Page 1

Technical Instructions

LGRM-E

Using the LGRM-E 2

Specifications 3

Mounting 3

Addressing 3

LGnet addressing 3

IP Addressing 4

Wiring 5

Power Wiring 5

Communications Wiring 5

Initializing the LGRM-E 6

Transferring Memory 7

Troubleshooting 7

Communicating with the Workstation 7

Formatting the Module 9

LEDs 9

Protection 10

Production Date 10

Automated Logic Corporation • 1150 Roberts Blvd. • Kennesaw, GA 30144 • 770/429-3000 • 770/429-3001 Fax •

www.automatedlogic.com • Copyright 2002 Automated Logic Corporation. All rights reserved. Automated Logic, the

Automated Logic logo, SuperVision, Eikon, and Alert are registered trademarks of Automated Logic Corporation.

InterOp is a trademark of Automated Logic Corporation. BACnet

and product names are trademarked by their respective companies.

®

is a registered trademark of ASHRAE. All other brand

Page 2

Using the LGRM-E

The LGRM-E is part of the Gateway family and

provides communication between a

workstation and a control module network

(CMnet) consisting of fewer than 100

modules. Up to 199 gateways can be

networked together on an LGnet, allowing

the LGRM-Es to route global information

between CMnets. While the LGRM-E supports

199 gateways, versions of SuperVision earlier

than 3.01 do not support more than 60

gateways.

The LGRM-E provides an Ethernet 10base-T

port for 10Mbps communication with the

LGnet. Two console ports that can be

connected to a workstation, portable

computer, or modem, an Auxiliary Device

Port (Keypad/Display Port), and an Access

Port are also provided.

Console Port 1 is a 9-pin EIA-232 connector.

Console Port 2 is a 5-pin terminal jumper.

TCP/IP (Transmission Control Protocol/

Internet Protocol) is a family of protocols used

for computer communications. The LGRM-E

uses the UDP/IP (User Datagram Protocol/

Internet Protocol) of the TCP/IP family. The

workstation must be configured to

communicate with the LGRM-E over TCP/IP

as discussed in the document

Windows 95/NT and SVW 2.6

TCP/IP Setup for

(Part number

LGTCPIP).

The LGRM-E must use v6.00g or later of the

LEM module driver; for more information, see

LEM Module Driver

the

document on the

Automated Logic website at

www.automatedlogic.com

or on the SupportPlus CD.

NOTE

This equipment has been tested and

found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide

reasonable protection against harmful

interference when the equipment is operated

in a commercial environment. This

equipment generates, uses, and can radiate

radio frequency energy and, if not installed

and used in accordance with the instruction

manual, may cause harmful interference to

radio communications. Operation of this

equipment in a residential area is likely to

cause harmful interference in which case the

user will be required to correct the

interference at his own expense.

