Page 1

Water Resistant Roll Up Door Opener

DOMINATOR

Instruction Manual

(Instruction d’Installation)

TM

ShedMaster

®

Conforms to UL 325

Certified to CSA

C22.2 No.247

Doc # 160089_01

Part # 86368

Released 15/11/18

Page 2

WARNING!: It is vital for the safety of persons to follow all

instructions. Failure to comply with the installation instructions

and the safety warnings may result in serious personal injury

and/or property and remote control opener damage. Please

save these instructions for future reference.

ELECTROCUTION!: To reduce the risk of electric shock, this

equipment has a grounding type plug that has a third (grounding)

pin. This plug will only fit into a grounding type outlet. If the

plug does not fit into the outlet, contact a qualified electrician

to install the proper outlet. Do not change the plug in any way.

This operator is not equipped for permanent wiring. Contact a

qualified electrician to install a suitable receptacle if one is not

available.

AVERTISSEMENT! pour la sécurité des usagers, il est

essentiel de suivre toutes les instructions. Le non- respect des

instructions d’installation et des avertissements de sécurité

peut causer de graves blessures et/ou endommager l’appareil

et la télécommande. Conservez ces instructions en lieu sûr.

AVERTISSEMENT! Pour réduire les risques d'électrocution,

cet appareil est équipé d’une fiche avec broche de mise à la

terre. Cette fiche ne peut être branchée que dans une prise

avec mise à la terre. S’il n’est pas possible de la brancher dans

la prise, faites poser une prise appropriée par un électricien

qualifié. Ne pas modifier la fiche.

Ce matériel est pas équipé pour le câblage permanent. En

l'absence de réceptacle approprié, contactez un électricien

qualifié pour en installer un.

2

GDO-8V3 Shed Master Instruction Manual

Page 3

Table of Contents

Installation Instructions

© Copyright 2017

1. Safety Information 4

2. Specifications 6

3. Kit Contents 7

4. Setup Requirements 8

4.1 The Opener: 8

4.2 Unsuitable Door Types 8

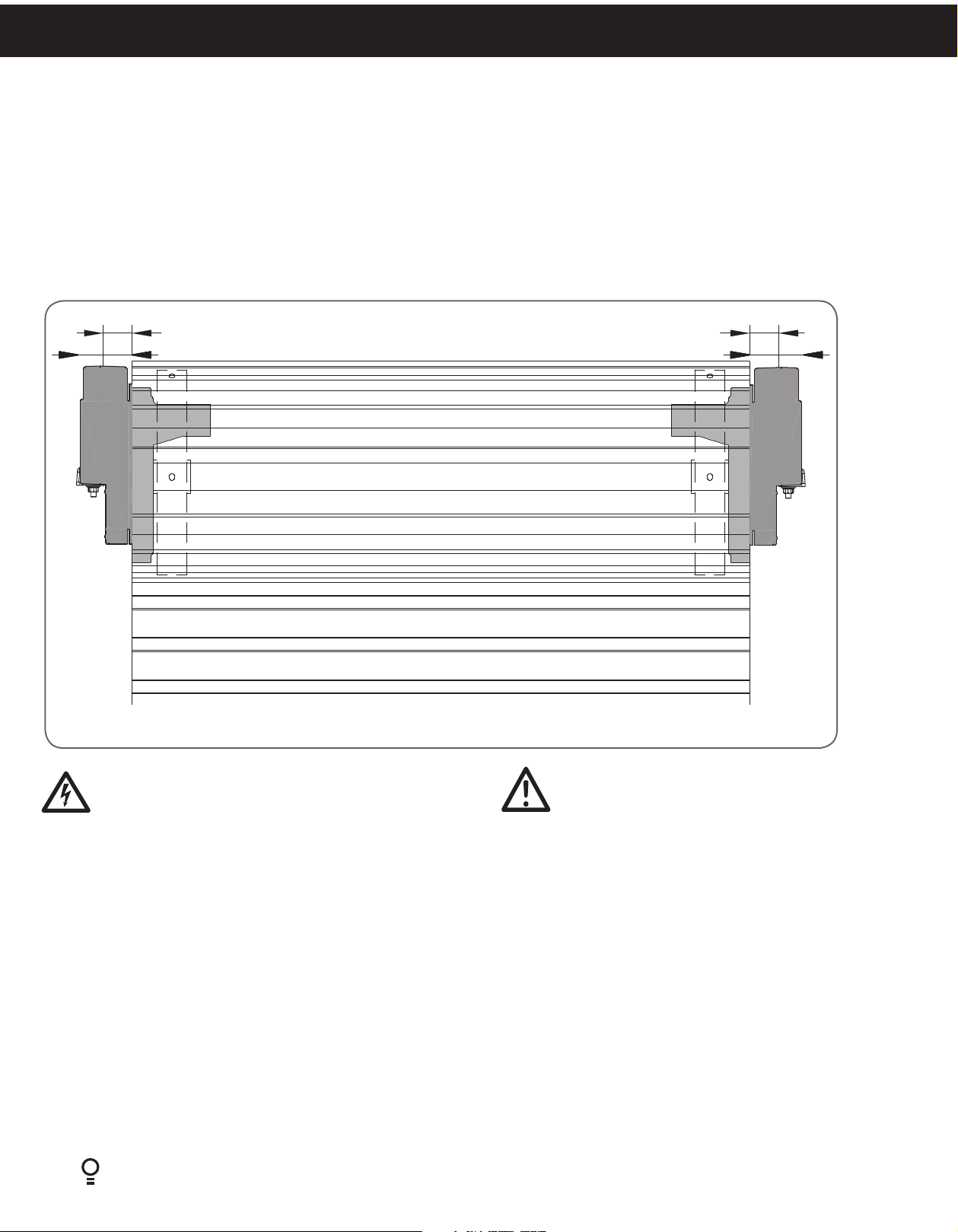

4.3 Sideroom 8

4.4 Check Operation of Door 8

5. Opener Safety & Security 9

5.1 Your Door CAN NOT be used when: 9

5.2 Your Door CAN be used when: 9

5.3 To Disengage the Opener: 9

5.4 To Re-Engage the Opener: 9

6. Before Installation 10

6.2 Fit the Weight Bar 11

6.2.1 If the door has a handle: 11

6.2.2 If the door does not have a handle: 11

6.3 Pinning the Door 12

6.4 Proping the Door 12

6.9 Safety Testing 17

6.9.1 Testing the Close Cycle 17

6.9.2 Testing the Open Cycle 17

6.9.3 To Increase Force Pressure 17

6.9.4 To Decrease Force Pressure 17

6.9.5 To Recall Factory Set Force 17

6.10 Attach Warning Labels 18

6.11 Accessories 18

6.12 Coding a Transmitter 20

6.12.1 Storing the Transmitter Code 20

6.12.2 Coding to Enable Vacation Mode 20

6.12.3 Remotely Coding Transmitters 20

6.12.4 Erasing a Stored Transmitter Code 20

6.12.5 Erasing All Transmitter Codes 20

Home Owner Instructions

6.5 Mounting the Opener 13

6.5.1 Raising the Door: 13

6.5.2 Mounting the Opener: 13

6.6 Safety Beam Installation 14

6.6.1 Mounting the beam 14

6.6.2 Wiring Connection 14

6.7 Setting the Datum 15

6.8 Setting the Travel Limits 16

6.8.1 Initial Preparation: 16

6.8.2 Set the Limit Positions: 16

6.8.3 Resetting the Door Limit Positions 16

6.8.4 Reset all Factory Defaults 16

7. Operation Instructions 21

7.1 How to Use Your Operator 22

7.1.1 To Operate the opener: 22

7.1.2 Replacing the Battery: . 22

7.2 User Operating Controls 23

7.3 Door Status Indicators 23

8. User Maintenance Instruction 24

8.1 Door Maintenance 24

8.2 If You Need a Service Call 24

9. Troubleshooting 25

10. Customer Agreement & Warranty 26

Shed Master Instruction Manual GDO-8V3

Diamond PD Power Drive : Instruction Manual

3

Page 4

1. Safety Information

WARNING!

• This operator should be installed in accordance with relevant US and

Canada Standards.

• Place the attached Entrapment Warning Label on wall next to wall

mounted transmitter, within sight of door.

• This operator is not suitable for commercial, industrial or common

entry applications.

• This operator is a plug in domestic appliance and is designed for

indoor use only. It must be installed in a dry position that is protected

from the weather.

• Door must have Safety Beams fitted.

• Activate the operator only when the garage door is in full view, free of

obstructions and with the operator properly adjusted.

• Watch the moving door and keep people away until the door is

completely opened or closed.

ELECTROCUTION:

• Installation and wiring must be in compliance with your local building

and electrical codes.

• This operator is not equipped for permanent wiring. Contact a

qualified electrician to install a suitable receptacle if one is not

available.

• To reduce the risk of electric shock, this equipment has a grounding

type plug that has a third (grounding) pin. This plug will only fit into

a grounding type outlet. If the plug does not fit into outlet, contact

a qualified electrician to install the proper outlet. Do not change the

plug in any way.

• If the power cord is damaged, it must be replaced by the manufacturer,

its service agent or a similarly qualified person in order to avoid a

hazard.

• Connect the power cord only to properly earthed mains. If an

extension lead must be used, make sure it is a 3-core lead and

approved to 7 amp capacity.

Please read these important safety rules

These safety alert symbols indicate a personal

safety or property damage instruction exists.

READ THESE INSTRUCTIONS CAREFULLY.

This automatic garage door operator is designed and tested

to offer safe service provided it is installed and operated

in strict accordance with the following safety rules. Failure

to comply with the installation instructions and the safety

warnings may result in death, serious personal injury and/or

property damage.

CAUTION:

• If your garage has no pedestrian entrance door, an emergency

access device should be installed. This accessory allows manual

operation of the garage door from outside in case of power failure.

• Keep the garage door balanced. Sticking or binding doors must be

repaired. Garage doors, door springs, brackets and their hardware

are under extreme tension and can cause serious personal injury.

Do not attempt any garage door adjustment. Do not use if repair

or adjustment is needed. Call for professional garage door service.

• Position the Garage Door Operator so that the power plug is

accessible when inserted into the power outlet.

• Install the wall transmitter in a location where the garage door is

visible, but out of the reach of children at a height of at least 5 feet

(1.53m).

• To avoid serious personal injury from entanglement, remove all

unnecessary ropes or chains and disable any equipment such as

locks which are not needed for powered operation.

• Do not wear rings, watches or loose clothing while installing or

servicing a garage door operator.

• Ensure ladder is the correct type for the job and is on flat ground.

We recommend the user has 3 points of contact while on ladder.

