Elite®

INSTALLATION INSTRUCTIONS | OWNERS COPY

Swing Gate Opener

Technical Document

Installation Manual

v

3.01

14 Dec 2011

English

Part # 13295 (Manual)

2

Elite® - Swing Gate Opener Owner Installation Instructions

WARNING: It is vital for the safety of persons to follow all

instructions. Failure to comply with the installation instructions

and the safety warnings may result in serious personal injury

and/or property and remote control opener damage. Please

save these instructions for future reference.

Automatic Technology Australia Pty Ltd to the extent that such may be lawfully excluded hereby expressly disclaims all

conditions or warranties, statutory or otherwise which may be implied by laws as conditions or warranties of purchase of

an Automatic Technology Australia Pty Ltd Elite® Swing Gate Opener. Automatic Technology Australia Pty Ltd hereby

further expressly excludes all or any liability for any injury, damage, cost, expense or claim whatsoever suffered by any

person as a result whether directly or indirectly from failure to install the Automatic Technology Australia Swing Gate

Opener in accordance with these installation instructions.

Owner Installation Instructions Elite® - Swing Gate Opener 3

Elite®

Swing Gate Opener

Important Safety Instructions 4

Features 6

Kit Contents 8

Drive Unit Installation 9

Installing Drive Unit Arms 11

Installing Minimum Sideroom Kit 12

Mounting Control Box 12

Five Wire Connection Single Leaf 14

Five Wire Connection Dual Leaf 15

Three Wire Connection Single Leaf 16

Three Wire Connection Dual Leaf 17

Control Board Layout 18

Menu Structure 20

Setting Travel Limits 21

Coding Transmitters 23

Standard Operating Modes 24

Control Board Adjustments 25

Menu 2 Current Trips 25

Menu 3 Auto-Close Times 26

Menu 4 Lock Times 27

Menu 5 Light Times 27

Menu 6 Motor Settings 27

Menu 7 Operating Modes 28

Diagnostic Tools 30

Menu 8.1 Test Inputs 30

Menu 8.2 Test Tx’ers 30

Menu 8.3 Display History 30

Menu 8.4 Memory Usage 30

Menu 8.5 Service Counter 31

Menu 8.6 Counters 31

Memory Tools 32

Menu 9.1 Clr Control 32

Menu 9.2 Clr Tx’ers 32

Setting Pedestrian Position 32

PE Beam installation 33

Accessories Installation 34

Battery Backup Installation 35

Troubleshooting Guide 36

Specifi cations 37

Spare Parts List 38

Warranty 40

4

Elite® - Swing Gate Opener Owner Installation Instructions

FOR ADDITIONAL SAFETY protection we strongly recommend the fi tting of a Photo

Electric (PE) Beam. In most countries, PE Beams are mandatory on all gates fi tted with

automatic openers. For a small additional outlay, Automatic Technology recommends

that Photo Electric Beams be installed with the automatic opener ensuring

additional safety and peace of mind.

DO NOT operate the gate opener unless the gate is in full view and free from objects such as

cars and children/people. Make sure that the gate has fi nished moving before entering or

leaving the driveway.

DO NOT operate the gate opener when children/people are near the gate. Children

must be supervised near the gate at all times when the gate opener is in use. Serious

personal injury and/or property damage can result from failure to follow this warning.

DO NOT allow children to operate the swing gate opener. Serious personal

injury and/or property damage can result from failure to follow this warning.

Make sure that the Safety Obstruction Force system is working correctly,

and is tested every month. Test as per the Installation Instructions Manual.

Adjust if necessary and recheck. Failure to follow this rule could result

in serious personal injury and/or property damage. This test must be

repeated at regular intervals and the necessary adjustments made as

required.

DO NOT disengage the swing gate opener to manual operation

with children/people or any other objects including motor

vehicles within the gateway.

If using a key switch, keypad or any device that can operate

the swing gate opener, make sure it is out of reach of

children and that the gateway is in full view at all times.

If the power supply cord is damaged, it must be

replaced by an Automatic Technology service agent

or suitably qualifi ed person.

Make sure that remote transmitters are kept out

of reach of children.

WARNING: It is vital for the safety of persons to follow all

instructions. Failure to comply with the following Safety

Instructions may result in serious personal injury and/or

property damage.

Important Safety Instructions

Owner Installation Instructions Elite® - Swing Gate Opener 5

The Elite® swing gate opener should not be immersed in water or sprayed directly by a hose or other water

carrying device.

The gate(s) must be well balanced and in good working order. Faulty gates must be repaired by a

qualifi ed technician prior to opener installation.

Remove or disengage all gate locks and mechanisms prior to installation of the opener.

Connect the gate opener to a properly earthed general purpose 240V mains power outlet

installed by a qualifi ed electrical contractor.

Disconnect the power cord from mains power before making any repairs or removing

covers. Only experienced service personnel should remove covers from the gate opener.

Keep hands and loose clothing clear of the gate and opener at all times.

When using Auto-Close mode, a Photo Electric Beam must be fi tted correctly and

tested for operation at regular intervals. Extreme caution is recommended when

using Auto-Close mode. All safety instructions above must be followed.

In order for the gate opener to sense an object obstructing the gateway,

some force must be exerted on the object. As a result the object, gate

and/or person may suffer damage or injury.

Make sure that the gate is fully open before driving into or out of

the driveway. Make sure the gate is fully closed before leaving the

driveway.

The gate opener is not intended for use by young children or

infi rm persons without adequate supervision. Children should

be supervised to ensure that they do not play with the

remote transmitters or the opener.

Frequently examine the installation and mountings for

signs of wear, damage or imbalance. DO NOT use if

repair or adjustment is needed since a fault in the

installation or an incorrectly balanced gate may

cause injury.

Important Safety Instructions

Please read this instruction manual fully before attempting

to install or use the opener. Failure to comply with the

installation instructions may result in serious injury and/or

property damage.

6

Elite® - Swing Gate Opener Owner Installation Instructions

Dual Leaf Gate

A dual leaf gate can be controlled with the addition of a second drive unit. Mains

power is only required for the control box and a 5-core low voltage cable for the

drive units.

Operation

To activate the gate simply press a button on the TrioCode® transmitter,

keypad or other optional control devices. During an open or close cycle, the

gate can be stopped by pressing the button whilst it is in motion. The next

actuation will move the gate in the opposite direction.

Operator Console

The DCB-05 gate controller features a LCD display operator console which

simplifi es installation, adjustments and status indication. Features include editing

transmitter storage and names, setting parameters, selecting specialised operating

modes and performing system diagnostics.

TrioCode™ Code Hopping Technology

Every time a TrioCode™ transmitter is used, a new security code is randomly generated

from over 4.29 billion possibilities. This greatly enhances the security of the system and

makes “code grabbing” a thing of the past.

These transmitters also overcome interference issues by simultaneously sending a signal over

three different frequencies. Even if two of the three signals are jammed, the system will still work.

Security Code Store

The Elite® Swing Gate Opener uses revolutionary technology to securely store up to fi ve hundred and

eleven (511) transmitters in its memory with the ability to assign an 11 character name to each.

Installation

The display console on the DCB-05 gate controller “holds your hand” through the installation and setup

process. Also, during installation a handheld transmitter can be used to set gate travel limits, allowing the

installer to closely monitor the gate’s position and stop points instead of having to be within arms reach of

the console.

Gate Sync Delay

If the gate leafs overlap, a delay can be used to start one leaf moving without interfering with the other.

Features

Thank you for purchasing the Elite® Swing Gate

Opener from Automatic Technology. Designed

for residential hinged swing gates by our world

renowned team of engineers, this unit will give

years of smart, simple and secure operation.

Listed below are some of its many features.

Owner Installation Instructions Elite® - Swing Gate Opener 7

ISS (Intelligent Safety System)

Should the gate hit an obstacle or be restricted in some manner, it will automatically reverse. The

amount of force the gate should encounter before reversing is automatically adjusted by the

control system during the initialisation of the automatic opener. The gate will also stop if

restricted whilst opening. The Safety Obstruction Force should be checked at least once a

month. See installation manual for instructions.

Status Indicator

The LCD console display screen indicates through text the status of the Elite®

Swing Gate Opener. When the MAIN SCREEN is displayed, the current position

of the gate or the result of the last movement can be viewed. The display also

shows the countdown timer for Auto-Close operations. Any active input will also

be displayed along with the state of various features such as periodic service,

battery backup operation and vacation mode.

Control of Lock and Lights

The incorporated controller has dedicated outputs for operating an electric

lock, warning or courtesy lights. The timing of these outputs can be adjusted

to suit your needs. In addition, a button on a remote transmitter can be

coded to operate the light output.

Extensive Operating Modes Via Control Inputs

The DCB-05 gate controller can be confi gured to operate in many

different ways via the seven (7) control and safety inputs which include

P.E, AUXILIARY OPEN, STOP, CLOSE, OSC, SWIPE and PEDESTRIAN.

Operating Modes Via Remote Controls

Operation is provided with each transmitter’s button being able to be confi gured

to operate one of OSC, PEDESTRIAN, SWIPE, CLOSE, OPEN, STOP, LIGHT or

VACATION functions.

The functionality of the transmitter is further enhanced by four (4) Auto-Close modes, three

(3) PE Beam response modes and two (2) pedestrian response modes.

SmartSolar™ and Battery Backup Compatibility (optional)

The Elite® swing gate opener can be fi tted with a SmartSolar™ or Battery Backup kit for operation in the event of

a power outage, or where mains power access is not available.

