Automatic Heating Modulex EXT 440, Modulex EXT 550, Modulex EXT 660, Modulex EXT 770, Modulex EXT 900 Installation And Servicing Instructions

Modulex EXT

440 - 550 - 660 - 770 - 900

Modular Condensing Boiler

Installation and Servicing Instructions

Warning: this manual contains instructions to be used exclusively by the

installer and/or a competent person in accordance with the current laws in

force.

The end user MUST not make any alterations to the boiler.

Failure to follow the instructions indicated in this manual, which is supplied

with the boiler, could cause injury to persons, animals or damage to property.

UNICAL shall not be held liable for any injury and/or damage.

CONTENTS

1 GENERAL INFORMATION ................................................................................................................................................................................... 4

1.1 Symbols used in this guide .......................................................................................................................................................................... 4

1.2 Correct use of the appliance ....................................................................................................................................................................... 4

1.3 IInformation to be passed over to the person in charge of the appliance ................................................................................................ 4

1.4 Safety warnings ............................................................................................................................................................................................ 5

1.5 Data badge .................................................................................................................................................................................................... 6

1.6 General warnings ......................................................................................................................................................................................... 7

2 TECHNICAL FEATURES AND DIMENSIONS ..................................................................................................................................................... 8

2.1 Technical features ........................................................................................................................................................................................ 8

2.2 Dimensions ................................................................................................................................................................................................... 9

2.3 Performance data ....................................................................................................................................................................................... 10

2.4 RHS view showing main components ....................................................................................................................................................... 11

3 INSTRUCTIONS FOR THE INSTALLER ............................................................................................................................................................ 12

3.1 General warnings ...................................................................................................................................................................................... 12

3.2 Installation standards ................................................................................................................................................................................ 13

3.3 Packaging .................................................................................................................................................................................................. 14

3.4 Installation .................................................................................................................................................................................................. 16

3.5 Boiler location in a boiler room .................................................................................................................................................................. 17

3.6 Boiler connection ....................................................................................................................................................................................... 17

3.7 Gas connection ......................................................................................................................................................................................... 18

3.8 Connection return and flow system pipes ............................................................................................................................................... 19

3.9 Primary circuit pump or boiler pump ........................................................................................................................................................ 20

3.10 Additional safety and control devices, according to the Italian Law + primary circuit kit ..................................................................... 21

3.11 Wiring diagram for additional safety devices ........................................................................................................................................... 22

3.12 Safety pressure relief valve ..................................................................................................................................................................... 23

3.13 Mixing header filter .................................................................................................................................................................................... 23

3.14 Ballstop valves .......................................................................................................................................................................................... 23

3.15 Boiler freeze protection ............................................................................................................................................................................. 24

3.16 Mixing header and plate heat exchanger ................................................................................................................................................ 24

3.17 Condensing drain ...................................................................................................................................................................................... 25

3.18 Water treatment ......................................................................................................................................................................................... 26

3.19 Flue chimney connection .......................................................................................................................................................................... 27

3.20 Flue manifold connection .......................................................................................................................................................................... 27

3.21 Operation ................................................................................................................................................................................................... 29

3.22 Electrical connections ............................................................................................................................................................................... 31

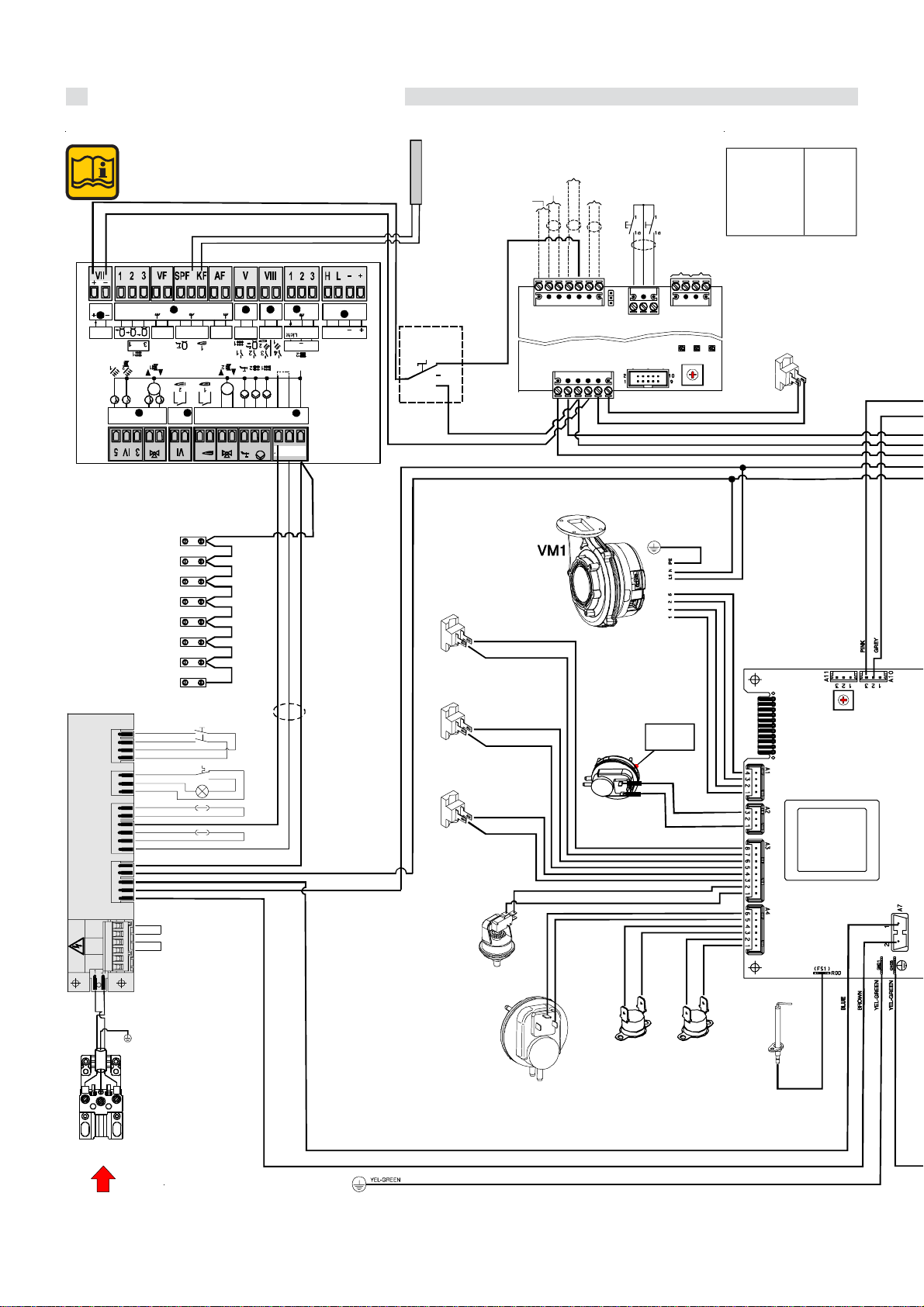

3.23 Functional wiring diagram......................................................................................................................................................................... 32

3.24 Wiring diagram for connection and managing......................................................................................................................................... 34

3.25 Installation examples (functional wiring and connections description) .................................................................................................. 36

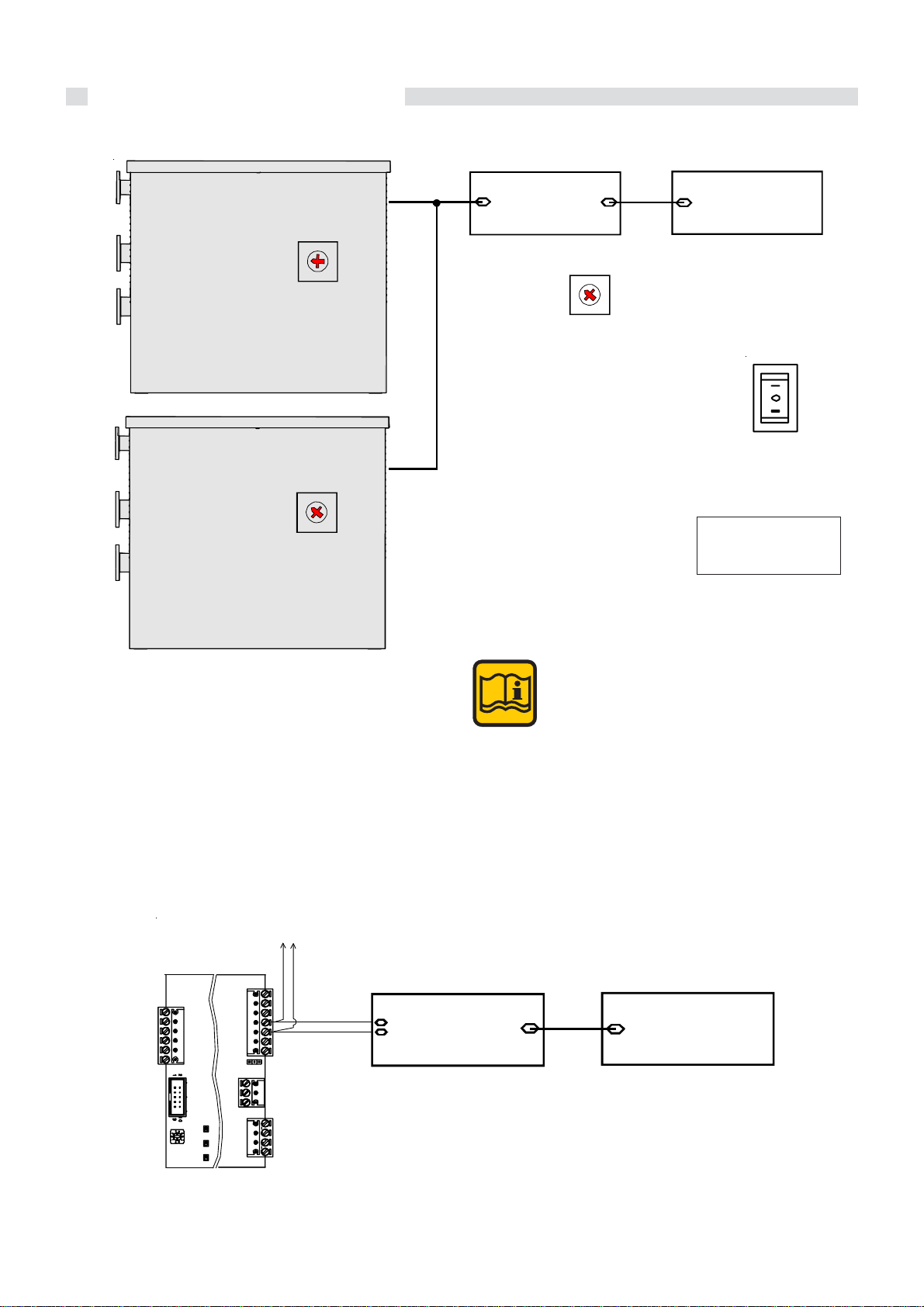

3.26 Cascade manager BCM ........................................................................................................................................................................... 40

