Page 1

ATS Series

Sectional Door Opener

Instruction Manual

Doc # 160091_02

Part # 86296

Released 03/06/19

TEMPO ATS-2

SECTIONAL DOOR OPENER

Page 2

ATS Series Instruction Manual2

Table of Contents

Installation Instructions

1. Installation Safety Warnings! 3

2. Before you Begin 4

3. Tools Required 4

4. Kit Contents 5

5. Position 5

6. Fit the Opener 6

7. Bracket Position 6

Wall Bracket Position: 6

Mounting The Wall Bracket: 6

Attach The Rail To The Wall Bracket 6

8. Perforated Angle 7

9. Mounting Brackets and Arms 7

Mounting The Door Bracket: 7

Attaching the Arms 7

10. Optional Safety Beam Kit 8

11. Setting Limits 9

Set the Limit Positions and adjust drive speed: 9

Clearing the Door Limit Positions 9

Re-profiling the Door 9

12. Safety Testing 10

Test the Close Cycle 10

Testing the Open Cycle 10

Test the Manual Door Operation 10

Home Owner Instructions

15. Home Owner Safety Warnings! 12

16. Opener Safety & Security 13

Your Door CAN NOT be used when: 13

Your Door CAN be used when: 13

To Disengage the Opener: 13

To Re-Engage the Opener: 13

17. Operating your Opener 13

18. User Operating Controls 14

19. Specifications 15

20. Troubleshooting 16

21. Maintenance 18

22. Battery Replacement 19

23. Battery Disposal 19

24. Appendix 20

A - Status Indication during Operating Mode. 20

B - Adjustment Mode Instructions 21

C - Adjusting Force Margins 21

D - Battery Functions 21

E - Setting limits via Transmitter 22

F - Setting the PET Mode position 22

25. Warranty 23

13. Auto-Close 10

14. Coding a Transmitter 11

Storing the Transmitter Code 11

Installation of the Wall Mounted Transmitter 11

Remotely Coding Transmitters 11

Erasing All Transmitter Codes 11

Vacation Mode 11

Page 3

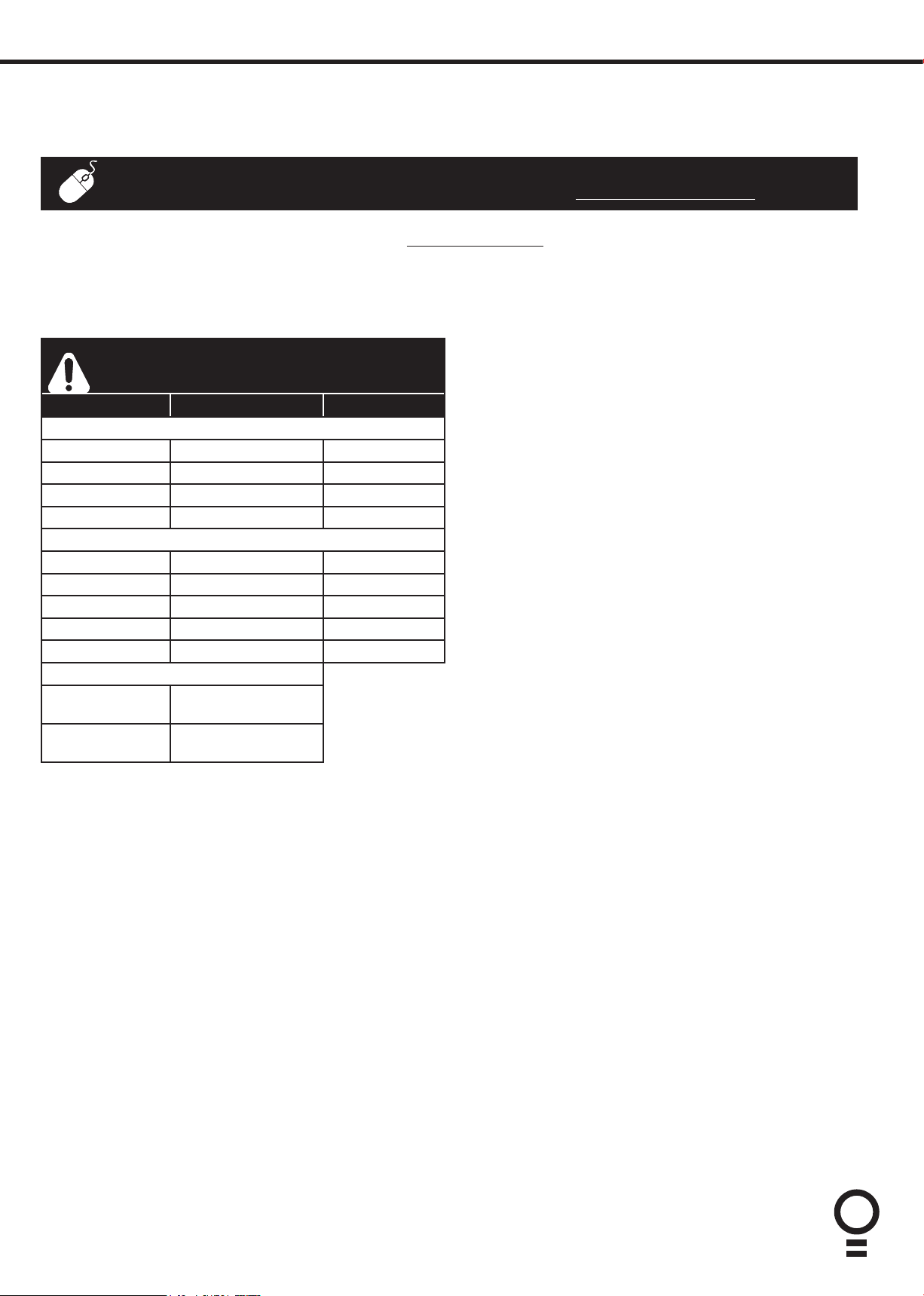

1. Installation Safety Warnings!

This automatic garage door opener is designed and tested to offer safe service provided it is

installed and operated in strict accordance with the following safety warnings. Failure to comply

with the following instructions may result in death, serious personal injury or property damage.

3ATS Series Instruction Manual

WARNING!

ELECTROCUTION!

• The door may operate unexpectedly, therefore do not allow anything to stay in the path of

the door.

• When operating the manual release while the door is open, the door may fall rapidly due

to weak or broken springs, or due to being improperly balanced.

• The drive must not be used with a door incorporating a wicket door, unless the drive cannot

be operated with the wicket door open.

• The drive is intended to be installed at least 2.5m above the floor.

• Do not disengage the opener to manual operation with children/persons or any objects

including motor vehicles within the doorway.

• If the door is closing and is unable to re-open when obstructed, discontinue use. Do not

use a door with faulty obstruction sensing

• When using auto close mode, a Photo Electric beam must be fitted correctly and tested

for operation at regular intervals. Extreme caution is recommended when using auto close

mode. All safety rules must be followed.

• Place opener in protected area so that it does not get wet.

• Do not spray with water .

• Disconnect the power cord from mains power before making any repairs or removing covers.

Only experienced service personnel should remove covers from the opener.

• If the power supply cord is damaged, it must be replaced by an Automatic Technology

service agent or suitably qualified person.

• Connect the opener to a properly earthed general purpose 240V mains power outlet

installed by a qualified electrical contractor.

CAUTION:

Emergency Access • If garage has no pedestrian entrance door, an emergency access device should be

installed. This accessory allows manual operation of the garage door from outside in case

of power failure.

Muscular strain • Practice correct lifting techniques (carton weighs approx 9kgs)

• Practice correct lifting techniques when required to lift the door as per installation instructions.

Fall from ladder • Ensure ladder is the correct type for job.

• Ensure ladder is on flat firm ground that will take the weight without the legs sinking.

• Ensure user has 3 points of contact while on ladder.

Crush injury from unsecured

door

Garage Door • Examine the door installation, in particular, springs and mountings for signs of wear, damage

Entanglement • Never plug in and operate opener prior to installation.

Entrapment under

operating door

• Place a 2 metre exclusion zone around area under the door while it is unsecured.

• Follow the installation instructions

and imbalance.

• The garage door must be well balanced. Sticking or binding doors must be repaired by a

qualified garage door installer prior to installation of the opener.

• Remove or disengage all garage door locks and mechanisms prior to installation of the opener.

• Keep hands and loose clothing clear of door and guides at all times.

• DO NOT operate the opener unless the garage door is in full view and free from objects

such as cars and children/people. Make sure that the door has finished moving before

entering or leaving the garage

• In order for the opener to sense an object obstructing the door way, some force must be

exerted on the object. As a result the object, door and/or person may suffer minor damage

or injury.

