Page 1

T-Line (TNI v4.7)

Technical Instructions

Contents

Description ................................................................................................... 3

Specifications .............................................................................................. 3

Point Capacity.............................................................................................. 4

Limitations ................................................................................................... 5

T-Line Modules Not For Time Critical Applications............................ 5

Trending................................................................................................. 5

T-Line Mounting........................................................................................... 5

Addressing ................................................................................................... 6

Virtual Modules...................................................................................... 6

Default Algorithm Downloader............................................................. 6

Power and Communication Wiring............................................................. 8

Important Notice................................................................................... 8

Calculating Wire and Transformer Requirements for a

Bus Power Wiring Configuration ................................................... 9

T-Line Module Wiring .......................................................................... 10

Adding T-Line Modules ............................................................................. 14

Hardware Procedure ........................................................................... 14

Software Procedure ............................................................................ 14

Zone Sensor Wiring ................................................................................... 14

Standard Zone Sensor ........................................................................ 14

(Using the Enhanced Zone Sensor Port) ........................................... 14

Enhanced Zone Sensor....................................................................... 14

Using the Enhanced Zone Sensor............................................................ 15

Local Setpoint Adjust ......................................................................... 15

Timed Local Override.......................................................................... 16

Occupancy Indication ......................................................................... 16

Local Access (Optional) ............................................................................ 16

Procedure ............................................................................................ 16

Input Wiring................................................................................................ 17

Table 1: Input Wiring Guidelines....................................................... 17

Procedure ............................................................................................ 17

Custom Translation Tables....................................................................... 18

Procedure ............................................................................................ 18

Channel Numbers ...................................................................................... 20

Table 2: T540 and T320 Module Outputs .......................................... 20

Table 3: T540v and T320v Module Outputs ...................................... 21

Table 4: All T-Line Module Inputs ..................................................... 22

Digital Output Wiring ................................................................................. 23

Connecting the Flow Sensor

(T320V, T540V only) ............................................................................ 23

Calibrating the Flow Sensor ..................................................................... 23

Adjusting the Zero Point..................................................................... 23

Parameter Page.......................................................................................... 24

Applies to models:

T320 T320v T540 T540v

Rev. (29-JUN-99) • TNI v4.7

1

©1995-99 Automated Logic Corporation

Page 2

Status Page ................................................................................................ 24

Adjusting the Flow Sensor Gain ........................................................ 25

Checkout & Troubleshooting.................................................................... 25

Downloading Memory ............................................................................... 25

LEDs ........................................................................................................... 26

LED Power-up Sequence .................................................................... 26

Fuses .......................................................................................................... 26

Production Date ......................................................................................... 27

Using Quick-Disconnects ......................................................................... 27

Crimping & Terminating Quick-Disconnects .................................... 27

Removing Quick-Disconnects............................................................ 28

Rev. (29-JUN-99) • TNI v4.7

2

©1995-99 Automated Logic Corporation

Page 3

Description

Specifications

The T-Line is part of the I/O Hardware family of control

modules and is designed specifically for zone control.

The T-Line consists of the T320, T320v, T540, and

T540v ("v" indicates the board has a flow sensor). A

single main board provides the power circuitry, the

microprocessor, and nonvolatile memory. The name of

the module indicates the number of outputs and inputs

which it provides. The T-Line modules are designed to

be mounted directly on the equipment being controlled,

such as VAV boxes, heat pumps, unit ventilators, and fan

coil units.

Each T-Line module communicates with the CMnet

through a Tnet Interface module (TNI) (see Figure 6).

Each T-Line module can store an optional default

algorithm (see T-Line Default Algorithm Downloader TI

for more information) which maintains the space

temperature in the event that communications is lost with

the TNI module.

Each T-Line module is associated with a single T-Line

Graphic Function Block (GFB) downloaded into the TNI

module. Sample T-Line GFBs are available from the

BBS which can be used as a starting point for

customizing the GFBs for your specific application.

However, before customized FBs can be downloaded,

they must be made in Eikon according to the Zone GFBs

standards. The small percentage of Zone GFBs which

can not be made in Eikon can be reviewed and encrypted

by Dealer Services.

NOTE: To operate this module based on a schedule, it

must be networked with a Gateway module.

Power: 24 VAC ±10%, 50-60 Hz, 2.4 VA (0.10A)

maximum.

Inputs: T320/T320v - (2) Dry contact or thermistor.

T540/T540v - (4) Dry contact or thermistor, two of which

can be configured as 0-5 VDC.

Custom translation tables allow nonstandard signals.

If used, the RSZ+ requires 2 inputs.

Outputs: (T320,T320v = 3; T540, T540v = 5): Digital

outputs, rated 1 Amp @ 24 VAC. See Figure 2 for

allowable configuration.

Flow Sensor: (T320v, T540v only) Range of 0-2" w.c.,

0.003" wc resolution.

Status Indicator: LED indicators for visual status of

receive, transmit/run, and each output.

Communications: EIA-485 port for communicating

on the Tnet.

Memory (T-Line): Non-volatile storage of default

control algorithm.

Memory (TNI): 128k bytes of non-volatile storage

divided into 8 banks of 16k per module (virtual and real).

Protection: Bussed output relays to eliminate phasing

problems, surge protection on network lines and on input

power, arc suppression on relays. (Use the Optional

T-net Protection Board (TNPB) which is available for

additional network surge protection.)

4"

Rev. (29-JUN-99) • TNI v4.7

61/2"

37/8"

Figure 1: T540 Top and Side View Dimensions

3

©1995-99 Automated Logic Corporation

11/2"

Page 4

Fault Detection: Hardware watchdog timer.

Temperature: Operating temperature range is 0-130 °F

(-17.8 to 54.4 °C), non-condensing.

Dimensions: (T320, T540) 4" x 4" x 1 1/2"

(T320V, T540V) 5" x 4" x 1 7/8".

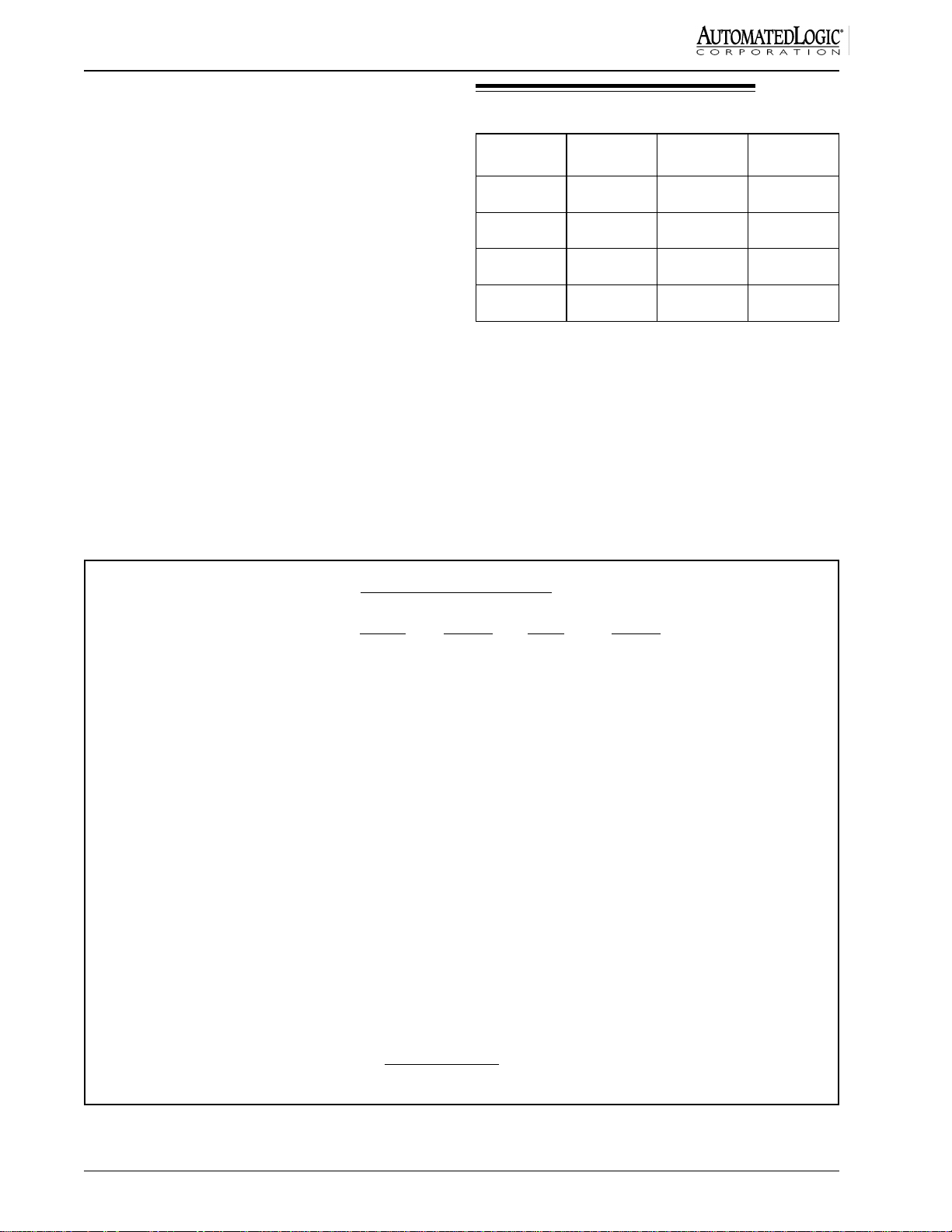

Point Capacity

No. of DO

T320v 3 2 0-2" WC

No. of

AI/DI*

Velocity

Pressure

A/D Input Resolution: 10 bit.

