Page 1

GDO-9v2 SecuraLift

Overhead Garage Door Opener

®

Featuring TrioCode

Part # 13212 (Manual)

INSTALLATION INSTRUCTIONS | OWNERS COPY

™

Technology

Page 2

WARNING: It is vital for the safety of persons to follow

all instructions. Failure to comply with the installation

instructions and the safety warnings may result in serious

personal injury and/or property damage.

Please save these instructions for future reference.

Automatic Technology (Australia) Pty Ltd to the extent that such may be lawfully excluded hereby expressly disclaims all

conditions or warranties, statutory or otherwise which may be implied by laws as conditions or warranties of purchase of an

Automatic Technology (Australia) Pty Ltd Garage Door Opener. Automatic Technology (Australia) Pty Ltd hereby further

expressly excludes all or any liability for any injury, damage, cost, expense or claim whatsoever suffered by any person

as a result whether directly or indirectly from failure to install the Automatic Technology (Australia) Pty Ltd Garage Door

Opener in accordance with these installation instructions.

2

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 3

GDO-9v2 SecuraLift

Overhead Garage Door Opener

Important Safety Instructions 4

Features 6

Operating Controls 8

Kit Contents 10

Installation 11

Knockdown C-Rail Assembly 11

C-Rail Attachment 12

Determine Door Type 13

Mounting - Track Type Door 14

Mounting - Spring Loaded Door 15

Mounting Door Bracket & Arms 16

Programming the Opener 17

Setting Travel Limits - Control Panel 17

Setting Travel Limits - Transmitter 18

Safety Obstruction Forces 19

Safety Obstruction Force Test 19

Adjusting Safety Obstruction Forces 20

Coding Transmitters 21

Door 21

Courtesy Light 21

Pet Mode 21

Vacation Mode 21

Remotely Coding Transmitters 22

Erasing Transmitter Codes 22

Accessories 23

Photo Electric Beam Installation 23

Auto-Close Setup 23

SmartSolar™ Installation 24

Battery Back Up installation 25

Final Set Up 26

Courtesy Light Time 26

Pet Mode Door Height 26

Wall Mounted Transmitters 26

Re-Initialising 26

Parameters 27

Default Settings & Specifi cations 27

Door Status Indicators 28

Troubleshooting Guide 30

Maintenance Record 31

Parts Listing 32

Warranty 34

®

Owner Installation Instructions GDO-9v2 SecuraLift

®

3

Page 4

Important Safety Instructions

WARNING: It is vital for the safety of persons to follow

all instructions. Failure to comply with the following

Safety Rules may result in serious personal injury and/or

property damage.

CAUTION: If your garage has no pedestrian entrance door, an emergency access device should be installed.

This accessory allows manual operation of the garage door from outside in case of power failure.

For ADDITIONAL SAFETY protection we STRONGLY recommend the fi tting of a Photo Electric (P.E.)

Beam. In most countries P.E. Beams are mandatory on all garage doors fi tted with automatic openers.

For a small additional outlay Automatic Technology recommends that Photo Electric Beams be

installed with the automatic opener ensuring additional safety and peace of mind.

DO NOT operate the opener unless the garage door is in full view and free from objects such

as cars and children/people. Make sure that the door has fi nished moving before entering or

leaving the garage.

DO NOT operate the opener when children/persons are near the door. Children must be

supervised at all times when the SecuraLift® is in use. Serious personal injury and/or

property damage can result from failure to follow this warning.

DO NOT allow children to operate the SecuraLift®. Serious personal injury and/or

property damage can result from failure to follow this warning.

Regularly check to make sure that the safety obstruction force is working

correctly, and is tested and set as per page 19 of this manual. Failure to

follow these instructions could result in serious personal injury and/or

property damage. This test must be repeated at regular intervals and the

necessary adjustments made as required.

Doors requiring over 400N of force to move must have P.E. Beams

installed.

DO NOT disengage the door opener to manual operation with

children/persons or any other objects including motor vehicles

within the doorway.

The door opener is not intended for use by young children

or infi rm persons without adequate supervision. Children

should be supervised to ensure that they do not play

with the remote transmitters or the opener.

Keep hands and loose clothing clear of the door

and door opener at all times.

4

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 5

Important Safety Instructions

The unit should be installed so that it is protected from the elements. It should not be exposed to water or rain.

It is not to be immersed in water or sprayed directly by a hose or other device.

The garage door must be well balanced. Sticking or binding doors must be repaired by a qualifi ed garage

door installer prior to installation of the opener.

Frequently examine the installation, in particular cables, springs and mountings for signs of wear, damage

or imbalance. DO NOT use if repair or adjustment is needed since a fault in the installation or an

incorrectly balanced door may cause injury. DO NOT attempt to repair the door yourself as hardware

is under extreme tension.

Remove or disengage all garage door locks and mechanisms prior to installation of the opener.

Connect the opener to a properly earthed general purpose 240V mains power outlet installed

by a qualifi ed electrical contractor.

Disconnect the power cord from mains power before making any repairs or removing

covers. Only experienced service personnel should remove covers from the opener.

When using auto close mode, a photo electric beam must be fi tted correctly and

tested for operation at regular intervals. Extreme caution is recommended when

using auto close mode. All safety rules must be followed.

In order for the SecuraLift® to sense an object obstructing the door way, some

force must be exerted on the object. As a result the object, door and/or

person may suffer damage or injury.

If the power supply cord is damaged, it must be replaced by an

Automatic Technology service agent or suitably qualifi ed person.

Make sure that the door is fully open before driving in or out of the

garage and fully closed before leaving the driveway.

Make sure that remote controls are kept out of reach of

children.

Install the wall switch or wall mounted transmitter in

a location where it is out of reach of children and the

garage door is visible.

control be fixed at a hight of at least 1.5 metres

and within sight of the door but away from

moving parts.

We recommend that the wall

Owner Installation Instructions GDO-9v2 SecuraLift

®

5

Page 6

Features

Thank you for purchasing the Automatic Technology

®

GDO-9v2 SecuraLift

Opener. Designed to suit sectional overhead and one

piece tilt up doors, the components and materials

used ensure this opener will provide years of

smart, simple and secure operation. Listed

below are some of the many features:

Operation

To open or close the door simply press a button on a TrioCode™ handheld

transmitter, a wall mounted transmitter, or optional wall switch for two seconds.

During open and close cycles the door can be stopped by pressing the button

again. The next actuation will move the reverse the door’s direction.

Overhead Garage Door

TrioCode™ Code Hopping Multi-Frequency Technology

Every time a TrioCode™ transmitter is used a new security code is randomly

generated from over 4.29 billion possibilities. This greatly enhances the security

of the system and makes “code grabbing” a thing of the past

These transmitters also overcome interference issues by simultaneously sending a

signal over three different frequencies. Even if two of the three signals are jammed,

the system will still work.

ALPS (Automatic Limits Positioning System)

ALPS does away with manual adjustment of the door’s limits position using mechanical

parts, such as cams and microswitches. During installation the hand held transmitter

can be programmed to set the door limits positions.

ISS (intelligent safety obstruction system)

While the door is performing a close cycle, should it hit an obstacle or be restricted in some

manner, it will automatically reverse. The amount of force the door should encounter before

reversing is automatically adjusted by the doors control system during the initial installation of the

automatic door opener. The door will also stop if restricted whilst opening. The Safety Obstruction

Force should be checked monthly.

Auto courtesy light

The courtesy light comes on automatically for three minutes whenever the door is activated. The light can also

be operated independently of the door by coding a dedicated button on a transmitter.

6

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 7

SmartSolar™ and Battery Back Up Compatibility (optional)

The opener can be fi tted with a SmartSolar™ or Battery Back Up kit for operation in the

event of a power outage, or where mains power access is not available. NOTE: If the

door is the only entrance to the garage, and a battery back up kit is not fi tted, a

keyed cable release should be fi tted external to the garage.

Vacation mode

A hand held transmitter can be programmed to lock and unlock all other

transmitters that have been programmed into the openers’ memory. The vacation

mode can be used when the door is left idle for long periods of time.

Pet/Pedestrian mode

The transmitter can be programmed to open the door to an adjustable partial

height so that the family pet can enter and exit the garage at any time. You may

also wish to open the door to a height suitable only for pedestrian access.

Auto-close mode

The opener can be programmed to automatically close after an open cycle. The auto-

close time is adjustable. It is compulsory to install a P.E. Beam if this mode is selected,

otherwise the door may cause personal injury or damage to property.