Pedestrian Mode

The gate can be programmed to open partially to allow pedestrian access. In a dual leaf gate, only one leaf

opens to allow pedestrians through without permitting vehicle access.

Manual Operation

The opener can be disengaged and the gate operated manually by opening the drive unit cover and

disengaging the gearbox. If power to the opener is disrupted for any reason, it can be disengaged. This will

allow you to manually open or close the gate.

8

Elite® - Swing Gate Opener Owner Installation Instructions

Kit Contents

01

02

03

04

09

07

05

ITEM DESCRIPTION QTY

1. Drive Unit 1

2. Drive Arm Extension 1

3. Slave Arm 1

4. Gate Mounting Bracket 1

5. Plastic Washer 4

6. Shoulder Screw 2

7. Hex Head Screw 2

8. Spring Washer 2

9. Flat Washer 2

10. Control Box 1

11. Control Box Mounting Bracket 4

12. PTX-5 Keyring Transmitter 2

08

06

10

11

12

01

fi g

Owner Installation Instructions Elite® - Swing Gate Opener 9

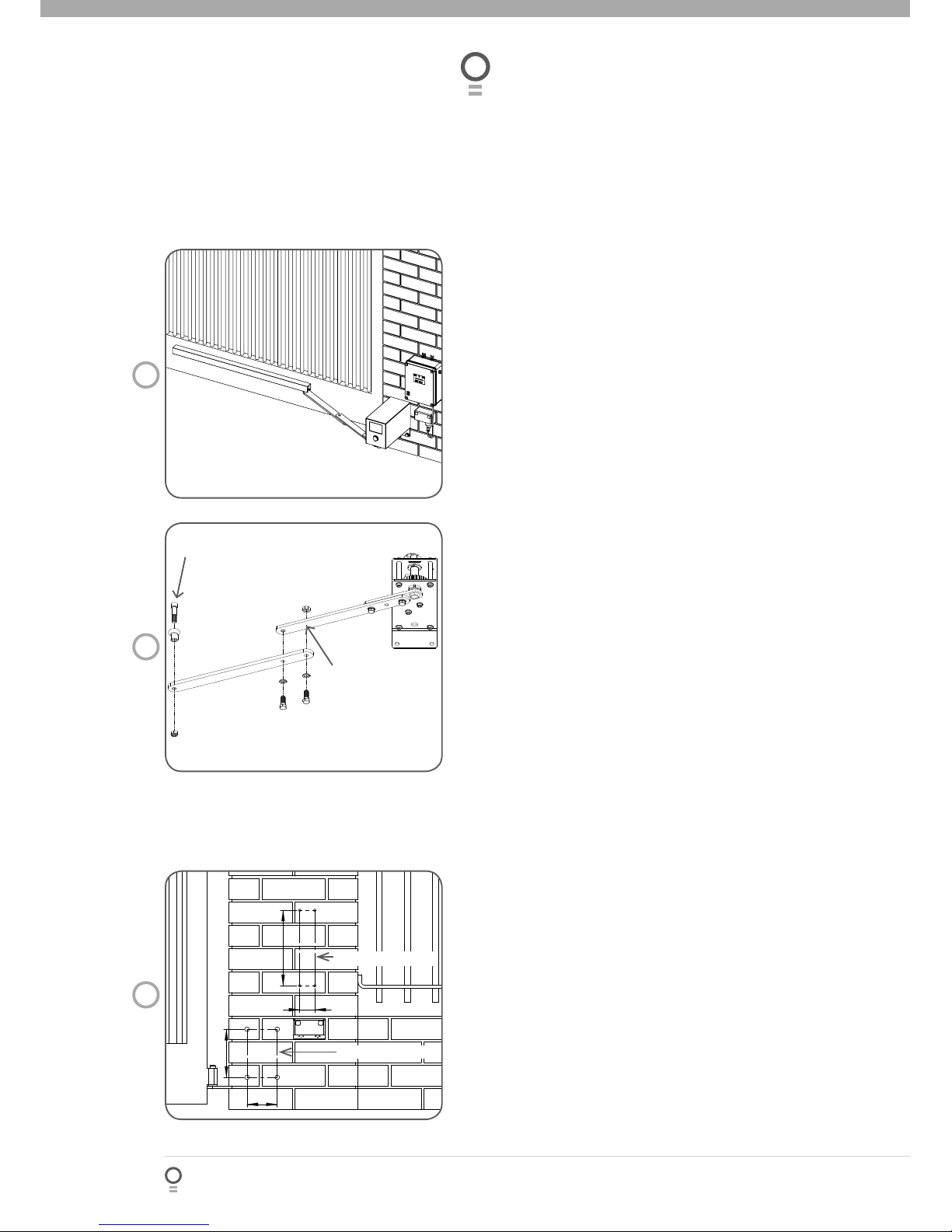

Drive Unit Installation

Mounting The Drive Unit

The Elite® swing gate opener is designed to operate

most residential swing gates. The gates must be in

good working condition and should operate by hand

relatively freely. Wind loading may affect the operation

of the opener in high wind areas. Correct obstruction

and reversing settings should be chosen for trouble

free operation.

Pre-installation Inspection

Before commencing installation, check the following:

The gate moves freely by hand for the full length of

open and close travel.

The pier or post for mounting must be of solid

construction (Brick, solid timber or steel). It must

bear most of the force applied by the drive unit.

A weatherproof 240V 10A general purpose power

point should be available within one metre of the

pier/post. If Elite® gate openers are required,

provision for underground cabling should be made

from one post to the other.

1.

2.

3.

02

fi g

Gate in open

position

Ensure sideroom clearance is adequate. Refer

to Table on page 10. If there is not enough

sideroom available, the Minimum Sideroom Kit

(Page 12) is required.

The mount distance of the Drive Unit should be

recorded. This value will be used later.

4.

5.

Mount

distance

Sideroom clearance

Hinge

distance

Wall/Pier

Fence

10

Elite® - Swing Gate Opener Owner Installation Instructions

04

fi g

05

fi g

Drive Unit Installation

Mount

Distance Hinge Distance

0 50 100 125 150 180 200 220 mm

Sideroom clearance

90 470 470 470 470 470 470 465 460 mm

120 450 470 480 470 465 460 435 425 mm

140 470 465 470 465 460 440 420 390 mm

200 470 465 445 430 400 350 390 250 mm

The mount distance for the drive unit and the hinge

distance for the gate can be selected to optimise the

sideroom clearance. See Fig. 03.

NOTE: If the gate is already installed, measure the

hinge distance and use this table to optimise the mount

distance.

Mount drive unit using four (4) 10mm loxins or

dynabolts.

Make sure that the Drive Unit is mounted at

an appropriate height from the ground - allow

minimum 35mm clearance for drive arm extension.

NOTE: If the gateway slopes away from pier/post, make

sure an allowance is made for clearance of the drive arm

extension and slave arm to not touch the ground.

Manual Operation

Disengage drive motor by pulling manual release pin up

using the release ring. While holding the ring, rotate the

motor assembly clockwise. (Fig. 04, 05 & 06)

To re-engage, pull pin and rotate motor assembly anticlockwise until manual release pin clicks into place.

1.

2.

Engaged

position

Disengaged

position

06

fi g

03

fi g

Owner Installation Instructions Elite® - Swing Gate Opener 11

Installing Drive Unit Arms

07

fi g

Gate in closed position

Drive unit

Wall/Pier

Slave Arm

Affi xing Arms And Brackets To Gate

Position gate in close position.

Attach drive arm extension to drive arm (fi xed to

the drive unit) (Fig. 07), using two (2) Hex Head

screws, spring and fl at washers supplied.

Attach slave arm to drive arm extension using

plastic washers and shoulder screw supplied. (See

Page 8).

Assemble Gate Mounting Bracket and Slave Arm

using shoulder screw and plastic washers. Do not

tighten yet.

Extend arms out straight and mark position where

the Gate Mounting Bracket touches the gate

(Fig. 07). From this mark, measure 10mm toward

Drive Unit and mark again. This is where the Gate

Mounting Bracket will be mounted.

Remove the Gate Mounting Bracket from the Slave

Arm and secure the Gate Mounting Bracket to the

gate at second mark.

Reassemble Slave Arm to Gate Mounting Bracket

using shoulder screw and plastic washers. Secure

fi rmly.

1.

2.

3.

4.

5.

6.

7.

Drive arm extension

Gate mounting bracket

12

Elite® - Swing Gate Opener Owner Installation Instructions

Mounting Control Box

Installing Minimum Sideroom Kit

Minimum Sideroom Kit

If you have limited sideroom, an optional minimum

sideroom kit reduces the gate opener’s required

sideroom to the width of the drive unit (135mm). (ATA

Order code 90182).

Fitting Minimum Sideroom Kit

Secure the extension arm from the Minimum

Sideroom Kit onto drive arm extension with supplied

M12 screws.

Drill Ø12 hole in the Drive Arm Extension (use hole

in extension arm as a guide).

Insert the other M12 screw and secure with spring

washer and nut. Check that the screws are tight

(Fig. 09)

Check that the Drive Unit is disengaged and the

gate is closed. Slide the Guide Track over the idler.

Locate Track on the gate and check travel of the

Arm. The idler should always be inside the Guide

Track in the closed and open positions (Fig. 08).

Secure the track to the gate (weld if possible).

NOTE: If a shorter arm is required, drill the drive arm

extension and extension arm where appropriate. You

should not have to cut the arms and you should still

be able to use pre-threaded hole in the drive arm

extension.

1.

2.

3.

4.

5.