• Activate the operator only when the garage door is in full view,

free of obstructions and with the operator properly adjusted.

• This unit is not user serviceable. Unplug the power cord before

removing the cover. Ensure that the power cord is attached clear of

all moving parts. Ignoring these instructions can cause electric shock.

4

GDO-8V3 Shed Master Instruction Manual

• The operator is not intended for use by young children or infirm

persons without supervision.

• Keep transmitters away from children.

• Do not allow children to play with door controls.

Page 5

Sécurité

© Copyright 2017

AVERTISSEMENT!

• Cet appareil doit être installé conformément aux normes US et

canadiennes en vigueur.

• Placez l’étiquette avertissant du risque de se faire piéger sur le mur

à proximité de l’émetteur, en vue de la porte.

• Cet appareil n'est pas conçu pour des applications commerciales,

industrielles ou d'entrée commune.

• Cet appareil est un accessoire domestique conçu pour être utilisé

uniquement à l'intérieur. Il doit être installé au sec et à l'abri des

intempéries.

• La porte doit être équipée de faisceaux de sécurité.

• Activez l'appareil uniquement lorsque la porte du garage est à la vue,

exempte d'obstacles et avec l'appareil bien réglé.

• Suivez la porte pendant l'ouverture ou la fermeture, et veillez à

ce que personne ne se trouve à proximité tant qu'elle n'est pas

complètement ouverte ou fermée.

Lisez attentivement ces règles de

sécurité.

Ces pictogrammes indiquent une consigne

de sécurité pour les personnes ou les biens.

LISEZ CES INSTRUCTIONS ATTENTIVEMENT.

Cette commande automatique pour porte de garage est

conçue et testée pour fonctionner en toute sécurité. Pour

ce faire, elle doit être installée et utilisée dans le strict

respect des règles de sécurité suivantes. Le non-respect des

instructions d'installation et des avertissements présent un

risque de mort, de blessure grave et/ou de préjudice pour

les biens.

PRUDENCE:

• Si votre garage ne comporte pas de porte pour piétons, il convient

d'installer un dispositif d'accès d'urgence. Cet accessoire permet

d'actionner la porte de garage manuellement de l'extérieur en cas

de panne d'électricité.

ÉLECTROCUTION:

• L'installation et le câblage doivent être effectués conformément aux

codes de la construction et de l'électricité en vigueur.

• Cet appareil n'est pas équipé pour un câblage permanent. En

l'absence de réceptacle, contactez un électricien qualifié pour en

installer un.

• Pour réduire le risque d'électrocution, cet équipement est pourvu

d'une prise avec broche de mise à la terre. Celle-ci ne peut être

branchée que dans une prise compatible. Sinon, demandez à un

électricien qualifié d'installer une prise de courant adéquate. Ne la

remplacez pas vous-même.

• Si le cordon électrique est abîmé, il doit être remplacé par le fabricant,

son SAV agréé ou un technicien qualifié.

• Branchez le cordon électrique uniquement à une prise secteur

dûment reliée à la terre. Si vous devez utiliser une rallonge, assurezvous qu'elle est tripolaire et d'une capacité de 7ampères.

• Cet appareil n'est pas réparable par l'utilisateur. Avant de retirer

le capot, débranchez le cordon électrique. Assurez-vous qu'il ne

risque pas d'entrer en contact avec des pièces en mouvement. Le

non-respect de ces instructions peut avoir une électrocution pour

conséquence.

• Veillez à ce que la porte du garage soit bien équilibrée. Si une

porte reste «collée» ou qu'elle «accroche», elle doit être réparée.

Les portes de garage, les ressorts de porte, les pattes de fixation

et les éléments matériels sont soumis à une tension extrême et

peuvent blesser gravement. Ne tentez pas de régler la porte de

garage par vous-même. Ne l'utilisez pas si une réparation ou un

réglage est nécessaire. Faites appel à un technicien spécialisé.

• Positionnez le dispositif de commande de manière à ce que la

prise de courant soit accessible lorsqu'elle est branchée.

• Installez l'émetteur mural à un emplacement où la porte du garage

est visible, mais hors de portée des enfants, à une hauteur d'au

moins 1,50m.

• Rangez cordes et chaînes pour éviter de vous blesser, et désactivez

les serrures et autres équipements qui ne sont pas nécessaires

pour une utilisation sous tension.

• Pendant l'installation ou la réparation d'un dispositif de commande

de porte de garage, retirez bijoux et montre, et attachez vos

vêtements.

• Utilisez un escabeau adéquat et stable. Lorsque l'utilisateur se

tient sur un escabeau, il est conseillé de veiller à ce que les points

de contact soient au nombre de trois.

• Activez l'appareil uniquement lorsque la porte du garage est à la

vue, exempte d'obstacles et avec l'appareil bien réglé.

• L'appareil ne doit pas être utilisé sans supervision par de jeunes

enfants ou des personnes infirmes.

• Les émetteurs doivent rester hors de portée des enfants.

• N'autorisez pas les enfants à jouer avec les commandes de porte.

Shed Master Instruction Manual GDO-8V3

Diamond PD Power Drive : Instruction Manual

5

Page 6

2. Specifications

Technical Specifications DOMINATOR ShedMaster

GDO-8V3

Power supply 120Va.c. 60Hz

Maximum door opening

Width:

Height:

Maximum Door Weight:

Door Area:

Door must be well balanced and able to be operated by

hand, as per warranty conditions and standard

AS/NZS 4505:2012

Minimum sideroom 40mm

Lift Force 450N

Nominal force 120N (12kg)

Receiver type Multi-frequency UHF FM

(433.47, 433.92 & 434.37MHz)

Receiver code storage capacity 8 X Triocode

Coding System TrioCode

5500mm

2700mm

100kg

2

16.5m

TM

128

4-button Transmitters

TM

128 Type

®

Coding type Code Hopping

Number of code combinations Over 100 billion random codes

Transmitter battery CR2032 (3 Volts)

Courtesy light Light Module (Optional)

Network connectivity Not Available

Note: Intermittent operations may occur in areas which experience very strong winds. The strong wind puts extra pressure on the

door and tracks which may in turn intermittently trigger the safety obstruction detection system.

6

GDO-8V3 Shed Master Instruction Manual

Page 7

3. Kit Contents

© Copyright 2017

3

4

5

6

7

2

1

8

9

1

1. 1 x GDO-8V3 drive unit

2. 1 x Safety Beam Kit

3. 1 x PTX-5 Transmitters

4. 1 x Wall Transmitter

5. 1 x Weight Bar

Fastner Bag

6. 2 x Nilock Nut

7. 2 x 3/16 x 1/2 flat washers

8. 2 x Pan Head Screw M4 x 50

9. 2 x Locking Bar Covers

Fig. 3.1

Shed Master Instruction Manual GDO-8V3

Diamond PD Power Drive : Instruction Manual

7

Page 8

4. Setup Requirements

4.1 The Opener:

a. MUST BE installed in a dry position, protected from weather. (Moisture or corrosion not covered by W arranty)

b. Is factory set for RIGHT HAND SIDE installation (from inside garage), but capable of LEFT HAND SIDE installation.

c. REQUIRES properly earthed 3 pin single phase power within an arms length of door and at a suitable height

d. Requires a MINIMUM SIDEROOM of 40mm from the edge of the door to the inside of the door bracket and 85mm to the

wall.

e. CAN NOT be installed on a Door Axle Diameter that exceeds 35mm.

40mm

85mm

LEFT HAND SIDE RIGHT HAND SIDE

40mm

85mm

Fig. 4.1

WARNING! This operator is not equipped for

permanent wiring. Contact a qualified electrician to

install a suitable receptacle if one is not available.

4.2 Unsuitable Door Types

The drive must not be used with a door incorporating a wicket

door, unless the drive cannot be operated with the wicket

door open. The fitting of an opener to doors with removable

mullions is not recommended.

4.3 Sideroom

Fig.4.1 shows the minimum and recommended sideroom

that is required to mount the opener. The distance between

the edge of the door curtain and the inside of the bracket

must be at least 1½ inch (40mm).

8

GDO-8V3 Shed Master Instruction Manual

CAUTION: Do not connect opener to power source

until instructed to do so.

4.4 Check Operation of Door Before Beginning the

Installation of the Shed Master.

The door must be well balanced and be in a reasonable

operating condition. Install only on a properly balanced

garage door. An improperly balanced door has the potential

to inflict severe injury. Have a qualified service person make

repairs to cables, spring assemblies, and other hardware

before installing the opener. You should be able to lift the

door smoothly and with little resistance. It should stay open

around 3 feet (900mm) to 4 feet (1200mm) above the floor.

The door should not stick or bind in the guide tracks. The

ideal operational effort in raising or lowering the door should

not exceed a force of 20kg (44lb). Make sure that all door

locks, ropes, chains etc. are either released or disabled and

remove unnecessary accessories.

Page 9

5. Opener Safety & Security

5.1 Your Door CAN NOT be used by the opener when:

a. There is a locking device installed.

b. There is a power failure.

MANUAL RELEASE

© Copyright 2017

5.2 Your Door CAN be used when:

a. There is an emergency, by disengaging the opener.

b. There is a power failure, by disengaging the opener.

5.3 To Disengage the Opener:

a. It is recommended to do so with the door in the closed position.

b. Pull down on the manual release cord, until you hear a click.

c. Move the door manually.

CAUTION: When the opener is manually disengaged,

the door is no longer locked. To lock the door

manually, re-engage the opener after the door is

closed.

5.4 To Re-Engage the Opener:

a. Check the door has not been locked by a locking device.

b. Pull down on the manual release cord, until you hear a click.

c. The door will now operate from the opener.

WARNING! Please test the manual release mechanism

to ensure that the manual release is easy to operate.

No more than 20kg (44lb) of force should be required

to disengage the door using the manual release cord.

If excessive force is required reset the close limit

position (Section 6.8.3 Resetting Door Limits).

WARNING! When operating the manual

release (while the door is open) the door

may fall rapidly due to weak or broken

springs, or due to being improperly

balanced.

Do not disengage the operator to manual

operation with children/persons or any

objects including motor vehicles within

the doorway.

IN THE EVENT THE DOOR BECOMES OBSTRUCTED

DETACH DOOR FROM OPERATOR AS FOLLOWS:

1.

TO DISENGAGE:

PULL HANDLE DOWN & RELEASE

SI LA PORTE EST BLOQUÉE, DÉTACHEZ-LA DU

DISPOSITIF DE COMMANDE EN PROCÉDANT

COMME SUIT :

1.

POUR DÉBLOQUER:

TIRER VERS LE BAS ET RELACHER

TO RE-ENGAGE: REPEAT ACTION

2.