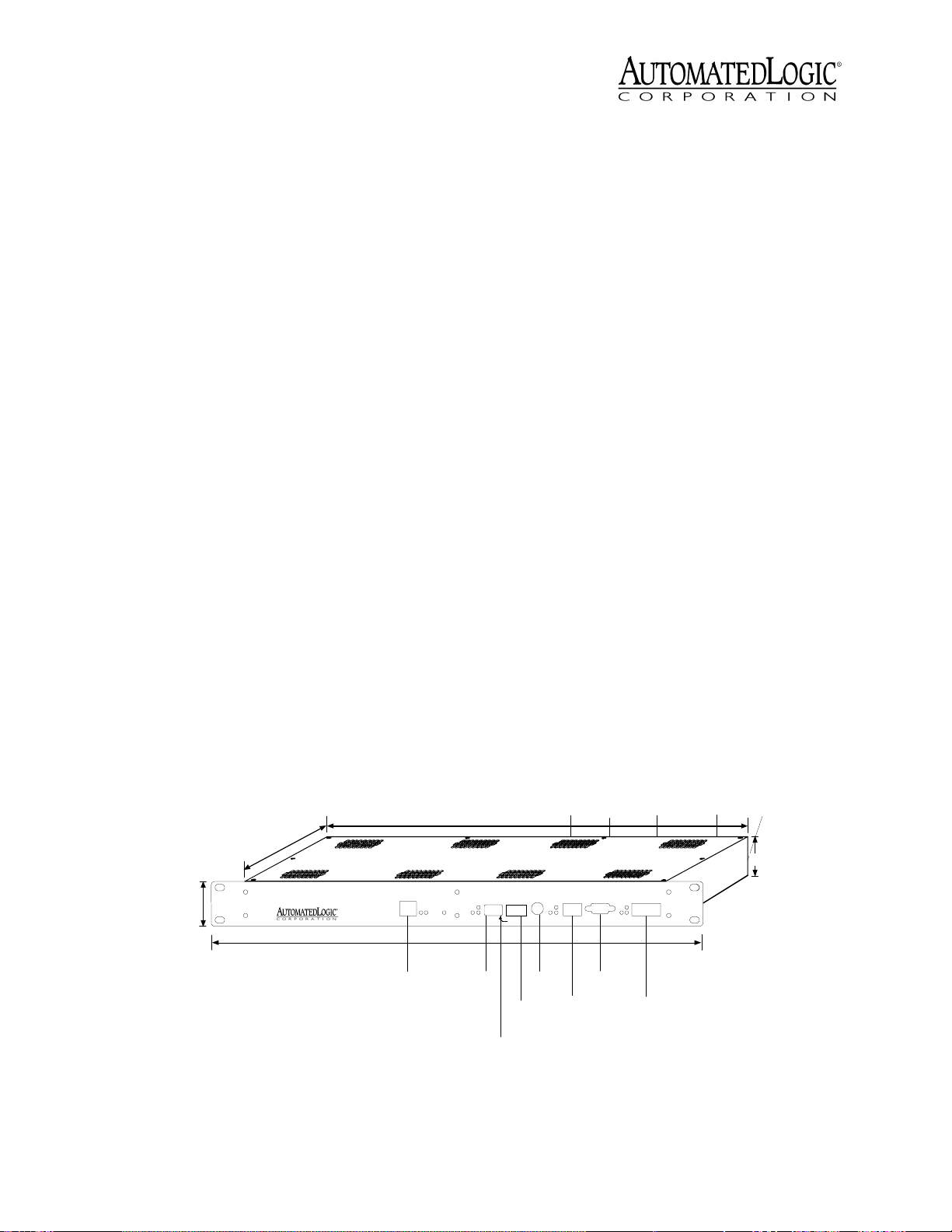

13/4"

4.45cm

10 3/16"

25.88cm

LGRM-E

RJ45

10base

T

Ethernet

10baseT

Port

K

N

I

L

N

A

L

t

e

r

n

r

e

e

w

h

o

t

P

E

19 1/16"

48.42cm

17"

43.18cm

e

l

r

u

e

Error

d

w

o

o

P

M

Run

DIP

Switches

Addressing

e

c

n

a

g

g

i

s

e

s

k

k

k

L

4

4

4

/

A

.

.

.

/

6

t

8

8

8

l

5

3

3

3

u

1

/

/

/

d

d

d

a

0

0

0

C

f

u

u

u

0

0

0

R

e

a

a

a

6

6

6

A

b

9

b

9

b

9

d

D

r

1

2

d

d

n

n

a

o

d

o

o

g

A

M

C

y

C

e

P

c

L

I

DIP

Switch

s

'

