Page 1

Technical Instructions

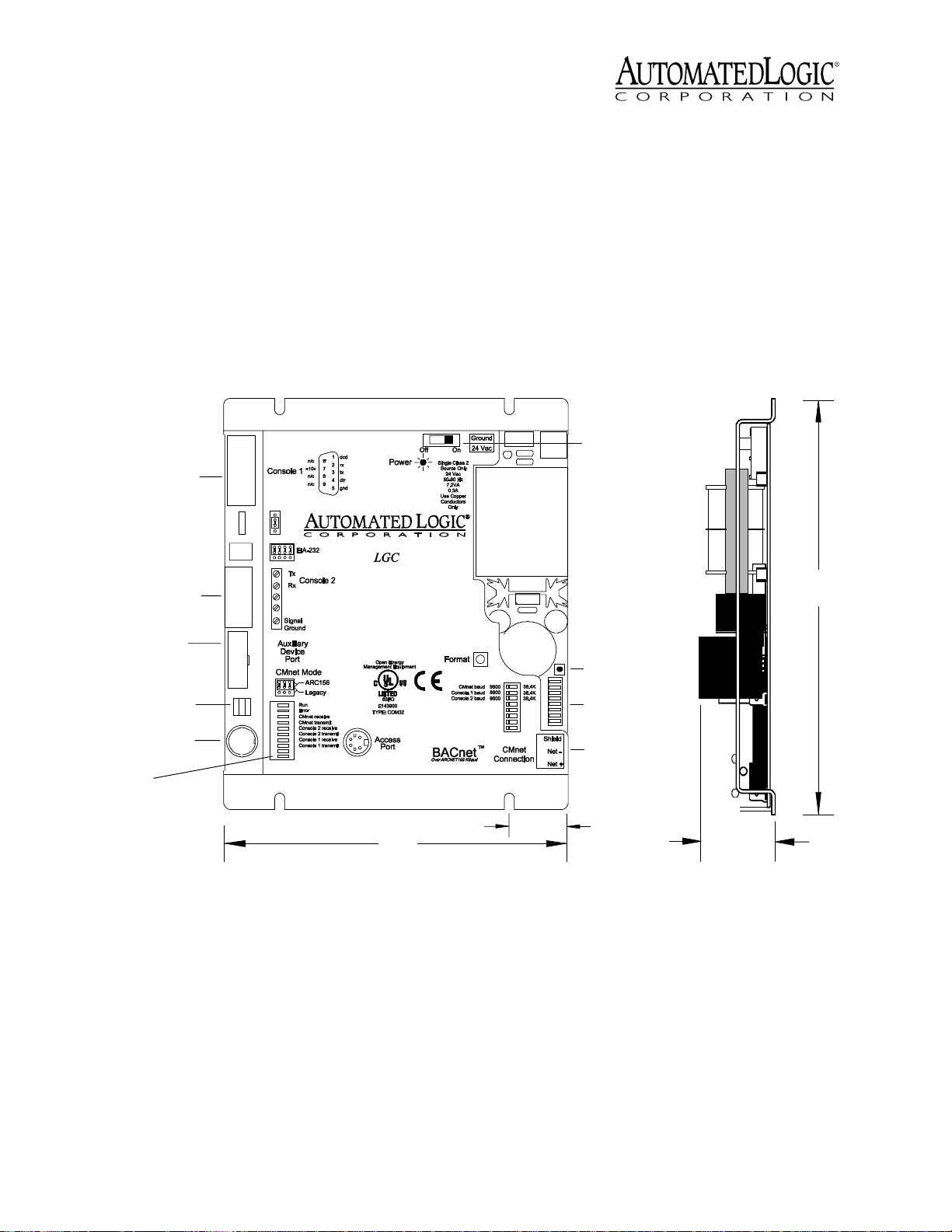

LGC

Using the LGC 2

Specifications 3

Mounting 3

Wiring 3

Power 3

Communications Wiring 4

Addressing 4

Transferring Memory 4

Troubleshooting 5

Communicating with the Workstation 5

Formatting the Module 6

LEDs 7

Protection 7

Production Date 7

Automated Logic Corporation • 1150 Roberts Blvd. • Kennesaw, GA 30144 • 770/429-3000 • 770/429-3001 Fax •

www.automatedlogic.com • Copyright 2000 Automated Logic Corporation. All rights reserved. Automated Logic, the

Automated Logic logo, SuperVision, Eikon, Alert and InterOp are registered trademarks of Automated Logic

Corporation. BACnet

their respective companies.

®

is a registered trademark of ASHRAE. All other brand and product names are trademarked by

Page 2

Using the LGC

The LGC is part of the LANgate family and

provides communication between a

workstation and a control module network

(CMnet) consisting of fewer than 100

modules.