Connections for boilers in cascade, controlled by outer compensators ............................................................................................... 43

3.27 Configuration with a modulating pump ..................................................................................................................................................... 44

3.28 Filling the system ...................................................................................................................................................................................... 45

3.29 Burner Adjustment .................................................................................................................................................................................... 46

3.30 Emergency functions ............................................................................................................................................................................... 49

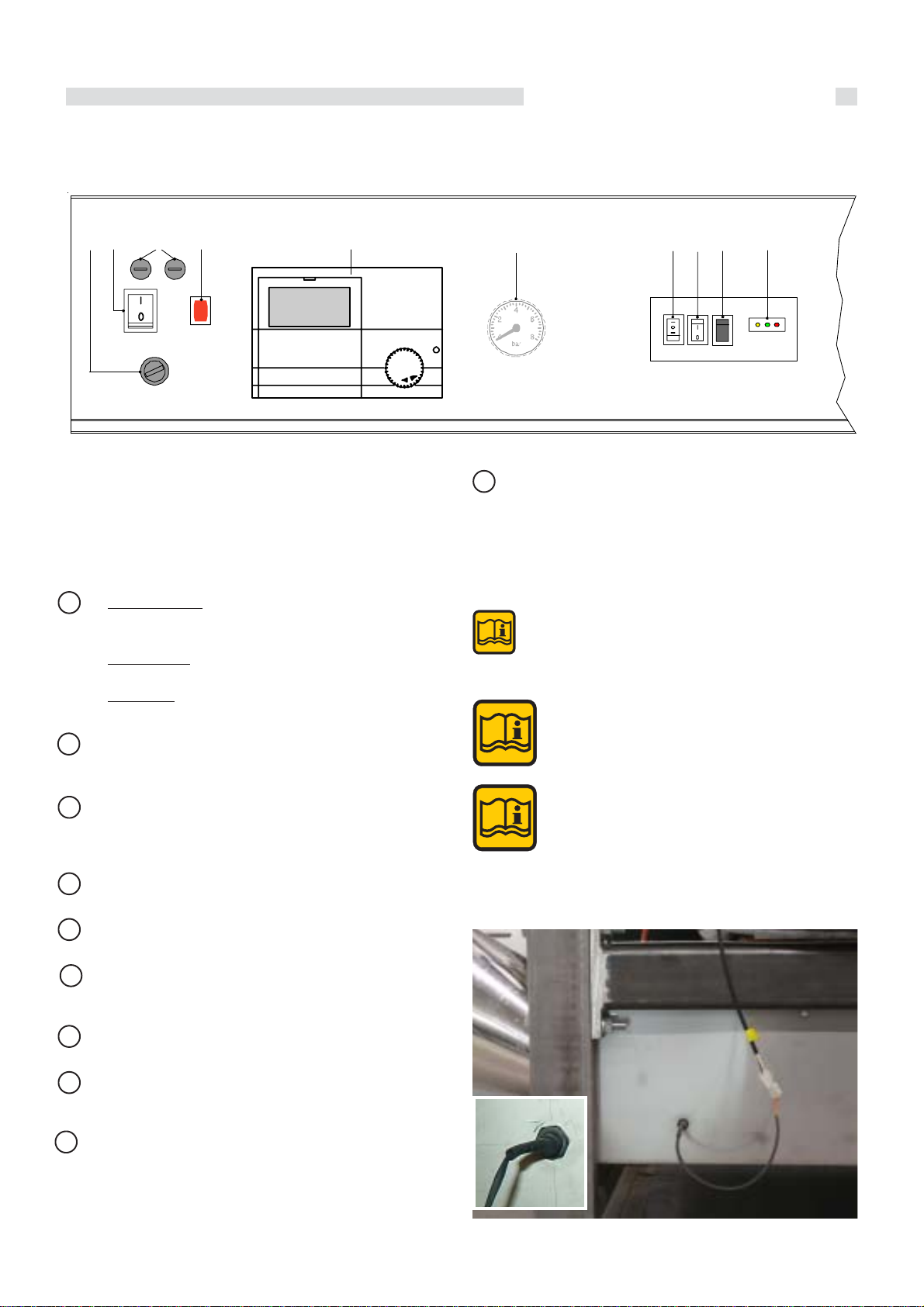

3.31 Initial Lightning ........................................................................................................................................................................................... 50

4 SERVICING SCHEDULE .................................................................................................................................................................................... 51

5 CE CERTIFICATE ............................................................................................................................................................................................... 56

3

General information

1

GENERAL INFORMATION

1.1 -SYMBOLS USED IN THIS GUIDE

When reading this guide particular care has to be given to the parts marked with the followings symbols:

DANGER!

Indicates serious danger

for your personal safety

and for your life

WARNING!

Indicates a potentially dangerous

situation for the product and the

environment

NOTE!

Suggestions for the

user

1.2 - CORRECT USE OF THE APPLIANCE

The MODULEX appliance has been designed utilizing today’s heating technology and in compliance with the

current safety regulations.However, following an improper use, dangers could arise for the safety and life

of the user or of other people, or damage could be caused to the appliance or other objects.The appliance

is designed to be used in pumped hot water central heating systems. Any other use of this appliance will be

considered improper. UNICAL declines any responsibility for any damages or injuries caused by an improper

use; in this case the risk is completely at the user’s responsibility.In order to use the appliance according

to the scopes it was designed for it is essential to carefully follow the instructions indicated in this guide.

1.3 - INFORMATION TO BE HANDED OVER TO THE USER

The user has to be instructed on the use and operation of his heating system, in particular:

• Hand over these instructions to the end user, together with any other literature regarding this appliance,

placed inside the envelope contained in the packaging. The user has to keep these documents in a safe

place in order to always have them at hand for future reference.

• Inform the user on the importance of air vents and of the flue outlet system, stressing the fact that is absolutely

forbidden to make any alterations to the boiler.

• Inform the user how to check the system’s water pressure as well as informing him how to restore the correct

pressure.

• Explain the function of time and temperature controls, thermostats, heating controls and radiators, to ensure

the greatest possible fuel economy.

• Remind the user that it is obligatory to carry out a comprehensive service annually and a combustion analysis

every two years (in compliance with the national law).

• If the appliance is sold or transferred to another owner or if the present user moves home and leaves the

appliance installed, ensure yourself that the manual always follows the appliance so that it can be consulted

by the new owner and/or installer.

Failure to follow the instructions indicated in this guide, which is supplied with the boiler, could cause injury

to persons, animals or damage to property . The manufacturer shall not be held liable for any such injury and/

or damage.

4

1.4 -SAFETY W ARNINGS

WARNING!

The device should not be used by people with reduced physical, mental and sensory , experience and

knowledge. These people must be well-informed and supervised during the work. Children must be

supervised so they do not play with the appliance.

WARNING!

The installation, adjustment, and servicing of this appliance must be carried out by a competent person and

installed in accordance with the current standards and regulations. Failure to correctly install this appliance

could cause injury to persons, animals or damage to property. The manufacturer shall not be held liable for

any injury and/or damage.

DANGER!

Servicing or repairs of the appliance must be carried out by UNICAL authorised service technicians; UNICAL

recommends drawing up a service contract. Bad or irregular servicing could compromise the safe operation

of the appliance, and could cause injury to persons, animals or damage to property for which UNICAL shall not

be held liable.

Modifications to parts connected to the appliance

Do not carry out any modifications to the following parts:

- the boiler

- to the gas, air, water supply pipes and electrical current

- to the flue pipe, safety relief valve and its drainage pipe

- to the constructive components which influence the appliance’s safe operation

WARNING!

When tightening or loosening the screw pipe connections, use only adequate fork spanners.

The improper use and/or the use of inadequate equipment can cause damages (for example water or gas

leakages).

General information

WARNING!

Indications for appliances operating with propane gas

Ensure yourself that before installing the appliance the gas tank has been purged.

For a correct purging of the tank contact the liquid gas supplier or a competent person who has been legally

authorized.

If the tank has not been correctly purged problems could occur during ignition.

If this occurs contact the liquid gas tank’s supplier.

Smell of gas

If you smell gas follow these safety indications:

- Do not turn on or off electrical switches

- Do no smoke

- Do not use the telephone

- Close the main gas tap

- Open all windows and doors where the gas leakage has occurred

- Inform the gas society or a company specialized in installing and servicing heating systems

Explosive and easily inflammable substances

Do not use or leave explosive or easily inflammable material (as for example: petrol, paint, paper) in the room

where the appliance has been installed.

WARNINGS

The boiler has to be installed in such way to avoid,

under the foreseen operation conditions, the congelation of the water and

to prevent that the control devices are exposed to a temperature

lower than -15°C and higher than 40°C.

The boiler has to be protected against environmental variations with:

- The insulation of the hydraulic pipelines and the condensate evacuation

- The adoption of specific antifreeze products in the C.H. installation.

5

General information

1.5 - DATA PLATE

CE Marking

The CE marking documents that the boilers satisfy:

- The essential requirements of the Directive regarding gas

appliances (Directive 2009-142 EC)

- The essential requirements of the Directive regarding

electromagnetic compatibility (Directive 2004/108 EC)

- The essential requirements of the Efficiency Directive

(Directive 92/42/EEC)

- The essential requirements of the low voltage Directive

(Directive

2006/95EC).

®

3

5

7 8

A

B

C D

21 22

E

27

9

11

13

15

17

19

23

1

2

4

6

10

12

14

16

18

20

24

25

26

LEGEND:

1 = Y ear of CE certification issue

Boiler type

2=

3=Boiler model

4=Number of stars (Directive 92/42/CEE)

5=(S.N°) Serial number

6=P.I.N. code

7=Approved fluing configurations

8=(N0x) N0x class

A = Central Heating circuit features

(Pn) Nominal output

9=

10 = (Pcond) Condensing nominal output

11 = (Qmax) Nominal heat input

12 = (Adjusted Qn) Adjusted for nominal Heat input

(PMS) Max. pressure C.H. system

13 =

14 = (T max) Max. C.H. temperature

B = Domestic Hot Water circuit features

15 = (Qnw) Nominal heat input in D.H.W. mode (if different from Qn)

16 = (D) Specific D.H.W. flow rate according to EN 625 - EN 13203-1

6

28

17 = (R factor) N° taps based on the quantity of water declared EN

13203-1

18 = (F factor) N°stars based on the quality of water declared

EN 13203-1

19 = (PMW) Max. pressure D.H.W. system

20 = (T max) Max. temperature D.H.W system

C = Electrical features

21 = Electrical power supply

22 = Consumption

23 = Protection grade

D = Countries of destination

24 = Direct and indirect country of destination

25 = Gas family

26 = Supply pressure

E = Factory setting

27 = Adjusted for gas type X

28 = Space for national brands

1.6 - GENERAL WARNINGS

General information

This instruction manual is an integral and indispensable part

of the product and must be retained by the person in charge

of the appliance.

