Page 1

C2-08DR-6C Option Slot Module

4

-

20mA

OUT

0

-

20mA

IN

AD1I

AD2I

AD3I

AD4I

DA1I

DA+V

DA2I

ACOM

ACOM

4

3

2

1

C2

6

-

27V 1A / 6

-

240V 1A

OUT

4

3

2

1

C1

24V 6.5mA

IN

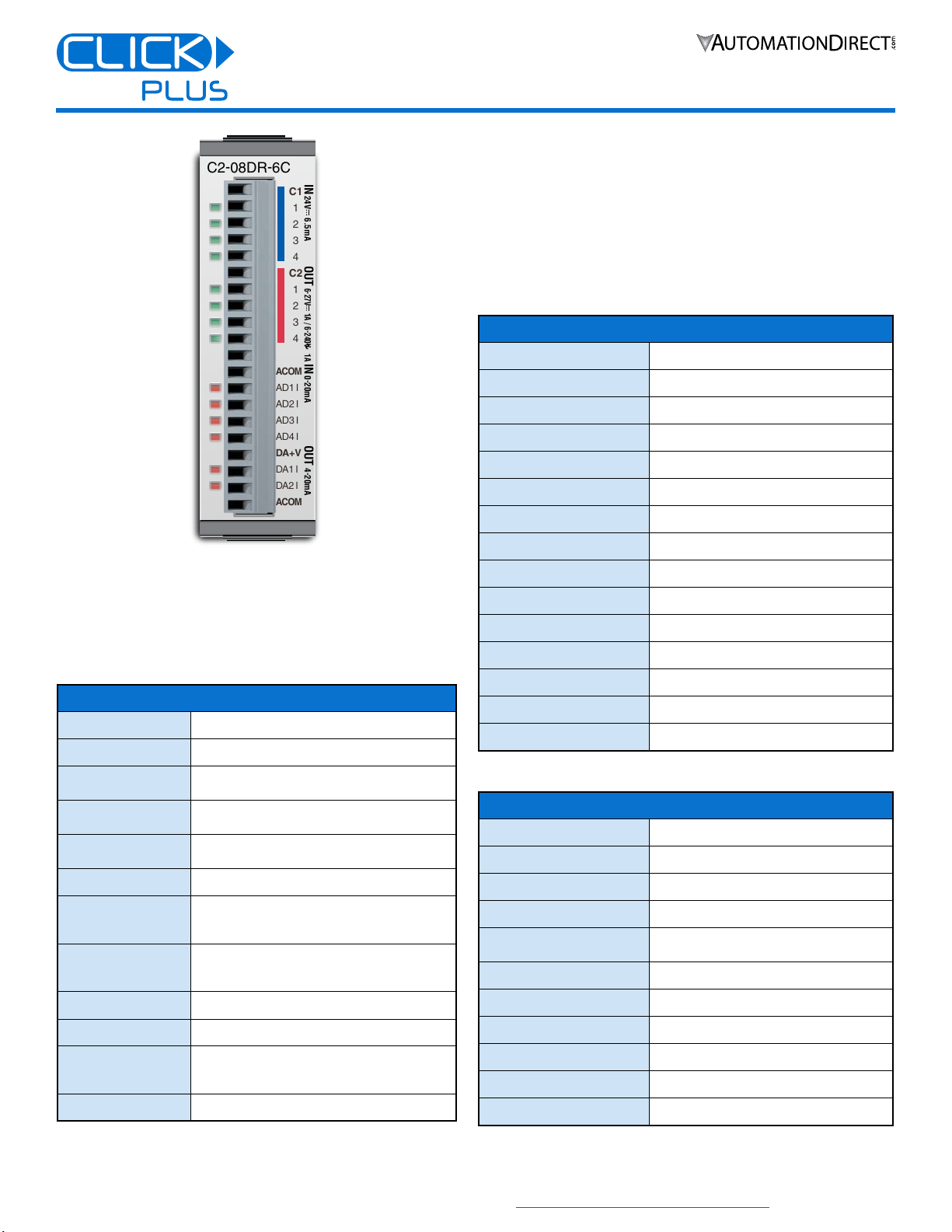

C2-08DR-6C

Installation Instructions

C2-08DR-6C

OPTION SLOT MODULE

4 discrete DC sinking/sourcing inputs

4 discrete relay outputs

4 analog current inputs

2 analog current outputs

General Specifications*

Operating Temperature

Storage Temperature

Ambient Humidity

Altitude

Environmental Air

Environment

Vibration

Shock

Weight

Bus Power Required

Agency Approvals

Other

* Isolate from shock, vibration and electric or ferromagnetic eld.

