Automatic Heating Gasogen, Gasogen G3 25 2S, Gasogen G3 40 2S, Gasogen G3 50 2S, Gasogen G3 65 2S Installation And Servicing Manual

...

Gasogen

Wood Fired Boiler

Installation and Servicing Manual

29 - 93kW

Gasogen

General Information

CONTENTS

1 GENERAL INFORMATION ................................................................................................................................................................................. 3

1.1

Symbols used in this manual ....................................................................................................................................................................... 3

1.2

Correct use of the appliance ........................................................................................................................................................................ 3

1.3

Water treatment ............................................................................................................................................................................................. 3

1.4

Information to be passed over to the end user or the person in charge of the appliance ......................................................................... 3

1.5

Safety warnings ............................................................................................................................................................................................. 4

1.6

Data badge .................................................................................................................................................................................................... 5

1.7

General warnings .......................................................................................................................................................................................... 5

TECHNICAL FEATURES AND DIMENSIONS ................................................................................................................................................... 6

2

2.1

Technical features ......................................................................................................................................................................................... 6

2.2

Dimensions and water connections ............................................................................................................................................................. 7

2.3

Main components .......................................................................................................................................................................................... 8

2.4

General information ...................................................................................................................................................................................... 8

INSTALLATION INSTRUCTIONS ..................................................................................................................................................................... 12

3

3.1

General warnings ....................................................................................................................................................................................... 12

3.2

Installation Codes of Practice ................................................................................................................................................................... 13

3.3

Packaging................................................................................................................................................................................................... 14

3.4

Transportation ............................................................................................................................................................................................ 14

3.5

Installation .................................................................................................................................................................................................. 15

3.6

Boiler system connection .......................................................................................................................................................................... 15

3.7

Connection to the heat exchanger’s drainage .......................................................................................................................................... 16

3.8

Recycling pump ......................................................................................................................................................................................... 16

3.9

Installation instructions .............................................................................................................................................................................. 17

3.10

Water and electrical connection diagrams with standard control panel, without hot water storage tank .............................................. 21

3.11

Water and electrical connection diagrams with optional control panel, without hot water storage tank ............................................... 23

3.12

Water and electrical connection diagrams with optional control panel, with hot water storage tank .................................................... 27

3.13

Flue outlet connection ............................................................................................................................................................................... 40

3.14

Filling the system ....................................................................................................................................................................................... 41

ELECTRICAL CONNECTIONS ........................................................................................................................................................................ 42

4-5

4.1

Standard control panel .............................................................................................................................................................................. 43

5.1

Optional control panel ............................................................................................................................................................................... 45

5.2

Functional wiring diagram (Flow chart) .................................................................................................................................................... 46

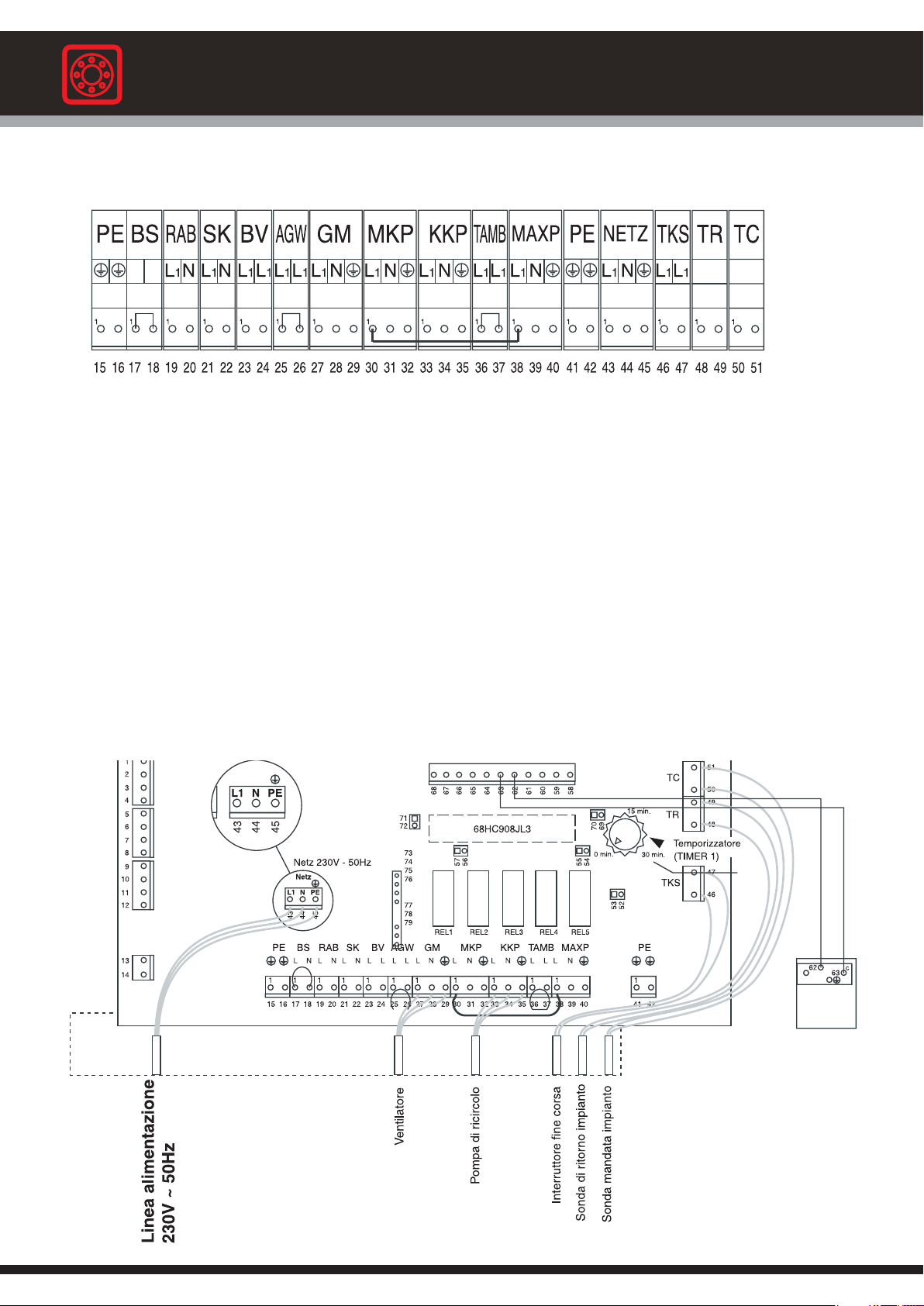

5.3 Loads and sensors connection diagram ................................................................................................................................................... 48

5.4

Functional description of optional control panel ...................................................................................................................................... 49

5.4.1

Ignition ............................................................................................................................................................................................. 49

5.4.2

Normal boiler operation ................................................................................................................................................................... 49

5.4.3

No wood ........................................................................................................................................................................................... 49

5.4.4

Oil/gas boiler operation ................................................................................................................................................................... 50

5.4.5

5.5

5.6

BOILER START-UP ........................................................................................................................................................................................... 54

6

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

6.12

6.13

6.14

Domestic hot water production ....................................................................................................................................................... 50

Special functions ....................................................................................................................................................................................... 51

5.5.1

Overheating ..................................................................................................................................................................................... 51

5.5.2

Combustion gas temperature control ............................................................................................................................................. 51

5.5.3

Fan overheating protection system ................................................................................................................................................ 51

5.5.4

Temperature sensor failure alarm .................................................................................................................................................. 51

5.5.5

Fireproof thermostat ........................................................................................................................................................................ 52

5.5.6

Waiting time .................................................................................................................................................................................... 52

5.5.7

Return flow sensor installation ....................................................................................................................................................... 52

Optional control panel wiring diagram ...................................................................................................................................................... 53

Initial lighting ............................................................................................................................................................................................. 54

Fire wood .................................................................................................................................................................................................... 55

Wood moisture ........................................................................................................................................................................................... 55

Fire wood dimensions ................................................................................................................................................................................ 55

Initial lighting checks ................................................................................................................................................................................. 55

Start-up ...................................................................................................................................................................................................... 56

Combustion air adjustment ....................................................................................................................................................................... 57

Checks to carry out after first start-up ...................................................................................................................................................... 58

Warnings .................................................................................................................................................................................................... 58

Thermostat adjustments ............................................................................................................................................................................ 59

Summer operation ..................................................................................................................................................................................... 59

Burner adjustment on the back up boiler ................................................................................................................................................. 59

Fault finding for boilers with standard control panel ................................................................................................................................ 60

Fault finding for boilers with optional control panel .................................................................................................................................. 61

SERVICING AND MAINTENANCE SCHEDULE ............................................................................................................................................. 62

7

2

General Information

Warning: this manual contains instructions to be used exclusively by the installer and/or a competent person in

accordance with the current laws.