Please read carefully the instructions contained in this manual

as they provide important indications regarding the safe

installation, use and servicing of this appliance.

Keep this manual in a safe place for future reference.

The installation and servicing must be carried out in

accordance with the regulations in force according to the

manufacturer’s instructions and by legally competent

authorized persons.

By a competent person, we imply a person who has a

specific technical qualification in the field of components

for central heating systems for domestic use, domestic

hot water production and servicing. The person must have

the qualifications foreseen by the current laws in force.

Bad or irregular servicing could compromise the safe

operation of the appliance, and could cause injury to persons,

animals or damage to property. The manufacturer shall not

be held liable for any such injury and/or damage.

Before carrying out any cleaning or servicing turn off the

electrical supply to the boiler by means of the ON/OFF switch

and/or by means of the appropriate shutdown devices.

In the event of failure and/or faulty functioning of the appliance,

switch off the boiler. Do not attempt to make any repairs:

contact qualified technicians.

Any repairs must be carried out by Unical authorized

technicians and using only original spare parts. Nonobservance of the above requirement may jeopardize the

safety of the appliance.

To guarantee the efficiency and correct functioning of the

appliance it is indispensable to have the boiler serviced

annually by a qualified person.

If the boiler remains unused for long periods, ensure that any

dangerous parts are rendered innocuous.

If the appliance is sold or transferred to another owner or if

the present user moves home and leaves the appliance

installed, ensure yourself that the manual always follows the

appliance so that it can be consulted by the new owner and/

or installer.

Only original accessories must be used for all appliances

supplied with optionals or kits (including electrical ones).

This appliance must be used only for the purposes for which

it has been expressively designed. Any other use shall be

considered incorrect and therefore dangerous

(*).

Do not obstruct the intake/outlet terminal ducts.

7

Technical features and dimensions

TECHNICAL FEATURES

2

AND DIMENSIONS

2.1 - TECHNICAL FEATURES

• MODULEX is a compact, gas fired, Low NOx, condensing

boiler, made up by one sectional boiler body,

This boiler body consists of two or more modules (from 4 to

8), which cannot be separated from each other, being under the same protecting casing, and are set to operate separately or in cascade. These modules are connected to a

single smoke exhaust manifold and are controlled by a

single microprocessor (BMM), which manages completely

the temperatures from the point of view, both operational

and safety. This version is suitable for only central heating

CAUTION: These devices are not suitable for the

production of water for human consumption

• Efficiency at full load with temperature 30/50°C = 101,1%.

At part load (30% of the nominal) with 30°C return temperature = 107,2%.

• Efficiency Class:

• Each module, is composed of a combustion chamber, metallic fiber pre-mix burner, modulating fan, gas valve, ignition electrode, flame detection, NTC sensor for management control (BMM), local temperature control and afety

thermostat.

• Each single boiler is equipped with NTC sensors for global

temperature control on the flow and return manifolds.

• Integral, non allergic, synthetic wool insulation.

• Total premix burner, modulating burner with a radiant “metal sponge” (NIT). Premix antechamber combustion. Automatic backflow valve, preventing gas in the place of installation.

• Fully pre-mixed, radiating, modulating, metallic sponge

burner, Automatic no return diaphragm for separation from

combustion chamber.

• Nominal input, per module: max. 108 kW, min. 22 kW.

• Noise level at maximum output: lower than 50 dBA.

• Modules configuration possibilities:

• Possible cascade installation of 2 or more Modulex

•Heating Operation: setting of instantaneous output by a

main microprocessor, with a comparison parameters presetting between the requested temperature (or calculated by the outer compensator) and the global flow tem-

perature.

• Logic of operation:

A) Output sharing on as many modules as possible at min.

load (down to 22 kW) for the max. efficiency..

B) Automatic operation hour splitting-up system for each

module to guarantee the best homogeneous use.

C) D.H.W. production, via a storage tank loading pump or a

three way diverting valve, controlled by a priority sensor

through the E 8 heating controller.

D) Output check of each module for any calibration and/or

assistance by secret access code.

• Possibility of controlling the output of each single module.

•

Heating request control: temperature set point

andmodulation level.

•

Monitoring of boiler and temperature status.

•

Alarm control.

•

Parameters setting.

•

Relay for control of the operation of a pump at constant

flow rate.

•

0÷10V analogical output for control of a modulating pump.

•

Emergency operation: it avoids C.H. system shut down

caused byan interruption in communication with the boiler

plant’s automation system: : (in case of remote control of

the complete boiler house):

•

Input for “Constant setpoint”: 82°C, maximum output 50%.

•

Alarm reset input.

•

Alarm relay signal.

• Gas connecting pipes, flow/return water pipes, arranged

for any connection (by the opposite end).

• Integral easily removable panel set (painted steel panels).

• Smoke exhaust pipe, adjustable on the right, the left and

behind the heating system.

• Condensate collecting tank equipped with drain siphon

and stainless steel smoke chamber.

• Built-in air vent.

• Weights and dimensions are limited (see table at par. 1.2)

•Instrument panels secreted (POP-UP)

SENSORS supplied with the boiler:

• 00262208 outdoor temperature sensor

• 00262209 flow temperature sensor for mixed zone

• 00262210 boiler temperature sensor

• 00262211 D.H.W. storage temperature sensor

Optional accessories:

• 00262603 Sensor (Solar) PT1000

• 00262829 Acid condensate inhibitor 1500 kW

• 00361044 Cleaning kit bodies

• 00361332 Kit thermoregulation E8

• 00361358 Remote control kit BM8

• 00361359 Kit custody thermoregulation

• 00361545 Kit expansion module E8

4

5

6

7

8

8

440

550

660

770

900

• Primary circuits: COMPO S - PREMO S - PREMO C -

COMPO S RING BOX COVER. - Safety devices - , see cap.

3.10

• 00361997 Mixing header

• 0036..... gas terminal Support kit

• 0036....... Boiler support Kit 10 cm

144

8

2.2 - DIMENSIONS

Technical features and dimensions

287

FRONT VIEW

L

62,5

LEFT HAND SIDE VIEW

122

L1

RIGHT HAND SIDE VIEW

S

24

UPPER VIEW

=

=

G

M

R

327

1267

534

235

S

946

MODULEX

Dimension

No. of Modules

Height mm

Width ‘’L’’ mm

Width ‘’L1’’ mm

Depth mm

395

Smoke outlet:

Left side (standard condition)

Right side

Back side

440

1448

1087

1039

946

550

4

1448

1355

1307

946

660

5

1448

1355

1307

946

770

6

1448

1623

1575

946

900

7

8

1448

1623

1575

946

Connections

300

40

80 (3)

100 (4)

100 (4)

300

40

9

Gas mm (inch)

C.H. system Flow M mm (inch)

C.H. system Return R mm (inch)

Chimney connection mm

Condensate drain diameter mm

80 (3)

100 (4)

100 (4)

300

40

80 (3)

100 (4)

100 (4)

300

40

80 (3)

100 (4)

100 (4)

300

40

80 (3)

100 (4)

100 (4)

Technical features and dimensions

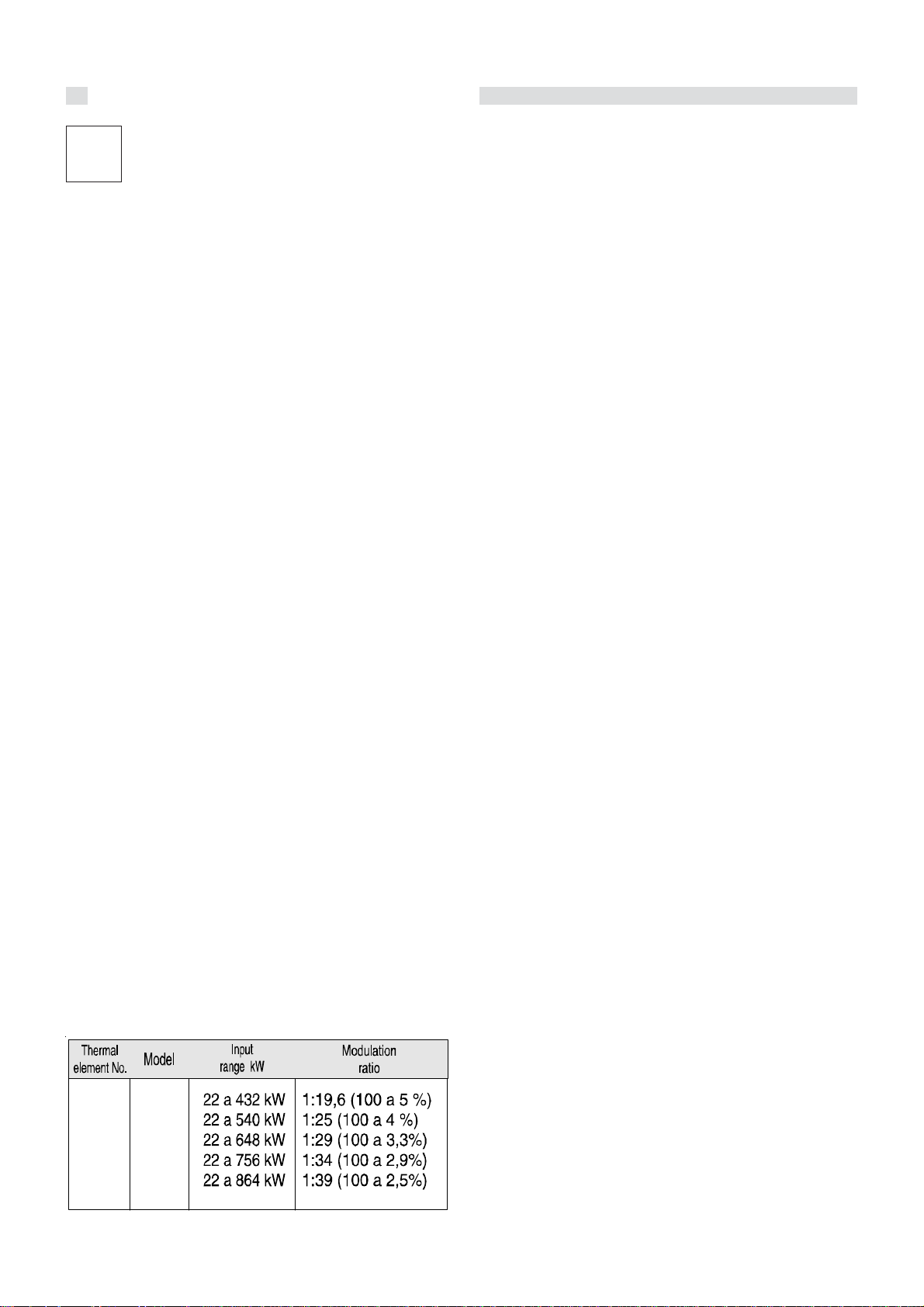

2.3 - PERFORMANCE DATA

BOILER TYPE

Appliance category II

Nominal Heat Input on P.C.I.

