Page 1

ZN551 Control Module

Technical Instructions

What is the ZN551 control module? ........................................................................... 2

Module driver and control program ................................................................ 2

Specifications ...............................................................................................2

Inputs ...........................................................................................................3

Room sensors................................................................................................3

Digital outputs...............................................................................................3

Analog outputs..............................................................................................3

To mount the ZN551.................................................................................................. 4

Wiring for power ........................................................................................................ 4

To wire for power............................................................................................4

To address the ZN551................................................................................................ 5

Wiring for communications ........................................................................................ 5

Wiring specifications .....................................................................................5

To wire the ZN551 for communications ..........................................................5

Wiring inputs and outputs.......................................................................................... 6

Wiring specifications .....................................................................................6

To wire inputs and outputs............................................................................. 7

Downloading memory................................................................................................ 9

To download memory in WebCTRL..................................................................9

To assign inputs or outputs to points........................................................................... 9

Input values.................................................................................................10

Output values..............................................................................................10

Resolution values ........................................................................................11

Offset/Polarity values.................................................................................. 11

Using flow sensors................................................................................................... 12

To connect the duct tubes to the flow sensors...............................................12

To wire the flow sensor to the control module................................................12

To set up the Airflow Control microblock.......................................................12

To set up the module driver ...................................................................................... 13

Driver ..........................................................................................................13

Device......................................................................................................... 14

Notification Class #1...................................................................................14

Common Alarms.......................................................................................... 15

Custom Translation Tables...........................................................................15

To communicate through the local access port .......................................................... 16

To set up a Local Access connection in WebCTRL.......................................... 16

Troubleshooting ...................................................................................................... 16

Formatting the control module.....................................................................17

LED's..........................................................................................................17

Manufacture date........................................................................................18

Compliance ............................................................................................................ 18

Automated Logic Corporation • 1150 Roberts Blvd. • Kennesaw, GA 30144 • 770/429-3000 • Fax 770/429-3001 •

www.automatedlogic.com • © 2005 Automated Logic Corporation. All rights reserved throughout the world. Automated

Logic Corporation, the Automated Logic logo, WebCTRL, EIKON, BACview, SuperVision, and InterOp are registered

trademarks, and Alert is a trademark of Automated Logic Corporation. BACnet

All other brand and product names are trademarked by their respective companies.

®

is a registered trademark of ASHRAE.

Page 2

What is the ZN551 control module?

The ZN551 control module is used for zone control.

Module driver and control program

Specifications

Module driver DRV_ZN

Maximum number of control

programs

Maximum number of

BACnet objects*

* Depends on available memory

Power

CMnet port

Rnet port

LStat port

Local access port For system start-up and troubleshooting

Inputs

Input resolution 10 bit A/D

1

200

24 Vac ±10%, 50–60 Hz, 15 VA

26 Vdc (25 V min, 30 V max)

For communication with the control module network using

ARC156 or MS/TP (9600 bps–76.8 kbps)

For RS room sensors. The Rnet port supports up to four

RS sensors and one RS Pro or RS Plus sensor for

averaging or high/low select control.

NOTE The ZN551 does not support BACview.

For LogiStat and LogiStat Plus room sensors. The LogiStat

port uses two universal inputs.

NOTE The ZN551 does not support the LogiStat Pro. Use

an RS Pro on the Rnet port instead.

5 inputs configurable for thermistor or dry contact. Inputs

1 and 2 are also configurable for 0–5 Vdc. Inputs 4 and 5

are used when a LogiStat sensor is connected, but are

available if an RS room sensor is connected.

Digital outputs

Analog output 1 analog output, 0–10 Vdc (5 mA max)

Output resolution 8 bit D/A

Memory

Battery

Protection

ZN551 Control Module • Rev. 3/17/2005 2 © 2005 Automated Logic Corporation

5 digital outputs, relay contacts rated at 1 A max. @ 24

Vac/Vdc. Configured normally open.

512 kB non-volatile battery-backed RAM, 1 MB Flash

memory, 16-bit memory bus

10-year Lithium CR2032 battery provides a minimum of

10,000 hours of data retention during power outages

Incoming power and network connections are protected

by non-replaceable internal solid-state polyswitches that

reset themselves when the condition that causes a fault

returns to normal. The power, network, analog inputs,

analog outputs, and relay output connections are also

protected against voltage transient and surge events.