110

175

55

275

Mounting Control Box

CAUTION: do not use any cables which carry green/

yellow wires as this signifi es earth, and do not comply

with electrical authority regulations.

The control box should be mounted near the drive

unit using four (4) 6mm screws.

Drill holes as per (Fig. 10). When locating the

control box, allow ample space around the unit for

easy access and wiring connections.

Remove cover from control box.

Determine which leaf you would like to open fi rst

and close last. This gate leaf must be connected to

Motor 1 (M1) terminals on the control board.

Connect drive unit(s) to control board using 5core or 3-core cable.Two diodes IN4001 per drive

unit must be used with 3-core cable instalation. For

detailed electrical connection see (Fig. 14 -21).

1.

2.

3.

4.

5.

Socket head screw M12 x 60

Idler

Nylock nut M12

Slave arm

Drive arm extension

Drill 12.5 mm

Shoulder screw

Control box mounting

Drive unit mounting

08

fi g

09

fi g

10

fi g

Owner Installation Instructions Elite® - Swing Gate Opener 13

Note: To determine left or right hand installation,

stand inside the driveway looking out to the street.

Antenna

Mount the antenna at or above the height of the gate

or fence for optimal reception, which ever is higher.

(Fig. 11). Do not cut antenna or coaxial cable.

Cams Setup

Setting of limits for open and closed position is

performed with opener in the manual position.

WARNING: do not switch power on or engage

motor drive.

For Right Hand Side Installation:

When gate is closed, turn lower cam in a clockwise

direction (Fig. 12 & 13) until an audible click can be

heard from the lower micro-switch. Open the gate to

the required opening position and turn top cam in an

anticlockwise direction until a click can be heard from

top micro-switch.

For Left Hand Side Installation:

When gate is closed turn lower cam in a anticlockwise

direction (Fig. 12 & 13) until an audible click can be

heard from the lower micro-switch. Open the gate

to the required opening position and turn top cam in

an clockwise direction until a click can be heard from

lower micro-switch.

Mounting Control Box

Top cam

Lower cam

Motor

Microswitch

11

fi g

12

fi g

13

fi g

Antenna

Top cam

Lower cam

14

Elite® - Swing Gate Opener Owner Installation Instructions

Five Wire Connection - Single Leaf

MOTOR 2 CONNECTOR 1

MOTOR 2 CONNECTOR 2

MOTOR 2 CLOSE LIMIT SWITCH INPUT

MOTOR 2 OPEN LIMIT SWITCH INPUT

COMMON FOR MOTOR 1 & 2 LIMIT SWITCHS

MOTOR 1 CLOSE LIMIT SWITCH INPUT

MOTOR 1 OPEN LIMIT SWITCH INPUT

MOTOR 1 CONNECTOR 1

MOTOR 1 CONNECTOR 2

24 VOLTS DC OUTPUT PLUS (+)

24 VOLTS DC OUTPUT MINUS (-)

MOTOR 2 CONNECTOR 1

MOTOR 2 CONNECTOR 2

MOTOR 2 CLOSE LIMIT SWITCH INPUT

MOTOR 2 OPEN LIMIT SWITCH INPUT

COMMON FOR MOTOR 1 & 2 LIMIT SWITCHS

MOTOR 1 CLOSE LIMIT SWITCH INPUT

MOTOR 1 OPEN LIMIT SWITCH INPUT

MOTOR 1 CONNECTOR 1

MOTOR 1 CONNECTOR 2

24 VOLTS DC OUTPUT PLUS (+)

24 VOLTS DC OUTPUT MINUS (-)

Orange

Red

White

Black

Blue

Orange

Red

White

Black

Blue

14

fi g

15

fi g

Drive unit installed on right hand side of the gate

Drive unit installed on left hand side of the gate

M1

M1

Owner Installation Instructions Elite® - Swing Gate Opener 15

M2

MOTOR 2 CONNECTOR 1

MOTOR 2 CONNECTOR 2

MOTOR 2 CLOSE LIMIT SWITCH INPUT

MOTOR 2 OPEN LIMIT SWITCH INPUT

COMMON FOR MOTOR 1 & 2 LIMIT SWITCHS

MOTOR 1 CLOSE LIMIT SWITCH INPUT

MOTOR 1 OPEN LIMIT SWITCH INPUT

MOTOR 1 CONNECTOR 1

MOTOR 1 CONNECTOR 2

24 VOLTS DC OUTPUT PLUS (+)

24 VOLTS DC OUTPUT MINUS (-)

MOTOR 2 CONNECTOR 1

MOTOR 2 CONNECTOR 2

MOTOR 2 CLOSE LIMIT SWITCH INPUT

MOTOR 2 OPEN LIMIT SWITCH INPUT

COMMON FOR MOTOR 1 & 2 LIMIT SWITCHS

MOTOR 1 CLOSE LIMIT SWITCH INPUT

MOTOR 1 OPEN LIMIT SWITCH INPUT

MOTOR 1 CONNECTOR 1

MOTOR 1 CONNECTOR 2

24 VOLTS DC OUTPUT PLUS (+)

24 VOLTS DC OUTPUT MINUS (-)

M1

M1

M2

Orange

Red

White

Black

Blue

Orange

Red

White

Black

Blue

Orange

Red

White

Black

Blue

Orange

Red

White

Black

Blue

16

fi g

17

fi g

Left hand leaf opens fi rst and close last

Right hand leaf opens fi rst and close last

Five Wire Connection - Dual Leaf

16

Elite® - Swing Gate Opener Owner Installation Instructions

Three Wire Connection - Single Leaf

MOTOR 2 CONNECTOR 1

MOTOR 2 CONNECTOR 2

MOTOR 2 CLOSE LIMIT SWITCH INPUT

MOTOR 2 OPEN LIMIT SWITCH INPUT

COMMON FOR MOTOR 1 & 2 LIMIT SWITCHS

MOTOR 1 CLOSE LIMIT SWITCH INPUT

MOTOR 1 OPEN LIMIT SWITCH INPUT

MOTOR 1 CONNECTOR 1

MOTOR 1 CONNECTOR 2

24 VOLTS DC OUTPUT PLUS (+)

24 VOLTS DC OUTPUT MINUS (-)

MOTOR 2 CONNECTOR 1

MOTOR 2 CONNECTOR 2

MOTOR 2 CLOSE LIMIT SWITCH INPUT

MOTOR 2 OPEN LIMIT SWITCH INPUT

COMMON FOR MOTOR 1 & 2 LIMIT SWITCHS

MOTOR 1 CLOSE LIMIT SWITCH INPUT

MOTOR 1 OPEN LIMIT SWITCH INPUT

MOTOR 1 CONNECTOR 1

MOTOR 1 CONNECTOR 2

24 VOLTS DC OUTPUT PLUS (+)

24 VOLTS DC OUTPUT MINUS (-)

White

Black

Blue

18

fi g

19

fi g

M1

M1

White

Blue

Black

Drive unit installed on right hand side of the

gate.

One diode IN4001 is connected between

1 and 4. The second diode IN4001 is connected

between 2 and 5 on the drive unit terminal.

Drive unit installed on right hand side of the

gate .

One diode IN4001 is connected between

1 and 4. The second diode IN4001 is

connected between 2 and 5 on the drive unit

terminal.

Owner Installation Instructions Elite® - Swing Gate Opener 17

M2

MOTOR 2 CONNECTOR 1

MOTOR 2 CONNECTOR 2

MOTOR 2 CLOSE LIMIT SWITCH INPUT

MOTOR 2 OPEN LIMIT SWITCH INPUT

COMMON FOR MOTOR 1 & 2 LIMIT SWITCHS

MOTOR 1 CLOSE LIMIT SWITCH INPUT

MOTOR 1 OPEN LIMIT SWITCH INPUT

MOTOR 1 CONNECTOR 1

MOTOR 1 CONNECTOR 2

24 VOLTS DC OUTPUT PLUS (+)

24 VOLTS DC OUTPUT MINUS (-)

MOTOR 2 CONNECTOR 1

MOTOR 2 CONNECTOR 2

MOTOR 2 CLOSE LIMIT SWITCH INPUT

MOTOR 2 OPEN LIMIT SWITCH INPUT

COMMON FOR MOTOR 1 & 2 LIMIT SWITCHS

MOTOR 1 CLOSE LIMIT SWITCH INPUT

MOTOR 1 OPEN LIMIT SWITCH INPUT

MOTOR 1 CONNECTOR 1

MOTOR 1 CONNECTOR 2

24 VOLTS DC OUTPUT PLUS (+)

24 VOLTS DC OUTPUT MINUS (-)

M1

M1

M2

White

Black

Blue

White

Black

Blue

White

Black

Blue

White

Black

Blue

20

fi g

21

fi g

Right hand leaf opens fi rst and close last.

One diode IN4001 is connected between

1 and 4. The second diode IN4001 is connected

between 2 and 5 on the drive unit terminal for

each motor.

Three Wire Connection - Dual Leaf

Left hand leaf opens fi rst and close last.

One diode IN4001 is connected between

1 and 4. The second diode IN4001 is connected

between 2 and 5 on the drive unit terminal for

each motor.

18

Elite® - Swing Gate Opener Owner Installation Instructions

03

02

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

29

01

PE V+ is used to power photo electric beam.

PE In for photo electric beam for safety

PE (v-) is used to supply (-) volt to photo

electric beam.