2.

POUR LA RÉENGAGER:

RÉPÉTER LE MOUVEMENT

PULL

HANDLE

TIRER LA POIGNEE

AVERTISSEMENT : Lorsque vous utilisez

le déclenchement manuel (alors que la

porte est ouverte), la porte peut tomber

rapidement si les ressorts sont fatigués

ou brisés, ou parce qu'elle est mal

équilibrée.

NE PAS désengager l’opérateur en mode

manuel lorsque des enfants/personnes,

ou des objets tels que des véhicules à

moteur, sont dans le passage.

DÉBLOCAGE MANUEL

Fig. 5.1

Shed Master Instruction Manual GDO-8V3

Diamond PD Power Drive : Instruction Manual

9

Page 10

6. Before Installation

IMPORTANT INSTALLATION INSTRUCTIONS.

WARNING - To reduce the risk of severe injury or death:

(1) READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

(2) Install only on a properly operating and balanced garage door. An improperly balanced door has the potential to inflict severe

injury. Have a qualified service person make repairs to cables, spring assemblies, and other hardware before installing the

opener.

(3) Remove all pull ropes and remove or make inoperative, all locks connected to the garage door before installing opener.

(4) Where possible, install the door opener 2.14m (7 feet) or more above the floor. For products having an emergency release,

mount the emergency release 1.83 (6 feet) above the floor and avoiding contact with vehicles to avoid accidental release.

(5) Do NOT connect the opener door operator to source of power until instructed to do so.

(6) Locate the control button:

(i) within sight of door,

(ii) at a minimum height of 1.53m (5 feet) above floors, landings, steps or any other adjacent walking surface so small children are

not able to reach it, and

(iii) away from all moving parts of the door.

(7) Install the Entrapment Warning Label next to the control button in a prominent location. Install the Emergency Release Label.

Attach the marking on or next to the emergency release.

(8) After installing the opener, the door must reverse within 2 seconds when it contacts a 1 1/2 -inch high object (or a 2 by 4 board

laid flat) on the floor.

(9) For products having a manual release, instruct the end user on the operation of the manual release. Exception: For horizontally

sliding doors, Item 2 shall be replaced with “Have a qualified service person make repairs and hardware adjustments before

installing the opener.

IMPORTANT - NOTICE D’INSTALLATION.

AVERTISSMENT - POUR RÉDUIRE LES RISQUES DE BLESSURES GRAVES OU DE MORT:

(1) LISEZ CETTE NOTICE ET CONFORMEZ-VOUS AUX INSTRUCTIONS.

(2) NE POSEZ CET OUVRE-PORTE QUE SUR UNE PORTE DE GARAGE CORRECTEMENT ÉQUILIBRÉE. UNE PORTE MAL

ÉQUILIBRÉE PEUT CAUSER DES BLESSURES GRAVES. CONFIEZ LA RÉPARATION DES CÂBLES, DES RESSORTS ET DE TOUT

AUTRE ÉLÉMENT À UN TECHNICIEN QUALIFIÉ AVANT D’ENTREPRENDRE L’INSTALLATION.

(3) ENLEVEZ LES CORDES ET ENLEVEZ OU NEUTRALISEZ TOUT DISPOSITIF DE VERROUILLAGE SOLIDAIRE DE LA PORTE DE

GARAGE AVANT L’INSTALLATION.

(4) DANS LA MESURE DU POSSIBLE, INSTALLEZ L’OUVRE-PORTE À AU MOINS 2.14M (7 PI) DU SOL. POSEZ LE DISPOSITIF DE

DÉSACCOUPLEMENT D’URGENCE À AU MOINS 1.83M (6 PI) DU SOL EN ÉVITANT LE CONTACT AVEC DES VÉHICULES

POUR ÉVITER TOUT DÉCLENCHEMENT ACCIDENTEL.

(5) NE BRANCHEZ PAS L’OUVRE-PORTE AVANT D’Y ÉTRE AUTORISÉ PAR LA NOTICE.

(6) INSTALLEZ LE BOUTON DE COMMANDE:

(i) À UN ENDROIT QUE L’ON PEUT VOIR DE L’EMBRASURE DE LA PORTE;

(ii) À UNE HAUTEUR MINIMALE DE 1.53M (5 PI) DU SOL - AFIN QUE LES JEUNES ENFANTS NE PUISSENT PAS L’ATTEINDRE,

(iii) À L'ÉCART DES PIECES MOBILES DE LA PORTE.

(7) APPOSEZ L’ÉTIQUETTE DE MISE EN GARDE RELATIVE AU DANGER DE HAPPEMENT À PROXIMITÉ DE BOUTON

DE COMMANDE ET L’ÉTIQUETTE RELATIVE AU RÉGLAGE DE LA COMMANDE À UN EMPLACEMENT EN ÉVIDENCE -

PAR EXEMPLE SUR LA PAROI INTÉRIEURE DE LA PORTE DE GARAGE OU SELON LES INSTRUCTIONS DE LA NOTICE

D’INSTALLATION. APPOSEZ L’ÉTIQUETTE RELATIVE AU DÉSACCOUPLEMENT D’URGENCE SUR LE DISPOSITIF OU À

PROMIXIMITÉ DE CE DERNIER.

(8) UNE FOIS L’OUVRE-PORTE INSTALLÉ, LE SENS DE LA COURSE DOIT S’INVERSER LORSQUE LA PORTE ENTRE EN CONTACT

AVEC UN OBJET D’UNE HAUTEUR DE 38 MM (1 ½ PO) (OU UN MADRIER DE 2 X 4 PO DE SECTION, À PLAT) POSÉ SUR LE

SOL.

(9) Pour les produits munis d’un dispositif de desaccouplement manual, indiquez a l’utilisateur final la procedure d’utilisation du

dispositif. Exception: Pour les portes coulissantes, le point 2 doit etre remplace par “Confiez la reparation et l’ajustement du

materiel a un technicien qualifie avant d’entreprendre I’installation de l’ouvre-porte”.

10

GDO-8V3 Shed Master Instruction Manual

Page 11

6.1 Door Preparation

6.1.1 Prepare the Door:

a. Clean the guides if there is any oil or wax present using a suitable

white spirit. The only lubricant suitable for use on door guides is

silicon spray. DO NOT use WD-40, RP-7, petroleum grease, or

similar.

b. Remove the locking bars or disable the lock.

c. Install the locking bar covers 9 if there are locking bar holes in

the guides. This ensures fingers cannot be placed in the holes

while the door operates. (Fig 6.1)

d. Affix the supplied warning labels where they are clearly visible on

the inside of the door.

© Copyright 2017

9

Fig. 6.1

6.2 Fit the Weight Bar

6.2.1 If the door has a handle a weight bar must be fitted to ensure the door doesn’t balloon during operation:

a. Remove the door handle

b. Fit the weight bar 5 and refit the handle using the two (2) M4x50mm Pan Head Screw 8 and the two (2) Flat Washer 7

and the two (2) M4 Nilock Hex nut 6. (Fig 6.2)

6.2.2 If the door does not have a handle:

a. Locate the centre of the door at the bottom rail.

b. Place the weight bar at this point and mark the two positions where the fasteners will go

c. Drill the two 4.5mm holes in the door and fit the weight bar 5 using the two (2) M4x50mm Pan Head Screw 8 and the

two (2) Flat Washer 7 and the two (2) M4 Nilock Hex nut 6.

d. Check that the door is still balanced and smooth. If not, then the door may require servicing.

WARNING! Door springs are under extreme

tension and should only be adjusted by a garage

door professional.

5

5

6

6

8

7

WITH HANDLE WITHOUT HANDLE

8

7

Fig. 6.2

Shed Master Instruction Manual GDO-8V3

Diamond PD Power Drive : Instruction Manual

11

Page 12

6.3 Pinning the Door

6.3.1 Pinning the Door to the drum:

NOTE: Pinning of the door is mandatory and is primarily required in order for

the inherent entrapment protection to function properly. Pinning the door’s

curtain to its drum maintains security when the opener is closed. If the curtain is not

pinned the door can be partially opened manually. (Fig 6.3)

a. Fully close the door.

b. Mark a minimum of two (2) drill holes on the drum to each end of the door. (Fig 6.4)

c. Drill holes using 3.2mm (1/8”) drill bit.

d. Fit M10 x 32mm screws and washers (not supplied) to each of the four (4) holes.

This screw should be positioned as low as possible in the grove, but make sure

that it does not alter the curtain’s normal lead in to the guide.

Screw into the

low part of

grove

Without locking

bars door can be

lifted

BALLOONING

DOOR

Not pinned and

without locking

bars door can be

lifted

PINNED DOORFREE DOOR

Door secure and

will not lift

Fig. 6.3

6.4 Proping the Door

WARNING! Do not allow children/persons around the door and prop.

Serious personal injury and/or property damage can result from failure to follow this warning.

6.4.1 Prepare the Door:

a. At the end opposite to where the opener will be fitted, check that the U-bolt

which holds the door axle to the bracket is tightened securely.

Pin Points

Fig. 6.4

WARNING! The U-bolt must be done up tightly to ensure the stored

energy in the springs cannot be unexpectedly released.

b. Open the door completely and tie rope around the door roll. Do not tie the

rope too tight as damage to the curtain may ensue. This will stop the door

unrolling when taken off the bracket

c. At the end where the opener is to be fitted, support the door with a door stand

or suitable prop. Place a towel between the door and the prop to protect the

door from damage.

WARNING! Make sure the prop is

snug under the door and is stable.

d. At the end where the opener will be fitted use a pencil to mark the position of

the U-bolt in the door bracket and the position of the door bracket on the wall

12

to assist in reassembling.

GDO-8V3 Shed Master Instruction Manual

Towel

Door stand

or prop

Fig. 6.5

U-bolts

Door

bracket

Page 13

6.5 Mounting the Opener

6.5.1 Raising the Door:

a. When in position, remove the U-bolt (or bolts) and saddle from the door

bracket.

b. Lift the door up and away from the wall until clear of the door bracket,

before lowering the door to rest on the door stand or prop. (Fig 6.6)

NOTE: If there is limited ceiling space to lift the door, the door bracket may

have to be removed. If this is required, when refitting the door bracket , use

the reference marks on the wall for correct position and ensure that it is secure

to the wall and will support the door.

WARNING! For tight sideroom installations the door may

have to be taken down.