• Ensure the garage door is in good working order by undertaking regular servicing.

• Install the optional wall transmitter in a location where the garage door is visible, but out

of the reach of children at a height of at least 1.5m.

• Photo Electric beams must be installed if the closing force at the bottom edge of the door

exceeds 400N (40kg)

Page 4

ATS Series Instruction Manual4

Screwdrivers

Adjustable End Wrench

Sockets and Wrench

Pencil

Drill

2 x Screws

(M6 x 20mm)

Stepladder

Perforated Angle

Metal pieces

(32 x 32 x 1.5mm) x 1200mm length

4 x Screws

(M8 x 20mm)

4 x Bolts and Nuts

(M8)

Drill Bits

Pliers

Hack saw

Tape Measure

Level

2. Before you Begin

Examine the conditions in the garage:

a. Look at the ceiling:

i. Is it plastered? The opener is mounted to a perforated angle which MUST be securely fastened to a structural support.

You will need to locate the structural beams in the ceiling which are generally 400mm apart.

ii. Does it have exposed beams? The opener is mounted to a perforated angle which must be securely fastened to a

structural support like the exposed beams. You may need to install a 40mm thick board (not supplied) between structural

supports.

b. Look at the wall above the garage door.

i. Is it brick? The wall bracket MUST be securely fastened to the wall with suitable screws and ensure it does not move.

ii. Is it timber? The wall bracket MUST be securely fastened to a structural

support. You may need to install a 40mm thick board (not supplied) between

structural supports to fasten the wall bracket to.

Test the following before commencing installation:

a. The door MUST BE in good operating condition.

b. Manually move the door up and down, the door should move freely without

binding or sticking.

c. The maximum force required to move the door should not exceed 20kg.

d. Lift the door to about halfway. When released, the door should stay in place.

DO NOT DO IT YOURSELF:

DIY

If any of the above door requirements are not met, DO

NOT attempt to fix yourself. Please contact a garage door

professional. (P) 13 62 63

3. Tools Required

Page 5

4. Kit Contents

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

10.00°

min

MINIMUM HEAD

ROOM FOR STEEL

RAIL 57mm

DOORS HIGHEST

POINT

5ATS Series Instruction Manual

1. 1 x ATS drive unit

2. 1 x Wall mount transmitter

3. 2 x Transmitters and batteries

4. 1 x Bent arm door attachment

5. 1 x Straight arm door attachment

6. 1 x Wall bracket TS01

7. 1 x Door bracket Locator

8. 1 x Door bracket

9. 3 x Pin Snap SSP 8 ZNU 31080

10. 2 x Hex Head screw M8x25

11. 1 x Pin 0890

12. 2 x Clevis Pin 0829

13. 2 x Hex Serration flange nut M8

14. 4 x Hex flange screw taptite ‘S’ M4 x 10

PLUS

15. 2 x Track Bracket

16. 1 x Pre-Assembled Rail

5. Position

The Opener:

a. MUST BE installed in a dry position, protected from weather.

b. REQUIRES properly earthed 3 pin single phase power on the ceiling within an arms length of the opener.

c. Requires a MINIMUM HEADROOM of 57mm between the highest point of the door’s travel and the ceiling.

d. Use the diagram below as a reference when completing the installation.

9

6

11

9

12

16

15

14

Perforated

Angle

5

1

13

7

129

8

4

10

Page 6

ATS Series Instruction Manual6

6. Fit the Opener

Secure C-Rail to Opener:

a. Remove the Opener from the box.

b. Locate and insert the shaft of drive unit 1 into the C-Rail’s sprocket.

c. Fix the two track brackets 15 with four (4) M4 x 8 screws 14 supplied in accessory pack.

d. Place drive unit back in packing box for protection.

1

Locate shaft into

the sprocket

16

14

15

7. Bracket Position

Wall Bracket Position:

a. Determine the centre of the door and mark this point with a line on the wall

above.

b. Raise the door and find the highest point of travel of the first (top) door panel.

WARNING! The Opener must be securely fastened to structural

supports, otherwise opener failure may ensue causing serious

personal injury and / or property damage.

WARNING! DO NOT

use tek screws to affix

rail. Only use the screws

provided, and fix these

into the threaded holes

in the chassis.

60mm

Level

c. Using step ladder and a level, transfer this height to the wall above the door

and mark a line 60mm above it, across the centre line.

DIY

DO NOT DO IT YOURSELF: If sufficient structural support can not

be found, contact a door professional for installation.

Mounting The Wall Bracket:

a. Draw two lines extending 21.5mm from each side of the centre point.

b. Centre the wall bracket 6 over the intersection of these two lines. Mark

centres for at least two holes and ensure it is into a solid mounting point.

c. Drill holes in the wall with an appropriate bit.

d. Secure to the wall using:

i. IF CONCRETE OR BRICK:

8mm (5/6”) loxins/dynabolts.

ii. IF TIMBER:

wood screw #20 or similar (min. 50mm).

Attach The Rail To The Wall Bracket

a. Leave the drive unit in its packing box on the floor for protection and lift the

other end of the C-Rail.

b. Attach the C-Rail assembly 16 to the wall bracket 6 with the

90mm long pin 11 and secure with the supplied pin snap 9.

6

16

11

6

9

Page 7

7ATS Series Instruction Manual

8. Perforated Angle

(Not supplied)

Attach Perforated Angle (not supplied) or equivalent

a. Measure across the ceiling from the centre point 3155mm (+/- 50mm) to find a supporting beam.

b. Create a perforated angle which best suits your site. Use a hack saw to cut the L shape metal strips. Secure the perforated

angle to a supporting beam using diagrams shown below.

c. Raise the drive unit to the ceiling mounted perforated angle and secure with M8x20mm screws and nuts (not supplied). Strips

should not extend more than 18mm below centre of drive unit mounting holes.

d. To prevent moisture on the C-rail running into the powerhead it is recommended a strip of silicon sealant is placed across the

top of the C-rail just before the opener.

Ceiling Beams that run towards the door requires:

1 x perforated L shape metal strip and

2 x shorter perforate L shape metal drop down strips.

Ceiling Beams that run parallel to the door requires:

2 x perforated L shape metal strips and

2 x shorter perforate L shape metal drop down strips.

9. Mounting Brackets and Arms

Mounting The Door Bracket:

a. The door bracket locator 7 is placed over the door bracket

8

, on the door’s centre line one-third down the top panel and

mounted using M6 or equivalent screws (not supplied),

b. STEEL DOORS ONLY: Bracket can be welded in place.

NOTE: If in doubt about the door’s strength, reinforcement

may be added to the door’s frame where necessary. Door

damage may occur if the bracket is installed on a panel

with insufficient strength. The opener’s warranty does not

cover damage caused to the door and/or door panels.

7

8

6

13

9

5

4

A

12

10

12

Attaching the Arms

a. Assemble the bent arm 4 (connecting to the door) to the

right side of the straight arm 5 with bolts 10 and nuts 13

supplied in the accessory pack. Connect the straight arm 5 to

the shuttle with a clevis pin 12 and a pin snap 9. Always use both bent and straight arms.

b. Connect the assembled arm to the bracket with clevis pin 12 and pin snap 9. The angle “A” must be more than 10°.

7

8

9

Page 8

ATS Series Instruction Manual8

10. Optional Safety Beam Kit

Safety Beams

The Safety Beam Kit provides additional safety by preventing the door closing when

the beam is blocked by a car, child etc. When the Safety Beam Kit is installed the

Auto-close feature can be enabled if required.

a. To install the Safety Beam Kit, refer to the Safety Beam instruction supplied with

the kit.

b. After the beams are installed the beam alignment feature of the opener can be

used.

c. Turn power on to the opener.

d. Align the safety beams using the main light as a guide:

i. bright = aligned

ii. dull = not aligned or blocked

When the beam is aligned or if no beam is fitted, continue with Setting Limits.

Page 9

11. Setting Limits

Set the Limit Positions and adjust drive speed:

The Limit Positions can vary due to site conditions, such as uneven

ground. When setting the Close limit, ensure the position is when the

door makes first contact with the ground. Alternatively for the Open

limit the position should be at the height of the garage opening.

9ATS Series Instruction Manual

NOTE: The drive speed is set to the fastest setting by default. This

may not be suitable for larger doors or for single piece doors.