Aux control input

OPN Programmable N/O or N/C input terminal

STP Programmable N/O or N/C input terminal

CLS N/O input terminal

OSC N/O input terminal

SWP N/O input terminal

PED N/O input terminal

COM terminal for input terminals 1 to 8

OUTPUT 2 (optional relay module coil drive)

OUTPUT 2 (optional relay module coil drive)

OUTPUT 1 N/C relay contact

OUTPUT 1 COM relay contact

OUTPUT 1 N/O relay contact

MOTOR 2 terminal 1

MOTOR 2 terminal 2

MOTOR 2 close limit switch input terminal

MOTOR 2 open limit switch input terminal

COM terminal for Terminals 16,17,19 & 20.

MOTOR 1 close limit switch input terminal

MOTOR 1 open limit switch input terminal

MOTOR 1 terminal 1

MOTOR 1 terminal 2

24VDC (+) output for powering accessories

24VDC (-) output for powering accessories

Standby battery / solar charger connector

24VAC power input (from transformer)

10 amp fuse

Programmer Input

Console keypad

Console display (LCD)

Antenna connector

28

30

31

32

33

34

Control Board Layout

Owner Installation Instructions Elite® - Swing Gate Opener 19

Control Board Layout

01

02

22

fi g

03

04

05

06

07

08

09

10

11

12

13

14

15

17

19

21

23

25

27

16

18

20

22

24

26

28

29

30

31

32

33

34

20

Elite® - Swing Gate Opener Owner Installation Instructions

Menu Structure

Menu 8

Diagnostics

Menu 9

Memory tools

Menu 10

Travel limits

Menu 1

Code

transmitter

Menu 2

Current Trips

Menu 3

Auto-close

times

Main Screen

Gate status &

information

Menu 10.1

Set gate

travel

Menu 10.2

Set pedestrian

Code

transmitter

procedure.

See page 23

Parameter list

1. M1 margin

2. M2 margin

3. Settle time

See page 25

Parameter list

1. STD Auto Close

2. PE Auto Close

3. Pedestrian Auto

Close

4. PE Ped’n

Auto Close

See page 26

Travel limit set

up procedure.

See page 21-22

Pedestrian

position set up

procedure.

See page 32

Menu 9.1

CLR control?

Menu 9.2

CLR Tx’ers?

Memory reset operations see page 32

Menu 8.1

Test inputs

Menu 8.2

Test tx’ers

Menu 8.3

Display history

Menu 8.5

Service counter

Menu 8.6

Counters

Menu 8.4

Memory Usage

Control input

status display.

See page 30

Transmitter

testing

See page 30

Event history

display

See page 30

Periodic service

cycle counter

See page 31

Cycle and

event counter

See page 31

Memory usage

See page 30

Parameter list

1. On after

cycle time

2. On before

opn time

3. On before

cls time

See page 27

Parameter list

1. Sync delays

3.Full speed voltage

5.Slow speed voltage

6. Slow time

7.Homing/Setup

speed (voltage)

8.Stop pause

time ... etc

see page 27

Parameter list

1. PE input

response

2. Ped input

response

3. Remote code

enable

4. Activity report

ETC

See page 28

Parameter list

1. Open lock time

2. Close lock time

3. Pre-opn lock

time

4. Pre-cls lock

time.

See page 27

NOTES

1. Press PREV/NEXT buttons move to Left/Right.

2. Press OPEN/CLOSE buttons to change setting.

3. Press SET button to save changes.

4. Press EXIT to return to MENU without saving changes.

Note: System will automatically return to the main screen

after 30 secs if a menu screen is displayed and no buttons

are pressed.

Menu 5

Light times

Menu 6

Motor settings

Menu 7

Operating

Modes

Menu 4

Lock times

Owner Installation Instructions Elite® - Swing Gate Opener 21

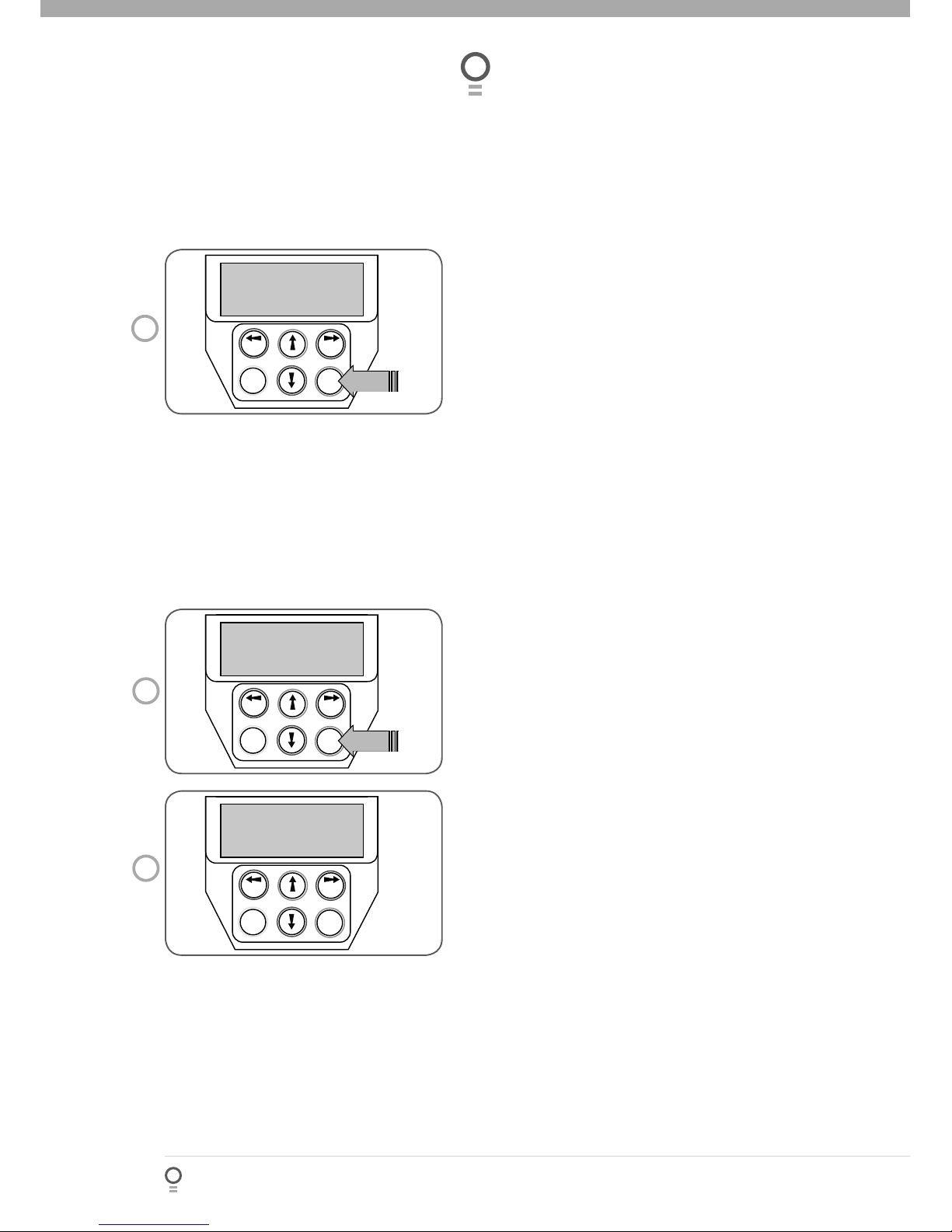

PLEASE NOTE - Before plugging the gate

control system in, check the power cord

for damage and ensure it cannot become

entangled in any moving parts

WARNING: make sure the obstruction sensitivity

is adjusted correctly on installation so that

the gate(s) reverse to the open position when

obstructed with minimum pressure and stops on

opening cycle when obstructed with minimum

pressure. Failure to comply with the set up

procedure may result in serious personal injury

and/or property damage.

Connect the fi ve/three core cable from the control

box to the drive unit(s).

Fully open the gate and engage the motor

assembly.

After checking the initial wiring, apply power to the

DCB-05. The controller will go through a startup

sequence displaying the STARTUP SCREEN which

indicates the controller type and fi rmware version

Fig. 23.

After a short delay the MAIN SCREEN will be

displayed. If this is the fi rst time the DCB-05 has

been used, the MAIN SCREEN should indicate that

the limits are not set Fig. 24.

If the display shows that some input is active, rectify

the situation before proceeding. If a default setting

is to be changed, it should be done now before

setting the travel limits.

Step 1. Navigating To “Limit/Amp Travel

Menu”

To navigate to Menu 10.1 from the main screen, simply

scroll to the left using the PREV button to access MENU

10, followed by SET to display MENU 10.1 (Fig. 25).

Press SET again to start the limit setting procedure.

Step 2. Confi rming Ready To Start

DCB-05 will prompt you to confi rm that the motor wiring

is complete (Fig. 26) and that the gate(s) are in a fully

open position and engaged. Press SET to confi rm (Fig.

27).

1.

2.

3.

23

fi g

24

fi g

A.T.A DCB-05

FIRMWARE #.##

PREV NEXT

EXIT

SET

Limits Not Set!

Press <> To Acess MENU

PREV NEXT

EXIT

SET

Setting Travel Limits

MENU 10.1

LIMIT/AMP Travel

PREV NEXT

EXIT

SET

Motor Wiring

Completed?

PREV NEXT

EXIT

SET

25

fi g

26

fi g

Fully Open Gate

Engage Mtrs, SET

PREV NEXT

EXIT

SET

27

fi g

22

Elite® - Swing Gate Opener Owner Installation Instructions

Step 3. Confi rming Correct Wiring Detected

DCB-05 will now automatically detect the type of drive

unit used by the number of wires used. If the correct

number of wires is displayed (Fig. 28) then press SET to

continue. Otherwise press EXIT and check the wiring.

