Page 1

1-800-633-0405

3 Standard Drives ... 8 Standard Motors ... 100W to 3kW

... over 50 gearboxes (both inline and right angle) with four ratios

For the latest prices, please check AutomationDirect.com.

®

AC Servo Systems

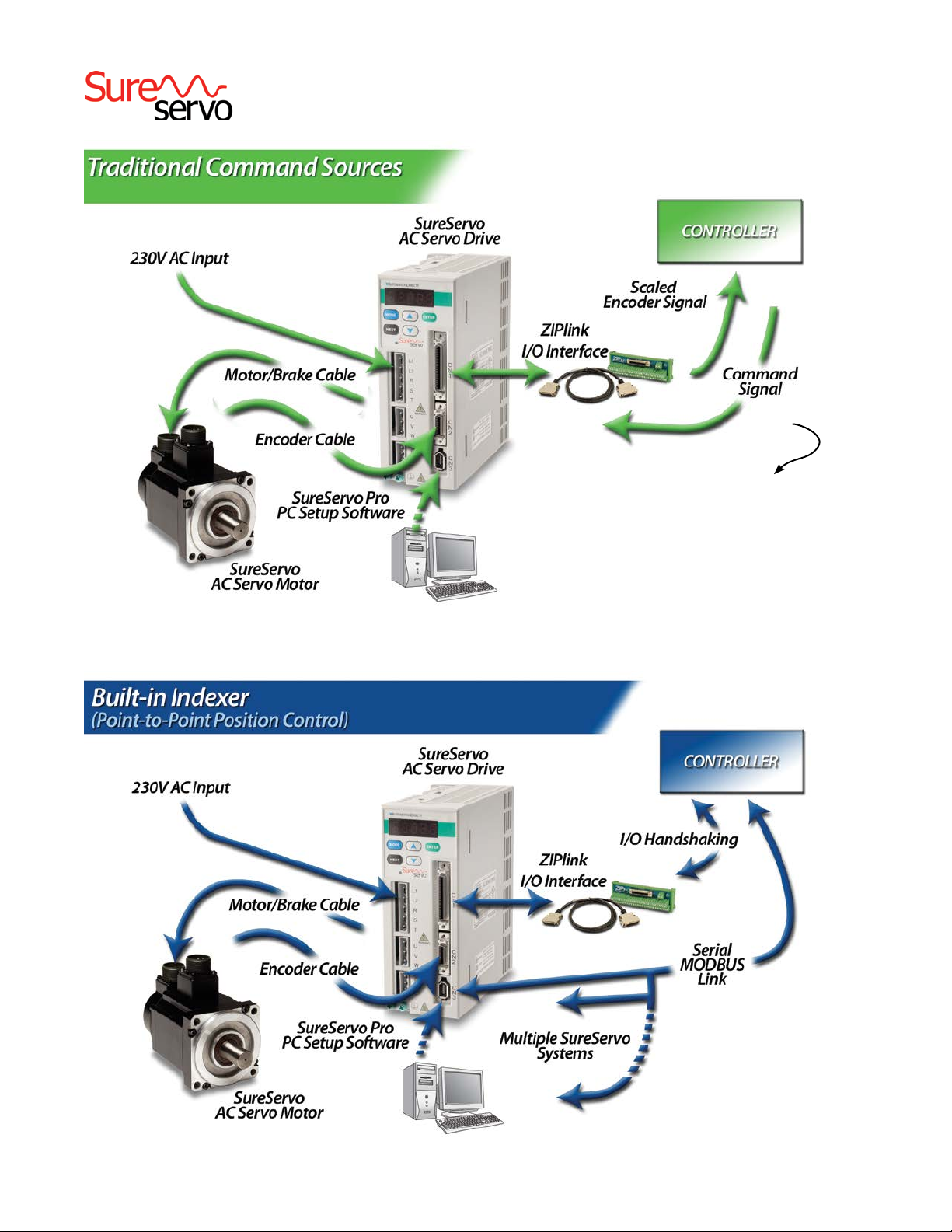

Drive features

• Main Power and Control Power Inputs

» Main Power: 230 VAC 1-phase/3-phase (2kW and 3kW systems

are 3-phase only)

» Control Power: 230 VAC Single Phase; 50/60 Hz

• Fully digital with up to 450 Hz velocity loop response

• Easy setup and diagnostics with built-in keypad/display or the

SureServo Pro PC-based software

• Five-in-one command options include:

» ± 10V torque or velocity command

» Pulse train or master encoder position command (accepts

line driver or open collector) with electronic gearing

» Built-in indexer for position control using 8 preset positions

and/or position setpoint with serial Modbus

• Tuning aids include inertia estimation and easy tuning for up to 10

levels of response

• Optically isolated digital inputs (8) and outputs (5), analog outputs

for monitor signals (2), and line driver output for encoder (with

scalable resolution)

SureServo

SureServo

tuning technology

The SureServo drive closes the loop on

current, velocity, and position

(depending on control mode selection).

Proportional gain, integral gain, feed

forward compensation, command low

pass filter, and a notch filter for resonance suppression are available. There

are three tuning modes:

1. “Manual Mode” for user-defined

adjustments

2. “Easy Mode” for default settings over

a wide range of programmed inertia

with 10 response levels

3. “Auto Mode” for automatic adjust-

ment using an estimated (or

measured) value of inertia

built-in motion controller

While the SureServo drives can accept

traditional commands from host controls,

they can also provide their own internal

motion control. For example, up to

eight index moves can be pre-defined

and stored in the drive and then selected

and executed using up to three discrete

inputs. The predefined index profiles can

also be changed via serial communications. The motion can be incremental or

absolute (homing routines are available

in the drive) and acceleration can be

linear or S-curve.

Multiple drives can be daisy-chained

and addressed separately using the

drive’s serial port. This allows very

simple yet powerful control of multi-axis

processes that do not need precise path

control but only precise starting and stopping points. Applications include press

feeds, auger fillers, rotary tables, robots

for pick and place, test or assembly

operations, drilling, cutting, tapping, and

similar applications using simple index

moves for single or multi-axis motion.

Motor features

• Low inertia models:

» 100W, 200W, 400W, 750W and 1kW

» Speeds up to 5,000 rpm.

• Medium inertia models:

» 1kW, 2kW and 3kW

» Speeds up to 3,000 rpm.

• Square flange mounting with metric dimensions:

» 40, 60, 80, 100, 130 and 180 mm flanges

• Permanent magnet 3-phase synchronous motor

• Keyless drive shafts support clamp-on style coupling

• Integrated encoder with 2,500 (x4) pulses/revolution plus marker

pulse (once per revolution)

• Optional 24 VDC spring-set holding brakes

• Standard hook-up cables for motor power/brake and encoder

• Standard DIN-rail mounted ZIPLink break-out kit for the drive’s

CN1 connector (with screw terminal connections)

SureServo

Optional Holding Brake

Each SureServo motor can be ordered

with an optional 24VDC spring-set

holding brake that holds the motor in

place when power is removed.

SureGear® Precision

Gearboxes for

Servo motors

Inertia

balancing

issue in

your design?

The SureGear PGA

series easily mates to SureServo

motors. Everything you need to mount

your SureServo motor is included!

• Four gear ratios available (5, 10, 15, 25:1)

• Mounting hardware included for attaching

to SureServo motors

• Industry-standard mounting dimensions

• Thread-in mounting style

• Best-in-class backlash (5 arc-min)

• 5-year warranty

www.automationdirect.com

Motion Control

tMNC-166

Page 2

1-800-633-0405

For the latest prices, please check AutomationDirect.com.

For the latest prices, please check AutomationDirect.com.

®

AC Servo Systems

• Pulse Train Positions:

• Step and direction

• CW and CCW

• Encoder follower

• Analog Velocity (±10V)

• Analog Torque (±10V)

• Mode Switching

• “On-the-Fly” Control Mode

Switching

mMNC-6

www.automationdirect.com

Motion Control

Stand-alone operation

using internal presets

• Preset selection with

digital inputs

• Ability to change preset

values with serial bus

(RTU/ASCII Modbus

protocols)

1-800-633-0405

Motion Control

tMNC-167

Page 3

1-800-633-0405

®

AC Servo Systems

How to select and apply SureServo systems

The primary purpose of the AC servo system is to precisely

control the motion of the load. The most fundamental

considerations in selecting the servo system are

“reflected” load inertia, servo system maximum speed

requirement, servo system continuous torque requirement, and servo system peak torque requirement. In a

retrofit application, select the largest torque SureServo

system that most closely matches these parameters for

Motion Profile

Desired

Load

Velocity

Required

Motor

Torque

time

For the latest prices, please check AutomationDirect.com.

the system being replaced. In a new application, these

parameters should be determined through calculation and/or

measurement.

AutomationDirect has teamed with Copperhill Technologies

to provide free servo-sizing software. “VisualSizer-SureServo”

software will assist in determining the correct motor and drive

for your application by calculating the reflected load inertia

and required speed and torque based on the load configuration. “VisualSizer-SureServo” software can be downloaded

from www.sureservo.com/downloads.htm.

Information for selecting SureServo systems is also included

in Appendix B of the SureServo User Manual, which can be

downloaded from the AutomationDirect.com website.

Servo

System

Mechanical

Transmission

Load

1. “Reflected” load inertia

The inertia of everything attached to the servo motor driveshaft needs to be considered and the total “reflected” inertia

needs to be determined. This means that all elements of any

mechanical transmission and load inertia need to be translated into an equivalent inertia as if attached directly to the

motor driveshaft. The ratio of “reflected” load inertia to motor

inertia needs to be carefully considered when selecting the

servo system.

In general, applications that need high response or bandwidth will benefit from keeping the ratio of load inertia to

motor inertia as low as possible and ideally under 10:1.

Systems with ratios as high as 200:1 can be implemented,

but corresponding lower bandwidth or responsiveness must

be accepted. The servo response including the attached load

inertia is determined by the servo tuning. SureServo systems

may be tuned manually, adaptively with measurement of the

load inertia, or set with default tuning based on a programmed

value of load inertia.

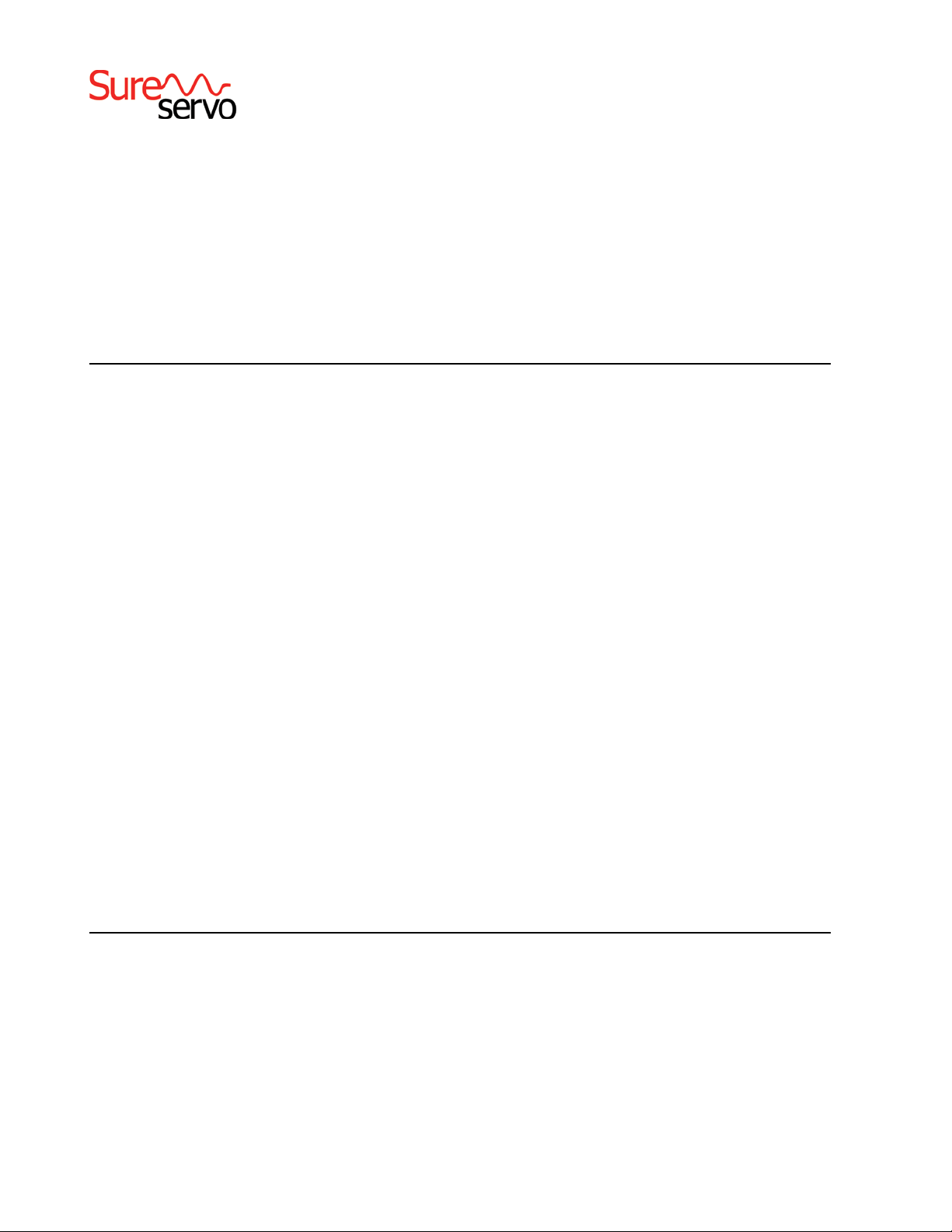

2. Torque and speed

With knowledge of the motion profile and any mechanical transmission between the motor and load, calculations can be made to determine the required servo motor continuous torque, peak torque, and

maximum motor speed. The required amount of continuous torque

must fall inside the continuous operating region of the system torquespeed curve (you can check the continuous torque at the average

speed of the motion profile). The required amount of peak torque

must also fall within the servo system’s intermittent operating region

of the system torque-speed curve (you need to check this value at the

required maximum speed).

