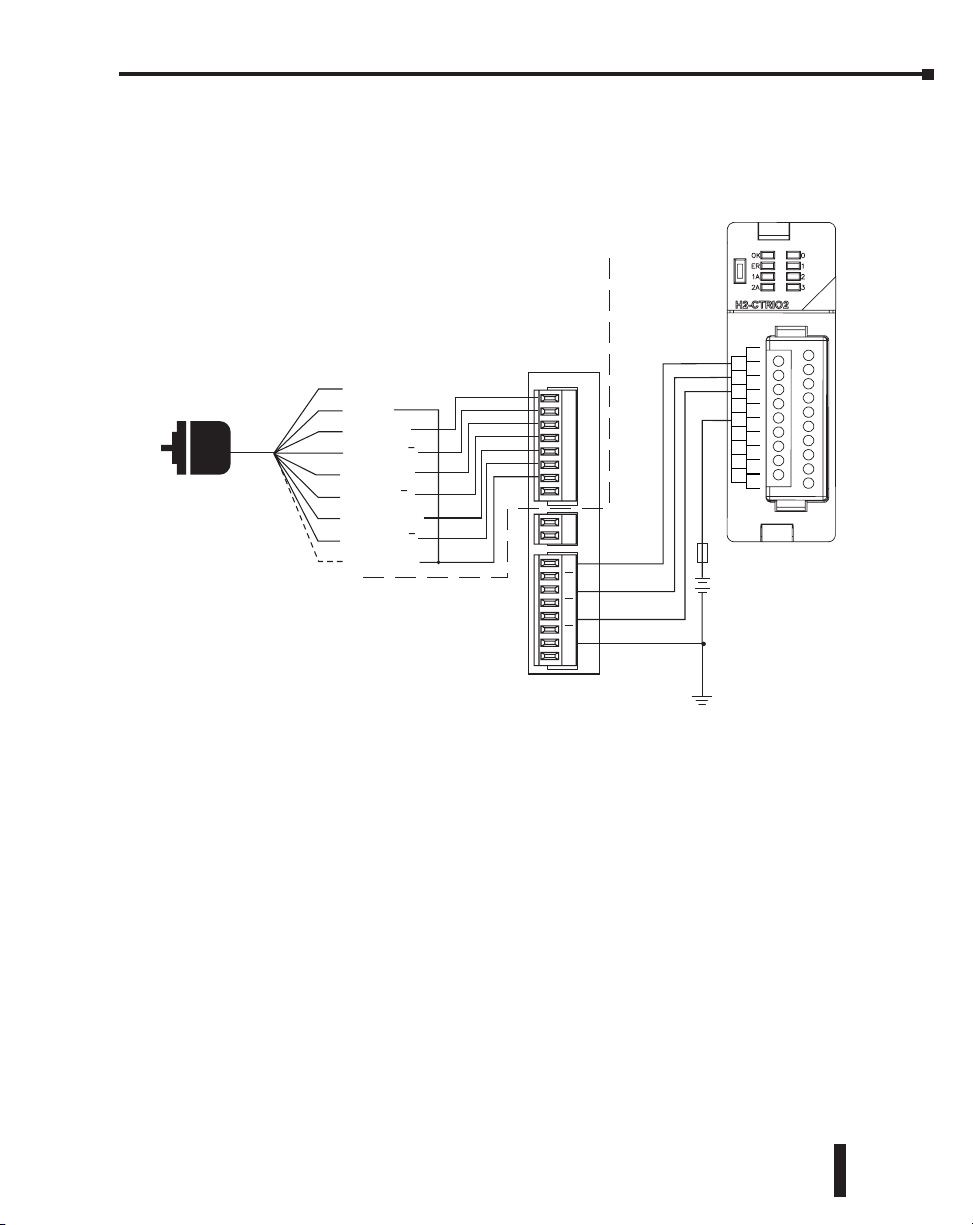

Detailed Example: Configure and Test a Quadrature Input

This example walks through the steps required to get the counts from a quadrature encoder

connected to a CTRIO(2) to appear in the CPU memory of a DirectLOGIC PLC. The

example uses DL06 hardware, but is applicable to DL05 and DL205 hardware as well.

The Basic Steps

1: Gather and connect the hardware (not covered here).

2: Launch CTRIO Workbench.

3: Use Config I/O to configure the appropriate inputs to recognize the encoder.

4: Use I/O Map to map the CTRIO(2) to the controller’s memory and print the I/O

Map Report.

5: Write the configuration to the CTRIO(2) module and put the CTRIO(2) in Run.

6: Use Monitor I/O to verify the encoder movement is being interpreted by the

CTRIO(2) properly.

7: Launch DirectSOFT and use Data View to check that position data is appearing in

the mapped addresses .

Equipment Needed

DirectLOGIC 06 base and H0-CTRIO2 installed in slot 41. A quadrature encoder properly

powered and connected to the H0-CTRIO2.