The end user is not qualified to carry out any service work on the boiler.

Failure to follow the instructions indicated in this manual, which is supplied with the boiler, could cause injury to

persons, animals or damage to property. Automatic Heating shall not be held liable for any injury and/or damage.

1

GENERAL INFORMATION

1.1 - SYMBOLS USED IN THIS MANUAL

When reading this manual particular care has to be given to the parts marked with the followings symbols:

DANGER! Indicates serious

danger for your personal safety

and for your life

WARNING! Indicates a potentially

dangerous situation for the

product and the environment

NOTE! Suggestions for the

user

1.2 - A CORRECT USE OF THE APPLIANCE

The GASOGEN G3 2S appliance has been designed utilizing today’s heating technology and in compliance

with the current safety regulations.

However, following an improper use, dangers could arise for the safety and life of the user or of other

people, or damage could be caused to the appliance or other objects.

The appliance is designed to be used in pumped hot water central heating systems.

Any other use of this appliance will be considered improper.

Automatic Heating declines any responsibility for any damages or injuries caused by an improper use;

in this case the risk is completely at the user’s responsibility.

In order to use the appliance according to the foreseen scopes it is necessary to carefully follow the

instructions indicated in this manual.

1.3 - WATER TREATMENT (refer to specific guide)

The hardness of the mains water supply conditions the frequency with which the heat exchanger is cleaned.

In hard water areas where the main water can exceed 15°f total hardness, a scale reducing device is recom-

mended. The choice of this device has to be made taking into consideration the characteristics of the water.

We recommend you to check the state of cleanliness of the domestic hot water heat exchanger at the end of the

first year and subsequently every two years; in this occasion check the state of wear of the anode.

1.4 - INFORMATIONTO BE HANDED OVERTO THE USER OR PERSON IN CHARGE OF THE

APPLIANCE

The user or the person in charge has to instructed on the use and operation of his heating system, in particular:

- Hand over these instructions to the end user or person in charge of the appliance, together with any other literature regarding this appliance placed inside the envelope contained in the packaging. The user has to keep these

documents in a safe place in order to always have them at hand for future reference.

- Inform the user on the importance of air vents and of the flue outlet system, stressing the fact that it is absolutely

forbidden to make any alterations to the boiler.

- Inform the user how to check the system’s water pressure as well as informing him how to restore the correct

pressure.

- Explain the function of time and temperature controls, thermostats, heating controls and radiators, to ensure the

greatest possible fuel economy.

- Remind the user that it is obligatory to service the appliance at least annually and to carry out a combustion

analysis in compliance with the schedule indicated in the national Codes of Practice.

- If the appliance is sold or transferred to another owner or if the present user moves home and leaves the appliance

installed, ensure yourself that the manual always follows the appliance so that it can be consulted by the new

owner and/or installer.

3

Gasogen

General Information

1.5 - SAFETY WARNINGS

WARNING!

The installation, adjustment, and servicing of this appliance must be carried out by a competent, qualified

person and installed in accordance with the current standards and regulations. Failure to correctly install

this appliance could cause injury to persons, animals or damage to property. The manufacturer shall not

be held liable for any injury and/or damage.

DANGER!

NEVER try to carry out any repairs or service work on the boiler on your own initiative.

Servicing or repairs of the appliance must be carried out by qualified service engineers;

Automatic Heating recommends drawing up a service contract.

Bad or irregular servicing could compromise the safe operation of the appliance, and could cause injury to

persons, animals or damage to property for which shall not be held liable.Automatic Heating

Modifications to parts connected to the appliance

Do not carry out any modifications to the following parts:

- the boiler

- to the gas, air, water supply pipes and electrical current

- to the flue pipe, safety relief valve and to the central heating’s drainage pipe

- to the constructive components which influence the appliance’s safe operation

WARNING!

When tightening or loosening the screw pipe connections, use only adequate fork spanners.

The improperuse and/or theuse of inadequateequipment can causedamages (for example water or gas leakages).

Explosive and easily inflammable substances

Do not use or leave explosive or easily inflammable material (as for example: petrol, paint, paper) in the room

where the appliance has been installed.

4

General Information

1.6 - DATA BADGE

The data badge is adhesive and placed inside the documentation envelope;it must be glued on to one side of the casing, on the

external part, by the installer.

The boiler’s serial number is indicated on the plate screwed on the boiler’s front plate (front side, upper right hand side).

1.7 - GENERAL WARNINGS

This instruction manual is an integral and indispensable part

of the product and must be retained by the person in charge of

the appliance.

Please read carefully the instructions contained in this manual

as they provide important indications regarding the safe

installation, use and servicing of this appliance.

Keep this manual in a safe place for future reference.

The installationand servicing mustbe carried out in accordance

with the regulations in force according to the manufacturer’s

instructions and by legally competent authorized persons.

By a competent person, we imply a person who has a specific

technical qualification in the field of components for central

heating systems for domestic use, domestic hot water

production and servicing. The person must have the

qualifications foreseen by the current laws in force.

Bad orirregular servicing could compromise the safe operation

of the appliance, and could cause injury to persons, animals

or damageto property.The manufacturer shall notbe held liable

for any such injury and/or damage.

Before carrying out any cleaning or servicing turn off the

electrical supply to the boiler by means of the ON/OFF switch

and/or by means of the appropriate shutdown devices.

Do not obstruct the intake/outlet terminal ducts.

In the event of failure and/or faulty functioning of the appliance,

switch off the boiler.Do not attempt to make any repairs:contact

qualified technicians.

Any repairs must be carried out by Automatic heating authorized

technicians and using only original spare parts. Nonobservance of the above requirement may jeopardize the safety

of the appliance.

To guarantee the efficiency and correct functioning of the

appliance itis indispensable to have the boiler serviced annually

by a qualified person.

If the boiler remains unused for long periods, ensure that any

dangerous parts are rendered innocuous.

If the appliance is sold or transferred to another owner or if the

present user moves home and leaves the appliance installed,

ensure yourself that the manual always follows the appliance

so that it can be consulted by the new owner and/or installer.

Only original accessories must be used for all appliances

supplied with optional accessories or kits (including electrical

ones).

This appliance must be used only for the purposes for which it

has been expressively designed. Any other use shall be

considered incorrect and therefore dangerous

5

Gasogen

Technical features and dimensions

2

TECHNICAL FEATURES

AND DIMENSIONS

2.1 - TECHNICAL FEATURES

The GASOGEN G3 2S boiler is a steel made wood fired unit

, with complete wood gasification combustion, inverted flame,

with a pressurised room chamber.

The following models are available:

GASOGENG3252S

GASOGENG3402S

GASOGENG3502S

GASOGENG3652S

GASOGENG3802S

The GASOGEN G3 2S boiler is equipped with all the safety

and control devices in compliance to the current standards.

DESCRIPTION OF COMPONENTS

- Steel body with a partially refractory-lined combustion

chamber;

- Refractory burner;

- Horizontal flue channels;

- Front fire box lined with refractory material;

- Intermediate door complete with combustion air regulations;

- Lower cleaning door lined with refractory material and

equipped with a flame inspection sight;

- Rear flue chamber with side inspection doors and ash

removal

-

Flue evacuation via a pressure blower.

- Patented thermostatic valves system

- Safety heat exchanger

- Insulated boiler body with 60 mm thickness mineral wool

mattress

- Powder painted steel casing

- Recirculation pump kit (optional)

- Recirculation pump kit for buffer tank (optional), provided

the standard control panel is replaced by the model code

23557

- Standard control panel for electromechanical operation

- Optional control panel, code 23557, for integral control of a

buffer tank, according to the Standard EN 303-5 and with

the possibility of operating with a back up oil or gas fired

boiler.