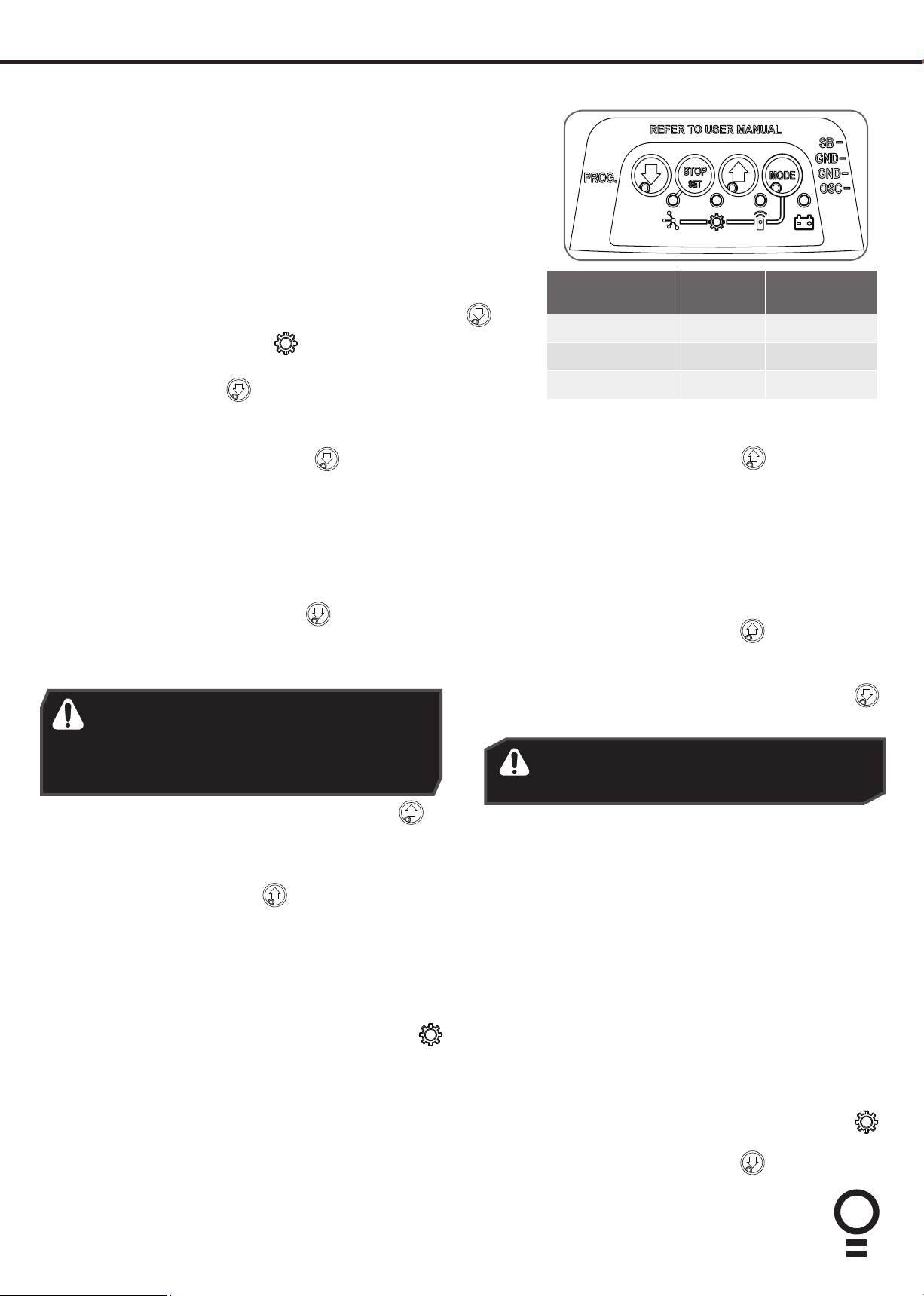

a. Switch power on and the BLUE LED on the CLOSE button

will start to flash and the GEAR

opener is ready to set the Close travel limit.

b. Press either the CLOSE

to the halfway point.

CLOSE limit:

i. Press and hold the CLOSE button

the door, taking note of the speed the door moves.

ii. If the close speed is not suitable, to make a change,

press and hold the CLOSE button and by pressing the

STOP / SET button on the opener it will cycle through

all three speed modes as shown in table.

iii. Once at the desired speed, release the CLOSE button.

iv. To set the close limit, inch the door by making single

presses of the CLOSE button

position. We recommend the CLOSE limit position

being the first point of contact of the rubber strip ( at

the bottom of the door) with the ground.

WARNING! In setting the close limit position,

do not force the door into the floor with

excessive force, as this can interfere with

the ease of operation of the manual release

mechanism.

or OPEN button to move the door

LED is lit to indicate that the

to start closing

to the desired

Door Opener

Speed Mode

OPEN limit:

i. Press and hold the OPEN button

ii. If the open speed is not suitable, to make a change,

iii. Once at the desired speed, release the OPEN button.

iv. Continue inching the door to the desired position.

v. To set the open limit, inch the door by making single

vi. If the door overshoots, press the CLOSE button

Fast (Default)

Medium

Slow

the door, taking note of the speed the door moves.

press and hold the OPEN button and by pressing the

STOP / SET button on the opener it will cycle through

all three speed modes as shown in table.

presses of the OPEN button

position. We recommend the OPEN limit position

being the height of the garage opening.

to move the door in the CLOSE direction.

WARNING! The door will automatically close,

open and close again after the next step.

Ensure that nothing is in the door’s path.

STATUS MAIN LIGHT

On 3 Flash

On 2 Flashes

On 1 Flashes

to start opening

to the desired

v. If the door overshoots, press the OPEN button

move the door in the OPEN direction.

vi. When the door is at the desired CLOSE position, press

the STOP / SET button on the opener, the GREEN

LED on the OPEN button

NOTE: If unhappy with the speed or travel limit setting,

restart this procedure by resetting the door limit positions

as per below first.

will now flash.

Clearing the Door Limit Positions

Limit positions can be deleted by:

a. Press the MODE button repetitively until the GEAR

LED is lit.

b. Press and hold the MODE button for 10 secs, let the

MODE button go when the main light stops flashing.

c. The close LED will flash continuously to indicate limits

have been cleared.

NOTE: If no action is taken within 30 seconds, the opener

will return to normal operating mode and restore the original

settings.

d. Follow from CLOSE limit: above to set new limit positions.

to

vii. When the door is at the desired OPEN position,

press the STOP / SET button The door will now

automatically close and open to calculate the safety

obstruction settings.

Re-profiling the Door

Re-profiling is a simplified way of re-learning the travel

characteristic of a previously setup Limit Switch travel

installation. Re-profiling can be used when the travel

characteristics of the door change due to mechanical

adjustments etc. To initiate a re-profile:

a. Limits must be set.

b. Press the MODE button repetitively until the GEAR

LED is lit.

c. Press and hold the CLOSE button

seconds, the door will open and close by itself to

record profile.

for two

Page 10

ATS Series Instruction Manual10

12. Safety Testing

Test the Close Cycle

a. Press the OPEN button or transmitter button to open the door

(If the door starts closing, press the transmitter button to stop the

door, then press transmitter again to open).

b. Place a piece of timber 40mm high on the floor directly under the

door.

c. Press the transmitter button to close door.

d. The door should strike the object and re-open.

e. Remove the timber.

WARNING! If the door is closing and is unable

to re-open when obstructed, discontinue use.

Do not use a door with faulty obstruction sensing.

Testing the Open Cycle

a. Press the CLOSE button or transmitter button to close the

door.

b. Press the transmitter button again to open the door.

c. When the door reaches approximately half way, firmly grab the

door’s bottom rail - the door should stop.

If the door does not reverse readily when closing, or stop when

opening, put the door into manual by pulling down on the manual

release string to disengage the motor and contact 13 62 63 for

support.

CAUTION: Take care when completing a

safety test. Failure to follow this warning

can result in serious personal injury and/or

property damage.

Wood 40mm high

WARNING! If the door fails these tests,

put the opener into manual mode, only

operate the door by hand and call for

service.

Test the Manual Door Operation

Periodically disengage the opener and manually operate the door.

The door must be smooth to operate by hand. The force required on

the bottom rail should not exceed 20kg.

13. Auto-Close

Auto-Close mode is a function that automatically closes the door after

a pre-set time. Safety beams must be installed in order to run the AutoClose function. There are two types of Auto-Close available:

i. Standard auto-close - the door will Auto-Close after a

programmed time. In this mode the timer starts to countdown

as soon as the door is fully open. This function is useful in case

the safety beam does not get triggered.

ii. Safety Beam triggered auto-close - the door will auto-close

after a programmed time. In this mode the timer starts counting

down only when the safety beam is triggered. ie car leaving the

garage.

To enable the Auto-Close function:

a. Press the MODE button until the GEAR

b. Press the OPEN button

i. two (2) times to get to PE auto-close or

ii. three (3) times to get to standard auto-close.

c. Press STOP / SET button to enter parameter.

until the GEAR LED flashes:

LED starts flashing.

