Page 1

17514_ins_alc_lsp2h_lsb2h

(0 to 5 VDC - 0 to 100% RH)

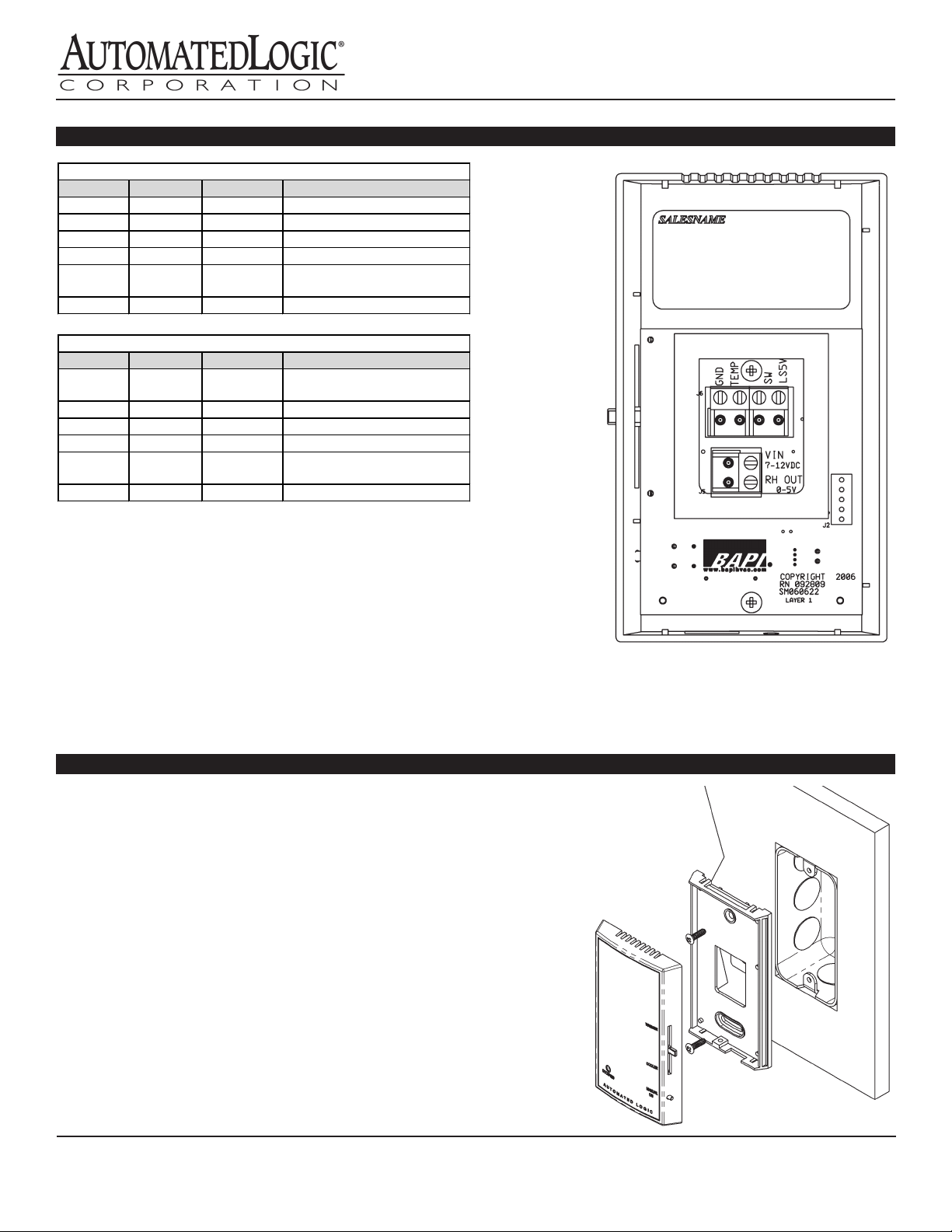

LSBASE2H Terminal Connections

LED, RH)

TEMP Tx Green Room Temperature (sensor)

SW Rx Yellow Setpoint Adjust and TLO

LS5V PWR Red LED

RH OUT

Relative Humidity

VIN 7 to 12VDC for Humidity

LSPLUS2H Terminal Connections

Termination

Terminal Alt. Name Lead Color Function

GND GND Black Ground (sensor, RH)

TEMP Tx Green Room Temperature (sensor)

SW Rx Yellow Not Used

LS5V PWR Red Not Used

RH OUT Relative Humidity

VIN 7 to 12 VDC for Humidity

Terminal Alt. Name Lead Color Function

GND GND Black Ground (sensor, setpoint, TLO,

(0 to 5 VDC - 0 to 100% RH)

LSPLUS2H and LSBASE2H

Installation & Operations

rev. 10/15/12

The relative humidity signal (“RH OUT” terminal) should be taken to an

unused analog input on the controller.