Keep out iron powder, moisture, oil or chemicals.

Indoor use only. Keep out of direct sunlight.

Copyright© 2020, Automationdirect.com Incorporated/All Rights Reserved Worldwide

32°F to 131°F [0°C to 55°C]

–4°F to 158°F [–20°C to 70°C]

30% to 95% relative humidity

(non–condensing)

Up to 2,000m

No corrosive gases

Pollution Degree 2 (UL840)

For Indoor Use Only

5–9Hz: 3.5 mm amplitude; 9–150Hz: 1.0 G

10 sweep cycles per axis on each of

3 mutually perpendicular axes.

15G peak, 11ms duration,

3 shocks in each direction per axis,

on 3 mutually perpendicular axes.

58g

Max 100mA (all points ON)

UL61010 (File No. E157382);

CE (EN61131-2);

CUL Canadian C22.2

RoHS 2011/65/EU Amendment (EU)2015/863

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

Please read and understand the information in these

installation instructions prior to installation, operation, or

servicing this equipment. This module is intended to be used

with a CLICK PLUS CPU. Ensure the CPU is installed in

accordance with its installation and safety instructions.

PLEASE REVIEW SAFETY WARNINGS ON PAGE 2!

DISCRETE I/O SPECIFICATIONS

Discrete Input Specifications

Inputs per Module

Nominal Voltage

Input Voltage Range

Input Current

Max. Input Current

Input Impedance

ON Voltage Level

OFF Voltage Level

Minimum ON Current

Maximum OFF Current

OFF to ON Response

ON to OFF Response

Input Filter

Status Indicators

Commons

* Set from CLICK Tool.

4 (Source/Sink)

24.0 VDC`

21.6–26.4 VDC

6.5 mA @ 24VDC, typical

7mA @ 26.4 VDC

3.9 kΩ @ 24VDC

> 19.0 VDC

< 2.0 VDC

4.5 mA

0.5 mA

3μs typical, 5μs maximum

1μs typical, 5μs maximum

1ms unit (set from 1 to 99 ms)*

4 Green LEDs

1 (4 points/common)

Discrete Output Specifications

Outputs per Module

Operating Voltage Range

Output Voltage Range

Output Type

Max. Output Current

Min. Load Current

Max. Inrush Current

OFF to ON Response

ON to OFF Response

Status Indicators

Commons

4

6–27VDC, 6–240VAC (47–63Hz)

5–30VDC, 5–264VAC (47–63Hz)

Relay, Form A(SPST)

1A/point,

C2: 4A/common

5mA @ 5VDC

3A for 10ms

< 15ms

< 15ms

4 Red LEDs

1 (4 points/common)

www.automationdirect.com/click-plc

1

Page 2

C2-08DR-6C Option Slot Module

Installation Instructions

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

Technical Specs, continued

ANALOG I/O

Analog Input Specifications

Number of Channels

Input Type

Input Range

Resolution

Conversion Time

Input Impedance

Input Stability

Full-scale Calibration Error

Oset Calibration Error

Accuracy vs Temperature Error

Largest Instant Deviation

During Noise Test

Analog Output Specifications

Number of Channels

Output Type

Output Range

Resolution

Conversion Time

Load Impedance

Loop Power Supply

Full-scale Calibration Error

Oset Calibration Error

Accuracy vs Temperature Error

Largest Instant Deviation

During Noise Test

4

Current

4–20mA

12 bit

50ms

125Ω

±2 LSB, maximum

±2%, maximum

±0.1 mA, maximum

±100ppm/°C, maximum

±20% of full scale

2

Current

4–20mA

12 bit

2.5 ms

250Ω typical (200–800Ω)

24VDC typical (21.6–26.4 VDC)

±2%, maximum

±0.1 mA, maximum

±120ppm/°C, maximum

±20% of full scale

Safety Warnings

Please follow these instructions for personal and operational safety.

