Page 1

Technical Instructions

S6104

Using the S6104 2

Specifications 3

Mounting 3

Addressing 3

Power Wiring 4

Network Communications 4

Using the S6104 on an ARC156 Segment 5

Using the S6104 on a Legacy CMnet 5

Connecting the S6104 to the Network 5

Communicating with the Workstation Using SuperVision 6

Communicating Through the LogiStat Port Using SuperVision 6

Communicating Through the Access Port Using SuperVision 7

Inputs 8

LogiStat Wiring 10

Digital Outputs 11

Analog Outputs 12

Writing GFBs for the S6104 12

Point Identifiers 13

Point Identifiers in WebCTRL 13

Channel Numbers in SuperVision 13

Transferring Memory 14

Transferring Memory in WebCTRL 14

Transferring Memory in SuperVision 15

Troubleshooting 15

Formatting the Module 15

LEDs 15

Protection 16

Production Date 16

Automated Logic Corporation • 1150 Roberts Blvd. • Kennesaw, GA 30144 • 770/429-3000 • 770/429-3001 Fax •

www.automatedlogic.com • Copyright 2002 Automated Logic Corporation. All rights reserved. Automated Logic, the

Automated Logic logo, SuperVision, Eikon, Alert, InterOp, and WebCTRL are registered trademarks of Automated Logic

Corporation. BACnet

their respective companies.

®

is a registered trademark of ASHRAE. All other brand and product names are trademarked by

Page 2

Using the S6104

The S6104 is part of the S-Line, designed

specifically for controlling rooftop Air

Handling Units (AHUs). The module can be

mounted directly in or on the rooftop

equipment.

The table below outlines the limitations and

requirements depending on whether you are

using WebCTRL or SuperVision to

communicate with your S6104.

WebCTR L Super Vision

Module Driver DRV_S6104 SLM

Number of Function

Blocks*

Number of BACnet

Objects*

* depending on available memory

11

1000 1000

For more information, see the appropriate

module driver document on the Automated

Logic website at www.automatedlogic.com.

The S6104 has:

• 6 digital outputs

• 10 universal inputs

• 4 analog outputs

A single board provides the power circuitry,

microprocessor, and non-volatile memory

(stores data even during a power failure). The

Access Port allows communication with

WebCTRL or SuperVision. The 4-pin LogiStat

Port provides the interface for a LogiStat

room sensor. With certain restrictions, the

LogiStat Port can also be used to

communicate with WebCTRL or SuperVision

(see Figure 1).

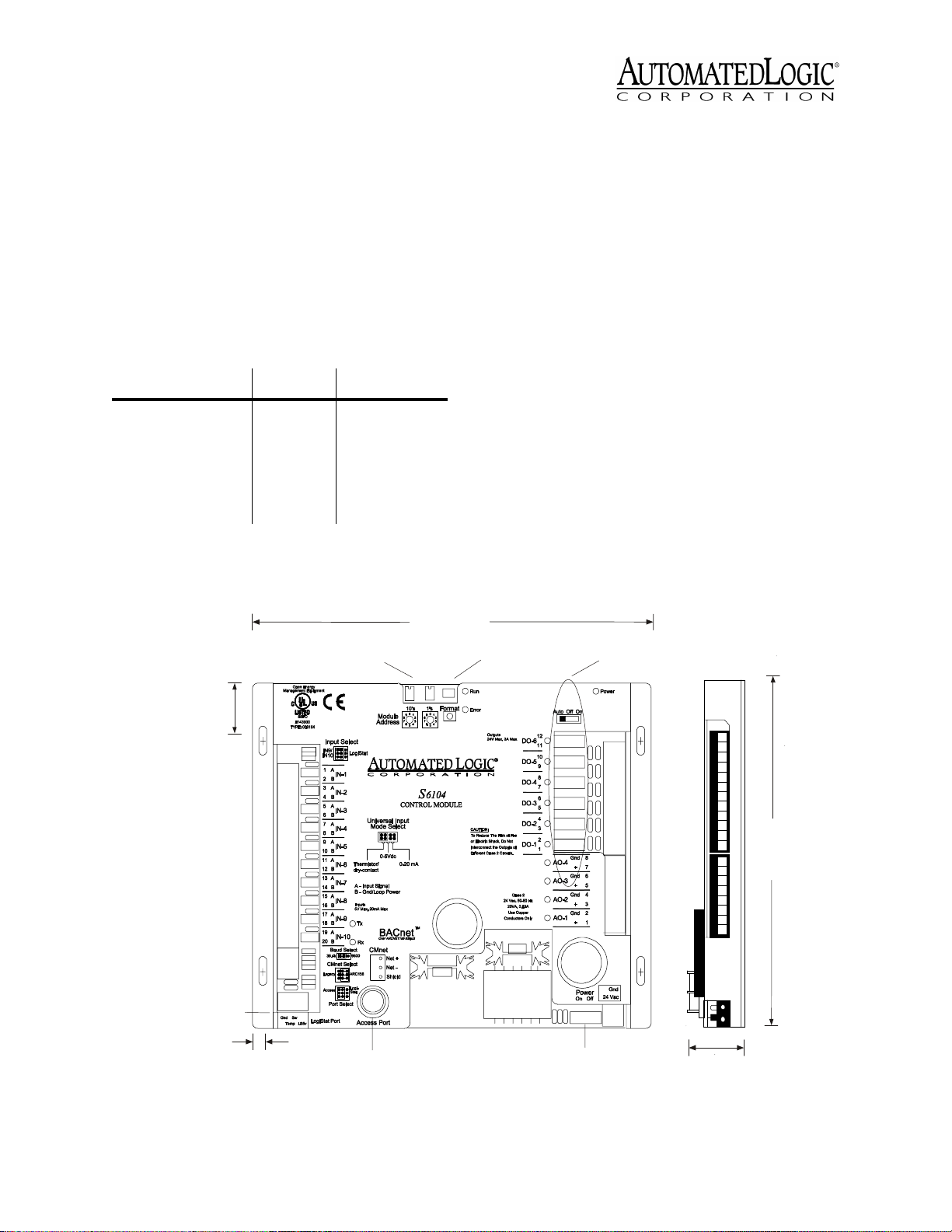

11/4"