Step 4. Confi rming Motors Detected

DCB-05 will now automatically detect if one or two

motor are connected. If the correct number is displayed,

then press SET to confi rm. Otherwise press EXIT and

check the wiring (Fig. 29).

Step 5. Adjusting Close Limit(s)

DCB-05 will now prompt one at a time for the motor(s)

to be driven to the desired close limit and for the limit

switches to be adjusted so that the motor stops at the

desired position (Fig. 30).

The motor can be driven using the UP and DOWN

buttons on the console keypad or Button 1 and 4 of a

transmitter. In the limits setup mode, the display will

show the percentage of the power used to move the

gate (Fig. 31).

After making adjustments to the limit switch positions

always re-approach the limit at full speed by driving the

motor open a short distance and then driving it close

again. When the close limit has been adjusted, press

SET to continue.

Note: If the motor drives in the wrong direction (UP

closes gate / DOWN opens gate), the motor wires need

to be swapped.

Step 6. Adjusting Open Limit(s)

DCB-05 will now prompt for the motor(s) to be driven

to the desired open limit and for the limit switches to be

adjusted so that the motor stops at the desired position.

The motor can be driven using the UP and DOWN

buttons on the console keypad or Button 1 and 4 of a

transmitter. In the limits setup mode, the display will

show the percentage of the power used to move the

gate.

After making adjustments to the limit switch positions

always re-approach the limit at full speed by driving the

motor close a short distance and then driving it open

again. When the open limit has been adjusted, press

SET.

Step 7. Automatic Profi ling

After a brief pause, DCB-05 will automatically close and

open gate several times and learn the gates load and

travel characteristics. When the setup is complete, the

MAIN SCREEN will be displayed “Gate is closed”. The

gate can now be used.

29

fi g

28

fi g

Motor=5 Wire

PREV NEXT

EXIT

SET

Press Set If OK

PRESS

M1&2 Detected

PREV NEXT

EXIT

SET

Press Set If OK

PRESS

30

fi g

Confi rming Detected Motor Wiring

Confi rming Detected Motor Wiring

PREV NEXT

EXIT

SET

Press SET

DRIVE M2 CLOSE

OR

PRESS

PRESS

Adjusting The CLOSE LIMIT

31

fi g

PREV NEXT

EXIT

SET

10%

DRIVE M2 CLOSE

PRESS

OR

PRESS

Setting Travel Limits (Cont.)

Owner Installation Instructions Elite® - Swing Gate Opener 23

Coding Transmitters

DCB-05 can store up to fi ve hundred and eleven (511)

transmitters in its memory. Each transmitter can be

allocated an alpha-numeric ID label up to eleven (11)

characters in length. Each button can be assigned to

one of several control functions.

The settings for a transmitter are represented in Fig.

32. It shows the transmitter’s store number, ID label or

serial number and the functions assigned to each of its

four buttons.

To toggle between ID/SN display, press UP/DOWN

with the cursor on the ID/SN indicator.

BRAND OF TRANSMITTERS

First memory location sets the type of transmitters

which can be stored into the memory of the receiver.

It either can be ATA Trio C ode™ or B &D Tri-Tran™

transmitters.

For example, if the fi rst transmitter stored is

Trio Code™ then rest of transmitters can only be the

TrioCode™ type and mixing of TrioCode™ ,Tri-Tran™

is not possible.

Deleting all stored transmitter codes from the

receivers memory will allow you to choose either

Trio C ode™ or Tr i -Tr an™ trans m it ters ag ain.

Coding Transmitter Buttons

Step 1. Navigating to “code transmitter”

menu

Press NEXT to navigate to the Menu 1 (Fig. 33).

Press SET to enter code set procedure.

Step 2. Storing transmitter code

DCB-05 will prompt to press one of the transmitter’s

buttons.

Press the transmitter button you wish to use to

operate the Gate Opener (e.g. button 1) (Fig. 34).

Press same transmitter button again as prompted by

display (Fig. 35).

Step 3. Selecting function of the button

DCB-05 will now show the transmitter’s record, with

a cursor on the fi eld for the button being coded (Fig.

36). Use UP/DOWN to select the function for the

button.

Available functions:

VAC (Vacation Mode) LGT (Courtesy Light)

STP (Stop) OPN (Open)

CLS (Close) SWP (Swipe)

PED (Pedestrian access) OSC (Open/Stop/Close)

OFF (No action)

Press SET to save the settings (Fig. 37) or EXIT to

abort without saving. Press EXIT to return to the MAIN

SCREEN and test the transmitter.

1.

2.

1.

2.

3.

)$.AME3.

/3#0%$,'46!#

34

fi g

MENU 1

PREV NEXT

EXIT

SET

Code Transmitter

PRESS

35

fi g

36

fi g

37

fi g

PREV NEXT

EXIT

SET

OSC OFF OFF OFF

# 1[No Name]

PRESS

OSC

PREV NEXT

EXIT

SET

OSC OFF OFF OFF

# 1[No Name]

PRESS

PRESS

C

PREV NEXT

EXIT

SET

Again! View>

Press Tx’er

PRESS

33

fi g

PREV NEXT

EXIT

SET

Button! LIST>

Press Tx’er

PRESS

32

fi g

I.D label/Serial number

Button 4 function

Button 3 functionButton 2 function

Button 1 function

Store number

ID/SN display indicator

24

Elite® - Swing Gate Opener Owner Installation Instructions

This section describes the standard operation of DCB-05 with the factory set default values.

Motor Control.

DCB-05 drives the motor in the appropriate direction as instructed by the control inputs. Once a cycle is

started, the motor will continue to travel until:

DCB-05 is instructed to stop by a control input.

The motor’s travel limit is reached.

The motor is obstructed, overloaded or stalls

When the control inputs instruct DCB-05 to change the motor direction, DCB-05 brakes the motor, waits for

the motor to stop and then starts the motor in the other direction.

Motor Obstruction Detection

If a motor is obstructed while opening, the motor is stopped. If the motor is obstructed while closing, the

motor is stopped and then reversed to the open position. Obstruction detection is achieved by monitoring the

motor’s current and comparing it to the “normal” current profi le for the motor.

If the current of the motor rises above the “normal” MARGIN AMP setting, then the motor is said to be

obstructed. In addition to the normal motor obstruction detection, motor overload and stall detection is

provided to protect the gate opener and DCB-05.

Motor Speed Control

The motor’s speed is controlled by varying the voltage applied to the motor. When the motor is started, the

voltage is increased to the OPEN or CLOSE Speed Voltage parameter. When the limit switch of a drive unit is

activated, the motor is slowed so as to come to a gentle stop.

Lock Release Output

The lock release output is confi gured to pulse for 0.5 seconds at the start of each cycle. The output is turned on

at the same time the motors are started. The output is provided on OUTPUT1.

Courtesy Light

The courtesy light is normally used to illuminate the driveway. The light will be turned on each time the gate is

activated (day or night) and automatically turned off 1 minute after the drive cycle has fi nished.

The light can also be activated and deactivated by pressing a transmitter button assigned the LGT function. The

light output is provided on OUTPUT2 (requires additional light relay module RO-1).

Open / Stop / Close (Osc) Input

(Activated by OSC terminal with N/O switch or by transmitter button with OSC function assigned)

If the gate is stopped, the OSC input will cause the gate to move in the opposite direction to that last travelled. If

the gate is moving, the OSC input will cause the gate to stop.

Pedestrian Access (Ped) Function

(Activated by PED terminal with N/O switch or by transmitter button with PED Function assigned)

The pedestrian access operation partly opens the gate to allow pedestrian access but prevent vehicle access.

The position is automatically set to fi ve (5) seconds from the fully closed position during setting of the travel

limits, but can be manually adjusted.

Pedestrian access mode is entered when the input is activated and the gate is in the closed position. If the

gate is not in the pedestrian access mode, the PED input will stop the gates if moving, or close the gates, if

stopped.

While in pedestrian access mode, the pedestrian access position temporarily becomes the open limit for the

gate leaf. The PED input then acts with an OSC type function. The pedestrian access mode is exited when the

gate is closed or when another input is activated.

1.

2.

3.

Standard Operation Modes

Owner Installation Instructions Elite® - Swing Gate Opener 25

Close (Cls) Input

(Activated by CLS terminal with N/O switch, by transmitter button with CLS function assigned or by the DOWN

button on the console.) Activating the CLS input will cause the gate to close. Holding the input active will

prevent opening.

Swipe (Swp) Input

(Activated by SWP terminal with N/O switch or by transmitter button with SWP function assigned)

Activating the the SWP input will cause the gate to be opened. If the terminal input is held, it will prevent the

gate being closed. The swipe input also effects P.E TRIGGERED AUTO CLOSE.

Open (Opn) Input

(Activated by OPN terminal with N/O switch, by transmitter button with OPN function assigned or by console’s

UP button) Activating the OPN input will cause the gate to open. Holding the input will prevent closing.

Stop (Stp) Input

(Activated by STP terminal with N/O switch, by transmitter button with STP function assigned or by console’s

EXIT button) Activating the STP input while the gate is moving will cause the gate to be stopped. If the STP

terminal is held, it will prevent the gate from being moved.

Photo Electric Safety Beam (PE) Input

When the PE input is active, the gate is prevented from being closed. If the PE input is triggered while the gate

is closing, DCB-05 will stop the motors and then open the gate. The PE input has no effect while the gate is

opening.