Launch CTRIO Workbench

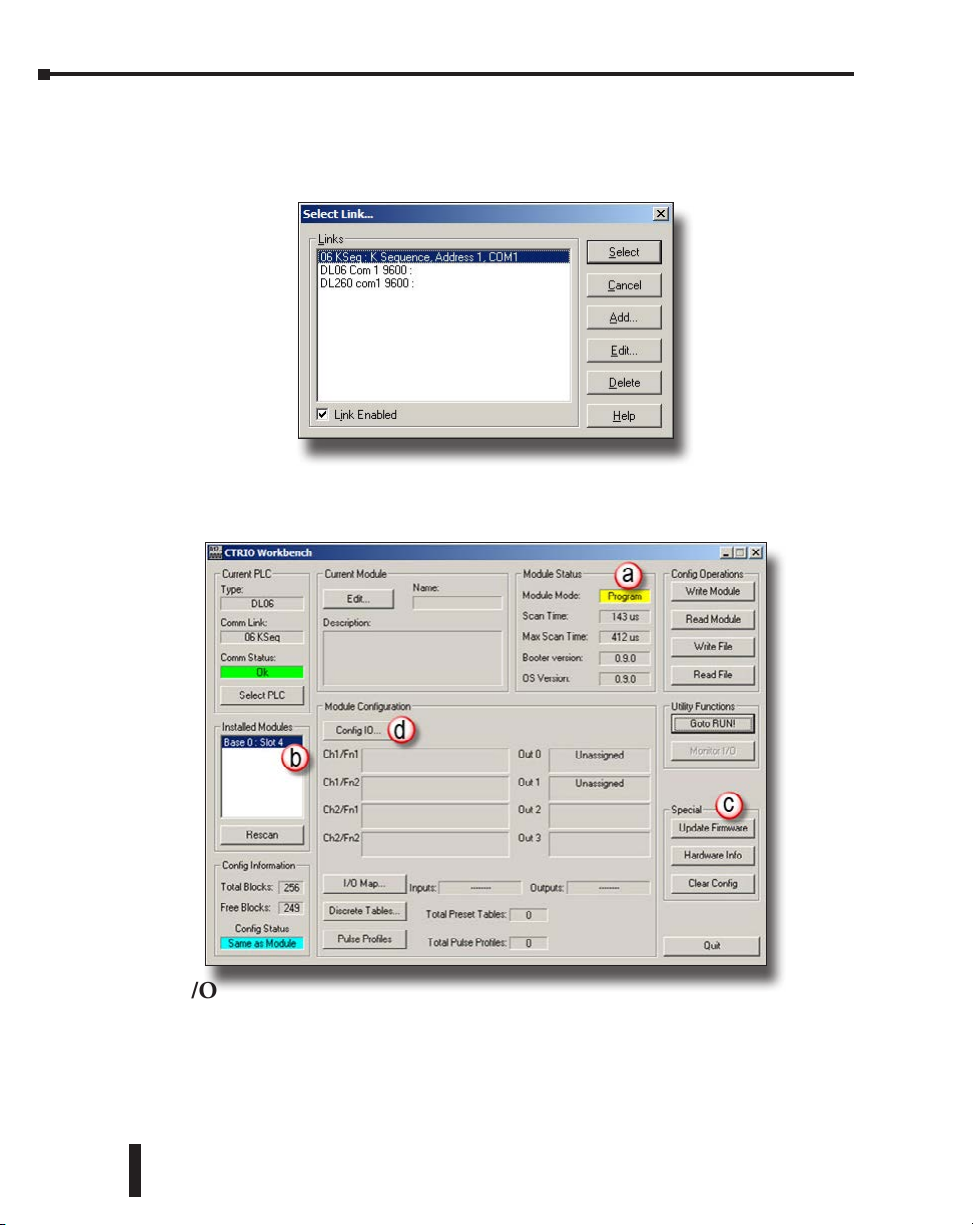

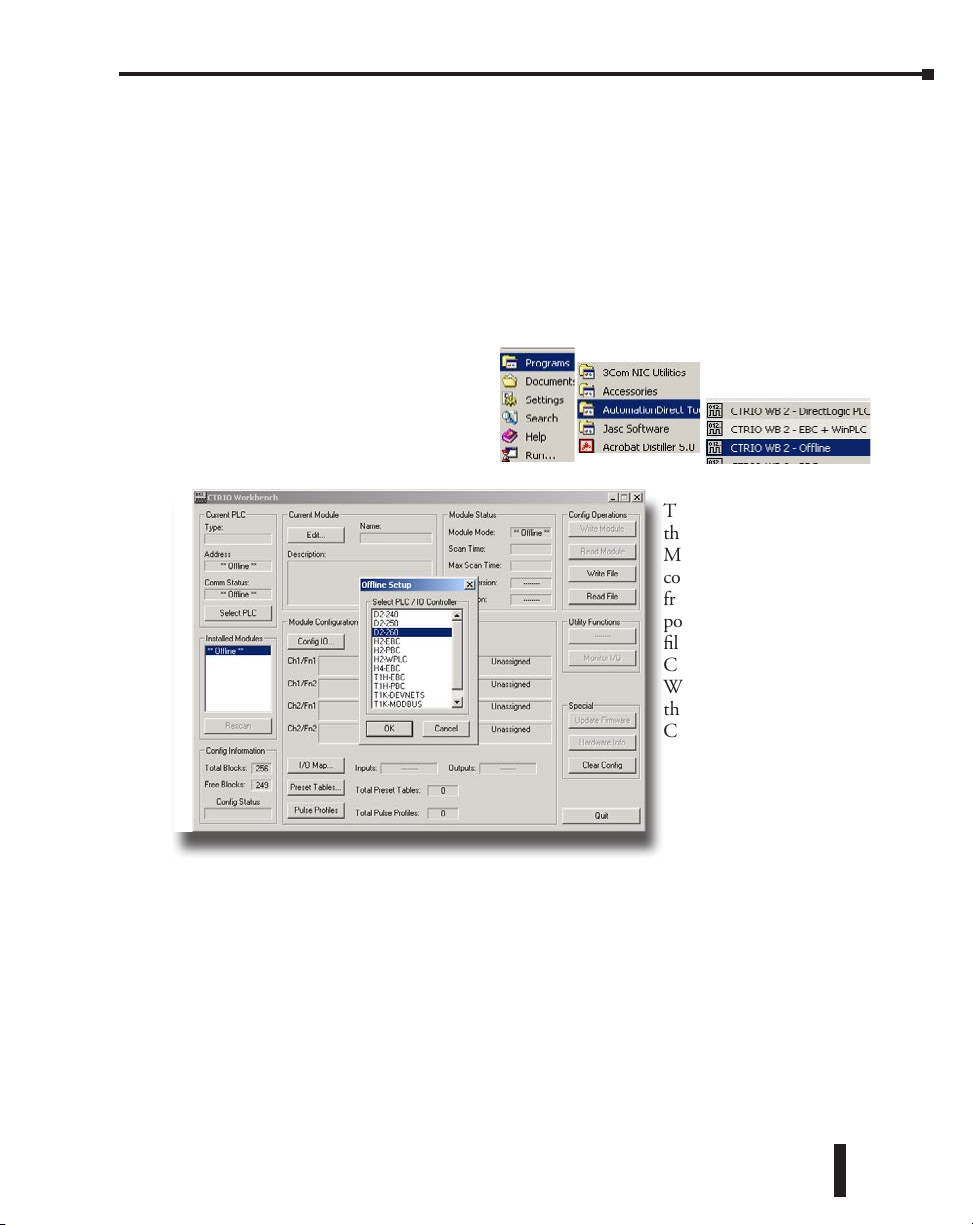

When using CTRIO Workbench with a DirectLOGIC CPU and the latest version of DirectSOFT,

the best way to launch it is from DSLaunch. DSLaunch is installed when installing DirectSOFT.

Open DSLaunch.exe.

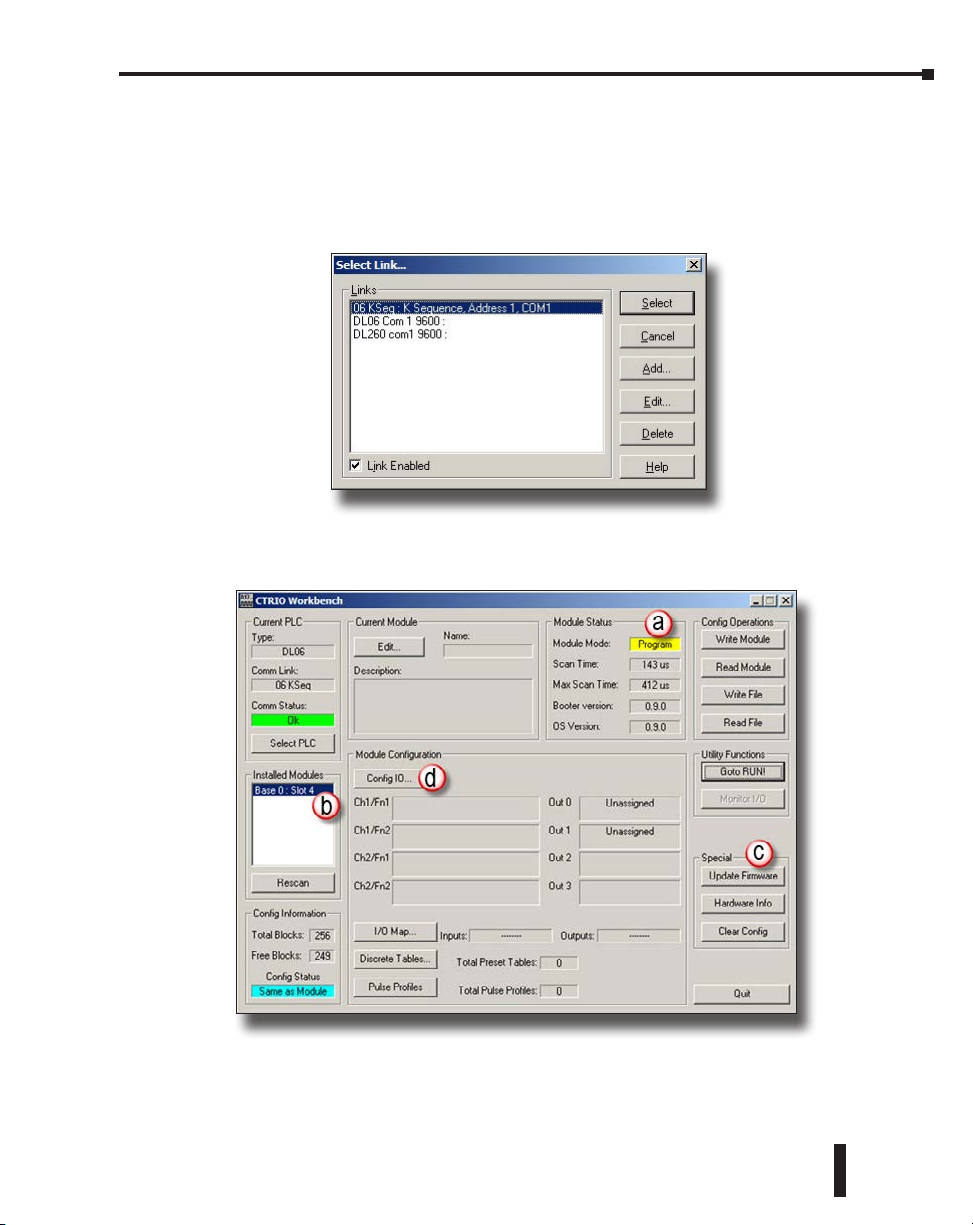

Click “CTRIO WB 2 – DirectLOGIC PLC” to open CTRIO Workbench. The Select

1. If using DirectLOGIC 205 hardware, the CTRIO(2) cannot be installed directly next to the CPU slot.

Counter I/O User Manual, 3rd Ed., Rev. E

2-7

Page 36

Chapter 2: Getting Started

Link… dialog box appears. Select the appropriate PLC communication link to use. If it does

not appear in the list, check power and the communications cable or, create a new link by

clicking on ‘Add’.