WARNING

CAUTION

Don’t use this equipment in a flammable or explosive

environment in order to avoid accidental injury or fire.

You should use external electromechanical devices that are

independent of the PLC (Programmable Logic Controller)

system to provide protection for any part of the system;

otherwise malfunction or output failures may result in a

hazardous accident.

24VDC power is required from a secondary circuit or a specific

power supply unit only.

Ensure the Ground Terminal of the Power Supply (C0-00AC/

C0-01AC) for the CLICK PLUS CPU is connected to Earth

Ground to avoid electric shock or equipment damage during a

short circuit.

Don’t operate the equipment with a nonconforming external

power supply to avoid electric shock, equipment damage or fire.

Don’t intentionally fault the wiring; this may cause equipment

damage or fire.

To avoid electric shock or malfunctions which might result in an

accident, don’t touch any terminal while the PLC power is on.

Don’t put metals (e.g. screwdriver) into vent holes, or drop trash

or foreign objects (e.g. wire cut-offs) into the device, in order to

avoid electric shock or equipment damage.

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

invalidated.

For use in Pollution Degree 2 Environment. Use and store the

equipment in an environment described in the specifications

(regarding temperature, humidity, vibrations, shock, etc.) in

order to avoid equipment damage or fire.

Ensure all wiring has strain reliefs in order to avoid damage to

insulation that might result in electric shock or fire.

Ensure secondary external power circuits are only live after PLC

control program is started; otherwise a malfunction or output

failure may result in a hazardous accident.

Don’t block the vent holes. This may cause an increase of inter-

nal temperature resulting in equipment damage or fire.

Don’t disassemble or modify equipment so as to avoid electric

shock, equipment damage, or fire.

Cut off all phases of the external power source before mainte-

nance work, thus avoiding electric shock or equipment damage.

Assumes that incorrect handling may cause hazardous

conditions, resulting in severe injury or death.

Assumes that incorrect handling may cause hazardous

conditions, resulting in medium or slight injury, or

may cause equipment damage.

WARNING

CAUTION

Copyright© 2020, Automationdirect.com Incorporated/All Rights Reserved Worldwide

www.automationdirect.com/click-plc

2

Page 3

C2-08DR-6C Option Slot Module

3 Push the top and bottom locking clips

backward until they click into place.

1 Remove the Option Slot Cover (#C2-FILL)

if it was installed in the CPU, by grasping its

top and bottom front corners, squeezing and

pulling it forward.

3 Push the top and bottom locking clips

backward until they click into place.

Lift slightly on the locking clips until they

release, then slide each clip forward.

Reverse the procedure.

To install an Option Slot Module To install an Option Slot Module

To remove an Option Slot Module

To remove an Option Slot Module

3 Push the top and bottom locking clips

backward until they click into place.

Installation Instructions

Hardware Installation

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

CAUTION

Discharge static electricity before installation or

wiring to avoid electric equipment damage.

CAUTION

Cut off all phases of the power source externally

and wait 5 seconds before installing or removing

the Option Slot Module of a running system.

INSTALL OR REMOVE THE OPTION SLOT MODULE

To install an Option Slot Module To install an Option Slot Module

1 Remove the Option Slot Cover (#C2-FILL)

if it was installed in the CPU, by grasping its

top and bottom front corners, squeezing and

pulling it forward.

2 Hold the

Option Slot

Module by the

top and bottom front

corners, align the PCB card

edge with the guide slots in the

CPU, and slide the module into

its slot. Press the module into place until it is

fully seated

3 Push the top and bottom locking clips

backward until they click into place.

To remove an Option Slot Module

To remove an Option Slot Module

WIRING

16–28 AWG wiring is supported. We recommend using

crimping ferrules on all wire terminations for a more secure

connection. The following crimping ferrules are recommended

for the I/O terminals.

Company

AutomationDirect

* Rated torque is 0.22 to 0.25 N·m.