Photo Electric (P.E.) Beam (optional)

The opener has an input to connect a P.E. Beam for extra safety and use of the auto-close mode.

We highly recommend that Photo Electric Beam be installed.

Manual operation

The opener is equipped with a unique manual disengaging device. If the power to the opener is disrupted the

door can be put into manual mode by pulling down on the string handle on an angle towards the door. This

allows for manual operation of the door. To re-engage the opener pull the string handle away from the door.

Owner Installation Instructions GDO-9v2 SecuraLift

®

7

Page 8

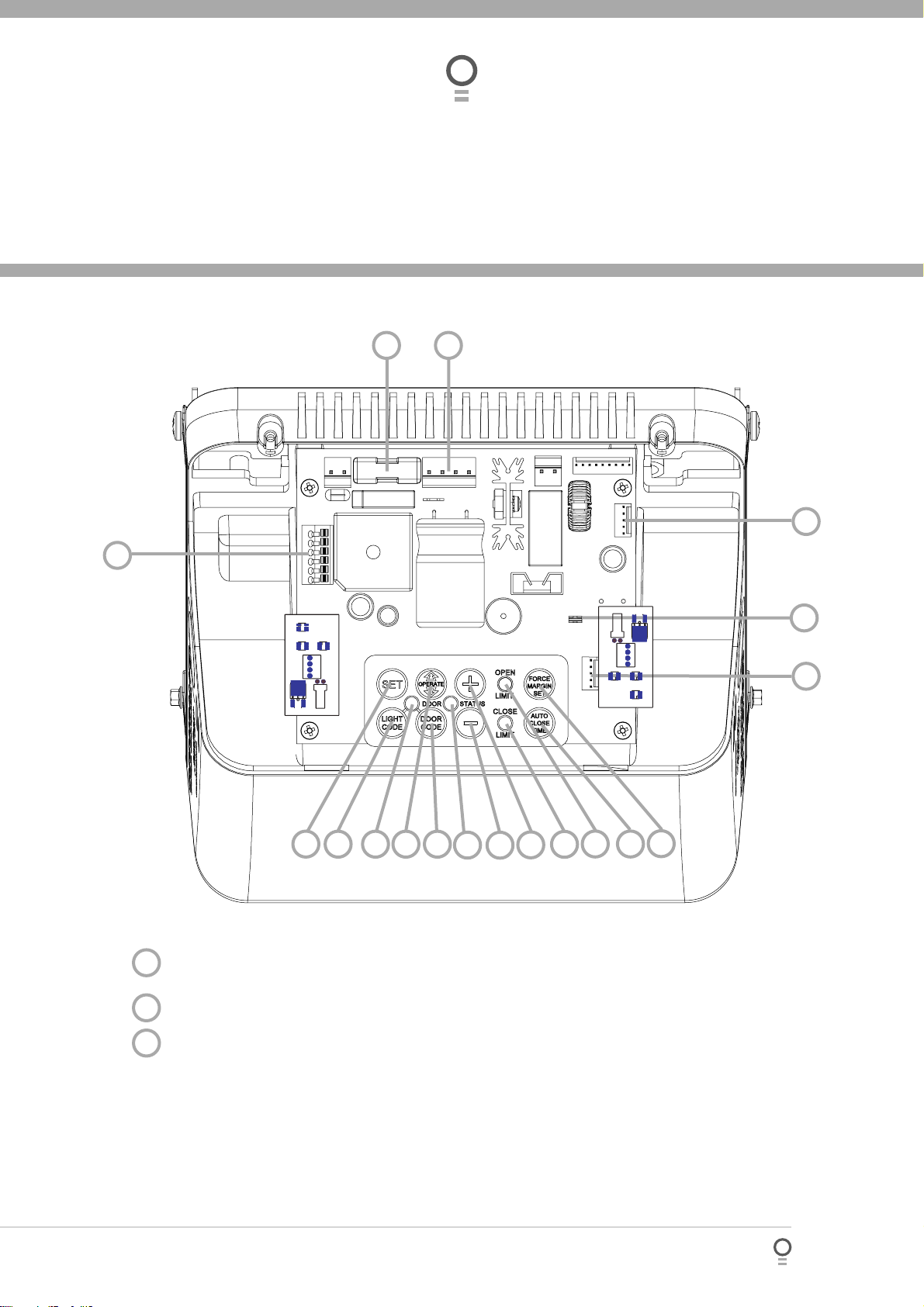

Operating controls

Terminal Block (J2).

01

30V PWR is used to power devices such as:

Photo electric beam (PE-2) for safety and auto-close function (P.E. and P.E.(0V) terminals);

GND is used for common ground of accessories;

OSC is used for the connection of a wired switch (momentary contact). This switch can then be used to

open, stop or close the door. Install the wall switch in a location where the switch is out of reach of

children and the garage door is visible;

AUX OUT (open collector output) - A transmitter button can be programmed to trigger an input.

SET

02

03

04

05

06

07

button (yellow) is used during the installation phase together with the Open and MINUS (-) buttons to

set the door limit positions. The Set button is also used to re-initialize the Opener.

LIGHT CODE

to switch the courtesy light on the opener on or off.

C

CODING LED (red) light flashes when a code is being stored or when a transmitter button is pressed.

OPERATE button (Yellow) is used during installation to test the open, stop and close cycles for the

opener. The opener has to be initialised by the Reset button to make the O/S/C button operable.

DOOR CODE BUTTON (blue) is used for storing or erasing transmitter buttons for door operation.

DOOR STATUS LED (Yellow).

MINUS (-) button (red) is used during installation to help set the close limit position. Pressing and holding

08

this button will move the door in the close direction. Movement stops when the button is released.

NOTE: The safety obstruction detection is inoperable when the CLOSE button is used to move door.

button (white) is used for storing or erasing the transmitter button (code) you wish to use

PLUS (+) button (green) is used during installation to help set the open limit position. Pressing and holding

09

this button will move the door in the open direction, releasing stops the door.

NOTE: The safety obstruction detection is inoperable when the PLUS (+) button is used to move door.

CLOSE LIMIT LED (red) the LED is very helpful during installation. It illuminates and flashes when the

10

door is closing and remains steady on when the close limit position has been reached.

OPEN LIMIT LED (green) the LED is very helpful during installation. It illuminates and flashes when the

11

door is opening and remains steady on when the open limit position has been reached.

AUTO CLOSE TIME button (White) is used to adjust the auto close time. While holding in the AUTO

12

CLOSE TIME button and then pressing the PLUS (+) button the time is increased. Each press will increase

the time by 5 seconds. Pressing the MINUS (-) button will decrease the time.

FORCE MARGIN SET Button: The obstruction force margin is set automatically during installation. The

margin can be adjusted manually using the Force Margin Set button (White). Holding the Force Margin Set

13

button and pressing PLUS (+) or MINUS (-) buttons will increase or decrease the amount of force. The Force

Margin Set should only be used if environmental factors (wind, etc.) affect the door's operation.

14

J8 is the ICSP connector.

JP1 (SOLAR)

15

The shunt supplied with the control board (OFF position) must be fitted (ON position) for solar operation.

8

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 9

01

LT01-1.00

18 17

SOLAR

JP1

16

-

+

15

LT01-1.00

+

-

02

03 04 05

PROG INPUT is used to connect the Automatic Technology Handheld Programmer for editing control

16

and receiver functions, accessing diagnostic tools, and activating special features and operating modes.

17

SBY-3 CONNECTOR is used to connect both Battery Back Up Kits and SmartSolar’ kits.