Vacation Mode

DCB-05 supports a Vacation mode where remote control access is disabled. The mode is activated by pressing

a transmitter button with the VAC function assigned until the console displays that vacation mode is enabled

(approx. 5 seconds).

When activated any transmitter button which is assigned VAC will be ignored. To turn the Vacation mode off,

simply press a transmitter button with the VAC function assigned (only requires a brief activation). Vacation

mode can also be turned on or off manually by editing the VACATION MODE parameter.

DCB-05 can be instructed, via the pedestrian control feature, to partly open and provide pedestrian access but

prevent vehicle access. This is achieved by partly opening the motor 1 gate leaf. If dual motors are used, motor

2’s gate leaf is held closed. The partly open position of motor 1’s gate leaf is initially set to a position halfway

between open and closed. This initial position can be adjusted by the installer to any position within the gates

travel range by selecting a pedestrian access travel time (from closed). The setting is accessed from “MENU

10.4 Set Pedestrian”. The time is adjustable in 1 second steps.

Parameter (Limit Switch) Min Max Default Step Unit Menu

No.

M1 MARGIN Sets obstruction detection margin for M1 0.0 5.0 0.7 0.1 AMPS 2

M2 MARGIN Sets obstruction detection margin for M2 0.0 5.0 0.7 0.1 AMPS 2

SETTLE TIME disable the obstruction detection in the

start of the cycle

0.1 2.0 1.0 0.1 SEC 2

Control Board Adjustments

DCB-05’s standard operation can be altered by editing various parameters. This section describes the

parameters and the effect they have.

Menu 2. Current Trips

The obstruction margins are used to alter the sensitivity of the allowable variation between the “normal” speed

profi le and DCB-05 to obstructions. Increasing the value increases the force required to detect an obstruction.

Standard Operation Modes

26

Elite® - Swing Gate Opener Owner Installation Instructions

Menu 3. Auto-Close times

The Auto-Close modes automatically closes the gate after it has been operated. To implement this, DCB05 starts a timer once the gate has reached its desired open position. The timer then counts down and

when it expires, the DCB-05 starts to close the gate. Details of the four Auto-Close modes are outlined

below. Automatic Technology strongly recommend using a PE Beam for added safety.

Standard Auto-Close

This mode is selected by entering a non-zero time

for the STD Auto-Close parameter.

When selected, the gate will Auto-Close after being

fully opened (except when the gate has reversed

to the open position after a motor obstruction or

overload).

Countdown is suspended by: PE, OPN or SWP

input being active. The countdown is aborted if the

STP input is activated.

If the gate is already open and the OPN or the SWP

input is activated, then the countdown will start.

PE Triggered Auto-Close

This mode is selected by entering a non-zero time

for the “PE Auto-Close” parameter.

This mode is used to auto-close the gate but only

after a vehicle have passed through the gateway

and triggered the PE input. The swipe input can

be used to clear the PE triggered status so that

the PE input must be activated again before the

countdown will start.

As with the other PE modes, the STP input will

abort countdown and the OPN and SWP inputs will

restart the countdown if the gate is OPEN.

Parameter Min Max Default Step Unit Menu No.

STD AUTO-CLOSE TIME

Sets and enables the standard Auto-Close time

0.0 300.0 0.0 1.0 Sec 3

PE AUTO-CLOSE TIME Sets and enables the PE

triggered Auto-Close time

0.0 60.0 0.0 1.0 Sec 3

PEDESTRIAN AUTO-CLOSE TIME Sets and

enables the Pedestrian Auto-Close time

0.0 60.0 0.0 1.0 Sec 3

PE PEDESTRIAN AUTO-CLOSE TIME Sets and

enables the PE Pedestrian Auto-Close time

0.0 60.0 0.0 1.0 Sec 3

AUTO-CLOSE AFTER CLOSE OBSTRUCTION

Enables Auto-Close feature after close

obstructions

Off On Off 3

AUTO-CLOSE AFTER OPEN OBSTRUCTION

Enables Auto-Close feature after open

obstructions

Off On Off 3

AUTO-CLOSE AFTER POWERUP

Enables Auto-Close feature after powerup

Off On Off 3

Control Board Adjustments (Cont.)

Pedestrian Access Auto-Close

This mode is selected by entering a non-zero time for

the “Ped’n A/C” parameter.

When selected, the gate will Auto-Close after being

opened for pedestrian access unless it was following a

reverse from an obstruction.

PE Triggered Pedestrian Auto-Close

This mode is selected by entering a non-zero time

for the “PE Ped’n A/C” parameter.

This mode is the same as the PE triggered autoclose mode, but it only operates during pedestrian

access. As the SWP input is not available during

pedestrian access, the PED input can be confi gured

to act in a SWP mode by setting the “PED I/P =

PED SWIPE MODE” parameter to ON.

Auto-Close After Obstruction

Two parameters are provided to enable the Auto-Close

feature to be activated after obstructions. Normally the

Auto-Close feature is not enabled after obstructions

for safety reasons. PE beams must be used for these

features to be activated.

Owner Installation Instructions Elite® - Swing Gate Opener 27

Menu 4. Lock times

DCB-05’s lock function can be programmed for both hold and pulse operation. The lock output can also be

programmed to activate prior to the motor starting. The open and close cycle actions can be programmed

differently. The lock can be either OUTPUT1 or OUTPUT2 (see OPERATING MODES).

Parameter Min Max Default Step Unit Menu No.

OPEN LOCK TIME Set the time the lock is

activated for on open cycles

0.0 Hold 0.5 0.1 Sec 4

CLOSE LOCK TIME Set the time the lock is

activated for on close cycles

0.0 Hold 0.5 0.1 Sec 4

PRE-OPEN LOCK TIME

Time the lock is activated for prior to opening

0.0 25.5 0.0 0.1 Sec 4

PRE-CLOSE LOCK TIME

Time the lock is activated for prior to closing

0.0 25.5 0.0 0.1 Sec 4

Menu 5. Light times

DCB-05’s light function can be programmed to operate a courtesy light or a warning light. The time the light

stays on for after a cycle is adjustable.

The light can also be activated prior to the gate moving so that a warning can be given of the pending movement.

Note the light output can be selected to be either OUTPUT1 or OUTPUT2. The parameters are shown below.

Parameter Min Max Default Step Unit Menu No.

ON AFTER CYCLE LIGHT TIME

Time light remains on for after a cycle

0 255 60 1 Sec 5

ON BEFORE OPEN CYCLE LIGHT TIME

Minimum time light is activated for prior to

opening

0 255 0 1 Sec 5

ON BEFORE CLOSE CYCLE LIGHT TIME

Minimum time light is activated for prior to

closing

0 255 0 1 Sec 5

Menu 6. Motor settings

The motor settings adjust various aspects of the gate travel. When a single gate installation is used, the SYNC

DELAY TIMES and M2 settings are ignored. The default value for the CLOSE SYNC DELAY time is automatically

calculated for LIMIT SWITCH/AMP TRAVEL installations.

The value calculated is selected so that the delay between M2 and M1 reaching the close position is equal to the

OPEN SYNC DELAY TIME. The MAX OVERRUN TIME is set to 0 for TIMED TRAVEL installations.

Control Board Adjustments (Cont.)

28

Elite® - Swing Gate Opener Owner Installation Instructions

Parameter Min Max Default Step Unit Menu

No.

CLOSE SYNC DELAY TIME

Time delay between M2 and M1 closing

0.0 25.5 2.0 0.1 SEC 6.1

OPEN SYNC DELAY TIME

Time delay between M1 and M2 opening

0.0 25.5 2.0 0.1 SEC 6.2

OPEN SPEED VOLTS

Voltage applied to motors when opening

12 24 22 1 VOLTS 6.3

CLOSE SPEED VOLTS

Voltage applied to motors when closing

12 24 20 1 VOLTS 6.4

SLOW SPEED VOLTS

Voltage applied to motors when slowing down

6 24 8 1 VOLTS 6.5

SLOW TIME

The time between slow down and end of cycle

0.1 10.0 3.0 0.1 SEC 6.6

HOMING / SETUP SPEED VOLTS

Voltage applied to motors when setting up the

travel limits

12 24 Norm 1 Volts 6.7

STOP PAUSE TIME

Pause time used between motor direction

changes

0.0 2.0 0.2 0.1 SEC 6.8

M1 NORMAL OPEN TIME

Normal open time for motor 1

0.0 60.0 0.0 0.1 SEC 6.9

M1 NORMAL CLOSE TIME

Normal close time for motor 1

0.0 60.0 0.0 0.1 SEC 6.10

M2 NORMAL OPEN TIME

Normal open time for motor 2

0.0 60.0 0.0 0.1 SEC 6.11

M2 NORMAL CLOSE TIME

Normal close time for motor 2

0.0 60.0 0.0 0.1 SEC 6.12

MAX OVERRUN TIME

Extra time allowed for cycle to complete (beyond

normal cycle time)

0 60 5 1 6.13

Menu 7. Operating modes

PE input response mode

The PE input can be confi gured to respond in one

of three modes.

Open and close cycles stop

In this mode, all cycles are prevented from being

completed or initiated when the PE input is active.

Close cycles stop

In this mode, the PE input has no effect when

opening but will stop the gate when closing.

Reverses close cycles

In this mode, the PE input has no effect when opening

but will cause the gate to reverse if activated when

closing.

PED input function

The PED input can be confi gured to a SWIPE type

input for pedestrian access. This provides full

functionality with the PE Triggered Pedestrian AutoClose function.