The LGC communicates with the CMnet using

an EIA-485 connection. The CMnet is a peerto-peer network that allows all control

modules to communicate with equal

authority using a token-passing protocol.

EIA-232

ConsolePort 1

EIA-232

ConsolePort 2

A workstation can communicate with the LGC

directly or through a modem. The LGC

provides two EIA-232 Console Ports and an

Access Port that can be connected to a

workstation, portable computer, or a modem.

The LGC must use v6.00g or later of the LGM

module driver. For more information, see the

LGM Module Driver

document on the

Automated Logic website at

www.automatedlogic.com.

Power Switch

71/8"

Auxiliary

Device Port

CMnet Baud

Rate Jumper

Access Port

LEDs

61/4"

Figure 1. Module dimensions and layout

NOTE

This equipment has been tested and

found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide

reasonable protection against harmful

interference when the equipment is operated

in a commercial environment. This

equipment generates, uses, and can radiate

radio frequency energy and, if not installed

Manual Format

Button

Addressing

DIP Sw itch

CMn et

Connection

1"

15/8"

and used in accordance with the instruction

manual, may cause harmful interference to

radio communications. Operation of this

equipment in a residential area is likely to

cause harmful interference in which case the

user will be required to correct the

interference at his own expense.

Revised 6/16/00 • LGC 2 © 2000 Automated Logic Corporation

Page 3

Specifications

Power

Communications

Environmental Operating Range

Status Indication

Memory

Protection

Bat t e ry

Listed By

24VAC ±10%, 0.3A [(7.2VA), 5060Hz, power consumption] (single Class

2 source only, 100VA or less).

CMnet Port with EIA-485,

twisted pair, selectable for 156 kbps, 38.4

kbps, or 9600 bps. Two Console Ports,

selectable for 38.4 kbps or 9600 bps, for

direct connect or modem. One Access

Port for direct network using an APT. One

Auxiliary Device Port for a keypad/

display.

0 to

130°F (-17.8 to 54.4°C); 10 to 90% relative

humidity, non-condensing.

Visual (LED) status of

Console Port 1 and CMnet

communications, errors, running, and

power.

1MB Flash, 1MB RAM.

Built-in surge and transient

protection circuitry.

7-year lithium BR2325 battery

provides a minimum of 10,000 hours of

data retention during power outages.

UL 916 (PAZX), cUL C22.2

No.205 - M1983 (PAZX7), FCC Part 15 Subpart B - Class A.

Mounting

Screw the LGC into an enclosed panel using

the mounting holes provided on the cover

plate. Be sure to leave about 2 inches (5

centimeters) on each side for wiring.

BACview

the auxiliary device port.

You must use SuperVision to transfer memory

to the LGC. You can connect a portable

computer running SuperVision to the LGC

using the module’s Access port. For more

information about connecting to a

workstation, refer to “Formatting the Module”

on page 6.

1

or BACview2 keypad display unit to

Power

CAUTION

device (less than 30VAC, 100VA maximum).

Take appropriate isolation measures when

mounting the LGC module in a control panel

where non-class 2 devices or wiring are

present.

You can power several modules from the

same transformer if you maintain the same

polarity.

The LGC has an operating range of 21.6VAC

to 26.4VAC. If voltage measured at the

module’s power input terminals is outside this

range, the module may not work properly.

Since the module’s address is factory-set as

#1, you do not need to set the address.

1. Turn the module’s power off. This

prevents the module from being powered

up before the proper voltage is verified.

2. Make sure the 24VAC power source is off.

The LGC module is a Class 2

CAUTION

unit not expressly approved by the party

responsible for compliance could void the

user’s authority to operate equipment.

Changes or modifications to this

Wiring

The LGC connects to the CMnet through a

CMnet Connection port. The LGC also

provides an EIA-232 port for diagnostic

purposes. You can connect an optional

Revised 6/16/00 • LGC 3 © 2000 Automated Logic Corporation

3. Connect the power wires to the module’s

power terminals labeled Ground and

24VAC (see Figure 1 on page 2 for

location).

4. Apply power to the transformer.

5. Make sure that 24VAC is present at the

module’s power input terminals.

When the module turns on, the Run and

Error LEDs turn on and the Run LED

begins blinking. See Table 2 on page 7 to

Page 4

troubleshoot the LEDs. If the module does

not respond, call Technical Support at

(770) 429-3002.

Communications Wiring

The LGC can connect to the CMnet at 9600

bps, 38.4 kbps, or 156 kbps. When

communicating at 156 kbps, the CMnet uses a

unique implementation of the industry

standard ARCNET protocol called ARC156.

For a summary of the differences between

ARCNET and ARC156, please refer to

CMnet Wiring Technical Instructions

ARC156

.