3.175 cm

LogiStat Port

Dual Rotary

Address Switches

87/8"

22.543 cm

Manua l Format

Button

Digital O utput Mode

(H O A ) S witch e s

71/2"

19 cm

1/4"

.635 cm

Revised 7/30/02 • S6104 2 © 2002 Automated Logic Corporation

Access

Port

Figure 1. S6104 Dimensions and Layout

Power

Switch

11/8"

2.858 cm

Page 3

CAUTION

unit not expressly approved by the party

responsible for compliance could void the

user’s authority to operate equipment.

NOTE

found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide

reasonable protection against harmful

interference when the equipment is operated

in a commercial environment. This

equipment generates, uses, and can radiate

radio frequency energy and, if not installed

and used in accordance with the instruction

manual, may cause harmful interference to

radio communications. Operation of this

equipment in a residential area is likely to

cause harmful interference in which case the

user will be required to correct the

interference at his own expense.

Changes or modifications to this

This equipment has been tested and

Specifications

Power

Inputs

NOTE

Input Resolution

Digital Outputs

Analog Outputs

24VAC ± 10%, 50-60Hz, 20VA

(0.83A) maximum (single Class 2 source

only, 100VA or less). (24VAC ± 10%, 60Hz

when ordered for UUKL Smoke Control

Systems.)

One LogiStat Port and 10 universal

inputs, configurable for 0-5VDC, 0-20mA,

or thermistor/dry contact.

Universal inputs 9 and 10 are

inaccessible if using a LogiStat or a

LogiStat Plus. Temperature and setpoint

adjust inputs replace universal inputs 9

and 10 in this situation.

10 bit A/D.

6 digital outputs (Form

A), 3A max.

4 analog outputs (0 to

10VDC), 20mA source capability.

For SuperVision, 156 kbps BACnet-overARCNET, 9600 bps or 38.4 kbps legacy

Control Module network (CMnet). Access

Port: 9600 bps or 38.4 kbps EIA-485.

Environmental Operating Range

to 150°F (-28.9° to 65.6°C); 10 to 90%

relative humidity, non-condensing.

When ordered for UUKL Smoke Control

Systems, 32°-120.2°F (0°-49° C); 10 to

85% relative humidity, non-condensing.

Status Indication

communication, running, errors, and all

outputs.

Memory

non-volatile battery-backed SRAM, and

128 bytes of serial EEPROM.

Real Time Clock

time clock that keeps track of time in the

event of a power failure.

Protection

protection circuitry.

Bat t e ry

provides a minimum of 10,000 hours of

data retention during power outages.

Listed by

No. 205-M1983 (PAZX7), FCC Part Subpart B - Class A.

512KB Flash memory and 512KB

Built-in surge and transient

Seven-year lithium BR2325 battery

UL 916 (PAZX), cUL C22.2

Visual (LED) status of

A battery-backed real

-20°

Mounting

Screw the S6104 into an enclosed panel using

the mounting holes provided on the cover

plate. Be sure to leave about 2 inches (5

centimeters) on each side for wiring.

Addressing

Before setting or changing the address, make

sure the S6104’s power is off. The S6104 only

reads the address when the module is turned

on. After changing the address, you must

transfer memory to the module. Refer to

“Transferring Memory” on page 14.

Output resolution

Communication

BACnet-over-ARCNET and 9600 bps or

38.4 kbps EIA-485 BACnet MS/TP.

Revised 7/30/02 • S6104 3 © 2002 Automated Logic Corporation

8 bit D/A.

For WebCTRL, 156 kbps

Page 4

The S6104 has two rotary switches for

addressing:

• For WebCTRL systems, use the switches

to assign the device’s MAC (medium

access control) address on the BACnetover-ARCNET network segment. The

rotary switches define the MAC address

portion of the device’s BACnet address

which is composed of the network

address and the MAC address.

• For SuperVision systems, use the

switches to assign the device’s module

number.

The S6104 has an operating range of 21.6VAC

to 26.4VAC. If voltage measured at the

module’s power input terminals is outside this

range, the module may not work properly.

1. Turn the module’s power off. This

prevents the module from being powered

up before the proper voltage is verified.

2. Make sure the 24VAC power source is off.

3. Connect the power wires to the module’s

power terminals labeled Gnd and 24VAC

(see Figure 1 on page 2 for location).