Processor: Microchip PIC16C57, 11.06 MHz, 2k

ROM, 72 bytes RAM.

Listed by: PAZX (UL 916).

Allowable Digital Outputs

T540* T540V* T320 T320V

Start/Stop 1,2,3,4,5 3,4,5 1,2,3 3 only

T320 3 2 --

T540v 5 4 0-2"WC

T540 5 4 --

* Two inputs (the only inputs on the T320 and

T320v) may be accessed through the enhanced

sensor port using an Insulation Displacement

Connector (IDC). If used, the Enhanced Zone

Sensor (RSZ+) will require two of the available

inputs.

Pulse Width

Modulation 1,2,3,4 3,4 1,2,3 3 only

FM Output 1 -

Open 1 3 1 none

Close 2 4 2 none

FM Output 2 -

Open 3 none none none

Close 4 none none none

VAV Flow

Output** -

Open none 1 none 1

Close none 2 none 2

* - Digital output 5 can only be used for start/stop control.

** - Digital outputs 1 and 2 can only be used for VAV Flow control on the

T540v and T320v.

Figure 2: Allowable T-Line Digital Output Configuration

Rev. (29-JUN-99) • TNI v4.7

4

©1995-99 Automated Logic Corporation

Page 5

Limitations

1. No pulse accumulation inputs are allowed on T-Line

FBs, except for the TLO button reserved for the

enhanced zone sensor (RSZ+).

2. The TLO button on the RSZ+ can only be connected

to Universal Input #2 on the T-Line's enhanced zone

sensor port (pin 3).

Trending

Using virtual modules to increase the number of FBs in

the TNI decreases the memory available for trending. If

all 40 FBs are used, only a very limited number of points

can be trended. No enhanced trending capabilities are

available.

3. For T540 and T540V, digital output 5 can only be

used for start/stop control.

4. Digital outputs 1 and 2 can only be used for VAV

Flow Control on the T540v and T320v.

Figure 2 lists the possible output configurations of the

T-Line modules.

T-Line Modules Not For Time Critical

Applications

T-Line modules have been designed to meet low-end,

high-volume terminal control applications. As a result,

time-critical applications (such as short time delays and

trend intervals of less than one minute) should not be used

with these modules. ALC recommends that all time delay

functions and trend intervals on T-Line FBs be set to

greater than or equal to 1 minute.

No pulse accumulation inputs are allowed on T-Line FBs,

except for the TLO button reserved for the ALC enhanced

zone sensor (RSZ+).

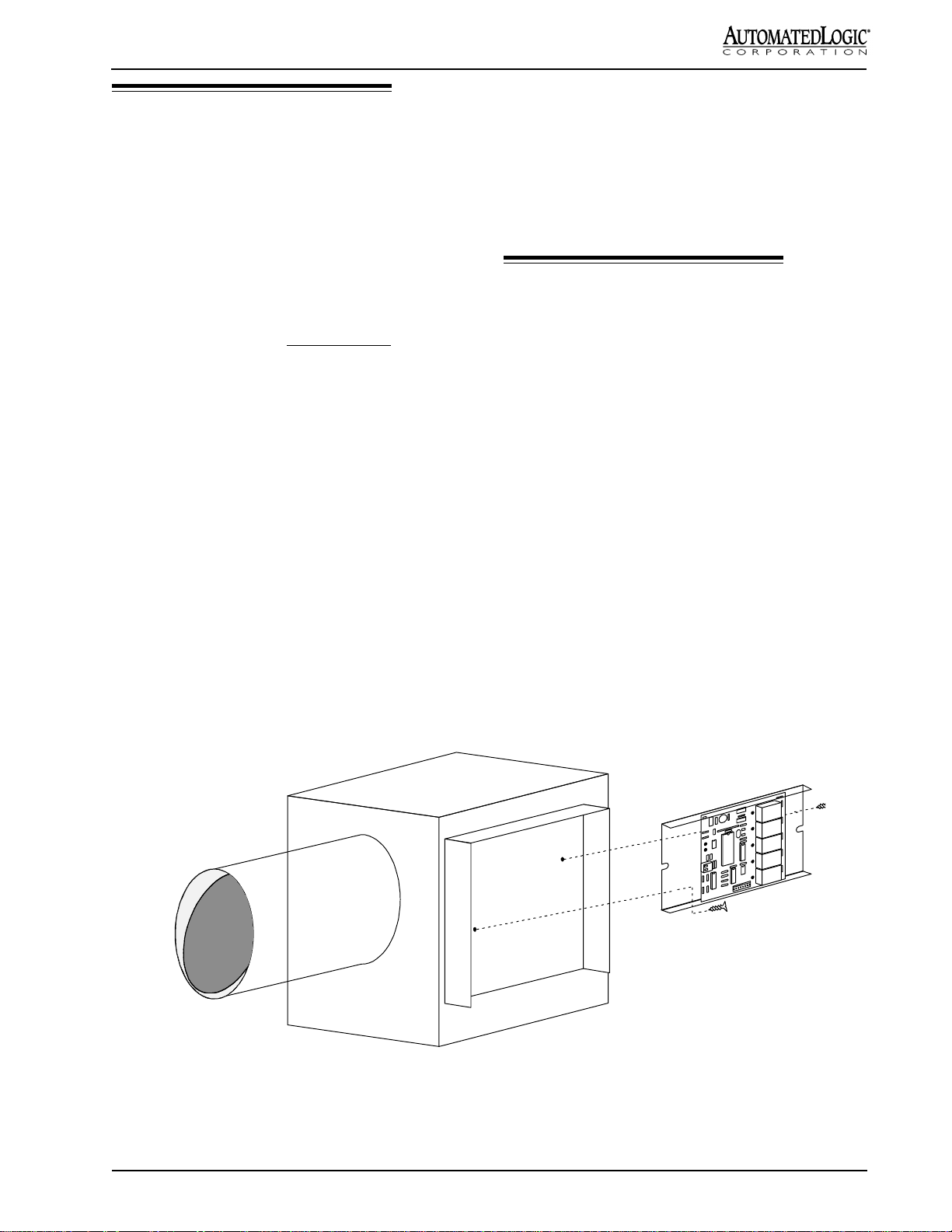

T-Line Mounting

NOTE: Before mounting any T-Line board, make note

of the board's I.D. number. The board I.D. number can be

found on the large 28 pin integrated circuit (I.C.) (see

Figure 5).

1. Remove the T-Line board from the Snap-Track.

2. Position the Snap-Track in a convenient location,

providing at least 1½" clearance on each side for

wiring purposes. Mount by using self-drilling screws

and drill directly into the plastic near the edges of the

Snap-Track so that the screws will be visible when

the T-Line board is installed (see Figure 3). This

prevents loose screws from shorting out the back of

the T-Line Board.

3. Mount the T-Line board on the Snap-Track by

pushing it firmly into the grooves.

Rev. (29-JUN-99) • TNI v4.7

VAV BOX

Figure 3: Mounting a T-Line Module

5

T540 MODULE

©1995-99 Automated Logic Corporation

Page 6

Addressing

T-Line modules are not addressed by dip switches;

instead they are programmed with an I.D. number at the

factory. The board I.D. number can be found on the large

28 pin I.C. Enter this number on the parameter page of

the TNI Function Block (FB #15). See Parameter Page

on page 24.

Virtual Modules

NOTE: The use of virtual modules decreases the

memory available for trending.

use the maximum of 40 GFBs per TNI, the TNI will use

the real module and at least three virtual modules to store

GFBs.

In some cases, a module (real or virtual) will not support

10 GFBs due to the size of the GFBs. For those cases, it

is necessary to add one or more virtual modules and

distribute the GFBs among them. For example, a TNI

may contain 8 modules (1 real and 7 virtual), each

containing 5 GFBs (8 x 5 = 40). Some room should be

left in the physical module's memory for enhancement

and features to be added to the module driver. See the

section "Adding T-Line Modules" for more information

on hardware and software procedures.