300%

Torque

200%

100%

Peak Torque

Limited by Current

Limit

Intermittent Operating

Region

Continuous Operating

Region

Limited by Voltage

Peak Torque

Limit

www.automationdirect.com

1000 2000 3000 4000

Speed (r.p.m.)

Motion Control

5000

tMNC-168

Page 4

1-800-633-0405

®

For the latest prices, please check AutomationDirect.com.

AC Servo Systems

Application tip -

coupling considerations

The SureServo motors have keyless shafts that are designed for

use with clamp-on or compression style couplings. Couplings

using keys and/or set screws should NOT be used with

SureServo motors as they are likely to come loose or damage

the motor shaft. “Servo-grade” clamp-on or compression

style couplings are usually the best choice when you consider

Coupling Suppliers: www.sureservo.com/couplingconsiderations.htm

Mechanical transmissions

Common mechanical transmissions include leadscrews, rack

& pinion mechanisms, conveyors, gears, and timing belts. The

use of leadscrew, rack & pinion, or conveyor are common

the stiffness, torque rating, and inertia. Higher stiffness

(lb-in/radian) is needed for better response but there is a

trade-off between the stiffness and the added inertia of the

coupling. Concerning the torque rating of the coupling, use a

safety factor of 1.25 over the SureServo peak torque requirement of your application.

ways to translate the rotary motion of the servo motor into

linear motion of the load. The use of a speed reducer such

as a gearbox or timing belt can be very beneficial as follows:

1. Reduction of reflected

load inertia

As a general rule, it is beneficial to

keep the reflected load inertia as low as

possible while using the full range of servo

speed. SureServo systems can go up to

5,000 rpm for the low inertia motors and

up to 3,000 rpm for the medium inertia

motors.

Example: A gearbox reduces the required

torque by a factor of the gear ratio, and

reduces the reflected load inertia by a

factor of the gear ratio squared. A 10:1

gearbox reduces output speed to 1/10,

increases output torque 10 times, and

decreases reflected inertia to 1/100.

However, when investigating the effect

of different speed reduction ratios DO

NOT forget to include the added inertia

of couplings, gearbox, or timing belt

pulleys. These added inertias can be

significant, and can negate any inertia

reduction due to the speed reduction.

www.sureservo.com/mechanical_trans.htm

2. Low speed and high torque

applications

If the application requires low speed and

high torque then it is common to introduce a speed reducer so that the servo

system can operate over more of the

available speed range. This could also

have the added benefit of reducing the

servo motor torque requirement which

could allow you to use a smaller and

lower cost servo system. Additional

benefits are also possible with reduction

in reflected inertia, increased number of

motor encoder counts at the load, and

increased ability to reject load disturbances due to mechanical advantage of

the speed reducer.

3. Space limitations and motor

orientation

SureServo motors can be mounted in

any orientation, but the shaft seal should

not be immersed in oil (open-frame

gearbox, etc.). Reducers can possibly

allow the use of a smaller motor or

allow the motor to be repositioned. For

example, some reducers would allow for

in-line, right angle, or parallel mounting

of the motor.

For more information, refer to the

website listed below.

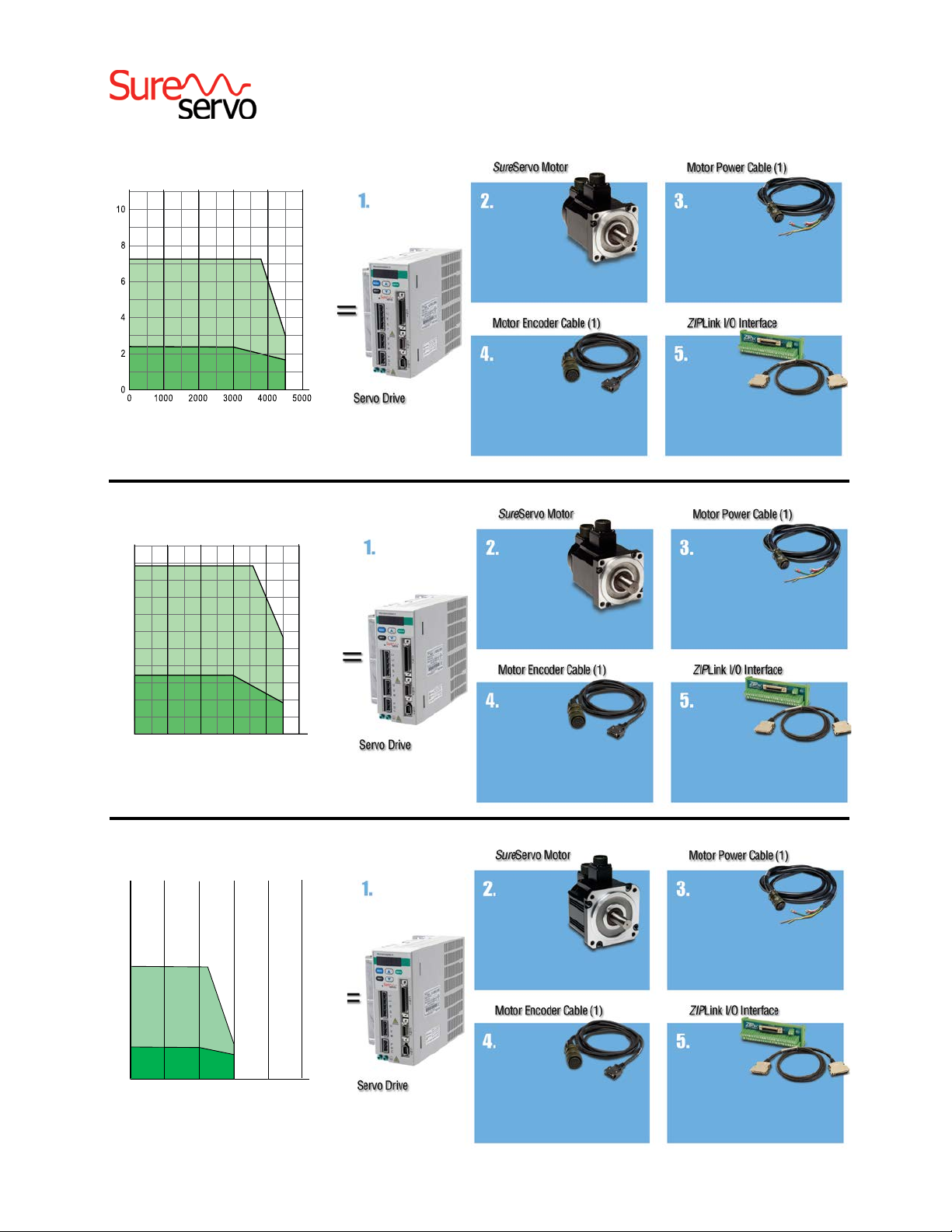

Ordering guide instructions

The following four pages are your ordering guide for the

eight standard SureServo systems. Each of the eight standard

systems has a torque-speed curve including the motor inertia

for reference. This is the fundamental information that you

need to select the servo drive and matching motor for your

application.

www.automationdirect.com

Don’t forget the cables and ZIPLink break-out board kit!

Included in the ordering guide are the available connection

cables from the drive to motor in standard lengths from 10 to

60 feet. The break-out board kit includes a 0.5m (19 inch)

cable for the CN1 I/O interface, and is listed for your convenience. We highly recommend all five items per system as a

minimum. All cables are 100% factory tested to make your

system installation as easy and quick as possible. See the

Accessories section for regeneration resistors, AC line filters,

fuses, contactors, and RF noise filters.

Motion Control

tMNC-169

Page 5

SV A - 2 04 0

2: 230VAC; 50/60 Hz

1-800-633-0405

®

AC Servo System Configuration

SureServo series drives and motors part numbering system

For the latest prices, please check AutomationDirect.com.

Series

SV: SureServo AC servo

Component Type

A: Drive

L: Low inertia motor

M: Medium inertia motor

Component Option

0: Drive

Blank: Motor without brake

B: Motor with brake

Rated Output Power

01: 100W 10: 1000W

02: 200W 20: 2000W

04: 400W 30: 3000W

07: 750W

Nominal Input Voltage

Here is what you will need to order a complete servo system:

Servo Drive

Servo Motor Motor Power

Cable

Motor Encoder

Cable

ZIPLink I/O

Interface

Note: uNit caN be programmed via keypad.

optioNal programmiNg software (free dowNload) aNd optioNal programmiNg cable available.

Note: if you Need a gear box for your coNfiguratioN, you caN do it easily oNliNe:

http://www.sureservo.com/gearbox/selector

SureServo AC servo drive, motor, and cable combinations

Inertia

& Power

Inertia

Low inertia

Medium inertia

Drive and Motor

Servo

Servo

Motor

Motor

without

Power

Servo Drive

100W

200W SVL-202 SVL-202B

400W SVL-204 SVL-204B

750W

1000W SVL-210 SVL-210B

1000W SVM-210 SVM-210B

2000W

3000W SVM-230 SVM-230B

SVA-2040

SVA-2100

SVA-2300

with

brake

brake

(note)

(note)

SVL-201 SVL-201B

SVL-207 SVL-207B

SVM-220 SVM-220B

10 ft 20 ft 30 ft 60 ft 10 ft 20 ft 30 ft 60 ft

SVCPFL-010

SVCPHM-010

SVCPHH-010

Note: each servo motor requires aN eNcoder feedback cable aNd a power cable.

the motor power cable iNcludes brake power wires for the optioNal motor brake.

Power Cables

(from Drive to Motor)

SVC-

SVCPFL-030

SVCPHM-030

SVCPHH-030

SVCPFL-060

SVCPHM-060

SVCPHH-060

PFL-020

SVCPHM-020

SVCPHH-020

Encoder Feedback Cables Miscellaneous

SVCEFL-010

SVCEHH-010

SVCEFL-020

SVCEHH-020

SVCEFL-030

SVCEHH-030

SVCEFL-060

SVCEHH-060

ZIPLink I/O

Interface

ZL-RTB50

and

ZL-SVC-CBL50

or

ZL-SVC-CBL50-1

or

ZL-SVC-CBL50-2

RS-422/485

Serial Communication

Cable

SVC-MDCOM-CBL

www.automationdirect.com

Motion Control

tMNC-170

Page 6

Torque

Torque

(rpm)

Torque

Torque

Torque

1-800-633-0405

100W Low Inertia System

(N-m)

For the latest prices, please check AutomationDirect.com.

®

AC Servo System Configuration

For all systems:

Order programming software &

programming cable if needed.

See pgs. tMNC-171 & 45.

Torque

(in-lb)

8.9

7.1

Intermittent

Duty Zone

Continuous

5.3

3.5

1.8

Duty Zone

0

100W Low Inertia

Speed

(rpm)

SVA-2040 $483.00

Jm= Motor Inertia = 0.000027 lb-in-s2 (0.000003 kg - m2)

200W Low Inertia System

(N·m)

2.5

2.0

1.5

1.0

0.5

Intermittent

Duty Zone

Continuous Duty Zone

0

0

1000 2000

3000 4000

200W Low Inertia

Jm= Motor Inertia = 0.00016 lb-in-s2 (0.000018 kg - m2)

(in·lb)

5000

Speed

22.1

17.7

13.3

8.9

4.4

0

SVA-2040 $483.00

SVL-201 $322.00

SVL-201B (w/brake) $567.00

SVC-EFL-010 (10’) $56.00

SVC-EFL-020 (20’) $92.00

SVC-EFL-030 (30’) $108.00

SVC-EFL-060 (60’) $137.00

SVL-202 $425.00

SVL-202B (w/brake) $629.00

SVC-EFL-010 (10’) $56.00

SVC-EFL-020 (20’) $92.00

SVC-EFL-030 (30’) $108.00

SVC-EFL-060 (60’) $137.00

SVC-PFL-010 (10’) $33.50

SVC-PFL-020 (20’) $63.00

SVC-PFL-030 (30’) $79.00

SVC-PFL-060 (60’) $143.00

ZL-RTB50 $52.00

and one cable below:

ZL-SVC-CBL50 (0.5m) $34.00

ZL-SVC-CBL50-1 (1m) $35.00

ZL-SVC-CBL50-2 (2m) $40.50

SVC-PFL-010 (10’) $33.50

SVC-PFL-020 (20’) $63.00

SVC-PFL-030 (30’) $79.00

SVC-PFL-060 (60’) $143.00

ZL-RTB50 $52.00

and one cable below:

ZL-SVC-CBL50 (0.5m) $34.00

ZL-SVC-CBL50-1 (1m) $35.00

ZL-SVC-CBL50-2 (2m) $40.50

400W Low Inertia System

35.4

26.6

17.7

Speed

(rpm)

(in-lb)

44.3

8.9

0

(N·m)

Intermittent

Duty Zone

Continuous

Duty Zone

400W Low Inertia

Jm= Motor Inertia =0.0003 lb-in-s2 (0 .000034 kg - m2)

www.automationdirect.com

SVA-2040 $483.00

SVL-204 $520.00

SVL-204B (w/brake) $733.00

SVC-EFL-010 (10’) $56.00

SVC-EFL-020 (20’) $92.00

SVC-EFL-030 (30’) $108.00

SVC-EFL-060 (60’) $137.00

SVC-PFL-010 (10’) $33.50

SVC-PFL-020 (20’) $63.00

SVC-PFL-030 (30’) $79.00

SVC-PFL-060 (60’) $143.00

ZL-RTB50 $52.00

and one cable below:

ZL-SVC-CBL50 (0.5m) $34.00

ZL-SVC-CBL50-1 (1m) $35.00

ZL-SVC-CBL50-2 (2m) $40.50

Motion Control

tMNC-171

Page 7

Torque

(rpm)

Torque

(rpm)

Torque

10.0

17.7

35.4

53.1

70.8

88.5

1-800-633-0405

750W Low Inertia System

(N-m)

For the latest prices, please check AutomationDirect.com.