Minimum Heat Input on P.C.I.

Qn

Qmin

Nominal Output (Tr 60 / Tm 80 °C)

Minimum Output (Tr 60 / Tm 80 °C)

Nominal Output (Tr 30 / Tm 50 °C)

Minimum Output (Tr 30 / Tm 50 °C)

MODULEX

Pn

Pn min

Pcond

Pcond min

2H3P

kW

kW

kW

kW

kW

kW

Efficiency at max. output (Tr 60 / Tm 80°C) %

Efficiency at min. output (Tr 60 / Tm 80°C) %

Efficiency at max. output (Tr 30 / Tm 50°C) %

Efficiency at min. output (Tr 30 / Tm 50°C) %

Efficiency Class acc. to Directive 92/42 CEE

Combustion efficiency at nominal load %

Combustion efficiency at part load %

Stand-by losses with burner in operation %

Flue losses with burner with burner off %

Flue losses with burner with burner in operation %

Flue gas temperature tf-ta (max) °C

Flue gas mass flow rate (max) kg/h

Excess of air λ %

(**) CO2 at min/max. output) %

NOX (value according EN 297/A3 + EN 483)

mg/kWh

NOX class

Min. water flow rate in CH circuit (ΔT 20°C) l/h

Minimum pressure in CH circuit bar

Maximum pressure in CH circuit bar

Water content l

Gas Consumption Natural gas G 20 (20 mbar) Qn m3/h

Gas Consumption Natural gas G 20 (20 mbar) Qmin m3/h

Gas Consumption G25 (supply pressure 25 mbar) Qn m

Gas Consumption G25 (supply pressure 25 mbar) Qmin m

3

/h

3

/h

Gas Consumption G31 (supply pressure 37/50 mbar) Qn kg/h

Gas Consumption G31 (supply pressure 37/50 mbar) Qmin kg/h

Max. available pressure at the chimney base Pa

Condensate production max kg/h

Emissions

CO with 0% of O2 in the flue system ppm

NOx with 0% of O2 in the flue system ppm

Sound level dBA

Electrical Data

Voltage / Frequency V/Hz

Fuse on main supply A (F)

Max power absorbed W

(***) Insulation degree IP

Standby Consumption W

440

432

22

424,35

20,57

446,93

23,59

98,23

93,5

102,3

107,22

97,7

98,5

0,2

0,1

2,58

46,7

693

24,25

64

18247

0,5

67

45,68

2,33

53,13

2,71

33,53

1,71

100

73,4

<95

<30

<49

230/50

626

X5D

20

4

-

5

6

4

550

540

22

530,44

20,57

552,42

23,59

98,23

93,5

102,3

107,22

97,7

98,5

0,2

0,1

2,53

46,7

866

24,25

64

22809

0,5

80

57,10

2,33

66,41

2,71

41,92

1,71

100

91,7

<95

<30

<49

230/50

783

X5D

20

4

5

6

4

-

660

648

22

636,53

20,57

662,90

23,59

98,23

93,5

102,3

107,22

97,8

98,5

0,2

0,1

2,51

46,7

1040

24,25

64

27371

0,5

94

68,52

2,33

79,69

2,71

50,30

1,71

100

110

<95

<30

<49

230/50

940

X5D

20

4

-

5

6

4

770

756

22

742,62

20,57

773,38

23,59

98,23

93,5

102,3

107,22

97,8

98,5

0,2

0,1

2,58

46,7

1213

24,25

64

31933

0,5

108

79,94

2,33

92,97

2,71

58,68

1,71

100

128,4

<95

<30

<49

230/50

1096

X5D

20

4

-

5

6

4

900

864

22

849,05

20,57

873,93

23,59

98,27

93,5

101,15

107,22

4

97,8

98,5

0,2

0,1

2,58

45,8

1386

24,25

-

64

5

36509

0,5

6

122

91,36

2,33

106,25

2,71

67,07

1,71

100

146,7

<95

<30

<49

230/50

4

1252

X5D

20

10

(*) Room Temperature = 20°C

(**) See paragraph ‘’

SURES’’

(***) The protection IP X5D is obtained with

cap down.

INJECTORS – PRES

The Technical data plate is placed under the

casingand is positioned near to the BCM.

Technical features and dimensions

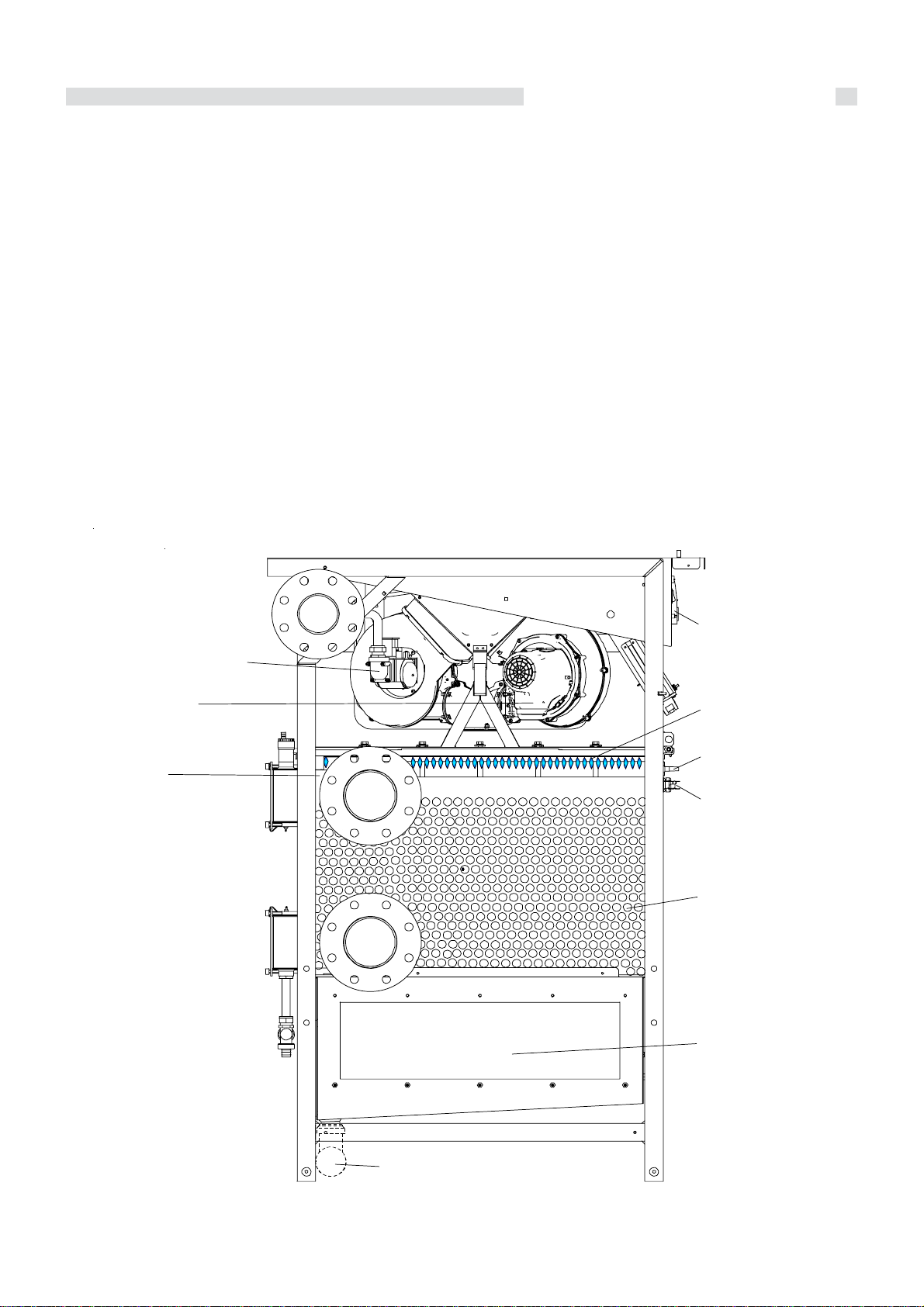

2.4 - R.H. SIDE VIEW, WITH MAIN COMPONENTS

GAS PIPE

GAS VALVE

FAN

AUTOMATIC

AIR VENT

C.H.

FLOW

C.H.

RETURN

CONTROLL

PA N E L

BURNER

COVER

IGNITION

ELECTRODE

H. LIMIT

THERMOSTAT

BURNER

ALUMINIUM/

SILICON HEAT

EXCHANGER

CONDENSATE

COLLECTING

TRAYSMOKE

MANIFOLD

BOILER

FRAME

Min. Depth 100 mm

Smoke outlet on the L.H. side, on R.H. side, on the BACK side

C.H. flow connection on the L.H. side

C.H. return connection on the L.H. side

Gas connection on the L.H. side

BCM: under the frontal panel

11

Instructions for the installer

INSTRUCTIONS FOR

3

THE INSTALLER

3.1 - GENERAL WARNINGS

WARNING!

This boiler has to be destined for the use for

which it has been expressively designed for.

Any other use shall be considered improper

and therefore dangerous.

This boiler is designed to heat water at a

temperature inferior to boiling point at an

atmospheric pressure.

WARNING!

These appliances are exclusively designed

to be installed inside adequate boiler rooms.

Therefore these appliances must not be

installed and operated externally .

Before installing the boiler the following points

have to be carried out by a competent engineer:

a) The whole system should be thoroughly

flushed in order to remove any residual dirt or

grime which could compromise the correct

boiler operation.

b) Check that the boiler has been preset for

operating with the gas type available.

This is verifiable via the indication on the

packaging and on the data badge;

c) Check that the chimney/flue pipe has an

adequate draught,does not have any

constrictions, and that no other appliance’s

flue outlets have been fitted, unless the chimney

is serving more than one heating appliance,

according to the specific standards and

regulations in force.