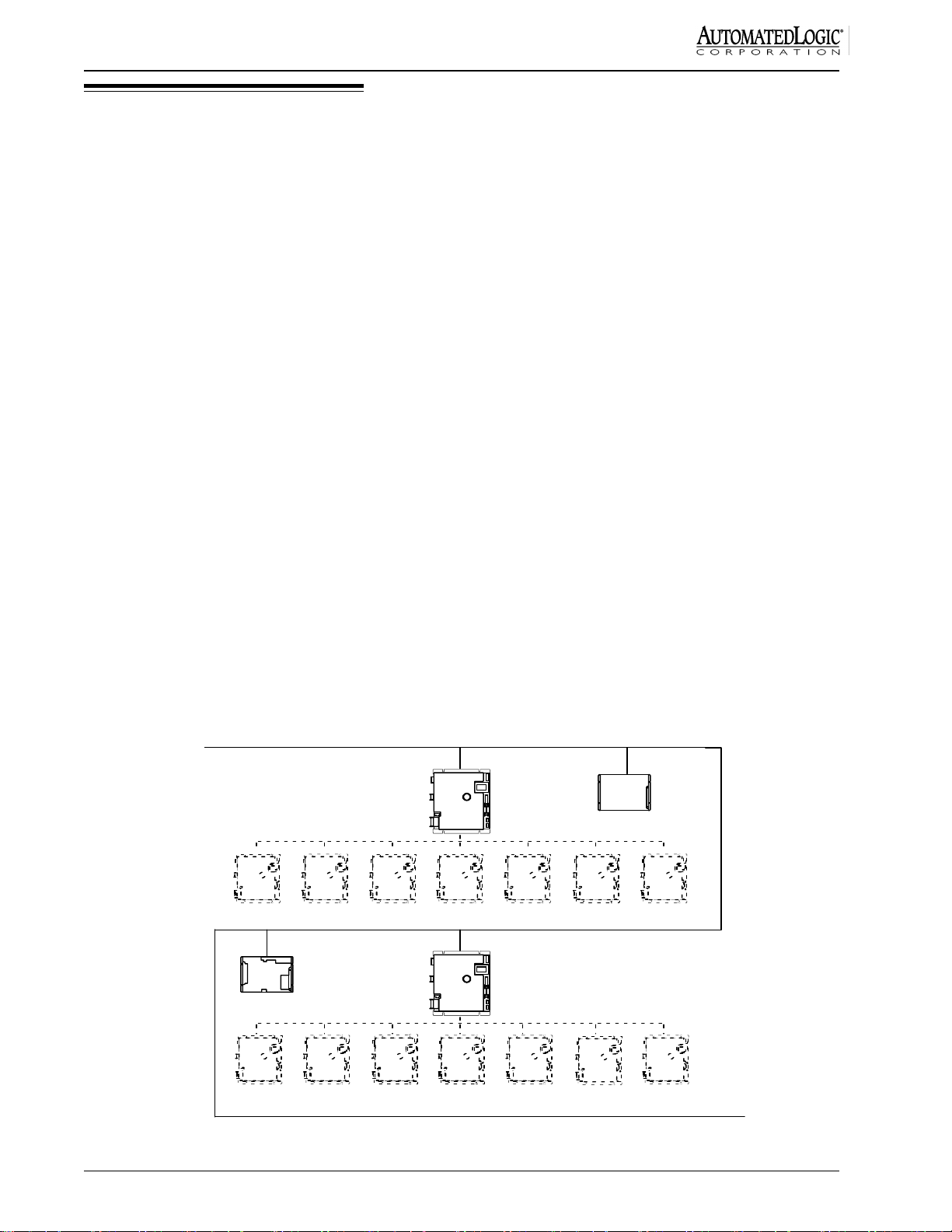

As shown in Figure 4, a TNI has the capability of acting

as one real module and seven virtual modules. This

allows one TNI to have a total of eight addresses either in

sequence or not. Each module (real or virtual) contains

16k bytes of memory. Virtual modules are addressed on

the module driver (FB #15) parameter page. The virtual

module addresses do not have to be contiguous if the TNI

exec is 4.07 or higher. The TNI itself (real module) is

physically addressed using the hardware dip switches.

TNI modules allow for the use of virtual modules in order

to increase the maximum number of GFB's that may exist

in each TNI (see Figure 4). Each TNI virtual module is

an addressable node on the CMnet that may contain up to

10 GFBs (if memory allows) and one module driver (FB

#15) as long as the maximum of 40 GFBs per TNI

module (including virtual modules) is not exceeded. To

CMnet - Maximum 700 GFBs

address = 10

The CMnet can support up to 100 control modules (1 FB

each) and 700 GFBs (not including module drivers) for a

total of 800 FBs.

Default Algorithm Downloader

NOTE: For more information, please reference the

T-Line Default Algorithm Downloader TI (part no.

TITDAD).

Each T-Line module has the capability of storing a

default algorithm which maintains the space temperature

in the event that communications are lost with the TNI

module.

NOTE: Each T-Line FB uses channel 27 to indicate

whether communications are good (DI=ON) or bad

(DI=OFF).

TNI

Real

module

address = 18

G4106e

Virtual

Modules

address = 27

Rev. (29-JUN-99) • TNI v4.7

11 12 13

G4106e

address = 19

2526 23 22

Figure 4: Addressing the TNI

14 15

16

17

TNI

Real

module

Virtual

24

21

Modules

20

CMnet

6

©1995-99 Automated Logic Corporation

Page 7

VAV Flow

Sensor *

Tnet

Universal **

Inputs

Sensor Inputs

Grounds

Tnet

Fuses

Power

Jumper

HI

LO

+

IN1

-

IN2

IN3

24 VDC

GND

1.1

V

18315

IN4

Input Jumpers **

* - Not present on T540 and T320 models

** - Not present on T320v and T320 models

T-card Address

1

2

3

4**

5**

Enhanced Zone Sensor

Port (UI’s 1 & 2)

Output

Bus

Digital

Outputs

TNI

Tnet

TNPB

CMnet

Figure 5: T540v module layout

Maximum 100 Control Modules

R683

Maximum 40T-LineModulesPerTNI

Maximum 20 Modules Before REPOPT

T-Mod

1500 ft. Maximum Length of Tnet Wire

before REPOPT

T-Mod

G8102 Z540v

T-Mo d

RSZ+RSZ+

Maximum 20 Modules

Beyond REP OPT

REPO PT

1500 ft. Maximum Length

of Tnet Wire after REPOPT

(Distance c an be extended

with additional REPOPTs)

TNPB

RSZ+

Rev. (29-JUN-99) • TNI v4.7

Figure 6: Tnet Architecture

7

©1995-99 Automated Logic Corporation

Page 8

The T-Line Default Algorithm Downloader is a

communications program which enables you to download

default algorithms from your computer directly to the

T-Line modules. The computer connects with the T-Line

modules through an Opto Repeater or Tnet Adapter.

Refer to the T-Line Default Algorithm Downloader

Technical Instructions for more details.

Power and Communication Wiring

1. Connect the 24 VAC power wires to a single T-Line

module as described in the following steps.

a. Terminate AC power at the wiring source

(usually a circuit breaker or other AC source).

b. Terminate power to the high voltage side of the

transformer.

c. Remove the T-Line's power jumper (see Figure

5). This prevents the module from being

powered up until proper voltage is verified.

Important Notice

Avoid damaging the T-Line modules

communication circuits.

• IF you have multiple T-Line modules powered

by the same transformer,

OR

• IF you have multiple T-Line modules powered

by separate transformers, but have their grounds

connected (either through wires or through

conduit),

THEN you must observe the same polarity on the

T-Line modules’ AC-power connections.

CAUTION: The T-Line modules are Class 2 devices

(less than 30 VAC). Take appropriate isolation

measures when mounting a T-Line module in a control

panel where Class 1 devices or wiring are present.

NOTE: If wiring the T-modules together in a bus power

configuration (several T-modules sharing a single

transformer as shown in Figure 8), care must be taken in

the wiring and transformer sizing. The average current

value for a T-module is 100 mA (0.1 Amps), but the peak

current value for a T-540v with all outputs on is 670 mA.

Therefore, the wire and transformer must be sized larger

than apparent from the averaged value of the module VA

rating. See Figure 7 on calculating wire and transformer

requirements for a bus power configuration.

NOTE: To protect the Tnet communication wires,

ALC highly recommends installing TNPBs at the

beginning and end of each Tnet leg as shown in Figure

6.

d. Terminate the two power wires to the 24 VDC

and GND terminals indicated in Figure 5. Note

the polarity. See "Using Quick Disconnects"

later in this document for guidelines.

e. Verify that 24 VAC is present at the power input

and replace the power jumper.

2. Connect the Tnet communication wires to the same

T-Line module as described in the following steps.

a. Remove the module's power jumper.

b. Check the Tnet communication wiring for shorts

and grounds.

c. Terminate the Tnet communication wires to the

Tnet screw terminals indicated in Figure 5.

Note the polarity of the Tnet wires coming

from the TNPB.

d. Replace the module's power jumper.

3. Go to the next T-Line module on the Tnet and

connect the AC power wires as in step 1, using the

same polarity as on the first T-Line module. Do not

connect the communication wires yet.

4. To check for proper power polarity, measure the AC

voltage between one of the communication wires and

one of the communication terminals. If the AC

voltage is greater than 5 VAC, reverse the T-Line

module’s power wires and remeasure.

• If the voltage is still greater than 5 VAC, then

check for one of the improper wiring

configurations on page 12. Rewire the T-Line

modules according to one of the figures on

page 10 and remeasure.

NOTE: Whenever possible, terminate and verify power

and communications to all modules before terminating

any inputs or outputs.

BEFORE wiring power or communications to any

T-Line modules on the Tnet, use the following procedure.