10A FUSE

18

06

07

08

09

10

11

12

13

14

Owner Installation Instructions GDO-9v2 SecuraLift

®

9

Page 10

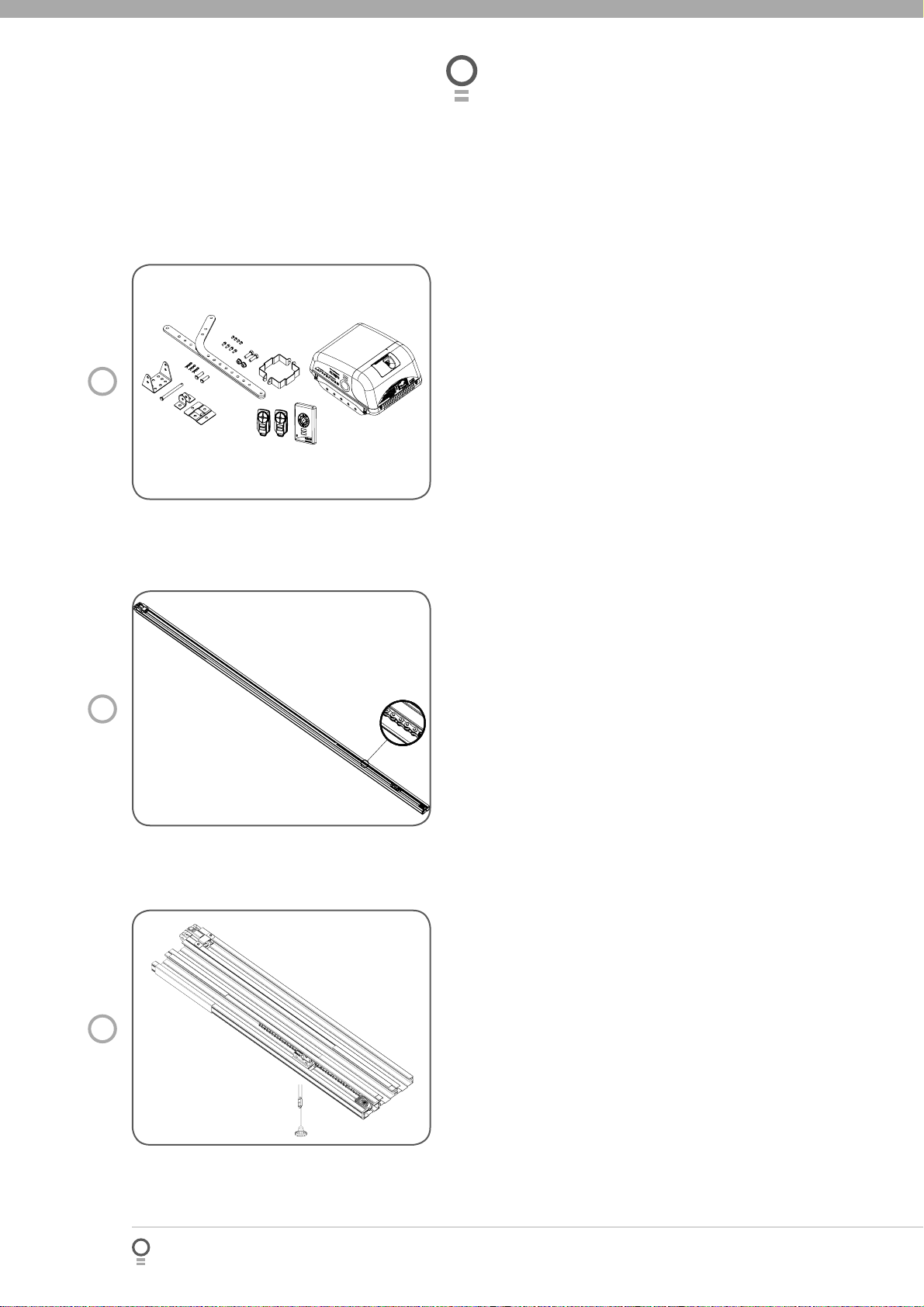

fi g

Kit contents

01

Drive Unit

1 x GDO-9v2 SecuraLift® Trio drive unit (Fig. 01)

1 x TrioCode™ Transmitter pack (Fig. 01)

(Pack includes two keyring transmitters and batteries)

1 x Wall mount transmitter with battery (Fig. 01)

2 x Door attachment arms (Fig. 01)

1 x Accessory and hardware pack (Fig. 01)

1 x Manual Disengage Cord (Fig. 01)

1 x Installation Manual

PLUS

Pre-Assembled Single Piece C-Rail

NOTE: The chain or belt in the one piece rail has been

tensioned by the factory. Do not adjust the tension of

the chain.

fi g

fi g

IMPORTANT NOTE: If a modifi cation to the length of the

track is required, the adjustment must be made from the

drive unit end only.

02

OR

Pre-Assembled Multi Piece C-Rail

Note: The chain or belt in the multi piece rail has been

tensioned by the factory. Do not adjust the tension of

the timing belt.

IMPORTANT NOTE: If modifi cation to the track length

is required, adjustment must be made only from drive

unit end only.

03

10

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 11

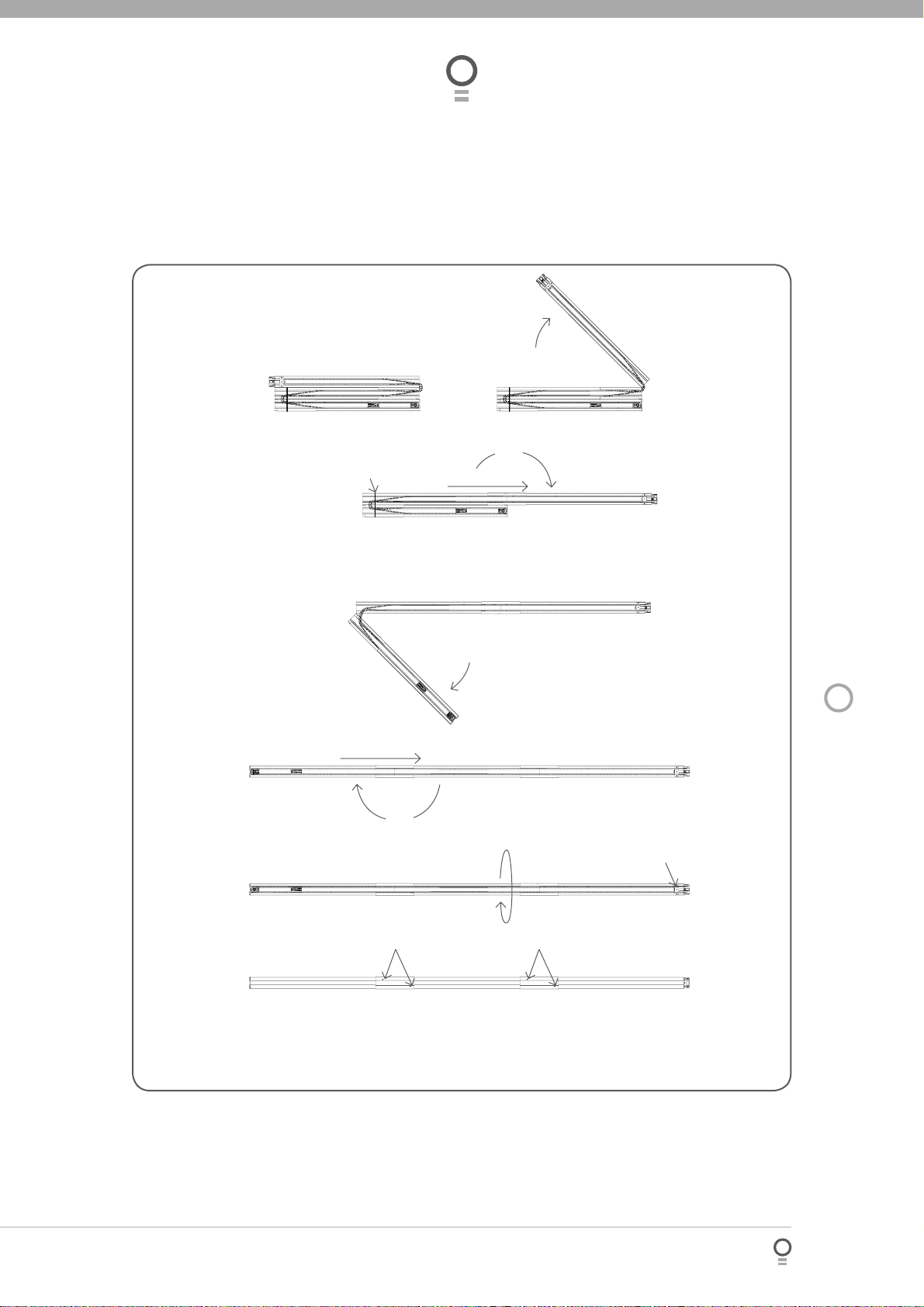

Knockdown C-Rail Assembly

Start

Cut cable tie

7

Slide sleeve

Slide sleeve

34

5

Swing

1

Swing

2

Swing and straighten

fi g

04

Swing and straighten

Adjust chain tension: Move the shuttle to middle of track. Use a spring scale to

measure required force to pull the shuttle adjust 1/2” hex bolt to tension chain.

Recommended pull force: 8kg (80N)

6

Turn tracks around 9 Tension 1/2” hex bolt 8

Screws10 Screws

Step 1 - Knockdown C-Rail Assembly

Unpack and assemble the C-Rail as shown above in Fig 04.