Baud 156K

Bau d 156K

Baud 9 600/38.4K

Consolebaud 9600

address

(Module)

CMnetbaud 9600

LGnet

38.4K

38.4K

On

Off

4

2

1

Figure 2. Using an ARC156 CMnet

Use the appropriate wire for CMnet

communications. When using the ARC156

protocol, use an A3ARC156 wire available

from:

Magnum Cable Corporation

Cleveland, OH 44110-0500

(800) 421-0820

Use a dedicated 22AWG to 18AWG twisted

pair EIA-485) for legacy CMnet wiring. For

more information about CMnet wiring, refer

to the

Technical Handbook

CMnet Wiring Technical Instructions

or to

ARC156

.

1. Turn off the power.

2. Attach the two CMnet EIA-485

communications wires to the CMnet

Connection port labeled Net - and Net +

on the LGC (see Figure 1 on page 2). On

an ARC156 CMnet, you must also connect

the Shield.

Be sure to follow the same polarity as

used throughout the rest of the CMnet.

3. Make sure the LGC is configured for the

correct baud rate. All modules on the

CMnet must use the same baud rate.

On an ARC156 CMnet, set the CMnet Baud

Rate jumper to Baud 156K. Refer to Figure

2 for the jumper’s location.

If you are using a legacy CMnet, set the

CMnet Baud Rate jumper to Baud 9600/

38.4K and select the proper speed with

the first switch on the Addressing DIP

switch. Refer to Figure 3 for the switch’s

location.

CMnet Baud 9600

Baud 9600/38.4 K

Bau d 156K

Baud 9 600/38.4K

Console 1 Baud 9600

Console 2 Baud 9600

CMnetbaud 9600

Consolebaud 9600

LGnet

Off

address

4

2

(Module)

1

Figure 3. Using a Legacy CMnet

38.4K

38.4K

38.4K

38.4K

38.4K

On

Addressing

The LGC’s address is factory-set as control

module #1 and cannot be changed.

Transferring Memory

The LGC module stores the LGM module

driver. To transfer the module driver to the

LGC, you must use SuperVision v2.6 or later

software, and you must use FBLINK version

2.7a or later. For more information about

using SuperVision, refer to the

User’s Guide

.

SuperVision

Revised 6/16/00 • LGC 4 © 2000 Automated Logic Corporation

Page 5

The first memory transfer to the LGC takes

9

Rx

6

1

2-Tx out

3-Rx in

5-Gnd

1,6,8-+10V or floating

Tx +5V

APT

5

Exec. 4 relay

Isolate Network

Mode Select

TTL

485

ACCESS

PORT

EIA-232

Port

Mode Select

Switch

Exec. 4 relay

Switch

Access

Port

Ground

24Vac

Optiona

l

She

i

l

d

Net-

Net+

longer than subsequent memory transfers.

1. Log in to SuperVision on a workstation

connected to the CMnet. You can also

connect directly to the gateway using the

Access Port; see “Communicating with the

Workstation” .

2. Navigate to the module driver and look at

the module status page in SuperVision to

make sure the gateway type and number

agree with the module.

• To view the module status page in

SuperVision v3.0, click Tools Troubleshooting - Module Status.

• To view the module status page in

SuperVision v2.6, press the Esc key,

type

MO ,,module address,15

and press Enter.

3. Transfer memory to the module.

• In SuperVision v3.0, click Tools Troubleshooting - Transfer Memory to

Module.

• In SuperVision v2.6, choose Download

Memory for This Module.

When the memory transfer is finished, check

the module status page again. Make sure the

FB List shows all the FBs you intended to

transfer.

Figure 4. Using the Access Port

speed for each Console Port is set individually

using the eight-position DIP switch. DIP

switch 1 sets the baud rate for Console Port 1

and switch 2 set the baud rate for Console

Port 2 (see Figure 3 on page 4). Use the wiring

diagrams in Figure 5 on page 6 to connect a

Console Port to a workstation or a modem.

Use the following procedure to connect the

Access Port to a workstation.

1. Connect the computer’s serial port to the

EIA-232 port of the APT using a standard

straight-through cable (see Figure 4).

2. Set the APT’s Mode Select switch.

• On an ARC156 CMnet, use the TTL

setting.

• On a legacy CMnet, use the 485 setting.

3. Connect the Access Port of the APT to the

Access Port of the module.

Troubleshooting

4. In SuperVision, define the connection type

using Table 1

Communicating with the Workstation

The LGC can connect to a workstation

through the Access port using an APT (see

Figure 4) or through the Console Ports. A

Console Port can connect directly to the

workstation’s serial port or to a modem,

through which you can dial the workstation.