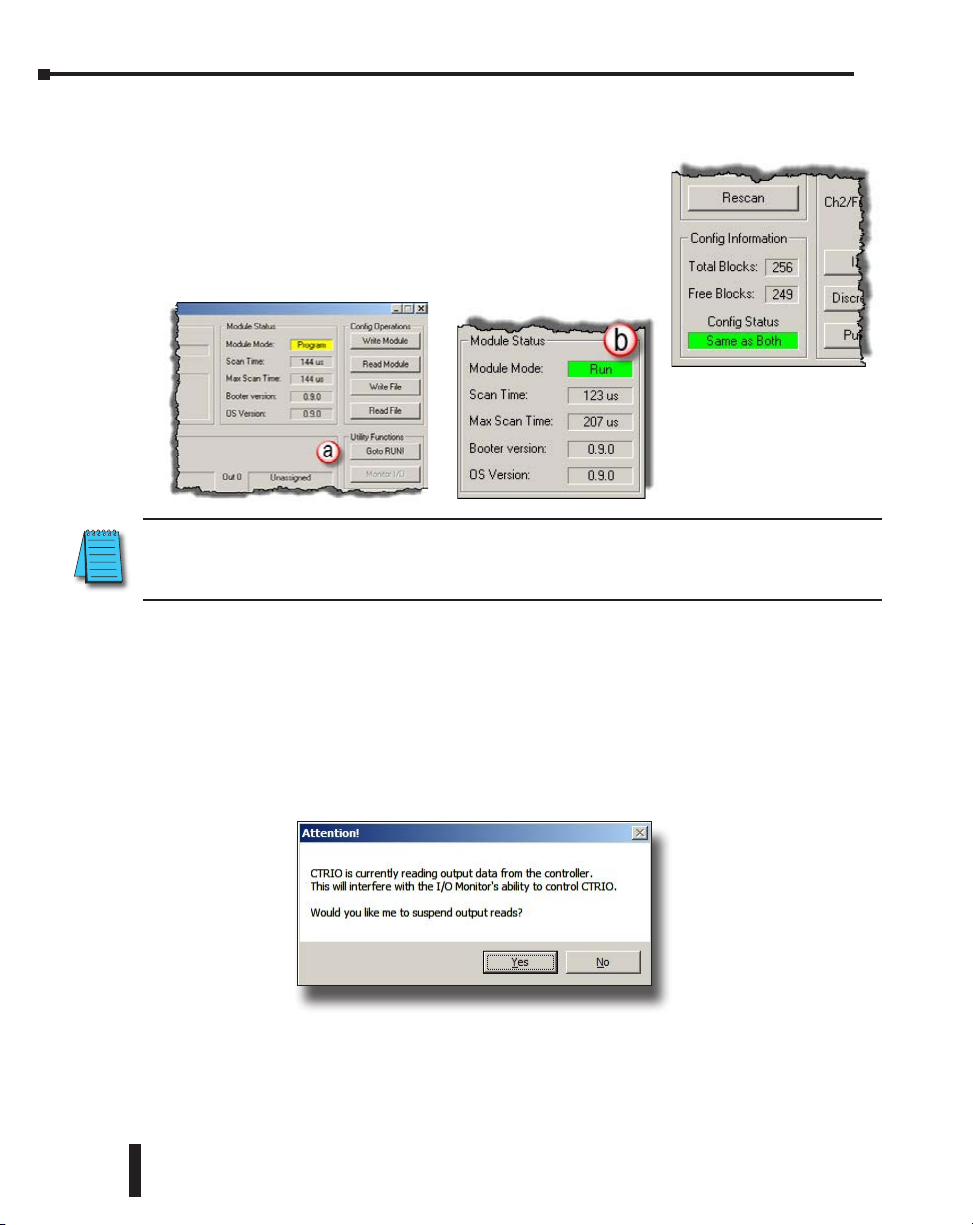

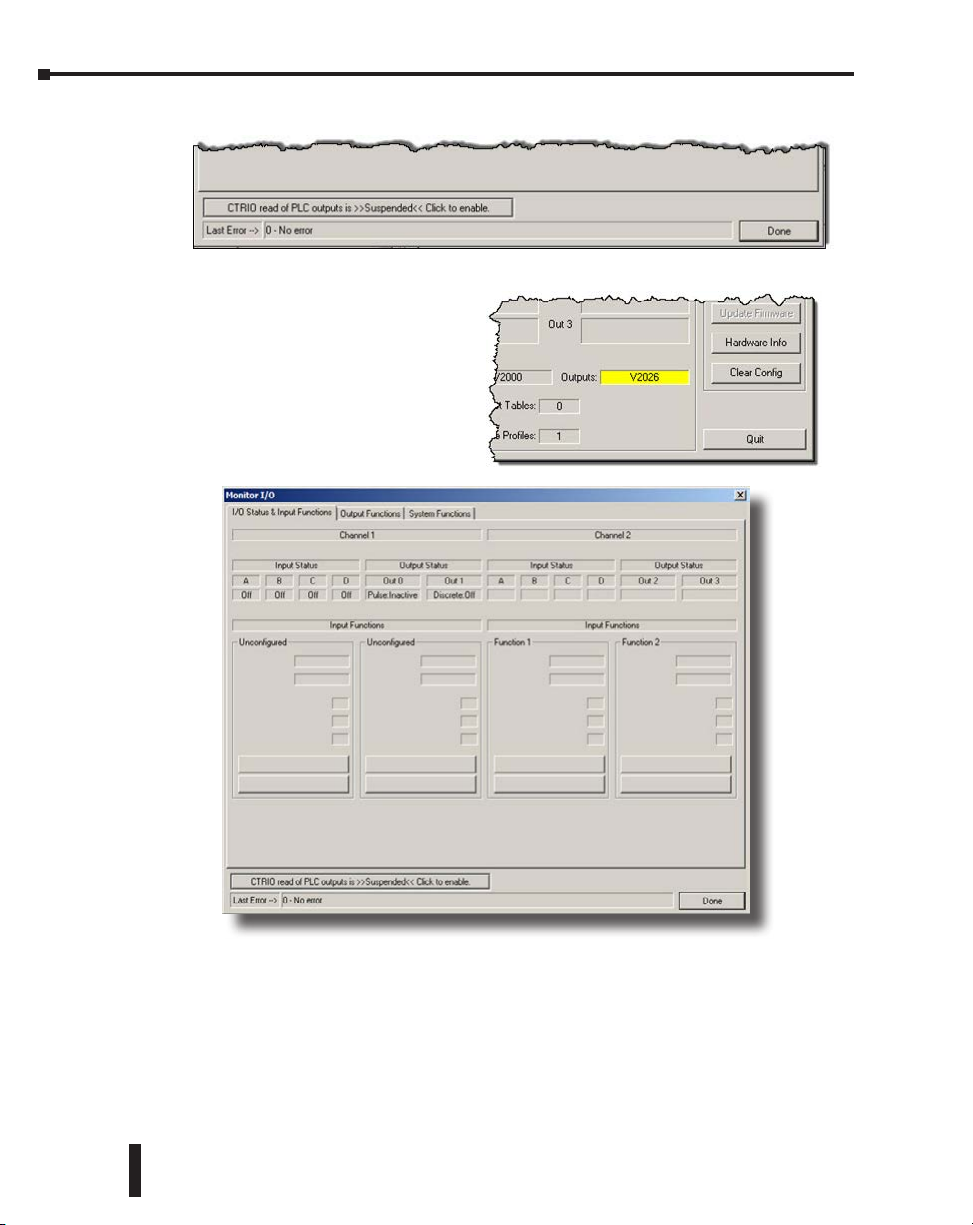

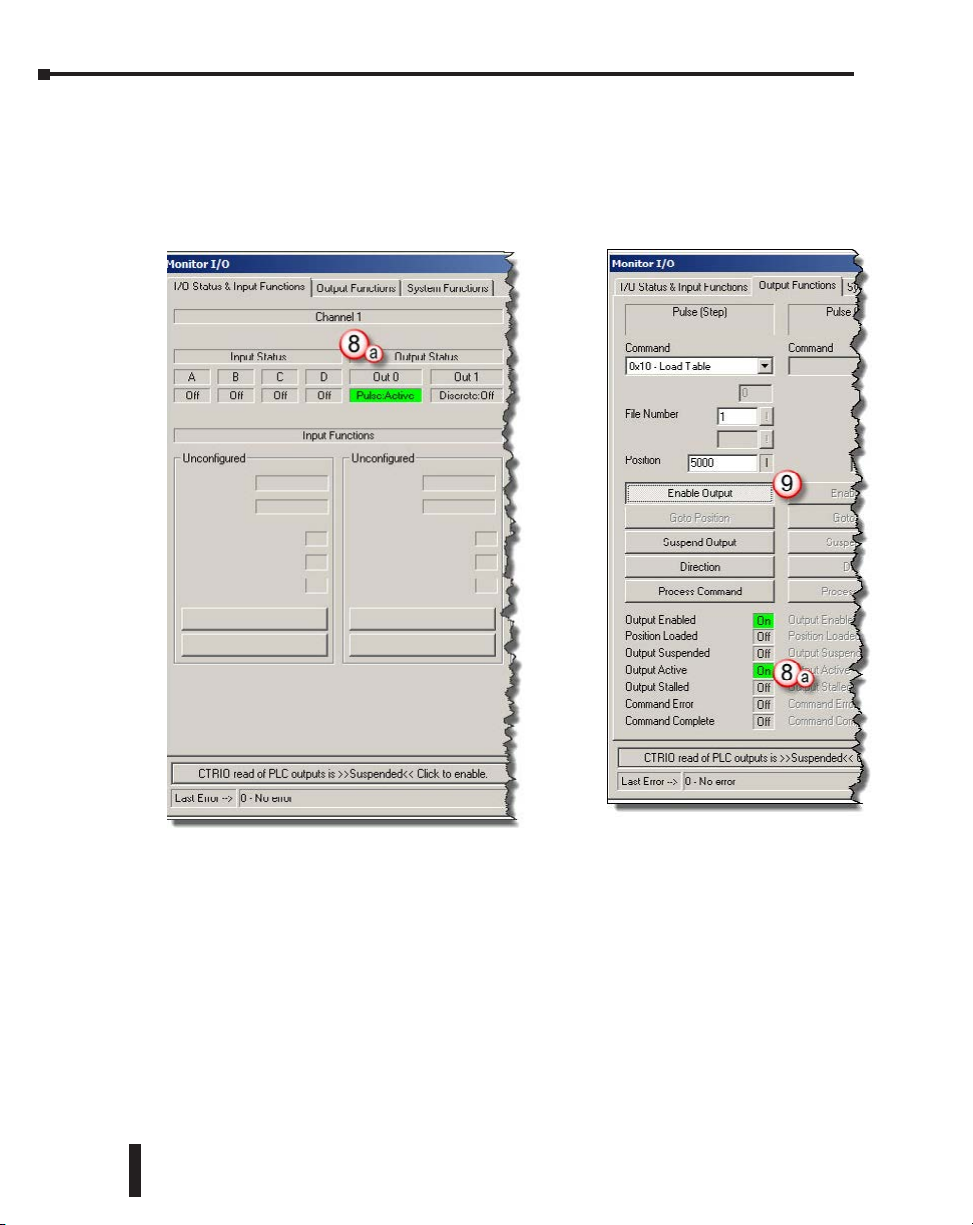

Once connected, CTRIO Workbench will look like the one below. The H0-CTRIO2 shown

is new and has no configuration. It is in Program mode (a). It is installed in slot 4 (b). Now

is a good time to check the firmware version and make sure it’s current (c).

2-8

Config I/O

For this example, it is only necessary to configure the inputs of the H0-CTRIO2 to recognize

a quadrature encoder. Click Config I/O (d) command box.