The connection between the boiler and

chimney/flue outlet can be made only after this

verification has been carried out.

WARNING!

In rooms where there is the presence of

aggressive vapours or dust the appliance

must operate independently from the air

present in the boiler’s location room!

WARNING!

The appliance must be installed by a qualified

engineer, who complies to the technicalprofessional requirements according to the

national applicable law and who, under his

own responsibility, guarantees the

compliance with the standards according to

the latest regulations.

WARNING!

Install the appliance respecting the minimum

clearances for operation and servicing.

The boiler must be connected to a heating

system which is compatible to its performances

and output.

12

3.2 - STANDARD CODES FOR

INSTALLATION

Instructions for the installer

The appliance must be installed in compliance to the

instructions contained in this manual.

The installation must be carried out by a competent qualified

engineer, whom will assume the responsibility of complying

to all the local and/or national regulations published in the

official publications, as well as all the applicable codes of

practice.

Before installing the appliance please contact the gas supply

company.

The installation must be carried in accordance to the codes

of practice, the regulations and the requirements hereby

indicated which constitute an indicative list, but not a complete

one, as these continue to undergo evolve devolpments.

Moreover, the boiler must be installed in accordance to all the

regulations regarding the boiler room, the building regulations

and the prescriptions regarding central heating plants in force

in the country where the boiler is installed.

The appliance must be installed, commissioned and serviced

according to the regulations in force. This is also valid for the

hydraulic system, the flue outlet system and the boiler location

room.

13

Instructions for the installer

3.3 - PACKING

The boiler MODULEX is delivered assembled

and protected by a plastic bag inside a strong

cardboard box and fixed on pallet. This allows

the boiler to be handled also by forklift. The boiler, with the packaging, can go through a door of

800 mm, whereas, without packaging, it can go

through a door of 700 mm.

Remove both straps and finally the cardboard

box from above, making sure the product is

intact. The packing elements (cardboard box,

straps, plastic bags, etc…) shall not be left to

children’s hand since they may be dangerous.

For the removal of the boiler from the pallet it is necessary

to have a jib crane, to avoid to damage, during the removal.

- Remove the casings and make the sling with the belts

‘’A‘’ fig. 3, having care to pass the belts bearing bars

frame

- Tie the belts to thearm ‘’ B ‘’; during these operationsact

with caution.

C

On the L.H. side of the boiler:

- There is the terminal of the smoke chamber, fixed.

- A carton box containing:

• Gasket between smoke chamber and its terminal,

• Gasket for the base of flue socket, gasket Ø 300

• Two curves + a Te piece + a plastic plug, for the

condensate evacuation system

• The fixing screws

• The sensors (3x).

• Nipple for smokes sampling test

• Kit resistance

•

Metal plate and passage cable for power output

- A carton box containing:

• The flanges

Inside the casing, on the back side:

- Two pipes for the condensate evacuation system of 1 m

each.

Above the top cover of the boiler:

- A plastic bag containing:

- This instructions manual for the installer

- Instructions manual for the user

- Instruction manual for the use of the E8 controller

440

550

660

770

900

B

1263

1531

1531

1799

1799

1120

1120

1120

1120

1120

A

1515

1515

1515

1515

1515

kg

551 kg

kg

806 kg

kg

14

BOILER UNLOADING AND PACKAGE REMOVAL

Instructions for the installer

WARNING!

Handling with forklift or hoist bands,

T max

50°C/122°F

T min

Max. admitted b oilers

Do not turn upside down Do not expose to r ain Fragile Do not expose to sunligh t Do not store at

stacked

temperature:

lower than - 5 ° C / 23 °F

superior than 50 °C / 122 °F

-5°C/23°F

1

WARNING!

Waypoints bands for lifting. Brackets must be

mounted on bearing stringers.

4

Max. admitted boilers

Do not turn upside down Do not expose to rain Frag ile Do n ot expose to sunlight Do not store at

stacked

2

Max. admitted bo ilers

Do not turn u pside down Do n ot expose to rain Fragile Do not expose to sunlight Do no t store at

stacked

3

temperature:

lower than - 5 ° C / 23 °F

superior than 50 °C / 122 °F

temperature:

lower than - 5 ° C / 23 °F

superior than 50 °C / 122 °F

T max

50°C/1 22°F

T min

-5°C/23°F

T max

50°C/122°F

T min

-5°C/23°F

15

Instructions for the installer

3.4 - BOILER LOCATION INSIDE A BOILER HOUSE

Special attention shall be paid to local regulations and laws

about boiler houses and particularly to the obligation of

keeping minimum clearances and empty space around the

boiler. The installation shall be in compliance with all latest

regulations and laws about boiler houses, installations of

heating and hot-water systems, ventilation, chimneys capable

of evacuating the flue gases of condensing boilers and any

other applicable requirement.

The boiler can be put on a flat and sufficiently strong base

with the same dimensions as the boiler ones and at least

100mm high (see fig. 25), in order to assemble the condensate drain siphon. An alternative to this base may be a 100mm

deep well next to the boiler as siphon housing (see fig. 25).

After installation the boiler shall be perfectly horizontal and

stable, to reduce any possible vibrations or noises.

A > 400 mm

B > 400 mm

A

B

D

C

16

C = 100 mm

D = 500 mm

Sifone

Give the boiler the minimum clearances as shown

in the drawing, in order to be able to make the

normal service and cleaning operations.

3.5 - INSTALLATION

Instructions for the installer

When the appliance is installed on existing systems, ensure

yourself that:

- The flue outlet pipe is suitable for condensing boilers, for

the temperature of the products of combustion, calculated

and manufactured according to the regulations in force. It

must be installed as much as possible in a straight line,

tested for soundness, insulated and must not have any

occlusions or restrictions.

- The flue outlet pipe has a connection for the discharge of

condensate.

- The boiler room has a suitable outlet for the discharge of

condensate produce by the boiler.

- The electrical system has been fitted in compliance to the

specific norms and the work has been carried out by a

competent person.

- The circulation pump’s output, the head and flow direction

are suitable.

- The gas feeding supply pipe and the eventual tank are

constructed according to the regulations in force.

- The expansion vessels assure the total absorption of the

dilatation of the fluid contained in the system.

- The system has been cleaned of impurities and lime scale.

When a Modulex boiler is installed onto an existing

heating system:

In case the replacement of an existing boiler in an old system

can be programmed, it

out the system with a basic solution. The system must be

cleaned 4 weeks before the substitution, with the system

firing at a temperature of 35°C to 40°C.

WARNING!

If it is noticed that a new Modulex has replaced,

in an old system the existing boiler without having first performed what said in the previous paragraph, Do not wash now the system, as residual products, present in the circuit, could lead

to system gathering in the boiler body, causing

damage. UNICAL recommends contacting a specialised company for water treatment.

Instead, if installing a Modulex boiler in a new system, it is

still recommended to thoroughly clean out the system with an

adequate product and fit a Y filter with two isolating valves

onthe boiler’s return pipe, so that, when necessary, it can be

cleaned. This filter will protect the boiler from the dirt coming

from the heating system.

When sizing pumps, it is necessary to take into consideration

the pressure losses which occurin the primary circuit.

is necessary to thoroughly clean

3.6 - BOILER CONNECTION

The boiler Modulex leaves the factory predisposed for the

hydraulic / gas connection and smoke outlet on the Left side

of the boiler.

For the smoke chamber fixing, use the screws and gaskets

included into the carton box, and a 10 mm key.

The smoke collector is a standard on the left side, you can

also exit on the right side and rear side.

F

F

G

RM

F

G

RM

F

F

F

Diaphragm Gaskets

A

A

B

The sealing gasket with diaphragm Ø18 (A) are fitted only in the

flow connection seat of the first and last aluminium section of

the boiler.

The sealing gasket with diaphragm Ø 27 (B) are fitted in the

other fow connection seats of the remaining aluminium sections.

In all the return connection seats of the aluminium sections,

only sealing gasket (C), without, is fitted.

C

17

Instructions for the installer

3.7 - GAS CONNECTION

The gas supply pipe must be connected to the boiler via the

respective pipe connection

The gas supply pipe must have a section which is identical or

greater then the one used on the boiler and must assure a

correct gas pressure.

It is however important to comply with the specific norms and

requirements in force, foreseeing on-off valves, gas filter,

anti-vibrating joint etc.

Before commissioning an internal gas distribution system

and therefore before connecting it to the gas meter, the

complete installation must be tested for gas soundness.

If any part of the system is concealed from view the gas

soundness test must be carried out before covering the pipes.

DANGER!

The gas connection must be carried out by a

registered engineer who will have to respect

and comply to the regulations in force and to

the requirements indicated by the local gas

supplier. An incorrect installation could

cause injury to persons, animals or damage

to property. The manufacturer shall not be

held liable for any injury and/or damage.

R 3” as indicated on page 9.

Before installing the boiler it is recommended

to thoroughly clean all the supply piping in order

to remove any eventual residual grime which

could compromise the boilers correct

functioning.

If you smell gas:

a. Do not turn on or off electrical switches, use

the telephone or any other object which can

provoke sparks;

b. Open all doors and windows in order to

allow fresh air to enter and purify the room;

c. Close all gas cocks

d. Contact a service engineer, qualified

installer or the gas supply company.

As a safety measure against gas leaks, Unical

recommends installing a surveillance and

protective system made up of a gas leakage

detector combined with an on-off selenoid valve

on the gas supply line.

1 2 3 4 5 66

1. On-off gas supply valve

2. Double membrane regulator

3. Gas filter

4. Anti-vibrating joint

5. Selenoid valve

6. On-off cock

EXAMPLE OF A GAS SUPPL Y SYSTEM

INSIDE

BOILER

ROOM

OUTSIDE

BOILER

ROOM

18

3.8 - FLOW AND RETURN PIPE CONNEC-

TIONS

Instructions for the installer

The CH flow and return circuits have to be connected to the

boiler via the respective connections

on page 9.

When determining the size of the CH circuit pipes it is

essential to bear in mind the pressure losses induced by any

of the system’s components and by the configuration of the

same system.

The route of the piping has to be conceived taking all the

necessary precautions in order to avoid air locks and to

facilitate the continuous purging of the system.

WARNING!

Before installing the boiler we recommend

that the system is flushed out with a suitable

product in compliance to the norm UNI-CTI

8065, in order to eliminate any metallic

tooling or welding residues, oil and grime

which could reach the boiler and affect the

proper running of the boiler.

Non-observance of these instructions could

cause injury to persons, animals or damage

to property. The manufacturer shall not be

held liable for any such injury and/or damage.

4” M and R as indicated

WARNING!