STANDARD CONTROL PANEL COMPONENTS:

- Power On light indicator

- Boiler thermometer

- Safety thermostat in case of boiler overheating

- Boiler temperature adjustment thermostat

OPTIONAL CONTROL PANEL COMPONENTS:

- Power On light indicator

- Boiler thermometer

- Safety thermostat in case of boiler overheating

- Boiler temperature adjustment thermostat

6

2.2 - DIMENSIONS AND

WATER CONNECTIONS

Technical features and dimensions

1. Control panel

2. Primary air adjustment

1

A

3. Secondary air adjustment

4. Flame sight control

5. Cleaning door

6. Rear smoke chamber

7. Loading door

8. Fan

7

9. Bottom inspection and cleaning door

T1. Central Heating flow

T2. Central Heating return

T3. Chimney connection

T4. Safety heat exchanger connections

T5. Bulb holderconnection for heat discharge

valve

T6. Bulb holder for safety thermostat

T7. Bulb holderfor thermometer and high limit

8

3

2

4

9

and minimum working thermostat,

T8. Boiler drainage

MODELS

MINIMUM OUTPUT

AVERAGE OUTPUT

MAXIMUM USEFUL OUTPUT*

MAXIMUM OUPUT

DIMENSIONS:

A

B

C

D

E

F

G

CONNECTIONS T1 - T2

T3

T4

T5 - T6 - T7 - T8

BOILER WATER CONTENT

WATER SIDE PRESSURE DROP**

SMOKE SIDE PRESSURE DROP

MAX. WORKING PRESSURE

FIRE BOX STORAGE VOLUME

FIRE BOX DIMENSIONS

WEIGHT

WOOD LOGS LENGTH

(kW)

(kW)

(kW)

(kW)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

UNI ISO 7/1

(Ø mm)

UNI ISO 7/1

UNI ISO 7/1

(l)

(m c.a.)

(mm c.a.)

(bar)

(l)

(mm)

(kg)

(cm)

GASOGEN

G3 25 2S

15 23 29

26 37 47

29 47 58

34

560

700

1225 1355

190

315

245

1030

Rp 1¼

150

R½

Rp ½

90

0,10

3

95

290x340

386

50 50 70

* Output obtained with good quality wood with a 15% .moisture content.

** Pressure losses for a flow rate corresponding to 15 K DeltaT.

D

C

F

T4

T3

6

G

5

T2-T8

GASOGEN

G3 40 2S

55 69

655

700

190

315

1140 1140

Rp 1½

200

R½

Rp ½

110

0,08

3

135

350x440

475

T1

B

GASOGEN

G3 50 2S

655

900

1355

190

315

245245

Rp 1½

200

R½

Rp ½

140

0,12

0,60,40,3

3

185

350x440

593

E

30

T4

T5

T8

GASOGEN

G3 65 2S

41

64

76

88

755

955

1405

190

315

245

1180

Rp 2

220

R¾

Rp ½

170

0,06

0,3

3

235

340x520

630

70

T1

GASOGEN

G3 80 2S

52

76

93

109

755

1255

1405

190

315

245

1180

Rp 2

220

R¾

Rp ½

220

0,10

0,5

3

325

340x520

850

100

fig. 1

T7

T4

T6

T3

T2

7

Gasogen

Technical features and dimensions

2.3 - MAIN COMPONENTS

1. Control panel

2. Upper casing panel

3. N° 2 side casing panels

4. Smoke proof hinged door

5. Refractory-lined loading door with sealing gasket

6. Central door with gasket and primary and secondary

air adjustment screws

7. Fan

8. Refractory-lined combustion chamber door, sealing

gasket and flame sight

9. Thick steel plated combustion chamber

10. Heat exchange baffle

11. Boiler drainage

12. Safety heat exchanger

13. By-pass with command rod

14. Boiler body mineral wool insulation

15. Steel boiler body

16. Refractory burner with fire bars and grate

17. Flue chamber

19. Thermostatic valve

MC.H.flow

R C.H. return

12

17

18

121413

M

3

5

15

16

4

6

7

8

R

N.B.:

The firebars and the refractory steel grate are subject to wear;it is therefore advisable

to carry out an annual inspection to prevent bad boiler operation.

2.4 - GENERAL INFORMATION:

REVERSED FLAME COMBUSTION

Every body knows that to make a match last it must be held

with its head upwards.

This is because it is necessary that the flame, in its convective

motion, does not meet anotherfuel in addition to the one which

it has generated it. As in residential heating the fuel is in form

of wood logs which are loaded from the top, the flame has to

go in the opposite way, i.e. downwards.

Natural draught is a very variable source of depression,

according to the type of chimney, on the weather conditions,

onthetypeoffuel,etc.

Therefore it is necessary to integrate it with forced ventilation

in order to stabilize it.

By fitting a fan it is possible to considerably reduce the section

of the gas passages on the grate and furthermore there are no

problems with cold starts.

The small grate permits a more controlled passage of

combustion air, contrarily to what happens with the large

traditional grates.

The air can be perfectly dosed because the grate covered with

fired wood has the same crossing resistance and thus the

combustion will be always optimal.

Automatic Heating has already used this principal for many

years with the GASOGEN G3 2S boiler.

11

The GASOGEN G3 2S boiler today has reached such a high

level of perfection that it can pass all the most stringent tests

foreseen by the European Standards in force concerning the

environment.

10

9

fig. 2

8

GASOGEN G3 2S - BOILER CONSTRUCTION

The boilerbody is made of two oval elements, one placed inside

the other, so as to form a water cavity (fig.3).

The large fire box , in its rear wall, has a refractory insulation,

which is particularly resistant to heat and mechanicalstresses,

in order to keep the by-pass zone dry in every working

condition.

Technical features and dimensions

M

9

10

We can distinguish the following parts (fig.3):

1. Fire box, drying area

2. Gasification zone

3. Embers zone

4. Refractory burner

5. Combustion chamber

6. Heat exchange surface

7. Refractory steel cradle

8. Boiler water

9. Thermostatic system

10. Safety heat exchanger

M C.H. system flow

R C.H. system return

GASIFICATION ZONE (2)

The gasification takes place In the lower part of the fire box .

It isvery important thatthe gasification isas regular as possible,

so as not to overburden the burner with gas. The gasification

speed dependson the quantity of the wood and the dimensions

of the drying area. Generally, it is better to use large logs if

they are dry and small logs if the wood is wet .The quantity of

primary air, proportional to the delivered output, is regulated

via the adjustment system.

EXCHANGE SURFACE (6)

As the boiler operates on wood, and because the sulphur

concentrations are not very high , it is important to obtain very

low smoke temperatures in order to increase the water

efficiency.

To obtain this Automatic Heating has opted for an exchange

surface with dry smoke passes (fig. 4), which have already

been extensivelytested in oil fired boilers working at low water

temperature, thus permitting low smoke temperatures without

danger of condensate forming.

The surfaces ofthe dry passages“A” (fig.4) have had incisions

made on them in order to avoid dilatation problems.

The solid residues of combustion (ashes), which lie on the

high temperature refractory-lined cradle (fig. 3, pos. 7,) will

become with time always lighter until they will be dragged by

the gas speed and will deposit themselves in the lowest area

of the rear smoke chamber, from which they will be removed

during the cleaning operation.

1

2

3

4

5

6

7

8

R

fig. 3

fig. 4

REFRACTORY BURNER (4)

The burner is made up of refractory stone (fig. 3, pos. 4).

This stonehas an oval central opening through which the flame

passes.

The embers lie directly on the main stone which divides the

fire box from the lower combustion chamber.

Furthermore the main refractory stone has a rectangular seat

in which the opportunely grooved cast iron fire bars are placed

(fig. 5, pos. 2), which receive the secondary air from a front

distributor.

The embers are prevented from falling by cylindrical pieces of

refractory steel. The combustion gases, poor in oxygen and

fig. 5

1. Metallic grate

2. Cast iron fire bars

9

Gasogen

Technical features and dimensions

still rich in carbon not yet combined, travel across the embers

and enter the opening in the centre of the main stone.