0

0

10's 1's

y

1

LGnet

e

Address

Access

Addressing

Rotary

Switches

Com

Sta

m

t

Access

CMn

Por

et

t

Port

Connecti on

Auxiliary

Power

-

t

t

e

e

N

N

+

Rx

Tx

CMn

Connec-

et

tion

CMnet

Auxiliary

Device

Console

d

l

e

i

Connec-

1

h

S

tion

x

D

R

C

2

1

D

C

/

N

Console

Port 1

Format

Button

Port

D

R

C

T

x

x

D

R

T

D

D

R

T

N

x

T

D

G

3

4

5

Rx

Com

Sta

m

t

7

Tx

V

C

C

/

/

0

Console 2

1

6

9

N

8

N

Console

+

Connec-

2

tion

Console

Port 2

Power

Connector

l

n

a

u

n

o

r

g

i

d

G

S

Power

Switch

125/32"

4.5cm

Figure 1. Module dimensions and layout

Revised 11/6/02 • LGRM-E 2 © 2002 Automated Logic Corporation

Page 3

Specifications

Addressing

Power

115VAC ±10%, 15W, 60Hz wall

outlet adapter.

Adapter Output

9VDC, 0.75A minimum,

supplied.

Auxiliary Device Power

24VAC ±10%,

0.5A, 12VA, 60/50Hz.

Communications

LGnet Port with Ethernet

10base-T (10Mbps). CMnet Connection

with EIA-485, twisted pair, selectable for

156 kbps, 38.4 kbps, or 9600 bps. One

9-pin EIA-232 connector Console Port for

direct connect or modem. One 5-pin

connector Console Port for direct connect

or modem. One Access Port for direct

network using an APT. One Auxiliary

Device Port (Keypad/Display Port).

Environmental Operating Range

130°F (-17.8 to 54.4°C); 10 to 90% relative

humidity, non-condensing.

Status Indication

Visual (LED) status of

CMnet, Console Ports and Ethernet

communications, errors, running, and

power.

Memory

256KB Flash, 512KB

battery-backed static RAM.