Page 3

Inputs

Status indicators

Environmental operating

range

Physical Rugged GE C2950 Cycoloy plastic

Overall dimensions

Mounting dimensions 5 9/16" (14.1 cm) between mounting slot centerlines

Weight 0.6 lbs (0.27 kg)

BACnet support

Listed by

The ZN551 has 5 inputs that accept the following signal types:

These

inputs...

All Thermistor

All Dry contact

IN-1, IN-2 0–5 Vdc

IN-4, IN-5 LogiStat IN-4–See Thermistor.

Support this

signal type...

LED's indicate status of communications, running, errors,

power, and digital outputs

0 to 130°F (-17.8 to 54.4°C), 10–90% relative humidity,

non-condensing

Width:

Height:

Conforms to the Advanced Application Controller (B-AAC)

Standard Device Profile as defined in ANSI/ASHRAE

Standard 135-2004 (BACnet) Annex L

UL-916 (PAZX), cUL-916 (PAZX7), FCC Part 15-Subpart BClass A, CE EN50082-1997

Description

Precon type 2 (10 kOhm at 77°F). Input voltages will be

from 0.33 Vdc to 2.52 Vdc for thermistors.

A 3.3 Vdc wetting voltage detects contact position,

resulting in a 0.3 mA maximum sense current when the

contacts are closed.

The output impedance of a 0–5 Vdc source must not

exceed 100 Ohms. The input impedance of the ZN551

is approximately 30 kOhm.

IN-5–Setpoint adjust. Input voltages should be from

1.4–3.4 Vdc.

5 1/16 in. (12.9 cm)

5 11/16 in. (14.4 cm)

NOTE A LogiStat sensor connected to the ZN551 uses IN-4 and IN-5. An RS

room sensor connected to the Rnet port does not use these inputs.

Room sensors

Digital outputs

Analog outputs

ZN551 Control Module • Rev. 3/17/2005 3 © 2005 Automated Logic Corporation

You can wire an RS Standard, RS Plus or RS Pro to the ZN551's Rnet port.

Or you can wire a LogiStat or LogiStat Plus to the ZN551's LStat port. See the

RS Room Sensors Technical Instructions (http://info.automatedlogic.com) or

the LogiStat Sensors Technical Instructions (http://info.automatedlogic.com).

NOTE The ZN551 does not support the LogiStat Pro.

The ZN551 has 5 digital outputs. You can connect each output to a

maximum of 24 Vac/Vdc. Each output is a dry contact rated at 1 A, 24 V

maximum and is normally open.

The ZN551 has 1 analog output that supports voltage devices from 0-10 Vdc.

The controlled device must have a minimum of 2000 Ohms resistance

Page 4

t

t

To mount the ZN551

measured from its input to ground and must share the same ground as the

control module.

Screw the ZN551 into an enclosed panel using the mounting slots provided

on the cover plate. Leave about 2 in. (5 cm) on each side of the control

module for wiring.

Mounting slo

Wiring for power

To wire for power

Mounting slo

CAUTIONS

• The ZN551 is a Class 2 device (less than 30 Vac, 100 VA). Take

appropriate isolation measures when mounting it in a control panel

where non-Class 2 devices (120 Vac or greater) are present.

• Do not power pilot relays from the same transformer that powers the

ZN551.

NOTE You can power several control modules from the same transformer if

you maintain the same polarity.

1 Remove power from the 24 Vac transformer.

2 Pull the screw terminal connector from the control module's power

terminals labeled Gnd and 24 Vac.

3 Connect the transformer wires to the screw terminal connector.

4 Apply power to the transformer.

5 Measure the voltage at the ZN551’s power input terminals to verify that

the voltage is within the operating range of 21.6–26.4 Vac.