Inside this pre-combustion chamber, the gases combine with

the pre-heated secondary air coming through the grooves of

the two cast iron fire bars.

The resulting flame will be highly oxygenated and have a light

blue colour. This flame comes out from the oval opening and

invades the combustion chamber.

Due to the high temperatures therefractory burner will become

a bright red colour.

THERMOSTATIC VALVE (9)

As well known, wood normally has a high moisture content

when compared with other types of fuels. The first operation

which occurs inside the fire box is therefore the drying phase.

The high moisture content can then cause condensation

phenomena within the boiler and also in the chimney.

To limit the inconvenience in the boiler it is necessary to

maintain high working temperatures.

For this reason the boiler is equipped with a patented

thermostatic system (fig. 6) which permits the boiler

temperature to be kept constantly high and in particular, in the

fire box, where

the condensation phenomena is more likely to occur.

In order to reduce the consequences of condensate formation

(formation of layers of tar, corrosion, etc.) it is advantageous

to dimension, time by time, the wood load to the actual needs,

so as to prevent long stop overs with the wood storage

completely full of humid wood.

Nevertheless all these expedients do notimpede the formation

of condensate in the chimney. Therefore we suggest, when

building the chimney, to use air-tight components, to avoid the

condensate damaging the building structure.

COMBUSTION CHAMBER (5)

The combustion is optimised by increasing the flame

temperature and producing a strong turbulence in the bottom

chamber.

For this reason the flame, in addition to not to touching cold

walls irrigated by the water, rebounds and is divided on a

semicircular cradle which rests on the lower exchange surfaces

(baffles), which, as well delimiting the smoke passages, also

has the task of collecting the ashes and possible embers.

The flames, after having bounced off the walls of the bottom

area and the refractory ones, direct themselves with a whirling

motion towards the front part of the combustion chamber and

enter theflue ducts.The combustion will be complete and clean

and the dominant colour will be that of the ashes: white.

Firewood, as is well known, normally has a high moisture

content when compared to other types of fuels. The first

operation which occurs inside the fire box is therefore the

drying phase.

The high moisture content can cause condensate

phenomenons inside the boiler and also in the chimney.

In order to limit this problem it is necessary to maintain the

boiler at a high working temperature.

Therefore, in order to adjust the flow temperature it is necessary

toinstalla3or4waymixingvalve.

If the mixing valve is not installed it will make the guarantee

void.

Always in order to reduce the consequences of condensate

formation (tar formation , corrosion, etc.) it is advantageous to

dimension, time by time, the wood load to the actual needs, so

F

F

R

M=C.H.flow

R=C.H.return

P = Primary air

S = Secondary air

F = Flue

T1

3

2

1

fig. 6

M

P

P

P

P-S

SSS

S

F

fig. 7

10

as to prevent long stop overs with the wood storage completely

full of humid wood. Nevertheless all these expedients do not

impede the formation of condensate in the chimney. Therefore

we suggest, when building the chimney, to use air-tight

components, to avoid the condensate damaging the building

structure.

Technical features and dimensions

11

Gasogen

Instructions for the installer

INSTALLATION

3

INSTRUCTIONS

3.1 - GENERAL WARNINGS

WARNING!

This boiler is to be destined only to the use

for which it has expressly been designed for.

Every other use is to be considered improper

and therefore dangerous.

This boiler is designed to heat water at a

temperature inferior to boiling point at an

atmospheric pressure.

WARNING!

These appliances are exclusively designed

for indoor installations or installed in

adequate sitings.Therefore these appliances

must not be installed and operated

outdoors. An outdoor installation could

cause malfunctioning and could be

dangerous. For outdoor installations, it is

recommended to use appliances which have

been specifically designed for this purpose.

Before installing the boiler the following points

have to be carried out by a professionally

qualified person:

a) The whole system should be thoroughly

flushed in order to remove any residual dirt or

grime which could compromise correct boiler

operation.

b)

Check that the chimney/flue pipe has an

adequate draught, does not have any

constrictions, and that no other appliance’s flue

outlets have been fitted, unless the chimney is

serving more than one heating appliance,

according to the specific standards and

regulations in force. The connection between

the boiler and chimney/flue outlet can be made

only after this verification has been carried out.

WARNING!

The appliance must be installed by a

qualified, registered engineer, whom, under

his own responsibility, guarantees the

compliance of the standards according to

the latest regulations.

12

NOTE:

The boilermust be connected to a heating system

which iscompatible to its performance and output.

3.2 - INSTALLATION CODES OF PRACTICE

The GASOGEN G3 2S is a boiler foreseen for operation with

firewood. The appliance must be installed in compliance with

all applicable laws and regulations.

Instructions for the installer

13

Gasogen

Instructions for the installer

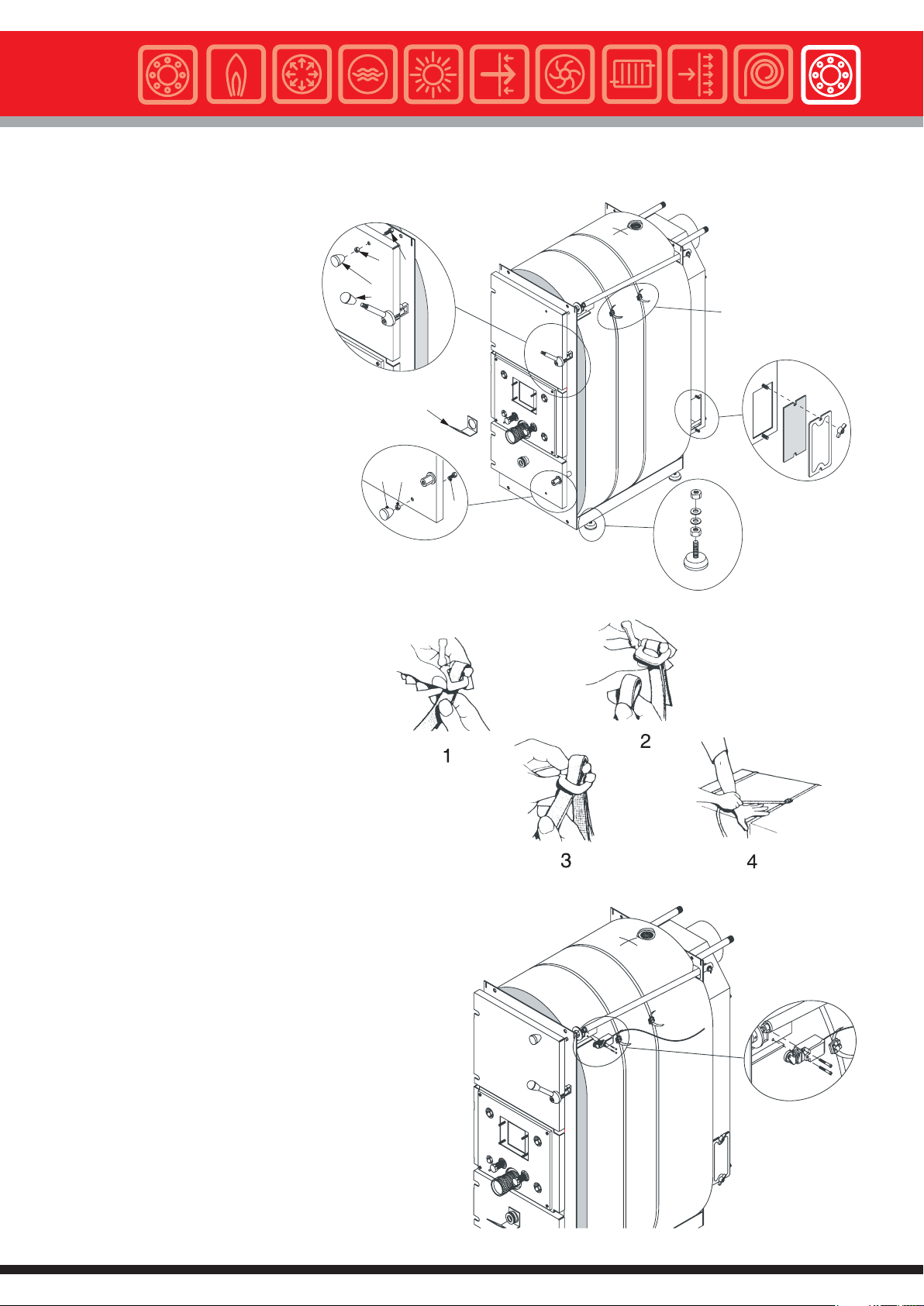

3.3 - PACKAGING

The GASOGEN G3 2S is supplied dismantled: the casing, the

fan, the controlpanel, the handlesand the cleaning accessories

are delivered separately in carton boxes

(fig. 8).