0 to

LGnet addressing

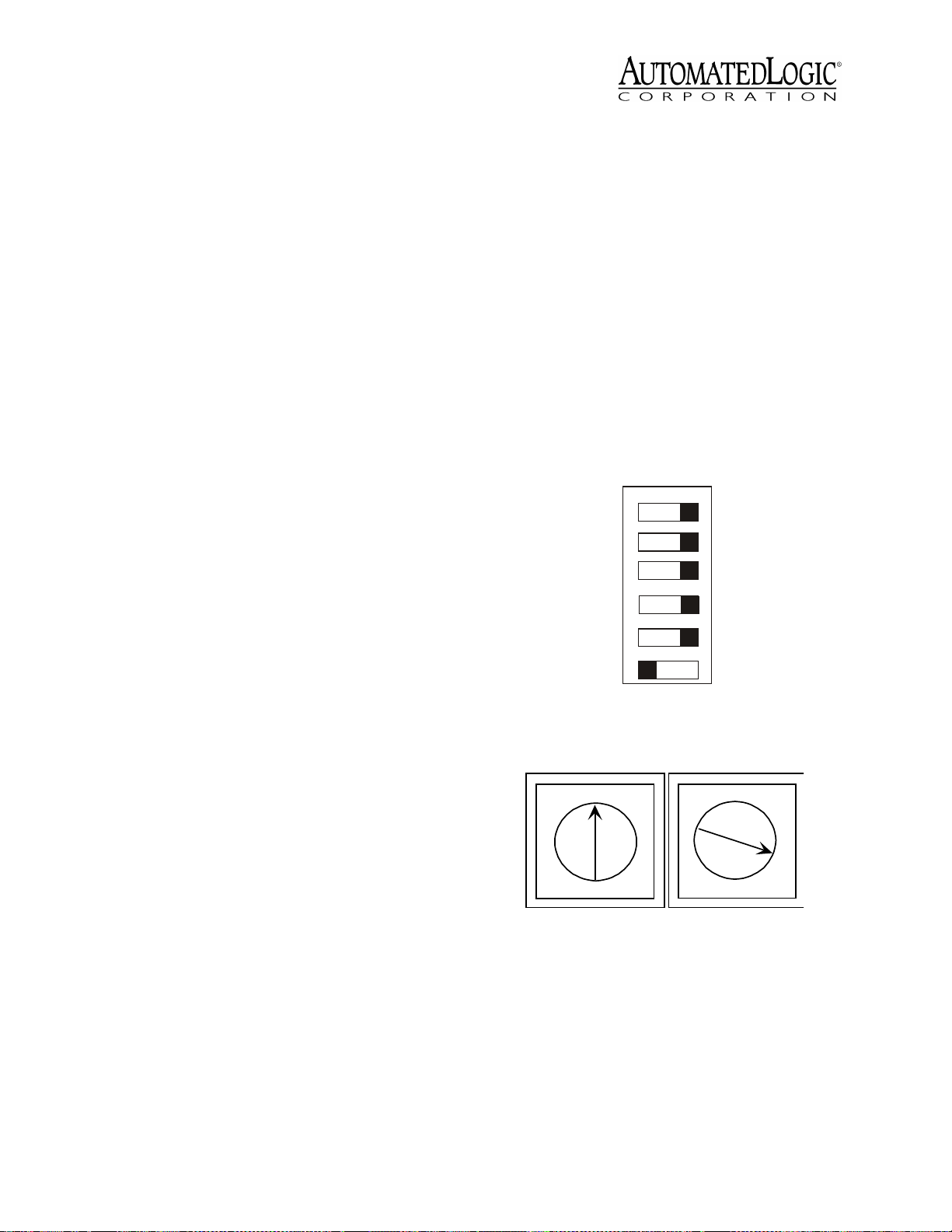

The LGRM-E has two rotary switches and a

DIP switch used to assign the LGRM-E’s

address. One rotary switch corresponds to the

tens digit and the other corresponds to the

ones digit. DIP switch six corresponds to the

100s digit.

NOTE

may not recognize an LGRM-E if the its

address is higher than 60. However, LGRM-Es

recognize peer gateways with addresses from

1 to 199.

SuperVision v2.6 and some gateways

Switch

Number

CMnet

1

Con 1

2

Con 2

3

IP ADD

4

Mode

5

9600/38.4k baud

9600/38.4k baud

9600/38.4k baud

Default/Assigned

Legacy/ARC156

Protection

Built-in surge and transient

protection circuitry.

Listed By

UL 916 (PAZX), cUL C22.2

No.205 - M1983 (PAZX7).

Mounting

The LGRM-E is rack-mounted using four

holes on the faceplate (see Figure 1 on page

2). If a rack is not available, the LGRM-E can

be mounted with mounting brackets.

The LGRM-E is designed to be mounted inside

the building. All warranties are void if

mounted outside.

CAUTION

unit not expressly approved by the party

responsible for compliance could void the

user’s authority to operate equipment.

Changes or modifications to this

6

0

Figure 2. DIP Switches

100s

10's 1's

0

9

8

7

6

Figure 3. rotary Switches

1

2

3

4

5

0

9

8

7

6

1

2

3

4

5

For example, if the LGRM-E’s address is 3, set

DIP switch six to zero (see Figure 2), the tens

rotary switch to zero, and the ones rotary

switch to three (see Figure 3).

Revised 11/6/02 • LGRM-E 3 © 2002 Automated Logic Corporation

Page 4

Before setting or changing the address, make

sure the LGRM-E’s power is off. The LGRM-E

only reads the address when the module is

turned on. After changing the address, you

must transfer memory to the module. Refer to

“Transferring Memory” on page 7.

Default mode

Use the following procedure to set the IP

address when using the Default mode:

1. Set the IP ADD DIP switch to Default.

2. Turn the LGRM-E’s power on.

IP Addressing

TCP/IP must be set up on the workstation

with an active IP address before configuring

the module’s IP address (refer to the

Setup for SuperVision Workstations Technical

Instructions

for a detailed procedure).