4. Apply power to the transformer.

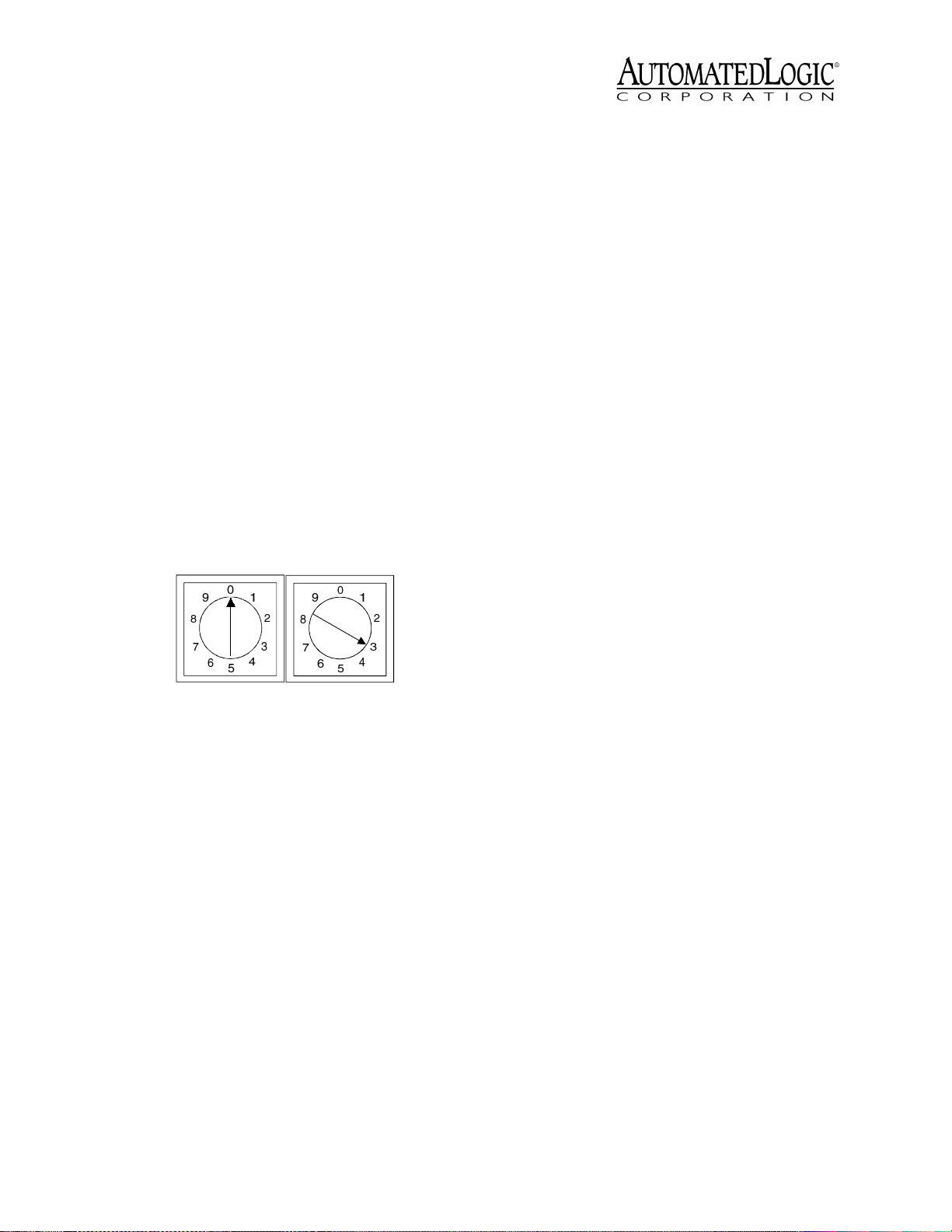

One switch corresponds to the tens digit and

the other corresponds to the ones digit. For

example, if the module’s address is three, set

the tens switch to zero and the ones switch to

three, as shown in Figure 2.

10s 1s

Figure 2. Setting the Module’s Address

Power Wiring

CAUTION

device (less than 30VAC, 100VA maximum).

Take appropriate isolation measures when

mounting the S6104 module in a control

panel where non-Class 2 devices (for

example, 120VAC) or wiring are present.

You can power several modules from the

same transformer if you maintain the same

polarity.

The S6104 module is a Class 2

5. Make sure that 24VAC is present at the

module’s power input terminals.

6. Set the module’s address. Refer to

“Addressing” on page 3 for details about

setting the address.

7. Turn the S6104’s power switch on.

When the module turns on, the Run and

Power LEDs turn on. The Run LED begins

blinking and the Error LED turns off. See

Table 9 on page 16 to troubleshoot the

LEDs. If the module does not respond, call

Technical Support at (770) 429-3002.

Network Communications

The S6104 module supports several

communications options through its CMnet

port.

On a SuperVision system, the S6104 module

can connect to a legacy CMnet at 9600 bps or

38.4 kbps, or to a BACnet-over-ARCNET

network segment at 156 kbps.

Revised 7/30/02 • S6104 4 © 2002 Automated Logic Corporation

Page 5

Using the S6104 on an ARC156 Segment

When communicating at 156 kbps, the

network segment uses a unique

implementation of the industry standard

BACnet-over-ARCNET protocol called

ARC156. For a summary of the differences

between ARCNET and ARC156, please refer to

ARC156 CMnet Wiring Technical Instructions

.

Use the appropriate wire for network

communications. When using an ARC156

network, use an A3ARC156 wire available

from:

Magnum Cable Corporation

Cleveland, OH 44110-0500

(800) 421-0820

When the CMnet Select jumper is set to

ARC156, the CMnet port is connected to an

ARCNET processor, enabling the S6104 to

communicate on an ARC156 network

segment. Communication speed is 156 kbps

regardless of the Baud Select jumper setting

(see Table 1).

Table 1. Jumper positions

CMnet

Type CMnet Select Port Select Baud Select

ARC156 ARC156 Access or

LogiStat

Legacy

CMnet Legacy Access

Not

Applicable

9600 bps or

38.4 kbps

Using the S6104 on a Legacy CMnet

Use a dedicated 22AWG to 18AWG twisted

pair wire for legacy CMnet (EIA-485) wiring.

For more information about CMnet wiring,

refer to the

When the CMnet Select jumper is set to

Legacy, the module communicates on a

legacy CMnet at the baud rate set by the Baud

Select jumper (see Table 1). The Port Select

jumper must also be set to Access.

Technical Handbook

.

NOTE

Setting the CMnet jumper to Legacy

disables the industry standard BACnet-overARCNET (ARC156) protocol for the network

segment and enables the proprietary ALC

CMnet protocol.