Remote code

DCB-05 supports the Remote Code Set feature. This

parameter can be used to disable the feature for security

or transmitter management reasons.

Control Board Adjustments (Cont.)

Owner Installation Instructions Elite® - Swing Gate Opener 29

Vacation mode

Vacation mode can be turned on or off using this

parameter.

Battery/solar mode

Solar mode can be turned on or off using this

parameter.

Open input polarity

The OPN input is normally confi gured for N/C

operation. This parameter allows its operation to be

changed to N/O.

Password protection

The password feature enables all parameters and

confi guration settings to be protected unless a

password is entered. When this feature is turned on

the user is requested to enter the desired password

to be used. The password protection feature has a

time-out that expires after 60 seconds of inactivity.

Alternately the user may log out manually by pressing

exit when the main screen is displayed.

Parameter Min Max Default Menu

No.

PE INPUT RESPONSE MODE Sets the PE response

mode. Options are OPEN and CLOSE cycles stop, Close

cycles stop or Close cycle reverse

NOT USED

OPN & CLS stop

CLS to stop

CLS to reverse

CLS to

reverse

7.1

PED INPUT = SWIPE MODE Selects PED input functions

as pedestrian access swipe input

Off On Off 7.2

REMOTE CODE ENABLED

Selects remote transmitter coding function

Off On On 7.3

VACATION MODE

Selects vacation mode - disables remote control

Off On Off 7.4

BATTERY/SOLAR MODE

Selects Battery Backup/Solar operation

Off On On 7.5

PASSWORD

Selects password protection for all changes

Off On Off 7.6

TX # GROUPING

Selects transmitter number group display format

Off Off 7.7

OPN INPUT N/C OPERATION

Selects operating polarity of OPN input

Off On Off 7.8

STP INPUT N/C OPERATION

Selects operating polarity of STP input

Off Off 7.9

OUTPUTS 1&2

Selects function of OUTPUT1 and OUTPUT2

OUTPUT1=

LOCK

OUTPUT2=

LIGHT

OUTPUT1=

LIGHT

OUTPUT2=

LOCK

OUTPUT1=

LOCK

OUTPUT2=

LIGHT

7.10

OPN INPUT = 2ND PE

Open input acts as 2nd PE input

7.11

FAULT AUTO RESET 7.12

Control Board Adjustments (Cont.)

30

Elite® - Swing Gate Opener Owner Installation Instructions

Diagnostic Tools

DCB-05 provides several diagnostic tools from within

the diagnostics menu (Menu 8). This section details the

function of each tool.

Navigating to diagnostics menu

1. Press PREV to navigate to Menu 8.

2. Press SET to display menu of available functions (Fig.

38).

3. Press PREV or NEXT to cycle through diagnostic

tool.

4. Press SET to select.

Menu 8.1 Test Inputs

This tool is used to view the state of the control inputs.

When selected, a screen is displayed (Fig. 39) which

indicates the state of each input. If the name of the input

is in uppercase, then the input is active. Conversely if

the input is in lower case, then the input is inactive.

For normal operation all inputs should be inactive. When

fi nished press EXIT. The example shows the status as

OSC input is active.

Menu 8.2 Test Tx’ers

This tool is used to test receiver/transmitter functionality.

When selected, a screen is displayed which prompts

for a transmitter button to be pressed (Fig. 40) and

whether ID or serial numbers are to be displayed.

DCB-05 will then beep each time a transmission is

received. If the transmitter button is stored in the DCB05’s memory and has a function assigned to it, a second

screen will be displayed that shows the transmitter

details along with the button pressed (Fig. 41).

The example shows the case when transmitter number

12 is activated by button 4. Note ID is selected for

display.

Menu 8.3 Display History

DCB-05 keeps a record of the last 64 events that have

taken place. The events include the type of drive cycles

executed, obstruction detection, various faults, power

failures etc.

When this tool is selected, the screen displays the last

event that occurred (Fig. 42). Press NEXT or PREV

to view each event. The “EVENT#” fi eld shows the

sequence of the events, with (1) being the fi rst and (64)

being the last.

The example shows that the last event was a close cycle

which succeeded in closing the gate. When fi nished

viewing the events, press EXIT.

Menu 8.4 Memory Usage

This tool displays the number of transmitter store

location used and the number free (Fig. 43).

PREV NEXT

EXIT

SET

Diagnostics

MENU 8

PRESS

40

fi g

PREV NEXT

EXIT

SET

cls osc swp ped

I/P pe opn stp

41

fi g

42

fi g

43

fi g

PREV NEXT

EXIT

SET

Memory Tools

MENU 9

PRESS

PREV NEXT

EXIT

SET

EVENT# 64

Close Complete

PREV NEXT

EXIT

SET

OSC PED LGT>VAC

124 ID B B SMITH

PRESS

39

fi g

PREV NEXT

EXIT

SET

/ Shows ID/SN

PRESS TX’ER

38

fi g

Owner Installation Instructions Elite® - Swing Gate Opener 31

PREV NEXT

EXIT

SET

(CYCLES) 60000

Service Counter

PREV NEXT

EXIT

SET

1234

1:Open Cycles

45

fi g

44

fi g

Menu 8.5 Service Counter

DCB-05 provides a periodic service counter which can

be set to expire after a number of drive cycles.

When expired, DCB-05 will beep at the beginning

of each drive cycle and a message will be displayed

on the MAIN SCREEN (Fig. 44). This tool displays

the current value of the service counter and allows

the user to set its value using the normal parameter

editing techniques (See PARAMETER VIEWING AND

EDITING).

If the service counter is not to be used it can be set to

the maximum number (60,000).

Menu 8.6 Counters

The opener keeps a count of number of times a

particular event occurs. The list of event counters kept

is shown below.

When this tool is selected, the fi rst event counter is

shown (Fig. 45). Press NEXT or PREV to step through

the list.

The example below shows the OPEN CYCLE event

counter with a value of 1234. When fi nished viewing

press EXIT.

Open Cycles

Close Cycles

Ped Cycles

Warranty cycles

Setup Limits

Overlaps

M1 Open Obstructions

M2 Open Obstructions

M1 Close Obstructions

M2 Close Obstructions

M1 Open Overloads

M2 Open Overloads

M1 Close Overloads

M2 Close Overloads

M1 Drive Faults

M2 Drive Faults

M1 Volt Faults

M2 Volt Faults

M1 Amp Faults

M2 Amp Faults

Supply Hi Fault

Supply Low Fault

M1 Amp Trip Fault

M2 Amp Trip Fault

Three Wire Limits Fault

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

Diagnostic Tools

32

Elite® - Swing Gate Opener Owner Installation Instructions

The Memory Tools accessed from within Menu 9 are

used to backup, restore or clear the controller. Once

selected, the PREV or NEXT buttons can be used

to view the Memory Tool options. To execute the

displayed option simply press SET (Fig. 46).

Menu 9.1 Clr Control

This option will clear the gate control memory and

reload the factory set defaults for parameters such as

the lock time, light time, Auto-Close times etc. It will

also clear the travel limits.

Menu 9.2 Clr Tx’ers

This option will clear the transmitter storage memory.

Memory Tools

PREV NEXT

EXIT

SET

Memory Tools

MENU 9

PRESS

46

fi g

DCB-05 can be instructed, via its pedestrian control

feature, to partly open and provide pedestrian access

but prevent vehicle access. This is achieved by partly

opening the motor 1 gate leaf.

If dual motors are used, motor 2’s gate leaf is held

closed. The partly open position of motor 1’s gate

leaf is initially set to fi ve (5) seconds from fully closed

position. This initial position can be adjusted by the

installer to any position within the gates travel range

by selecting a pedestrian access travel time (from

closed). The setting is accessed from “MENU 10.4 Set

Pedestrian” (Fig. 47).

The time is adjustable in 1 second steps.

Step 1. Navigating to “set pedestrian menu”

1. Press PREV to navigate to Menu 10

2. Press SET - MENU 10.1 is displayed.

3. Press NEXT to go to MENU 10.4.

4. Press SET to enter Set Pedestrian procedure (Fig.

48).

Step 2. Setting pedestrian position

1. Press OPEN or CLOSE to adjust pedestrian drive time.

2. Press SET to record position

3. Press transmitter coded for pedestrian function or push

button wired into pedestrian input to test.

Setting Pedestrian Position

PREV NEXT

EXIT

SET

Set Pedrestrian

MENU 10.4

PRESS

PREV NEXT

EXIT

SET

Time 5

Ped’n Opening

47

fi g

48

fi g

Owner Installation Instructions Elite® - Swing Gate Opener 33

PE Beam Installation

49

fi g

50

fi g

51

fi g

Fitting Photo Electric (PE) Beams

Attach the mounting bracket (4) to adjustment

bracket (3) with the pan head screw (6) (supplied)

(Fig. 49).

Attach the PE 2000TS bracket (2) to PE beam

transmitter (IR-200TS-TX) with four taptite screws

(m3x5) and attach the other side to adjustment

bracket (3) with the pan head screw (6) (supplied).

Repeat steps a and b to assemble the PE Beam

receiver ( IR-200TS-RX).

Locate the Photo Electric (PE) Beams in a strategic

location in the gateway. Automatic Technology

recommend that the sensor is placed 150 mm above the

fl oor level. Connect as per the wiring diagram (Fig. 51).

Use 5.6 kilo ohm resistor with the colour code green,

blue, red and gold on the PE Beams receiver between

the V- and NC terminals as shown in (Fig. 51).

Alignment

Power up the PE Beams. The green LED on the

transmitter and red LED on the receiver should turn

ON to indicate power is present.