You can use a default IP address for the

LGRM-E that is created by the module, or

assign an IP address if required by the

customer. The IP ADD switch (Figure 2 on

page 3) determines which IP address is used.

• Default: When the IP ADD switch is set

to Default, the following IP networking

parameters are automatically set on the

LEM Parameter page:

IP Address = 192.168.168.XXX

XXX is the LGRM-E’s LGnet address (see

“LGnet addressing” on page 3).

TCP/IP

, where

3. If using SuperVision v2.6, edit your HOSTS

file to include the following line for each

gateway (see the

TCP/IP Setup for

SuperVision Workstations Technical

Instructions

for a detailed procedure):

192.168.168.x

Where x is the gateway’s address as

defined in “LGnet addressing” on page 3.

4. If using SuperVision v2.6, run Setup.exe

on the disk shipped with your LGRM-E.

This setup copies updated Portman files to

your emsys folder.

5. Configure the connection as Network in

SuperVision Plus v3.01 and later or

NetBIOS in SuperVision v2.6.

Assigned mode

Use the following procedure to set the IP

address when using the Assigned mode:

Subnet Mask = 255.255.255.0

Default Gateway Address =

19 2 . 168.168.254

NOTE

The default gateway address is

an intranet address. This means that the

data packets from this address are

dropped by all internet routers and are

not sent beyond the local network

segment.

• Assigned: When the IP ADD DIP switch

is set to Assigned, you must set the

above parameters on the LEM

Parameter page.

1. Obtain an IP address from the job site’s

Network Administrator.

2. Set the IP ADD DIP switch to Assigned.

3. If using SuperVision v2.6, edit your HOSTS

file to include the following line for each

gateway (see

Workstations Technical Instructions

TCP/IP Setup for SuperVision

for a

detailed procedure):

IP Address LGx

Where IP Address is the address assigned

by the Network Administrator and x is the

gateway’s LGnet address.

4. If using SuperVision v2.6, run Setup.exe

on the disk shipped with your LGRM-E.

Revised 11/6/02 • LGRM-E 4 © 2002 Automated Logic Corporation

Page 5

This setup copies updated Portman files

files to your emsys folder.

Use the following procedure to connect

power to the LGRM-E.

NOTE

If SuperVision is running, exit and

restart SuperVision before performing step 5.

5. Establish communication with the

LGRM-E through SuperVision using one of

the connection types in Table 1.

Table 1. Connecting with the Workstation

Port Cable

Access Port APT Access Port Direct

Console

Ports

DC95, DC99,

or APT

SuperVision

v3.01

Direct

Connect

SuperVision

v2.6

Network

Direct

Connect

6. Enter the following information, provided

by the Network Administrator, on the LEM

Parameter page and transfer parameters:

• the Assigned IP address

• the Assigned Subnet Mask

1. Turn off the LGRM-E’s power switch.

2. Connect the terminal strip connector (see

Figure 4) to the power connector on the

back of the LGRM-E (see Figure 5 on page

6).

3. Plug the power adaptor into an outlet.

4. Turn the module’s power switch on.

When the module turns on, the Run and

Power LEDs turn on. The Run LED begins

blinking and the Error LED turns off. See

Table 3 on page 10 to troubleshoot the

LEDs. If the module does not respond,

call Technical Support at (770) 429-3002.

To use the Auxiliary Device Port (Keypad/

Display Port), plug the ALC #240034 wall

transformer into an outlet and attach the

other end to the auxiliary power connector.

• the Default Gateway Address

7. Configure your connections page for

Network in SuperVision Plus v3.01 and

later, or NetBIOS in SuperVision v2.6.

Wiring

Power Wiring

Whenever possible, make sure the module’s

power and communications connections are

working properly before connecting any input

or output points.

CAUTION

device (less than 30VAC, 100VA maximum).

Take appropriate isolation measures when

mounting the LGRM-E module in a control

panel where non-Class 2 devices (for

example, 120VAC) or wiring are present.