®

AC Servo System Configuration

For all systems:

Order programming software &

programming cable if needed.

Torque

See pgs. tMNC-172 & 45.

(in-lb)

88.5

70.8

Intermittent

Duty Zone

Continuous

Duty Zone

750W Low Inertia

53.1

35.4

17.7

0

Speed

Jm= Motor Inertia = .00096 lb-in-s2 (0.000108 kg - m2)

1 kW Low Inertia System

8.0

6.0

4.0

Torque

(N·m)

Intermittent

Duty Zone

Torque

(in·lb)

SVA-2100 $683.00

SVL-207 $556.00

SVL-207B (w/brake) $794.00

SVC-EFL-010 (10’) $56.00

SVC-EFL-020 (20’) $92.00

SVC-EFL-030 (30’) $108.00

SVC-EFL-060 (60’) $137.00

SVL-210 $663.00

SVL-210B (w/brake) $993.00

SVC-PFL-010 (10’) $33.50

SVC-PFL-020 (20’) $63.00

SVC-PFL-030 (30’) $79.00

SVC-PFL-060 (60’) $143.00

ZL-RTB50 $52.00

and one cable below:

ZL-SVC-CBL50 (0.5m) $34.00

ZL-SVC-CBL50-1 (1m) $35.00

ZL-SVC-CBL50-2 (2m) $40.50

SVC-PHM-010 (10’) $105.00

SVC-PHM-020 (20’) $114.00

SVC-PHM-030 (30’) $190.00

SVC-PHM-060 (60’) $224.00

Continuous

2.0

Duty Zone

0

1000

0

2000 3000 4000

1 kW Low Inertia

Jm= Motor Inertia = .0023 lb-in-s2 (0.00026 kg - m2)

5000

Speed

(rpm)

0

SVA-2100 $683.00

1 kW Medium Inertia System

(N-m)

......................................................................

......................................................................

25

......................................................................

......................................................................

20

......................................................................

......................................................................

15

......................................................................

Intermittent

......................................................................

10

......................................................................

Duty Zone

......................................................................

5

Continuous

......................................................................

Duty Zone

................................................................................

0

0 1000 2000 3000 4000 5000

1 kW Medium Inertia

Jm= Motor Inertia = .0053 lb-in-s2 (0.000598 kg - m2)

................................................................................

................................................................................

................................................................................

(in-lb)

221.3

177.0

132.8

88.5

44.3

................................................................................

0

Speed

SVA-2100 $683.00

SVC-EHH-010 (10’) $99.00

SVC-EHH-020 (20’) $112.00

SVC-EHH-030 (30’) $125.00

SVC-EHH-060 (60’) $163.00

SVM-210 $852.00

SVM-210B (w/brake) $1,184.00

SVC-EHH-010 (10’) $99.00

SVC-EHH-020 (20’) $112.00

SVC-EHH-030 (30’) $125.00

SVC-EHH-060 (60’) $163.00

ZL-RTB50 $52.00

and one cable below:

ZL-SVC-CBL50 (0.5m) $34.00

ZL-SVC-CBL50-1 (1m) $35.00

ZL-SVC-CBL50-2 (2m) $40.50

SVC-PHM-010 (10’) $105.00

SVC-PHM-020 (20’) $114.00

SVC-PHM-030 (30’) $190.00

SVC-PHM-060 (60’) $224.00

ZL-RTB50 $52.00

and one cable below:

ZL-SVC-CBL50 (0.5m) $34.00

ZL-SVC-CBL50-1 (1m) $35.00

ZL-SVC-CBL50-2 (2m) $40.50

www.automationdirect.com

Motion Control

tMNC-172

Page 8

(rpm)

Torque

1-800-633-0405

®

AC Servo System Configuration

2 kW Medium Inertia System

(N-m)

......................................................................

......................................................................

25

......................................................................

......................................................................

20

......................................................................

Intermittent

......................................................................

15

Duty Zone

......................................................................

......................................................................

10

......................................................................

......................................................................

Continuous

5

Duty Zone

......................................................................

................................................................................

................................................................................

................................................................................

................................................................................

0

0 1000 2000 3000 4000 5000

2 kW Medium Inertia

Jm= Motor Inertia = .014 lb-in-s2 = (0.00158 kg - m2)

................................................................................

Speed

For all systems:

Order programming software &

programming cable if needed.

See pgs. 44 & 45.

Torque

(in-lb)

221.3

177.0

132.8

88.5

44.3

0

SVA-2300 $1,140.00

SVM-220 $900.00

SVM-220B (w/brake) $1,231.00

SVC-EHH-010 (10’) $99.00

SVC-EHH-020 (20’) $112.00

SVC-EHH-030 (30’) $125.00

SVC-EHH-060 (60’) $163.00

For the latest prices, please check AutomationDirect.com.

SVC-PHH-010 (10’) $126.00

SVC-PHH-020 (20’) $165.00

SVC-PHH-030 (30’) $204.00

SVC-PHH-060 (60’) $332.00

ZL-RTB50 $52.00

and one cable below:

ZL-SVC-CBL50 (0.5m) $34.00

ZL-SVC-CBL50-1 (1m) $35.00

ZL-SVC-CBL50-2 (2m) $40.50

3 kW Medium Inertia System

Torque

(N-m)

......................................................................

......................................................................

50

......................................................................

......................................................................

40

......................................................................

......................................................................

30

Intermittent

......................................................................

Duty Zone

......................................................................

20

......................................................................

......................................................................

10

Continuous

......................................................................

Duty Zone

................................................................................

................................................................................

0

0 1000 2000 3000 4000 5000

................................................................................

................................................................................

3 kW Medium Inertia

Jm= Motor Inertia = 0.038 lb-in-s2 = (0.00433 kg - m2)

Torque

(in-lb)

442.5

354.0

SVM-230 $1,373.00

265.5

177.0

88.5

................................................................................

0

Speed

(rpm)

SVA-2300 $1,140.00

SVM-230B (w/brake) $1,567.00

SVC-EHH-010 (10’) $99.00

SVC-EHH-020 (20’) $112.00

SVC-EHH-030 (30’) $125.00

SVC-EHH-060 (60’) $163.00

SVC-PHH-010 (10’) $126.00

SVC-PHH-020 (20’) $165.00

SVC-PHH-030 (30’) $204.00

SVC-PHH-060 (60’) $332.00

ZL-RTB50 $52.00

and one cable below:

ZL-SVC-CBL50 (0.5m) $34.00

ZL-SVC-CBL50-1 (1m) $35.00

ZL-SVC-CBL50-2 (2m) $40.50

Note: all motor power cables iNclude brake

power wires for the optioNal motor brake.

SureServo Communications Cables for Muti-drop Networks

Product Price Description

RS-422/485 serial communication cable for use with multidrop networks; 3ft length; IEEE 1394

plug to unterminated wires; compatible with all SureServo systems.

SVC-MDCOM-CBL

SVC-232RJ12-CBL-2 *

SVC-485RJ12-CBL-2 *

SVC-485HD15-CBL-2 *

* Refer to the ZIPLinks Wiring Solutions section for complete information regarding the ZIPLink cables.

$28.00

Facilitates connection between the SureServo drive serial port and host controllers.

ZIPLink SureServo Drives cable with 6-pin RJ12 connector to a 6-pin IEEE 1394 connector, shield-

$8.50

ed, twisted pair, 2.0 meter (6.6 ft.) length. For RS-232 connection to all SureServo amplifiers.

ZIPLink SureServo amplifier communication cable, RJ12 male to 6-pin IEEE 1394 connector,

$10.00

shielded, twisted pair, 2.0 meter (6.6 ft.) length. Cable used in conjunction with ZL-CDM-RJ12xxx

distribution module can access a compatible RS-485 device network.

ZIPLink SureServo Drives cable with a HD 15-pin male to a 6-pin IEEE 1394 connector, shielded,

$9.00

twisted pair, 2.0 meter (6.6 ft.) length. For RS-485 connection to all SureServo amplifiers.

www.automationdirect.com

Motion Control

tMNC-173

Page 9

1-800-633-0405

®

AC Servo System Software

Parameter views

The SureServo Pro configuration tool logically organizes over

165 servo drive parameters into five tabbed groups. Each

parameter has a factory default that usually allows the servo to

run “out-of-the-box”.

The parameters can be easily changed with available options

or setting ranges displayed. Tuning modes and parameters

can also be changed using SureServo Pro. After the parameters have been defined, the complete setup can be stored

and archived. Drive configurations can be uploaded, edited,

saved, and downloaded as often as necessary.

For the latest prices, please check AutomationDirect.com.

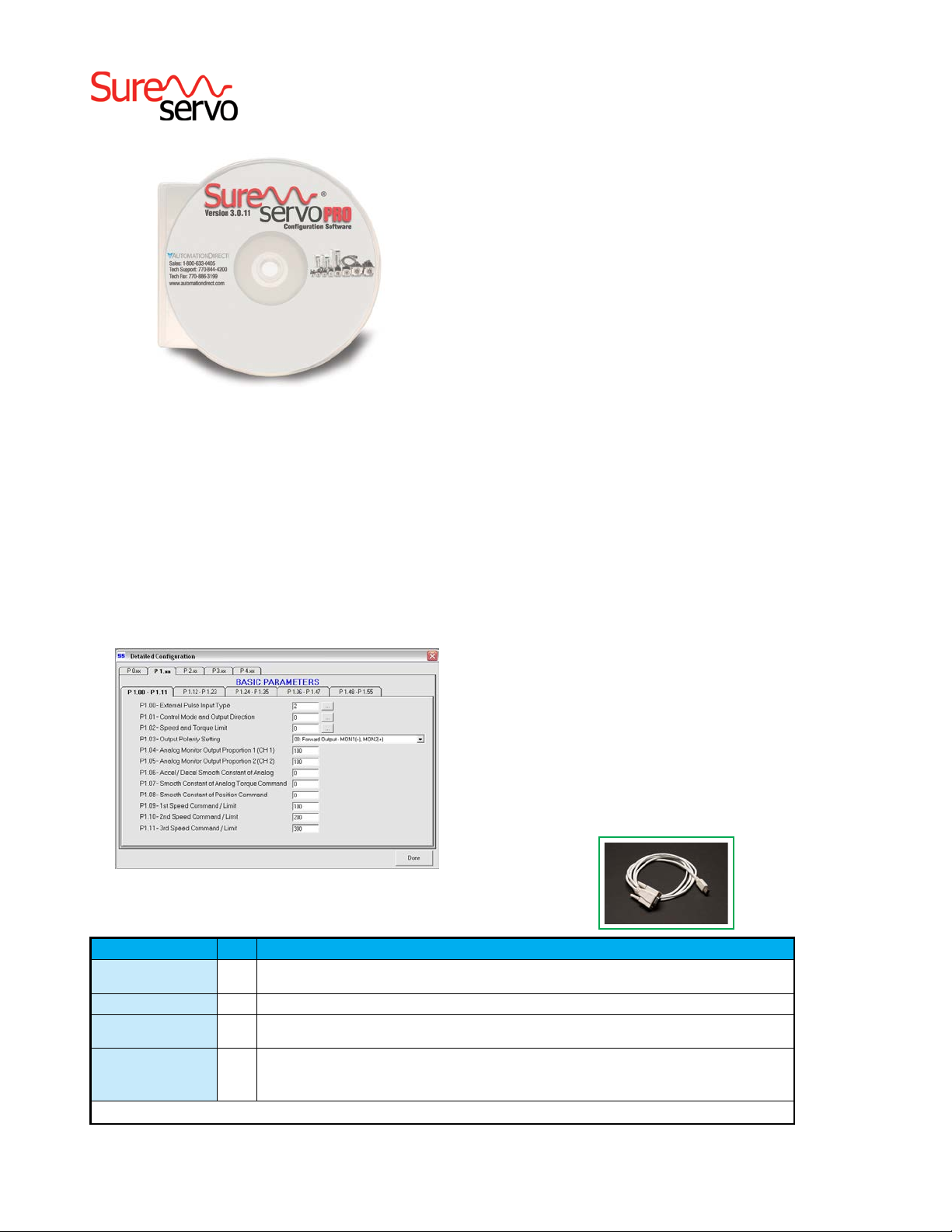

SureServo Pro configuration software

SureServo Pro is an optional free downloadable configuration

software package for the SureServo drives. With SureServo Pro

installed, the personal computer may be directly connected to

the servo drive’s serial port via the PC’s RS-232 serial port*.

A six-foot configuration cable (SVC-PCCFG-CBL, $19.50) is

available to make the connection between the drive serial port

and PC DB-9 serial port simple.

*Note: Use our USB-RS232 converter cable in conjunction with the SVC-PCCFGCBL cable on PCs having only USB ports.

Features

• • Quick Start - The basic setup when you have limited time and just

want to get up and running ASAP.