WARNING! Safety beams must be

installed if the closing force at the bottom

edge of the door exceeds 400N (40kg).

WARNING! It is compulsory to have

Safety Beams installed when using

Auto-Close mode.

d. The default setting for Auto-Close is OFF. Press the

OPEN button

light’s brightness will change accordingly.

e. Press STOP / SET button to save the parameter’s new

value or press MODE to leave the value unchanged.

to move through options and the

Parameter Value options = Indicated by brightness of

main light (DEFAULT parameter underlined)

Name Flashes 1 2 3 4 5 6

PE AUTO-CLOSE 2 OFF 15sec 30sec 60sec 90sec -

AUTO-CLOSE 3

OFF 15sec 30sec 60sec 90sec 120sec

Page 11

14. Coding a Transmitter

11ATS Series Instruction Manual

Storing the Transmitter Code

The opener can only operated from remote control

transmitters that have been programmed into its

memory. Up to 64 codes can be stored in the memory.

a. Press the MODE button until the TRANSMIT

LED is lit.

b. Press and HOLD the button/s indicated in the table

to set the required transmitter function. The Main

light will start to flash rapidly.

c. Press one of the four (4) buttons on the transmitter

until the main light starts to flash rapidly, then release

transmitter button.

d. Press the remote control button again until the main

light stops flashing rapidly.

e. Release both buttons. The transmitter button is now

coded, press to test.

NOTE: Refer to the Light indicator table for the details

of the transmitter status.

MAIN LIGHT TRANSMITTER

STATUS

ON Button added

OFF Button removed

2 FLASHES, then OFF Remote control deleted

BUTTON

TRANSMITTER

FUNCTION

Open / Stop / Close

PET (Pedestrian) Mode

Open

Light

Vacation Mode

HOLD

HOLD

HOLD

HOLD HOLD

HOLD HOLD

Erasing All Transmitter Codes

a. Press the MODE button until the TRANSMIT LED is lit.

b. Press and hold the MODE button for 10 secs, let the MODE

button go when the main light stops flashing.

c. Follow steps a - e in Storing the Transmitter Code to code

new transmitters.

Vacation Mode

a. To turn on Vacation mode and lock out all remotes, press the

button on the remote programmed with Vacation Mode.

b. To turn off Vacation Mode, press the transmitter button

programmed to vacation mode to turn off.

4 FLASHES, then OFF Memory full

Installation of the Wall Mounted Transmitter

a. Store the transmitter code as per instructions

above. Test the transmitter button.

b. Mount the transmitter in a convenient location, yet

out of reach of children and at least 1.5m off the

ground.

c. Make sure the door is visible from this location.

Remotely Coding Transmitters

Using this method transmitters can be coded without access to

the opener’s control panel as long as a pre-coded transmitter is

available.

a. Take any pre-coded transmitter. Press the button for the

function to be duplicated and release.

b. Using a small needle / pen, press and hold firmly for two

seconds the middle button, through the Coding Hole.

c. Within ten (10) seconds take the additional transmitter you

wish to code. Hold the new transmitter’s button for two

seconds, pause for two seconds, hold again for two seconds

and then release.

d. Wait for ten (10) seconds and then press the new transmitter’s

button to test.

Page 12

ATS Series Instruction Manual12

15. Home Owner Safety Warnings!

This automatic garage door opener is designed and tested to offer safe service provided it is

installed and operated in strict accordance with the following safety warnings. Failure to comply

with the following instructions may result in death, serious personal injury or property damage.

Please read these important safety warnings!

DIY

WARNING!

ELECTROCUTION!

DO NOT DO IT

YOURSELF

• When operating the manual release while the door is open, the door may fall rapidly due to

weak or broken springs, or due to being improperly balanced.

• DO NOT disengage the opener to manual operation with children/persons or any objects

including motor vehicles within the doorway.

• If the door is closing and does not re-open when obstructed, discontinue use. DO NOT use a

door with faulty obstruction sensing.

• Place opener in protected area so that it does not get wet.

• DO NOT spray with water .

• DO NOT open the protective covers.

• DO NOT operate opener if cable is damaged.

• Keep the garage door balanced. Sticking or binding doors must be repaired. Garage doors,

door springs, brackets and their hardware are under extreme tension and can cause serious

personal injury. DO NOT attempt any garage door adjustment. DO NOT use if repair or

adjustment is needed. Call for a professional garage door service.

CAUTION:

Emergency access • If your garage has no pedestrian entrance door, an emergency access device should be

installed. This accessory allows manual operation of the garage door from outside in case of

power failure.

Entrapment under

operating door

Fall from Ladder • Ensure ladder is the correct type for the job.

Entanglement in or

laceration from

moving door

• Watch the moving door and keep people away until the door is completely opened or closed.

DO NOT operate door when persons are near the door.

• DO NOT allow children to play with door controls or transmitters.

• Regularly conduct Open and Close cycle testing.

• Ensure the garage door is in good working order by undertaking regular servicing.

• Wall transmitters should be installed in a location where the garage door is visible, but out of

the reach of children at a height of at least 1.5m.

• Install Safety Beams (recommended).

• Ensure ladder is on flat ground.

• Ensure user has 3 points of contact while on ladder.

• Keep hands and loose clothing clear of door and guides at all times.

• Keep hands clear of moving door as sharp edges can cause cuts or lacerations.

Page 13

16. Opener Safety & Security

13ATS Series Instruction Manual

Your Door CAN NOT be used by the opener when:

a. There is a locking device installed.

b. There is a power failure.

Your Door CAN be used when:

a. There is an emergency, by disengaging the opener.

b. There is a power failure, by disengaging the opener.

To Disengage the Opener:

a. It is recommended to do so with the door in the closed position.

b. Pull the manual release cord towards the door, until you hear a click.

c. Move the door manually.

CAUTION: When the opener is manually disengaged,

the door is no longer locked. To lock the door

manually, re-engage the opener after the door is

closed.

To Re-Engage the Opener:

a. Check the door has not been locked by a locking device.

b. Pull the manual release cord away from the door, until you hear a click.

c. The door will now operate from the opener.

CAUTION: Do not use the string handle as a

mechanism to open the door. Failure to comply may

cause serious injury.

WARNING! When operating the manual

release (while the door is open) the door

may fall rapidly due to weak or broken

springs, or due to being improperly

balanced.

Do not disengage the opener to manual

operation with children/persons or any

objects including motor vehicles within

the doorway.

17. Operating your Opener

To Operate the opener:

a. Press the programmed transmitter button until your

door begins to move (usually 2 seconds). Make sure

you can see the door when you use the transmitter.

b. If you are in a vehicle you should aim the transmitter

through your windscreen as shown.

c. Check that the door is fully open or closed before you

drive in or away.

d. If you press the transmitter whilst the door is moving

the door will stop. The next press of the transmitter

will move the door in the opposite direction.

Page 14

ATS Series Instruction Manual14

18. User Operating Controls

Button Function

1. DOWN ARROW (Blue) Closes the door

2. DOWN ARROW LED (Blue) Illuminates when the door is closed and flashes when the door is obstructed on close

or stopped.

3. STOP (Red) Stops the door

4. UP ARROW (Green) Opens the door

5. UP ARROW LED (Green) Illuminates when the door is open and flashes when the door is open with the autoclose timer running, obstructed on opening or stopped.

6. MODE (Yellow) Enables Load Diagnostics Mode

7. MODE STATUS LED (Yellow) Illuminates when in Diagnostics Mode

8. BATTERY STATUS LED (Yellow) Illuminates when battery is charged and flashes when battery is charging, in use or

battery failed. Battery function not available with ATS-2 model.

9. REMOTE CONTROL

STATUS LED (Red)

10. ADJUSTMENT LED (Yellow) Flashes a certain number of times depending on the parameter being changed.

11. NETWORK LED

(Not Available with ATS-2)

01

02

Flashes on remote lockout and flickers on remote control activity

03 04

05 06 07

08091011

Page 15

19. Specifications

Technical Specifications ATS-2

Rated voltage range: 230V - 240Va.c.

Rated frequency: 50Hz / 60Hz

Rated power input: 165W

15ATS Series Instruction Manual

Door opening:

Maximum Door Area:

Maximum Door Weight:

Door must be well balanced and able to be operated by hand, as per

warranty conditions and AS/NZS 4505:2012

Minimum headroom 57mm

Rated Operating Time 4 mins

Rated Temp +5

Short Term Peak force: 1100N

Rated load 400N

Nominal force 200N (20kg)

Receiver type Multi-frequency UHF FM

(433.47, 433.92 & 434.37MHz)

Receiver code storage capacity 64 X 4-button Transmitters

Transmitter battery CR2032 (3 Volts)

Main light LED (Light Emitting Diodes)

Network connectivity Network compatible,

(requires optional Smart Phone Control Kit)

2

18m

200kg*

o

C to +40oC

* Gross door weight, including all fittings

Note: Intermittent operations may occur in areas which experience very strong winds. The strong wind puts extra pressure on the

door and tracks which may in turn intermittently trigger the safety obstruction detection system.