You can power several modules from the

same transformer if you maintain the same

polarity.

The LGRM-E module is a Class 2

Terminal Strip

Connnector

120 VAC

50-60Hz

(230V, 50Hz)

Figure 4. AC Power Ad apter

Output: 9VDC

.75 Amps

minimum

Communications Wiring

When communicating at 156 kbps, the CMnet

uses a unique implementation of the industry

standard ARCNET protocol called ARC156.

For a summary of the differences between

ARCNET and ARC156, please refer to the

ARC156 CMnet Wiring Technical Instructions

Use the appropriate wire for CMnet

communications. When communicating with

the ARC156 protocol, use an A3ARC156 wire

available from:

.

Revised 11/6/02 • LGRM-E 5 © 2002 Automated Logic Corporation

Page 6

Power

Switch

Off On

Power

Connector

+9 Vdc Gnd

700mA Min

Source Only

Format

Auxiliary

Device

Port

Auxiliary

Power

24 Vac Gnd

Single Class 2Singl e Cl ass 2

Source Only

Power

Switch

Power

Connector

Format

Button

Figure 5. Bac k View of L GRM-E

Magnum Cable Corporation

Cleveland, OH 44110-0500

(800) 421-0820

Use a dedicated 22AWG to 18 AWG twisted

pair (EIA-485) for legacy CMnet. For more

information about CMnet, refer to the

Technical Handbook

Wiring Technical Instructions

ARC156 CMnet

or to

.

Configure the communication speeds using

the DIP switches (see Figure 1 on page 2 for

location). Each switch functions as follows:

Auxiliary

Power

Auxiliary

Device

Port

(Keypad/Display Port)

Connector

Be sure to follow the same polarity as

used throughout the rest of the CMnet.

3. Make sure the LGRM-E is configured for

the correct communication speed.

Connecting to the LGnet

Connect a LAN 10base-T cable to the

Ethernet port.

Connecting to a Workstation or Modem

Connect the DC95 or DC99 cable to console

port 1 or 2. See “Communicating with the

Workstation” on page 7 for more details.

CMnet

Sets the CMnet baud rate at 9600/

38.4 baud.

Con 1

Sets Console Port 1’s baud rate at

9600 or 38.4 baud.

Con 2

Sets Console Port 2’s baud rate at

9600 or 38.4 baud.

IP Add

Sets the addressing mode to either

Default or Assigned on the 10base-T

Ethernet connection (see “IP Addressing”

on page 4 for more information).

Mode

Sets the CMnet to either ARCNET (156

kbps) or Legacy (9600/38.4 baud).

1. Turn off the power.

2. Attach the two CMnet communications

wires to the CMnet connection labeled

Net - and Net + on the LGRM-E (see Figure

1 on page 2). Also connect the Shield if on

an ARC156 CMnet.

NOTE

The EIA-232 connection should not

exceed 50 ft (15.24 m) in length without an

Opto Repeater. Refer to the

Technical Instruction

for further information.

Opto Repeater

Initializing the LGRM-E

Before the LGRM-E can communicate with

the CMnet or the workstation, you must

initialize it with the following information:

• The maxnet value, which is the total

number of modules on the CMnet

(including the LGRM-E) plus one. The

LGRM-E uses maxnet to determine

when to begin the token passing cycle

on the CMnet.

• If the workstation is connected to the

LGRM-E by modem, the workstation

Revised 11/6/02 • LGRM-E 6 © 2002 Automated Logic Corporation

Page 7

telephone number from the SuperVision

connections page.

• The system’s line number.

• The three-letter system name.

Initialize the gateway module when:

• The LGRM-E is replaced or reformatted.

• A new module is added to the CMnet.

• The workstation phone number is

changed in SuperVision.

• The three-letter system name is

changed.

• The LGRM-E’s LGnet address is

changed.