• • Maintenance keypad allows the user to operate the servo system

from the PC. This is a great aid during start-up to allow the servo to

perform some basic motion and to check the I/O.

• • Detailed - The complete setup for all the drive parameters

• • Tune and check the servo response live using the scope feature.

• • Upload and download the drive setup. Save the drive setup as a

file for future use.

• • Edit the drive setup

• • View all drive faults

• • Trend drive variables in real time

Parameter View Example Screen - Basic Parameters

SureServo Software and Configuration Cables

Product Price Description

SureServo Pro configuration software for use with all SureServo servo systems.

SV-PRO

SV-PRO

SVC-PCCFG-CBL

SVC-485CFG-CBL-2

* Refer to the ZIPLinks Wiring Solutions section for complete information regarding ZIPLink cable SVC-485CFG-CBL-2.

Free

FREE download from www.sureservo.com or www.automationdirect.com websites.

$9.50 CD with SureServo Pro configuration software

Six-foot RS-232 communications cable; connects servo drive serial port to PC DB-9 serial port.

$24.50

For PCs having only USB ports, use our USB-RS232 converter cable in conjunction with the SVC-PCCFG-CBL cable.

ZIPLink SureServo amplifier configuration cable, 6-pin IEEE 1394 connector to RJ45 connector, shielded, twisted pair,

2.0 meter (6.6 ft.) length.

$12.00

Use this cable in conjunction with our USB-485M serial adapter to connect any SureServo amplifier to a PC. Eliminates the need to

reprogram networked servo drives from RS485 to RS232 when connecting to a PC.

www.automationdirect.com

Motion Control

tMNC-174

Page 10

®

1-800-633-0405

Precision Servo Gearboxes

SureGear® Servo Gearbox Overview

PGA In-line Series

The SureGear PGA series of high-precision servo gear reducers

is an excellent choice for applications that require good accuracy and reliability at an exceptional value. This in-line planetary

gear reducer has a thread-in mounting style, along with a level of

precision and torque capacity that is best in its class. Offered in a concentric

shaft design with a maximum seven arc-min backlash rating, the SureGear

PGA series is an accurate, high-performance, and cost effective solution for

any OEM.

The machining quality of the SureGear PGA helical planetary

gears provides a very quiet and more efficient reducer than other

competitive products that are similarly priced. The SureGear PGA

series easily mates to SureServo motors, and is the perfect solution for applications such as gantries, injection-molding machines,

pick-and-place automation, and linear slides.

PGB Right-angle Series

The SureGear PGB series of high-precision right-angle servo gear reducers

is an excellent choice for applications that require a more compact footprint.

The PGB right-angle planetary gear reducers offer similar technical specifications to the PGA series in-line gear reducers, and provides the customer with

an excellent solution when space and clearance requirements are limited.

Offered with a six arc-min backlash rating for 2-stage and nine arc-min

backlash for 3-stage, the SureGear PGB series performs to OEMs’

demanding expectations.

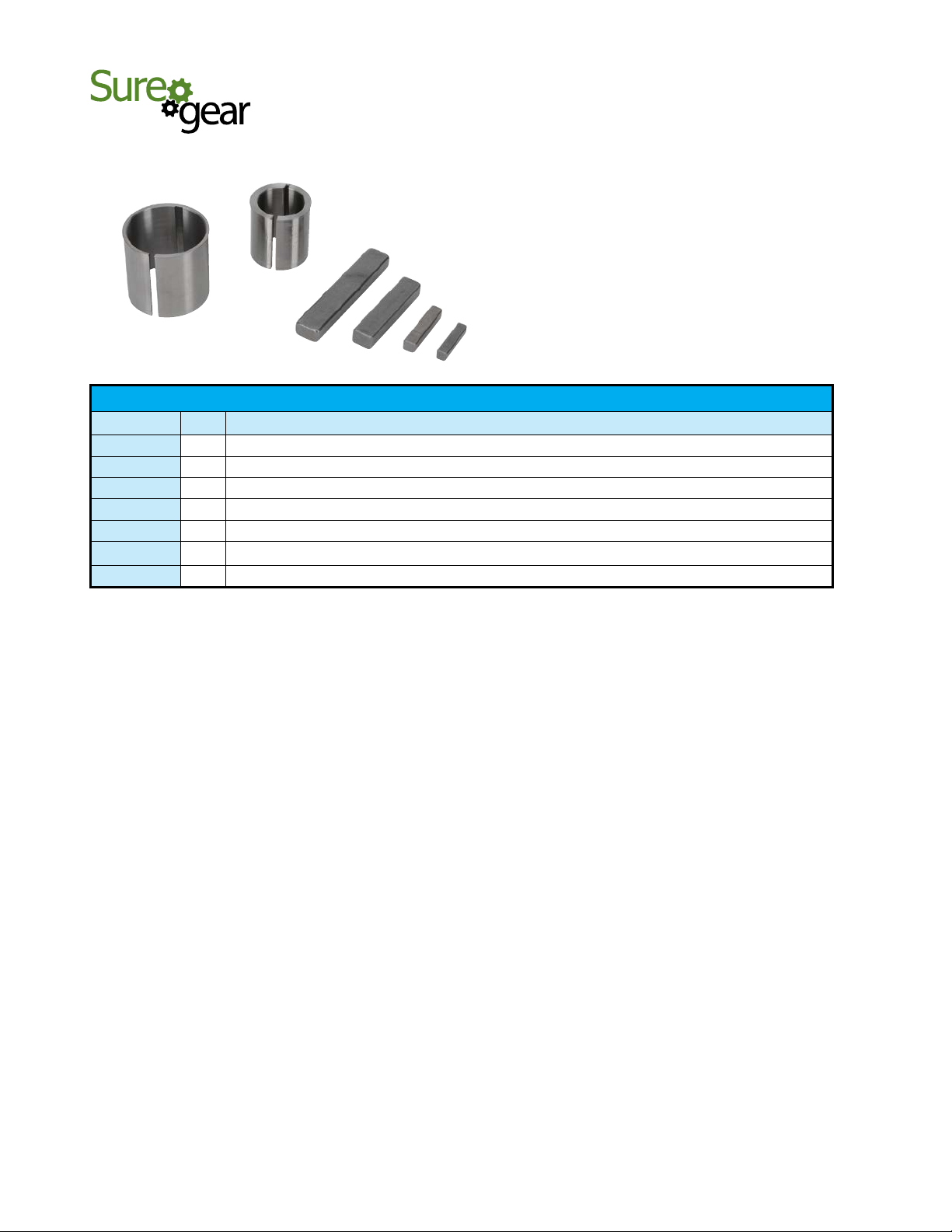

PGD Hub Style In-line Series

The SureGear PGD series sets a new standard in applications requiring

extremely high-torque ratings and rigidity. The compact design and hubstyle output is ideal for equipment that requires high-speed, high-precision

indexing movement. The remarkable torsion stiffness and the low backlash

of the planetary gearing combine to provide outstanding positioning accuracy.

With a backlash rating less than 3 arc-minutes and exceptional torque

handling capabilities, the PGD series offers a high performance robust

planetary solution for OEM customers. The PGD reducer is often used

for larger indexing applications and dial tables commonly found in

packaging and filling equipment and assembly automation systems.

For the latest prices, please check AutomationDirect.com.

SureGear

PGA Gearbox

SureGear PGB Gearbox

SureGear

Hub Style PGD Gearbox

Features

• • Thread-in mounting style

• • Best-in-class backlash

• • Four gear ratios available (5:1, 10:1, 15:1, 25:1), Two additional for PGD

models (35:1 and 50:1)

• • Mounting hardware included for attaching to SureServo motors

• • Helical-cut planetary gears for quiet operation and reduced vibration

• • Right-angle reducer utilizes a spiral bevel gear; motor can be located at a

90° position from the reducer, providing a more compact footprint

• • Uncaged needle roller bearings for high rigidity and torque

• • Adapter bushing connection for simple and effective attachment to most

servo motors

• • High-viscosity, anti-separation grease does not migrate away from the

gears; no leakage through the seal

• • Maintenance free: No need to replace the grease for the life of the unit

• • At nominal speed, service life is 20,000 hours

• • Can be positioned in any orientation

• • IP55 environmental rating

• • 5-year warranty

www.automationdirect.com

SureGear

2-Stage Cutaway View

Applications

• • Gantries

• • Injection-molding machines

• • Pick-and-place automation

• • Linear slides

• • Packaging machines

• • Conveyors

Motion Control

tMNC-188

Page 11

®

1-800-633-0405

For the latest prices, please check AutomationDirect.com.