Owner Installation Instructions GDO-9v2 SecuraLift

®

11

Page 12

fi g

C-Rail Attachment

05

Shaft

Step 2 - Attach Manual Disengage Cord

a.

If not already disengaged, fl ick the yellow clutch

lever up so it sits perpendicular to the rail.

b.

Thread the loose end of the cord through the hole

in the yellow clutch lever (Fig. 05).

c.

Thread the cord down to red toggle and knot

through the spare hole.

d.

Test if secured properly by pulling back towards

sprocket end to engage, and the towards door end

to disengage.

Step 3 - Secure C-Rail to Drive Unit

Locate and insert the shaft of drive unit into the C-

a.

Rail’s sprocket (Fig. 06).

Fix the two track brackets with four screws supplied

b.

in accessory pack (Fig. 07).

fi g

fi g

06

Locate shaft into sprocket

Hex fl ange screw taptite ‘S’ M4 x 10

Track bracket (x2)

07

12

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 13

Determine the Door Type

Step 4 - Determine Door Type

Determine which type of garage door you have as

illustrated below. (Fig. 08 to 10).

For a sectional (panel) door on tracks (Fig. 08)

proceed with the installation from Step 5.

Door

Sectional door with track

For a one-piece door on tracks (Fig. 09)

proceed with the installation from Step 5.

Track

fi g

08

For a one-piece door without tracks (on springs) (Fig. 10)

proceed with the installation from Step 9.

One piece door with

track

Door

One piece door

without track

fi g

fi g

09

10

Owner Installation Instructions GDO-9v2 SecuraLift

®

13

Page 14

fi g

fi g

Mounting on a Track Type Door

WARNING: The opener must be securely

fastened to structural supports, otherwise opener

failure may ensue causing serious personal injury

and/or property damage.

Step 5 - Determine Bracket Position

a.

Open the door and fi nd the highest point of travel of

the top door panel.

b.

Using a level, transfer this height to the wall above

the door (Fig. 11) and mark a line 60mm above it.

c.

Determine the centre point on the wall above and on

top of the door. Draw two lines extending 21.5mm

from each side of the centre point. (Fig. 12)

Step 6 - Mounting the Wall Bracket

Centre the bracket over the intersection of these two

a.

lines. Mark centres for at least two holes (Fig. 12).

Ensure this is into a solid mounting point

•

Drill holes into the wall with an appropriate bit.

b.

Secure to the wall using:

c.

IF CONCRETE OR BRICK - 8mm (5/16”) loxins/dynabolts.

IF TIMBER - wood screw #20 or similar (min. 50mm).

11

12

Level

Track

Door

Level

Track

Door

fi g

fi g

13

14

Drilled holes

Structural member

WARNING: Make sure concrete, brick wall or

timber lintels are solid and sound so as to form a

secure mounting platform.

Step 7 - Attach the Rail to the Wall

Bracket

a.

Attach the C-Rail assembly to the wall bracket

with the 90mm long clevis pin and secure with the

supplied snap pin (Fig. 13)

b.

Leave the powerhead in its packing box for protection

during installation.

Step 8 - Secure the Powerhead to the Ceiling

Raise the powerhead from the packing box and

a.

support it in the horizontal position with a step

ladder.

Open the garage door. Rest the opener on the open

b.

door and use a scrap piece of wood to bring it to

horizontal level.

Line up the track perpendicular to the wall.

c.

Secure the perforated angle (not supplied) to

d.

the ceiling above where powerhead’s mounting

holes will be once fully installed. A representative

mounting is shown (Fig. 14)

Connect the powerhead to the ceiling mounted

e.

perforated angle with M8x20mm screws and nuts.

Strips should not extend more than 18mm below

centre of powerhead mounting holes.

Go to Step 14 on page 14.

14

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 15

Mounting on a non-Track Type Door

25mm

XAMmm6

)DAEHTLOBFOTHGIEH(

WARNING: The opener must be securely fastened to

structural supports, otherwise opener failure may ensue

causing serious personal injury and/or property damage.

Step 9 - Determine the Door’s Centre

a.

Find the centre of the door and mark this location

both above the door and on top of the door.

b.

Draw two lines 21.5mm either side of this (Fig. 15).

Step 10 - Prepositioning the Opener

Raise the door to open position.

a.

Rest the opener on the top edge of the door with

b.

end of the rail against the wall (Fig. 16).

Support the powerhead level with the lowest point

c.

of the open door (Fig. 16).

NOTE: Do not slide rail along the face of the door.

Step 11 - Mounting the C-Rail

Close the door slowly. The rail will be elevated by

a.

the top edge of the door as it moves.

Stop the door when it is at its highest point of travel.

b.

Allow 25mm additional height for clearance between

the door and the track (Fig. 17).

Support the Rail in this position and close the door

c.

The height determined in Step 11(b) will be the

d.

height at which to mount the wall bracket.

Centre the bracket along the line determined in Step

e.

9

Using the bracket as a template, mark a minimum of

f.

two holes and drill with appropriate size bit. For a

more secure fi tting, the wall bracket can be anchored

using more than two holes.

Secure the bracket to the wall using:

g.

IF CONCRETE OR BRICK - 8mm (5/16”) loxins/dynabolts.

IF TIMBER - wood screw #20 or similar (min. 50mm)

Attach the bracket and C-Rail with supplied pins (Fig. 13).

h.

WARNING: Make sure concrete, brick wall or

timber lintels are solid and sound so as to form a

secure mounting platform.

Centre of Door

Door

C rail

Step

ladder

Highest point

of door travel

Step

ladder

fi g

fi g

fi g

15

16

17

Step 12 - Secure the Powerhead to the Ceiling

Secure the perforated angle (not supplied) to the

a.

ceiling above where powerhead’s mounting holes

will be. See (Fig.14) for a representative mounting.

Connect the powerhead to the ceiling mounted

b.

perforated angle with M8x20mm screws and nuts.

Strips should not extend more than 18mm below

centre of powerhead mounting holes (Fig. 14).

Step 12.1 - Alternative Mounting Option

The opener can be fastened to the roof by driving a bolt

through the C-Rail into a structural timber support. The

bolt head’s height must not exceed 6mm (Fig. 14).

Drill hole at centre of

track (recommended

bolt size M6 or M8)

Ceiling

Aluminium rail

Shuttle VP2 assembly

Owner Installation Instructions GDO-9v2 SecuraLift

fi g

18

®

15

Page 16

fi g

fi g

fi g

Mounting Door Bracket & Arms

Step 13 - Mounting Door Bracket

The door bracket comes in two parts. The bottom plate

with two mounting holes is used on its own for one piece

doors. For sectional doors, the top plate is placed over

the bottom plate and is fi xed with four (4) screws (Fig.

19

20

21

10

0

19).

Mount the door bracket, or bracket assembly,

a.

on the door’s centre line one-third down the top

panel (Fig. 19) using M6 or equivalent screws (not

supplied),

STEEL DOORS ONLY: Bracket can be welded in

b.

place.

NOTE: If in doubt about the door’s strength,

reinforcement may be added to the door’s frame

where necessary. Door damage may occur if the

bracket is installed on a panel with insuffi cient

strength. The opener’s warranty does not cover

damage caused to the door and/or door panels.

Step 14 - Attaching the Arms

FOR SECTIONAL AND ONE PIECE DOORS WITH

TRACK:

Assemble the bent and straight arms with bolts

a.

and nuts supplied in the accessory pack (Fig. 20).

Always use both bent and straight arms.

Connect the assembled arm to the bracket and the

b.

disengaged trolley with clevis and snap pins. The

angle “A” must be more than 10° (Fig. 21).

WARNING: Connecting the bent arm other way

around may damage the door. The straight arm

should not protrude beyond heal of bent arm

FOR ONE PIECE DOORS WITHOUT TRACK

Assemble the bent and straight arms as shown

a.

in (Fig. 22) with bolts and nuts supplied in the

accessory pack. Always use both the bent and

straight arms.

Connect the assembled arm to the bracket and the

b.

disengaged trolley with clevis and snap pins.

If installing on a door with a bad wave action,

c.

lengthening the arm will assist in reducing this

effect.

IMPORTANT NOTE: Adjust the length of the

cord so that its toggle is no more than 1.8m from

fi g

22

16

GDO-9v2 SecuraLift® Owner Installation Instructions

the ground.