Counter I/O User Manual, 3rd Ed., Rev. E

Page 37

Chapter 2: Getting Started

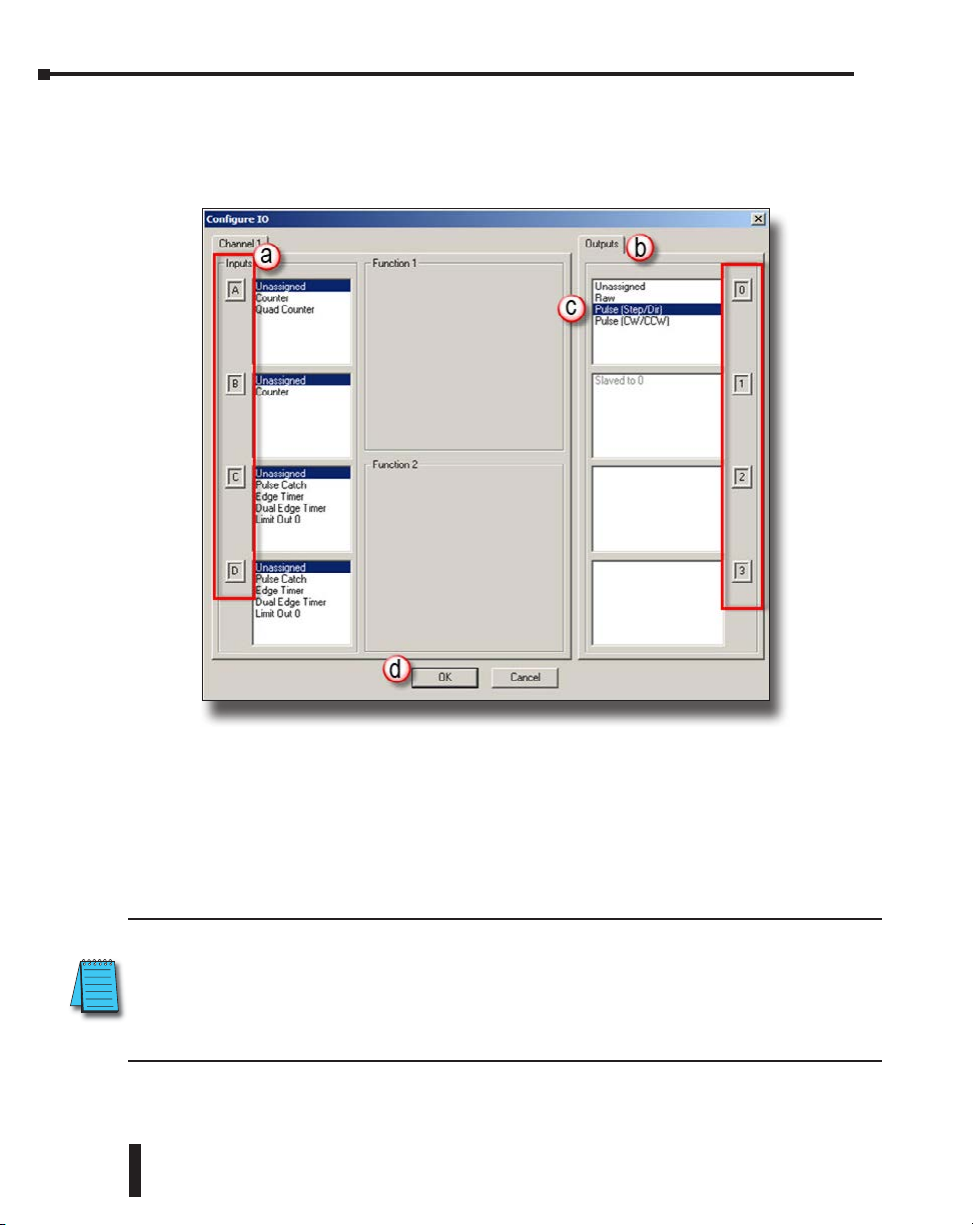

The Configure I/O panel is divided into two sections. One section is for Channel 1 Inputs

(A-D) and the other section is for the Outputs (0-3). If working with an H2-CTRIO2, there

would also be a tab for Channel 2.

Within Channel 1, note there are Function 1 (a) and Function 2 (b). Each Channel on a

CTRIO(2) module may have up to two Functions assigned.

On Channel 1, select Quad Counter (c). This tells the CTRIO(2) to expect quadrature signals

on Channel 1 Inputs A and automatically, B.

NOTE: Many other defaults change when a selection is made:

• The option for Input B to be a simple counter disappears and it is

assigned as Slave to A and can no longer be directly changed.

• Some options for Input C disappear and a new option appears.

• Channel 1 Function 1 area displays Quadrature Counter and

offers multiple options that apply to that counter input.

• New options for the Outputs appear that reference Ch1/

Fn1, the quadrature input function created.

Counter I/O User Manual, 3rd Ed., Rev. E

2-9

Page 38

Chapter 2: Getting Started

NOTE: This automatic reconfiguring of available options is an important feature of CTRIO Workbench.

The primary benefit is that it prevents the user from selecting options that will not work together. It is

not possible to create an invalid configuration. However, keep this feature in mind when going about

configuring a CTRIO(2). If a function cannot be found, it’s likely that some dependency has not yet been

enabled, or a feature that has been enabled is consuming an exclusive resource the desired feature also

requires.