Precision Servo Gearboxes

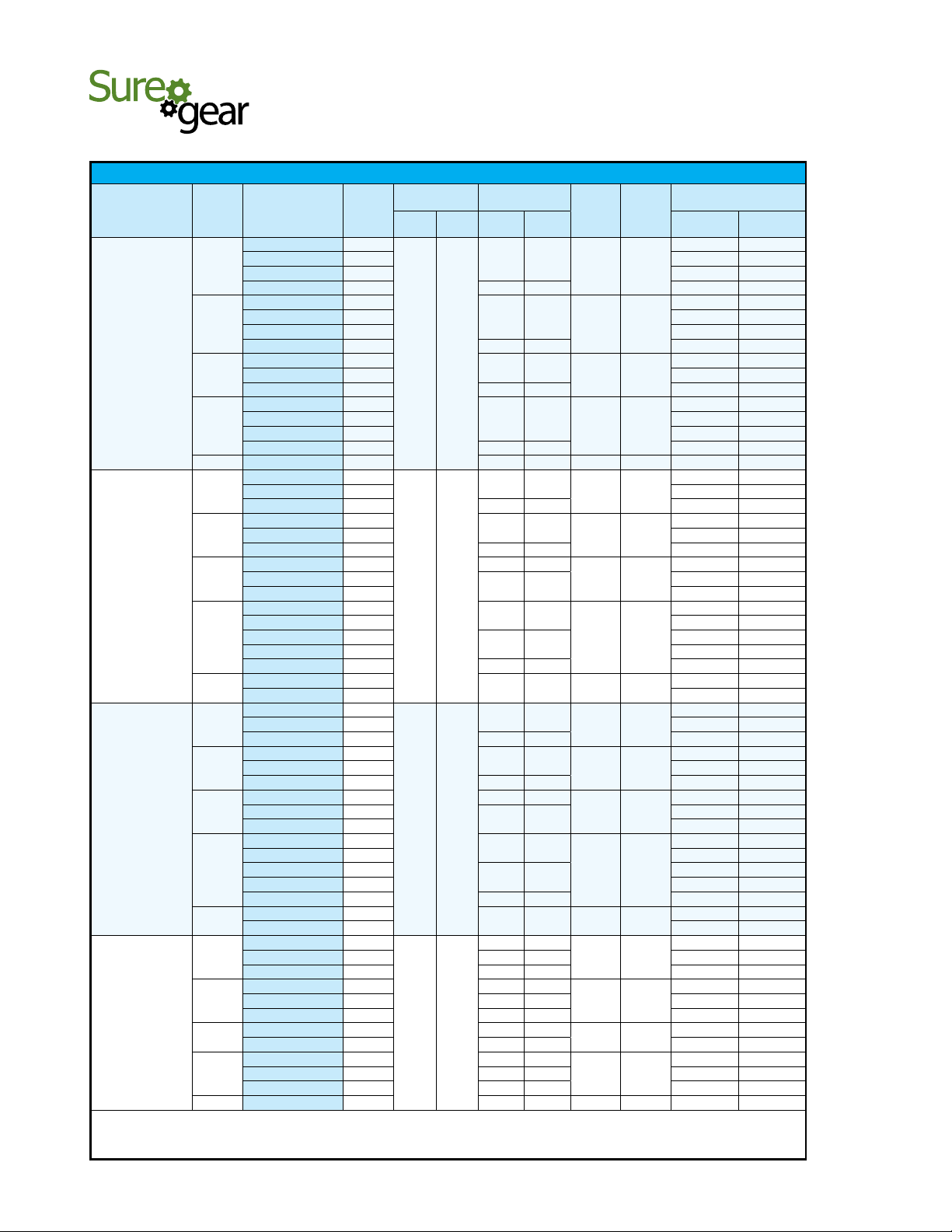

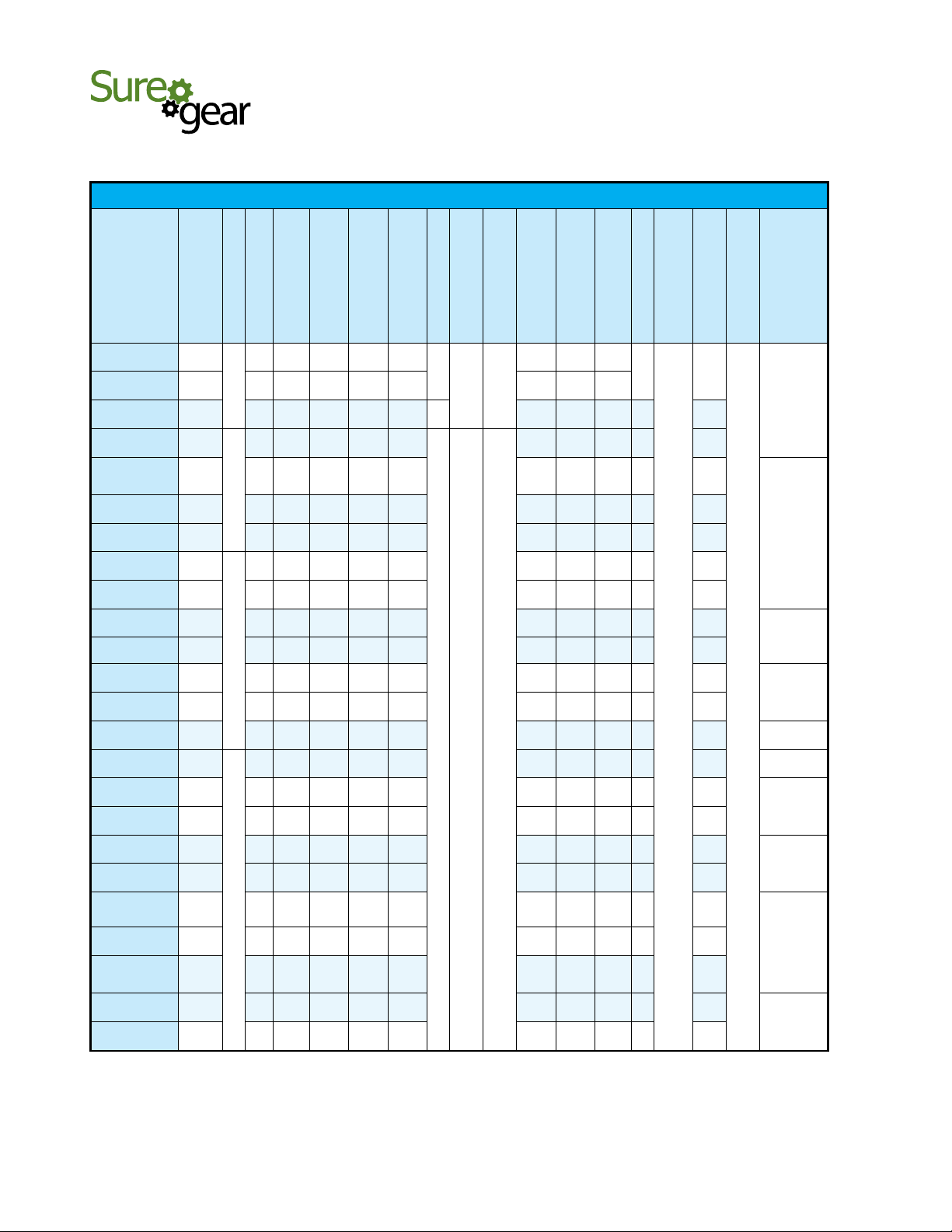

SureGear® Servo Gearbox Selection

SureGear® Servo Gearbox Selection

Sure

Servo

Motor

SVL-201(B)

SVL-202(B)

SVL-204(B)

SVL-207(B)

* Available load inertia is calculated based on servo motor inertia using the formula: Available Inertia = (5 x Motor Inertia – Gearbox Inertia) x (Gear Ratio)2

A 5:1 inertia mismatch is a good target for design purposes. Systems with lower or higher mismatch may be possible, depending on operating conditions.

** This gearbox is NOT a suitable choice at a 5:1 mismatch. If inertia balancing is a selection criteria for your end use, please use a mismatch of 8:1 to 10:1.

Gear

Ratio

5:1

10:1

15:1

25:1

50:1

5:1

10:1

15:1

25:1

50:1

5:1

10:1

15:1

25:1

50:1

5:1

10:1

15:1

25:1

50:1

SureGear

Gearbox

PGD047-05A1

PGA050-05A1

PGA070-05A1

PGB070-05A1

PGD047-10A1

PGA050-10A1

PGA070-10A1

PGB070-10A1

PGA050-15A1

PGA070-15A1

PGB070-15A1

PGD047-25A1

PGA050-25A1

PGA070-25A1

PGB070-25A1

PGD064-50A1

PGD064-05A2

PGA070-05A2

PGB070-05A2

PGD064-10A2

PGA070-10A2

PGB070-10A2

PGA070-15A2

PGB070-15A2

PGB090-15A2

PGD064-25A2

PGA070-25A2

PGB070-25A2

PGB090-25A2

PGD090-25A2

PGD090-50A2

PGD110-50A2

PGD064-05A2

PGA070-05A2

PGB070-05A2

PGD064-10A2

PGA070-10A2

PGB070-10A2

PGA070-15A2

PGB070-15A2

PGB090-15A2

PGD064-25A2

PGA070-25A2

PGB070-25A2

PGB090-25A2

PGD090-25A2

PGD090-50A2

PGD110-50A2

PGA070-05A3

PGB090-05A3

PGD090-05A3

PGA090-10A3

PGB090-10A3

PGD090-10A3

PGA090-15A3

PGB090-15A3

PGA090-25A3

PGB090-25A3

PGD110-25A3

PGD110-50A3

Motor Nominal

Frame

Output Torque

Size

(mm)

N·m lb·in N·m lb·in kg·cm

47

50 2.85 0.003

70 1.83 0.002

70 1.49 13.16 -2.50** -0.002**

47

50 12.00 0.011

70 9.40 0.008

70 2.98 26.32 -8.00** -0.007**

0.32 2.83

50

70 21.38 0.019

70 4.22 37.36 17.33 0.015

47

50 72.50 0.064

70 60.63 0.054

70 7.04 62.26 49.38 0.044

64 14.40 127.35 60 100 252.50 0.223

64

70 20.58 0.018

70 2.98 26.51 16.25 0.014

64

70 84.40 0.075

70 5.95 53.01 67.00 0.059

70 8.64 76.95

70

0.64 5.7

90 126.00 0.112

64

70 529.38 0.468

70

90 362.50 0.321

90 14.40 128.25 481.25 0.426

90

110 1250.00 1.106

64

70 40.58 0.036

70 5.91 52.08 36.25 0.032

64

70 164.40 0.145

70 11.81 104.16 147.00 0.130

70 17.15 151.20

70

1.27 11.2

90 306.00 0.271

64

70 1029.38 0.911

70

90 862.50 0.763

90 28.58 252.00 981.25 0.868

90

110 3250.00 2.876

70

90 11.11 98.58 90.00 0.080

90 11.35 100.70 120.50 0.107

90 22.71 201.40

90 22.23 197.16 371.00 0.328

90 22.71 201.40 507.00 0.449

2.39 21.2

90 32.27 286.20

90 31.55 279.84 1138.50 1.008

90 53.78 477.00

90 52.58 466.40 3175.00 2.810

110 53.78 477.00 2937.50 2.600

110 107.55 954.00 60 100 12500.00 11.063

Combo Nominal

Output Torque

1.52 13.44

3.04 26.89

4.32 38.21

7.20 63.68

3.04 27.08

6.08 54.15

8.45 75.24

14.40 128.25

14.08 125.40

28.80 256.50 60 100

6.03 53.20

12.07 106.40

16.76 147.84

28.58 252.00

27.94 246.40

57.15 504.00 60 100

11.35 100.70

Nominal

Output

Speed

( rpm )

600 1,000

300 500

200 333

120 200

600 1,000

300 500

200 333

120 200

600 1,000

300 500

200 333

120 200

600 1000

300 500

200 333

120 200

Max

Output

Speed

( rpm )

Available Load Inertia

@ 5:1 Mismatch *

2

2.68 0.002

11.80 0.010

25.88 0.023

72.50 0.064

20.00 0.018

83.80 0.074

190.13 0.168

186.08 0.165

528.75 0.468

518.13 0.459

2000.00 1.770

40.00 0.035

163.80 0.145

370.13 0.328

366.08 0.324

1028.75 0.910

1018.13 0.901

4000.00 3.540

133.08 0.118

511.00 0.452

1185.75 1.049

3300.00 2.921

lb·in·s

2

www.automationdirect.com

Motion Control

tMNC-189

Page 12

®

1-800-633-0405

Precision Servo Gearboxes

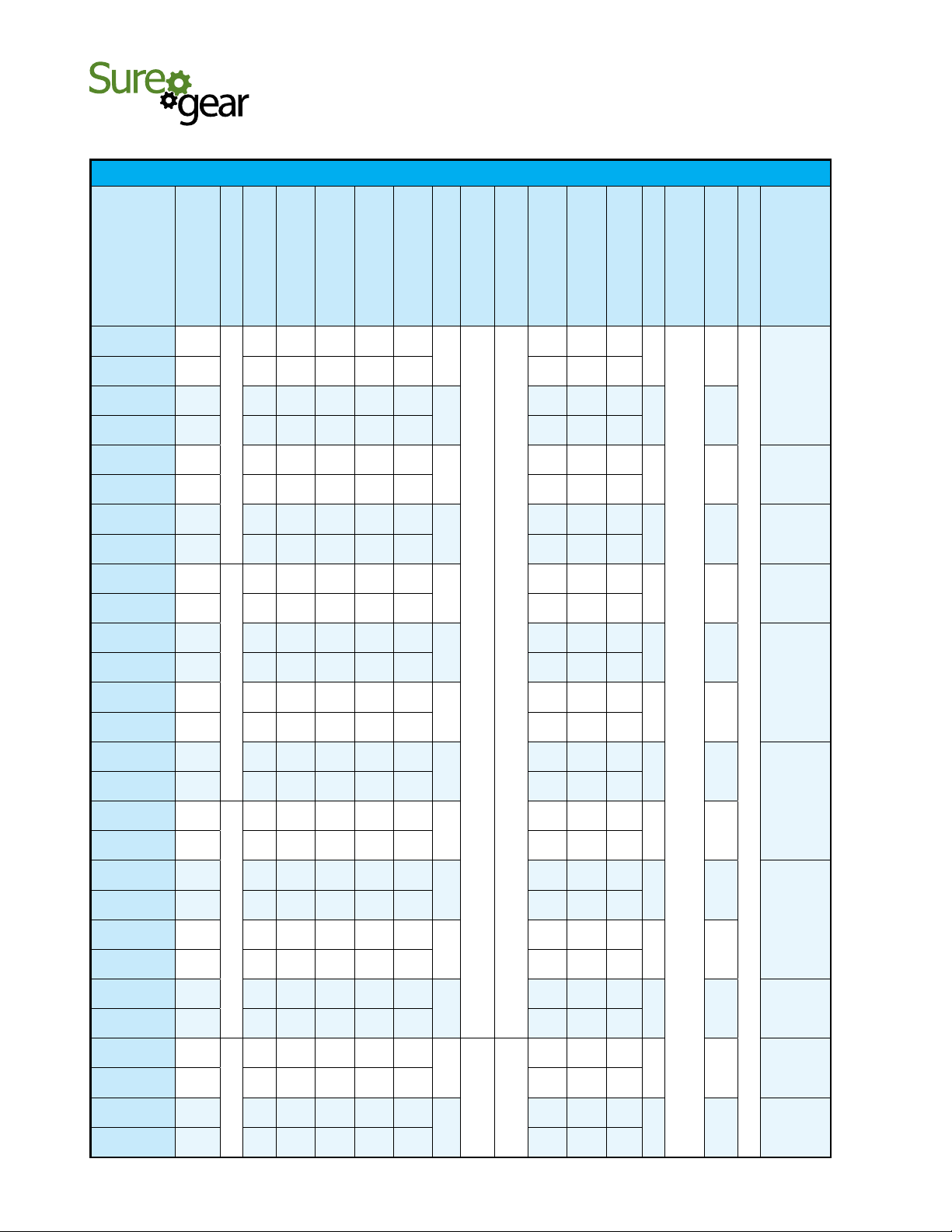

SureGear® Servo Gearbox Selection (continued)

For the latest prices, please check AutomationDirect.com.

Sure

Servo

Motor

SVL-210(B)

SVM-210(B)

SVM-220(B)

SVM-230(B)

Gear

Ratio

5:1

10:1

15:1

25:1

50:1

5:1

10:1

15:1

25:1

35:1

5:1

10:1

15:1

25:1

5:1

10:1

15:1

25:1

SureGear

Gearbox

PGA090-05A4

PGB090-05A4

PGD090-05A4

PGA090-10A4

PGB090-10A4

PGD090-10A4

PGA120-15A4

PGB120-15A4

PGD110-25A4

PGA120-25A4

PGB120-25A4

PGD110-50A4

PGA090-05A5

PGD090-05A5

PGB120-05A5

PGA090-10A5

PGD110-10A5

PGB120-10A5

PGA120-15A5

PGB120-15A5

PGD110-25A5

PGA120-25A5

PGB120-25A5

PGD110-35A5

PGD110-05A6

PGA120-05A6

PGB120-05A6

PGB155-05A6

PGD110-10A6

PGA120-10A6

PGB120-10A6

PGB155-10A6

PGA155-15A6

PGB155-15A6

PGA155-25A6

PGB155-25A6

PGD110-05A6

PGA120-05A6

PGB120-05A6

PGD110-10A6

PGA120-10A6

PGB120-10A6

PGB155-10A6

PGA155-15A6

PGB155-15A6

PGA155-25A6

PGB155-25A6

SureGear® Servo Gearbox Selection

Motor Nominal

Frame

Output Torque

Size

(mm)