Page 17

Setting Limits

Step 15.1 - Setting Travel Limits

NOTE: If P.E. Beams are to be used they must be installed

before setting the travel limits.

WARNING! Use caution when operating the manual

release with the door open since it may fall rapidly

due to weak or broken springs, or an improperly

balanced door.

CAUTION! Do not disengage the opener to manual

operation with children, persons or any objects

including motor vehicles within the doorway.

Engage the C-Rail’s trolley (attached to the door via

a.

the arms) with the chain index by moving the door.

If the trolley does not “click” fi rmly onto the

»

chain index, ensure that the manual release

cord is not in the disengaged position by

pulling it backwards.

Turn on the power to the opener. The CLOSE LIMIT

b.

LED will be fl ashing.

Remove the button cover with a small blade

c.

screwdriver (Fig. 23).

Press and hold the MINUS (-) button - the door will

d.

start closing (Fig. 24).

Release the MINUS (-) button when the door is near

e.

the desired closed position. Single presses of the

MINUS (-) button will “inch” the door closed.

If the door overshoots press the PLUS (+) button

»

to move the door in the open direction.

When the door is at the desired close position, press

f.

the SET button to record the close limit position. The

OPEN LIMIT LED will now fl ash.

Press and hold the PLUS (+) button to open the door

g.

(Fig. 25).

Release the PLUS (+) button when the door is near the

h.

desired open position. Single presses of the PLUS (+)

button will “inch” the door open.

If the door overshoots press the MINUS (-) button

»

to move the door in the open direction.

fi g

fi g

23

24

WARNING! Once the next step is performed, the

door will automatically close and open to calculate

force settings. Keep persons and objects clear of the

door until it stops and the opener sounds a beep.

Press the SET button to store the open limit. Please

i.

read the above warning.

Step 15.2 - Resetting Travel Limits

To reset the limits press and hold the MINUS (-) button for

6 seconds until the CLOSE LIMIT LED fl ashes quickly. If no

action is taken within 30 seconds, the opener will return to

normal operating mode and restore the original settings.

Owner Installation Instructions GDO-9v2 SecuraLift

fi g

25

®

17

Page 18

fi g

fi g

Setting Limits: via Transmitter

The GDO-9v2 has the alternate ability to set travel limits

using the transmitter, allowing free movement around

the garage to better assess the desired limit positions.

Step 16.1 - Code a Transmitter for Limit Setting

Ensure the opener is powered up.

a.

Press and hold the DOOR CODE button (Fig. 26).

b.

Press Button 1 on the transmitter for two seconds

26

Button 1

(Inch Open)

Button 4

(Inch Close)

27

Button 2

(Set)

Button 3

(Switch between

fast and slow

inching)

c.

(Fig. 27). Release and pause for two seconds.

Press the Button 1 again for two seconds.

Release the DOOR CODE button.

d.

Step 16.2 - Setting Limits via Transmitter

Engage the C-Rail’s trolley (attached to the door via

a.

the arms) with the chain index by moving the door.

If the trolley does not “click” fi rmly onto the

»

chain index, pull the cord backwards until it

locks in place, and try again.

Press and hold Button 4 on the transmitter to close

b.

the door. When the door is approx. 20mm from the

ground, press and hold Button 3 for two seconds

and release (Fig. 27).

Each press of Button 4 will allow you to “inch” the

c.

door closed. Keep doing this until the door reaches

the desired close limit position.

If the door closes too far, press Button 1 to

»

“inch” the door towards open

When happy with the close limit position, press

d.

Button 2 to store this in memory.

Press Button 1 to open the door. When approx.

e.

20mm from the desired open position, press and

hold Button 3 for two seconds then release.

Each press of Button 1 will allow you to “inch” the

f.

door open. Keep doing this until the door reaches

the desired open limit position.

If the door is opened too far, press Button

»

4 to “inch” the door towards closed

IMPORTANT WARNING: The door will

automatically close, open and close again once

Step 16.2(f) is performed. Ensure that no persons

or objects are in the door’s path.

When happy with the open limit position, press

f.

Button 2 on the transmitter to store into memory.

The door will now automatically close and open to

g.

calculate the safety obstruction settings. After this, the

opener can be operated with the OPERATE button.

Step 16.3 - Resetting the Door Limit Positions

Limit positions can be deleted by the following steps:

Follow Steps 15.2 (a) and (b), as outlined previously.

a.

Repeat Steps 16.1 and 16.3 to set new travel limit

b.

positions.

There is no need to re-code the transmitter

»

(Step 16.2) upon resetting travel limits. The

transmitter will still be stored in memory.

18

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 19

Safety Obstruction Force Test

WARNING! Take care when testing or adjusting

the Safety Obstruction Force. Excessive force

may cause SERIOUS PERSONAL INJURY and/or

PROPERTY DAMAGE.

Step 17.1 - Testing Close Cycle

a.

Press the OPERATE button to open the door (Fig.

28).

b.

Place a piece of timber approximately 40mm high

on the fl oor directly under the door (Fig. 29).

c.

Press the OPERATE button to close door. The door

should strike the object and start to re-open.

Step 17.2 - Testing Open Cycle

Press the OPERATE button to close the door (Fig.

a.

28).

Press again to open the door. When the door

b.

reaches the half open point, grab the bottom rail of

the door fi rmly and the door should stop.

If the door does not reverse readily when closing,

c.

or stop when opening, the force may be excessive

and need adjusting, refer below.

fi g

28

DANGER! If the door fails these tests, put the

opener into manual mode, only operate the door

by hand and call for service.

fi g

29

Owner Installation Instructions GDO-9v2 SecuraLift

®

19

Page 20

fi g

fi g

Adjusting Safety Obstruction Forces

Adjusting Safety Obstruction Force

The Safety Obstruction Force is calculated automatically

during setup. Adjusting this is normally only necessitated

by environmental conditions such as windy or dusty areas,

and areas with extreme temperature changes.

WARNING: Doors that exert more than

30

31

400N (40kgf) closing force must have a

Photo Electric Beam (P.E. Beam, Model:

PE-2) fitted for safety.

Step 18.1 - To Increase Force Pressure

Hold down FORCE MARGIN SET button (Fig. 30)

a.

While holding the FORCE MARGIN SET button,

b.

press the PLUS (+) button. Each press increases the

force margin (Fig. 30).

The OPEN LIMIT LED will fl ash each time the PLUS

c.

(+) button is pressed to indicate a force increase

If the OPEN LIMIT LED fl ashes continuously

»

when pressing the PLUS (+) button this

indicates that the maximum setting has

been reached.

Test the force again as per Steps 8.1 and 8.2

d.

Step 18.2 - To Decrease Force Pressure

Hold down FORCE MARGIN SET button (Fig. 30)

a.

While holding the FORCE MARGIN SET button,

b.

press the MINUS (-) button. Each press decreases

the force margin (Fig. 30).

The CLOSE LIMIT LED will fl ash each time the MINUS

c.

(-) button is pressed to indicate a force decrease

If the CLOSE LIMIT LED fl ashes continuously

»

when pressing the MINUS (-) button this

indicates that the maximum setting has

been reached.

Test the force again as per Steps 8.1 and 8.2

d.

Step 18.3 - To Recall Factory Set Force

While holding down the FORCE MARGIN SET

a.

button, press the SET button for two (2) seconds.

(Fig. 31)

Release both buttons. The default setting should

b.

now be recalled.

Step 18.4 - To Recalculate Force Margins

Press and hold the SET Button for two (2) seconds,

a.

the beeper will sound once (Fig. 32).

The door will start to move and re-calculate force

fi g

32

20

GDO-9v2 SecuraLift® Owner Installation Instructions

b.

margins. The door can move between the open and

close limit positions up to four (4) times (depending

on the position of the door and the power up

condition).

A single beep will be heard once the process is

c.

complete.

Test the force again as per Steps 8.1 and 8.2.

d.

Page 21

Coding Transmitters

Step 19.1 - Code a Transmitter Button for

Door Operation

Press and hold the DOOR CODE button (Fig. 33).

a.

Press one of the four buttons on the transmitter for

b.

two (2) seconds, pause for two (2) seconds, then

press the same button again for two (2) seconds.

Release the DOOR CODE BUTTON.

c.

Press the transmitter button to test.

d.

Step 19.2 - Coding a Transmitter Button to

the Courtesy Light

The transmitter can be programmed to operate the

courtesy light on the opener independently of the door

moving.

Press and hold LIGHT CODE button (Fig.34).

a.