Rev. (29-JUN-99) • TNI v4.7

8

©1995-99 Automated Logic Corporation

Page 9

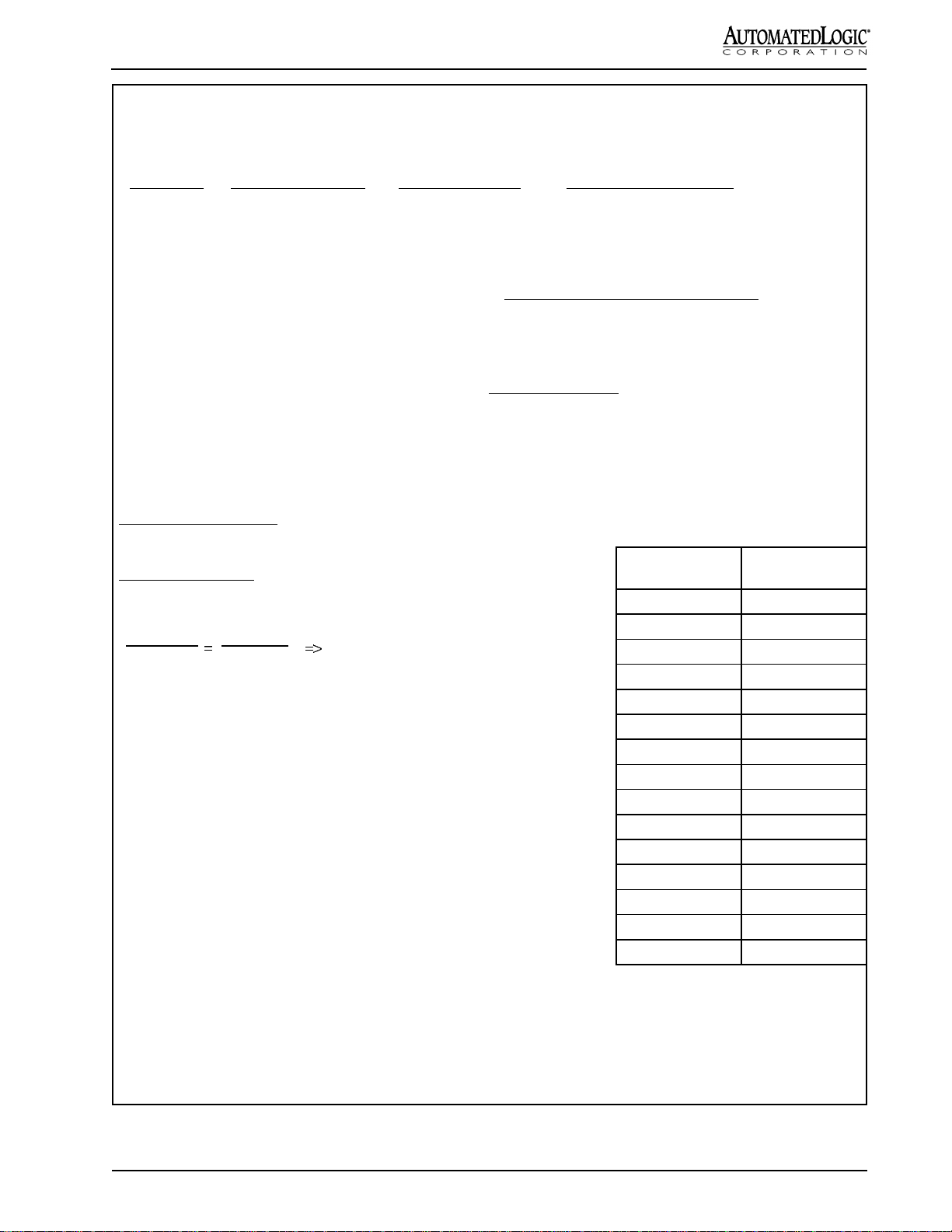

Calculating Wire and Transformer Requirements for a

Bus Power Wiring Configuration

BB

oard Typeoard Type

B

oard Type

BB

oard Typeoard Type

Max. Peak CurrentMax. Peak Current

Max. Peak Current

Max. Peak CurrentMax. Peak Current

Average CurrentAverage Current

Average Current

Average CurrentAverage Current

(Fluke model 77)(Fluke model 77)

(Fluke model 77)

(Fluke model 77)(Fluke model 77)

True RMS CurrentTrue RMS Current

True RMS Current

True RMS CurrentTrue RMS Current

(Beckman model 4410)(Beckman model 4410)

(Beckman model 4410)

(Beckman model 4410)(Beckman model 4410)

T540/T540v 0.670 A 0.176 A 0.117A (all outputs on)

T320/T320v 0.575 A 0.148 A 0.095 A (all outputs on)

To avoid excessive voltage drops, use the following formula (copper wire):

Wire Resistance =

(# of T-modules) * (max. peak current)

5 V drop allowed

Example: Six T540v modules

1.24 Ohms =

5 Volts

6 * 0.670 A

The above formula and resulting values in feet are conservative and do not take into account the decreased current as

the wire pair extends past each module.

From the above Formula:

The total resistance allowed when wiring six T540v modules = 1.24 ohms

From the Wire Table:

12 AWG wire has a resistance of 1.588 ohms per 1000 feet.

1.588 Ohms

1000 ft

1.24 Ohms

X

1.588 X = 1240 => X = 780.85 ft.

Thus, you can use a total of 780 ft. of 12 AWG wire to

connect the six T540v modules. This means that you can

run a pair of wires to the modules a distance of 390 ft.,

after that distance you will need to add another

transformer.

The sizing of the transformer should be adjusted to

compensate for the non-sinusoidal waveshape of the

current requirements. The VA rating of the T-module

should be multiplied by three (3) when computing

multiple T-modules being supplied by one transformer.

Example: Six T540 modules

(6 modules) ∗ (2.4 VA per module ∗ 3) = 43 VA

Gauge No. (AWG)

Wire Table

Ohms per 1000 ft

at 20 C (= 68 F)

10 0.9989

11 1.260

12 1.588

13 2.003

14 2.525

15 3.184

16 4.016

17 5.064

18 6.385

19 8.051

20 10.15

21 12.80

22 16.14

23 20.36

24 25.67

(A 40 VA transformer would be reasonable since all

outputs would not be on simultaneously.)

Figure 7: Calculating Wire and Transformer Requirements for a Bus Power Configuration

Rev. (29-JUN-99) • TNI v4.7

NOTE: Resistances shown in the table above are for

solid wire only. If you are using stranded wire, refer to

the wire manufacturer’s specifications to determine the

proper resistances.

9

©1995-99 Automated Logic Corporation

Page 10

PR I

SEC

24VAC

T-Line Module Wiring

RIGHT

POLARITY IS

IMPORTANT

EQUIPMENT

GROUND

BONDED TO

EARTH

GROUND

T-modT-mod

ISOLAT ED

LOAD

COM M LINE

TW ISTE D PAIR

(POLARITY IS IMPORTANT)

ISO L A T E D

LOA D

Figure 8: Multiple T-Line modules powered by the same transformer, grounded to Earth Ground

PRI

SEC

24VAC

EQUIPMENT

GRO U ND

BONDED TO

EAR T H

GRO U ND

IS O LA T ED

LOA D

COMM LINE

TWISTED PAIR

PRI

SEC

24V AC

T-modT-mod

(POLA R I TY IS IM P OR TA NT)

ISO LAT E D

LOAD

Figure 9: Multiple T-Line modules powered by separate transformers

PRI

SEC

24V AC

PRI

SEC

24VA C

T-mod T-m od

EQUIPMENT

GROUND

BONDED TO

EARTH

GROUND

IS OLATED

LOA D

COMM LINE

TW ISTED PAIR

(POLARITY IS IMPORTANT)

EQUIPMENT

GROUND

BONDED TO

EARTH

GROUND

ISO LA T ED

LOAD

Figure 10: Multiple T-Line modules powered by separate transformers, each grounded to Earth Ground

Rev. (29-JUN-99) • TNI v4.7

10

©1995-99 Automated Logic Corporation

Page 11

(

)

TNI

24 VAC

GND

+

NET

-

GND

T-net Protection Board

TNPB

+

NET

T-Board

24 VAC

OUT

Bussed

GND

Power

24 VAC 2 4 VAC

T-net

Load

Independent Power Supplies Common Power Supply

(Preferred Method)

Figure 11: T-Line modules powered by separate transformers

(loads have both separate and common power supplies)

24 VAC

T-Board

24 VA C

GND

-+

NET

OUT

Bussed

Power

Join wires close

to transf ormer.

TNPB

GND

Load

24 VAC

GND

24 VAC

TNI

+

NET

-

TNPB

GND

T-net Protection Board

-

NET

T-Board

24 VAC

GND

+

Bussed

Power

T-net

OUT

Load

24 VAC

Independent Power Supply

for load circuits.

Preferred Method

Figure 12: T-Line modules powered by the same transformer

(loads have both separate and common power supplies)

-

+

T-Board

24 VAC

GND

NET

OUT

Bussed

Power

Load

TNPB

GND

Common Power Supply

for load circuits and modules.