When used with an ALC module equipped with RNet, the RNet 12 VDC

supply may be used to power the unit. If there is not a convenient source of

7 to 12 VDC power, an ALC/VC350A or ALC/VC350A-EZ may be used.

Note: The connectors use a rising block screw terminal to hold the wires.

If the block is in a partially up position, the wire may be inserted under the

block and the wire will not be held when the screw is tightened. To avoid

improper wiring, turn the male connector screws counterclockwise until the

block is below the wire opening before inserting the wire. Lightly tug on

each wire after tightening to verify proper termination.

Mounting

1. Secure the base to the junction box using the #6-32 x 1/2” mounting

screws provided.

2. For drywall installation, pre-drill two 3/16” holes 3.275” apart on

center. Insert the drywall anchors and secure the base using the #6 x

1” sheet metal screws provided.

3. Terminate the unit as shown in the Terminations section.

4. Attach the cover by latching it to the top of the base.

5. Rotate the cover down.

Automated Logic Corporation

1150 Roberts Boulevard

Kennesaw, GA 30144

Phone: (770) 429-3000

Fax: (770) 429-3001

www.automatedlogic.com

Page 2

17514_ins_alc_lsp2h_lsb2h

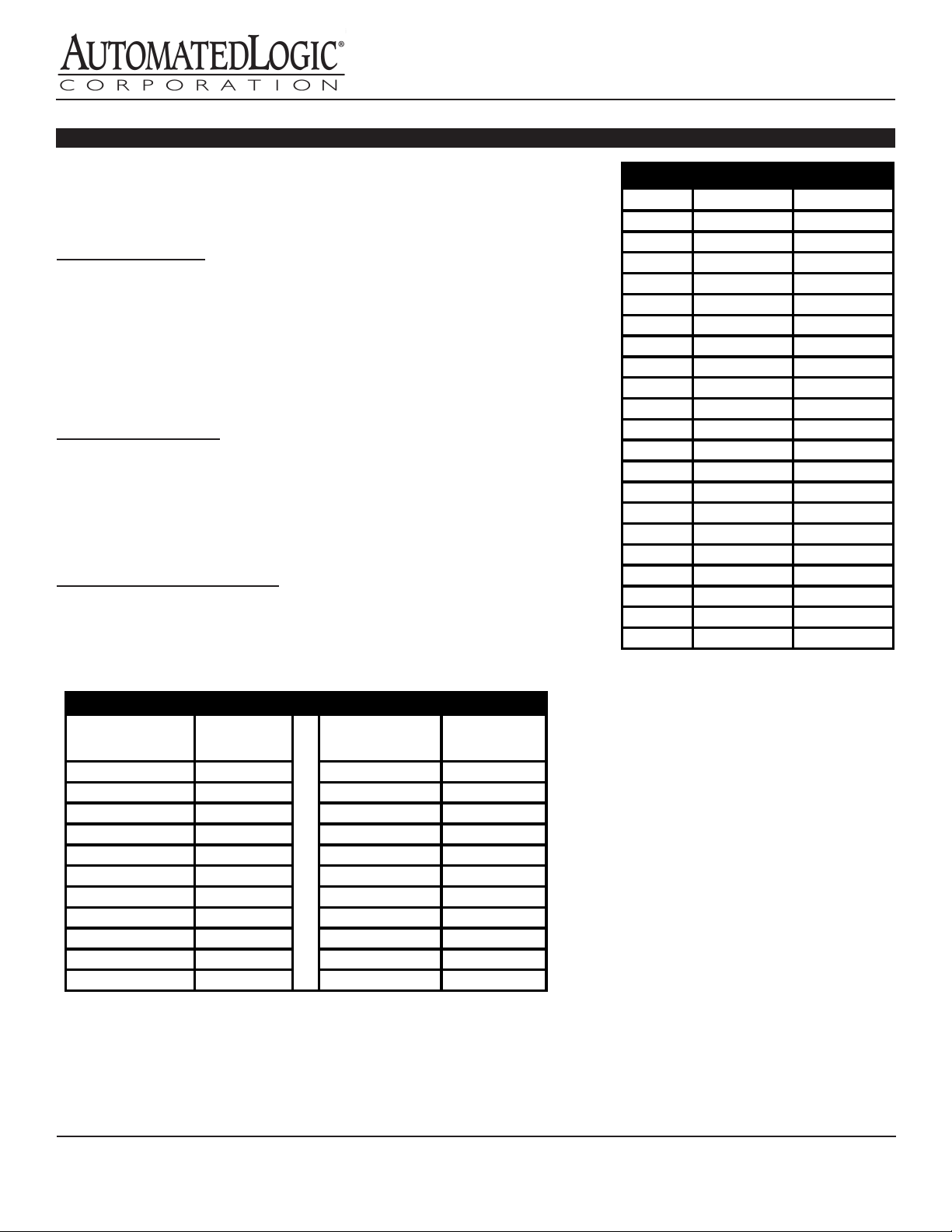

Deg F Deg C 10K-2 Ω

55°F 12.8°C 17,439

62°F 16.7°C 14,546

66°F 18.9°C 13,139

72°F 22.2°C 11,307

80°F 26.7°C 9,298

84°F 28.9°C 8,448

88°F 31.1°C 7,685

90°F 32.2°C 7,333

100°F 37.8°C 5,826

0% 0 55% 2.750 VDC

10% 0.500 VDC 65% 3.250 VDC

25% 1.250 VDC 80% 4.000 VDC

50% 2.500 VDC

Diagnostics

LSPLUS2H and LSBASE2H

Installation & Operations

rev. 10/15/12

If the unit does not respond properly, please go through the following steps:

1. Set a meter to the “Ohms” setting