6 Insert the screw terminal connector into the ZN551's power terminals.

7 Verify that the Power LED is on and the Run LED is blinking.

ZN551 Control Module • Rev. 3/17/2005 4 © 2005 Automated Logic Corporation

Page 5

10's1

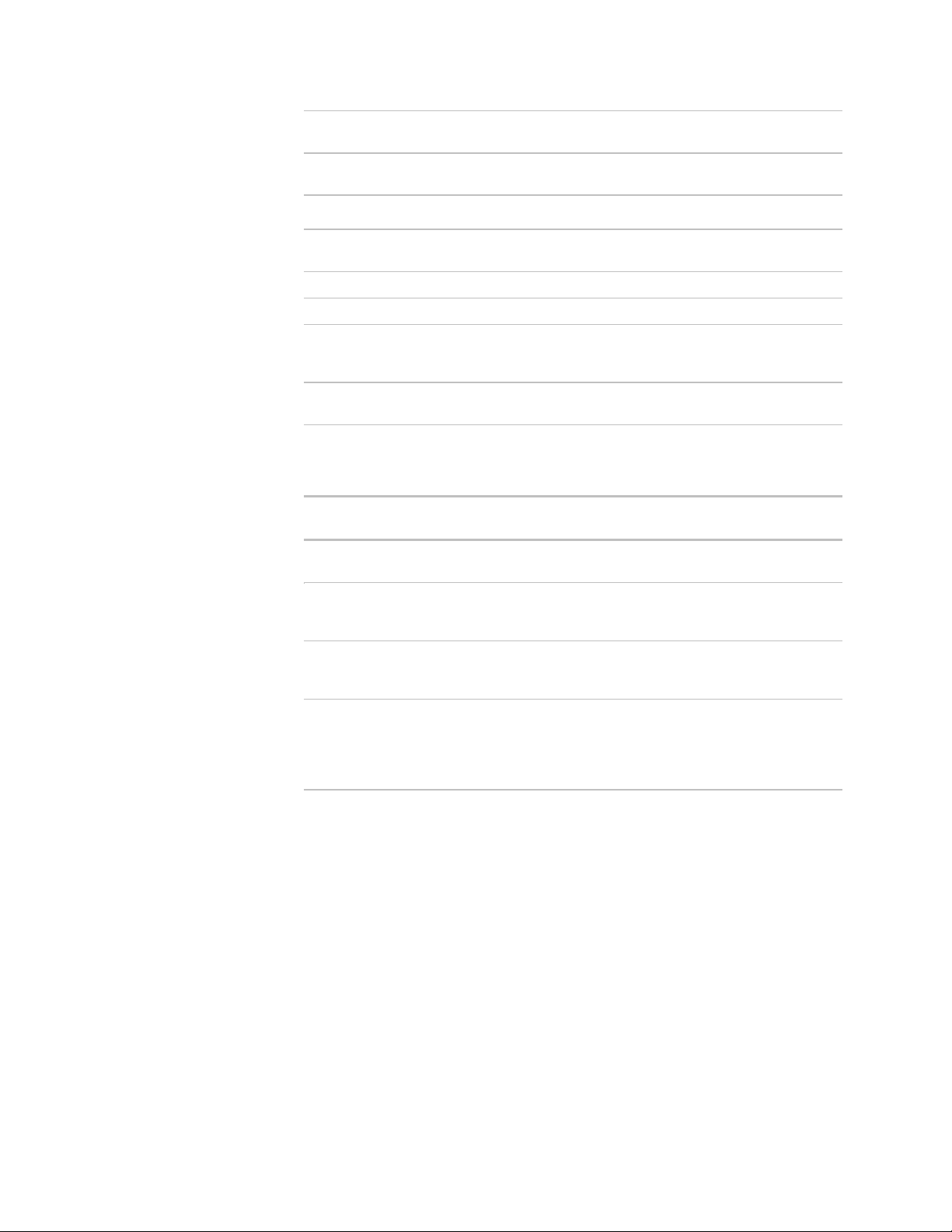

To address the ZN551

You can address the ZN551 before or after you wire the control module for

power.

1 If the ZN551 has been wired for power, pull the screw terminal connector

2 Using the rotary switches, set the control module's address to match the

from the control module's power terminals labeled Gnd and 24 Vac. The

control module reads the address each time you apply power to it.

Address in the control module's Device Properties dialog box in

SiteBuilder. Set the Tens (10's) switch to the tens digit of the address,

and set the Ones (1's) switch to the ones digit.

EXAMPLE If the control module’s address is 35, point the arrow on the

Tens (10's) switch to 3 and the arrow on the Ones (1's) switch to 5.

's

Wiring for communications

The ZN551 communicates using BACnet on the following types of network

segments:

• ARC156 communicating at 156 kbps

• MS/TP communicating at 9600 bps, 19.2 kbps, 38.4 kbps, or 76.8 kbps

NOTE ARC156 is a unique implementation of the industry standard

ARCNET. For a summary of differences between ARCNET and ARC156, see

the ARC156 Wiring Technical Instructions (http://info.automatedlogic.com).

Wiring specifications

To wire the ZN551 for communications

For... Use... Maximum Length

ARC156

MS/TP

* See the ARC156 Wiring Technical Instructions (http://info.automatedlogic.com).

1 Pull the screw terminal connector from the control module's power

terminals labeled Gnd and 24 Vac.