Rev. (29-JUN-99) • TNI v4.7

11

©1995-99 Automated Logic Corporation

Page 12

PRI

SEC

24VAC

Wrong

WIRE

POLARITY IS

REVERSED

EARTH

GROUND

T-mod

ISOLA T E D

LOAD

T-mod

ISOLAT ED

LOAD

COMM LINE

TW IST ED P AIR

Figure 13: Multiple T-Line modules powered by the same transformer, but with polarity reversed

PRI

SEC

24V A C

LO AD

COMM LIN E

TWISTED PAIR

PRI

SEC

24VA C

T-modT-mod

LOAD

CHASSIS

GROUN D

G R E A T E R T H A N

7 V D IF FE R E N C E

CH AS SIS

GROUN D

Figure 14: Multiple T-Line modules powered by separate transformers, grounded to Chassis Ground

PRI

SEC

24 VAC

EARTH

GROUND

IS OLATED

LOAD

GROUND POLARITY

REVERSED

COMM LINE

TWISTED PAIR

PRI

SEC

24V AC

EARTH

GROUND

T-modT-m od

IS OLATED

LOAD

Figure 15: Multiple T-Line modules powered by separate transformers, each grounded to

Earth Ground from opposite poles

Rev. (29-JUN-99) • TNI v4.7

12

©1995-99 Automated Logic Corporation

Page 13

T-net Topologies

MAX = 20 T-Boards

TNI

TNI

TNI

TNPB

TNPB

TNPB

T

TT

T

TT

T

TT

MAX = 20 T-Boards

T

TT

T

T

T

T

T

T

T

T

T

TNPB

TNPB

REPOPTO

TNPB

MAX = 20 Boards

MAX = 20 T-Boards

T

T

TT

TNPB

T

MAX = 20 T-Boards

TNI

TNPB

T

REPOPTO

T

TT

T

TT

MAX = 20 T-Boards

T

T

TNPB

T

T

T

TNPB

T

Figure 16: Possible T-net Topologies

• If the voltage is still greater than 5 VAC, contact ALC Technical Support.

5. Connect the Tnet communication wires to the T-Line module using the same polarity as on the first T-Line module.

Repeat steps 3 through 5.

NOTE: If the T-modules are models that have resistors on the CMnet terminals instead of fuses and if more than 20

Rev. (29-JUN-99) • TNI v4.7

13

©1995-99 Automated Logic Corporation

Page 14

T-modules are used on a T-net, then an Opto Repeater

(part no. REPOPT) must be inserted into the T-net after

the first 20 modules (see Fig. 6). A maximum of 40

modules may be on a T-net with the use of an Opto

Repeater.

Zone Sensor Wiring

CAUTION: Because the standard zone sensor inputs

are not surge protected, they should only be used for

thermistors or the enhanced zone sensor. Any other

use could result in damage to the hardware.

Adding T-Line Modules

Hardware Procedure

1. Add the new T-Line module(s) to the existing T-net

(see the section "Power and Communications

Wiring" for more details).

2. Enter the I.D. number for the new module on the

parameter page of the TNI module driver (FB #15).

Refer to the section on Addressing for more

information.

3. Use one of the two methods described below to make

the TNI recognize the new T-Line module(s). Either

method is sufficient.

Software Method -- Zap the TNI as follows:

a. Go to the Modstat page for the TNI.

b. Press [Esc] to get a pop-up menu.

c. Type in ZAP.

Hardware Method -- Turn the TNI module's power

off then back on.

Standard Zone Sensor

(Using the Enhanced Zone Sensor Port)

1. Remove the module's power jumper.

2. For input 1 (UI 1), connect the zone sensor wires to

pins 1 and 2 on the 8-pin receptacle on the T-Line

module (see Figure 17).

3. Replace the power jumper.

4. Input the channel number, offset, and gain on the

Figure 17: Standard Zone Sensor connections

Software Procedure

1. Run FBfit to determine if the new T-Line FB will fit

with the other T-Line FBs into an existing real or

virtual module (16 kB).

2. If it fits, add the FB to config.txt, compile, and

download memory to the real or virtual TNI modules

to which the FB is being added.

3. If it doesn't fit, add a new virtual module and the FB

to config.txt, enter the new virtual module address on

the real TNI module driver parameter page, and

download parameters to the real TNI and download

memory to the new virtual module (see the section

"Downloading Memory" for more details).

Rev. (29-JUN-99) • TNI v4.7

T-Line zone FB parameter page (UI 1 uses channel

number 31 and UI 2 uses channel number 32).

5. If using input 2 (UI 2) on the Enhanced Zone Sensor

Port, repeat steps 1-4, connecting the sensor between

pins 1 and 3 on the 8-pin connector on the T-Line

module see Figure 17.

NOTE: When making a sensor cable, disregard the

numbers imprinted on the plastic connector.

Enhanced Zone Sensor

1. Remove the module's power jumper.

2. Plug the Amp 8-pin connector to the 8-pin receptacle.

If you are constructing your own cable, use the

crimper shown in Figure 20. Refer to Figure 18 for

the cable wiring configuration. Use 22 AWG wire.

14

©1995-99 Automated Logic Corporation

Page 15

T-LINE

TERM

1

2

4

5

6

7

8

WIRE

COLOR

BLACK

BROWN

RED

ORANGE

YELLOW

GREEN

BLUE

WHITE

FUNCTION

GND

THERMISTOR

SW IT C H INPU T

RSZ+ LED

NOT USED *

NOT USED **

5V+, LED Power

NOT USED

RSZ+

J1

87654321

T-Line Module

12345678

SENSOR

TERM

1

2

33

4

5

6

7

8

*

If Local Access is d esired, this

wire w ill b e + c o mm .

If Local Access is d esired, this

**

wire w ill b e - co m m .

Figure 18: Enhanced Zone Sensor Wiring Configuration

NOTE: If local access is desired (see "Local

Access" section), leave the yellow and green wires

(pins 5 and 6) unconnected at the T-Line module.

These will be connected to the CMnet.

3. Replace the power jumper.

4. Enter the channel number, offset, and gain on the

T-Line FB parameter page as listed in the "Channel

Number" section.

ALC part no. CON is a package of 8-wire connectors and

covers (AMP part nos. 641237-8 and 640550-8) which

require a 22 AWG stranded wire. Other connectors are

available by calling your local Amp distributor at 800526-5142. The cable wiring configuration is shown

above. The cable should not exceed 50 ft.

NOTE: When making a sensor cable, disregard the

numbers imprinted on the plastic connector.

Using the Enhanced Zone Sensor

REMOTE

TERMINAL

CONNECTOR

LOCAL

SETPOINT

ADJUST

COOLER

GND

(pin 1)

+5 V

(pin 3)

J2

D1

J1

87654321

R3

SW1 SW2

NORMAL

SETPOINT

WARMER

TLO COOLER WARMER

OCCUPIED

INDICATOR

SENSING

ELEMENT

TIMED

LOCAL

OVERRIDE

22k Ohm10k Ohm

Figure 19: Enhanced Zone Sensor Functions

WIRE

Shown in Figure 19, the enhanced zone sensor provides

local setpoint adjust, timed local override, and occupancy

indication.

Local Setpoint Adjust

Use the sensor's left switch to adjust the occupied

setpoints. When this switch is placed in the middle

position, the setpoints specified on the T-Line FB

parameter page are in effect. The switch's left position

lowers the setpoints by an amount specified on the

parameter page (default is 3 degrees). The switch's right

position raises the setpoints by the same amount.

Rev. (29-JUN-99) • TNI v4.7

FEED

SLIDE

A

CAM

HANDLE

M

P

Figure 20: AMP Crimper (ALC part no. CRIMP)

15

©1995-99 Automated Logic Corporation

Page 16

CMnet

G4106e

G8102

Z540v

Opto R epeater

Tnet

TNI

T-Mod

RSZ+

Figure 21: Local Access Wiring

Timed Local Override

Use the sensor's right switch to activate the zone override.

The switch is spring loaded and always returns to the

right position. This switch has no effect when the zone is

scheduled occupied. When the zone is scheduled

unoccupied, toggling the switch causes the zone to

become occupied. The amount of override time is equal

to the number of times the override switch is toggled

multiplied by the "override increment per toggle"

parameter as defined on the parameter page. For

example, if the increment is set at 60, toggle the switch

once for an occupancy of 60 minutes, twice for 120

minutes, etc. Once the zone is occupied from this switch,

pressing it again and holding it in the left position for the

reset interval (three seconds default) causes the zone to

become unoccupied.

Occupancy Indication

The LED on top of the sensor lights up whenever the

zone is occupied, whether from a regular schedule, the

action of the Local Override Switch, or a telephone

override.

NOTE: Pins 4 and 7 must be connected to utilize the

occupancy indicator.

CMnet

T-Mod

RSZ+

Dedicated

to T - L in e

TNPBTNPB

J3

NI485N Cable

Yellow (5) to CMnet +

Green (6) to CMnet -

T-Line M odule

12345678

Yellow

CMnet

+

_

Green

To RSZ+

Figure 22: Local Access Wiring to RSZ+

access the T-Line modules locally through the CMnet

connections provided by ALC's RSZ+.