N·m lb·in N·m lb·in kg·cm

90

90 15.35 135.78 280.00 0.248

90 15.68 138.70 313.00 0.277

90 31.45 277.40

90 30.69 271.56 1131.00 1.001

90 31.35 277.40 1267.00 1.121

120 44.55 394.20

120 43.56 385.44 2418.75 2.141

110

120 7887.50 6.980

120 72.60 642.40 6762.50 5.985

110 148.50 1314.00 60 100 31500.00 27.878

120 22.32 197.63 622.00 0.550

110 2957.00 2.617

120 44.64 395.25 2544.00 2.251

120 64.80 573.75

120 63.36 561.00 6221.25 5.506

110

120 18450.00 16.328

120 105.60 935.00 17325.00 15.333

110 151.20 1338.75 86 143 35770.00 31.656

110

120 5372.50 4.755

120

155 4989.75 4.416

110

120 21555.00 19.076

120

155 20184.00 17.863

155 126.90 1123.20

155 124.08 1098.24 47272.50 41.836

155 211.50 1872.00

155 206.80 1830.40 131468.75 116.350

110

120 5372.50 4.755

120 66.50 588.69 5287.00 4.679

110

120 21555.00 19.076

120

155 20184.00 17.863

155 193.05 1709.10

155 188.76 1671.12 47272.50 41.836

155 321.75 2848.50

155 314.60 2785.20 131468.75 116.350

3.3 29.2

90

90 735.50 0.651

90

4.8 42.5

9.4 83.2

14.3 12.6

Combo Nominal

Output Torque

15.68 138.70

74.25 657.00

22.80 201.88

45.60 403.75

108.00 956.25

44.65 395.20

43.71 386.88

89.30 790.40

87.42 773.76

67.93 601.35

135.85 1202.70

132.99 1177.38

Nominal

Output

Speed

( rpm )

600 1000

300 500

200 333

120 200

600 1000

300 500

200 333

120 200

600 1000

300 500

200 333

120 200

600 1000

300 500

200 333

120 200

Max

Output

Speed

( rpm )

Available Load Inertia

@ 5:1 Mismatch *

2

315.00 0.279

1271.00 1.125

2828.25 2.503

7687.50 6.803

737.50 0.653

2961.00 2.620

6630.75 58.68

18250.00 16.151

5355.00 4.739

5287.00 4.679

21540.00 19.063

21204.00 18.766

48420.00 42.852

134625.00 119.143

5355.00 4.739

21540.00 19.063

21204.00 18.766

48420.00 42.852

134625.00 119.143

lb·in·s

2

* Available load inertia is calculated based on servo motor inertia using the formula: Available Inertia = (5 x Motor Inertia – Gearbox Inertia) x (Gear Ratio)2

A 5:1 inertia mismatch is a good target for design purposes. Systems with lower or higher mismatch may be possible, depending on operating conditions.

www.automationdirect.com

Motion Control

tMNC-190

Page 13

®

1-800-633-0405

Precision Servo Gearboxes

Pricing & Specifications – In-Line Shaft PGA Series

SureGear® Precision Servo Gearboxes – In-Line Shaft PGA Series

For the latest prices, please check AutomationDirect.com.

)

2

Part Number

PGA050-05A1

PGA050-10A1

PGA050-15A1

PGA050-25A1

PGA070-05A1

PGA070-10A1

PGA070-15A1

PGA070-25A1

PGA070-05A2

PGA070-10A2

PGA070-15A2

PGA070-25A2

PGA070-05A3

PGA090-10A3

PGA090-15A3

PGA090-25A3

PGA090-05A4

PGA090-10A4

PGA090-05A5

PGA090-10A5

PGA120-15A4

PGA120-25A4

PGA120-15A5

PGA120-25A5

PGA120-05A6

PGA120-10A6

PGA155-10A6

PGA155-15A6

PGA155-25A6

Price

Ratio

Frame Size (mm)

$430.00

$453.00 10:1 single

$621.00 15:1 double

$621.00 25:1 double

$430.00

$453.00 10:1 single

$621.00 15:1 double

$621.00 25:1 double

$469.00 5:1 single

$469.00 10:1 single

$643.00 15:1 double

$643.00 25:1 double

$469.00 5:1 single

$556.00

$734.00 15:1 double

$734.00 25:1 double

$555.00 5:1 single

$555.00 10:1 single

$555.00 5:1 single

$555.00 10:1 single

$922.00

$922.00 25:1 double

$922.00 15:1 double

$922.00 25:1 double

$735.00 5:1 single

$735.00 10:1 single

$908.00

$1,236.00 15:1 double

$1,236.00 25:1 double

5:1 single

50

5:1 single

70

10:1 single

90

15:1 double

120

10:1 single

155

Reduction

Nominal Output

Torque ( N·m [lb·in] )

9

[80]

[159]

6

[53]

[106]

6

[53]

[106]

9

[80]

[159]

27

[239]

[443]

18

[159]

[310]

18

[159]

[310]

27

[239]

[443]

27

[239]

[443]

18

[159]

[310]

18

[159]

[310]

27

[239]

[443]

27

[239]

[443]

50

[443]

[708]

50

[443]

[708]

75

[664]

[1106]

75

[664]

[1106]

50

[443]

[708]

75

[664]

[1106]

50

[443]

[708]

120

[1062]

[1991]

180

[1593]

[2921]

120

[1062]

[1991]

180

[1593]

[2921]

180

[1593]

[2921]

120

[1062]

[1991]

240

[2124]

[4160]

240

[2124]

[4160]

360

[3186]

[6196]

Emergency Stop

Max. Acceleration

Torque ( N·m [lb·in] )

18

12

12

18

50

35

35

50

50

35

35

50

50

80

[1770]

80

[1770]

125

[2213]

125

[2213]

80

[1770]

125

[2213]

80

[1770]

225

[4425]

330

[5532]

225

[4425]

330

[5532]

330

[5532]

225

[4425]

470

[8851]

470

[8851]

700

[11063]

Backlash (arc-min)

Torque ( N·m [lb·in] )

35

[310]

5

30

[266]

30

[266]

7

35

[310]

100

[885]

80

[708]

80

[708]

100

[885]

100

[885]

80

[708]

80

[708]

100

[885]

100

[885]

200

200

250

250

5

200

250

200

500

625

500

625

625

500

1000

1000

1250

Speed (rpm)

Nominal Input

4000 8000

3000 6000

2000 4000

Max. Input

Speed (rpm)

Allowable Radial

290

[65]

360

[81]

410

[92]

490

[110]

510

[115]

640

[144]

740

[166]

870

[196]

510

[115]

640

[144]

740

[166]

870

[196]

510

[115]

1200

[270]

1400

[315]

1600

[360]

960

[216]

1200

[270]

960

[216]

1200

[270]

2300

[517]

2700

[607]

2300

[517]

2700

[607]

1600

[360]

2000

[450]

4700

[1057]

5400

[1214]

6400

[1439]

Load ( N [lb] )

Load ( N [lb] )

Allowable Thrust

Moment of Inertia

330

0.036

[74]

450

0.030

[101]

540

0.035

[121]

640

0.034

[144]

390

0.077

[88]

530

0.056

[119]

630

0.055

[142]

790

0.053

[178]

390

0.160

[88]

530

0.140

[119]

630

0.140

[142]

790

0.130

[178]

390

0.360

[88]

1600

0.750

[360]

1900

0.720

[427]

2200

0.710

[495]

1200

2.900

[270]

1600

2.800

[360]

1200

2.900

[270]

1600

2.800

[360]

3000

2.800

[674]

3700

2.800

[832]

3000

2.800

[674]

3700

2.800

[832]

1900

11.000

[427]

2500

11.000

[562]

4100

11.000 95

[922]

4900

11.000

[1102]

6100

11.000

[1371]

(kg·cm

Efficiency (%)

95

90

95

90

95

90

95

90 °C

[194 °F]

90

95

90

95

90

Temperature

Max. Housing

Approx Weight

0.7

[1.5]

0.8

[1.8]

1.5

[3.3]

1.7

[3.7]

1.5

[3.3]

1.7

[3.7]

1.5

[3.3]

3.5

[7.7]

4.0

[8.8]

3.5

[7.7]

3.5

[7.7]

8.7

[19.2]

8.7

[19.2]

7.8

[17.2]

16

[35.3]

18

[40.0]

Rating

( kg [lb] )

Environmental

IP55

Servo Motor

Fits SureServo

SVL-201(B)

SVL-202(B)

SVL-204(B)

SVL-207(B)

SVL-210(B)

SVM-210(B)

SVL-210(B)

SVM-210(B)

SVM-220(B)

SVM-230(B)

www.automationdirect.com

Motion Control

tMNC-191

Page 14

®

1-800-633-0405

For the latest prices, please check AutomationDirect.com.

Precision Servo Gearboxes

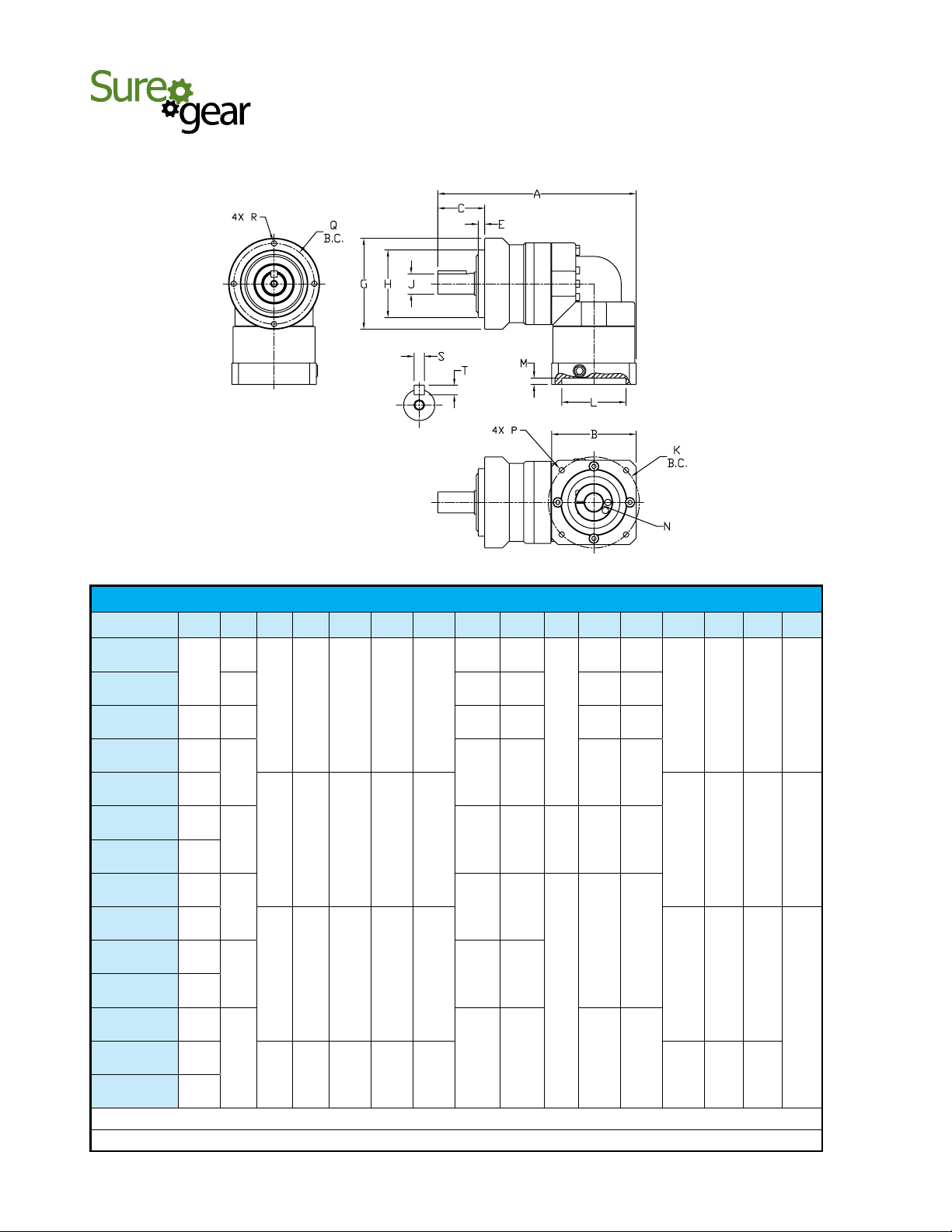

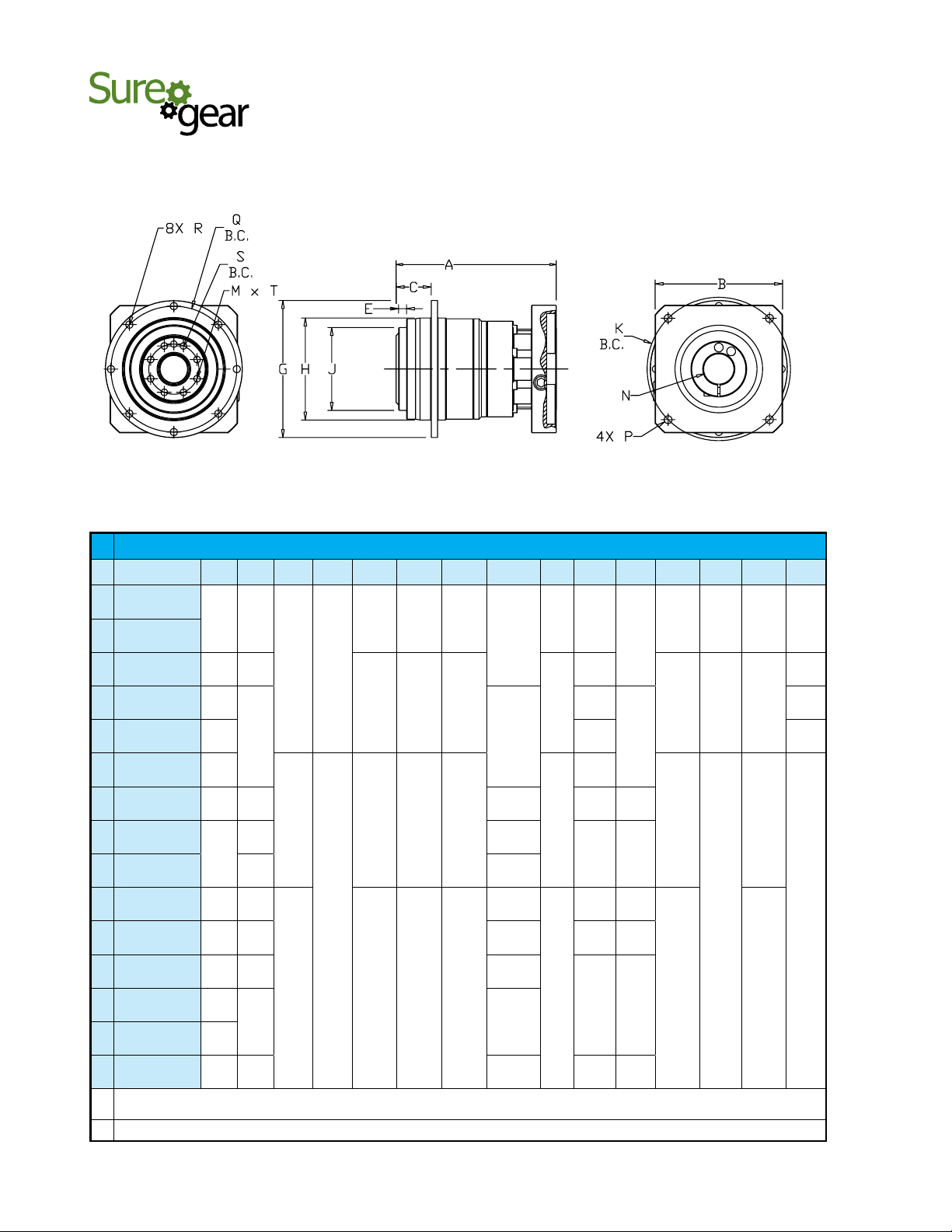

Dimensions – In-Line Shaft PGA Series

SureGear PGA Series In-Line Shaft Gearboxes Dimension Drawing

SureGear® Precision Servo Gearbox Dimensions – In-Line Shaft PGA Series ( dimensions = mm [in] )