Page 16

ATS Series Instruction Manual16

20. Troubleshooting

Symptom Possible cause Remedy

The opener does not

work from the transmitter

One transmitter works

but the other/s do not

The chain / belt moves

but the door remains

stationary

The transmitter range

varies or is restricted

Garage door in poor condition e.g.

springs may be broken

The opener does not have power

The battery in the transmitter is flat

The opener has turned on “Vacation

Mode”

The transmitter button is not

programmed to operate the door.

Faulty transmitter

Flat battery

The opener is disengaged Re-engage the opener

Variations are normal depending on

conditions e.g. temperature or external

interference

The battery life is exhausted

Position of the transmitter in the motor

vehicle

Check the door’s operation

Plug a device of similar voltage (e.g. a hair dryer)

into the power point and check that it is OK

Replace the battery

Turn off “Vacation Mode”

(Section 14)

Code in the transmitter

Replace transmitter

Replace battery

Make sure you can see the door when you use the

transmitter.

Check the battery status by pressing a button

(flashing or no light requires battery to be changed)

Aim the transmitter through the windscreen.

The Courtesy light does

not work

The door reverses for no

apparent reason

Auto Close not working Safety Beam or wiring faulty Repair Safety Beam or replace wiring.

The door stops or moves

very slowly under battery

(Optional Battery Back

Up Accessory)

The Main light is

repeatedly flashing OFF a

number of times followed

by a pause

The CLOSE (Blue) LED is

flashing

LED has failed Change LED.

This may occur occasionally from

environmental conditions such as areas

that are windy, dusty or have extreme

temperature changes.

If Safety beams are installed they may

be partially obstructed.

The batteries may have little OR no

charge

Generally the opener can still be used. The issue type is indicated by the number of

Limits are not set Set Up Limits (Section 11).

Ensure the door runs smoothly before increasing the

force pressure.

Ensure the beam path is not obstructed. Check the

Alignment.

Re-align optics. See Safety Beam instructions.

Connect mains power and leave the batteries to

charge. The batteries may take 24 to 48 hours to

reach their maximum charge capacity.

flashes shown.

Page 17

20. Troubleshooting

Main Light = Service / Warning Indicator:

Requirements for a service and user warnings are indicated after operation by the main light repeatable flashing OFF a

number of times followed by a pause. The below table identifys the issues and remedies.

Flashes Issue Remedy

1 Normal operation (door is fully open)

2 PE is preventing door from moving Clear away any obstructions. Test Door. If unable to move the

door and suspect beam is faulty, enter Safety Beam Emergency

Close by pressing and holding a pre-coded button on transmitter

for more than five seconds and the door will start closing.

3 NOT AVAILABLE

4 Wireless PE battery is low Change PE Battery

5 NOT AVAILABLE

6 Maintenance is due after pre-set number of cycles. Contact dealer to arrange service.

7 Standby battery is faulty Contact 1300 769 850 within Australia for assistance

8 Door was obstructed Clear away any obstructions and test door opens/closes

correctly. (If door is damaged, contact your door professional)

9 Motor overloaded or stalled Check the doors operation by disengaging the motor and

ensuring the door runs smoothly. If necessary make door

adjustments or contact your door professional.

10 Unit running on battery power Main light will flash (3) three times at the start of the cycle to

indicate opener is running from battery backup.

Check power supply.

17ATS Series Instruction Manual

If You Need a Service Call

If the opener needs a service please call the dealer who installed the garage door opener (their contact details are usually

on a sticker on the back of your garage door). For product assistance contact 13 62 63 within Australia.

BEFORE CALLING you should have the following information to assist in providing the appropriate service:

1. Has anything happened since the opener last operated OK, e.g. a storm, a jolt to the door etc.?

2. What is the current light status on the opener?

3. Manually disengage the door (Section 16).

How easy is it to manually open and close the door?

4. What model is the opener? (Model no. information is located at the rear of the opener)

5. Who installed the opener? (Dealer details should be on a sticker on the back of your garage door)

6. When was it installed? (If known)

Page 18

ATS Series Instruction Manual18

21. Maintenance

Door Maintenance

A poorly maintained door could cause fatal / serious injuries or damage

to property.

• Frequently examine the door, particularly the cables, springs and

mountings for signs of wear, damage or imbalance. DO NOT USE if

repair or adjustment is needed since a fault in the installation or an

incorrectly balanced door may cause injury.

• Fasteners: Check all screws, nuts and bolts to ensure they are secure.

• Spring Tension: It is natural for springs to lose tension. Should the

door become hard to operate or completely inoperative, contact a

door professional.

• Guide Tracks: Clean the internal sections of the guide tracks every

3 - 6 months with a cloth dampened with mineral turps or methylated

spirits.

WARNING! Failure to maintain your

garage door may void the warranty on

your garage door opener.

DO NOT DO IT YOURSELF:

DIY

Door adjustments should only be

carried out by experienced persons,

as this function can be dangerous if

not performed under strict safety

procedures.

Run the Safety Testing procedures

MONTHLY in Section 12 to ensure

tip

garage door is fit for use.

Page 19

19ATS Series Instruction Manual

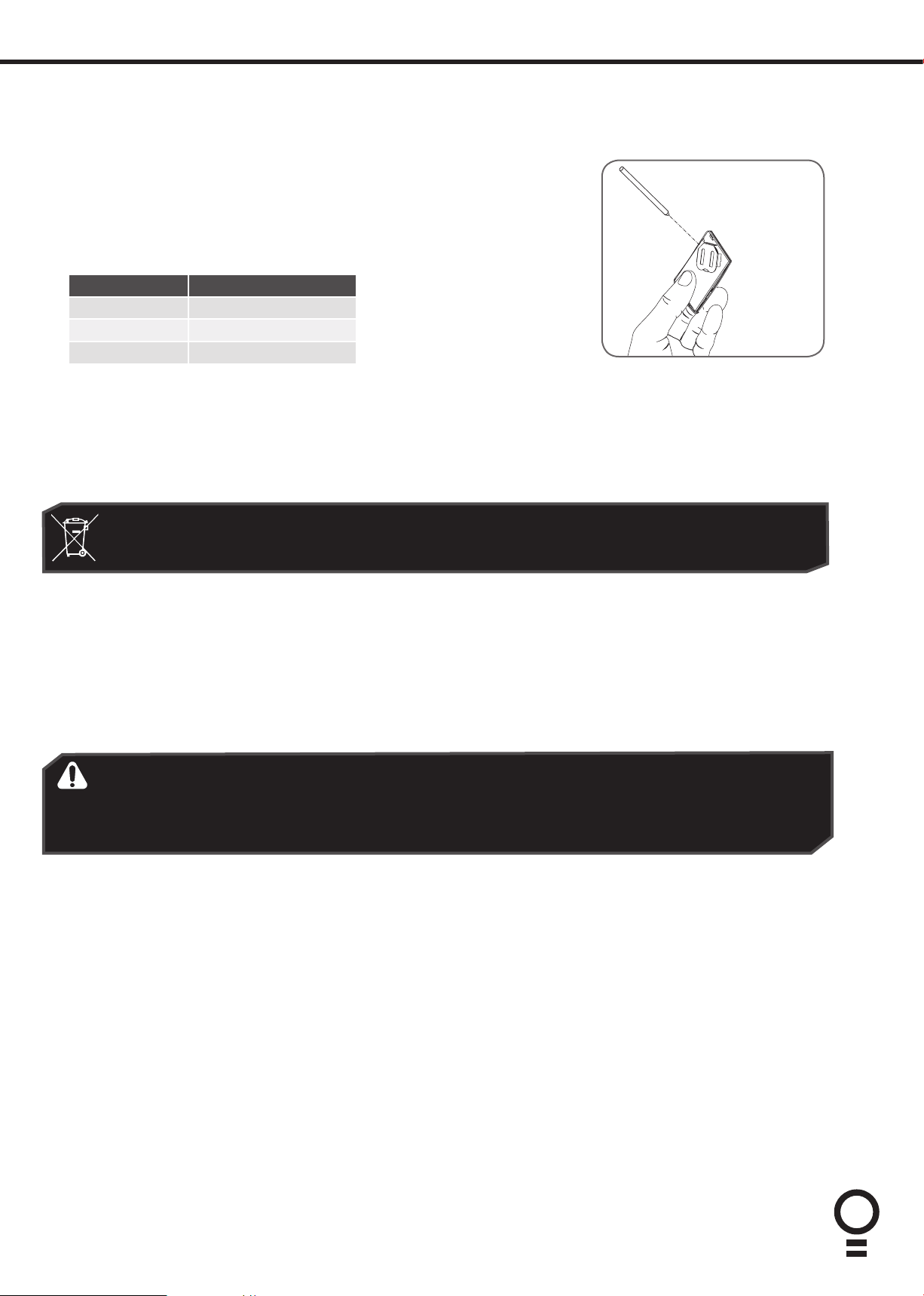

22. Battery Replacement

Battery Type:

3V Lithium Battery CR2032.