Connecting the S6104 to the Network

Before connecting the S6104 to the CMnet, be

sure the S6104’s power is off.

1. Set the CMnet mode (ARC156 or legacy

CMnet) using the CMnet Select jumper.

2. If communicating on a legacy CMnet, set

the Baud Select jumper for either 9600 bps

or 38.4 kbps.

NOTE

use the same baud rate.

3. Set the Port Select jumper:

• On a legacy CMnet, set the Port Select

jumper for Access.

• On an ARC156 CMnet on a WebcTRL

system, set the Port Select jumper for

LogiStat.

• On an ARC156 CMnet on a

SuperVision system, set the Port

Select jumper for either Access or

LogiStat depending on which port will

be used for serial communications

(see “Communicating with the

Workstation Using SuperVision” on

page 6).

4. Check the network communication wiring

for shorts and grounds.

5. Connect the CMnet wires to the module’s

screw terminals as shown in Figure 3 on

page 6. Be sure to follow the same

polarity as the rest of the CMnet.

All modules on the CMnet must

Revised 7/30/02 • S6104 5 © 2002 Automated Logic Corporation

Page 6

ARC156 network segment

Net

Net

Shield

To communicate through the LogiStat Port,

+

-

the S6104 must:

• be on an ARC156 CMnet

• use module driver v6.01d or later.

Communication speed is fixed at 1200 baud.

Figure 3. Wiring the CMnet

Communicating with the Wo rk s tat io n Us i n g SuperVision

The S6104 can communicate with

SuperVision through the Access Port or the

LogiStat Port. The CMnet type determines

whether the Access Port or LogiStat Port can

be used for workstation communications (see

Tabl e 2 ).

Although communication is slower through

the LogiStat Port, the LogiStat sensor may be

more accessible than the S6104 module.

NOTE

for communications when the S6104 is on an

ARC156 CMnet.

Table 2. Configuring Module/Workstation

Communications

CMnet Type

ARC156 Base and Plus

The LogiStat Port can only be used

LogiStat

Sensor Port Select Baud Rate

Base, Plus, Pro

Access

LogiStat

9600/38.4 kbps

1200 bps

CONTRO LMO DULE

LogiStat

Port

LogiStat

LogiPort

LogiStat Adaptor Cable

Exec. 4 Relay

Switch

Exec.4 relay

Isolate Network

APT

Rx

Tx +5V

Mode Select

ModeSelect

TTL

Switch

ACCESS

PORT

485

Access

Port

EIA-232

Port

5

9

6

1

2- Tx out

3- Rx in

5- Gnd

1,6,8- +10V orfloati ng

Figure 4. Using the LogiPort

1. Connect the computer’s serial port to the

EIA-232 port of the APT using a standard

straight-through cable.

Legacy Std and Plus Access 9600/38.4 kbps

2. Set the APT’s Mode Select switch to TTL

(see Figure 4.)

Communicating Through the LogiStat Port Using SuperVision

The S6104 communicates with SuperVision

through the LogiStat connected at the

module’s LogiStat Port. While connected, the

S6104 does not allow a restart, a memory

transfer, or any other action that would break

the pass-through connection.

If you are using a LogiStat Plus without

supplemental power to the APT, make

sure the LED on the LogiStat Plus is on

indicating that it can provide power to the

APT. If the LED is not on, you can provide

power to the APT using the Supplemental

Power +5V dc connection and the special

power cable to a laptop keyboard jack or

an external supply, such as a 5V dc

transformer.

Revised 7/30/02 • S6104 6 © 2002 Automated Logic Corporation

Page 7

3. Set the Port Select jumper for LogiStat to

enable communications through the

LogiStat Port.

Legacy

ARC156

Access

Logi-

Stat

Gnd Sw

LogiStat Port

Temp LS5v

Access

Port Select

LogiStat

Access Port

Figure 5. Port Select to LogiStat

4. In SuperVision, define the connection

using Table 3 on page 8.

5. In SuperVision, set the baud rate at

1200 bps.

6. Attach the LogiStat Adaptor Cable (part

number 235022) to the APT cable. Use this

assembly to connect the APT’s Access

Port to the LogiStat’s LogiPort.

While connected, the LogiStat Pro

displays “LP” indicating that the LogiStat

Pro will not respond to input from the

keypad.

NOTE

When the LogiStat Adaptor Cable

is inserted into the LogiPort, the S6104

can no longer read the LogiStat Inputs.

The S6104 will continue to use the last

valid temperature and setpoint adjust

readings obtained before the cable was

inserted into the LogiPort. If the

Occupancy Override Timer was active

when the connection was made, it will

continue to count down, but no new

inputs can be made until the LogiStat

Adaptor Cable is removed. See the

Microblock Reference Guide

for more

Eikon

information about the LogiStat

microblock.

Communicating Through the Access Port Using SuperVision

When using SuperVision, you can connect a

workstation or portable computer directly to

the S6104 module using an APT and the

module’s Access Port (see Figure 6). This type

of connection can be used to troubleshoot the

module or transfer memory. If you are using

an ARC156 CMnet, you can receive colors

while connected to a module’s Access Port if

a gateway module is on the CMnet. You

cannot receive alarms through the Access

Port, however.

CONTROLMODULE

Exec. 4 Relay

Switch

Exec. 4 re lay

Isolate Network

APT

Rx

Mode Select S witch

Tx +5V

Mode Select

TTL 485

ACCESS

PORT

EIA-232

Port

5

9

6

1

2-Tx o ut

3-R x in

5-G nd

1,6,8-+10V or floating

Figure 6. Using the Access Port

1. Connect the computer’s serial port to the

APT’s EIA-232 port using a standard

straight-through cable.