2 Check the communications wiring for shorts and grounds.

3 Connect the communications wiring to the control module’s screw

terminals labeled Net +, Net -, and Shield.

NOTE Use the same polarity throughout the network segment.

22 AWG, low-capacitance, twisted,

stranded, shielded copper wire*

A dedicated 22 AWG to 18 AWG

twisted pair wire (EIA-485)

2000 feet (610 meters)

3000 feet (914.4 meters) for 9600

bps, 19.2 kbps, or 38.4 kbps

2000 feet (610 meters) for 76.8 kbps

ZN551 Control Module • Rev. 3/17/2005 5 © 2005 Automated Logic Corporation

Page 6

4 Set the communication type and baud rate.

For...

ARC156 ARC156 N/A. Baud rate will be 156 kbps

MS/TP MSTP The appropriate baud rate. See the MSTP

NOTE Use the same baud rate for all control modules on the network

segment.

5 Insert the power screw terminal connector into the ZN551's power

terminals.

6 Verify communication with the network by viewing a module status

report in WebCTRL.

Wiring inputs and outputs

Wire the ZN551's inputs and outputs as follows.

Wiring specifications

Input wiring

Input Maximum length Minimum gauge Shielding

Set Communications

Selection jumper to...

Set DIP switches 1 and 2 to...

regardless of the DIP switch settings.

Baud diagram on the control module.

0–5 Vdc

1000 feet

26 AWG Shielded

(305 meters)

Thermistor

Dry contact

RS room sensors

LogiStat

1000 feet

(305 meters)

500 feet

(152 meters)

100 feet

22 AWG Shielded

22 AWG,

4 conductor

22 AWG

2

1

Shielded or

unshielded

Unshielded

(30 meters)

1

See the RS Room Sensors Technical Instructions (http://info.automatedlogic.com).

2

See the LogiStat Sensors Technical Instructions (http://info.automatedlogic.com).

Output wiring

To size output wiring, consider the following:

• Total loop distance from the power supply to the control module, and

then to the controlled device

NOTE Include the total distance of actual wire. For 2-conductor wires,

this is twice the cable length.

• Acceptable voltage drop in the wire from the control module to the

controlled device

• Resistance (Ohms) of the chosen wire gauge

• Maximum current (Amps) the controlled device requires to operate

ZN551 Control Module • Rev. 3/17/2005 6 © 2005 Automated Logic Corporation

Page 7

To wire inputs and outputs

1 Verify that the ZN551's power and communications connections work

properly.

2 Pull the screw terminal connector from the control module's power

terminals labeled Gnd and 24 Vac.

3 Connect the input wiring to the screw terminals on the ZN551.

NOTE Connect the shield wire to the GND terminal with the ground

wire.

Any input

thermistor

Relay,

dry contact

+V

DC

power

supply

Gnd

4 To wire a room sensor to the ZN551, wire the ZN551's terminals to the

room sensor's terminals.

○ For an RS room sensor, wire each terminal on the ZN551's Rnet port

to the terminal of the same name on the RS room sensor.

NOTE If wiring an RS room sensor with shielded wire, connect the

shield wire to the GND terminal with the ground wire.

○ For a LogiStat room sensor, use the following table.

+V

Gnd

Out

0-5Vdc

Gnd

Any input

Gnd

Gnd

Wire this terminal

on the LStat port...

Gnd

IN-4

IN-5

LED

5 Set the appropriate jumpers on the ZN551.

To use... For...

IN-1 or IN-2 Thermistor

Dry contact

0–5 Vdc

IN-4 or IN-5 Thermistor

Dry contact

IN-4 and IN-5 LogiStat 1. Remove the jumper from LStat/IN-4.

Rnet Port RS sensor Set the LStat/Rnet jumper to Rnet.

ZN551 Control Module • Rev. 3/17/2005 7 © 2005 Automated Logic Corporation

To this terminal on

the LogiStat sensor

Gnd

Temp

SW

LS5v

Set jumpers IN-1 or IN-2 to the type of signal the

input will receive.

Verify the LStat/IN-4 jumper is on.

2. Set the LStat/Rnet jumper to LStat.

Page 8

LStat

Rnet

LStat

IN-4

IN-1

Thermistor/dry contact

0-5Vdc

IN-2

Thermistor/dry contact

0-5Vdc

6 Connect the digital output wiring to the screw terminals on the ZN551

and to the controlled device.

Any DO

Motor

Any DO

24 Vac or

Bus

24 Vdc

7 Connect the analog output wiring to the screw terminals on the ZN551

and to the controlled device.