IT IS ABSOLUTEL Y FORBIDDEN TO FIT ON-OFF

VAL VES ON THE GENERA TOR TO THE FORE

OF THE SAFTEY DEVICES

Ensure yourself that the system’s piping is not

used as the earth clamps for the electrical or

telephonic system. They are absolutely

unsuitable for this use. In a short time this could

cause serious damage to the piping, boiler

and radiators.

19

Instructions for the installer

Pressur

e Losse

s

(m/H)

2

O

3.9 - DETERMINATION OF PRIMARY BOILER PUMP OR BOILER SYSTEM PUMP

The boiler pump must have a delivery head which can ensure

the water flow rate as shown in the diagram “Water pressure

losses”.

The following table gives an indication of the pump’s flow rate

in function of the Δt of the primary circuit if the installation has

a mixing header.

Boiler Model

440 550 660 770

Max water flow rate

Demanded in l/h ( t=15 K)

Δ

Max water flow rate

Demanded in l/h ( t=20 K)

Δ

The size of the pumps must be determined

by installers or technical engineers

according to boiler data and system design.

The water side resistance curve of the boiler

is shown in the following diagram.

The pump is not an integral part of the boiler.

It is recommended to choose a pump with

the rate and delivery head at about 2/3 of its

characteristic heating curve.

900

24326

30404

18243 22804 27365 31926 36487

36487 42570 48647

6

5,8

5,6

5,4

5,2

5

4,8

4,6

4,4

4,2

4

3,8

3,6

3,4

3,2

3

2,8

2,6

2,4

2,2

2

1,8

1,6

1,4

1,2

1

0,8

0,6

0,4

0,2

0

0

4000 6000 8000 100 00 12000 14000 16000 20000 22000 24000

2000

28000 30000 32000 34000 36000 38000 40000 42000 44000 46000 48000 50000 52000 5400018000

WATER FLOW

(l/h)

440 EXT

550 EXT

660 EXT

770 EX T

900 EXT

For a DT 20 K, of a MODULEX 900 boiler, the max. water flow rate requested is 36289 l/h.

From the graph of the boiler’s pressure losses, it can be determined that the pump must be able

to guarantee a delivery head of at least 1,8 m/H2O.

NOTE: The use of a mixing header fitted between the boiler circuit and the system circuit is

always advisable. It becomes INDISPENSABLE if the system requires flow rates superior to the

maximum permitted boiler flow rates, which is to say lower than 15K.

20

Instructions for the installer

3.10 - ADDITIONAL SAFETY AND CONTROL DEVICES ACCORDING TO THE ITALIAN LAW

pressure existing in the generator. It must be graduated in

CERTIFICATION OF THE ADDITIONAL SAFETY DEVICES:

DISPOSITIVI DI SICUREZZA

1. On-off gas valve: a device which has the function of cut-

ting off the gas supply when the water temperature reaches the max. predetermined value. The sensible element

has to be installed as nearest as possible to the generator (flow pipe) at a distance which has to be < 500 mm and

must not be able to be cut-off.

Not supplied by Unical.

2 Pressure relief valve: it has the function of discharging in

the atmosphere the fluid contained in the generator when

this has, for whatever motive, reached the maximum

working pressure. Not supplied by Unical.

2a Visible drain funnel. Not supplied by Unical.

PROTECTIVE DEVICES

10 Overheat thermostat: it has the function of shutting down

the generator if the safety thermostat fitted in the boiler

malfunctions. It must be calibrated to a value of < 100°C,

which MUST not be changed.

15 Minimum pressure switch: it has the function of shutting

down the generator In case of low pressure (can be cali-

brated from 0.5 to 1.7 bar). It must be able to be reset

manually.

16 Additional plug G1'’:

18 Safety pressure switch: it has the function of shutting

down the generator if it reaches the maximum working

pressure (can be calibrated from..

“bar” and must have the maximum operating pressure in

scale and be equipped with a 3-way valve with the connection

for the manometer.

14 Thermometer: it indicates the effective water temperatu-

re contained in the generator. It must be graduated in degrees Celsius with a temperature scale not exceeding

120°C.

17 Inspection pocket: approved for inserting the control ther-

mometer

19 Plug ¼’’: for the safety valves connection

3 Calibrated expansion vessel: it permits the absorption of

the increase in volume of the system’s water following an

increase in temperature; The pressure must not exceed

the safety valve set pressure.

Not supplied by Unical.

8 Y filter

7 Modulating pump ( Not supplied in kit ISPELS)

5

Mixing bottle (Not supplied in kit ISPELS)

4

Automatic air vent. Not supplied by Unical

6 Drain cock. Not supplied by Unical.

kit ISPELS

CONTROL DEVICES

11. Pressure indicator with shock absorber tube (12) and

pressure gauge holder valve (13): it indicates the effective

3

1a

4

2a

2

17

19

15

181013

16

11

1214

MODULEX 440 - 550 - 660 - 770: 00361998

MODULEX 900: 00361999

1

6

21

Instructions for the installer

V

V

PRIMARY OR BOILER CIRCUIT KIT, WITH ADDITIONAL SAFETY

DEVICES

MODULEX 440 - 550 - 660 - 700:

(COMPO S. 00361994) (PREMO S. 00362065) (PREMO C. 00362067)

MODULEX 900

(COMPO S. 00361995) (PREMO S. 00362066) (PREMO C. 00362068)

COMPO S.

3.11 - WIRING DIAGRAM FOR ADDITIONAL

SAFETY DEVICES

ON-OFF PUMP

Pump management via E8

to the terminal 4 (A 1 0)

LINE

from the IV connector

Safety devices

L

N

kit

RELAY

In case of safety devices intervention, the

pump ON / OFF continues to work in order to

decrease the high temperature..

Boile r main s

supply

230 V

L1

N

LINE

230

PREMO S.

PREMO C.

LINE

MODULATING PUMP

Terminals EXT-MIN

interface WILO

modu la ti ng pu m p

Safety devices

L

N

kit

In case of safety devices intervention, the

Modulating pump continues to work at the

minimum in order to decrease the high

temperature

RELAY

Boile r m ain s

supply

230 V

L1

N

LINE

230

22

3.12- PRESSURE RELIEF VALVE DRAIN

PIPE

A pressure relief valve must be fitted on the flow

pipe, within 0,5 m from the boiler. It must be

dimensioned for the capacity of the boiler and

must comply to the regulations in force,

Instructions for the installer

Note:

Modulex 660 - 770 - 900 need 2 security

valve.

WARNING!

Please remember that it is forbidden to

interpose, between the boiler and the

pressure relief valve, any type of cutting-off

device. Moreover it is recommended to use

cutting-off valves which do not exceed the

maximum allowable operating pressure.

WARNING!

In correspondence to the heating pressure

relief valve foresee the installation of a

discharge pipe with a funnel and a siphon

which lead to an adequate drainage. The

drainage has to be controllable by sight.

If this precaution is not made, an eventual

intervention of the pressure relief valve could

cause injury to persons, animals or damage

to property. The manufacturer shall not be

held liable for any injury and/or damage.

3.13 - MIXING HEADER FILTER

UNICAL suggests the installation of a Y filter

on the return pipe so that it can be cleaned if

necessary.

This filter will protect the boiler from the heating

system dirt.

VISIBLE

DRAIN

FUNNEL

17

SAFETY V ALVE

3.14 - BALLSTOP VALVES

The installation of ballstop gate valves, on the C.H. flow and

return connection, is recommended.

Doing so, in case of normal or extraordinary service, the boiler can be drained without emptying the whole C.H. sistem.

WARNING!

IT IS NOT ALLOWED TO ISOLATE THE SAFETY

DEVICES, as the safety valve and the expansion vessel, FROM THE BOILER.

Secondary

circuit

23

Instructions for the installer

3.15 - BOILER FREEZE PROTECTION

Should the flow temperature (measured at global flow temperature NTC) decrease under 7°C, the system pump is set up. Shoul

temperature decrease to under 3°C, all modules will start at min.

output until the return temperature reaches 10°C.

Such protection device is exclusively for the boiler. For the protection of the system, a second freeze protection thermostat is

necessary to switch on the heating system pump.

To protect the C.H. system from freezing when boiler is not in

operation during cold season, it is necessary to add to the C.H.

system water an anti freezing solution.

NB: The antifreezing solution must be compatible with the

3.16 - MIXING HEADER AND PLATE HEAT EXCHANGER

materials present in the system, and mainly with the

aluminum.

THIS CAN BE ALLOWED ONLY IF YOU ARE SURE THAT AN

ANTIFREEZE SOLUTION HAS BEEN ADDED, IN THE PROPER

PERCENTAGE , TO THE C.H. WATER.

WARNING

AFTER A LONG INOPERATION PERIOD OF THE

BOILER, IN CASE THE BOILER TEMPERATURE

IS BELOW 3°C,

START THE BOILER.

ABSOLUTELY DO NOT TRY TO

n order to ensure correct boiler operation it is necessary to

use a mixing header which guarantees:

- the separation and collection of circuit dirt

- optimal air venting

- hydraulic de-coupling of the two hydraulic circulation

circuits

- balancing of the circuits

M

Boiler

Circuit

M

R

Heating

System

R

Circuit

he plate heat exchanger, conveniently dimensioned, has the

advantage to keep hydraulically the two circuits (primary and

secondary),protecting the boiler heat exchanger water / smo-

ke. allows subsequently, by adding or removing additional

plates to adjust the system as needed.

5

0

°

C

(

b

t

7

0

4

6

)

°

C

(

h

t

)

0

°

C

(

b

t

0

)

°

C

(

h

t

)

0

7

8

)

t

b

(

C

°

)

t

h

(

C

°

0

)

t

b

(

C

°

5

5

6

)

t

h

(

C

°

5

Mixing HeaderModulex Ext 440 - 900

cod. 00361997

M = DN 100 - (G 4’’)

R = DN 100 - (G 4’’)

See the Unical catalogue and the price list to

identify the most convenient mixing header and

primary circuit.

24

Plate Heat exchanger:

High temperature:

Boiler Circuit

M = 80 °C - R = 65 °C

Heating System Circuit

M = 70 °C - R = 60 °C

Low Temperature:

Boiler Circuit

M = 70 °C - R = 55 °C

Heating System Circuit

M = 50 °C - R = 40 °C

Modulex Modulex

Ext 440 code 00362093* Ext 440 code 00362098

Ext 550 code 00362094* Ext 550 code 00362099

Ext 660 code 00362095 Ext 660 code 00362100

Ext 770 code 00362096 Ext 770 code 00362101

Ext 900 code 00362097 Ext 900 code 00362102

* = G2

COLD OUT CH FLOW to System circuit (G 4’’)

COLD IN CH RETOUR from System circuit(G 4’’)

HOT IN CH FLOW from boiler (G 4’’)

HOT OUT CH RETOUR to boiler (G 4’’)

3.17 - CONDENSATE DRAIN

Instructions for the installer

Discharge of condensate must be:

- Built in order to prevent the escape of gas products of the

combustion in the location or sewer (siphon).