ALC part no. CON is a package of 8-wire connectors and

covers (AMP part nos. 641237-8 and 640550-8) which

require 22 AWG standard wire. Other connectors are

available by calling your local AMP distributor at 800526-5142. The cable wiring configuration is show in

Figure 18. The cable should not exceed 50 ft.

NOTE: When making a sensor cable disregard the

numbers imprinted on the plastic connector.

Procedure

Local Access (Optional)

The T-Line modules are not equipped with direct access

ports. This means that troubleshooting the modules can

be difficult for one person since the controlling TNI may

not be located near the T-Line module undergoing

maintenance. Using this procedure, it is possible to

Rev. (29-JUN-99) • TNI v4.7

1. Pull CMnet cable to each T-Line module at the same

time the Tnet communications cable is run (see

Figure 21).

NOTE: It is very important to isolate the CMnet cable

from the T-Line modules with an Opto Repeater at the

TNI (see Figure 21). Otherwise a shorted sensor could

crash the entire CMnet.

16

©1995-99 Automated Logic Corporation

Page 17

Input Signal

0-5 VDC

V+

Dry Con tact

OUT

PWR

GND.

.

(ALC part no . RSZ)

Jumper ON = Digital / Thermistor

Jumper OFF = 0 - 5 VDC

Thermistor

+

Gnd

IN3 or IN4

Jumper OFF

IN3 or IN4

Jumper ON

IN3 or IN4

Jumper ON

Figure 23: Input connections and jumpers for Modules T540 and T540v (bottom)

+-

+-

+-

+-

IN3

IN4

In3

Therm/Volt

IN3

IN4

Groun d

Jumpers

T540 module

In4

Jumpers

In3

In4

Therm/Volt

T540v module

2. Check the CMnet wires for shorts and grounds.

3. Remove the module's power jumper.

4. Terminate the CMnet wires to the yellow and green

wires of the sensor cable (pins 5 and 6) at the T-Line

module as shown in Figure 22. Observe the proper

polarity.

5. Insert the module's power jumper. The CMnet may

now be accessed at the Enhanced Zone Sensor using

its Remote Terminal Connector port.

NOTE: This method bypasses the priority arbitration

provided by the gateway module (GCM2 or the

LANgate). To avoid potential communication errors,

make sure that no one attempts to communicate with the

system at the same time this method is used.

Input Wiring

The T-Line's inputs may accept dry contact, thermistor, or

0-5 VDC signals (see Figure 23 for jumper settings). For

non-standard inputs, refer to section "Custom Translation

Tables."

One input is dedicated to measuring space temperature. A

second input is used for either the Enhanced Zone

sensor's local setpoint adjust/TLO switch, or a general

purpose 10k Ohm thermistor/dry contact input. Inputs 3

and 4 of the T540 and T540v modules are jumper

selectable for either 0-5 VDC (with a sensor output

impedance of 10k Ohm or less), or 10k Ohm thermistor/

dry contact (see Figure 23). Note that the enhanced zone

sensor, if used, requires two of the T-Line's inputs.

Some current switches that are not true contact closures

may not go to zero Ohms when the switch is closed. Any

switch which has more than 412 Ohms effective

resistance (0.2 V) when closed must have an interposing

relay when used with T-Line modules.

NOTE: The output impedance of any 0-5 VDC source

should not exceed 10k Ohms.

Table 1: Input Wiring Guidelines

Type Input

0-5 VDC 50

Thermistor/Dry

Contact

Enhanced Zone

Sensor

Max Length

(feet)

50

50

Gauge Wire

(AWG)

24

(minimum)

24

(minimum)

24

(minimum)

Shielding

shielded

(grounded to Gnd

terminal)

shielded

(grounded to Gnd

terminal)

unshielded

Procedure

1. Remove the T-Line's power jumper.

2. Check the sensor wiring for shorts and grounds.

3. Terminate the sensor wires to the Input and GND

terminals as shown in Figure 23. See "Using Quick

Disconnects" for guidelines.

4. Select the proper jumper settings for inputs 3 and 4

(modules T540 and T540v only).

5. Replace the T-Line's power jumper.

Rev. (29-JUN-99) • TNI v4.7

17

©1995-99 Automated Logic Corporation

Page 18

6. Verify the input by measuring the voltage between

the GND terminal of the analog input and the

positive terminal. The input voltage for thermistors

should be between 0 and 5 V.

7. Enter the channel number, offset, and gain on the

T-Line zone FB parameter page as listed in the

"Channel Number" section.

Custom Translation Tables

In addition to the inputs already mentioned, it is possible

to create custom translation tables for non-standard

thermistor or slidepot inputs. Provided on the parameter

page of the TNI module driver are two user-definable

tables for translating these inputs.

The following are typical applications for the custom

translation tables:

• Thermistors other than Type 2 (such as Type 3).

• Slide potentiometer inputs.

• Non-linear voltage inputs (0-5 VDC maximum

range).

These tables use a 10 point linear translation method to

approximate a non-linear curve of resistance or voltage to

the desired units.

Procedure

Input Ohms Input Value

0 x 10 Ohms = 300

230 x 10 Ohms = 150

405 x 10 Ohms = 120

752 x 10 Ohms = 90

935 x 10 Ohms = 80

1172 x 10 Ohms = 70

1478 x 10 Ohms = 60

1879 x 10 Ohms = 50

2406 x 10 Ohms = 40

7032 x 10 Ohms = 0

32767 x 10 Ohms = -60.8

Figure 24: Example Custom Table for a Precon Type 3

Thermistor Sensor

4. Determine the resistance or voltage at the desired

settings. This information may be obtained either

from manufacturer reference tables or through

testing.

5. Select a custom translation table that is not currently

in use. Record the custom gain from this table for

use when defining inputs which will use the custom

translation table in the module.

6. Enter the scaled voltage or resistance input on the

left and then enter the corresponding value on the

right (see Figures 24 and 25 for examples).

1. Display the TNI module driver parameter page

(FB #15).

2. For thermistor, slidepot, and other resistance inputs

set the option "Is input specified in voltage?" to NO.

For voltage inputs, set the option to YES.

3. Determine the accuracy and range needed. Note the

following:

• Values which lie between two defined entries are

interpolated linearly by the FB.

• The first and last entries of the resistance table

should always be set to zero and infinity (32767

x 10 represents infinity) in the event that the

sensor should short or open. In the case of

voltage inputs, the first and last input voltages

should be set to zero and 5 V. These are the

default values.

The resistance values of the slidepot in Figure 25

(left column) were obtained by measuring the

Input Ohms Input Value

0 x 10 Ohms = -1.00

474 x 10 Ohms = -1.00

607 x 10 Ohms = -0.75

910 x 10 Ohms = -0.50

1210 x 10 Ohms = -0.25

1540 x 10 Ohms = 0.00

1860 x 10 Ohms = 0.25

2150 x 10 Ohms = 0.50

2360 x 10 Ohms = 0.75

2400 x 10 Ohms = 1.00

32767 x 10 Ohms = 1.00

Figure 25: Example Custom Table for a Sample

Slidepot Installed in Place of RSZ+

(Tested Resistance Entered on the Left)

Rev. (29-JUN-99) • TNI v4.7

18

©1995-99 Automated Logic Corporation

Page 19

resistance of the positions of the slidepot in 1/8

increments (far left, 1/8, 1/4, 3/8... far right).

Note that the slidepot input values (see Figure 25,

right column) are defined with a setpoint-bias rather

than absolute temperatures. These input values are

multiplied by the "Enhanced Sensor: Setpoint Input

Bias" parameter (see Figure 31) as the slidepot is

adjusted (see Note #3 below) and then added to the

zone setpoint. This method allows you to globally

modify the above parameter for all T-Line function

blocks in the TNI module instead of changing the

lookup table parameters for each zone.

7. Download parameters to this FB.

8. To activate these tables enter the gain of the

translation table used (either 15.00 or 15.06) on the

T-Line FB parameter pages that contain the input for

which the table applies. Set the offset to 0.00.

NOTES:

1. The minimum resistance for the slide pot can not go

below 4.7k Ohms. If the resistance does go below

4.7k Ohms, insert a 4.7k Ohm resistor in series with

the slide pot. A zero Ohm reading may simulate a

TLO pulse to the module in cases where a TLO

momentary contact may be in parallel with the

slidepot.

2. The lowest resistance range allowed on a slidepot

input is 5k Ohms. This guarantees that sufficient

resistance exists between steps to allow for good

linear approximation.

3. To be able to set the "Enhanced Sensor: Setpoint

Input Bias" parameter for slidepots, the slidepot must

be connected to input 2 (pins 3 and 1 in place of the

RSZ+).

TO 24 VAC TERMINAL

TO GND TERMINAL

24 V a c

GN

D

* - Not present on T320 and T320v models

Figure 26: Output Terminations

TO CIRCUIT BREAKER

PRIMARY

(PRI)

SECONDARY

24VAC

(SEC)

DO

*

DO

*

Rev. (29-JUN-99) • TNI v4.7

19

©1995-99 Automated Logic Corporation

Page 20

Channel Numbers

Table 2: T540 and T320 Module Outputs

IMPORTANT NOTE: This table is only for modules WITHOUT flow sensors. See table 3 for

modules with flow sensors.