2. Disconnect the TEMP, SW and RH OUT terminals from the system

Temperature Sensor

3. Measure the resistance from terminal GND to TEMP

4. Compare the resistance reading to the resistance listed in the output table.

5. If the sensor reads signicantly lower or 0 Ohms, then the sensor is shorted

6. If the sensor reads signicantly higher or OL (overload) then the sensor is

open.

7. If the sensor reads properly, verify that the controller is operating correctly.

Setpoint and Override

8. Measure the resistance from terminal GND to SW.

9. The resistance should range from 4.75 kΩ to 24.75 kΩ (±10%) as the slide

pot is moved from left to right.

10. Pushing the override switch should cause the resistance reading to go to

approximately 0Ω.

Relative Humidity Diagnostics

11. Measure the voltage from terminal GND to RH OUT.

12. The relative humidity is found by solving the following equation:

%RH = RH OUT * 20

Relative Humidity Output Table

Relative

Humidity

Output

Voltage

Relative

Humidity

Output

Voltage

10K-2 Thermistor Output Table

50°F 10.0°C 19,903

60°F 15.6°C 15,313

64°F 17.8°C 13,822

68°F 20.0°C 12,493

70°F 21.1°C 11,884

74°F 23.3°C 10,762

76°F 24.4°C 10,247

77°F 25.0°C 10,000

78°F 25.6°C 9,760

82°F 27.8°C 8,862

86°F 30.0°C 8,056

95°F 35.0°C 6,530

Note: The temperature table shown

above is a portion of the entire

operating range of the sensor.

5% 0.250 VDC 60% 3.000 VDC

15% 0.750 VDC 70% 3.500 VDC

20% 1.000 VDC 75% 3.750 VDC

30% 1.500 VDC 85% 4.250 VDC

35% 1.750 VDC 90% 4.500 VDC

40% 2.000 VDC 95% 4.750 VDC

45% 2.250 VDC 100% 5.000 VDC

Automated Logic Corporation

1150 Roberts Boulevard

Kennesaw, GA 30144

Phone: (770) 429-3000

Fax: (770) 429-3001

www.automatedlogic.com

Loading...

Loading...