6.5.2 Mounting the Opener:

a. Remove the opener from the box.

b. Check the drive gear rotates freely, by pulling

the string handle down (there will be a click) to

disengage opener. Then move the forks from

side to side by hand.

c. Slide the opener over the door axle and into

the drum of the door as shown in Fig 6.7.

d. Push the opener in as far as possible (without

interfering with the curtain) SO ONE OF THE

DOOR DRUM’S WHEEL SPOKES IS BETWEEN

THE OPENER’S DRIVE FORKS.

e. Raise the door off the door stand or suitable

prop.

f. Lift up and over the door bracket and use your

reference marks on the door bracket to position

the door.

g. Refit the U-bolt and nuts and tighten (Fig 6.8).

h. Remove the safety rope and door stand or prop.

i. Connect the power cort to a suitable powerpoint, but DO NOT SWITCH ON.

j. Secure the power cord away from any moving object (e.g the door) with the

cable clip supplied.

k. With the opener still disengaged, pull the door up and down to make sure it

runs freely.

Slide

opener

over door

axle

Pull string

down to

disengage

opener

© Copyright 2017

Lift door

up, away

from wall

and down

onto prop

Fig. 6.6

Fig. 6.7

NOTE: After Installation, ensure that parts do not extend over public footpaths

or roads.

Tighten

U-bolts

Fig. 6.8

Shed Master Instruction Manual GDO-8V3

Diamond PD Power Drive : Instruction Manual

13

Page 14

Resistor 2k2

CABLE 1

CABLE 2

RED

BLACK

WHITE

WHITE

WHITE/BLACK

V+ V- NO NC COM

V+ V-

J3

PE

+ I -

Control Board

DCB04-1.04

R1

6.6 Safety Beam Installation

WARNING! The Safety Beam must be installed and

connected before the travel limits are set. The Opener will

not operate without connected Safety Beam.

3

6.6.1 Mounting the beam

A Safety Photo Electric (PE) Beam extends across the door opening. This

Beam is designed to detect an obstruction while the door is closing and to

send a signal to the door opener to reverse or stop the door movement.

itting the Safety Photo Electric (PE) Beam

4

a. Attach the mounting bracket

to adjustment bracket 3 with the

pan head screw (6) (supplied) (Fig 6.9)

b. Attach the PE 2000TS Bracket 2 to PE Beam Transmitter (IR200TS-TX)

with four taptite screws (M3x5) and attach the other side to adjustment

bracket 3 with the pan head screw 6 (supplied).

c. Repeat steps 1 and 2 to assemble the PE Beam Receiver (IR200TS-RX).

Locate the PE Beams in a strategic location in the door opening. The

PE Beams must be placed as close as possible to the door opening at a

height to detect any object 100mm or higher at any point along the floor.

6.6.2 Wiring Connection

A resistor 2.2kOhm is required to detect a short in the wiring of the PE

Beam Receiver. The supplied resistor is to be used inside the PE Beam

Receiver. Install the 2.2kOhm resistor in the PE Beam Receiver between

the V- and NC terminals. Refer to the wiring diagram (Fig 6.10). Remove

membrane 7 (Fig 6.11).Undo 6 taptite screws 9 M4x10 and open

control cover 8 (Fig 6.12). Connect the supplied Harness 10 to the

IR2000TS set (3 core cable (Cable1) to Receiver; 2 core cable (Cable2) to

Transmitter) from one side and to the J3 of the DCB04 control board from

other side.

a. Power up the Opener. The green LED on the PE Beam Transmitter and

red LED on the PE Beam Receiver should turn ON to indicate power.

b. If the PE Beam Receiver is connected to power and the red LED is ON

while the green LED is ON, the PE Beam Transmitter and Receiver are

not aligned.

c. Make horizontal and/or vertical adjustment of the PE Beam Transmitter

and/or Receiver until the red LED of the PE Beam Receiver turns OFF,

indicating alignment (Fig. 6.13).

4

5

Fig. 6.9

6

1

2

Fig. 6.10

Fig. 6.11

7

WARNING:When the Safety Beam is fitted, the doorway must

be clear of all obstructions and persons at all times. Incorrect

8

Fig. 6.12

location of the safety beams may not give safety protection at

all times. Check to make sure that the height of the beam gives

maximum protection.

9

10

WARNING: Install the Safety Beams as per diagram in

(Fig.6.10). Tampering with the Safety Beams could result in

serious personal injury and/or property damage and will void

the warranty.

14

GDO-8V3 Shed Master Instruction Manual

Fig. 6.13

Page 15

6.7 Setting the Datum

WARNING!Use caution when operating the

manual release with the door open since it may

fall rapidly due to weak or broken springs, or

an improperly balanced door.

CAUTION! Do not disengage the opener to manual

operation with children, persons or any objects

including motor vehicles within the doorway.

6.7.1 Datum Preparation:

a. Disengage the opener and move the door by hand to

approximately the mid open position.

b. Re-engage the opener.

c. Using a small blade screw driver turn the datum adjust

screw slowly until the yellow status LED just illuminates.

(Fig 6.14)

© Copyright 2017

WARNING! The safety obstruction detection

system is inoperable if the MINUS (-) and

PLUS (+) buttons are used to drive the door

and travels limits are not set.

NOTE: If the status LED is already illuminated when power is connected then turn the datum adjust screw until the LED goes

off then turn back one notch to illuminate again.

Fig. 6.14

Shed Master Instruction Manual GDO-8V3

Diamond PD Power Drive : Instruction Manual

15

Page 16

6.8 Setting the Travel Limits

WARNING! In setting the close limit position, do not force the door into the floor

with excessive force, as this can interfere with the ease of operation of the manual

release mechanism.

6.8.1 Initial Preparation:

a. With the door at the half way position and the opener engaged, switch power on to the opener.

The red MINUS (-) LIMIT LED will be flashing.

b. Press and hold the MINUS (-) button - the door should start closing. (Fig 6.15)

NOTE: If the door opens, release the MINUS (-) button and press the OPERATE button once to change the motor’s direction.

6.8.2 Set the Limit Positions:

The Limit Positions can vary due to site conditions, such as uneven ground. When setting the Close limits, ensure the position

is when the door makes first contact with the ground. Alternatively for the Open limits the position should be at the height of

the garage opening.

a. Press and hold MINUS (-) button until the door reaches your desired close limit position. The rubber strip at the bottom of

the door should form a good seal with the ground.

b. Release the MINUS (-) button when the door is near the

desired closed position. Single presses of the MINUS (-)

button will inch the door closer to the ground.

c. If the door overshoots press the PLUS (+) button to move

the door in the open direction.

d. When the door is at the desired close position, press the

SET button, the PLUS (+) LIMIT LED will now flash.

e. Press and hold the PLUS (+) button until the door reaches

your desired open limit position. Single presses of the PLUS

(+) button will inch the door open.

f. If the door overshoots press the MINUS (-) button to move

the door in the close direction.

WARNING! The door will automatically close,

open and close again after the next step. Ensure

that nothing is in the door’s path.

g. When the door is at the desired open position, press the

SET button.

h. The door will now automatically close and open to

calculate the safety obstruction settings.

6.8.3 Resetting the Door Limit Positions

Limit positions can be deleted by:

a. Press and hold MINUS (-) button for six (6) seconds until

the MINUS (-) LIMIT LED flashes quickly.

b. Release the MINUS (-) button.

NOTE: If no action is taken within 30 seconds, the opener

will return to normal operating mode and restore the

original settings.

c. Follow steps a - f in 6.8.2 Set the Limits Poisitions to set

new limit positions.

16

GDO-8V3 Shed Master Instruction Manual

Fig. 6.15

6.8.4 Reset all Factory Defaults

a. Turn power to the opener off.

b. Press and hold the SET Button.

c. Turn power on while holding the SET button.

Continue to hold until all LED’s are off.

d. This will NOT erase transmitter codes stored in memory.

Page 17

6.9 Safety Testing

© Copyright 2017

6.9.1 Testing the Close Cycle

a. Press the OPERATE button to open the door..

b. Place an object approximately 1-1/2”(38mm) high (or a 2”x 4”

board laid flat) on the floor under center of garage door opening

(Fig.6.16)

c. Press the OPERATE button to close the door.

d. When door contacts the object, the door must stop (within 2

seconds) and reverse to open position.

If the door does not properly reverse.

• Check the “close” limit position. It should not have reached its

“close” limit before hitting board.

• If the door STOPS but does not reverse, decrease FORCE (refer to

Section 6.9.4).

WARNING! If the door is closing and is unable

to re-open when obstructed, discontinue use.

Do not use a door with faulty obstruction sensing.

Repair fault and re-test before using.

6.9.2 Testing the Open Cycle

a. Press the OPERATE button to close the door.

b. Press again to open the door. When the door is reaching half of the

opening distance, grab the bottom rail of the door firmly, the door

should stop.

If the door does not stop when opening, the force may be excessive

and need adjusting, refer to Step 6.9.4.

WARNING! Risk of entrapment. After adjusting either

the force or limits of travel, re-test the door opener.

The door MUST reverse on contact with a 1-1/2 inch high

object (or a 2” by 4” board laid flat) at the center of

doorway on the floor

CAUTION: Take care when completing a

safety test. Failure to follow this warning

can result in serious personal injury and/or

property damage.

2”x 4” board

Fig. 6.16

WARNING! If the door fails these tests,

put the opener into manual mode, only

operate the door by hand and call for

service.

Adjusting Safety Obstruction Force

The safety obstruction force is calculated automatically and set in memory on the operator. It is usually not necessary to adjust

the safety obstruction force. The only time the force may need to be increased is due to environmental conditions, for example,

windy or dusty areas, and areas with extreme temperature changes.

6.9.3 To Increase Force Pressure

a. Press and hold the FORCE MARGIN SET button (Fig 6.17).

b. While holding down the FORCE MARGIN SET button, press the

PLUS (+) button. Each press increases the force margin.

c. The PLUS (+) LIMIT LED will flash each time the PLUS (+) button

is pressed to indicate an increase in force.

d. If the PLUS (+) LIMIT LED flashes continuously when the PLUS (+)

button is being pressed, this indicates that the maximum force

pressure setting has been reached.

e. Test the force again as per Section 6.9.1 and 6.9.2 above.

6.9.4 To Decrease Force Pressure

a. Press and hold the FORCE MARGIN SET button

(Fig 6.17).

b. While holding down the FORCE MARGIN SET button,

press the MINUS (-) Button. Each press decreases the

force margin. The MINUS (-) LIMIT LED will flash each

time the MINUS (-) button is pressed to indicate a

decrease in force.

c. If the MINUS (-) LIMIT LED flashes continuously when

the MINUS (-) button is being pressed, this indicates

that the minimum force setting has been reached.

d. Test the force again as per Step 6.9.1 and 6.9.2

above.