2. Set the APT’s Mode Select switch.

• On an ARC156 network segment, use

the TTL setting.

• On a legacy CMnet, use the 485 setting.

3. Connect the APT’s Access Port to the

module’s Access Port.

Access

Port

Access Port

7. Disconnect the LogiStat Adaptor Cable

from the LogiStat's LogiPort when

finished to allow the S6104 to receive

4. Set the Port Select jumper to Access to

enable communications through the

Access Port.

inputs from the LogiStat.

Revised 7/30/02 • S6104 7 © 2002 Automated Logic Corporation

Page 8

Baud Select

Baud Select

38.4K 9600

CMnet Select

Legacy

Access

Port Select

9600

ARC156

LogiStat

Access Port

Access

Port Select

38.4K

LogiStat

Gnd Sw

LogiStat Port

Temp LS 5v

Figure 7. Port Select and Baud Selects

5. Check the Baud Select jumper on the

S6104 for the communication speed of the

Access Port (9600 or 38.4K). If the jumper

needs to be changed, turn the module’s

power off first. The baud rate change

registers when the module is turned on.

6. In SuperVision, define the connection type

using Table 3.

Table 3. Connection Types

SuperVision

Ver s i o n

3.0 any n/a Access Port

2.6 ARC156 yes Direct Connect

2.6 ARC156 no Direct Network

2.6 legacy n/a Direct Network

Inputs

Type o f

CMnet

Gateway

Present?

Use Connection

Type

The S6104 provides 10 universal inputs. If you

are wiring the S6104 module to a LogiStat or

LogiStat Plus sensor, inputs 9 and 10 can be

disabled, allowing temperature and setpoint

adjust inputs to be read through the LogiStat

Port instead (see “LogiStat Wiring” on

page 10). Refer to Table 4 for information

about wire length, gauge, and shielding.

NOTE

On an ARC156 network segment,

inputs can be read through a LogiStat,

LogiStat Plus, or LogiStat Pro. However, on a

legacy CMnet, inputs can only be read on a

LogiStat or LogiStat Plus.

between 0.489V and 3.825V for

thermistors.

• 0 to 5VDC: The output impedance must

not exceed 10 kohms. The input

impedance of the S6104 is

approximately 1Mohm.

• 0 to 20mA: The input resistance on the

A input is 250 Ohms. The B terminal

supplies a voltage source to power the

4-20mA transducer. The B terminal is

capable of supplying 18 to 24VDC, but

the total current of all B terminals must

not exceed 200mA. If the voltage

measured from the B terminal to Gnd is

less than 18VDC, you need to use an

additional external power supply.

• Dry Contact: A 5VDC wetting voltage is

used to detect contact position. This

results in a 0.5mA maximum sense

current when contacts are closed.

Table 4. Input wiring restrictions

Input

0 to 5VDC 50 feet

Thermistor

Dry contact

0 to 20 mA 150 feet

LogiStat

Sensors

*Automated Logic Corporation recommends a specific

wire to connect the S6104 to the LogiStat. This 22AWG

solid copper wire is available from Magnum Cable

Corporation (part number A3LOGISTAT).

Maximum

Length

15 meters

50 feet

15 meters

46 meters

100 feet

30 meters

Minimum

Gauge Shielding

24AWG shielded and

grounded to

module’s B or

Gnd terminal

24AWG shielded and

grounded to

module’s B or

Gnd terminal

20AWG unshielded

22AWG * unshielded

• Thermistor: Precon type 2 (10 kohm at

77°F). Input voltages should range

Revised 7/30/02 • S6104 8 © 2002 Automated Logic Corporation

Page 9

Isolated DC

Powe r Supply

2Wire

4-20mA

4Wire

4-20mA

Isolated DC

Powe r Supply

Dry Contact

2Wire

4-20mA

2Wire

0-5VDC

4Wireusing

mod ule power

Input S elect

IN 9/

IN1 0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

38.4k

CM net Select

To Module G round

LogiStat

A

IN -1

B

A

IN -2

B

A

IN -3

B

A

IN -4

B

A

IN -5

B

A

IN -6

B

A

IN -7

B

A

IN -8

B

A

IN -9

B

A

IN-10

B

Baud Select

9600

Universal Input

Mode S elect

0-5Vdc

Thermistor/

dry-contact

A - Input Signal

B - Gnd/Loop P ower

Inp uts

5V Max, 20mA Max

Tx

Rx

0-20 mA

Figure 8. In put Wiring

1. Be sure the S6104’s power is off before

wiring any inputs or outputs.

2. Connect the input wiring to the screw

terminals on the module as shown in

Figure 8.

NOTE

If a 4-20mA sensor uses an

external 24VAC power supply, connect

one leg of the 24VAC supply to the module

ground.

3. If using inputs 9 and 10 when wiring the

S6104 to a rooftop AHU, set the Input

Select jumper to the IN9/IN10 position.

See Figure 9. If using a LogiStat or

LogiStat Plus, see “LogiStat Wiring” on

page 10.

Open Energy

Management Equipment

R

IN9/IN10

LogiStat

88FO

E143900

TYPE: 006104

Input Select

IN9/

IN10

Figure 9. Input Select set to IN9/IN10

4. Set the Universal Input Mode Select

jumper for each input to indicate the type

of sensor used. Make sure the jumper is

positioned correctly, and be sure to grip

the jumper by the sides only. See Figure

10.

LogiStat

Revised 7/30/02 • S6104 9 © 2002 Automated Logic Corporation

Page 10

Universal Input

Mode Select

0-5VDC

Thermistor/

dry-contact

Grip

here

0-20mA

Figure 10. Universal Input Mode Select

5. Turn the S6104’s power switch on.

6. For each input, enter the point identifiers.

Refer to the section “Writing GFBs for the

S6104” on page 12 for more information

about using a LogiStat sensor.