- Dimensioned and constructed as to allow the proper flow

of liquid discharges by preventing leaks (3% slope).

- Installed in order to prevent freezing of the liquid contents,

in function of the operating conditions.

- Easily inspected

The condensate, before being evacuated to the sewer, has to

be neutralized, neutralisation which can be obtained by mixing

the drain water coming from washing maschines, dish

washing maschines, etc., which normally have a basic pH.

Avoid the condensate stagnation inside the combustion

products evacuation system, (for this reason the evacuation

duct must have an inclination toward the drain of at least 30

mm/m (3/8 in. / ft) except the liquid column, inside the

condensate siphon, which needs to be filled with water after

installation: its minimum height, when all the fans are in operation, must be at least 25 mm (1 in.).

Is forbidden discharge the condensate through the rain

gutters, given the risk of ice and degradation of the

materials normally used.

The connection discharge should be visible.

due to the level of condensate acidity (pH 3 to 5) as a

material piping must be used only suitable plastics.

The outlet of the condensate drain pipe will be on the same

side of the smoke chamber, passing below the smoke chamber.

The recommended material must be PE (polyethylene) or

PPI (polypropylene).

Before commissioning the boiler fill the condensate siphon with water, from the dedicated filling-up plug.

150

PAV I M E N TO

DELLA C.T.

* Min. height of the condensate column, with all fans

operating at max. speed, requested by the EN standards.

La generatrice superiore del tubo di scarico

non dovrà trovarsi ad un livello superiore

al fondo della bacinella.

150

** Min. height of the condensate column, with all fans operating at max. speed. In the case it is not possible to create a

100 mm basement, install the boiler on the floor and foresee a min. 100 mm well to lodge the siphon.

25

Instructions for the installer

3.18 - WATER TREATMENT

The chemical-physical characteristics of the filling water and

reinstatement water in heating systems are of fundamental

importance for guaranteeing correct and safe boiler operation.

Before filling the CH circuit with water, it is necessary to analyse

the water and decide for a proper treatment.

The purpose of this treatment is finalized to eliminate or

substantially reduce the following problems:

- lime scale deposit

- corrosions

- deposits

- biological growths (moulds, bacteria, algae, fungi, etc)

The chemical treatment of the network water enables the

prevention of these problems and guarantees safe boiler

operation and economical advantages, in terms of

maintenance and global thermal efficiency.

The chemical analysis of the water enables us to obtain a lot

of information on the system’s condition and state of “health”.

It is essential to avoid any problems with the boiler.

The pH is a measure of the acidity or alkalinity of a solution.

The pH scale has a range of 0-14, where 7 is neutral.

Values inferior to 7 indicate acidity, values above 7 indicate

alkalinity.

The ideal pH value for water in heating systems fitted with

aluminium boilers is between 6,5 and 8, with a hardness of

15°F.

In heating systems where the water has a value outside this

range, this considerably accelerates the destruction of the

protective oxidized layer which naturally develops inside the

aluminium bodies: if the pH is below 6, acidity is present, if it is

above 8, the water is alkaline or it is caused by an alkaline

treatment (for example phosphate or glycol used as an

antifreeze) or in several cases it is due to the natural formation

of alkaline in the system.

Vice versa, if the pH value is between 6,5 and 8, the aluminium

surfaces of the boiler body are passivated and protected from

further corrosive attacks.

To minimize corrosion it is essential to use a scale inhibitor,

however in order for this to function correctly, the metallic

surfaces have to be clean.

The best corrosion inhibitors on sale also contain a

protective system for aluminium which acts by stabilizing

the water’s pH value, preventing unforeseen variations.

We recommend that the heating system’s water pH value

is systematically controlled (minimum twice a year). In order

to do this, it is not necessary to run a chemical analysis in

a laboratory, but it is sufficient to use a simple analytical

‘kit’ contained in portable cases, easily found on sale.

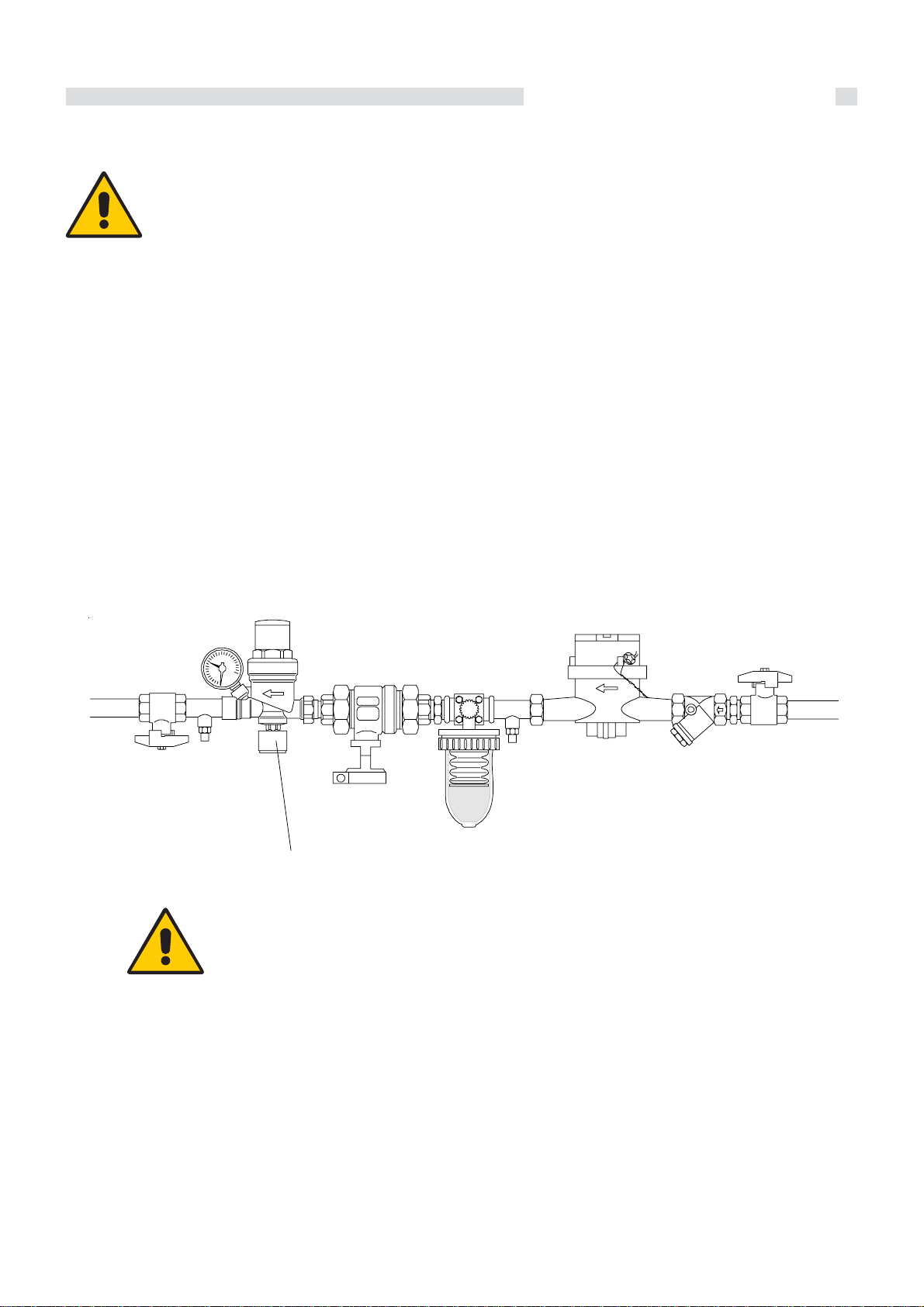

Therefore, prior to filling the heating system with water it will

be necessary to fit the devices indicated in the figure below

THE CONNECTION MUST BE FITTED ON THE

PRIMARY CIRCUIT’S RETURN PIPE

DOWNSTREAM OF THE CIRCULATING PUMP

All the necessary precautions must be taken in order to avoid

the formation and localization of oxygen in the system’s water.

For this reason, the plastic pipes used in underfloor heating

systems must be impermeable to oxygen.

If any antifreeze solutions are used ensure yourself that they

are compatible with aluminium and with any other components

and materials fitted on the system.

WARNING!

ANY DAMAGE CAUSED BY THE BOILER, DUE

TO THE FORMATION OF LIME SCALE OR DUE

TO CORROSIVE WATER WILL INVALIDATE THE

APPLIANCE WARRANTY.

26

3.19 - CONNECTION TO THE CHIMNEY

Instructions for the installer

In a condensing boiler the smokes are evacuated at a very

low temperature (Max about 84°C). Then it is necessary that

the chimney is perfectly impermeble to the condensate of the

combustion products and is made of materials corrosion resistant.

The different spigot joints must be well sealed and equipped

with suitable gaskets, in order to prevent the outlet of condensate and the inlet of air.

Concerning the cross section and the height of the chimney, it

is necessary to make reference to the national and local rules

in force.

For the dimensioning follow the instruction in pr EN 13384.

In order to prevent, during the operation, the formation of ice,

the temperatureof the internal wall of the combustion product

evacuation system, in all its length, has not to be below 0°C.

For condensation operating conditions of the appliance at the

external design temperature, it will be necessary to foresee a

condensate evacuation system, discharging, according to the

installation condition, in the boiler condensate tray or in

another dishpan separated from it.

In the construction of the flue duct it is necessary to use

materials resistant to the combustion products, in class

W1, according to EN 1443, as stainless steel or plastic certified materials.

As PVDF (polyvinildimethylfluorure) or PPS (polypropylene

transparent simple) certified for this use. Other materials ant

thicknesses are also autorized provided they can guarantee,

at least, equivalent characteristics.

Any contractual or extra-contractual responsibility of the supplier, for damages caused by

mistakes in the installation and in the use, and,

in any case, due to the non respect of the instructions given by the suplier, is excluded.

440

550

660

770

900

4

5

6

7

8

300

300

300

300

300

3.20 - FLUE MANIFOLD CONNECTION

For fixing the flue manifold use the 6 x nuts

CH 10 and washers supplied in the plastic bag.