After having unpacked everything, make sure that

the consignment is intact and undamaged.

In case of doubt do not to use the appliance and

inform the supplier.

Keep the packaging material (cardboard box,

plastic bags, polyester protection etc.) out of

the reach of children since they can be

dangerous.

Automatic Heatingrefuses all liability forinjury

to persons, animals or damage to property

deriving from not having respected the above

mentioned recommendations.

Packages description:

1

2

4

3

fig. 8

1. Boiler body

2. Package containing the casing and boiler insulation

3. Package containing the control panel

4. Package containing: insulation fixing kit, fan, air manifold

group, smoke

chamber inspection doors, handles, flame sight mirror.

In the documents, placed in the fire box, you will find:

- User’s instruction guide

- Installation and servicing instruction manual

- Warranty

- Adhesive data plate

- Adhesive label with ventilation requirements

If the boiler will not be used for a long period,

it should be adequately protected.

3.4 - TRANSPORTATION

To facilitate the transport, the loading and unloading of the

boiler, on the upper part of the boiler body there are suitable

hooks (fig. 8) for lifting.

14

3.5 - INSTALLATION

The boiler does not differ from a normal solid fuel fired boiler;

therefore there are no particular installation codes of practice

other than the applicable national and local safety regulations

and laws.

The installation room must be properly ventilated via openings,

which should have a total surface of at least 0,5 m².

To facilitate cleaning of the flue circuit,a free space, not inferior

to the length of the boiler, must be left in front of the boiler.

In addition ensure that thedoors can open 90° without meeting

any obstacles.

The boiler can be placed directly on the floor, because it is

equipped with a self-supporting frame.

Nevertheless, in case of installation in very damp boiler rooms,

it is preferable to fit a concrete support.

Instructions for the installer

1000

600

When installation is completed, the boiler should be in a

horizontal position and stable so as to reduce possible

vibrations and noise.

An adequate clearing must be left behind the boiler for

servicing.

INSTALLATION IN BOILER ROOM

Note:

The minimum clearances indicated in figure 9 are compulsory

only for boilers with an output higher than 35 kW.

3.6 - BOILER SYSTEM CONNECTION

Warning!

Make sure the connection of the pipelines

is free of mechanical stresses, in order to

avoid pressure losses!

The C.H. flow and return must be connected to the respective

connections in the boiler, as indicated on page 8.

600

1300

600

fig. 9

When determining the size of the CH circuit pipes it is essential

to bear in mind the pressure losses induced by any of the

system’s components and by the configuration of the same

system.

The piping route has to be designed taking all the necessary

precautions in order to avoid air locks and to facilitate the

continuous purging of the system.

Ensure yourself that the system’s piping is not

used as earth clamps for the electrical or

telephone system. They are absolutely

unsuitable for this use.In a short time this could

cause serious damage to the piping, boiler and

radiators.

15

Gasogen

Instructions for the installer

3.7 - CONNECTION TO SAFETY HEAT

EXCHANGER DRAIN

Solid fuel fired boilers have to be installed

with the safety devices foreseen by

applicable

regulation and laws.

For this purpose the GASOGEN G3 2S

boilers are fitted with a safety heat

exchanger.

On this safety heat exchanger the installer must fit a heat

discharge valve, whose control bulb has to be inserted in the

bulb holder placed onto the rear wall of the wood fired boiler.

The inlet and outlet connections can be inverted.

However we recommend that the valve be fitted on the cold

water inlet.

In correspondenceof the safety heat exchanger

outlet, we recommend fitting a drainage pipe

with a funnel and siphon that lead to an

adequate drainage. The drainage has to be

visible.

1

2

ALIMENTAZIONE

MAINS

SCARICO

DRAIN

Warning!

In absence of this precautionary measure, the eventual

intervention of the heat discharge valve could cause

damages to people, animals or property.The manufacturer

shall not be held liable for any such injury and/or damage.

3.8 - RECIRCULATION PUMP

For correct boiler operation it is necessary to

install a recirculation pump in the boiler.

The recirculation pump, supplied as an

optional kit in two different versions, basic or

for buffer storage tank control, will have to be

connected as shown in figs. 19 and 20.

If the recirculation pump is not installed, besides limiting

the boiler’s life span, it will invalidate the warranty.

WARNING!

The hardness of the mains water supply conditions the

boiler’s life span.

Depending on the hardness of the of the mains water

supply the possibility of installing a water

softener has to be taken into consideration.

In hard water areas where the main water can exceed 15°f

total hardness, water treatment is always recommended.

fig. 10

16

3.9 - INSTALLATION

INSTRUCTIONS

Instructions for the installer

A

Installation of the insulation and

casing

A) Fit the ball grip pos. 4 onto the upper

door closing handle.

B) Fit the screw and nut on the upper

and lower door and screw down the ball

grip (pos. 1, 2, 3).

C) Fit the 4 supporting feet on the lower

L profiles of the boiler body.

D) Fitthe cleaning doors onto the smoke

chamber.

E) Fit the flame sightmirror (pos.5) onto

the lower door’s sight glass.

F) Fit the thermal discharge valve’s bulb

holder (pos. 2, fig. 18).

G) Fit the body insulation and make a

suitable hole near the flow connection

pipe.

H) After fitting the fibre glass insulation

onto the boiler body, pass the plastic

strap provided around it, and insert an

end part in the slot as shown in detail 1

(fig. 12).

Make appropriate cuts in

correspondence of the thermostatic

valves.

2

1

3

4

FIG. 12

D

5

B

2

3

1

C

fig. 11

I) Keeping the end of the plastic strap

already inserted steady, proceed with

the other end by bending, towards the

inside, the plastic pin as shown in detail

2.

L) Pull the ends of the strap (as shown

in details 3 & 4) till it adheres completely

to the glass wool covering the boiler

body.

Please do not pull the strap too much,

as too much compression of the rock

wool insulation will cause an

uniformed insulation

If the boiler needs to be serviced it is possible to remove the

plastic strap by removing the blocking devices.

Fit the microswitch onto its support and adjust the pushing

washer axially in order to allow the microswitch to be regularly

controlled when the upper loading door is closed.

Check that the by-pass disk is perfectly closed when the door

is closed and the boiler in operation.

It is possible to verify this by simulating the closing of the upper

door and observing, from the inside of the fire box, if there are

any spaces.

If necessary, adjust the length of the by-pass shaft, acting on

the front threaded shaft.

fig. 12

fig. 13

17

Gasogen

Instructions for the installer

- Hook the L.H. side casing panel (pos. 1) to the boiler body.

- Hook the R.H. side casing panel (pos. 2) to the boiler body.

- Before fitting the upper panel (pos.3) to the side panel (pos.1

& 2), install the control panel (pos. 4).

- Fit the rear profile supporting the cable clamps (pos. 7).on

the upper panel

- Open the control panel by unscrewing the two side screws.

Lift the control panel’s cover, making it rotate frontwards.

Fit all the thermostat capillaries inside, unrolling them carefully,

the fan(s) connecting cable(s) (outlet), the microswitch cable

door opening control (inlet), and the incoming supply cable

through the two rectangular slots on the base of the control

panel.

- Position the upper casing panel onto the boiler by directing

the capillaries towards the boiler rear.

- Stick the boiler DATA PLATE onto the R.H. side casing panel

after having cleaned the interested area.

Remove the adhesive from the DATA PLATE and stick it on the

boiler making it adhere perfectly.