If the receiver is connected to power and the red

LED is on while the green LED is on, the transmitter

and receiver are not aligned.

Make horizontal and/or vertical (Fig. 50) adjustment

on the transmitter and/or receiver until the red LED

turns off on the receiver, indicating alignment.

WARNING: Tampering with the PE Beams could

result in serious personal injury and/or property

damage and will void the warranty.

a.

b.

c.

a.

b.

c.

1

2

3

4

6

5

RED

BLACK

RED

BLACK

RED

BLACK

YELLOW

R1=5.6K OHM

Green,Blue,Red,Gold

.25WATT 5% TOLERENCE

RESISTANCE

R1

YELLOW

BLACK

V- IN V+

P.E BEAM

R1

34

Elite® - Swing Gate Opener Owner Installation Instructions

Wiring Output1 And Output2

Outputs 1 and 2 are used to control a lock and a light.

Which output is to control which function and the way

it is controlled, is programmable.

If using these outputs make sure that the functions are

confi gured for correct operation prior to setting the

travel limits.

OUTPUT1 is a relay output with high current capability.

OUTPUT2 is used to activate an optional external relay

module (RO-1) which in turn is used to switch the load.

Fitting solenoid or magnetic locks

Install the lock mechanism on the gate as per the

manufacturers instructions. The wiring diagram on the

left is a representation of a typical lock with a bias for

normally closed contact (Fig. 52).

Fitting courtesy lights

An AC or DC courtesy light can be activated via an

output on the gate opener control board. Connect the

light as per the diagram on the left (Fig. 53).

WARNING: A qualifi ed electrician must perform

the installation where 240V AC power is used.

Wiring Control Inputs

The console switch inputs may be used for operating

the gate via any device that provides and switch contact

output.

AUX, OPN, STP, CLS, SWP, PED requires normally open

contact switches (Fig. 54). OPN and STP inputs can be

confi gured to take normally close contact switches.

53

fi g

52

fi g

Accessories Installation

SUITABLE

POWER SUPPLY

+ -

OUT1 N/C

OUT1 COMMON

OUT1 N/O

STOP

CLOSE

OSC

SWIPE

PEDESTRIAN

COMMON

OUT2 +

OUT2 -

LIGHT RELAY MODULE

POWER

SUPPLY

OUT1 N/C

OUT1 COMMON

OUT1 N/O

V+

IN

VAUX

OPEN

STOP

CLOSE

OSC

SWIPE

PEDESTRIAN

COMMON

OUT2 +

OUT2 -

OUT1 N/C

OUT1 COMMON

OUT1 N/O

P.E BEAM

54

fi g

Owner Installation Instructions Elite® - Swing Gate Opener 35

Battery Backup Installation

Connect the Battery Backup Kit

Disconnect power to the DCB-05.

Secure the SBY-3 Charger Board in the control box

with sticky pads (supplied with the battery charger

kit part number # 90188).

Connect the SBY-3 charger board to battery box

and to DCB-05 as shown (Fig. 55).

Reconnect power.

From menu 7.9 select the “battery enabled

option”

Testing Battery Backup

Press transmitter to test the gate opener.

Whilst gate is in motion, disconnect mains power.

The gate should continue to operate as normal.

NOTE: Wait for the gate to complete its travel.

Press the transmitter to activate the gate.

Whilst gate is in motion re-connect power. The gate

should complete the cycle as normal.

Troubleshooting

If gate stops or moves very slowly under battery

power, the batteries may be weak or have no charge.

Connect mains power and allow the batteries to

charge. This may take 24 - 48 hours to reach maximum

charge capacity.

1.

2.

3.

4.

5.

1.

2.

3.

4.

55

fi g

36

Elite® - Swing Gate Opener Owner Installation Instructions

Gate does not open or close Check that power is still available at mains power point.

Check that Control Box is plugged into mains power.

Check that motor is engaged for automatic operation.

Check all wiring from motor and microswitches to the control board are

sound.

Gate reverses while closing or

stops while opening

Check obstruction overload sensitivity adjustment.

Check for obstructions.

Disengage the drive unit to manual and check the gate is in good working

order.

If a P.E. beam is fi tted, ensure it is clear of obstructions or dirt on the lens.

Transmitter not functioning New transmitters must be coded to the receiver.

Check/change the battery in the transmitter (LED fl ashes to indicate low

battery).

Having the antenna behind a structure (gate or fence) or not in line of

sight may reduce optimal range/reception.

Interference from external/outside sources such as baby monitors, or radio

transmitter etc. The best solution is to remove the source causing the

interference.

Gate and/or opener requires

service

Contact the installer of the opener or local ATA dealer for service. They

will be able to inspect, service, adjust or repair the gate and opener as

necessary.

Troubleshooting guide

Owner Installation Instructions Elite® - Swing Gate Opener 37

Specifi cation

Drive unit

Motor Voltage 24V DC

Maximum Pulling Force 200N (20Kg)

Drive Arm Rotation Speed Approx. 8°/sec

Dimensions 135W x 290H x 230D (mm)

Weight 13Kg (incl. arms)

Max Weight Of The Gate 250 kg¹

Control Box

Protection rating 24V DC

24VDC accessory output 24VDC (unfi ltered) 3Amp maximum

Secondary voltage: 24V AC 150 VA

Receiver type: 433.92 MHz TrioCod e™ or Tri-Tran™

2

Receiver code storage capacity: 511 x 4 Button Transmitter Codes

Transmitter frequency: UHF Multi-frequency FM Transmitter

Coding type: Hopping Code

Code generation: Non-linear encryption algorithm

Transmitter battery: CR2032

Note:

The maximum weight gate that the opener can be installed on 250Kg. The gate must be well balanced.

A person of limited strength should be able to move the gate manually with very little effort (15Kg force

max.) in case of an emergency.

The fi rst memory location sets the type of transmitters which can be stored into the receivers memory. It

either can be ATA Trio C ode™ or B &D Tri-Tran™ t r a n s mitters.

1.

2.

38

Elite® - Swing Gate Opener Owner Installation Instructions

Spare Parts List

Owner Installation Instructions Elite® - Swing Gate Opener 39

1. This Warranty is given by Automatic Technology (Australia)

Pty Ltd (ABN 11 007 125 368) (ATA), 6-8 Fiveways Boulevard,

Keysborough 3173, 1300 133 944, sales@ata-aust.com.au

2. The Competition and Consumer Act 2010 (including the

Australian Consumer Law) and other relevant statutes provide a

set of statutory consumer guarantees and other legal rights that

cannot be excluded, restricted or modifi ed by contract. This

Warranty is in addition to and does not affect any of your rights

under the Australian Consumer Law and other relevant statutes.

3. Our goods come with guarantees that cannot be excluded

under the Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and for compensation

of any other reasonably foreseeable loss or damage. You are

also entitled to have the goods repaired or replaced if the

goods fail to be of acceptable quality and the failure does not

amount to a major failure.

4. Subject to your non-excludable rights under the Australian

Consumer Law, ATA expressly excludes any liability for

consequential loss, incidental or indirect damages (including

but not limited to damages for loss of business profi ts, business

interruption and loss of business information) due to a defect

of the SGO-1 Elite® (Product). In particular any loss or damage

caused to other equipment or accessories used with the

product or any loss resulting from a delay in repair is excluded

to extent permitted by law.

5. Subject to all of the matters set out below, ATA warrants in

relation to the Product that:

(a) the Product’s drive units will be free of any defects in material

and workmanship for at least 12 months after the date of

purchase (as evidenced by the sales docket receipt), or 2,500

cycles, which ever occurs fi rst; and

(b) the Product’s other components and accessories will be free of

any defects in material and workmanship for at least 12 months

after the date of purchase (as evidenced by the sales docket

receipt).

6. No additional warranty will apply for Products repaired during

the relevant warranty period.

7. For all Products repaired outside the warranty period, a six (6)

month warranty that the Product will be free of any defects in

material and workmanship will apply from the date of dispatch

of the Product to you. ATA may charge you for any repairs

undertaken outside the warranty period, and will provide you

with a quotation in relation to any such costs for your approval

before proceeding with any repairs.

8. This Warranty applies only where you:

(a) immediately notify ATA at the contact details provided

in paragraph 1 above or notify the or the retailer that you

purchased the Product from of the alleged defect;

(b) return the product to the retailer that you purchased the

Product from; and

(c) present the relevant sales docket and this Warranty document

to the retailer to confi rm the date of purchase.

9. Except for this Warranty, ATA gives no warranties of any kind

whatsoever (whether express or implied), in relation to the

product, and, subject to paragraph 1 above, all warranties of

whatsoever kind relating to the product are hereby excluded.

10. This Warranty excludes damage resulting from:

(a) normal wear and tear;

(b) accidental damage;

(c) incorrect installation of the Product;

(d) blown fuses, electrical surges, power surges or power spikes;

(e) theft, fi re, fl ood, rain, water, lightning, storms or any other acts

of God;

(f) any installation, confi guration or use of the Product contrary to

the instructions supplied with the Product;

(g) maximum continuous operating time exceeding 1 minute in 10;

(h) the operating force exceeding 15kg* (150 Newton) when moving

the door or gate manually to the open or closed position;

(i) residential gate weight exceeding 300kg;

(j) the gate used with the Product not being in safe working order and

condition;

(k) repairs which are not authorised by ATA;

(l) any failure to install or maintain the Product in accordance with the

instructions supplied with the Product;

(m) any use which is not in accordance with the instructions provided

with the Product;

(n) deliberate or negligent damage to the Product;