Press one of the four buttons on the transmitter for

b.

two (2) seconds, pause for two (2) seconds, then

press the same button again for two (2) seconds.

Release the LIGHT CODE button.

c.

Press the transmitter button to test.

d.

Step 19.3 - Code a Transmitter Button for Pet

(Pedestrian) Mode

a.

Briefly press the DOOR CODE button three times,

then press it again and hold (will beep four times

on fourth press (Fig.35)).

b.

Press one of the four buttons on the transmitter for

two (2) seconds, pause for two (2) seconds, then

press the same button again for two (2) seconds.

c.

Release the DOOR CODE button.

d.

Press the transmitter button to test. To change the

default pet (pedestrian) door opening position,

refer Step 2.

Step 19.4 - Code a Transmitter Button to

Enable Vacation mode

The opener can be programmed into a “Vacation Mode”

where the opener will not respond to any transmitter

except one preprogrammed unit.

Briefly press the DOOR CODE button once, then

a.

press it again and hold (will beep two times on

second press (Fig.35)).

Press one of the four buttons on the transmitter for two (2) seconds, pause for two (2) seconds, then two (2) seconds,

b.

pause for two (2) seconds, then press the same button again for two (2) seconds.

Release DOOR CODE button.

c.

To test, press and hold the transmitter button for seven (7) seconds to set Vacation Mode.

d.

To reset Vacation Mode press the same button for two seconds.

e.

fi g

fi g

fi g

33

34

35

Step 19.5 - Code a Transmitter Button to Enable AUX OUTPUT

Briefly press the DOOR CODE button two times, then press it again and hold (will beep three times on third press

a.

(Fig.35)).

Press one of the four buttons on the transmitter for two (2) seconds, pause for two seconds, then press the same

b.

button again for two (2) second.

Release the DOOR CODE button.

c.

Press the transmitter button to test.

d.

Owner Installation Instructions GDO-9v2 SecuraLift

®

21

Page 22

fi g

Remote Coding & Deleting

Transmitters

Step 20 - Remotely Coding Transmitters

Using this method transmitters can be coded without

access to the opener’s control panel as long as a precoded transmitter is available.

IMPORTANT NOTE: The door or courtesy light

must activate when the steps below are performed.

36

This indicates that the pre-coded transmitter is in

range of the opener, and the correct button has

been pressed.

Take any pre-coded transmitter. Press the button

a.

for the function to be duplicated and release.

Using a small needle, press and hold firmly for

b.

two seconds through the Coding Hole (Fig.36).

WITHIN 10 SECONDS take the additional

c.

transmitter you wish to code. Decide which

button that you want to activate the function to

be duplicated (e.g. activate the door, or turn on

the courtesy light)

Hold the new transmitter’s button for two

d.

seconds, pause for two seconds, hold again for

two seconds and then release.

Wait for 10 seconds and then press the new

e.

transmitter’s button to test.

fi g

37

Step 21 - Deleting Stored Codes

Step 21.1 - Deleting a Stored Transmitter

Code

a.

Select the transmitter you want to delete.

b.

Press and hold the DOOR CODE BUTTON (Fig.

37).

c.

Press the transmitter button you would like to

delete for two seconds, pause for two seconds,

press again for two seconds and then release.

d.

Release the DOOR CODE BUTTON. The code

should now be deleted. Confi rm this by pressing

the transmitter button - the function (e.g. door

opening) should not respond.

Step 21.2 - Deleting All Transmitter Codes

1. Turn off power to the opener.

a.

While switched off, press and hold the DOOR

b.

CODE BUTTON (Fig.37). Turn on power to the

opener while holding this button.

The OPEN LIMIT, CLOSE LIMIT and DOOR

c.

STATUS LEDs will illuminate for about fi ve

seconds. These LED’s will turn off and the

CODING LED will illuminate.

Release the DOOR CODE BUTTON. All stored

d.

codes will now be deleted. Confi rm this pressing

buttons on any previously coded transmitters the opener should not respond.

22

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 23

P.E. Beam & Auto-Close

Step 22 - Fitting the P.E. Beams (optional)

a.

Affix the P.E. Beams (PE-2) in a strategic location

within the doorway. We recommend 150mm above

the floor level and as close as possible to the door

opening, inside the garage.

b.

Connect the PE-2 (Order Code 90214) and the

P.E.Beam Interface Kit V2 (Order Code 01901) to

the Opener in accordance with (Fig.38).

Make sure to align the beams correctly. Follow the

manual supplied with the P.E. Beams.

WARNING: The P.E.Beams will be active only after

the Opener has moved the door through a

completed open or close cycle.

WARNING: When using Auto Close Mode and P.E.

beams, the doorway must be clear of all obstructions

and persons at all times. The location of the beams

and the manner in which it is installed might not

give safety protection at all times. Check to make

sure that the height of the beam and type used

give maximum protection possible.

Step 23 - Setting Up Auto-close Mode

IMPORTANT NOTICE: It is compulsory to have P.E.

Beams installed when using Auto-close mode.

RECEIVER

12V

24V

1

234

Y

R

B

R1

R

WIRE COLOUR: R-Red, B-Black, Y-Yellow

NOTE: Resistor R1 shall be 2.2kOhm, 1/4W

12V

24V

5

CABLE 2

CABLE 1

Model: PE-2 with harness

TRANSMITTER

1 2

R

B

3 4 5

fig

38

J2

R

PWR

Y

B

PE

PE-

Auto-close mode is a function that automatically closes

the door a preset time after the P.E. Beams recognise

that a vehicle has left the garage.

The Auto-close timer only starts after the P.E. Beam's

path is broken the Auto-close timer has been set. If

the P.E. path is not broken the door will remain open

until the path is broken. If the opener incurs a physical

obstruction (i.e. not from the P.E. Beams) while closing

the door will re-open and not Auto-close until the P.E.

Beam's path is broken again.

Step 23.1 - Setting Auto-close Time

a.

Hold down the AUTO CLOSE TIME button (Fig.39).

b.

While holding in the AUTO CLOSE TIME button,

press the OPEN button - each press will add one

second to the Auto-close delay.

c.

To decrease the delay time follow Step 15.1(a)

and press the CLOSE button - each press will

deduct one second from the Auto-close delay.

d.

Press the OPERATE button or transmitter to open

the door. When the door is fully opened the

OPEN LIMIT LED will flash to indicate that Autoclose mode is operational.

e.

Break the P.E. Beam's path momentarily to

initialise Auto-close. When the door reaches the

fully opened position, the door will pause for the

set Auto-close time and then close.

fig

39

Owner Installation Instructions GDO-9v2 SecuraLift

®

23

Page 24

Fig

B

l

a

c

k

(

F

r

o

m

B

a

t

t

e

r

y

)

R

e

d

(

F

r

o

m

B

a

t

t

e

r

y

)

R

e

d

B

l

a

c

k

(

F

r

o

m

S

o

l

a

r

P

a

n

e

l

)

R

e

d

(

F

r

o

m

So

l

a

r

P

a

n

e

l

)

Re

d

Wi

r

e

B

lack Wire

SmartSolar’ Installation

PLEASE NOTE: Control board firmware must be

v1.21 or higher for SmartSolar’ compatibility

WARNING: Do not connect batteries until Step

24.3

Step 24.1 - Mount the Charger Board

Unplug the drive unit from mains power.

40

B

R

W

Y

WIRE COLOUR:B- black

R- red

W-white

Y- yellow

a.

Remove the screws, swing open the main cover and

b.

remove the light diffuser. Then remove the transformer,

EMC board (if fitted) and mains power cable.

Fix the Charger Board under the timing assembly

c.

using three (3) M4x8 screws (Fig. 40).

Plug the Charger Board's three wire harness (red/

d.

yellow/black) into the control board's SBY-3

connector (Fig. 41).

Plug the Charger Board's white one wire harness into

e.

the control board s 24vac in connector (Fig. 41).

Plug the solar shunt (supplied) onto the control

f.

board's JP1 connector (Fig. 41).

Fig

41

SHUNT

SOLAR

-

LT01-1.00

+

JP1

IMPORTANT WARNING: Do not connect battery

or solar panel polarity incorrectly - this will result in

serious damage to components.

Step 24.2 - Connect the Solar Panel

Fig

Fig

42

43

+

-

J1

O

-SOLAR+

LT01-1.00

O

J2

J3

O

O

O

O

1 2

-BAT+

Mount the solar panel as outlined in the SmartSolar’

a.

Installation Manual.

Feed the Solar Panel s cable through black grommet

b.

located on the top of the plastic drive unit cover.