1. Be sure the S6104’s power is off before

wiring a LogiStat to the LogiStat Port.

2. If using a LogiStat or LogiStat Plus, set the

Input Select jumper to LogiStat (see Figure

11).

NOTE

Setting the jumper to LogiStat

disables universal inputs 9 and 10.

• In WebCTRL, enter the point number

and the point type on the Properties

page. For linear inputs, set the

minimum value and maximum value to

scale the point to engineering units.

• In SuperVision, enter the channel

number, offset, and gain using the

Configure Points or Point Help feature.

Valid channel numbers are listed in

“Channel Numbers in SuperVision” on

page 13.

7. To verify each input’s operation, have

each sensor create a known value and

compare it to the condition reported on

the FB’s Properties page in WebCTRL or

Status page in SuperVision.

LogiStat Wiring

The S6104’s LogiStat Port provides the

connection for a LogiStat room sensor (see

Figure 1 on page 2). The Input Select jumper

must be set to the LogiStat position when

using a LogiStat or LogiStat Plus. This allows

the S6104 to obtain analog temperature

readings from the LogiStat through pin 2

(Temp) of the LogiStat Port. The LogiStat Plus

also provides the slidepot position and TLO

inputs through pin 3 (Sw). The LogiStat Pro

provides temperature, setpoint adjust, and

TLO inputs through serial communications.

See Table 4 for the wiring restrictions for the

S6104.

Open Energy

ManagementEquipment

R

IN9/IN10

LogiStat

88FO

E143900

TYPE : 00 6104

Input Select

IN9/

IN10

LogiStat

Figure 11. Input Select set to LogiStat

If using a LogiStat Pro, set the Input Select

jumper to IN9/IN10 to make the inputs

available for use.

3. If using a LogiStat Pro, set the Port Select

jumper to LogiStat; this enables

communications through the LogiStat

port.

NOTE

The S6104 must be on an ARC156

network segment using a LogiStat Pro.

Revised 7/30/02 • S6104 10 © 2002 Automated Logic Corporation

Page 11

4. Use Figure 12 to wire a LogiStat, LogiStat

Plus, or LogiStat Pro to the S6104.

Power

Auto Off On

1234

Gnd Sw

Temp LS5v

LogiStat Port

S6104

1234

r

d

n

x

w

x

R

P

G

T

LogiStat

Figure 12. LogiStat Wiring

Strip 1/4 inch of the ends of the wires (see

Figure 13).

2. Press black

1. Insert w ire

into opening

Figure 13. Flip Lever Wiring

tabdownto

connect wire

12

DO-6

11

10

DO-5

9

8

DO-4

7

6

DO-3

5

4

DO-2

3

2

DO-1

1

Figure 14. Digital Outputs

To verify each output’s operation, lock the

output to a known condition using the

Function Block’s Properties page in WebCTRL

or Parameter page in SuperVision. Be sure the

equipment operates as specified.

Each digital output can be placed in Manual

(on or off) or Auto mode by setting the HOA

switches (see Figure 1 on page 2 for the

switches’ location). Table 5 on page 12 shows

the status of the digital output based on the

output’s configuration and the HOA switch

position.

You can monitor the status of the HOA

switches through WebCTRL or SuperVision. In

WebCTRL, assign each switch a digital input

in the FB using the point number and the HOA

Status Feedback point type.

5. Turn the S6104’s power switch on.

In SuperVision, assign each switch a digital

input in the FB using channel numbers 81

Digital Outputs

The S6104 has 6 digital outputs which can be

connected to a maximum of 24 Volts AC/DC

(see Figure 14). Each digital output is a dry

contact (rated at 3A maximum).

Be sure the S6104’s power is off before wiring

through 86. Channel 81 corresponds to HOA

switch number one, channel 82 corresponds

to HOA switch two, and so on.

An off status means the HOA switch is in Auto

mode. An on status means the HOA switch is

in Manual mode.

any inputs or outputs. Connect the output

wiring to the screw terminals on the module.

Revised 7/30/02 • S6104 11 © 2002 Automated Logic Corporation

Page 12

Table 5. HOA Switch Positions

Output

Configuration On Off Auto

Normally open

output

Results on

Properties page

in WebCTRL* or

Status page in

SuperVision**

DO

contacts

closed

ON ON OFF

DO

contacts

open

determined

by FB

programming

module’s analog output, the total resistance

of the load must be 500 Ohms. If necessary,

wire a 1/2 watt resistor in series with the

20mA device as shown in Figure 15.

Example:

To drive a 20mA device that has

100 Ohms of resistance, wire a 400 Ohm

resistor in series with the 20mA device (100

Ohms + 400 Ohms = 500 Ohms total

resistance).

* use point type of HOA Status Feedback and point

number

** use channel numbers 81 - 86

Analog Outputs

The S6104 module has 4 analog outputs that

support voltage devices in the 0 to 10VDC

range. The device that is being controlled

must have at least 500 Ohms resistance

measured from its input to ground and must

share the same ground as the module.

AO

0-10V

100

AO

4-20mA

AO-4

AO-3

AO-2

AO-1

Gnd

+

Gnd

+

Gnd

+

Gnd

+

Power

On Off

8

7

6

5

4

3

2

1

Gnd

24 Vac

400

Be sure the S6104’s power is off before wiring

any inputs or outputs. Connect the output

wiring to the screw terminals on the module.

To verify each output’s operation, lock the

output to a known condition using the

Function Block’s Properties page in WebCTRL

or Parameter page in SuperVision. Be sure the

equipment operates as specified.