I/O Type

Sig nal

Type

Outputs

Used

Channel

Number

Start/St op DO #1 Digital 1 11

Sta rt/St op DO # 2 Digital 2 12

Sta rt/St op DO # 3 Digital 3 13

Start /Stop DO #4 * Digit al 4 14

Start/Sto p DO # 5 * Digit al 5 15

Floating Mo tor AO #1 Analog

Floating Motor AO #2 * Analog

1 (Open)

2 (Close)

3 (Open)

4 (Close)

11 ( Open)

12 (Close)

13 ( Open)

14 (Close)

Pulse W idt h AO #1 An alog 1 11

Pulse W idt h AO #2 An alog 2 12

Range Offset Gain

-

-

-

-

-

-

-

-

-

--

--

--

--

--

--

--

--

--

Pulse W idt h AO #3 An alog 3 13

Puls e W i dth AO #4 * Analo g 4 14

Oc c upied Light † Digital N one 16

* T540 module only

† Required if Enhanced Zone Sensor (RSZ+) is used

Rev. (29-JUN-99) • TNI v4.7

20

-

-

-

©1995-99 Automated Logic Corporation

--

--

--

Page 21

Table 3: T540v and T320v Module Outputs

IMPORTANT NOTE: This table is only for modules WITH flow sensors. See table 2 for

modules without flow sensors.

Signal

Notes

1 Start/Stop DO #2 Digital 4 14 - - -

1 Start/Stop DO #3 Digital 5 15 - - -

1

1

I/O Type

Start/Stop DO #1 Digital 3 13 - - -

Floating Motor

AO #1

Pulse Width

AO #1

Pulse Width

AO #2

VAV Flow

Damper AO

(VP STPT on

Par Page)

Type

Analog

Analog 3 13 - - -

Analog 4 14 - - -

Analog

Outputs

Used

3 (Open) 13 (Open) - - -

4 (Close) 14 (Close) - - -

1 (Open)

2 (Close)

Channel

Number

41

Range Offset Gain

0-200

(0-2" WC)

0.00 1.00

VAV Flow

3

2 Occupied Light Digital None 16 - - -

Note 1: T540v module only

Note 2: Required if Enhanced Sensor (RSZ+) is used

Note 3: Required if VAV Flow Damper AO defined

Rev. (29-JUN-99) • TNI v4.7

Deadband

(VP DBND on

Par Page)

Analog None 42

21

0-200

(0-2" WC)

©1995-99 Automated Logic Corporation

0.00 1.00

Page 22

Table 4: All T-Line Module Inputs

Notes

3, 5, 6 Analog Input #1 Thermistor 1 31

3, 6 Analog Input #2 Thermistor 2 32

1, 6 Analog Input #3 Thermistor 3 33

1, 6 Analog Input #4 Thermistor 4 34

1 Analog Input #3 0 - 5 VDC 3 33 * * *

1 Analog Input #4 0 - 5 VDC 4 34 * * *

2

3 Digital Input #1 Digital 1 21 - - -

I/O Type

Flow Input

(VP ACTL on

Par Page)

Signal

Type

Input

Used

Flow

Sensor

Channel

Number

35

Range Offset Gain

-17 - 213 F 0.00 15.88

-27 - 100.6 C 0.00 15.69

-17 - 213 F 0.00 15.88

-27 - 100.6 C 0.00 15.69

-17 - 213 F 0.00 15.88

-27 - 100.6 C 0.00 15.69

-17 - 213 F 0.00 15.88

-27 - 100.6 C 0.00 15.69

0-200

(0-2" WC)

0.00 1.00

3 Digital Input #2 Digital 2 22 - - 1 Digital Input #3 Digital 3 23 - - 1 Digital Input #4 Digital 4 24 - - 4 T-Net Comm Digital None 27 - - -

* Depends on sensor used

Enhanced Sensor Inputs (All are required if an Enhanced Sensor is used)

-17 - 213 F 0.00 15.88

5, 6 Zone Temp Thermistor 1 31

-27 - 100.6 C 0.00 15.69

Setpoint Adjust 3-position 2 32 -1,0,1 0.00 15.94

Timed Local

Override

Note 1: T540 and T540v module only

Note 2: T540v and T320v module only

Note 3: On Enhanced Sensor port

Note 4: Required for all T-Line FBs, DI turns OFF when T-Line modules are not communicating

Digital 2 22 - - -

Note 5: Channel must be defined for all T-Line FBs

Note 6: Degrees Celsius can only be displayed in SVW 1.1 or later when the GFB is made in

Eikon 2.0 or later with the "METRIC=TRUE" command set in the alc.ini file

Rev. (29-JUN-99) • TNI v4.7

22

©1995-99 Automated Logic Corporation

Page 23

Digital Output Wiring

1. Remove the T-Line's power jumper.

2. Terminate the output wires to the output terminals

indicated in Figure 26. See "Using Quick

Disconnects" section for guidelines.

5. Input the channel number, offset, and gain on the

Function block Parameter page as listed in the section

"Channel Numbers."

Calibrating the Flow Sensor

3. Replace the T-Line's power jumper.

Connecting the Flow Sensor

(T320V, T540V only)

1. Remove the T-Line's power jumper.

2. Install an air filter on the duct's total (high) pressure

line.

TOTAL

PRESSURE

STATIC

PRESSURE

HI

LO

+

-

Some field adjustment of parameters may be necessary in

order for the flow readings on the T-Line VAV Control

FB to match the reading obtained during the test and

balance procedure. The calibration process consists of

two phases: (1) adjusting the flow sensor zero point, and

(2) adjusting the flow sensor gain.

This process may be conducted at the RSZ+ if the

procedure described in the "Local Access" section was

followed.

Adjusting the Zero Point

Use the following procedures to adjust the flow sensor's

zero point.

1. Turn off the AHU serving the VAV box to be

calibrated.

2. Select the TNI module driver (FB#15) for the module

to be calibrated.

3. Display the status page.

4. Note the FB's Current Value(s) and 0.00 Value(s)

from the Calibration Table (See Figure 29).

Figure 27: Flow Sensor connections

3. Connect the flow sensor by attaching the positive

total pressure line to the transducer's HI side and

attaching the static pressure line to the transducer's

LO side (see Figure 27).

NOTE When connecting tubing to the sensor ports,

grasp the housing between your thumb and forefinger so

that the port designation is covered and the port is

supported. Ease the tubing onto the port. Do not expose

the port to forces greater than 5 pounds in a direction

perpendicular to the port centerline. Thin-walled 1/4"

Tygon or equivalent tubing is recommended.

4. Replace the T-Line's power jumper.

Rev. (29-JUN-99) • TNI v4.7

5. Display the parameters page.

6. Note the Flow Zero Offsets line from the parameters

page (See Figure 28).

7. Calculate the Offsets for each FB as follows:

• FB# Flow Zero Offset = 0.00 Value - Current

Value

Example for determining the FB# Offset:

FB#1's 0.00 Value = 130

FB#1's Current Value = 128

FB#1's Flow Zero Offset = 130-128 = 2

8. Enter the calculated FB#(s)'s Flow Zero Offset in the

appropriate FB# on the parameter page (See Figure

27).

Continued on page 25...

23

©1995-99 Automated Logic Corporation

Page 24

Parameter Page Status Page

Function Block Type: TNI (T-Net Interface Module

Driver)

Name CM 14 User Defined Line 1 GCM 1

CM 14 FB 15 Flags —

ID ID26 Tele NB All

Options Y Type 32 Ver 1

Alarms Enabled -X——— Text 0 56 57 58 0

0 0 0

Messages Enabled ——X— Text 0 0 0 0 0

4 0 0

Enter T-card ID numbers for each FB:

FB 1-0 2-0 3-0 4-0 5-0

FB 6-0 7-0 8-0 9-0 10-0

Virtual module addresses are 0 0 0 0 0

0 0 (0=not used)

Flow Zero Offsets

FB 1-0 2-0 3-0 4-0 5-0

FB 6-0 7-0 8-0 9-0 10-0

This is the translation table for the custom

gain of 15.00.

Is input specified in voltage? NO .

0 x10 Ohms = 296.0

143 x10 Ohms = 168.8

334 x10 Ohms = 125.6

599 x10 Ohms = 98.69

779 x10 Ohms = 87.44

1000 x10 Ohms = 77.00

1285 x10 Ohms = 66.88

1666 x10 Ohms = 56.75

3007 x10 Ohms = 34.94

6995 x10 Ohms = 6.38

32767x10 Ohms = -60.2

This is the translation table for the custom

gain of 15.06.

Is input specified in voltage? YES.