Connect the red wire to the Charger Board’s

c.

SOLAR+ connector, and the black wire to the

-SOLAR connector (Fig. 42).

WARNING: During Step 24.3 the opener will

become active.

Step 24.3 - Mount & Connect the Battery

Mount the Battery Box close to the opener.

a.

Feed the 2-core 18AWG gauge cable (supplied)

b.

through the Battery Box s grommet.

Connect the red wire to the Battery Box s + terminal,

c.

and the black wire to the - terminal (Fig. 43).

Feed the other end of the battery cable through the

d.

drive unit s black grommet.

Connect the red wire to the Charger Board's

e.

BAT+ connector, and the black wire to the -BAT

connector (Fig. 42).

Refit the light diffuser and main cover.

f.

Step 24.4 - Re-setup and Test the Opener

Setup travel limits and code transmitters as per the

a.

GDO-9 instruction manual.

Press either the OPERATE button or use a transmitter

b.

24

GDO-9v2 SecuraLift® Owner Installation Instructions

to operate the opener.

Page 25

Battery Back Up Installation

Wiring diagram

Battery assembly (#01660)

9

6

11

10

10

Item Description Qty Order Code

1. SBY-3 Version 1.00 1 00852

2. SBY-3 charger harness 1 14115

3. SBY-3 battery harness 1 15660

4. Pan head screw w/washer M4 x 8 7 10320

5. Batteries cover 1 16460

6. Batteries 12V sec 12-2.2 AGM type 2 15470

7. Battery harness 1 15670

8. Battery coupling wire 1 12005

9. Batteries support 1 16480

10. Hexagon standoff M4 2 11190

5

8

7

3

1

2

1. Remove screws &

swing cover to open

5. Close cover and

re-secure with screw

3. Mount battery and

secure with item 4 & 10

2. Connect wires as shown.

Refer to wiring diagram.

4. Connect

4

2 3

10

4 1

Fig

44

Step 25.1 - Connect the Battery Back Up Kit

Disconnect power to the opener.

a.

Remove screws and swing open the cover (Fig. 44).

b.

Mount battery pack and secure with item 4 and 10.

c.

Mount the SBY-3 Charger Board on three hex

d.

spacers pre mounted on base and secure with

three (3) M4 x 8 screws.

Feed the 2-wire battery harness through the

e.

grommet on the base plate and connect to SBY-3.

Feed charger harness from SBY-3 to the control

f.

board and plug into the 4 pin connector marked

SBY-3 onto the control board.

WARNING: After Step 25.1(g) the opener may

become active (even when power is off). This is a

result of a residual charge in the batteries.

Connect battery harnesses item 3 and 7 together

g.

(Fig. 44).

Reconnect power.

h.

Step 25.2 - Testing Battery Back Up

a.

Press either the OPERATE button or transmitter

to test the opener.

b.

Whilst door is in motion disconnect mains

power the door should continue to operate as

normal.

NOTE: Wait for the door to complete its travel.

c.

Press the OPERATE button or transmitter to

activate the door.

d.

Whilst door is in motion re-connect power. The

door should complete the cycle as normal.

Step 25.3 - Troubleshooting

If door stops or moves very slowly under battery

power, the batteries may be weak or have no

charge. Connect mains power and allow the

batteries to charge. This may take 24 - 48 hours to

reach maximum charge capacity.

Owner Installation Instructions GDO-9v2 SecuraLift

®

25

Page 26

fi g

fi g

Final Set Up

45

46

Step 26 - Setting of Courtesy Light Time

The courtesy light time can only be adjusted with

the Universal Programmer (PG-3).

Step 27 - Setting the Pet Mode position

The default Pet Mode height can be changed as follows:

Make sure the door is closed, then press and

a.

hold the OPEN button for six (6) seconds (Fig.

45), until you hear three beeps and the OPEN

and CLOSE LEDs flash rapidly.

Press the OPEN or CLOSE button to move the

b.

door to the desired pet mode open position.

Press the SET button to record the new position.

c.

When activated, Pet Mode drives the door to the preset

position from either above or below. Pet Mode’s active

status is indicated by both the OPEN and CLOSE LIMIT

LEDs being illuminated. If a Pet Mode button is pressed

while the door is moving the door will stop. If a Pet

Mode button is pressed when the door is in the Pet

position, then the door will close.

Step 28 - Installing the Wall Mounted

Transmitter (Optional)

a.

Remove the faceplate from the transmitter.

b.

Affi x the baseplate in a convenient wall location

that is out of reach of children and convenient

to the customer (Fig 46). Make sure the door is

visible from this location.

c.

Replace the faceplate.

d.

To code the transmitter, see Steps 10.1 through

10.4 on page 19.

Step 29 - Reset all Factory Defaults

a.

Turn power to opener off.

b.

Press and hold the SET Button (Fig 47).

fi g

47

26

GDO-9v2 SecuraLift® Owner Installation Instructions

c.

Turn power on while holding the SET button.

Continue to hold until all LEDs are off.

»

This will not erase transmitter codes

stored in memory.

Page 27

Default Settings & Specifications

Factory Default Settings

Default Step Maximum

-- 3 minCourtesy light time

Obstruction force margin

2

0 secAuto close time

1 sec

Technical specifications

230-240V AC, 50HzMains

2.2 Wattsrewop ybdnatS

150 WattsRated input power

Shuttle travel distance in the C-Rail 2.8m approx (standard)

Maximum shuttle travel distance in the C-Rail 5m (with extended C-Rail)

2

Maximum door size

Maximum door weight

Minimum Clearance

(Bottom of C-Rail to highest point of door travel)

Recommended force for manual operation

(excessive force)

(5500mm (Width) x 3000mm (Height))

16.5m

225 kg

25mm

)gk08( N008ecrof kaep mret trohS

450N (45kg)Rated lift force: Chain / Timing Belt

No greater than 150N (15kg)

111

4 min

tengam tnenamrep CD V42epyt rotoM

4 minRated operating time

14 x 4 button Transmitter Codesyticapac egarots edoc revieceR

UHF Multi-frequemcy FM

Multi-frequency Code Hoppingepyt gnidoC

LEDs (Light Emitting Diodes)thgil ysetruoC

NOTE: Intermittent operations may occur in areas which experience very strong winds. The strong wind puts

extra pressure on the door and tracks which may in turn trigger the safety obstruction detection system

intermittently.

Owner Installation Instructions GDO-9v2 SecuraLift

Transmitter/Receiver type

sedoc modnar noillib 92.4 revOsnoitanibmoc edoc fo rebmuN

mhtirogla noitpyrcne raenil-noNnoitareneg edoC

CR2032 (3V)yrettab rettimsnarT

wolb wols A01esuf rellortnoC

®

27

Page 28

Parameters

Door Status Indicators

Door Opener State OPEN LED (Green) CLOSE LED (Red) Beeper

Open On

Close On

Opening Flashing

Closing Flashing

Door travel stopped Flashing Flashing

Door obstructed when opening Flashing

Door obstructed when closing Flashing Beeps as door moves

Opener overloaded Alternating fl ashes Alternating fl ashes

Door in open position with AutoClose mode selected

Pet Mode Engaged On On

Mains power interrupted Rapid fl ashes

One second fl ashes

28

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 29

Parameters

Button Functions

noitcnuFsnottuB

rood eht sesolC/spotS/snepOETAREPO

DOOR CODE

FORCE MARGIN SET & AUTO CLOSE TIME (then) SET Reloads the factory default light time

SET (then power on) & hold until all LEDs are off Deletes control parameters excluding transmitter

DOOR CODE (then power on) & hold until all LEDs

are off

SET & DOOR CODE (the power on) and hold until all

LEDs are off

Codes a transmitter button for operate function,

Pet and Vacation Modes, and AUX functions

noitcnuf thgil rof nottub rettimsnart a sedoCEDOC THGIL

gnittes nigram ecrof noitcurtsbo eht sesaercnINEPO & TES NIGRAM ECROF

gnittes nigram ecrof noitcurtsbo eht sesaerceDESOLC & TES NIGRAM ECROF

sgnittes nigram ecrof tluafed yrotcaf eht steseRTES )neht( TES NIGRAM ECROF

emit yaled esolc otua eht sesaercnINEPO )neht( EMIT ESOLC OTUA

emit yaled esolc otua eht sesaerceDESOLC )neht( EMIT ESOLC OTUA

emit yaled esolc otua tluafed yrotcaf eht steseRTES )neht( EMIT ESOLC OTUA

neht stimiL .snoitisop tes stimil rood eht sraelC).sces 6 rof( ESOLC

need to be reset

edom noitisop )nairtsedep( tep sretnE).sces 2 rof( ESOLC & TES

storage memory

Deletes all transmitter storage memory

Deletes all control parameters and transmitter

storage memory.