• To test the battery is working, press and

hold a transmitter button. Check Light

Status table to determine if battery needs

replacing

Light Status Battery Status

Solid OK

Flashing Requires replacement

No light Requires replacement

• Use finger nails to separate

the transmitter casing to

expose circuit board.

• Use a non-metallic object

(e.g. pen) to remove the

battery.

Use a pen

to push the

battery down

through the

side opening

to release

battery

23. Battery Disposal

When batteries reach the end of their usual life in accordance with Australian Battery Recycling Initiative please follow the next

simple steps for protecting the environment. Refer to the Automatic Technology website for information on where to recycle

batteries in Australia.

DO NOT throw the batteries in municipal waste. This symbol of the crossed out wheeled bin

indicates that the battery should not be placed in the municipal waste. Check your local regulations

for appropriate disposal of the batteries.

Recycling all batteries will have other environmental and social benefits:

• Some batteries are less toxic but hazardous for other

reasons. Lithium batteries can explode or catch fire in

landfill, while button cells are dangerous if swallowed

by children. Recycling offers a safe and environmentally

responsible solution for end of life batteries.

• Battery recycling recovers non-renewable materials such

as lead, cadmium, stella, zinc, manganese, cobalt, silver,

plastics and rare earth elements.

WARNING! Prior to disposal, recycling, or collection, all battery terminals must be securely

insulated with a non conductive material to prevent any two batteries from short circuiting

and generating heat during storage or transport. Battery terminals may be insulated with

electrical tape; or batteries may be individually packaged in a non conductive material

(e.g., plastic bag or original packaging).

• Removal of batteries and other hazardous household

products from household waste facilitates the recovery of

organic materials through alternative waste technologies

such as composting. Batteries and heavy metals are known

contaminants in compost.

• The community supports recycling because it reduces

waste to landfill and achieves environmental benefits.

Page 20

ATS Series Instruction Manual20

24. Appendix

A - Status Indication during Operating Mode.

LEDs Light Status Description

BLUE GREEN YELLOW RED PURPLE

DOOR OPEN

CLOSED 1 LEDS

MODE LED

BATTERY LED

2

AND

3

4

solid

flashing

flashing

solid

solid

flashing

flashing

flashing

solid

Open

Open with Autoclose timer running

Opening / Obstructed on Open

Closed

Closing / Obstructed on Close

Stopped

Partial Open

flashing Load Diagnostics mode

off

solid

flashing

rapid

flashing

Battery not used / not fitted

Battery charged

Battery charging, when connected

to power, without power battery

in use (holding STOP for 10s will

shutdown)

Battery failed

REMOTE CONTROL

STATUS LED

NETWORK LED

(not available on ATS-2

model)