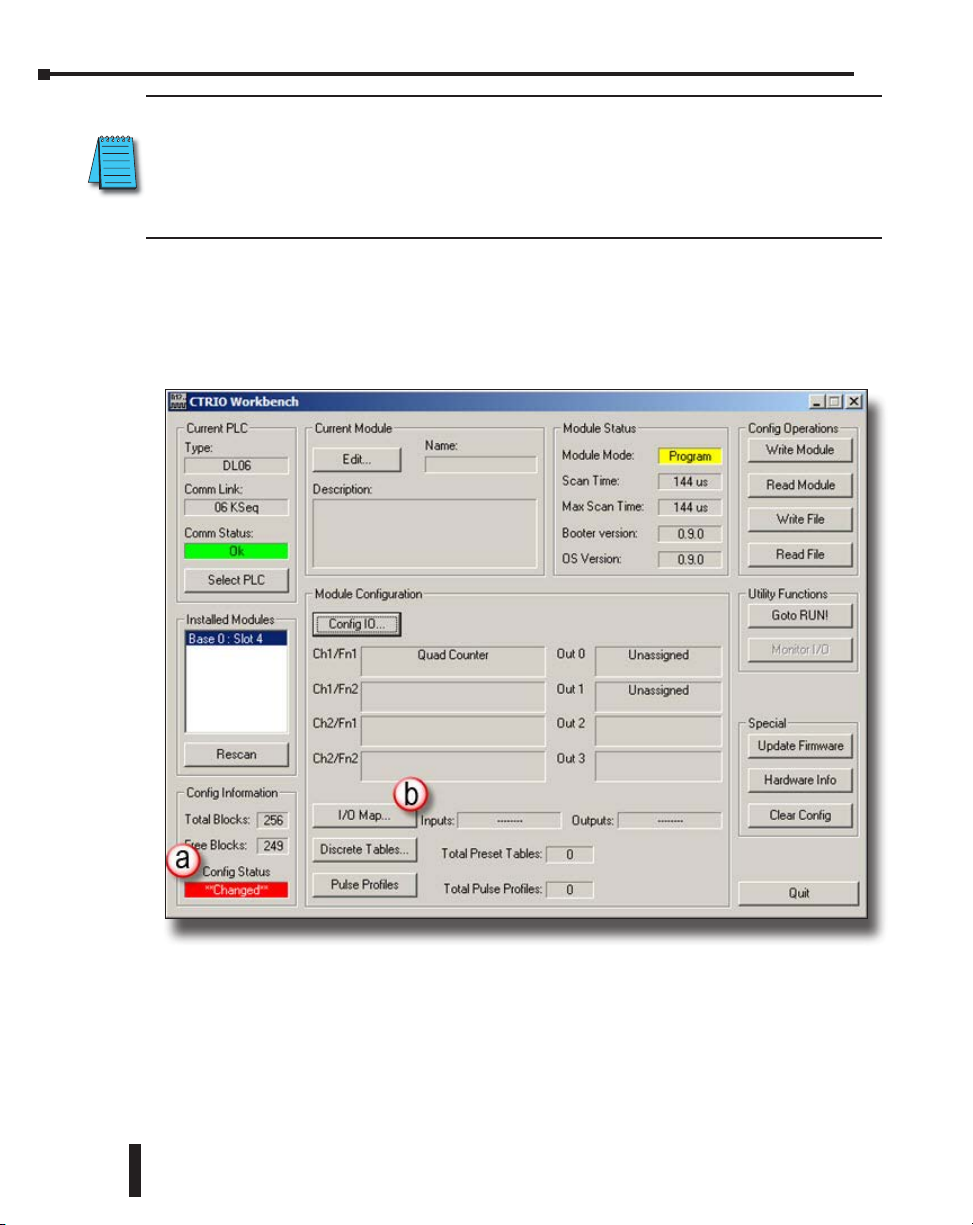

Click OK to keep the changes and go back to the CTRIO Workbench home screen.