margin

Owner Installation Instructions GDO-9v2 SecuraLift

ecrof etaluclac-er ot renepO eht sesilaitini-eRTES

®

29

Page 30

Troubleshooting guide

Symptom Possible cause Remedy

Door will not operate Mains power not switched on

Door is obstructed

Door is locked or motor jammed

Door tracks/hardware damaged

Door starts to close but

automatically reverses to

open position

Gate operates from drive unit

(operate) button but not from

transmitter.*

*See note

Door will not close fully Door limits position need to

Door will not open fully Door limits position need to

Courtesy light not working Faulty light Replace lamp

Auto close not working PE Beam or wiring faulty

Adverse weather conditions (wind

or cold) causing door to stiffen and

become tight in the tracks

Possible obstruction in

the doorway

Transmitter code not stored

in memory

Flat battery

be reset

be reset

PE Beam not aligned correctly

PE Beam is obstructed

Door obstructed when closing

Auto close time not set

Switch on mains power

Remove obstruction

Unlock door or remove jam

Door requires service/repair by

qualifi ed technician

Increase force margin setting.

See Step 18 on page 20

Remove obstruction

Code transmitter into opener’s

memory. Refer Step 19.1 on page

21

Replace battery

Reset limits positions. Refer Step

16.3 on page 18

Reset limits positions. Refer Step

16.3 on page 18

Repair P.E. Beam or replace wiring

Re-align optics. See P.E.

instructions

Remove obstruction from the path

of P.E. Beam

Remove obstruction

See Step 23 on page 23

PLEASE NOTE:

Some areas may be prone to excessive radio interference brought on by devices such as cordless telephones,

wireless stereo headphones and baby monitors. It is possible that these devices could cause a degree of

interference such as to greatly reduce the range of the transmitter. In such an instance please contact your ATA

dealer for an alternative frequency replacement kit. As this is not a warrantable situation but an environmental

issue charges may apply for the changeover.

30

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 31

Maintenance

Maintenance

Whilst your opener does not require any periodic

maintenance, the door that it is fi tted to does.

Your garage door is a large, heavy, moving object

and should be tested regularly to ensure it is in

good condition. A poorly maintained door could

cause fatal or serious injuries or serious damage to

property.

To ensure a long and trouble free life for your opener

the following is recommended:

Monthly

Disengage the opener and manually operate

•

the door: The door must be smooth to operate

by hand. An operating force on the bottom rail

should not exceed 150N (15kg) force.

Each month check that the opener reverses

•

when the door contacts a 40mm high object

placed on the fl oor (AS3350).

•

NOTE: If the door does not operate smoothly, call

your installer.

Yearly

Automatic Technology suggests you contact your

installer to perform an annual door service.

CAUTION: Frequently examine door, particularly

cables, springs and mountings for signs of wear,

damage or imbalance. Do not use if repair

or adjustment is needed since a fault in the

installation or an incorrectly balanced door may

cause injury. (AS3350)

Adjustments should only be carried out by

experienced persons, as this function can

be dangerous if not performed under strict safety

procedures.

WARNING! Failure to maintain your garage

door may void the warranty on your garage door

opener.

Service Record

Record any maintenance in the following table to assist in any warranty service.

Date Service by Signature Invoice No. Amount

Owner Installation Instructions GDO-9v2 SecuraLift

®

31

Page 32

Parts Listing

32

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 33

Owner Installation Instructions GDO-9v2 SecuraLift

®

33

Page 34

Warranty and Exclusion of Liability

1. This warranty is an addition to any non-excludable conditions or warranties that are implied into this contract

by relevant statute, including the Trade Practices Act 1974 (Cwth).

2. Subject to all of the matters set out below, Automatic Technology Australia Pty Ltd (“ATA”) warrants:

(a) overhead door opener drive units for twenty four (24) months or 5000 cycles, whichever occurs fi rst; and

(b) all components and accessories for twelve (12) months, from the date of purchase (specifi ed in the sales

docket receipt) as free of any defects in material and workmanship.

3. This warranty applies only where the purchaser:

(a) immediately notifi es ATA or the retailer of the alleged defect;

(b) returns the product to the retailer; and

(c) presents the relevant sales docket and this warranty document to the retailer to confi rm the date

of purchase.

4. Except for this warranty, ATA gives no warranties of any kind whatsoever (whether express or implied),

in relation to the product, and all warranties of whatsoever kind relating to the product are, to the extent

permissible by statute, hereby excluded.

5. To the extent permissible by statute, ATA disclaims any liability of whatsoever nature in respect of any claim

or demand for loss or damage which arises out of:

(a) accidental damage to or normal wear and tear to the product or to the product’s components;

(b) any cost relating to damage resulting from wear and tear;

(c) blown fuses, loss or damage caused by electrical surges, power surges or power spikes;

(d) loss or damage due to theft, fi re, fl ood, rain, water, lightning, storms or any other acts of God;

(e) maximum continuous operating time exceeding one (1) minute in ten (10);

(f) maximum operating force exceeding *20kg (200N) when moving the door manually to the open or

closed position;

(g) door surface area and/or weight exceeding 16.5m

(h) door not in safe and correct working order and condition;

(i) evidence of unauthorised repairs;

(j) any cost relating to damage caused by misuse, negligence or failure to maintain the equipment in a

proper working order as per clauses (d) through (h);

(k) installation, adjustment or use which is not in accordance with the instructions set out in installation

instruction manual

(l) attempted or complete modifi cation or repairs to the product carried out by a person who is not

authorised or has not been trained by ATA to carry out such modifi cation or repairs;

(m) faulty or unsuitable wiring of structure to which the product is fi xed or connected;

(n) radio (including citizen band transmission) or any electrical interference;

(o) damage caused by insects;

(p) loss or damage to any property whatsoever or any loss or expense whatsoever resulting or arising there

from or any consequential loss;

(q) any cost or expense arising due to manufacturer recall of any product;

(r) any cost or expense due to negligence of the approved service provider;

(s) installation of a residential garage door opener in a commercial or industrial situation or a non-single

residential dwelling.

6. ATA’s liability under this warranty is limited, at ATA’s absolute option, to replacing or repairing the product

which ATA, in its unfettered opinion, considers to be defective either in material and/or workmanship or to

credit the dealer with the price at which the product was purchased by the dealer.

7. This warranty does not extend to cover labour for installation.

8. This warranty is limited to Return-to-Base (RTB) repair and does not cover labour for on-site attendance.

9. This warranty is void if the Product is not returned to the manufacturer in original or suitably secure packaging.

10. This warranty is only applicable for repairs to the product carried out within Australia.

11. This warranty does not cover consumable items including globes, batteries and fuses.

12. This warranty is not transferable.

13. Where the Product is retailed by any person other than ATA, except for the warranty set out above, such

person has no authority from ATA to give any warranty or guarantee on ATA’s behalf in addition to the

warranty set out above.

2

and 100kg respectively;

NOTES:

1. One (1) cycle = one (1) open and one (1) close action of the door or gate.

2. This warranty is to be read in conjunction with the owner’s copy of the installation instruction manual.

3 *The door should be balanced in such a way that the user manually is able to open or close the door without using

force not greater than 150N (15kg ) although a greater force may be required for the start of the movement.

34

GDO-9v2 SecuraLift® Owner Installation Instructions

Page 35

Owner Installation Instructions GDO-9v2 SecuraLift

®

35

Page 36

© January 2008 Automatic Technology (Australia) Pty Ltd. All rights reserved. TrioCode™ and SecuraLift® are trademarks

of Automatic Technology (Australia) Pty Ltd. No part of this document may be reproduced without prior permission. In an

ongoing commitment to product quality we reserve the right to change specifi cation without notice. E&OE.

Automatic Technololgy (Australia) Pty Ltd

ABN 11 007 125 368

6-8 Fiveways Boulevard

Keysborough, Victoria, 3173, Australia

P 1300 133 944

+61 2 9722 5666

(International Enquiries Only)

E sales@ata-aust.com.au

www.ata-aust.com.au

GARAGE DOOR OPENERS | GATE OPENERS | REMOTE CONTROL ACCESS SOLUTIONS

Loading...

Loading...