6.9.5 To Recall Factory Set Force

a. While holding down the FORCE MARGIN SET

button, press the SET button for two seconds.

Fig. 6.17

b. Release both buttons. The default setting should

now be recalled.

Shed Master Instruction Manual GDO-8V3

Diamond PD Power Drive : Instruction Manual

17

Page 18

6.10 Attach Warning Labels

876542 31

DESCRIPTION

TEAR LINE

WARNING

876542 31

DESCRIPTION

TEAR LINE

6.10.1 Placement of Warning labels

• Attach the entrapment warning label on the wall near the door

control with tacks or staples at a minimum hright of 5 feet above

floors, landings, steps or other adjacent walking surface so shall

children are not able to reach it.

• Place the attached entrapment warning label on wall. Use an

additional mechanical means (plate, board etc.) which can secure

the labels to surfaces to which the adhesive will not adhere.

• DO NOT REMOVE OR PAINT OVER THIS LABEL

S’assurer que ce label de sécurité soit placé dans un emplacement

Les consignes de sécurité doivent être expliquées aux adultes et aux enfants et DOIVENT être

D’autres consignes de sécurité figurent dans le manuel des instructions d'installation.

ATTENTION!

respectées.

proéminent de façon à être vu et lu.

AVERTISSMENT

Un enfant peut être coincé sous une porte de garage

automaue. Ceci peut causer des blessures graves ou même

entraîner la mort.

1. Ne jamais laisser un enfant marcher ou courir sous une porte en mouvement.

2. Ne jamais laisser un enfant aconner l’oure-porte de garage.

3. Toujours surveiller la porte lorsqu’elle est en mouvement.

4. Au cas où une personne serait coincée sous une porte, appuyer sur le bouton de

contrôle, ou déclencher le déverrouillage de secours.

5. Maintenir toujours la porte de garage bien équilibrée.

6. Verifier l’ouver-porte chaque mois (consulter le manuel du propriétaire): uliser

un objet de 1-1/2 pouce de hauteur (ou une planche de 2x4 posée à plat) sur le sol

sous la porte qui se ferme. Si au contact, la porte ne remonte pas, il sera nécessaire

de procéder à un réglage, de réparer, ou de remplacer le mécanisme.

7. NE PAS ENLEVER CETTE ÉTIQUETTE NI LA COUVRIR DE PEINTURE.

8. Placer ce label de signalisaon de danger près du commutateur mural et installer

le commutateur mural hors de portée des enfants (au moins à 1.5 m (5’) du sol).

9. Ce système de l’operateur est équipée avec une

opéraon feature unaended. La porte pourrait passer inopinément. Personne ne

doit traverser la trajectoire d’une porte en mouvement.

Please ensure that this Safety Label is placed in a prominent location so that it can be viewed and read.

.

The warnings should be explained to all children and adults and MUST be followed.

Further Safety Information is available in the Owners Copy of the installation Instruction.

There is risk of a child becoming trapped under an

automatic garage door resulting in severe injury or

death.

Never let children walk or run under a moving door.1.

Never let children operate door operator controls.2.

Always keep moving door in sight.

3.

In the event a person is trapped under the door, push the control 4.

button or use the emergency release.

Keep Garage Door Properly Balanced.

5.

Test Door Operator Monthly (refer to your Owner’s Manual): Use a

6.

1-1/2-inch high object (or a 2 by 4 board laid flat) on the floor under

the closing door. In the event the door does not reverse upon

contact, adjust, repair, or replace the operator.

DO NOT REMOVE OR PAINT OVER THIS LABEL.

7.

Mount this label adjacent to the wall control, and mount the wall

8.

control out of children’s reach (at least 5 feet above floor).

This Operator System is equipped with an unattended operation

9.

feature. The door could move unexpectedly. No one should cross

the path of the moving door.

CAUTION!

Fig.6.18

6.11 Accessories

6.11.1 Installation of Wall Mounted Transmitter

Refer to the below warning before installing the wall transmitter

(Fig 6.19).

To set the transmitter codes refer to Section 6.11.1.

IMPORTANT WARNING

LOCATE THE WALL MOUNTED REMOTE CONTROL:

(1) WITHIN SIGHT OF DOOR.

(2) AT MINIMUM HEIGHT OF 5 FEET ABOVE FLOORS,

LANDINGS, STEPS OR OTHER ADJACENT WALKING

SURFACE SO SHALL CHILDREN ARE NOT ABLE TO REACH

IT, AND

(3) AWAY FROM MOVING PARTS OF THE DOOR.

(4) PLACE THE ATTACHED ENTRAPMENT WARNING LABEL ON

WALL NEXT TO WALL MOUNTED TRANSMITTER. USE AN

ADDITIONAL MECHANICAL MEANS (PLATE, BOARD, ETC.),

WHICH CAN SECURE THE LABELS TO SURFACES TO WHICH

THE ADHESIVE WILL NOT ADHERE.

(5) DO NOT REMOVE OR PAINT OVER THIS LABEL.

Fig.6.19

IMPORTANT

PLACEZ LA TÉLÉCOMMANDE MURALE:

(1) EN VUE DE LA PORTE.

(2) À UNE HAUTEUR D'AU MOINS 1,50M (5PIEDS) AU-DESSUS

DU SOL, DU PERRON, DES MARCHES, ETC. AFIN QUE LES

PETITS ENFANTS NE PUISSENT PAS L'ATTEINDRE,

(3) ET À DISTANCE DES ÉLÉMENTS MOBILES DE LA PORTE.

(4) PLACEZ L'ÉTIQUETTE AVERTISSANT DU RISQUE DE SE

FAIRE PIÉGER SUR LE MUR À PROXIMITÉ DE L'ÉMETTEUR.

UTILISEZ UN SUPPORT PHYSIQUE SUPPLÉMENTAIRE

(PLAQUE, PANNEAU, ETC.) PERMETTANT DE FIXER LES

ÉTIQUETTES SI ELLES N'ADHÈRENT PAS À LA SURFACE

DU MUR.

(5) CETTE ÉTIQUETTE NE DOIT PAS ÊTRE RETIRÉE NI PEINTE.

18

GDO-8V3 Shed Master Instruction Manual

Page 19

© Copyright 2017

6.12 Coding a Transmitter

TRANSMITTERS COMPLIANCE STATEMENT

TRANSMITTERS COMPLY WITH ALL UNITED STATES AND CANADIAN LEGAL REQUIREMENTS AS OF THE DATE OF

MANUFACTURE. TO COMPLY WITH FCC PART 15 AND OR RSS 210 OF INDUSTRY CANADA (IC) RULES, ADJUSTMENT OR

MODIFICATIONS OF THIS RECEIVER AND / OR TRANSMITTER ARE PROHIBITED, EXCEPT FOR CHANGING THE CODE

SETTING OR REPLACING THE BATTERY. THERE ARE NO OTHER USER SERVICEABLE PARTS. TESTED TO COMPLY WITH FCC

STANDARD FOR HOME OR OFFICE USE. OPERATION IS SUBJECT TO THE FOLLOWING TWO CONDITIONS:

(1) THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE, AND

(2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED

OPERATION.

NOTE: THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO COMPLY WITH THE LIMITS FOR A CLASS B DIGITAL DEVICE,

PURSUANT TO PART 15 OF THE FCC RULES. THESE LIMITS ARE DESIGNED TO PROVIDE REASONABLE PROTECTION

AGAINST HARMFUL INTERFERENCE IN A RESIDENTIAL INSTALLATION. THIS EQUIPMENT GENERATES, USES AND CAN

RADIATE RADIO FREQUENCY ENERGY AND, IF NOT INSTALLED AND USED IN ACCORDANCE WITH THE INSTRUCTIONS,

MAY CAUSE HARMFUL INTERFERENCE TO RADIO COMMUNICATIONS. HOWEVER, THERE IS NO GUARANTEE THAT

INTERFERENCE WILL NOT OCCUR IN A PARTICULAR INSTALLATION. IF THIS EQUIPMENT DOES CAUSE HARMFUL

INTERFERENCE TO RADIO OR TELEVISION RECEPTION, WHICH CAN BE DETERMINED BY TURNING THE EQUIPMENT OFF

AND ON, THE USER IS ENCOURAGE TO TRY TO CORRECT THE INTERFERENCE BY ONE OR MORE OF THE FOLLOWING

MEASURES:

REORIENT OR RELOCATE THE RECEIVING ANTENNA

INCREASE THE SEPARATION BETWEEN THE EQUIPMENT AND RECEIVER

CONNECT THE EQUIPMENT INTO AN OUTLET ON A CIRCUIT DIFFERENT FROM THAT TO WHICH THE RECEIVER IS

CONNECTED. CONSULT YOUR LOCAL DEALER OR AN EXPERIENCED RADIO/TV TECHNICIAN FOR HELP.

DÉCLARATION DE CONFORMITÉ DE L'ÉMETTEUR

LES ÉMETTEURS SONT CONFORMES À TOUTES LES EXIGENCES LÉGALES DES ÉTATS-UNIS ET DU CANADA À LA DATE

DE FABRICATION. POUR RESPECTER LES DISPOSITIONS DE LA FCC (PARTIE15) ET/OU RSS 201 D'INDUSTRY CANADA

(IC), LES RÉGLAGES OU MODIFICATIONS DE CE RÉCEPTEUR ET/OU ÉMETTEUR SONT INTERDITS, À L'EXCEPTION DU

CHANGEMENT DE CODE OU DU REMPLACEMENT DE LA BATTERIE. AUCUNE AUTRE PIÈCE NE PEUT ÊTRE RÉPARÉE PAR

L'UTILISATEUR. CONFORMITÉ À LA NORME FCC TESTÉE POUR UN USAGE DOMESTIQUE OU DE BUREAU. L'UTILISATION

EST SOUMISE AUX DEUX CONDITIONS SUIVANTES:

(1) CET APPAREIL NE DOIT PAS CAUSER D'INTERFÉRENCES;

(2) CET APPAREIL DOIT ACCEPTER TOUTE INTERFÉRENCE EXTÉRIEURE, Y COMPRIS CELLES QUI SONT SUSCEPTIBLES DE

PROVOQUER UN DYSFONCTIONNEMENT.