1

3

4

5

6

2

7

Ref. fig.15 (Models GASOGEN G3 25 2S,GASOGEN G3 40

2S,GASOGENG3502S)

- Fit the air manifold (pos. 1) on to the intermediate door.

- Fit the gasket (pos. 4) and the plate (pos. 5) to the manifold.

- Fit the fan (pos. 7) to the plate.

- Make sure the air non-return plate is not blocked, by moving

the air manifold’s external lever manually.

The primary and secondary air draught adjustmentis described

on page 57.

- Wire the electrical connections (see general wiring

diagram on page 44 and practical wiring

diagrams on

8

9

page 21 & 22).

On the optional control panel (code 23557)

DUPLO IT version, the wiring of the electrical

connections must be carried out as indicated

in the diagrams in 3.11 & 3.12, on pages 24, 26, 29, 31, 33,

36 and 39.

Ref. fig. 16 (Mod. GASOGEN G3 65 2S, GASOGEN G3 80

2S)

- Fit the air manifolds on to the intermediate door.

- Fit the gaskets and the plates to the manifolds.

- Fit the fans to the plates.

- Make sure the air non-return plates are not blocked,by moving

the air manifold’s external lever manually.

The primary and secondary air adjustment is

described on page 57.

- Wire the electrical connections (see general

wiring diagram on page 44 and practical wiring

diagrams on page 21 & 22).

2

3

1

4

5

6

7

Models: GASOGEN G3 25 2S

Models: GASOGEN G3 65 2S

DETTAGLIO B

DETAIL B

GASOGENG3402S

GASOGENG3502S

GASOGENG3802S

fig. 14

B

fig. 15

B

On the optional control panel (code 23557)

DUPLO IT version, the wiring of the electrical

connections must be carried out as shown in the

diagrams in 3.11 & 3.12, on pages 24, 26, 29, 31,

33, 36 and 39.

18

DETTAGLIO B

DETAIL B

fig. 16

Wire the electrical connections as indicated on the general

wiring diagram on page 44 and practical wiring diagrams on

page 21 & 22).

Insert the bulbs of the thermostats in their relevant bulb holders

as shown in fig. 17 and secure them in place with the fixing

springs.

In the optional control panel (code 23557) DUPLO IT

version, the bulbs of the sensors/thermostats to be placed

in the bulb holders are the following:

- Flow sensor (Tc).

- Boiler thermometer

- Safety thermostat (small bulb holder).

The flue sensor bulb must not be inserted.

For the return sensor’s electrical connection (Tr) and for

the relevant problems connected with it, see 5.5.7 (page

52) “Return sensor installation”.

TERMOSTATO

DI ESERCIZIO (Te)

TERMOMETRO

TERMOSTATO

DI MINIMA (Tsc)

MOLLA DI

FISSAGGIO

MOLLA

DI CONTATTO

Instructions for the installer

TERMOSTATO

DI MASSIMA (Tmax)

MOLLA DI

FISSAGGIO

TERMOSTATO

DI SICUREZZA (Ts)

Fit the heat discharge valve (pos. 1) on the safety coil inlet and

insert its sensor in the relevant bulb holder (pos. 2).

It is advisable to redirect the heat safety valve discharge to the

sewage.

The heat discharge valve can be fitted , indifferently, at the

inlet or outlet of the safety coil, provided the valve sensor is

inserted in it relevant bulb holder.

See also chapter 3.7.

fig. 17

1

ALIMENTAZIONE

2

SCARICO

fig. 18

TERMOSTATO DI ESERCIZIO (Te) = WORKING THERMOSTAT

TERMOMETRO = THERMOMETER

TERMOSTATO DI MINIMA (Tsc) = MINIMUM THERMOSTAT

MOLLA DI FISSAGGIO = FIXING CLIP

MOLLA DI CONTATTO = CONTACT SPRING

TERMOSTATO DI MASSIMA (Tmax) = HIGH LIMIT THERMOSTAT

MOLLA DI FISSAGGIO = FIXING CLIP

TERMOSTATO DI SICUREZZA (Ts) = SAFETY THERMOSTAT

19

Gasogen

Instructions for the installer

To ensure correct operation of the GASOGEN G3 2S boilers it

is necessary to fit a recirculation pump in order to avoid low

temperature water returns that could jeopardize the boiler’s

life span.

Automatic Heating, to favour her clients, has developed a water

recirculation kit that optimizes the water recirculation within

the boiler.

This kit is supplied separately as an option and is available, on

request, by indicating the appropriate part number .

The pump’s electric connection must be carried out according

to the general wiring diagram shown on page 44 and the

practical wiring diagrams shown on page 21 & 22.

On the optional control panel (code 23557) DUPLO IT

version, the wiring of the electrical connections must be

carried out as shown in the diagrams in 3.11 & 3.12, on

pages 24, 26, 29, 31, 33, 36 and 39.

14

15

1

2

13

12

11

10

9

8

7

6

RECIRCULATION KIT FOR OPERATION WITH HOTWATER

STORAGE TANK (see 3.12 on page 27)

NOTE: For correct control of the storage tank, in addition

to fitting the recirculation kit, foreseen for this purpose,

the optional control panel code 23577 must be fitted.

To ensure correct operation of the GASOGEN G3 2S boilers,

when a storage tank is used, it is indispensable to install

the return sensor (Tr), as shown in the diagrams in figs. 29,

31, 33, 35 and 37.

Automatic Heating has developed a RECIRCULATION KIT FOR

OPERATION WITH A STORAGE TANK.

This kit is supplied separately as an option and can be ordered

by indicating the code of your own boiler.

The return sensor (Tr) has to be inserted in the bulb holder

pos. 26, placed in the boiler C.H. return connection.

Please refer to the control panel’s instruction manual, in 5.5.7

“Return flow sensor installation” for the return sensor’s (Tr)

electrical connection and for any problems connected with it.

Note: The “MAXP” function (heat discharge pump) will be

carried out by the “MKP” pump (central heating pump) (see

5.3 “Loads and sensors connection diagram”); then connect

the jumper 30-38.

On the optional control panel (code 23557)

DUPLO IT version, the wiring of the electrical

connections must be carried out as shown in the

diagrams in 3.11 & 3.12, on pages 24, 26,

2

29, 31, 33, 36 and 39.

3

4

5

18

19

20

26

27

23

22

1

4

3

5

6

7

25

24

21

10

15

28

fig. 19

17

16

15

14

13

12

11

9

8

fig. 20

20

Instructions for the installer

3.10 - WATER AND ELECTRICAL CONNECTION DIAGRAMS WITH STANDARD CONTROL

PANEL, WITHOUT HOT WATER STORAGE TANK

Foreword!

The diagrams shown here below may be customized.

For particular requirements, please contact our After Sales Service.

Domestic hot water production for a central heating system

with boiler temperature control

via manual mixing valve.

The GASOGEN G3 2S boiler’s standard control panel

automatically switches off the fan and the recirculation pump

in case the boiler temperature, (once 30 minutes have passed

from closing the upper loading door for firing the boiler), does

not reach 65°C (minimum temperature).

The control panel (and the cycle) can only be reset by opening

the loading door for a new restart, or by switching OFF and ON

of the switch in pos. 11.

VE

Pi

VM

IR

The same control panel operation logic will switch OFF the fan

and the recirculation pump when all the wood has finished.

The C.H. system pump will operate only after the minimum

boiler temperature of 65°C has been reached.

When the boiler temperature falls below 65°C, the C.H. pump

will shut down.

Key:

Pr = recirculation pump (if not installed the guarantee is void)

VM = zone mixing valve (if not controlled correctly the guarantee is void)

Pi = central heating system pump

VE = open water tank

IR = heating circuit

TKS = microswitch controlling the opening of the loading door

TA = room thermostat

L1L1L1L1L1L1L1L1L1L1L1L1L1L

NNNN N

123456

4

5

6

-

-

M

L1 N

ALIMENTAZIONE

230V ~ 50Hz

VENTILATORE

M

VENTILATORE

Alimentazione: Mains supply 230V – 50Hz

Ventilatore:Fan

789

6

5

4

7

-

-

8

9

Pr

CALDAIA A LEGNA

WOOD FIRED BOILER

marrone

12 13

10 11

14 15 16 171819 20

13

9

8

7

VE

14

10

marrone

C

13/21

22

14

nero

TKS

19

15

blu

20

16

19

1617171818----

Pi

1

21 22 23 24

20

TA

IR

fig. 21

1011111212----

Pr

VM

fig. 22

21

Gasogen

Instructions for the installer

Domestic Hot Water (DHW) for central heating installation with boiler temperature control via a manual mixing valve.