Gnd

Motor

Any AO

+

0-10 V

Gnd

Valve

Any AO

+

0-10 V

NOTE Current from the analog outputs can drive a 20 mA device. To use

an analog output for this purpose, you may need to add a 1/2 watt

resistor in series with the device to achieve the required total resistance

of 500 Ohms. For example, to drive a device that has 100 Ohms of

resistance, wire a 400 Ohm resistor in series with the 20 mA device to

achieve 500 Ohms resistance.

8 Insert the power screw terminal connector into the ZN551's power

terminals.

ZN551 Control Module • Rev. 3/17/2005 8 © 2005 Automated Logic Corporation

Page 9

Downloading memory

Download memory to a control module to do either of the following:

• Send control programs, the module driver, editable properties, and

schedules to a control module for the first time. The first download takes

longer than subsequent downloads.

• Send changes such as a change to a control program, an upgrade to the

module driver, or a change to the control module's address.

The ZN551 can store one DRV_ZN module driver and one control program.

CAUTIONS

• The control module automatically halts before and restarts after a

memory download, causing the shutdown and restart of any equipment

controlled by the module.

• Downloading memory overwrites all control programs in the control

module causing it to lose stored data.

You download memory from WebCTRL. If your network is complete, you can

download from any network browser. If not complete, connect a laptop with a

local copy of the system database to the ZN551's local access port. See steps

1–3 of To communicate through the local access port (page 16).

To download memory in WebCTRL

1 On WebCTRL's CFG tree, click Download.

2 Select the Memory checkbox.

NOTE A memory download includes a Parameters and Schedules

download.

3 On the Network tree on the right, select the control module you want to

download to.

4 Click Add to add the control module to the Download Items list.

5 Click Download Selected Items.

If the download fails, the control module appears in the Failures box. Since

this indicates a system problem, do not clear the failure. Locate and resolve

the problem, then retry the download. To retry, select the control module in

the Failures box, then repeat steps 4 and 5 above.

To assign inputs or outputs to points

To use an input or output, you must assign it to its corresponding point in

the control program.

1 In WebCTRL's GEO tree, select the equipment controlled by the ZN551.

2 From the menu

, select Point Checkout.

ZN551 Control Module • Rev. 3/17/2005 9 © 2005 Automated Logic Corporation

Page 10

3 In the Num field for each point, type the number of the control module's

corresponding input or output. For example, if you use DO1 on the

ZN551 for the point Fan S/S, type 1 in the Num field for Fan S/S.

NOTE Exp (expander number) is 0 for the ZN551.

4 Enter the appropriate values for each input and output in the remaining

columns. See Input values, Output values, Resolution values and

Offset/Polarity values below.

NOTE You can also enter these values in EIKON for WebCTRL.

5 If you have not performed the initial memory download to the ZN551, you

must download now so you can verify inputs and outputs.

6 To verify each input's operation, force each sensor to a known value, then

compare it to the Value shown on the control program's Point Checkout

tool in WebCTRL.

7 To verify each output's operation, lock each output to a known condition

on the control program's Point Checkout tool in WebCTRL, then verify

that the equipment operates correctly.

Input values

Input I/O Type Sensor/Actuator Type Min/Max

Analog (BAI)

0–5 Vdc 0–5 Volt Linear Full Range

Engineering values

associated with 0 Vdc (Min)

and 5 Vdc (Max)1

Thermistor Thermistor

Select your Thermistor

N/A

type or set up and select

a Non-Linear, Custom

2

Table

Digital (Binary) (BBI)

Dry Contact Dry Contact N/A N/A

1

The sensor reads a value and sends a corresponding signal (Volt, mA, or psi) to the

ZN551's physical input. The Analog Input microblock uses the Min and Max values to

linearly translate the signal into the engineering value used in subsequent control logic.

For example, set Min to 0 and Max to 10 for a 4–20 mA sensor that measures velocity

from 0.0 to 10.0 inches/second so that when the input reads 4 mA, the microblock

outputs a value of 0. Similarly, when the input reads 8 mA, the microblock outputs a

value of 2.5.

2

To set up a custom translation table, see the module driver's Custom Translation Tables

properties page in WebCTRL.