REMARQUE: CET ÉQUIPEMENT A ÉTÉ TESTÉ ET DÉCLARÉ CONFORME AUX LIMITATIONS APPLICABLES À UN APPAREIL

NUMÉRIQUE DE CLASSE B, CONFORMÉMENT AUX DISPOSITIONS DE LA PARTIE 15 DES RÈGLES DE LA FCC. CES

LIMITATIONS VISENT À ASSURER UNE PROTECTION SUFFISANTE CONTRE LES INTERFÉRENCES DANS UNE INSTALLATION

RÉSIDENTIELLE. CET ÉQUIPEMENT DÉGAGE, UTILISE ET PEUT DIFFUSER DES ONDES RADIO. S'IL N'EST PAS INSTALLÉ

ET UTILISÉ CONFORMÉMENT AUX INSTRUCTIONS, LES INTERFÉRENCES PEUVENT PERTURBER LES COMMUNICATIONS

RADIO. IL N'Y A TOUTEFOIS AUCUNE GARANTIE QUE DES INTERFÉRENCES NE SE PRODUIRONT PAS DANS UNE

INSTALLATION DONNÉE. SI CET ÉQUIPEMENT VIENT À CAUSER DES INTERFÉRENCES AVEC LA RÉCEPTION DE LA RADIO

OU DE LA TÉLÉVISION, CE QUI PEUT ÊTRE DÉTERMINÉ EN L'ÉTEIGNANT ET EN LE RALLUMANT, L'UTILISATEUR EST INVITÉ

À Y REMÉDIER EN PRENANT UNE OU PLUSIEURS DES MESURES SUIVANTES:

RÉORIENTER OU DÉPLACER L'ANTENNE DE RÉCEPTION;

ÉLOIGNER L'ÉQUIPEMENT DU RÉCEPTEUR;

BRANCHER L'ÉQUIPEMENT DANS UNE PRISE DE COURANT D'UN CIRCUIT ÉLECTRIQUE DIFFÉRENT.

LE CAS ÉCHÉANT, CONSULTEZ VOTRE REVENDEUR OU UN TECHNICIEN RADIO/TV EXPÉRIMENTÉ.

Shed Master Instruction Manual GDO-8V3

Diamond PD Power Drive : Instruction Manual

19

Page 20

6.12 Coding a Transmitter

6.12.1 Storing the Transmitter Code

The opener can only operated from remote control transmitters

that have been programmed into its memory. Up to 64 codes

can be stored in the memory.

a. Press and hold the DOOR CODE button.

b. Press Button 1 on the transmitter for two seconds. Release

and pause for two seconds. Press the Button 1 again for two

seconds.

c. Release the DOOR CODE button. The transmitter button is

now coded, press to test.

6.12.2 Coding a Transmitter to Enable Vacation Mode

The opener can be programmed into a “Vacation Mode” where

the opener will not respond to any transmitter except the button

of the transmitter that was programmed for vacation mode.

a. Briefly press the DOOR CODE button once, then press it

again and hold (will beep two times on second press).

b. Press one of the four (4) buttons on the transmitter for two

(2) seconds, pause for two (2) seconds, then press the same

button again for two (2) seconds.

c. Release DOOR CODE button.

d. Press and hold the transmitter button for six (6) seconds to

set Vacation Mode. The door code LED will stay lit while

Vacation Mode is active.

e. To reset Vacation Mode, press the same button for two

seconds.

Button 1

Fig.6.19

6.12.3 Remotely Coding Transmitters

Using this method transmitters can be coded without access to

the opener’s control panel as long as a pre-coded transmitter

is available.

a. Take any pre-coded transmitter. Press the button for the

function to be duplicated and release.

b. Using a small needle / pen, press and hold firmly for two

seconds the middle button, through the Coding Hole.

c. Within ten (10) seconds take the additional transmitter you

wish to code. Hold the new transmitter’s button for two

seconds, pause for two seconds, hold again for two seconds

and then release.

d. Wait for ten (10) seconds and then press the new transmitter’s

button to test.

6.12.4 Erasing a Stored Transmitter Code

a. Select the transmitter you want to delete.

b. Press and hold the DOOR CODE BUTTON.

c. Press the transmitter button you would like to delete for two

seconds, pause for two seconds, press again for two seconds

and then release.

d. Release the DOOR CODE BUTTON. The code should now

be deleted. Confirm this by pressing the transmitter button

- the function (e.g. door opening) should not respond.

Fig.6.20

WARNING! The manufacturer is not responsible

for any radio or TV interference caused by

unauthorized modifications to this equipment.

Such modifications could void the user’s

authority to operate the equipment.

6.12.5 Erasing All Transmitter Codes

a. Turn off power to the opener.

b. While switched off, press and hold the DOOR CODE

BUTTON. Turn on power to the opener while holding this

button.

c. The OPEN LIMIT, CLOSE LIMIT and DOOR STATUS LEDs

will illuminate for about five seconds. These LED’s will turn

off and the CODING LED will illuminate.

d. Release the DOOR CODE BUTTON. All stored codes will

now be deleted. Confirm this pressing buttons on any

previously coded transmitters - the opener should not

respond.

20

GDO-8V3 Shed Master Instruction Manual

Page 21

© Copyright 2017

7. Operation Instructions

IMPORTANT SAFETY INSTRUCTIONS

WARNING! TO REDUCE THE RISK OF SEVERE INJURY OR DEATH:

(1) READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

(2) NEVER LET CHILDREN OPERATE OR PLAY WITH DOOR CONTROLS. KEEP THE REMOTE CONTROL AWAY FROM

CHILDREN.

(3) ALWAYS KEEP THE MOVING DOOR IN SIGHT AND AWAY FROM PEOPLE AND OBJECTS UNTIL IT IS COMPLETELY

CLOSED. NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

(4) NEVER GO UNDER A STOPPED, PARTIALLY OPEN DOOR.

(5) TEST DOOR OPENER MONTHLY. THE GARAGE DOOR MUST REVERSE ON CONTACT WITH A 1-1/2-INCH HIGH OBJECT

(OR A 2 BY 4 BOARD LAID FLAT) ON THE FLOOR. AFTER ADJUSTING EITHER THE FORCE OR THE LIMIT OF TRAVEL,

RETEST THE DOOR OPENER. FAILURE TO ADJUST THE OPENER PROPERLY INCREASES THE RISK OF SEVERE INJURY OR

DEATH.

(6) FOR PRODUCTS HAVING AN EMERGENCY RELEASE, WHEN POSSIBLE, USE THE EMERGENCY RELEASE ONLY WHEN THE

DOOR IS CLOSED. USE CAUTION WHEN USING THIS RELEASE WITH THE DOOR OPEN. WEAK OR BROKEN SPRINGS ARE

CAPABLE OF INCREASING THE RATE OF DOOR CLOSURE AND INCREASING THE RISK OF SEVERE INJURY OR DEATH.

(7) KEEP GARAGE DOORS PROPERLY BALANCED. SEE OWNER’S MANUAL. AN IMPROPERLY BALANCED DOOR

INCREASES THE RISK OF SEVERE INJURY OR DEATH. HAVE A QUALIFIED SERVICE PERSON MAKE REPAIRS TO CABLES,

SPRING ASSEMBLIES, AND OTHER HARDWARE.

(8) SAVE THESE INSTRUCTIONS.

AVERTISSEMENT!

POUR RÉDUIRE LE RISQUE DE BLESSURES GRAVES, VOIRE DE MORT:

(1) LISEZ ATTENTIVEMENT TOUTES LES INSTRUCTIONS D’INSTALLATION.

(2) NE LAISSEZ JAMAIS LES ENFANTS UTILISER LES COMMANDES DE LA PORTE OU JOUER AVEC. LA TÉLÉCOMMANDE

DOIT RESTER HORS DE PORTÉE DES ENFANTS.

(3) GARDEZ TOUJOURS LA PORTE EN MOUVEMENT DANS VOTRE LIGNE DE VISION, ET VEILLEZ À CE QU’ELLE RESTE

ENTIÈREMENT DÉGAGÉE JUSQU’À SA FERMETURE COMPLÈTE. PERSONNE NE DOIT SE TENIR DANS LE PASSAGE

PENDANT QUE LA PORTE EST EN MOUVEMENT.

(4) NE STATIONNEZ JAMAIS SOUS UNE PORTE PARTIELLEMENT OUVERTE.

(5) TESTEZ LE DISPOSITIF D’OUVERTURE UNE FOIS PAR MOIS. LA PORTE DOIT OBLIGATOIREMENT INVERSER SA COURSE

EN CAS DE CONTACT AVEC UN OBJET DE 25 À 40MM (1-1/2’’) (OU UNE PLANCHE DE 5X10 CM [2X4’’]POSÉE À

PLAT) AU MILIEU DU PASSAGE. APRÈS AVOIR RÉGLÉ LA FORCE OU LA LIMITE DE COURSE, REFAITES UN ESSAI DU

SYSTÈME D’OUVERTURE DE PORTE. LE DISPOSITIF D’OUVERTURE DOIT ÊTRE BIEN RÉGLÉ AFIN DE RÉDUIRE LE RISQUE

DE BLESSURES GRAVES, VOIRE DE MORT.

(6) DANS LE CAS DES PRODUITS ÉQUIPÉS D’UN DÉBLOCAGE D’URGENCE, UTILISEZ-LE DANS LA MESURE DU POSSIBLE

UNIQUEMENT QUAND LA PORTE EST FERMÉE. SOYEZ PRUDENT SI VOUS ACTIONNEZ CE DISPOSITIF DE DÉBLOCAGE

ALORS QUE LA PORTE EST OUVERTE. DES RESSORTS FAIBLES OU CASSÉS RISQUENT D’ACCÉLÉRER LA FERMETURE DE

LA PORTE ET DE CAUSER DES BLESSURES GRAVES, VOIRE DE PRÉSENTER UN DANGER DE MORT.

(7) LES PORTES DE GARAGE DOIVENT TOUJOURS ÊTRE CORRECTEMENT ÉQUILIBRÉES. REPORTEZ-VOUS AU MANUEL.

UNE PORTE MAL ÉQUILIBRÉE PRÉSENTE UN DANGER DE BLESSURES GRAVES, VOIRE DE MORT. LES RÉPARATIONS

DES CÂBLES, DES ASSEMBLAGES À RESSORT ET AUTRES ÉLÉMENTS MATÉRIELS DOIVENT ÊTRE EFFECTUÉES PAR UN

TECHNICIEN QUALIFIÉ.

(8) CONSERVEZ CES INSTRUCTIONS EN LIEU SÛR.

Shed Master Instruction Manual GDO-8V3

21

Diamond PD Power Drive : Instruction Manual

Page 22

7.1 How to Use Your Operator

For maximum efficiency of your operator, your

garage door must be in good operating condition.

An annual service of your garage door by door

professional is recommended.

Fig.7.1

REPLACE WITH BATTERY CR2032

CAUTION! Activate the operator only when the door is in full view,

free of obstructions and with the operator properly adjusted. No

one should enter or leave the garage while the door is in motion.

DO NOT allow children to play near the door.