The LGC’s Console Ports can communicate at

9600 bps or 38.4 kbps. The communication

Revised 6/16/00 • LGC 5 © 2000 Automated Logic Corporation

Table 1. Connection Types

SuperVision

Vers i o n

3.0 any n/a Access Port

2.6 ARC156 yes Direct Connect

2.6 ARC156 no Direct Network

2.6 legacy n/a Direct Network

Typ e o f

CMnet

Gateway

Present?

Use Connection

Type

Page 6

Console Po rt

(9 pin )

*DCD 1

RX 2

TX 3

*DTR 4

GND 5

Console Port 1

Workstation

(9 pin)

4DTR*

3TX

2RX

1 DCD*

5GND

Console P ort 2

Console Port

(5 pin)

TX 1

RX 2

GND 5

Workstation

(9 pin)

2RX

3TX

5GND

Console Port

(9 pin )

*DCD 1

RX 2

TX 3

*DT R 4

GND 5

Console Port

(9 pin)

*DCD 1

RX 2

TX 3

*DT R 4

GND 5

*DS R 6

**RTS 7

**CT S 8

*RI 9

W orkstation

(25 pin)

20 DTR*

2TX

3RX

8 DCD*

7GND

Modem

(25 pin )

8 DCD*

3RX

2TX

20 DTR*

7GND

6DSR*

4RTS**

5CTS**

22 RI*

Console P ort

GND 5

Console Port

(5 pin)

TX 1

RX 2

*D TR 3

*DCD 4

GND 5

* W ire connection usually not needed

** N eeded only if hardware handshaking is used

† DCD can be hooked up to the DTR signal for

self-handshaking

Figure 5. Wir ing Diagrams

(5 pin)

TX 1

RX 2

Workstation

(25 pin)

3RX

2TX

7GND

Modem

(25 pin )

2 TX (receive input)

3 RX (transmit output)

20 DTR*†

8 DCD*†

7GND

The baud rate of the Access Port is

determined by the CMnet Baud Rate DIP

switch on the module.

2. Press and hold the Format button (see

Figure 1 on page 2 for location). While

continuing to hold the Format button, turn

the module’s power on.

Formatting the Module

When you are unable to communicate with a

module, you can, as a last resort, manually

format the module to try to restore

communication. Formatting the module

erases all memory, so you need to transfer

memory back to the module once it is

3. Continue to hold the button until the Error

LED flashes three times in sync with the

Run LED.

4. Release the Format button.

5. Transfer memory to the module. Refer to

“Addressing” on page 4.

formatted.

1. Turn the module’s power off.

Revised 6/16/00 • LGC 6 © 2000 Automated Logic Corporation

Page 7

LEDs

The LGC has several LED indicators to show

the status of certain functions. Table 2

explains the Run and Error LED signals in

detail to assist troubleshooting. See Figure 1

on page 2 for location of LED signals.

Table 2. LED Signals

Run LED Error LED Condition

5 flashes

per second

7 flashes

per second

Off Firmware transfer in

progress

7 flashes

per second

Ten second recovery

period after brownout

Power - indicates power is being supplied to

the module.

CMnet receive -indicates when the LGC

receives data from the CMnet.

CMnet transmit - indicates when the LGC

transmits data over the CMnet.

Console receive - indicates when the Console

Port receives data.

Console transmit - indicates when the

Console Port transmits data.

An - blinks to indicate network activity.

Table 2. LED Signals

Run LED Error LED Condition

2 flashes

per second

2 flashes

per second

2 flashes

per second

Off Normal

1 flash per

second

2 flashes

alternating

per second

Normal, but module is

alone on the CMnet

Five minute auto-restart

delay after system error

14 flashes

per second

14 flashes

per second

Brownout

Protection

The LGC is protected by internal solid state

Polyswitches on the incoming power and

network lines. These Polyswitches are not

replaceable and will reset themselves if the

condition that caused the fault returns to

normal.

Production Date

To determine when a module was

manufactured, check the Module Status

report in SuperVision. Refer to the

User’s Guide

for more information about the

Module Status report.

A sticker on the back of the module also

shows the date the module was

manufactured. The first three characters on

the sticker indicate the type of module. The

next three characters show the year, month,

and week of manufacture. (The month digit is

in hexadecimal.)

SuperVision

2 flashes

per second

2 flashes

per second

2 flashes

per second

2 flashes

per second

5 flashes

per second

Revised 6/16/00 • LGC 7 © 2000 Automated Logic Corporation

2 flashes in

sync per

second

3 flashes

per second

4 flashes

per second

On Exec halted after frequent

On Exec start-up aborted, Boot

Module is configured for a

different baud rate than the

rest of the CMnet

Module has just been

formatted

Two or more items in the

database have the same

ARC156 CMnet address

system errors

is running

Loading...

Loading...