Writing GFBs for the S6104

You must use Eikon v3.0a or later to create

GFBs for the S6104. When using a LogiStat

sensor with the S6104, include a LogiStat

microblock in the module’s GFB (see Figure

16). The LogiStat microblock supports the

LogiStat, LogiStat Plus, and LogiStat Pro

sensors. You do not need to enter point

numbers or point types in SuperVision or

Eikon for WebCTRL. Likewise, you do not

need to enter channel numbers for this

microblock in SuperVision or Eikon. For more

information, refer to the

Reference Guide

.

Eikon Microblock

Figure 15. Analog Output Wiring

Although the S6104’s analog outputs were

not designed to output current, it is possible

to use these outputs for current mode

devices. To drive a 20mA device from the

Revised 7/30/02 • S6104 12 © 2002 Automated Logic Corporation

Page 13

Figure 16. Sample GFB for the S6104

Point Identifiers

A point can be identified in WebCTRL by its

point number and point type; in SuperVision,

a point is identified by its channel number. On

both systems, expander number zero

represents I/O points on the S6104.

Point Identifiers in WebCTRL

Enter the point identifiers in Eikon for

WebCTRL before the FB is made or on the FB’s

Properties page in WebCTRL. Set the type,

number, and minimum and maximum

present values for each point on the S6104.

Select a physical point type from the point

type field and enter the number of the input or

output. To scale a linear signal type, enter the

appropriate minimum and maximum present

values on the microblock’s dialog box.

Channel Numbers in SuperVision

The following tables show the valid channel

numbers for each point on the S6104. The

offset and gain values used depend on the

type of sensor or actuator attached to the I/O

point. You can select the channel number,

offset, and gain using SuperVision’s Point

Help feature or Configure Points utility.

Alternatively, you can preconfigure the points

by manually entering the channel number,

offset, and gain in Eikon using the values

shown in the following tables.

Table 6. Analog Output Channel Numbers

Point Signal Type

AO 1 Analog 41 0 to 10VDC 0.00 0.0625

AO 2 Analog 42 0 to 10VDC 0.00 0.0625

AO 3 Analog 43 0 to 10VDC 0.00 0.0625

AO 4 Analog 44 0 to 10VDC 0.00 0.0625

Channel

Number Range Offset Gain

Table 7. Digital Output Channel Numbers

Point Signal T ype

DO 1

DO 2

DO 3

DO 4

DO 5

DO 6

Digital

HOA Status

Digital

HOA Status

Digital

HOA Status

Digital

HOA Status

Digital

HOA Status

Digital

HOA Status

Channel

Number

11

81

12

82

13

83

14

84

15

85

16

86

Table 8. Universal Input Channel Numbers

Point Signal T ype

Thermistor 31

UI 1

mA or Volts 31

Digital 21

Channel

Number †Range Offset Gain

-17° to 213° F

-27° to 100.6° C

0 to 20mA

0 to 5V

0.00

15.88

0.00

15.69

§§

Revised 7/30/02 • S6104 13 © 2002 Automated Logic Corporation

Page 14

Table 8. Universal Input Channel Numbers

Point Signal Type

Thermistor 32

UI 2

UI 3

UI 4

UI 5

UI 6

UI 7

UI 8

UI 9 *

UI 10 *

* This input is not available when using a LogiStat or LogiStat Plus.

† Celsius values can only be displayed in SuperVision when the Function

Block is made in Eikon v2.0 or later with the Metric option enabled. Refer to

the Eikon User’s Guide for more information.

§ For ALC 0-20mA sensors, use the offset and gain printed on the sensor.

Otherwise use the Point Configuration or Point Help feature in SuperVision

v2.0 or later.

mA or Volts 32

Digital 22

Thermistor 33

mA or Volts 33

Digital 23

Thermistor 34

mA or Volts 34

Digital 24

Thermistor 35

mA or Volts 35

Digital 25

Thermistor 36

mA or Volts 36

Digital 26

Thermistor 37

mA or Volts 37

Digital 27

Thermistor 38

mA or Volts 38

Digital 28

Thermistor 39

mA or Volts 39

Digital 29

Thermistor 3A

mA or Volts 3A

Digital 2A

Channel

Number †Range Offset Gain

-17° to 213° F

-27° to 100.6° C

0 to 20mA

0 to 5V

-17° to 213° F

-27° to 100.6° C

0 to 20mA

0 to 5V

-17° to 213° F

-27° to 100.6° C

0 to 20mA

0 to 5V

-17° to 213° F

-27° to 100.6° C

0 to 20mA

0 to 5V

-17° to 213° F

-27° to 100.6° C

0 to 20mA

0 to 5V

-17° to 213° F

-27° to 100.6° C

0 to 20mA

0 to 5V

-17° to 213° F

-27° to 100.6° C

0 to 20mA

0 to 5V

-17° to 213° F

-27° to 100.6° C

0 to 20mA

0 to 5V

-17° to 213° F

-27° to 100.6° C

0 to 20mA

0 to 5V

0.00

15.88

0.00

15.69

§§

0.00

15.88

0.00

15.69

§§

0.00

15.88

0.00

15.69

§§

0.00

15.88

0.00

15.69

§§

0.00

15.88

0.00

15.69

§§

0.00

15.88

0.00

15.69

§§

0.00

15.88

0.00

15.69

§§

0.00

15.88

0.00

15.69

§§

15.88

0.00

15.69

Transferring Memory

You should download memory whenever you

make changes to your modules (for example,

change the module number, upgrade the

module driver, or change the FB).

The S6104 can store a single Function Block

in addition to the module driver. If any

problems occur during this procedure,

contact Technical Support at (770) 429-3002.

NOTE

performed with caution. When the module is

automatically restarted before and after

transferring memory, any equipment

controlled by the module is shut down and

restarted. Downloading memory also

overwrites all Function Blocks in the module

causing the module to lose any stored data.