Smoke plug outlet have to be positionned on the

rectilinear lenght into the 1st meter of the boiler

In order to fit the combustion gases sample

test nipple, drill a hole Ø 21 mm in the smoke

outlet and fit the test nipple following the

indicated sequence.

hole

Ø21 mm

27

Instructions for the installer

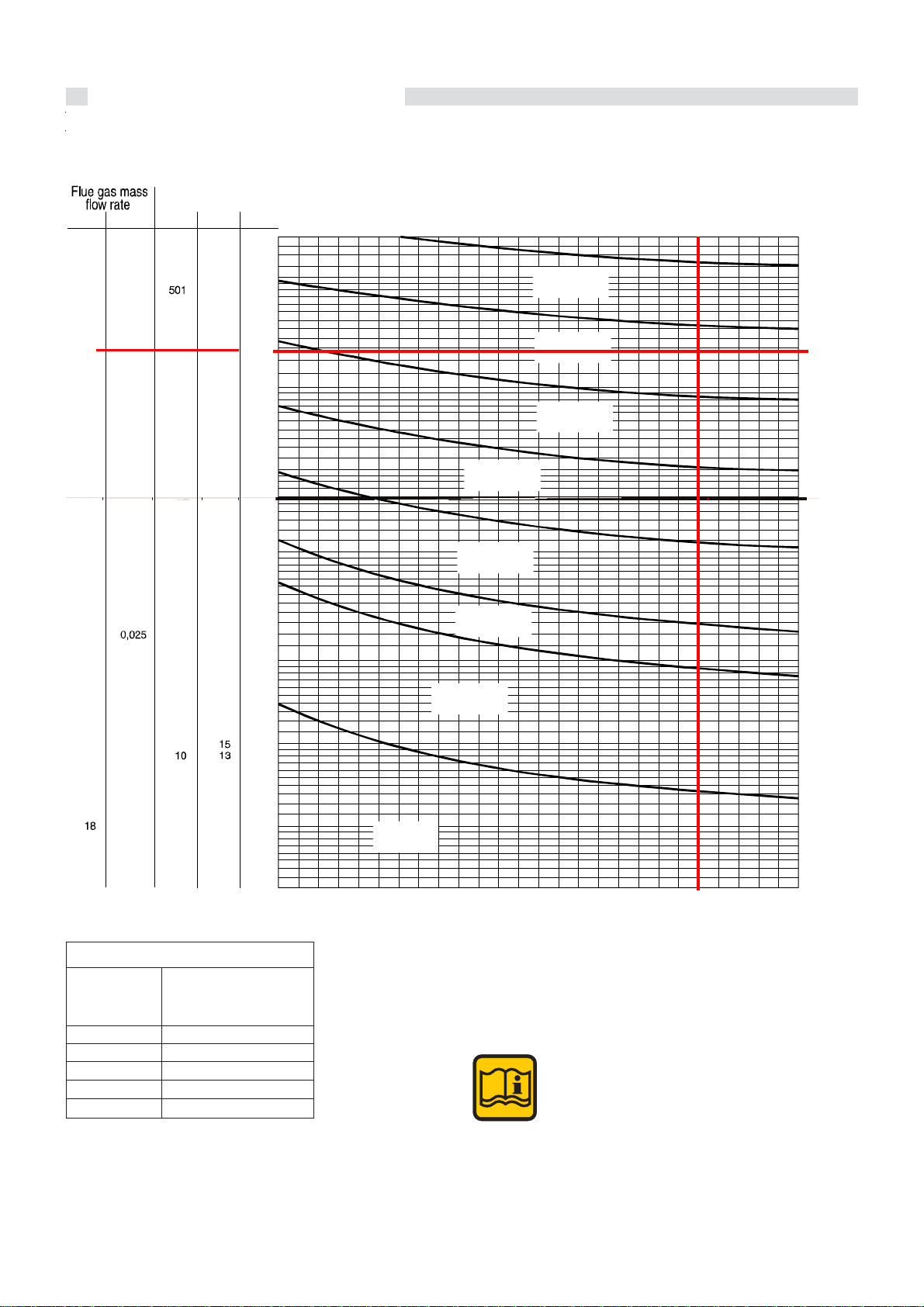

Chimney dimension

DIN 4705

CO levels

22

6%

2520

2160

1800

1440

1260

1080

900

kg/skg/h 10%

0,700

0,600

0,500

0,400

0,350

0,300

0,250

778

667

555

445

389

333

277

8%

1037

889

741

668

593

519

444

370

1400

1200

1000

900

800

700

600

500

5

Flue Gas Temperature

Pressure avaible

10 15 20 25 30

d400

a

d315

a

40°C

40 Pa

1400

1200

1000

900

800

700

600

500

720

606

540

360

324

288

252

216

180

144

126

108

90

72

54

36

32

29

25

22

14,4

12,0

10,8

9,0

0,200

0,150

0,100

0,090

0,080

0,070

0,060

0,050

0,040

0,035

0,030

0,020

0,015

0,010

0,009

0,008

0,007

0,006

0,005

0,004

0,003

0,002

0,001

222

167

111

100

5,6

5,0

4,4

3,9

3,4

Nominal Heat input (kW)

89

78

67

56

50

44

39

34

28

22

17

11

296

400

300

222

148

200

133

180

119

160

104

140

89

120

74

100

66

90

59

80

52

70

44

60

37

50

30

40

22

30

20

7,4

6,6

5,9

4,4

18

16

12

14

10

12

9

10

8

9

8

7

6

51015202530

d75

a

9

8

7

d200

d160

a

d125

a

d110

a

a

d250

a

400

300

200

180

160

140

120

100

90

80

70

60

50

40

30

2

20

18

16

14

12

10

9

8

7

6

Nominal Heat input (kW) with CO level at 10%

Flue gas mass flow rate

SuperModulex

440

550

660

770

900

28

Flue gas mass

flow rate (max)

kg/h

693

866

1040

1213

1386

Example:

SUPERMODULEX 660

Flue gas mass flow rate = 1040 Km/h

Chimney height = 25 m

Chimney connection Ø = 315 mm

NOTE:

the diagram provides indicative

value

g

3.20 - BOILER OPERATION

Instructions for the installer

The MODULEX EXT is made of inter-linked modules; each

module is made of:

- Combustion Chamber

- Burner

- Fan

- Gas valve

- Local NTC ((Negative Temperature Coefficient) sensor

(checks the flow temperature of each aluminium section)

- BMM (Burner Modular Manager)

- High Limit thermostat

- Ignition electrode

- Ionization electrode

- Air pressure switch

A module is able to supply a maximum power of 110 kW. So,

for instance, a boiler model 440 is constituted by 4 modules.

Each module has its temperature sensor NTC - Negative

T emperatures Coef ficient - that locally checks the temperature

of every single module.

The flow temperature at the boiler outlet and the return

temperature at the boiler inlet are controlled by global NTC

temperature sensors.

Gas valve

In case of more heat request by heating or DHW systems, the

boiler starts up and water will be heated by the aluminium

boiler body

Then the boiler pump will send the water to the mixing bottle

and from here to the radiators, according to the heating

system chosen.

The combustion air is supplied by fans which take it from the

boiler room. The combustion air is then pushed into the premixing chamber through a diaphragm.

Beyond the diaphragm, the air mixes with gas and such

mixture, passing through the non-return valve, is sent to the

burner.

Then, on leaving the burner surface, the air/gas mixture ignites

electrically and the resulting combustion gases, after being

transported (and cooled) through finned sections, enter the

condensate collecting manifold and then are evacuated

through the chimney.

Control

Panel

Fan

Combustion

Chamber

Burner

Ionization

electrode

H.L.

Thermostat

Thermic

element

Condensate

collectin

tray smoke

manifold

Siphon

29

Instructions for the installer

4

When there is a heat request from the E8 controller or from a

BCM (Boiler Cascade Manager), the E8 or BCM calculates

the necessary output according to the difference between the

set temperature (or the temperature calculated by the outer

compensator) and the global flow temperature. The number

of thermal elements (each thermal element represents a maximum input of 110 kW) x 100% determines the maximum

input expressed in %.

When the input has been determined, the boiler pump (not

supplied by Unical) is set up and the fan of one thermal element is set in motion at starting speed. The gas valve opens

and ignition is to occur within 5 sec. When the ionisation electrode detects the flame, the thermal element starts operating.

Subsequently other thermal elements are likely to start in the

same way. One of the operation principles for this boiler is

letting as many burners as possible operate simultaneously

at minimum load to reach the maximum efficiency.

For example, if a 4 thermal element boiler is requested to

operate at its max input, this shall be 400% i.e. :

110 kW x 4 thermal elements = 440 kW = 400%.

If it is requested to operate at 200% input, thanks to the input

sharing system on the highest number of thermal elements,

each thermal element will operate at 50% output i.e. :

200% : 4 moduli = 50 %

corrispondente a 100 kW totali

ossia 25 kW per ciascun modulo.

Such principle provides clearly efficiencies much higher than

those obtained in traditional groups of small boilers installed

in cascade.

When the input shared on each thermal element is less than

12 kW, one thermal element after the other is automatically

excluded and the remaining input is shared on thermal

elements having the smallest number of operation hours (by

the automatic operation-time calculating system).

Modulation, i.e. input reduction, is based on the difference

between the set temperature (or the temperature calculated

by the outer compensator) and the global flow temperature.

When no ignition occurs, the ignition device repeats two more

times the ignition sequence and then puts to lock out position

the thermal element concerned.

kW

% (p.c.i.)

109,6

109

104

100

4 thermal elements of 50 kW each working

at 50% of the output give = 100 kW = (200%),

i.e. 25 kW / thermal element

60

55

50

45

40

35

30

25

20

15

10

5

0

1 thermal

elemets

50 % = 54 kW

1 thermal

elemets

100 % = 108 kW

(kW)

108

P

1 Thermal element (module) = 108 kW = 100%

4 Thermal elem. = 108 kW x 4 = 432 kW = 400%

400% : 200 kW = 200% : X

20

22

30

60 70 80 90 100

50

5

10

Efficiency of a thermal element working at full capacity

108 kW = 103,2 % (in condensation)

Efficiency of a thermal element working at reduced

capacity 54 kW = 106,7 % (in condesation)

Efficiency of a thermal element working at minimum

capacity 22 kW = 108,8 % (in condesation)

40

X = (432x200) : 400 = 216 kW input shared on 4

thermal elements

Input shared on 4 thermal elements : total input

All the thermal elements work in parallel at the same output, equalizing, thus, the C.H. system efficiency to the one

of the thermal element.

= 216:432 = 0,5 = 50%

30

Instructions for the installer

3.22 - ELECTRICAL CONNECTIONS

Regulations in force

The gas and water feeding pipes and the CH system pipes

cannot be used as ground plates.

Ensure that the above safety electrical requirements subsist;

in case of doubt, ask for a professionally qualified technician

to check the appliance’s electrical system.

UNICAL refuses responsibility for any damages arising from