To initialize the LGRM-E using SuperVision

v2.6 or earlier, issue the SETGCM manual

command. In SuperVision 3.0, navigate to the

LGRM-E’s module driver parameter page,

then choose the Tools - Troubleshooting Initialize Gateway command.

Transferring Memory

The LGRM-E uses the LEM module driver. No

other FBs can be added to the LGRM-E. If any

problems occur during this procedure,

contact Technical Support at (770) 429-3002.

If you are transferring memory that includes

changing the module driver or its version

number, the transfer takes longer than

subsequent transfers.

1. Connect your workstation or portable

computer to the LGRM-E. Refer to

“Communicating with the Workstation” .

• To view the module status report in

SuperVision v2.6b, press the Esc key,

MO , , module address,15

type

and press Enter.

3. Transfer memory to the module.

• In SuperVision v3.0, click

Tools-Troubleshooting-Transfer

Memory to Module.

• In SuperVision v2.6b, choose Download

Memory for This Module.

4. When the memory transfer is finished,

check the module status report again.

Make sure the FB List on this page shows

all the FBs you intended to transfer.

Troubleshooting

Communicating with the Workstation

The LGRM-E has two console ports that can

connect to a workstation. Console ports can

connect directly to the workstation’s serial

ports or to a modem, through which you can

dial up the workstation. The Access Port must

connect to a workstation through an APT (see

Figure 6 on page 8).

Connecting Using the Console Ports

Use the wiring diagrams in Figure 7 on page 8

to connect Console Ports 1 and 2 to a

workstation or a modem. Use the diagram in

Figure 8 on page 9 to convert Console Port 2

from a 5-pin terminal connection to a 9-pin

EIA-232 port; this allows you to use the wiring

diagrams for Console Port 1.

2. Navigate to the module driver and look at

the module status report in SuperVision to

make sure the module type and number

agree with the module.

• To view the module status report in

SuperVision v3.0, click

Tools-Troubleshooting-Module Status.

Revised 11/6/02 • LGRM-E 7 © 2002 Automated Logic Corporation

Page 8

EIA-232

Port

Exec. 4 Relay

Switch

Access

Port

Mode Select

Switch

Figure 6. Usi ng the Access Port

Console Port

(9 pin)

*DCD 1

RX 2

TX 3

*DTR 4

GND 5

Console Port

(9 pin)

*DCD 1

RX 2

TX 3

*DT R 4

GND 5

Console Port

(9 pin)

*DCD 1

RX 2

TX 3

*DT R 4

GND 5

*DSR 6

**RT S 7

**C T S 8

*RI 9

Console Port 1

Workstation

Workstation

(9 p in )

4DTR*

3TX

2RX

1 DCD*

5GND

(25 pi n)

20 D TR*

2TX

3RX

8DCD*

7GND

Modem

(25 pin )

8 DCD*

3RX

2TX

20 DTR *

7GND

6DSR*

4RTS**

5CTS**

22 RI*

* W ire connection usually not needed

** Needed only if hardware hands haking is used

Figure 7. Wir ing Diagrams

Console Port 2

Console Port

(5 pin)

TX 1

RX 2

GND 5

Console Port

(5 pin)

TX 1

RX 2

GND 5

Console Port

(5 pin)

TX 1

RX 2

*DTR 3

*DC D 4

GND 5 7 GND

W orkstation

(9 pi n )

2RX

3TX

5GND

Workstation

(25 pi n)

3RX

2TX

7GND

Modem

(25 pin )

2TX

3RX

20 DTR*

8 DCD*

Revised 11/6/02 • LGRM-E 8 © 2002 Automated Logic Corporation

Page 9

Screw Terminal

(Numbered from left)

TX 1

RX 2

DTR 3

DCD 4

GND 5

13425

DE-9P

(Male pin)

3TX

2RX

4DTR

1DCD

5GND

5

1

9

6

Looking into Connector

Figure 8. Console Port t o 9-pin Su b-D

Connection

Connecting Using the Access Port

Use the following procedure to connect the

Access Port to a workstation.