Output values

Output I/O Type Sensor/Actuator Type Min/Max

Analog (BAO)

0–10 Vdc

Electrical

0–10 Volt

Linear Full Range

Engineering values

associated with 0 Vdc (Min)

and 10 Vdc (Max)1

2–10 Vdc

Electrical

0–10 Volt

ZN551 Control Module • Rev. 3/17/2005 10 © 2005 Automated Logic Corporation

Linear w/Offset,

2–10 Volts

Engineering values

associated with 2 Vdc (Min)

1

and 10 Vdc (Max)

Page 11

Output I/O Type Sensor/Actuator Type Min/Max

Digital (Binary) (BBO)

Resolution values

Relay

1

The Analog Output microblock uses the Min and Max values to linearly translate its

EIKON for WebCTRL wire value into a physical output signal (Volt, mA, or psi) sent from

the ZN551 to an actuator. For example, set Min to 0 and Max to 100 for an Analog

Output microblock that receives a 0 to 100% open signal from a PID microblock and

that controls a 0–10 Vdc actuator so that when the PID signal is 100%, the ZN551

output is 10 Vdc. Similarly, when the PID signal is 50%, the ZN551 output is 5 Vdc.

Resolution is not particular to a type of input or output, but the module

driver handles analog and digital (binary) inputs and outputs differently. To

set these values appropriately, you should understand how the module driver

uses them.

Resolution Notes

Analog Input (BAI)

Analog Output (BAO)

Digital Inputs and

Outputs

Relay/Triac

Output

N/A N/A

The driver truncates the microblock's present value according

to the resolution.

EXAMPLE If the calculated present value is 13.789 and you

set the Resolution to 0.1, the control program uses 13.7 for

any calculations downstream from the microblock.

The driver truncates the wire input value to the microblock

before performing any scaling calculations.

EXAMPLE If the wire input value is 13.789 and you set the

Resolution to 0.1, the microblock uses 13.7 for any scaling

calculations.

N/A

Offset/Polarity values

ZN551 Control Module • Rev. 3/17/2005 11 © 2005 Automated Logic Corporation

Offset/Polarity is not particular to a type of input or output, but the module

driver handles analog and digital (binary) inputs and outputs differently. To

set these values appropriately, you should understand how the module driver

uses them.

Offset/Polarity Notes

Analog Input (BAI)

Analog Output (BAO)

Offset value (positive or negative) adds a fine adjustment to a

sensor reading after all scaling for calibration.

EXAMPLE If a sensor reads 74.9°F when the actual

measured value is 73.6°F, enter an Offset of –1.3 to

calibrate the sensor to the measured value.

You can use the Offset value (positive or negative) to

calibrate an output, but you generally do not need to. If used,

the driver adds the offset value to the wire input value before

performing any scaling calculations to determine the ZN551's

output.

Page 12

Offset/Polarity Notes

Using flow sensors

Digital (Binary) Input

(BBI)

Digital (Binary) Output

(BBO)

In a single duct system, the ZN551 controls airflow in the zone using a USF

flow sensor and an actuator connected to two digital outputs.

In a dual duct system, the ZN551 controls airflow in the zone using a UDF

flow sensor and two actuators, with each actuator connected to two digital

outputs.

Polarity determines the microblock's present value when no

signal is received from the equipment.

When no signal is received from the equipment, if Polarity is

set to:

normal—present value is off

reversed—present value is on

Polarity determines the ZN551's output based on the control

program's signal to the microblock.

When the control program's signal to the microblock is on, if

Polarity is set to:

normal—output is on

reversed—output is off

NOTE Regardless of Polarity, the output will be off if the

ZN551 loses power.

To connect the duct tubes to the flow sensors

To wire the flow sensor to the control module

To set up the Airflow Control microblock

USF

1 Connect the duct’s total pressure tube to the USF's High connector.

2 Connect the duct’s static pressure tube to the USF's Low connector.

UDF

Follow the procedure for a USF, but connect one duct's tubes to the UDF's

Flow #1 connectors and the other duct's tubes to the UDF's Flow #2

connectors.

Use the cable included with the flow sensor (ALC part #235012) or a 20 AWG,

4-conductor cable, maximum length 4 feet (1.22 meters).

1 Turn off the control module's power.

2 Connect the ends of the cable to the 4-pin connector on the flow sensor

and to the 4-pin connector on the control module.

The ZN551's control program must include one Airflow Control microblock

for a single duct system or two of the microblocks for a dual duct system.

You must set up the Airflow Control microblock for each flow sensor.

ZN551 Control Module • Rev. 3/17/2005 12 © 2005 Automated Logic Corporation

Page 13

For a single duct system

1 In WebCTRL, on the control program's Logic page, select the U-Line

Airflow Control microblock.

2 On the Details tab in the Flow Sensor field under Hardware

Configuration, select External flow sensor.