Take care not to contact adjacent terminal.

Connector Type

Number of Pins

Pitch

Wire Size Range

Stripping Length

Wire Specication

Screw Thread

Tightening Torque

Type Model No. Compliant Wire

Ferrule

V30AE000009

V30AE000041

0.2–0.5 mm2 (22–26AWG)

Terminal Block Specifications

Pluggable Terminal Block

20

3.50 mm

16–28 AWG

7.0 mm

Lead-free, heat resistant,

polyvinyl chloride insulated copper wire,

rated over 80°C

M2.0

2.0–2.2 inch-lb [0.22–0.25 N·m]

WIRING DIAGRAM

C2-08DR-6C

C1

1

2

3

4

C2

1

2

3

4

ACOM

AD1I

AD2I

AD3I

AD4I

DA+V

DA1I

DA2I

ACOM

IN

24V 6.5mA

OUT

6

-

27V 1A / 6

-

240V 1A

IN

0

-

20mA

OUT

4

-

20mA

L

L

L

L

L

L

L

L

Transmitter P/S

+

24VDC

24VDC

+

+

6-27 VDC

6-27 VDC

6-240 VAC

6-240 VAC

Transmitter 0-20mA

Transmitter 0-20mA

Transmitter 0-20mA

Transmitter 0-20mA

+

24VDC

+

+

Lift slightly on the locking clips until they

release, then slide each clip forward.

Reverse the procedure.

Copyright© 2020, Automationdirect.com Incorporated/All Rights Reserved Worldwide

www.automationdirect.com/click-plc

3

Page 4

C2-08DR-6C Option Slot Module

+

Equivalent Discrete Input Circuit

Analog Current Input Circuit

Equivalent Discrete Output Circuit

6-240

Installation Instructions

Hardware Installation, continued

EQUIVALENT CIRCUITS

Internal Module Circuitry

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

3.3 V

24 VDC

+

INPUT

COM

6-27 VDC

VAC

Optical Isolator

VCC

GND

Internal Module Circuitry

24 VDC

L

Current

Transmitter

Copyright© 2020, Automationdirect.com Incorporated/All Rights Reserved Worldwide

+

Transmitter

P/S

ADxI

ACOM

Internal Module Circuitry

A/D

125Ω

Converter

www.automationdirect.com/click-plc

4

Page 5

C2-08DR-6C Option Slot Module

Surrounding Air Temperature (°C/°F)

°F

Points

Discrete Input Temperature Derating Chart

Surrounding Air Temperature (°C/°F)

°F

Points

Discrete Output Temperature Derating Chart

Installation Instructions

Hardware Installation, continued

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

EQUIVALENT CIRCUITS, CONTINUED

Analog Current Output Circuit

Internal Module Circuitry

DA+V

24VDC

DERATING CHARTS

+

External

Load

DAxI

+

–

ACOM

INSULATION

Basic insulation is provided between

DC input terminal and Relay output

terminal. In order to comply with

IEC/UL 61010-2-201, if the output

is connected to a circuit exceeding

30V, please externally provide an

+

–

D/A

Converter

isolation with basic insulation before

the DC input terminal.

Basic insulation requires a clearance

distance of 1.5 mm or more, a creepage distance of 2.5 mm or more,

and dielectric voltage withstand of

1500Vrms.

DC input

Relay output

Analog input

Analog output

Internal circuit

:

No insulation

:

Basic insulation

:

Reinforced insulation

4

3

2

1

0

0

32

10

50

20

68

30

85

40

104

Symbols listed on the equipment are shown below.

Name

DC

AC

CAUTION

Description Symbol

DC power supply IEC60417 No. 5031

AC power supply IEC60417 No. 5032

Use Copper Conductor Only ISO 7000 No.0434B

50

122

55 °C

131

4

3

2

1

0

0

32

10

50

20

68

30

85

40

104

50

122

55 °C

131

For additional technical support or

questions, call our Technical Support team

at 1-800-633-0405 or 770-844-4200.

Copyright© 2020, Automationdirect.com Incorporated/All Rights Reserved Worldwide

www.automationdirect.com/click-plc

5

Loading...

Loading...