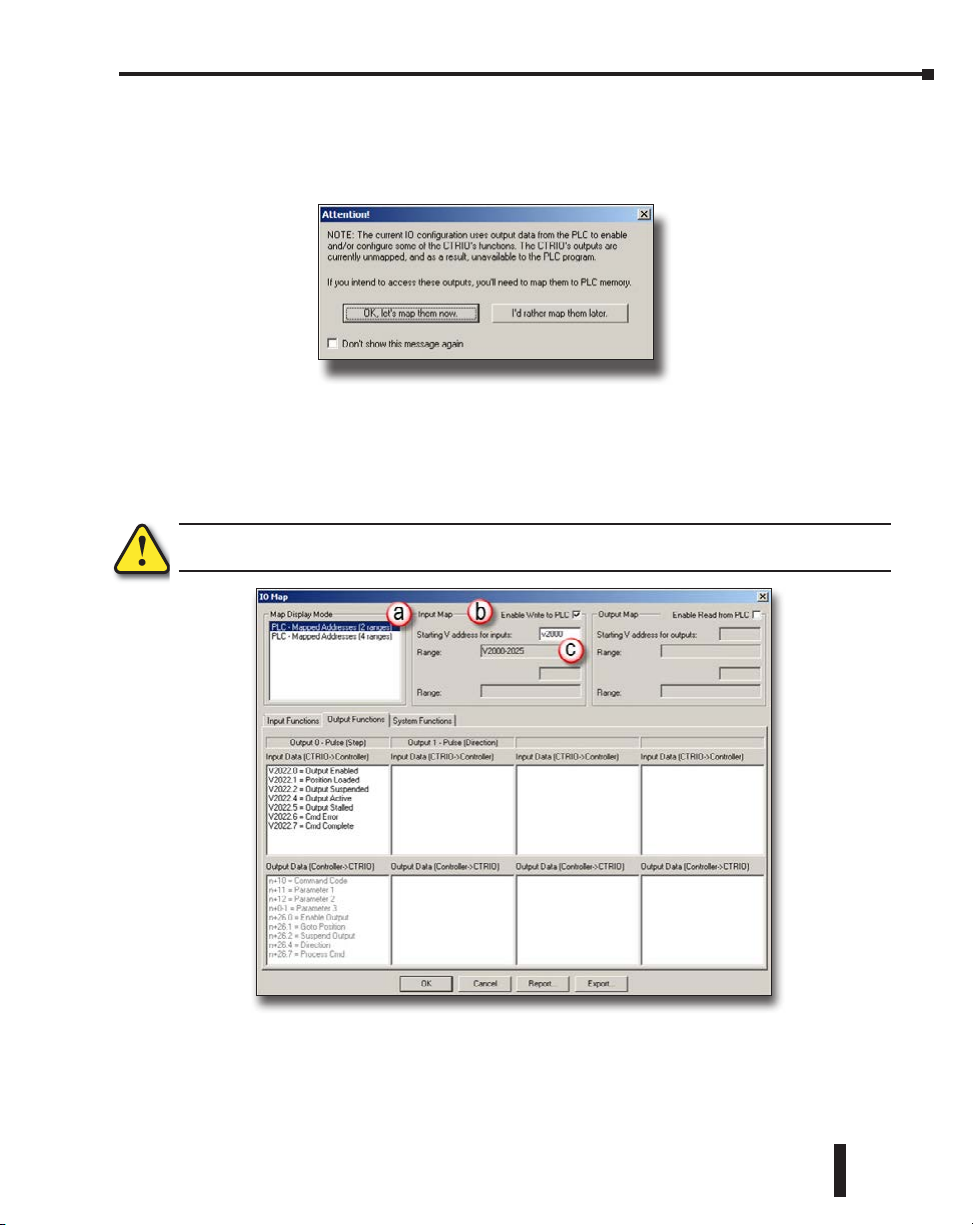

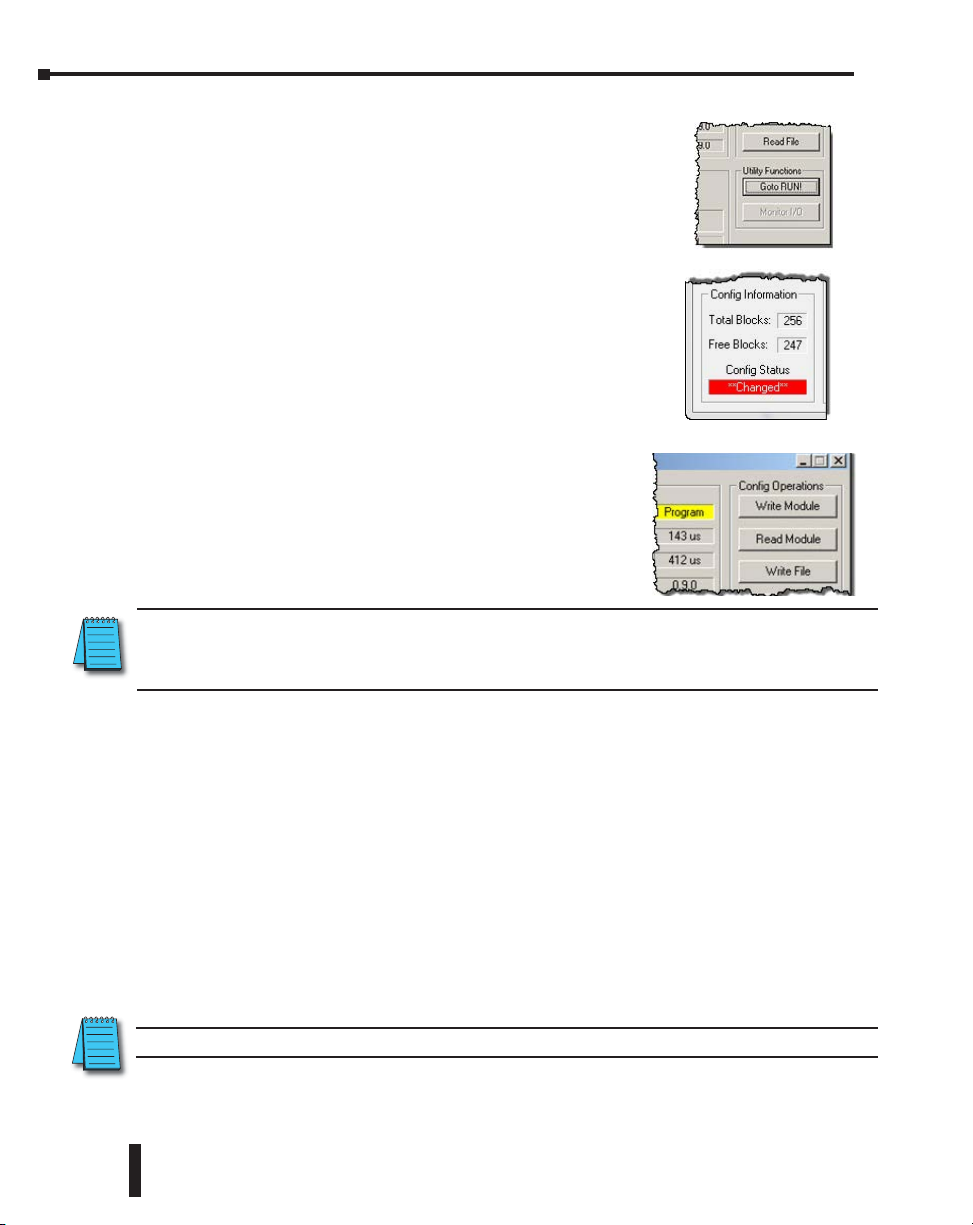

On the home screen, note the indication in the lower left (a), Config Status **Changed**. This

indicates that the configuration in Workbench does not match what was read from the module.

Before the new configuration is written to the module, there is one other thing that must be

done. Click I/O Map (b). This brings up the I/O Map dialog box.

2-10

Counter I/O User Manual, 3rd Ed., Rev. E

Page 39

Chapter 2: Getting Started

I/O Map

Depending on the configuration, the CTRIO(2) will have some number of variables to pass

back and forth to the CPU. The data does not fit in the normal structure that most I/O

modules use. Instead, the CTRIO(2) is able to write to and read from any CPU memory

specified. In this panel, map the variables into CPU memory.

Be careful to map memory addresses that will not be used for any other purpose.

In Map Display Mode (a), select “PLC - Mapped Addresses (2 ranges)” mode.

In the Input Map box (b) point the CTRIO(2) where to write input data to the PLC memory.