3 In the Input Number field, type 1.

4 In the I/O Type field, select Flow Input.

5 At the bottom of the Details tab, click the plus sign (+) to the left of Flow

Input (AI) Configuration.

6 In the Sensor Type field under Calibration, select No Translation.

For a dual duct system

1 In WebCTRL, on the control program's Logic page, select the Airflow

Control microblock for Flow #1.

2 On the Details tab in the Flow Sensor field under Hardware

Configuration, select External flow sensor.

3 In the Input Number field, type 1.

4 In the I/O Type field, select Flow Input.

5 At the bottom of the Details tab, click the plus sign (+) to the left of Flow

Input (AI) Configuration.

6 In the Sensor Type field under Calibration, select No Translation.

7 On the Logic page, select the airflow control microblock for Flow #2.

8 Repeat steps 2 through 6 for Flow #2, typing 2 in step 3.

NOTE When performing test and balance, follow the steps under Test and

Balance on the Airflow Control microblock's Properties page Details tab in

WebCTRL.

To set up the module driver

After you download the module driver and control program to the ZN551, you

may want to change the module driver's properties to suit your application.

1 On WebCTRL's NET tree, click the plus sign (+) to the left of your ZN551.

NOTE Driver properties are on the Driver Properties page and on its

children in the tree.

2 Click the page you want to view, then change properties as needed.

Driver

On this page, you can change the following properties:

• Module clock synchronization and failure. See table below.

• Network Input microblock communication properties.

ZN551 Control Module • Rev. 3/17/2005 13 © 2005 Automated Logic Corporation

Page 14

Module Clock

Device

Notification Class #1

Clock Fail Date and Time

Time Synch Sensitivity

(seconds)

On this page, you can change the following properties:

• BACnet device object properties for the ZN551

• ZN551 network communication

Configuration

Max Masters and Max Info

Frames

WebCTRL alarms use Notification Class #1. A BACnet alarm's Notification

Class defines:

Date and time control program uses when module's realtime clock is invalid.

TIP Use an occupied date and time (such as a Tuesday

at 10 a.m.) so the equipment does not operate in

unoccupied mode if the module loses power during

occupancy.

On a Time Synch signal, update the module clock only if

the module time differs from the signal time by more

than this value.

NOTE The three APDU fields refer to all networks over

which the ZN551 communicates.

Apply only if the ZN551's parent network is an MS/TP

network.

• Alarm priority for Alarm, Fault, and Return to Normal states

• Options for BACnet alarm acknowledgement

• Where alarms should be sent (recipients)

NOTE You may need to set up additional Notification Classes if your system

will handle Life Safety alarms or if you need to send certain types of alarms

only to an alarm manager other than WebCTRL.

Priorities

Priority of Off-Normal BACnet priority for Alarms.

Priority of Fault BACnet priority for Fault messages.

Priority of Normal BACnet priority for Return-to-normal messages.

NOTE BACnet defines the following Network message

priorities for Alarms and Events.

Priority range Network message priority

00–63 Life Safety

64–127 Critical Equipment

128–191 Urgent

192–255 Normal

ZN551 Control Module • Rev. 3/17/2005 14 © 2005 Automated Logic Corporation

Page 15

Ack Required for Off-Normal,

Fault, and Normal

Recipient List

Recipients

Recipient Description Name that appears in the Recipients table.

Recipient Type

Recipient Device Object

Identifier

Process Identifier

Issue Confirmed

Notifications

Requires a control module acknowledgement for each

message type. Normally not required.

TIP To require operator acknowledgement for an Alarm

or Return-to-normal message (stored in the WebCTRL

database) change the acknowledgement settings on

WebCTRL's Alarm > Enable/Disable tab for an alarm

source or an alarm category.

The first row in this list is the WebCTRL Server. Do not

delete this row. Click Add if you want other BACnet

devices to receive alarms.

Use Address (static binding) only for third-party BACnet

device recipients that do not support dynamic binding.

Type the Device Instance from SiteBuilder (or from the

network administrator for third-party devices) in the #

field.

Change for third-party devices that use a BACnet Process

Identifier other than 1. WebCTRL processes alarms for

any 32-bit Process Identifier.

Select to have a device continue sending an alarm

message until it receives delivery confirmation from the

recipient.

Common Alarms

On these pages, you can change the following control module alarm

properties:

• BACnet alarm object properties

• Enable/disable

• Delays

NOTE To set up alarm actions for control module generated alarms, see

Setting up alarm actions in WebCTRL Help.