WARNING! This operator has a grounding type plug and

there are no user serviceable parts inside this operator.

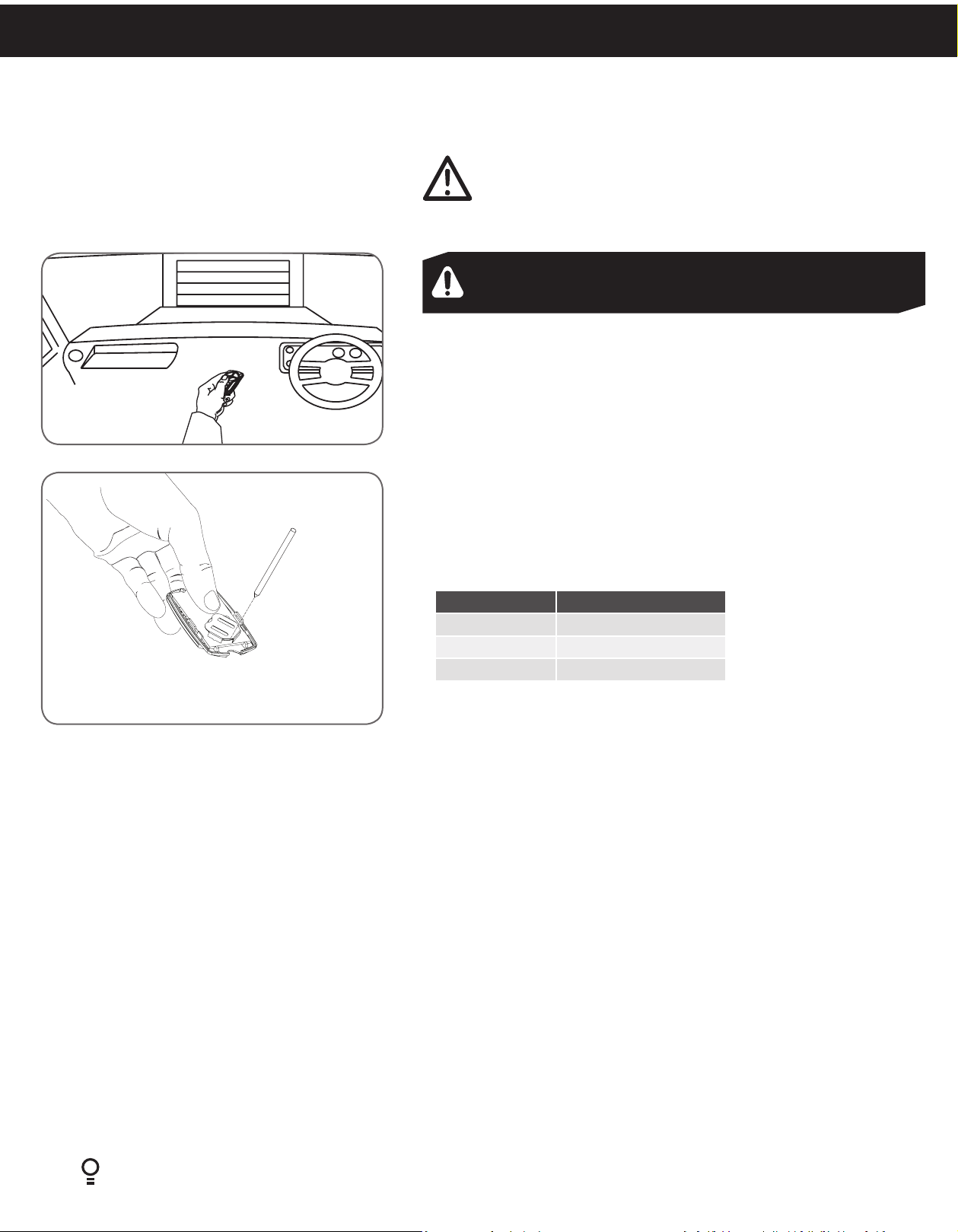

7.1.1 To Operate the opener:

a. Press the programmed transmitter button until your door begins to move

(usually 2 seconds). Make sure you can see the door when you use the

transmitter (Fig 7.1).

b. If you are in a vehicle you should aim the transmitter through your

windscreen as shown.

c. Check that the door is fully open or closed before you drive in or away.

d. If you press the transmitter whilst the door is moving the door will stop.

The next press of the transmitter will move the door in the opposite

direction.

7.1.2 Replacing the Battery: 3V Lithium Battery CR2032.

a. To test the battery is working, press and hold a transmitter button. Check

Light Status table to determine if battery needs replacing

Light Status Battery Status

Solid OK

Flashing Requires replacement

No light Requires replacement

Fig.7.2

b. Remove screw from back of cover.

c. Use screw driver to separate the transmitter casing to expose circuit

board.

d. Use a non-metallic object (e.g. pen) to remove the battery.

(Fig. 7.2).

22

GDO-8V3 Shed Master Instruction Manual

Page 23

© Copyright 2017

7.2 User Operating Controls

Button Function

1. OPERATE Opens/stops/closes the door

2. CODING LED (Red) Flashes when a code is being stored or when the transmitter button is pressed

3. DOOR CODE (Blue) Is used for storing or erasing transmitter buttons for door operation

4. PLUS (+) LED (Green) Illuminates and flashes as the door opens and remains on when the open limit position has

been reached.

5. DOOR STATUS LED (Yellow) Illuminates when Service is due.

6. MINUS (-) LED (Red) Illuminates and flashes as the door opens closes, and remains on when the close limit

position has been reached.

05

0203 04

01

06

Fig.7.3

7.3 Door Status Indicators

Door Status Indicators PLUS (+) LED (green) MINUS (-) LED (red) Beeper

Open On

Close On

Opening Flashing

Closing Flashing

Door travel stopped Flashing Flashing

Door obstructed when opening Flashing Beeps while door is

moving

Door obstructed when closing Flashing Beeps while door is

moving

Opener overloaded Alternating flashes Alternating flashes

Mains power interrupted Rapid flashes

Shed Master Instruction Manual GDO-8V3

Diamond PD Power Drive : Instruction Manual

23

Page 24

8. User Maintenance Instruction

WARNING! Run the Safety Testing procedures

MONTHLY in Section 6.9 to ensure garage door

is fit for use.

8.1 Door Maintenance

A poorly maintained door could cause fatal / serious injuries or

damage to property.

a. Frequently examine the door, particularly the cables, springs

and mountings for signs of wear, damage or imbalance. DO

NOT USE if repair or adjustment is needed since a fault in

the installation or an incorrectly balanced door may cause

injury.

b. Fasteners: Check all screws, nuts and bolts to ensure they

are secure.

c. Spring Tension: It is natural for springs to lose tension.

Should the door become hard to operate or completely

inoperative, contact a door professional.

d. Guide Tracks: Clean the internal sections of the guide tracks

every 3 - 6 months with a cloth dampened with mineral

turps or methylated spirits.

CAUTION! Frequently examine the installation, in

particular cables, springs and mountings, for signs of

wear, damage or imbalance. DO NOT USE if repair or

adjustment is needed since a fault in the installation or

an incorrectly balanced door may cause injury.

Adjustments should only be carried out by experienced

persons, as this function can be dangerous if not

performed under strict safety procedures.

WARNING! Failure to maintain your garage

door may void the warranty on your garage door

operator.

8.2 If You Need a Service Call

If the opener needs a service please call the dealer who installed

the garage door opener (their contact details are usually on a

sticker on the back of your garage door).

BEFORE CALLING you should have the following information to

assist in providing the appropriate service:

1. Has anything happened since the opener last operated OK,

e.g. a storm, a jolt to the door etc.?

2. What is the current light status on the opener?

3. Manually disengage the door (Section 5).

How easy is it to manually open and close the door?

4. What model is the opener? (Model no. information is located

at the rear of the opener)

5. Who installed the opener? (Dealer details should be on a

sticker on the back of your garage door)

6. When was it installed? (If known)

24

GDO-8V3 Shed Master Instruction Manual

Page 25

9. Troubleshooting

Symptom Possible cause Remedy

© Copyright 2017

The opener does not

work from the transmitter

One transmitter works

but the other/s do not

The motor is running

but the door remains

stationary

The transmitter range

varies or is restricted

The opener does not have power

The battery in the transmitter is flat

The opener has been put into

“Vacation Mode”

The transmitter button is not

programmed to operate the door.

Door Code LED is flashing yet the

opener is not working.

Faulty transmitter

Flat battery

The opener is disengaged Re-engage the opener

Variations are normal depending on

conditions e.g. temperature or external

interference

The battery life is exhausted

Position of the transmitter in the motor

vehicle

Plug a device of similar voltage (e.g. a hairdryer) into

the power point and check that it is OK

Replace the battery

Turn off “Vacation Mode”

(Section 6.12.2)

Code in the transmitter

Ensure the correct button on the transmitter is being

pressed.

Replace transmitter

Replace battery

Make sure you can see the door when you use the

transmitter.

Check the battery status by pressing a button (flashing

or no light requires battery to be changed)

Aim the transmitter through the windscreen.

The door reverses for no

apparent reason

The door stops or moves

very slowly.

The SERVICE LED has

started to flash and is

beeping numerous times

The Open (Green) LED

and MINUS (-) (Red) LED

are flashing alternatively

The Open (Green) LED

continues to flash

The MINUS (-) (Red) LED

continues to flash

This may occur occasionally from

environmental conditions such as areas

that are windy, dusty or have extreme

temperature changes.

If Safety beams are installed they may

be partially obstructed.

Garage door in poor condition e.g.

springs may be broken.

A Fault has been detected. The fault

will be active each time an attempt is

made to operate the door.

Opener is overloaded Check the doors operation by disengaging the motor

Door obstructed when opening Clear away any obstructions and test door opens

Door obstructed when closing

Ensure the door runs smoothly before increasing the

force pressure.

Ensure the beam path is not obstructed. Check the

Alignment.

Check the door’s operation.

Record opener function (How many beeps?) then

press the SET button once to reset the opener. If the

fault continues to be tripped contact your dealer for

support.

and ensuring the door runs smoothly. If necessary

make door adjustments or discontinue use and

contact your dealer for support.

correctly. (If door is damaged, contact your door

professionl).

Clear away any obstructions and test door closes

correctly. (If door is damaged, contact your door

professional).

Limits may be cleared

Remove all power sources. Wait till all lights are out

(10-15 secs), then reconnect power. If Red LED is

flashing, limits are not set. Reset Limits.