0 Millivolts = 0.00

500 Millivolts = 50.00

1000 Millivolts = 100.0

1500 Millivolts = 150.0

2000 Millivolts = 200.0

2500 Millivolts = 250.0

3000 Millivolts = 300.0

3500 Millivolts = 350.0

4000 Millivolts = 400.0

4500 Millivolts = 450.0

5000 Millivolts = 500.0

Mask Outside Air Invalid condition? NO

Function Block Type: TNI (T-Net Interface Module

Driver)

Name CM 14 User Defined Line 1 GCM 1

CM 14 FB 15 Flags —

ID ID26 Tele NB All

Options Y Type 0 Ver 0

Active Alarms ———— Status Code 0

Real Module Address 0

———————————— T Cards On-line ———————————————

FB 1-NO 2-NO 3-NO 4-NO 5-NO 6-NO 7-NO

8-NO 9-NO 10-NO

This module contains the following function

blocks:

Raw Flow Data:

——— Calibration Table

————

FB# Current Value 0.00 0.25 0.50

1.00 1.50 2.00

1 0 0 0 0 0

0 0

2 0 0 0 0 0

0 0

3 0 0 0 0 0

0 0

4 0 0 0 0 0

0 0

5 0 0 0 0 0

0 0

6 0 0 0 0 0

0 0

7 0 0 0 0 0

0 0

8 0 0 0 0 0

0 0

9 0 0 0 0 0

0 0

10 0 0 0 0 0

0 0

Trending Information:

FB Exp Chan Trending Interval Samples

— —— —— ———— ———— ———

This module should display old-style FB trends

NO

Enable debug screen NO (for Tech Support use)

For ALC use only:

Select alternate timing protocol for each FB:

FB 1-NO 2-NO 3-NO 4-NO 5-NO 6-NO 7NO 8-NO 9-NO 10-NO

Rev. (29-JUN-99) • TNI v4.7

24

©1995-99 Automated Logic Corporation

Page 25

...continued from page 23.

• Pick the Parameters Tab

Go to the status page of the T-Line zone FB (see

Figure 32). Observe the VP ACTL input. If input =

0.00, calibration is complete. If input does not equal

zero, calibration is incomplete; repeat steps 3 through

8 until VP ACTL input is equal to 0.00.

Adjusting the Flow Sensor Gain

Use the following procedure to adjust the flow sensor

gain parameter so that the status display of the VAV FB

will match the test and balance readings.

NOTE: Only proceed with this section after adjusting the

zero point as described above.

1. Turn on the AHV serving the VAV box to be

calibrated.

2. Display the parameters page for the T-Line zone FB

to be calibrated (see Figure 30 for example).

3. Note the following reading from the parameters

report:

"Duct Area is __ sq in."

• Wait approximately 1 minute.

9. Display the Status page.

10. Note the following reading from the status page:

"Corrected Flow Pickup Gain using flow measured

by Test and Balance = __."

11. Obtain the Parameters page for the T-Line zone FB.

12. Page down to the following line: (see Figure 32)

"Flow Calibration Only:"

"1. Flow Pickup Gain is __."

• Enter the Corrected Flow Pickup Gain obtained

from the status page on this line.

13. Move down to the following line:

"Flow Calibration Only:"

"3. Lock in CFM reading for flow gain correction?

YES"

• Change to "NO."

Change the Duct Area to match that of the VAV box.

4. Force the VAV damper open by doing the following:

• Lock the VP/STPT output to 200 (2" WC).

• Display the Parameters page.

• Wait until the VAV damper gets to the full open

position.

5. Obtain the CFM reading from Test and Balance.

6. Display the Parameters page for the T-Line zone FB.

7. Page down to the following line:

"Flow Calibration Only:" (Figure 32)

"2. Input Test and balance reading: 0 CFM."

• Enter CFM reading obtained from Test and

Balance on this line.

8. Move down to the following line:

"Flow Calibration Only:"

CALIBRATION IS COMPLETE.

Checkout & Troubleshooting

Checkout is performed using either the Workstationor a

portable computer that is direct-network (DN) connected

to the TNI module.

Check each input of the T-Line module by manually

causing each sensor to establish a known condition and

then comparing that to the condition reported on the

Function Block status page.

Check each output by locking it to a known condition on

the Function Block parameter page and then observing

that equipment's operation.

If you have any problems during this procedure, contact

Technical Support.

Downloading Memory

"3. Lock in CFM reading for flow gain correction?

NO"

• Change to "YES."

Rev. (29-JUN-99) • TNI v4.7

NOTE: All downloadable information (Function Blocks,

Parameters, Schedules) is stored in the TNI module. Use

25

©1995-99 Automated Logic Corporation

Page 26

the TDAD program to set up the T-line modules with

default algorithms in case of communications failure.

Please reference the T-Line Default Algorithm Downloader

TI for more information.

9. Repeat steps 2 through 7 for each virtual module.

1. Log into SuperVision, using a workstation or portable

computer that is direct connected, modem connected,

or connected directly on the ALC network. When

downloading multiple modules, a direct network

connection will yield the fastest memory download

time.

2. Press the [esc] key and type:

MO ,,(module no.), 15

NOTE: Enter the TNI's address for the module number.

If the module is on-line and communicating, this command

will bring up a Modstat screen.

3. Look at the Modstat screen and verify that the module

type and number agrees with the module to be

downloaded.

4. Download, Memory, This Module. This step will

begin the memory download which is indicated by a

banner on the screen. If you wish to download

memory to all modules, select Download, Memory,

All Modules instead.

LEDs

The T-Line modules have diagnostic LEDs which may

be used for troubleshooting purposes. These LEDs are

shown in Figure 28.

LED Identification:

(1) Tnet Receive (red): When lit, the module is

receiving data.

(2) Tnet Transmit/Run (red): When lit, the module is

transmitting data and/or running.

(3) Digital output 1 energized (red).

(4) Digital output 2 energized (red).

(5) Digital output 3 energized (red).

(6) Digital output 4 energized (red).*

(7) Digital output 5 energized (red).*

* - Not present on T320 and T320v models.

LED Power-up Sequence

5. Display the Modstat page. Check the display's FB

List to verify that the FBs you intended to download

are in the module.

6. Obtain the TNI module driver (FB #15) parameters

page

7. Enter the T-card addresses on the parameters page (see

Figure 28).

8. Enter the virtual module addresses on the parameters

page (see Figure 28).

LED3

LED1

LED2

- Not present on T320 and T320v models

*

LED 4

LED5

LED6

LED7

*

*

Figure 28: T-Line module LEDs

During power-up, the module goes through an

initialization and self test sequence. Proper module

power-up can be checked by observing the LEDs as the

module is powered ON. Shortly after power is restored

to the module, LED 2 flashes. If the module is not

responding and the LEDs do not appear to be going

through the appropriate initialization, call ALC

Technical Support for assistance.

Tnet fuses

(0.125 A)

HI

LO

Revs3and4only

Figure 29: T-Line Fuses

Rev. (29-JUN-99) • TNI v4.7

26

©1995-99 Automated Logic Corporation

Page 27

Fuses

Older versions of the T-line (Revs 3 and 4, see Figure 28)

had fuses and fuse sockets to protect the board from

surges and wiring errors on the communication terminals.

These fuses have been replaced with 100 Ohm resistors to

allow wiring mistakes and power surges to occur without

having to replace blown fuses. This change to 100 Ohm

resistors necessitated reducing the number of T-modules

to 20 modules maximum and 1500 feet of wire

maximum. For greater than 20 boards, or 1500 feet of

wire, a REPOPT must be used as shown in Figure 6. If

you are installing a newer T-module that has 100 Ohm

resistors into an existing older T-net that has more than 20

modules, replace the 100 Ohm resistors with 0.125 (1/8)

amp pico fuses (order ALC part number FUSEPKG).

Production Date

The production date of the module can be determined by

a sticker on the front of the module. The first three

characters indicate the type of module. The next three

indicate the date (year/month/week) of manufacture. The

month is in hexadecimal. The last four characters are

ALC production codes.

Figure 30: Crimping Quick-Disconnects

Figure 31: Terminating Quick-Disconnects

Using Quick-Disconnects

T-Line boards are designed with male quick-disconnect

terminals upon which female quick-disconnects are fixed.

A quick-disconnect connector is fastened to a wire by

means of a crimper. All quick-disconnect connectors for

the T-Line boards must be 0.032 inches thick. These

connectors are available from manufacturers such as

AMP, T&B, and 3M.

Crimping & Terminating QuickDisconnects

WARNING: Always follow proper safety precautions

when handling wires to avoid electrical shock or

equipment damage.

1. Using a wire stripper, strip about ¼" of insulation

from the wire.

2. Insert the bare wire into the cylindrical end of the

female quick-disconnect until it is almost within the

flatter portion.

3. Crimp the cylindrical end of the quick-disconnect to

Figure 32: Proper and Improper Quick-Disconnect

Removal

Rev. (29-JUN-99) • TNI v4.7

27

©1995-99 Automated Logic Corporation

Page 28

the wire using a crimper as shown in Figure 30.

4. Terminate the wire by firmly pushing the connector

onto the desired quick-disconnect terminal, as shown

in Figure 31.

Removing Quick-Disconnects

When removing connectors from the quick-disconnect

terminals, rock the connectors from side-to-side while

pulling, as shown in Figure 32.

Rev. (29-JUN-99) • TNI v4.7

28

©1995-99 Automated Logic Corporation

Loading...

Loading...