5

6

02

06

flashing

flashing

01

rapid

Remote lockout

Remote Control Activity

03

04

05

Page 21

24. Appendix

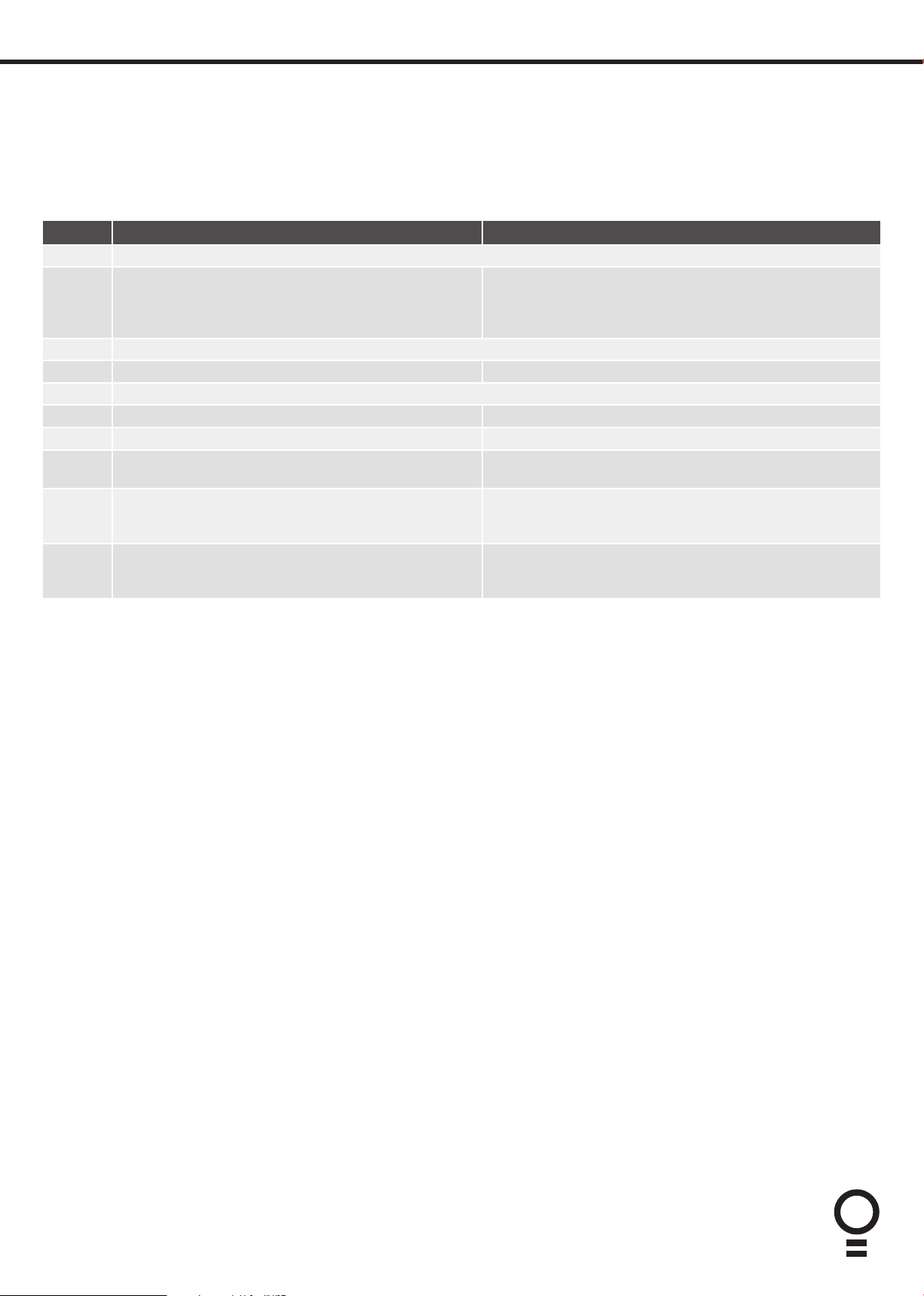

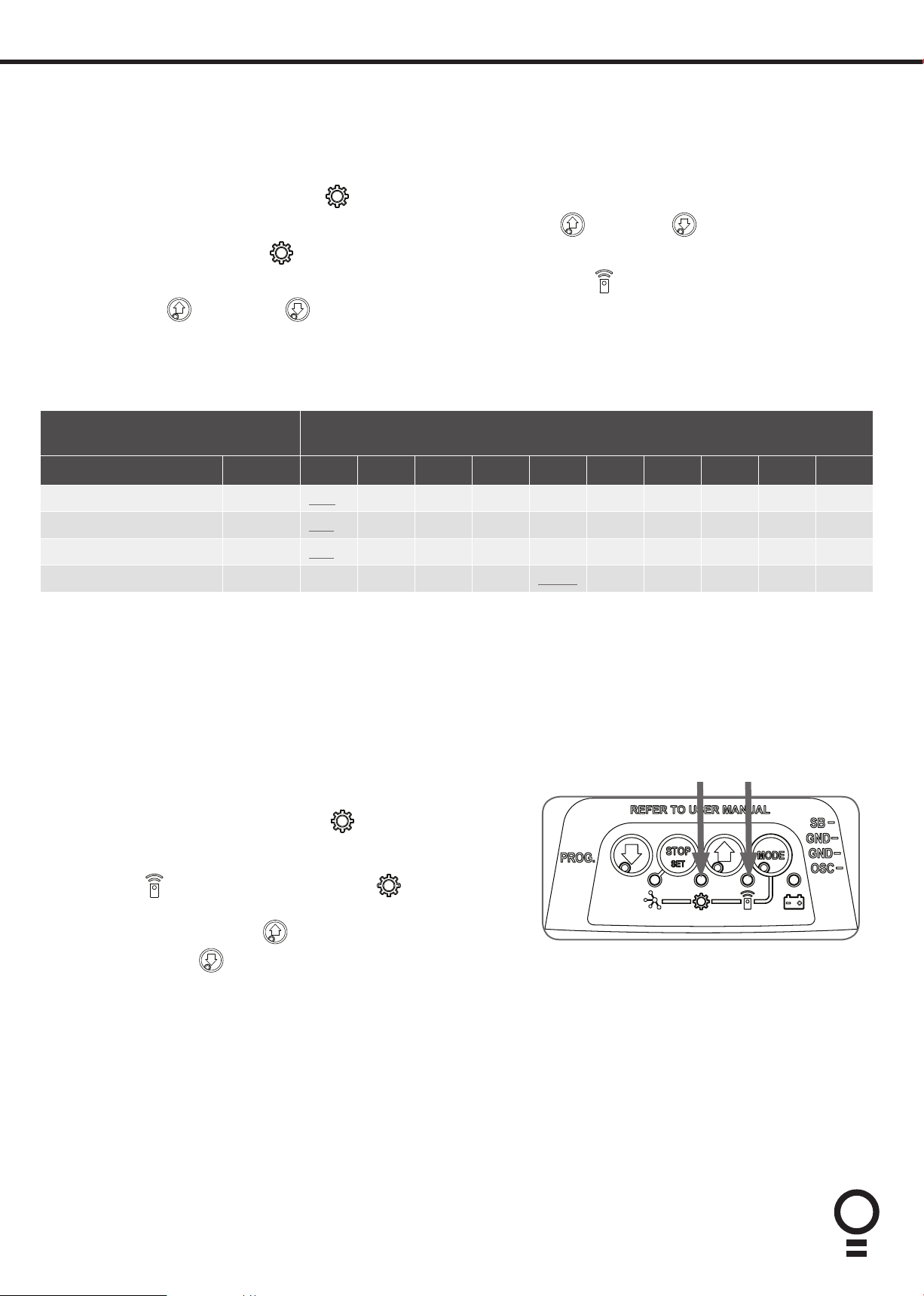

B - Adjustment Mode Instructions

a. Press the MODE button until the GEAR LED starts flashing

21ATS Series Instruction Manual

b. Referring to the table below, select the desired parameter using the OPEN

number of flashes on the GEAR

c. Press STOP / SET button to start editing the parameter’s value. The TRANSMIT

d. Use the OPEN

accordingly.

e. Press STOP / SET button to save the parameter’s new value or press MODE to leave the value unchanged.

f. Continue from a. above to select another parameter or press MODE to exit adjustment mode.

Parameter Value options = Indicated by brightness of main light

Name Flashes 1 2 3 4 5 6 7 8 9 10

MARGIN 1 0.7A 0.69A 1.2A 1.5A 2.0A - - - - -

PE AUTO-CLOSE 2

AUTO-CLOSE 3

LIGHT TIMER 4 30sec 60sec 90sec 120sec

and CLOSE buttons to step through the available options. The light’s brightness will change

LED. The selected parameter’s value is indicated by the main light’s brightness.

(DEFAULT parameter underlined)

OFF 15sec 30sec 60sec 90sec - - - - -

OFF 15sec 30sec 60sec 90sec 120sec - - - -

180sec 240sec - - - -

and CLOSE buttons and observing the

LED will turn on when editing is active.

C - Adjusting Force Margins

Adjusting Safety Obstruction Force

The Safety Obstruction Force is calculated automatically during

setup. Adjusting this is normally only necessitated by environmental

conditions such as windy or dusty areas, and areas with extreme

temperature changes.

To Increase / Decrease Force Pressure

a. Press the MODE button until the GEAR LED is flashing.

b. The LED will start flashing with one flash every second.

c. Press the STOP / STEP button and the MODE button LED and the

TRANSMIT

once every second.

d. By pressing the OPEN button

and CLOSE button

dim or brighten as the pressure is decreased or increased.

e. Press STOP / SET button to save the new value. (Refer to

Appendix B for margin settings)

f. Test the force again as per Testing Close Cycle and Testing Open

Cycle.

LED will be lit and the GEAR LED will flash

will increase the force pressure

will decrease the force - Main light will

D - Battery Functions

a. Holding the STOP button for 10secs when running from battery backup will shut the PCB down so as to reduce

battery current consumption to a minimum.

b. Holding the STOP button for 4secs when a battery is fitted and running from mains power will cause the controller

to test the battery state to determine if it is disconnected / open circuit, missing, faulty or ready.

Page 22

ATS Series Instruction Manual22

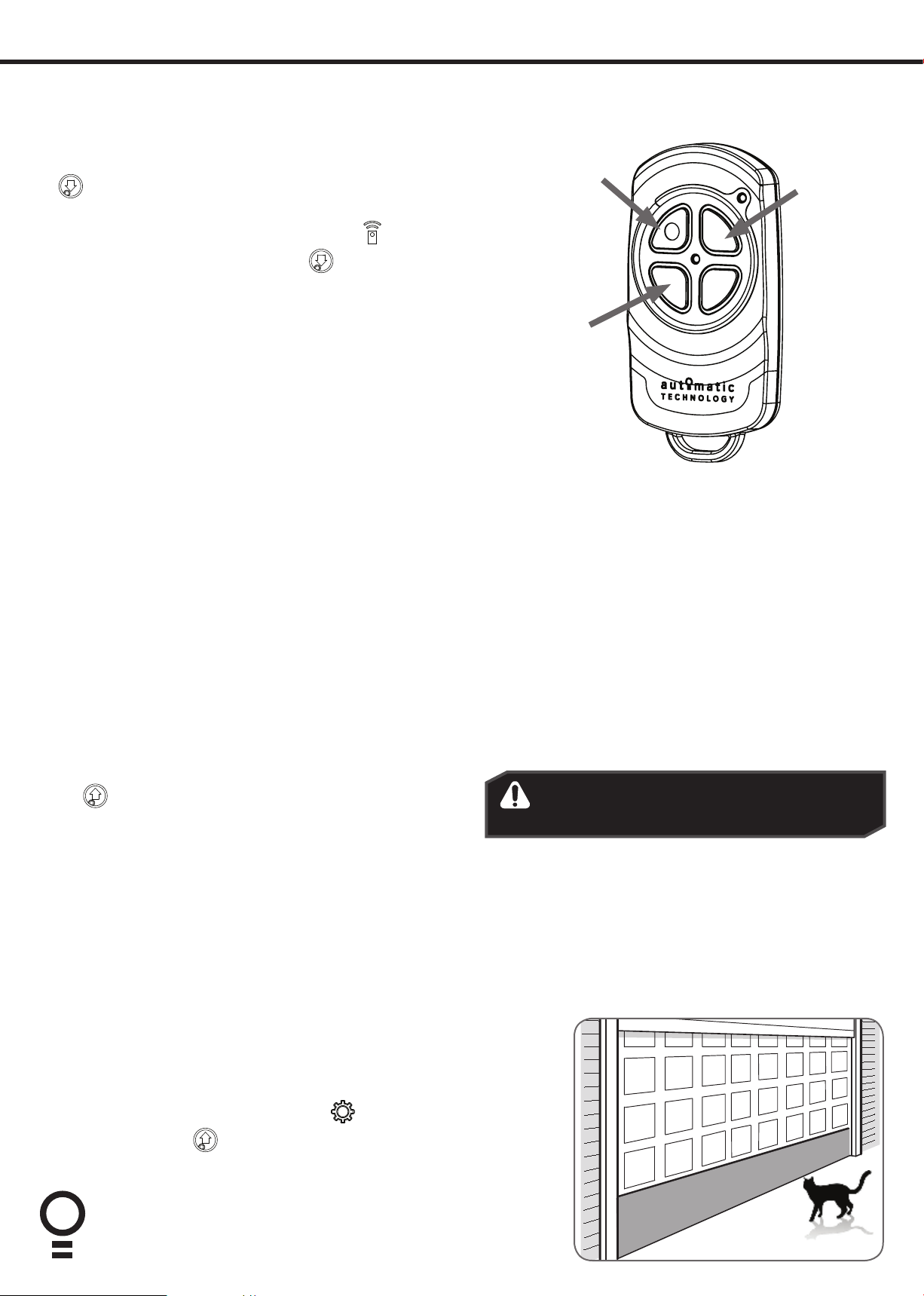

E - Setting limits via Transmitter

a. Switch power on and the BLUE LED on the CLOSE button

will start to flash to indicate that the opener is ready to

set the Close travel limit

b. Press the MODE button until the TRANSMIT

c. Press and HOLD the CLOSE button

Stop / Close function. The Main light will start to flash rapidly.