DHW production via a coiled hot water storage tank or plate heat exchanger with independent installation system and

dedicated loading pump

The GASOGEN G3 2S boiler’s standard

control panel automatically switches off

the fan and the recirculation pump in

case the boiler temperature, (once 30

minutes have passed from closing the

upper loading door for firing the boiler),

does not reach 65°C ( minimum

temperature).

The control panel (and the cycle) can

only bereset by opening theloading door

for a new restart, or by switching OFF

and ON of the switch in pos. 11.

The same control panel operation logic

will switch OFF the fan and the

recirculation pump when the wood is

finished.

The C.H. system pump will operate only

after the minimum boiler temperature of

65°C has been reached.

When the boiler temperature falls below

65°C, the C.H. pump will shut down.

CALDAIA A LEGNA

WOOD FIRED BOILER

IR

VE

Pr

Pi

VM

Pc

PRODUTTORE ACQUA

CALDA SANITARIA

DOMESTIC HOT WATER

fig. 23

STORAGE TANK

Key:

Pr = recirculation pump (if not installed the guarantee is void)

VM =zone mixing valve (if not controlled correctly the guarantee

is void)

Pi = central heating pump

VE = open water tank

IR = heating circuit

TKS = microswitch controlling the opening of the loading door

TA = room thermostat

L1L1L1L1L1L1L1L1L1L1L1L1L1L

NNNN N

123456

6

5

4

4

5

6

-

-

M

L1 N

ALIMENTAZIONE

230V ~ 50Hz

VENTILATORE

VENTILATORE

7

-

-

8

9

M

Alimentazione: Mains supply 230V – 50Hz

Ventilatore:Fan

789

9

8

7

10 11

12 13

12

13

10

marrone

13/21

22

14

nero

TKS

VE

101111

---

Pr

marrone

14 15 16 171819 20

16

14

17

15

C

blu

17

Pi

12

21 22 23 24

VM

1

IR

TA

2

16

C

1

TB (45÷60°C)

Pc

17

fig. 24

22

Instructions for the installer

3.11 - WATER AND ELECTRICAL CONNECTION DIAGRAMS WITH OPTIONAL CONTROL

PANEL BOARD, WITHOUT HOT WATER STORAGE TANK

Foreword!

The diagrams shown here below may be customized.

For particular requirements, please contact our After Sales Service.

Central heating installation with temperature controlled via a motorized mixing valve.

DHW is produced via a coiled hot water storage tank or plate heat exchanger with an independent installation system

and dedicated loading pump.

The two boilers are hydraulically connected in series, with the wood fired boiler system flow connected to the oil/gas

fired boiler’s system return.

There is no need to install a diverting valve, or DHW storage tank loading pump; the DHW tank can be incorporated in

the oil/gas fired boiler.

In the summer, DHW production can be supplied only by the oil/gas fired boiler.

The heating circuit water flows through both the boilers and, in this case, the heat losses are very important.

IMPORTANT: During the installation phase make sure the jumpers’ settings in the control panel are as indicated in

chapter 5.2.

The GASOGEN G3 2S boiler’s standard control panel

automatically switches off the fan and the recirculation pump if

the boiler temperature, (once 30 minutes have passed from

closing the upper loading door for firing the boiler), does not

reach 65°C (minimum temperature).

In this case, or when the wood finishes, the auxiliary boiler will

start firing automatically, provided the selector 22 of the panel

board is on (0) and the burner switch 23 is in pos. II, 30 minutes

after the wood fired boiler temperature falls below 60°C.

The wood fired boiler’s door must be kept closed.

The wood fired boiler, in this case, will be excluded and it will

be possible to restart it after opening the door in order to load

new wood.

If the burner switch 23 is always kept on pos. 0), the back-up

boiler’s burner will be always excluded.

Obviously, to permit operation of the back-up boiler, the control

panel must be in the ON position.

The GASOGEN G3 2S boiler’s control panel (and operation

cycle) can be reset only after the upper door is reopened for a

new restart, or by turning the mains switch 11. OFF and then

ON.

The logic operation of the GASOGEN G3 2S boiler’s control

panel, will switch off the fan and the recirculation pump once

the wood finishes.

The central heating system pump will operate only after the

boiler exceeds the minimum temperature of 65°C.

When the boiler temperature falls below 65°C, the central

heating pump will shut down.

The D.H.W. storage pump will operate in priority compared to

the central heating pump.

The flow sensor (Tc) must be always placed in the boiler’s

bulb holder (see fig. 17).

D.H.W. production will be given priority via the storage tank

loading pump (PR), controlled by a changeover thermostat.

The eventual D.H.W. recirculation pump must be connected to

the mains independently from the GASOGEN G3 2S boiler’s

control panel.

During the summer season we recommend that DHW is

requested via the back-up boiler, or with the wood fired boiler,

provided the indications given on paragraph 6.11, page 59,

are strictly followed.

CALDAIA A LEGNA

WOOD FIRED BOILER

Tc

KKP

IR

MKP

B

VM

VE

M

AB

A

PR

CALDAIA DI SOCCORSO

GASOLIO/GAS

BACK UP BOILER

PRODUTTORE ACQUA

CALDA SANITARIA

DOMESTIC HOT

WATER STORAGE TANK

fig. 25

23

Gasogen

Instructions for the installer

fig. 26

B4

S3

Alimentazione

pompa principale

N

L1

PANNELLO CALDAIA

A GASOLIO/GAS

24

21

22

14

30

11

12

A2

A1

20

T2

T1

NL1

ALLA PRESA A 7 POLI

DEL BRUCIATORE

not installed the guarantee is void)

TC

TR

1

L

1

TKS

L

N

1

NETZ

L

PE

N

1

MAXP

L

1

L

1

TAMB

L

N

1

KKP

L

1

L

NN

1

GM MKP

L

1

L

1

AGW

L

1

1

BV

L

1

SK

L

NNL

1

RAB

L

BS

PE

TYPE 95.05 - 230V

24

C

1

2

C

TA

1

RELÉ A 2VIE

FINDER

PR

51

50

51

-

50

1

49

48

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

C

47

TKS

46

1

44 45

43

41 42

40

39

38

37

36

35

33

34 35

--

34

33

32

31

30

30

29

272728282929---

28

27

26

25

28 29

24

24

23

22

21

20

20

19

18

17

16

15

-27

M

M

VENTILATORE 1

VENTILATORE 2

IR

AB

A

B

M

MKP

VM

5051-

Tc

34 35

-33

KKP

VE

24

Key:

KKP = recirculation pump (if not installed the guarantee is void)

Tc = wood fired boiler’s flow temperature sensor

VM = zone mixing valve (if

VE = open water tank

MKP = central heating pump

TKS = microswitch controlling the opening of the loading door

PR = D.H.W. buffer storage tank loading pump

PS = D.H.W. recirculation pump (controlled by the D.H.W. thermostat)

IR = central heating installation

TA = room thermostat

Instructions for the installer

Central heating installation with temperature controlled via a motorized mixing valve.

Domestic hot water with a separate coil type storage tank or plate heat exchanger and dedicated loading pump.

Back-up boiler with buffer function when fire wood is finished or for domestic hot water production during summer.

In summer the D.H.W. production can be supplied only by the back up boiler.

The two boilers are hydraulically connected in parallel and the motorized UV diverting valve, will ‘direct’the GASOGEN

G3 2S boiler in the system circuit or the auxiliary boiler alongside: in this circuit the heating circuit water will not flow

through the boiler not operating, thereby reducing the heat losses.

The D.H.W. storage tank will necessarily have to be installed and connected according to the diagram below.

IMPORTANT: During the installation phase make sure the jumpers’ settings in the control panel are as indicated in 5.2.