Transferring Memory in WebCTRL

If you are using WebCTRL to transfer memory,

you must use the DRV_S6104 module driver.

You must be logged in to WebCTRL with the

appropriate privilege to download memory.

For more information about using WebCTRL,

refer to the

1. Click the CFG button at the bottom of the

2. Click Download in the CFG tree control.

3. Click the Memory, Parameters, or

4. Expand the tree in the action pane, click

5. Click the Execute Download button.

A memory download should be

WebCTRL Configuration Guide

.

navigation pane.

Schedules boxes, depending on what you

want to download.

NOTE

A memory download includes a

parameter and schedule download.

the module you want to download to,

then click Add. Click on and Add any

other modules you want to download to.

If any downloads failed, they are listed in

the Failures section under the tree in the

Revised 7/30/02 • S6104 14 © 2002 Automated Logic Corporation

Page 15

action pane. To retry a failed download,

click the module in the Failures list, click

Add, and click the Execute Download

button again. If you do not want to retry a

failed download, click the Clear Failures

button.

NOTE

a system problem, you should never clear

a failure. Locate and resolve the problem,

then retry the download.

6. Click the Properties button to refresh the

screen. This removes the items from the

Download Items list.

Since a failed download indicates

Transferring Memory in SuperVision

If you are using SuperVision to transfer

memory, you must use SuperVision v2.6b or

later, FB Link v2.7a or later, and the SLM

module driver. The S6104 module using the

SLM module driver can store a single FB.

1. Log in to SuperVision on a workstation

connected to the CMnet. You can also

connect directly to the module using the

Access Port or LogiStat Port; see

“Communicating with the Workstation

Using SuperVision” on page 6.

2. Navigate to the module driver and look at

the module status report in SuperVision to

make sure the module type and number

agree with the module.

• To view the module status report in

SuperVision v3.0, click Tools Troubleshooting - Module Status.

• In SuperVision v2.6b, download

memory for This Module.

4. When the memory transfer is finished,

check the module status report again.

Make sure the FB List on this page shows

the FB you intended to transfer.

Troubleshooting

Formatting the Module

If you are unable to communicate with a

module after transferring memory, you can,

as a last resort, manually format the module

to try to restore communication. Formatting

the module erases all memory, so you need to

transfer memory back to the module once it is

formatted.

NOTE

formatted when you transfer memory, you

should only manually format the module if

communication was not established after the

memory transfer.

1. Turn the module’s power off. Make sure

2. Press and hold the Format button (see

3. Continue to hold the button until the Error

4. Release the Format button.

Since the module is automatically

the address switches are not set to ‘0 0’.

Figure 1 on page 2 for location). While

continuing to hold the Format button, turn

the module’s power on.

LED flashes three times in sync with the

Run LED.

• To view the module status report in

SuperVision v2.6b or later, press the

[ESC} key, type

MO ,,module address,15

and press Enter.

3. Transfer memory to the module.

• In SuperVision v3.0, click Tools Troubleshooting - Transfer Memory to

Module.

Revised 7/30/02 • S6104 15 © 2002 Automated Logic Corporation

5. Transfer memory to the module. Refer to

“Transferring Memory” on page 14.

LEDs

The S6104 module has several LED indicators

to show the status of certain functions.

Table 9 on page 16 explains the Run and Error

LED signals in detail to assist troubleshooting.

See Figure 17 for location of LED signals.

Page 16

Run Error

Power

Table 9. LED Signals (Continued)

Run LED Error LED Condition

Digital Output

Status

Analog Output

Status

CMnet

Tx

CMnet

Rx

S6104

Control Module

L

A

CO RPORATIO N

UTOMATED

OGIC

12

11

Figure 17. S6104 LED locations

Power - indicates power is being supplied to

the module.

CMnet Tx - lights when the module transmits

data over the CMnet.

CMnet Rx - lights when the module receives

data from the CMnet.

Digital Output Status - lights when the digital

output is activated.

Analog Output Status - lights when the

analog output is activated.

Table 9. LED Signals

Run LED Error LED Condition

2 flashes

per second

2 flashes

per second

2 flashes

per second

2 flashes

per second

2 flashes

per second

Off Normal

1 flash,

then pause

2 flashes

alternating

with LED

2 flashes in

sync with

LED, then

pause

3 flashes,

then off

Normal, but module is

alone on the CMnet

(this sequence doesn’t

occur in WebCTRL)

Five minute auto-restart

delay after system error

Module is configured for a

different baud rate than the

rest of the network

segment

Module has just been

formatted

2 flashes

per second

2 flashes

per second

5 flashes

per second

5 flashes

per second

7 flashes

per second

14 flashes

per second

4 flashes,

then pause

On Exec halted after frequent

On Exec start-up aborted, Boot

Off Firmware transfer in

7 flashes

per second,

alternating

with LED

14 flashes

per second,

alternating

with LED

Two or more devices on

this network have the

same ARC156 network

address

system errors or GFBs

halted

is running

progress, Boot is running

Ten second recovery

period after brownout

Brownout

Protection

The S6104 module is protected by internal

solid state Polyswitches on the incoming

power and network connections. These

Polyswitches are not replaceable and will

reset themselves if the condition that caused

the fault returns to normal.

Production Date

To determine when a module was

manufactured, check the module status

report for the module in WebCTRL or

SuperVision. Refer to the appropriate user’s

guide for more information about the module

status report.

A sticker on the back of the module also

shows the date the module was

manufactured. The first three characters on

the sticker indicate the type of module. The

next two characters show the year and month

(the month digit is in hexadecimal).

Revised 7/30/02 • S6104 16 © 2002 Automated Logic Corporation

Loading...

Loading...