1. Connect the computer’s serial port to the

EIA-232 port of the APT using a standard

straight-through cable (see Figure 6 on

page 8).

2. Set the APT’s Mode Select switch.

• On an ARC156 CMnet, use the TTL

setting.

• On a legacy CMnet, use the 485 setting.

3. Connect the Access Port of the APT to the

Access Port of the module.

4. In SuperVision, define the connection type

using Table 2.

Table 2. Connection Types

SuperVision

Ver s i o n

3.0 any n/a Access Port

2.6 ARC156 yes Direct Connect

2.6 ARC156 no Direct Network

2.6 legacy n/a Direct Network

Type o f

CMnet

Gateway

Present?

Use Connection

Type

The baud rate of the Access Port is

determined by the Baud Select jumper on the

module.

Formatting the Module

When you are unable to communicate with a

module, you can, as a last resort, manually

format the module to try to restore

communication. Formatting the module

erases all memory, so you need to transfer

memory back to the module once it is

formatted.

1. Turn the module’s power off. Make sure

the module’s address switches are not set

to ‘0 0’.

2. Press and hold the Format button (see

Figure 1 on page 2 for location). While

continuing to hold the Format button, turn

the module’s power on.

3. Continue to hold the button until the Error

LED flashes three times in sync with the

Run LED.

4. Release the Format button.

5. Transfer memory to the module. Refer to

“Transferring Memory” on page 7.

LEDs

The LGRM-E has several LED indicators to

show the status of certain functions. Table 3

on page 10 explains the Run and Error LED

signals in detail to assist troubleshooting.

Power - indicates power is being supplied to

the module.

Run - blinks when the processor is running.

Error - indicates an error has been detected.

CMnet transmit - indicates that the LGRM-E is

transmitting data over the CMnet.

CMnet receive - indicates that the LGRM-E is

receiving data from the CMnet.

Console transmit - indicates that the Console

Port is transmitting data.

Revised 11/6/02 • LGRM-E 9 © 2002 Automated Logic Corporation

Page 10

Console receive - indicates that the Console

Port is receiving data.

the condition that caused the fault returns to

normal.

LGnet receive - indicates the LGRM-E is

receiving data from the CMnet.

LGnet transmit - indicates the LGRM-E is

transmitting data over the CMnet.

Comm Status - indicates Bad Checksum,

noise, or garbled data is on the CMnet.

Link- Ethernet - indicates connection through

the Ethernet port.

Lan - indicates network activity.

Table 3. LED Signals

Run LED Error LED Condition

2 flashes

per second

2 flashes

per second

2 flashes

per second

Off Normal

1 flash per

second

2 flashes

per second

Normal, but module is

alone on the CMnet

Five minute auto-restart

delay after system error, or

module is configured for a

different baud rate than the

rest of the CMnet

Production Date

To determine when a module was

manufactured, check the module status

report in SuperVision. Refer to the

User’s Guide

for more information about the

module status report.

A sticker on the back of the module also

shows the date the module was

manufactured. The first three characters on

the sticker indicate the type of module. The

next three characters show the year, month,

and week of manufacture. (The month digit is

in hexadecimal.)

SuperVision

2 flashes

per second

2 flashes

per second

5 flashes

per second

5 flashes

per second

7 flashes

per second

14 flashes

per second

4 flashes

per second

On Exec halted after frequent

On Exec start-up aborted, Boot

Off Firmware transfer in

7 flashes

per second

14 flashes

per second

Two or more items in the

database have the same

node ID

system errors

is running

progress

Ten second recovery

period after brownout

Brownout

Protection

The LGRM-E is protected by internal solid

state Polyswitches on the incoming power

and network lines. These Polyswitches are

not replaceable and will reset themselves if

Revised 11/6/02 • LGRM-E 10 © 2002 Automated Logic Corporation

Loading...

Loading...