Part Number A B C E G H J K L M N P Q R S T

88.5

42.0

24.5

4.0

Ø50.0

Ø35.0

Ø12.0

Ø46.0

Ø30.0

5.0

Ø8.0

M4-

PGA050-05A1

PGA050-10A1

PGA050-15A1

PGA050-25A1

PGA070-05A1

PGA070-10A1

PGA070-05A2

PGA070-10A2

PGA070-05A3

PGA070-15A1

PGA070-25A1

PGA070-15A2

PGA070-25A2

PGA090-10A3

PGA090-05A4

PGA090-10A4

PGA090-05A5

PGA090-10A5

PGA090-15A3

PGA090-25A3

PGA120-05A6

PGA120-10A6

PGA120-15A4

PGA120-25A4

PGA120-15A5

PGA120-25A5

PGA155-10A6

PGA155-15A6

PGA155-25A6

* Dimension with supplied bushing

NOTE: See our website: www.AutomationDirect.com for complete engineering drawings.

[3.48]

105.0

[4.13]

112.0

[4.41]

115.0

[4.53]

130.0

[5.12]

131.0

[5.16]

136.0

[5.35]

153.0

[6.02]

170.0

[6.69]

165.0

[6.50]

175.0

[6.89]

225.0

[8.86]

231.5

[9.11]

231.5

[9.11]

264.0

[10.39]

298.5

[11.75]

[1.65]

42.0

[1.65]

52.0

[2.05]

65.0

[2.56]

80.0

[3.15]

52.0

[2.05]

65.0

[2.56]

80.0

[3.15]

100.0

[3.94]

130.0

[5.12]

80.0

[3.15]

180.0

[7.09]

100.0

[3.94]

130.0

[5.12]

180.0

[7.09]

180.0

[7.09]

[0.96]

24.5

[0.96]

36.0

[1.42]

36.0

[1.42]

36.0

[1.42]

36.0

[1.42]

36.0

[1.42]

46.0

[1.81]

46.0

[1.81]

46.0

[1.81]

46.0

[1.81]

70.0

[2.76]

70.0

[2.76]

70.0

[2.76]

97.0

[3.82]

97.0

[3.82]

[0.16]

4.0

[0.16]

5.0

[0.20]

5.0

[0.20]

5.0

[0.20]

5.0

[0.20]

5.0

[0.20]

7.0

[0.28]

7.0

[0.28]

7.0

[0.28]

7.0

[0.28]

9.0

[0.35]

9.0

[0.35]

9.0

[0.35]

12.0

[0.47]

12.0

[0.47]

[Ø1.97]

Ø50.0

[Ø1.97]

Ø70.0

[Ø2.76]

Ø70.0

[Ø2.76]

Ø70.0

[Ø2.76]

Ø70.0

[Ø2.76]

Ø70.0

[Ø2.76]

Ø90.0

[Ø3.54]

Ø90.0

[Ø3.54]

Ø90.0

[Ø3.54]

Ø90.0

[Ø3.54]

Ø120.0

[Ø4.72]

Ø120.0

[Ø4.72]

Ø120.0

[Ø4.72]

Ø155.0

[Ø6.10]

Ø155.0

[Ø6.10]

[Ø1.38]

Ø35.0

[Ø1.38]

Ø52.0

[Ø2.05]

Ø52.0

[Ø2.05]

Ø52.0

[Ø2.05]

Ø52.0

[Ø2.05]

Ø52.0

[Ø2.05]

Ø68.0

[Ø2.68]

Ø68.0

[Ø2.68]

Ø68.0

[Ø2.68]

Ø68.0

[Ø2.68]

Ø90.0

[Ø3.54]

Ø90.0

[Ø3.54]

Ø90.0

[Ø3.54]

Ø120.0

[Ø4.72]

Ø120.0

[Ø4.72]

[Ø0.47]

Ø12.0

[Ø0.47]

Ø16.0

[Ø0.63]

Ø16.0

[Ø0.63]

Ø16.0

[Ø0.63]

Ø16.0

[Ø0.63]

Ø16.0

[Ø0.63]

Ø22.0

[Ø0.87]

Ø22.0

[Ø0.87]

Ø22.0

[Ø0.87]

Ø22.0

[Ø0.87]

Ø32.0

[Ø1.26]

Ø32.0

[Ø1.26]

Ø32.0

[Ø1.26]

Ø40.0

[Ø1.57]

Ø40.0

[Ø1.57]

[Ø1.81]

Ø46.0

[Ø1.81]

Ø46.0

[Ø1.81]

Ø70.0

[Ø2.76]

Ø90.0

[Ø3.54]

Ø46.0

[Ø1.81]

Ø70.0

[Ø2.76]

Ø90.0

[Ø3.54]

Ø115.0

[Ø4.53]

Ø145.0

[Ø5.71]

Ø90.0

[Ø3.54]

Ø200.0

[Ø7.87]

Ø115.0

[Ø4.53]

Ø145.0

[Ø5.71]

Ø200.0

[Ø7.87]

Ø200.0

[Ø7.87]

[Ø1.18]

Ø30.0

[Ø1.18]

Ø30.0

[Ø1.18]

Ø50.0

[Ø1.97]

Ø70.0

[Ø2.76]

Ø30.0

[Ø1.18]

Ø50.0

[Ø1.97]

Ø70.0

[Ø2.76]

Ø95.0

[Ø3.74]

Ø110.0

[Ø4.33]

Ø70.0

[Ø2.76]

Ø114.0

[Ø4.49]

Ø95.0

[Ø3.74]

Ø110.0

[Ø4.33]

Ø114.0

[Ø4.49]

Ø114.0

[Ø4.49]

[0.20]

5.0

[0.20]

5.0

[0.20]

5.0

[0.20]

6.0

[0.24]

5.0

[0.20]

5.0

[0.20]

6.0

[0.24]

8.0

[0.31]

8.0

[0.31]

6.0

[0.24]

8.0

[0.31]

8.0

[0.31]

8.0

[0.31]

8.0

[0.31]

8.0

[0.31]

[Ø0.31]

Ø8.0

[Ø0.31]

Ø8.0

[Ø0.31]

Ø14.0

[Ø0.55]

Ø19.0

[Ø0.75]

Ø8.0

[Ø0.31]

Ø14.0

[Ø0.55]

Ø19.0

[Ø0.75]

Ø22.0 *

[Ø0.87]

Ø22.0 *

[Ø0.87]

Ø19.0

[Ø0.75]

Ø35.0 *

[Ø1.38]

Ø22.0 *

[Ø0.87]

Ø22.0 *

[Ø0.87]

Ø35.0 *

[Ø1.38]

Ø35.0 *

[Ø1.38]

0.7x9

M4-

0.7x9

M4-

0.7x9

M5-

0.8x11

M6-

1.0x13

M4-

0.7x9

M5-

0.8x11

M6-

1.0x13

M8-

1.25x17

M8-

1.25x17

M6-

1.0x13

M12-

1.75x25

M8-

1.25x17

M8-

1.25x17

M12-

1.75x25

M12-

1.75x25

Ø44.0

[Ø1.73]

Ø44.0

[Ø1.73]

Ø62.0

[Ø2.44]

Ø62.0

[Ø2.44]

Ø62.0

[Ø2.44]

Ø62.0

[Ø2.44]

Ø62.0

[Ø2.44]

Ø80.0

[Ø3.15]

Ø80.0

[Ø3.15]

Ø80.0

[Ø3.15]

Ø80.0

[Ø3.15]

Ø108.0

[Ø4.25]

Ø108.0

[Ø4.25]

Ø108.0

[Ø4.25]

Ø140.0

[Ø5.51]

Ø140.0

[Ø5.51]

1.25x16

1.25x16

1.25x16

1.50x28

1.50x28

M4-

0.7x8

M4-

0.7x8

M5-

0.8x10

M5-

0.8x10

M5-

0.8x10

M5-

0.8x10

M5-

0.8x10

M6-

1.0x12

M6-

1.0x12

M6-

1.0x12

M6-

1.0x12

M8-

M8-

M8-

M10-

M10-

4.0

[0.16]

4.0

[0.16]

5.0

[0.20]

5.0

[0.20]

5.0

[0.20]

5.0

[0.20]

5.0

[0.20]

6.0

[0.24]

6.0

[0.24]

6.0

[0.24]

6.0

[0.24]

10.0

[0.39]

10.0

[0.39]

10.0

[0.39]

12.0

[0.47]

12.0

[0.47]

4.0

[0.16]

4.0

[0.16]

5.0

[0.20]

5.0

[0.20]

5.0

[0.20]

5.0

[0.20]

5.0

[0.20]

6.0

[0.24]

6.0

[0.24]

6.0

[0.24]

6.0

[0.24]

8.0

[0.31]

8.0

[0.31]

8.0

[0.31]

8.0

[0.31]

8.0

[0.31]

www.automationdirect.com

Motion Control

tMNC-192

Page 15

®

1-800-633-0405

Precision Servo Gearboxes

Pricing & Specifications – Right-Angle Shaft PGB Series

SureGear® Precision Servo Gearboxes – Right-Angle Shaft PGB Series

For the latest prices, please check AutomationDirect.com.

)

2

Part Number

PGB070-05A1

PGB070-10A1

PGB070-15A1

PGB070-25A1

PGB070-05A2

PGB070-10A2

PGB070-15A2

PGB070-25A2

PGB090-15A2

PGB090-25A2

PGB090-05A3

PGB090-10A3

PGB090-15A3

PGB090-25A3

PGB090-05A4

PGB090-10A4

PGB120-15A4

PGB120-25A4

PGB120-05A5

PGB120-10A5

PGB120-15A5

PGB120-25A5

PGB120-05A6

PGB120-10A6

PGB155-15A6

PGB155-25A6

PGB155-05A6

PGB155-10A6

Price

Ratio

Frame Size (mm)

$729.00

$729.00 10:1 double

$922.00 15:1 triple

$922.00 25:1 triple

$729.00 5:1 double

$729.00 10:1 double

$922.00 15:1 triple

$922.00 25:1 triple

$1,125.00

$1,125.00 25:1 triple

$862.00 5:1 double

$862.00 10:1 double

$1,125.00 15:1 triple

$1,125.00 25:1 triple

$862.00 5:1 double

$862.00 10:1 double

$1,398.00

$1,398.00 25:1 triple

$1,125.00 5:1 double

$1,125.00 10:1 double

$1,398.00 15:1 triple

$1,398.00 25:1 triple

$1,125.00 5:1 double

$1,125.00 10:1 double

$1,637.00

$1,637.00 25:1 triple

$1,295.00 5:1 double

$1,295.00 10:1 double

5:1 double

70

15:1 triple

90

15:1 triple

120

15:1 triple

155

Reduction

Nominal Output

Torque ( N·m [lb·in] )

22

[195]

16

[142]

16

[142]

24

[212]

22

[195]

16

[142]

16

[142]

24

[212]

45

[398]

65

[575]

65

[575]

45

[398]

45

[398]

65

[575]

65

[575]

45

[398]

110

[974]

150

[1328]

120

[1062]

110

[974]

110

[974]

150

[1328]

120

[1062]

110

[974]

200

[1770]

300

[2655]

200

[1770]

200

[1770]

Max. Acceleration

40

[354]

32

[283]

32

[283]

45

[398]

40

[354]

32

[283]

32

[283]

45

[398]

65

[575]

110

[974]

90

[797]

65

[575]

65

[575]

110

[974]

90

[797]

65

[575]

200

[1770]

300

[2655]

240

[2124]

200

[1770]

200

[1770]

300

[2655]

240

[2124]

200

[1770]

400

[3540]

600

[5310]

400

[3540]

400

[3540]

( N·m [lb·in] )

Torque ( N·m [lb·in] )

Emergency Stop Torque

80

[708]

65

[575]

65

[575]