The GASOGEN G3 2S boiler’s control panel automatically

switches off the fan and the recirculation pump if the boiler

temperature, (once 30 minutes have passed from closing the

upper loading door for firing the boiler), does not reach 65°C

(minimum temperature).

In this case, or when the fire wood finishes, the back-up boiler

will start firing automatically, provided the selector 22 of the

panel board is on (0) and the burner switch 23 is in pos. II,30

minutes afterthe wood fired boiler temperature falls below 60°C.

The door of the wood fired boiler must be kept closed.

The wood fired boiler, in this case, will be excluded and it will

be possible to restart it after opening the door in order to load

new wood.

If the burner switch 23 is always kept on pos. 0), the auxiliary

boiler’s burner will be always excluded.

Obviously, to permit operation of the back-up boiler, the control

panel must be in the ON position.

The GASOGEN G3 2S boiler’s control panel (and operation

cycle) can be reset only after the upper door is reopened for a

new restart, or by turning the mains switch 11. OFF and then

ON.

The central heating system pump will operate only after the

boiler exceeds the minimum temperature of 65°C.

When the boiler temperature falls below 65°C, the central

heating pump will shut down.

The D.H.W. storage pump will operate in priority compared to

the central heating pump.

The diverting valve (UV), will direct the returns towards the

boiler ready to operate in that moment, thus reducing the heat

losses.

The flow sensor (Tc) must be always placed in the boiler’s

bulb holder (see fig. 17).

D.H.W productionwill have priority via the storage tank’s loading

pump (PR),controlled by a changeover thermostat.The D.H.W.

recirculation pump must be connected to the mains

independently fromthe GASOGEN G32S boiler’s control panel.

During summer we recommend that D.H.W. is requested via

the back-up boiler, or with the wood fired boiler provided the

indications given in 6.11, page 59, are strictly followed.

The operation logic of the GASOGEN G3 2S control panel, will

switch off the fan and the recirculation pump oncethe fire wood

finishes.

VE

MKP

B

VM

M

AB

Tc

KKP

CALDAIA A LEGNA

WOOD FIRED BOILER

A

AB

A

B

M

UV

IR

CALDAIA DI SOCCORSO

GASOLIO/GAS

BACK UP BOILER

PR

PRODUTTORE ACQUA

CALDA SANITARIA

DOMESTIC HOT

WATER STORAGE TANK

fig. 27

25

Gasogen

Instructions for the installer

fig. 28

B4

S3

Alimentazione

pompa principale

N

L1

PANNELLO CALDAIA

A GASOLIO/GAS

4

7

1

5

RELÉ A 3VIE

24

8

2

6

9

3

A2

A1

20

N

L1

230V~50Hz

ALIMENTAZIONE

30

C

1

2

30

T2

T1

NL1

ALLA PRESA A 7 POLI

DEL BRUCIATORE

not installed the guarantee is void)

TC

TR

1

L

1

TKS

L

N

1

NETZ

L

PE

N

1

MAXP

L

1

L

1

TAMB

L

N

1

KKP

L

1

L

NN

1

GM MKP

L

1

L

1

AGW

L

1

L

1

BV

L

1

SK

L

NN

1

RAB

L

BS

PE

C

TA

1

51

51

-

50

50

1

49

48

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

C

47

TKS

46

1

44 45

43

41 42

40

39

38

37

36

35

33

34 35

--

34

33

32

31

30

30

29

272728282929---

28

27

26

28 29

25

24

24

23

22

21

20

20

19

18

17

16

15

-27

M

M

VENTILATORE 1

VENTILATORE 2

IR

MKP

AB

A

B

M

VM

50

51

-

Tc

VE

AB

A

B

34 35

-33

UV

M

KKP

PR

26

Key:

KKP = recirculation pump (if not installed the guarantee is void)

Tc = wood fired boiler’s flow temperature sensor

VM = zone mixing valve (if

VE = open water tank

MKP = central heating pump

TKS = microswitch controlling the opening of the loading door

PR = D.H.W. storage tank loading pump

PS = D.H.W. recirculation pump (controlled by the D.H.W. thermostat)

IR = central heating installation

TA = room thermostat

Instructions for the installer

3.12 - WATER CONNECTIONS AND ELECTRICAL DIAGRAMS WITH OPTIONAL CONTROL

PANEL AND ACCUMULATOR

Dimensioning of the accumulator:

The Standard EN 303-5 says that the minimum heat output for automatically fed boilers should not be higher than 30% of the

nominal heat output (Qn); on the contrary, the minimum heat output can be higher than 30% on manually fed boilers.In our case

the Standard foresees the installation of an accumulator with a volume V equal to:

dove:

V=15xQnxT x(Q

min/Qn

-0,3)

V = volume dell'accumulo (litri)

Q

= potenza utile nominale (kW)

n

T = autonomia (h)

Q

= potenza utile minimale (kW)

min

where:

V = accumulator (buffer tank) volume (litres)

Qn = nominal heat output (kW)

T = autonomy (h)

Qmin = minimum heat output (kW)

The boiler’s nominal heat output (Qn) must be equal to the building’s heat losses. Some of the boiler models are equipped with

automatic or manual systems for the reduction of the nominal heat output in case of reduced load: the minimum heat output, in

which the boiler can work, remaining within the emission levels foreseen by the EN 303-5, is exactly the minimum heat output

Qmin.

The storage tank is not necessary when the requested volume is less than 300 litres.

NOTE: to correctly install the buffer tank it is necessary to use the RECIRCULATION KIT FOR OPERATION WITH THE

ACCUMULATOR which has to be positioned as shown in fig. 20.

27

Gasogen

Instructions for the installer

Foreword!

The system designs shown in the diagrams here below may be customized.

For particular requirements, please contact our After Sales Service.

Simplified water connections diagram between the wood fired boiler and the heat storage tank.

IMPORTANT: During the installation phase make sure the jumpers settings in the control panel are as indicated in

chapter 5.2.

The GASOGEN G3 2S boiler’s control panel automatically

switches off the fan and the recirculation pump if the boiler

temperature, (once 30 minutes have passed from closing the

upper loading door for firing the boiler), does not reach 65°C

(minimum temperature).

The GASOGEN G3 2S boiler’s control panel (and operation

cycle) can be reset only after the upper door is reopened for a

new restart, or by turning the mains switch 11. OFF and then

ON.

The operation logic of the GASOGEN G3 2S control panel, will

switch off the fan and the recirculationpump once the fire wood

finishes.

The central heating system pump will operate only after the

boiler exceeds the minimum temperature of 65°C.

When the boiler temperature falls below 65°C, the central

heating pump will shut down.

The thermal inertia of the wood fired boiler will always be

discharged on the central heating circuit.

VE

The flow sensor (Tc) must be always placed in the boiler’s

bulb holder (see fig. 17).

The return sensor must be always fitted (for the positioning

see fig. 20); see installation mode in paragraph 5.5.7.

The jumper 71-72 on the PCB must be removed.

The introduction of an accumulator in the system of (see

dimensioning on page 27), enables you to obtain a high

seasonal efficiency from the GASOGEN G3 2S boiler and a

better management of

the heating system, as well as a longer life span of the boiler,

by reducing the temperature peaks, caused by inconstant

drawing-offs from the heating system itself.

Moreover, the heat accumulator, makes you save a lot on your

gas bill

This type of installation is particularly effective during the “mid

seasons”, since it avoids having to use reduced wood fire loads

and, consequently, fire the GASOGEN G3 2S under its

minimum output,with the possibilityof creating flue condensate,

which would damage, in a short time, the wood fired boiler.

IR

TT (50-55°C)

Tc

RMV

B

AB

A

Tr

KKP

KRF

CALDAIA A LEGNA

WOOD FIRED BOILER

Legend:

Tc = wood fired boiler flow temperature sensor

Tr = wood fired boiler return temperature

KKP = recirculation pump (if not installed the guarantee is void)

RMV = non-condensing thermostatic valve

KRF = RMV thermostatic valve sensor

PMV1= accumulator thermostatic valve (optional)

VM = zone mixing valve (if not installed the guarantee is void)

28

SVA

PMV1

B

AB

A

SCAMBIATORE AD