Shed Master Instruction Manual GDO-8V3

Diamond PD Power Drive : Instruction Manual

25

Page 26

10. Customer Agreement & Warranty

PLEASE READ THIS AGREEMENT CAREFULLY TO ENSURE THAT YOU UNDERSTAND EACH PROVISION. THIS AGREEMENT REQUIRES THE USE OF

ARBITRATION ON AN INDIVIDUAL BASIS TO RESOLVE DISPUTES, RATHER THAN JURY TRIALS OR CLASS ACTIONS, AND ALSO LIMITS THE REMEDIES

AVAILABLE TO YOU IN THE EVENT OF A DISPUTE.

This Agreement, the product manual, Limited Warranty terms below, terms and conditions, and terms of service for garage door opener products, features, and

applications (“Products”) not otherwise described herein that are posted on applicable ATA websites or devices, and any documents expressly referred to herein or

therein, make up the complete agreement between you and ATA and supersede any and all prior agreements and understandings related to the subject matter of

this Agreement.

WARRANTY PERIOD

MOTOR & PARTS 5 years / 10,000 cycles

which ever occurs first

ACCESSORIES

1 Year

(e.g Safety Beams)

CONSUMABLES

(e.g Batteries in remote control

transmitters and light bulbs and fuses)

This Warranty is to be read in conjuction with the owner’s copy of the installation instruction

manual.

LIMITED WARRANTY

1. The product will operate properly providing you comply with the instructions

concerning installation, operation, and maintenance and testing. Failure to

act in accordance with those instructions may void all or part of this limited

warranty.

2. The warranty periods for different parts of this product are set out in the table

above. If during the relevant warranty period, this product appears to contain

a defect in a component covered by this limited warranty, call your Retailer,

who will advise you how to disassemble it and to send in a suitably secured

packaging, pre-paid and insured, to a service center. Please include a brief

description of the problem and a dated proof-of-purchase receipt.

3. If ATA confirms the product is defective and covered by this limited warranty,

ATA will be repair or replace it (at ATA’s sole option) and return it to you, at no

cost to you. Defective parts will be repaired or replaced with new or factoryrebuilt parts at ATAs sole option. (You are responsible for any costs incurred in

removing and/or reinstalling the product or any component).

4. THIS WARRANTY EXCLUDES DAMAGE RESULTING FROM:

(A) NORMAL WEAR AND TEAR;

(B) ACCIDENTAL DELIBERATE OR NEGLIGENT DAMAGE OR DAMAGE CAUSE

BY INSECTS;

(C) BLOWN FUSES, ELECTRICAL SURGES, POWER SURGES OR POWER SPIKES;

(D) THEFT, FIRE, FLOOD, RAIN, WATER, LIGHTNING, STORMS OR ANY OTHER

ACTS OF GOD;

(E) ANY INSTALLATION, CONFIGURATION OR USE OF THE PRODUCT

CONTRARY TO THE INSTRUCTIONS SUPPLIED WITH THE PRODUCT;

(F) MAXIMUM CONTINUOUS OPERATING TIME EXCEEDING 1 MINUTE IN 10;

(G) THE OPERATING FORCE EXCEEDING 33LBS (150 NEWTON) WHEN MOVING

THE DOOR MANUALLY TO THE OPEN OR CLOSED POSITION (THE DOOR

THAT THE PRODUCT IS USED WITH SHOULD BE BALANCED IN SUCH A

WAY THAT THE USER IS ABLE TO OPEN OR CLOSE THE DOOR MANUALLY

USING A FORCE NOT GREATER THAN 150 NEWTON (33 LBS), OTHER THAN

TO INITIALLY CAUSE THE DOOR TO START MOVING, WHICH MAY REQUIRE

FORCE IN EXCESS OF THAT SPECIFIED IN THIS PARAGRAPH) ;

(H) DOOR SURFACE AREA AND/OR WEIGHT EXCEEDING 92FT2 AND 595LBS

RESPECTIVELY;

(I) THE DOOR USED WITH THE PRODUCT NOT BEING IN SAFE WORKING

ORDER AND CONDITION;

(J) REPAIRS WHICH ARE NOT AUTHORIZED BY ATA;

(K) ANY UNAUTHORIZED MODIFICATION TO THE PRODUCT OR ACTS OR

OMISSIONS OF ANY PERSON (INCLUDING SERVICE PROVIDERS APPROVED

BY ATA) OTHER THAN ATA;

(L) FAULTY OR UNSUITABLE WIRING IN THE BUILDING IN WHICH THE

PRODUCT IS INSTALLED;

(M) ANY COST OR EXPENSE RELATING TO THE RECALL OF THE

PRODUCT;

(N) INSTALLATION OF A RESIDENTIAL GARAGE DOOR OPENER IN A

COMMERCIAL OR INDUSTRIAL PREMISES OR IN A DWELLING OTHER

26

THAN A SINGLE-FAMILY DWELLING;

GDO-8V3 Shed Master Instruction Manual

Not covered

(O) RADIO OR ELECTRICAL INTERFERENCE; OR LACK OF AVAILABILITY OR

(I) DOOR SURFACE AREA AND/OR WEIGHT EXCEEDING 92FT2 AND

595LBS RESPECTIVELY;

(II) THE DOOR USED WITH THE PRODUCT NOT BEING IN SAFE WORKING

ORDER AND CONDITION

5. This Warranty is not transferable.

6. No additional warranty will apply for Products repaired during the relevant

warranty period.

7. For all Products repaired outside the warranty period charges may apply and

a six (6) month warranty that the Product will be free of any defects in material

and workmanship will apply from the date of return of the Product to you.

8. Where the Product is sold by any person other than ATA, except for the

warranty set out above, such person has no authority from ATA to give any

warranty or guarantee on ATA’s behalf in addition to the warranty set out

above.

9. LIMITATION ON LIABILITY AND DAMAGES EXCLUSION - EXCEPT

AS EXPRESSLY PROVIDED IN THIS LIMITED WARRANTY AND THE

USER TERMS, ATA MAKES NO REPRESENTATIONS, GUARANTEES,

CONDITIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED. ANY

OTHER STANDARDS OF PERFORMANCE, GUARANTEES, CONDITIONS

AND WARRANTIES ARE HEREBY EXPRESSLY EXCLUDED AND

DISCLAIMED TO THE FULLEST EXTENT PERMITTED BY LAW. THIS

DISCLAIMER AND EXCLUSION SHALL APPLY EVEN IF THE EXPRESS

LIMITED WARRANTY CONTAINED IN THE LIMITED WARRANTY AND

USER TERMS FAILS OF ITS ESSENTIAL PURPOSE.

10. ANY IMPLIED WARRANTIES THAT MAY BE IMPOSED BY LAW

SHALL BE LIMITED TO THE DURATION OF THE LIMITED WARRANTY

ABOVE. OTHERWISE THE REPAIR, REPLACEMENT, OR REFUND AS

PROVIDED UNDER SUCH EXPRESS LIMITED WARRANTY IS PROVIDED

IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. TO THE

FULLEST EXTENT THESE DAMAGES MAY BE DISCLAIMED BY LAW,

ATA WILL IN NO EVENT BE LIABLE, WHETHER IN CONTRACT OR TORT

OR ANY OTHER LEGAL THEORY, INCLUDING WITHOUT LIMITATION

STRICT LIABILITY, GROSS NEGLIGENCE OR NEGLIGENCE, FOR ANY

DAMAGES IN EXCESS OF THE PURCHASE PRICE OF THE PRODUCT OR

FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, CONSEQUENTIAL

OR PUNITIVE DAMAGES OF ANY KIND REGARDLESS OF WHETHER ATA

WAS ADVISED OR THE POSSIBILITIES OF SUCH DAMAGES. ATA IS NOT

LIABLE FOR ANY CLAIM MADE BY A THIRD PARTY OR MADE BY YOU

FOR A THIRD PARTY.

TERMS RELATING TO THE USE AND LIMITATIONS OF SERVICE

1. WHAT ARE THE LIMITATIONS ON SERVICE AND LIABILITY?

a. Unless prohibited by law, the following limitations of liability apply. Service

may be interrupted, delayed, or otherwise limited for a variety of reasons,

including environmental conditions, unavailability of radio frequency

channels, system capacity, priority access by National Security and Emergency

Preparedness personnel in the event of a disaster or emergency, coordination

with other systems, equipment modifications and repairs, and problems with

the facilities of interconnecting carriers.

b. Additional hardware, software, subscription, credit or debit card, Internet

access from your compatible PC and/or special network connection may

be required and you are solely responsible for arranging for or obtaining all

such requirements. Some solutions may require third party products and/or

services, which are subject to any applicable third party terms and conditions

and may require separate purchase from and/or agreement with the third

party provider. ATA is not responsible for any consequential damages caused

in any way by the preceding hardware, software or other items/requirements

for which you are responsible.

c. Not all Services are available for purchase or use in all sales channels, in all

areas or with all devices. ATA is not responsible for loss or disclosure of any

sensitive information you transmit. ATA is not responsible for nonproprietary

services or their effects on devices.

Page 27

© Copyright 2017

2. INTELLECTUAL PROPERTY.

You must respect the intellectual property rights of ATA, our third-party content providers,

and any other owner of intellectual property whose protected property may appear on

any website and/or dialogue box controlled by ATA or accessed through the ATA’s

websites. Except for material in the public domain, all material displayed in association

with the Product is protected by copyright or trademarks. Except for personal, noncommercial use, this material may not be copied, downloaded, redistributed, modified

or otherwise exploited, in whole or in part, without the permission of the owner. The

ATA trademarks and logos are the exclusive property of ATA.

3. SEVERABILITY

If any provision of this Agreement is found to be unenforceable by a court

or agency of competent jurisdiction, the remaining provisions will remain in

full force and effect. The foregoing does not apply to the prohibition against

class or representative actions that is part of the arbitration clause; if that

prohibition is found to be unenforceable, the arbitration clause (but only the

arbitration clause) shall be null and void.

4. GOVERNING LAW

In the event of a dispute between you and ATA, Texas law, whether in

litigation or arbitration, shall govern that dispute and the interpretation

of this Agreement, except to the extent that such law is preempted by or

inconsistent with applicable federal law.

5. LANGUAGE

The original version of this Agreement is in the English language. Any

discrepancy or conflicts between the English version and any other language

version will be resolved with reference to and by interpreting the English

version.

HOW DO I RESOLVE DISPUTES WITH ATA?

1. DISPUTE RESOLUTION BY BINDING ARBITRATION

PLEASE READ THIS CAREFULLY. IT AFFECTS YOUR RIGHTS.

Most customer concerns can be resolved quickly and to the customer’s

satisfaction by calling our customer service department at (817)-873-5076.

In the unlikely event that ATA’s customer service department is unable to