Module Generated Alarm

Description

Events

Alarm Category and Alarm

Template

Enable

Notification Class Do not change this field.

Short message shown on WebCTRL's Alarm page or in an

alarm action when this type of alarm is generated.

See Customizing alarms in WebCTRL Help.

Clear these checkboxes to disable Alarm or Return to

normal messages of this type from this control module.

Custom Translation Tables

ZN551 Control Module • Rev. 3/17/2005 15 © 2005 Automated Logic Corporation

On the Custom Translation Table pages, you can edit the tables used to

translate raw sensor data to engineering units for inputs associated with

Non-Linear, Custom Table sensor/actuator types.

Page 16

t

To communicate through the local access port

Using a computer and an APT, you can communicate locally with the ZN551

to download memory or to troubleshoot.

PREREQUISITES

• A computer with an RS232 port

• An APT with cables. See the APT Technical Instructions

(http://info.automatedlogic.com).

1 Connect the computer to the APT, and then the APT to the control

module.

9-pin

APT cable

Connect to the

control module’s

Local Access por

Rnet

adapter

cable

To set up a Local Access connection in WebCTRL

8-pin

APT cable

2 Set the APT's Mode Select switch to 485.

3 Set the APT's Exec. 4 Relay switch to Network.

1 On the CFG tree, select Connections.

2 On the Configure tab, click Add.

3 From the Type drop-down list, select BACnet Local Access.

4 Optional: Edit the Description.

5 Type the computer's Port number where your APT is connected.

6 Set the Baud rate to 115200.

7 Click Accept.

8 On the View tab, click the drop-down arrow next to your device's

network Connection, then select BACnet Local Access.

9 Click Accept.

10 On the Configure tab, select BACnet Local Access, then click Start.

Troubleshooting

If you have problems mounting, wiring, or addressing the ZN551, contact

ALC Technical Support.

ZN551 Control Module • Rev. 3/17/2005 16 © 2005 Automated Logic Corporation

Page 17

Formatting the control module

LED's

If you cannot communicate with a control module after downloading memory

to it, as a last resort, you can manually format the control module to erase its

memory.

1 Pull the screw terminal connector from the control module's power

terminals labeled Gnd and 24 Vac. Make sure the address switches are

not set to 0, 0.

2 Short the Format jumper’s pins.

3 Insert the power screw terminal connector into the ZN551's power

terminals.

4 Continue to short the jumper until the Error LED flashes three times in

sync with the Run LED.

5 Remove the short.

6 Download memory to the ZN551.

The LED's on the ZN551 show the status of certain functions.

If this LED is on... Status is...

Power The ZN551 has power

Rx The ZN551 is receiving data from the network segment

Tx The ZN551 is transmitting data over the network segment

DO# The digital output is active

The Run and Error LED's indicate control module and network status.

If Run LED shows... And Error LED shows... Status is..

2 flashes per second Off Normal

2 flashes per second

2 flashes per second

2 flashes per second

2 flashes per second On

5 flashes per second On

5 flashes per second Off

7 flashes per second

2 flashes,

alternating with Run LED

3 flashes,

then off

4 flashes,

then pause

7 flashes per second,

alternating with Run LED

Five minute auto-restart delay

after system error

Control module has just been

formatted

Two or more devices on this

network have the same

ARC156 network address

Exec halted after frequent

system errors or control

programs halted

Exec start-up aborted, Boot is

running

Firmware transfer in

progress, Boot is running

Ten second recovery period

after brownout

ZN551 Control Module • Rev. 3/17/2005 17 © 2005 Automated Logic Corporation

Page 18

If Run LED shows... And Error LED shows... Status is..

Manufacture date

Compliance

14 flashes per second

When troubleshooting, you may need to know a control module's

manufacture date.

Obtain the manufacture

date from a...

Module status report (modstat) To obtain a modstat in WebCTRL:

Sticker on the back of the

main control module board

14 flashes per second,

alternating with Run LED

Notes

1. Select the control module in the NET tree.

2. Press Ctrl+M.

3. Type modstat.

4. Click OK.

The report shows the date under Main board

hardware.

The first three characters on the sticker show the

control module type. The next three characters

show the year, month, and day of manufacture.

(The month digit is in hexadecimal format.)

Brownout

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

CAUTION Changes or modifications not expressly approved by the

responsible party for compliance could void the user’s authority to operate

the equipment.

ZN551 Control Module • Rev. 3/17/2005 18 © 2005 Automated Logic Corporation

Loading...

Loading...