d. Press and hold button 1 on the transmitter, then release

transmitter button.

e. Press and hold button 1 on the remote control button again

until the main light stops flashing rapidly.

f. Release both buttons. The transmitter button is now coded,

press to test and observe the speed of the door through a

full cycle.

g. The drive speed is set to the fastest setting by default. This

may not be suitable for larger doors or for single piece doors:

CLOSE limit:

i. Using the programmed transmitter, press and hold the

button 4 to close. To inch the door, single presses of the

button 4 will move the door to desired limit.

ii. While inching (to CLOSE) to set the close speed, press

and hold button 4 on the remote and by pressing the

SET button 2 the opener will cycle through all three

speed modes as shown in table.

iii. Once at the desired speed, release the remote button 4.

iv. Continue inching the door to the desired position. We

recommend the CLOSE limit position being the first

point of contact of the rubber strip ( at the bottom of the

door) with the ground.

v. If the door overshoots, press the OPEN button 1 on the

remote to move the door in the OPEN direction.

vi. When the door is at the desired CLOSE position, press

the SET button 2, the GREEN LED on the OPEN button

will now flash.

to set the Open /

LED is lit.

Button 1

(inch Open)

Button 4

(inch Close)

OPEN limit:

i. Using the programmed transmitter, press and hold the

button 1 to open. To inch the door, single presses of

the button 1 will move the door to desired limit.

ii. While inching (to OPEN) to set the open speed, press

and hold button 1 on the remote and by pressing the

SET button 2 the opener will cycle through all three

speed modes as shown in table.

iii. Once at the desired speed, release the remote button

1.

iv. Continue inching the door to the desired position. We

recommend the OPEN limit position being the height

of the garage opening

v. If the door overshoots, press the CLOSE button 4 on

the remote to move the door in the CLOSE direction.

WARNING! The door will automatically close,

open and close again after the next step.

Ensure that nothing is in the door’s path.

Button 2

(Set)

vi. When the door is at the desired OPEN position, press

the SET button 2. The door will now automatically

close and open to calculate the safety obstruction

settings.

F - Setting the PET Mode position

When activated, PET mode drives the door to a preset position from the close

position, therefore allowing a pet or parcel to go under the door.

a. Drive and stop the door at the desired PET mode open position by pressing

the transmitter button coded for Open/Stop/Close operation.

b. Press the MODE button until the GEAR

c. Press OPEN button

OPEN and CLOSE LED will light up.

to save PET position - Main light will flash and both

LED is lit.

Page 23

25. Warranty

REGISTER ONLINE TODAY!

Register your Product to take advantage of convenient service and support at www.ata-aust.com.au/register

This Warranty is given by Automatic Technology (Australia) Pty Ltd (ABN 11 007 125 368) (ATA),

6-8 Fiveways Boulevard, Keysborough 3173, 1300 769 850, sales@ata-aust.com.au.

PLEASE NOTE:

• This Warranty is in addition to any statutory, non-excludable guarantees or warranty rights and remedies under the law. See section 5 below.

• This warranty applies to the original purchaser only and may not be transferred.

• This Warranty is to be read in conjunction with the owner’s copy of the installation instruction manual.

• In this warranty, ‘ATA Representative’ means an entity authorized by ATA to service ATA products. Please check the ATA website for details.

23ATS Series Instruction Manual

It is a condition of the below warranties that the

manual operating (opening and closing) force of the

door by hand does not exceed 20kg.

MODEL WARRANTY DOOR (MAX)

SECTIONAL

ATS-2 7 yrs / 20,000 cycles 200kg

GDO-9V2 7 yrs / 20,000 cycles 200kg

GDO-9V3 7 yrs / 20,000 cycles 175kg

GDO-11V3 5 yrs / 10,000 cycles 110kg

ROLLING

GDO-6V3 5 yrs / 10,000 cycles 110kg

GDO-6V4 7 yrs / 20,000 cycles 110kg

GDO-8V3 2 yrs / 5,000 cycles 100kg

GDO-10V3 2 yrs / 5,000 cycles 270kg

GDO-12V1 2 yrs / 10,000 cycles 270kg

EXTRAS

TRACK ASSEMBLY

1 year

(includes all parts)

TRANSMITTERS &

1 year

ACCESSORIES

NOTE: CONSUMABLES (eg Batteries in remote control transmitters and light bulbs

and fuses) are not covered by this warranty

1. MAKING A CLAIM

(a) The product parts in the above table should operate in accordance with the

product manual for the time period shown, provided you comply with the

manufacturer’s instructions concerning installation, operation, maintenance

and testing. Failure to do so may void all or part of this warranty.

(b) If, during the relevant warranty period, a product part in the table above

appears to contain a defect, call the retailer from whom you purchased the

product, or ATA on 03 9791 0240, and they will instruct you what to do next.

(c) You are responsible for the cost of making a claim under this Warranty.

Additional access expenses where the Product is not readily accessible must

be borne by you.

(d) If ATA or ATA’s Representative confirms the product is defective and covered

by this Warranty, ATA will repair or replace it (at ATA’s sole option) at no

cost to you. Goods presented for repair may be replaced or repaired by

refurbished goods or parts of the same type.

3. WARRANTY EXCLUSIONS

This warranty excludes defecrts or improper operation resulting from:

(a) excessive wear and tear that may cause the product to fail;

(b) accidental, deliberate or negligent damage or damage cause by nsects,

dirt, plants or other objects;

(c) blown fuses, electrical surges, power surges or power spikes or faulty or

unsuitable electrical wiring of structures to which the product is affixed;

(d) theft, fire, flood, rain, water, lightning, storms or any other acts of God;

(e) salt or other corrosion due to environmental conditions,

(f) any installation, configuration or use of the product contrary to the

instructions supplied with the product;

(g) maximum continuous operating time exceeding 1 minute in10 minutes;

(h) the manual operating (opening and closing) force of the door by hand

exceeding 20kg;

(i) weight exceeding amounts listed in table above;

(j) the door used with the product not being in safe working order and

condition;

(k) any modification to the product or acts of any person in respect of the

product which are not authorized by ATA; or

(l) radio or electrical interference or lack of availability of signal.

4. OTHER CONDITIONS

(a) This Warranty is not transferable.

(b) The warranty period stated in the table will not be extended for Products

or parts repaired or replaced during the relevant warranty period.

(c) Where the Product is sold by any person other than ATA, except for the

warranty set out above, such person has no authority from ATA to give

any warranty or guarantee on ATA’s behalf in addition to the warranty set

out above.

5. STATUTORY GUARANTEES OR WARRANTIES IN AUSTRALIA

If you are a consumer under the Australian Consumer Law, our goods come with

guarantees that cannot be excluded under the Australian Consumer Law. You are

entitled to a replacement or refund for a major failure and for compensation for

any other reasonably foreseeable loss or damage. You are also entitled to have the

goods repaired or replaced if the goods fail to be of acceptable quality and the

failure does not amount to a major failure.

This warranty certificate and other statements contained in this document or other

ATA documents given to you do not exclude, restrict or modify the application of all

or any of the provisions of the Australian Consumer Law.

Subject to your non-excludable rights under the Australian Consumer Law, ATA

expressly excludes any liability for consequential loss, incidental or indirect damages

(including but not limited to damages for loss of business profits, business interruption

and loss of business information) due to a defect of the Product. In particular, any

loss or damage caused to other equipment or accessories used with the product or

any loss resulting from a delay in repair is excluded to the extent permitted by law.

2. WARRANTY CONDITIONS

t is a condition of this warranty that:

(a) you provide a copy of the receipt of original purchase of the product, and

the serial number of the Product which can be found on the label adhered

to the Product.

(b) the door and opener are properly maintained by being serviced by a

qualified professional at regular, appropriate intervals. What is appropriate

may vary based on environmental factors (eg. weather, salt exposure) and

level of usage. Based on average use and environmental conditions, ATA

recommends that the product is serviced by ATA or an ATA Representative,

within 12 months of installation (to allow for new door to settle) and at

regular intervals not exceeding 2 years.

Page 24

Loading...

Loading...