90

[797]

80

[708]

65

[575]

65

[575]

90

[797]

170

[1505]

220

[1947]

220

[1947]

170

[1505]

170

[1505]

220

[1947]

220

[1947]

170

[1505]

450

[3983]

550

[4868]

500

[4425]

450

[3983]

450

[3983]

550

[4868]

500

[4425]

450

[3983]

750

[6638]

1100

[9736]

1100

[9736]

750

[6638]

Max. Input

Speed (rpm)

Speed (rpm)

Nominal Input

Backlash (arc-min)

6

9

6

9

9

6

3000 6000

9

6

9

6

9

6

9

2000 4000

6

Load ( N [lb] )

Allowable Radial

510

[115]

[88]

640

[144]

[119]

740

[166]

[142]

870

[196]

[178]

510

[115]

[88]

640

[144]

[119]

740

[166]

[142]

870

[196]

[178]

1400

1900

[314]

[427]

1600

2200

[360]

[495]

960

1200

[216]

[270]

1200

1600

[270]

[360]

1400

1900

[314]

[427]

1600

2200

[360]

[495]

960

1200

[216]

[270]

1200

1600

[270]

[360]

2300

3000

[517]

[674]

2700

3700

[607]

[832]

1600

1900

[360]

[427]

2000

2500

[450]

[562]

2300

3000

[517]

[674]

2700

3700

[607]

[832]

1600

1900

[360]

[427]

2000

2500

[450]

[562]

5400

4900

[1214]

[1102]

6400

6100

[1439]

[1371]

3800

3000

[854]

[674]

4700

4100

[1057]

[922]

Moment of

Load ( N [lb] )

Allowable Thrust

390

0.250

530

0.230

630

0.073

790

0.071

390

0.320

530

0.300

630

0.118

790

0.115

0.410

0.400

2.130

2.020

0.600

0.590

4.260

4.150

4.700

4.640

6.610

6.050

4.700

4.640

13.690

13.120

15.070

14.820

21.280

19.030

Temperature

Max. Housing

Efficiency (%)

Inertia (kg·cm

93

88

93

88

88

93

88

90 °C

[194 °F]

93

88

93

88

93

88

93

( kg [lb] )

Approx Weight

Environmental Rating

1.9

[4.2]

SVL-201(B)

1.7

[3.7]

1.9

[4.2]

1.7

[3.7]

4.3

[9.5]

4.9

[10.8]

4.3

[9.5]

4.9

[10.8]

10

[22]

10.2

[22.5]

10

[22]

10.2

[22.5]

20.4

[45.0]

19.8

[43.7]

SVL-202(B)

SVL-204(B)

SVL-202(B)

SVL-202(B)

SVL-204(B)

SVL-207(B)

IP55

SVL-210(B)

SVM-210(B)

SVM-220(B)

SVM-230(B)

SVM-220(B)

SVM-220(B)

SVM-230(B)

Servo Motor

Fits SureServo

www.automationdirect.com

Motion Control

tMNC-193

Page 16

®

1-800-633-0405

Precision Servo Gearboxes

Dimensions – Right-Angle Shaft PGB Series

For the latest prices, please check AutomationDirect.com.

SureGear PGB Series Right-Angle Shaft Gearboxes Dimension Drawing

SureGear® Precision Servo Gearbox Dimensions – Right-Angle Shaft PGA Series ( dimensions = mm [in] )

Part Number A B C E G H J K L M N P Q R S T

151.5

[5.96]

158.0

[6.22]

163.5

[6.44]

204.5

[8.05]

205.5

[8.09]

210.5

[8.29]

205.5

[8.09]

272.0

[10.71]

266.0

[10.47]

272.0

[10.71]

268.5

[10.57]

341.0

[13.43]

364.0

[14.33]

52.0

[2.05]

65.0

[2.56]

52.0

[2.05]

65.0

[2.56]

80.0

[3.15]

100.0

[3.94]

130.0

[5.12]

180.0

[7.09]

36.0

[1.42]

46.0

[1.81]

70.0

[2.76]

97.0

[3.82]

5.0

[0.20]

7.0

[0.28]

9.0

[0.35]

12.0

[0.47]

Ø70.0

[Ø2.76]

Ø90.0

[Ø3.54]

Ø120.0

[Ø4.72]

Ø155.0

[Ø6.10]

Ø52.0

[Ø2.05]

Ø68.0

[Ø2.68]

Ø90.0

[Ø3.54]

Ø120.0

[Ø4.72]

PGB070-05A1

PGB070-10A1

PGB070-05A2

PGB070-10A2

PGB070-15A1

PGB070-25A1

PGB070-15A2

PGB070-25A2

PGB090-15A2

PGB090-25A2

PGB090-05A3

PGB090-10A3

PGB090-15A3

PGB090-25A3

PGB090-05A4

PGB090-10A4

PGB120-15A4

PGB120-25A4

PGB120-05A5

PGB120-10A5

PGB120-15A5

PGB120-25A5

PGB120-05A6

PGB120-10A6

PGB155-05A6

PGB155-10A6

PGB155-15A6

PGB155-25A6

* Dimension with supplied bushing

NOTE: See our website: www.AutomationDirect.com for complete engineering drawings.

Ø16.0

[Ø0.63]

Ø22.0

[Ø0.87]

Ø32.0

[Ø1.26]

Ø40.0

[Ø1.57]

Ø46.0

[Ø1.81]

Ø70.0

[Ø2.76]

Ø46.0

[Ø1.81]

Ø70.0

[Ø2.76]

Ø90.0

[Ø3.54]

Ø115.0

[Ø4.53]

Ø145.0

[Ø5.71]

Ø200.0

[Ø7.87]

Ø30.0

[Ø1.18]

Ø50.0

[Ø1.97]

Ø30.0

[Ø1.18]

Ø50.0

[Ø1.97]

Ø70.0

[Ø2.76]

Ø95.0

[Ø3.74]

Ø110.0

[Ø4.33]

Ø114.0

[Ø4.50]

5.0

[0.20]

6.0

[0.24]

8.0

[0.31]

Ø8.0

[Ø0.31]

Ø14.0

[Ø0.55]

Ø8.0

[Ø0.31]

Ø14.0

[Ø0.55]

Ø19.0

[Ø0.75]

Ø22.0 *

[Ø0.87]

Ø35.0 *

[Ø1.38]

M4-

0.7x9

M5-

0.8x11

M4-

0.7x9

M5-

0.8x11

M6-

1.0x13

M8-

1.25x17

M12-

1.75x25

Ø62.0

[Ø2.44]

Ø80.0

[Ø3.15]

Ø108.0

[Ø4.25]

Ø140.0

[Ø5.51]

M5-

0.8x10

M6-

1.0x12

M8-

1.25x16

M10-

1.5x20

5.0

[0.20]

6.0

[0.24]

10.0

[0.39]

12.0

[0.47]

5.0

[0.20]

6.0

[0.24]

8.0

[0.31]

www.automationdirect.com

Motion Control

tMNC-194

Page 17

®

1-800-633-0405

Precision Servo Gearboxes

Pricing & Specifications – Hub Style In-Line PGD Series

SureGear® Precision Servo Gearboxes – Hub Style In-Line PGD Series

For the latest prices, please check AutomationDirect.com.

)

2

Part Number

PGD047-05A1

PGD047-10A1

PGD047-25A1

PGD064-50A1

PGD064-05A2

PGD064-10A2

PGD064-25A2

PGD090-25A2

PGD090-50A2

PGD090-05A3

PGD090-10A3

PGD090-05A4

PGD090-10A4

PGD090-05A5

PGD110-50A2

PGD110-25A3

PGD110-50A3

PGD110-25A4

PGD110-50A4

PGD110-10A5

PGD110-25A5

PGD110-35A5

PGD110-05A6

PGD110-10A6

Price

Ratio

Frame Size (mm)

$780.00

$780.00 10:1 single

$976.00 25:1 double

$1,181.00

$1,008.00 5:1 single

$1,008.00 10:1 single

$1,181.00 25:1 double

$1,354.00

$1,354.00 50:1 double

$1,181.00 5:1 single

$1,181.00 10:1 single

$1,181.00 5:1 single

$1,181.00 10:1 single

$1,181.00 5:1 single

$1,727.00

$1,727.00 25:1 double

$1,727.00 50:1 double

$1,727.00 25:1 double

$1,727.00 50:1 double

$1,468.00 10:1 single

$1,727.00 25:1 double

$1,727.00 35:1 double

$1,468.00 5:1 single

$1,468.00 10:1 single

5:1 single

47

50:1 double

64

25:1 double

90

50:1 double

110

Reduction

Nominal Output

Torque ( N·m [lb·in] )

9

[80]

6

[53]

9

[80]

27

[239]

27

[239]

18

[159]

27

[239]

75

[664]

[1106]

75

[664]

[1106]

75

[664]

[1106]

50

[443]

75

[664]

[1106]

50

[443]

75

[664]

[1106]

180

[1593]

[2921]

180

[1593]

[2921]

180

[1593]

[2921]

180

[1593]

[2921]

180

[1593]

[2921]

120

[1062]

[1991]

180

[1593]

[2921]

180

[1593]

[2921]

180

[1593]

[2921]

120

[1062]

[1991]

Emergency Stop

Max. Acceleration

Torque ( N·m [lb·in] )

Torque ( N·m [lb·in] )

18

35

[159]

[310]

30

[266]

35

[310]

100

[885]

100

[885]

80

[708]

100

[885]

250

[2213]

250

[2213]

250

[2213]

200

[1770]

250

[2213]

200

[1770]

250

[2213]

625

[5532]

625

[5532]

625

[5532]

625

[5532]

625

[5532]

500

[4425]

625

[5532]

625

[5532]

625

[5532]

500

[4425]

≤ 3

≤ 5

≤ 3 3000 6000

12

[106]

18

[159]

50

[443]

50

[443]

35

[310]

50

[443]

125

125

125

80

[708]

125

80

[708]

125

330

330

330

330

330

225

330

330

330

225

Max. Input

Speed (rpm)

Speed (rpm)

Nominal Input

Backlash (arc-min)

300

[67]

4000 8000

370

[83]

510

[115]

850

[191]

400

[90]

500

[112]

680

[153]

1300

[292]

1700

[382]

780

[175]

980

[220]

780

[175]

980

[220]

780

[175]

10000

[2248]

8200

[1843]

10000

[2248]

8200

[1843]

10000

[2248]

6200

[1394]

8200

[1843]

9000

[2023]

5000

[1124]

6200

[1394]

Load ( N [lb] )

Load ( N [lb] )

Allowable Thrust

Allowable Radial

330

[74]

450

[101]

550

[124]

750

[169]

390

[88]

530

[119]

750

[169]

1400

[315]

1700

[382]

680

[153]

920

[207]

680

[153]

920

[207]

680

[153]

6800

[1529]

5500

[1236]

6800

[1529]

5500

[1236]

6800

[1529]

4200

[944]

5500

[1236]

6100

[1371]

3400

[427]

4200

[944]

(kg·cm

Moment of Inertia

0.043

0.032

0.034 90

0.049 90

0.1 95

0.062 95

0.054 90

0.130 90

0.099 90

0.580 95

0.330 95

0.580 95

0.330 95

0.580 95

0.400 90

0.700 90

0.400 90

0.700 90

0.400 90

1.100 95

0.700 90

0.700 90

2.300 95

1.100 95

Temperature

Efficiency (%)

Max. Housing

95

90 °C

[194 °F]

Approx Weight

0.7

[1.5]

0.8

[1.8]

1.6

[3.5]

1.4

[3.1]

1.4

[3.1]

1.6

[3.5]

4

[8.8]

4

[8.8]

3.6

[7.9]

3.6

[7.9]

3.6

[7.9]

3.6

[7.9]

3.6

[7.9]

8.6

[19]

8.6

[19]

8.6

[19]

8.6

[19]

8.6

[19]

7.8

[17.2]

8.6

[19]

8.6

[19]

7.8

[17.2]

7.8

[17.2]

Rating

( kg [lb] )

Environmental

IP54

(IP65)

Servo Motor

Fits SureServo

SVL-201(B)

SVL-202(B)

SVL-204(B)

SVL-207(B)

SVL-210(B)

SVM-210(B)

SVL-202(B)

SVL-204(B)

SVL-207(B)

SVL-210(B)

SVM-210(B)

SVM-220(B)

SVM-230(B)

www.automationdirect.com

Motion Control

tMNC-195

Page 18

®

1-800-633-0405

Precision Servo Gearboxes

Dimensions – Hub Style In-Line PGD Series

For the latest prices, please check AutomationDirect.com.

SureGear PGD Series Hub Style In-Line Gearboxes Dimension Drawing

SureGear® Precision Servo Gearbox Dimensions – Hub Style In-Line PGD Series ( dimensions = mm [in] )

Part Number A* B* C E G H J K M N** P Q R S T

PGD047-05A1

1

PGD047-10A1

2 PGD047-25A1

2 PGD064-50A1

PGD064-05A2

1

PGD064-10A2

2 PGD064-25A2

PGD090-25A2

2

PGD090-50A2

PGD090-05A3

1

PGD090-10A3

PGD090-05A4

1

PGD090-10A4

1 PGD090-05A5

2 PGD110-50A2

PGD110-25A3

2

PGD110-50A3

PGD110-25A4

2

PGD110-50A4

1 PGD110-10A5

PGD110-25A5

2

PGD110-35A5

PGD110-05A6

1

PGD110-10A6

* Length will vary depending on motor

** Bushing will be inserted to adapt to motor shaft

NOTE: See our website: www.AutomationDirect.com for complete engineering drawings.

66.5

[2.62]