Page 1

Technical Instructions

InterOP8500

Introduction 2

Specifications 3

Mounting 4

Connecting Expander Modules 4

Addressing 4

Power Wiring 5

Using the ALC Power Supply 6

Using the Johnson Power Supply 7

Network Communications 7

Communicating with the Workstation 8

Input/Output 9

Analog Inputs 9

Unswitched and Switched Inputs 10

Calculating Offset and Gain 12

Binary I/O Power Jumper 12

Binary Inputs 13

Binary Outputs 13

Point Identifiers 15

Point Identifiers in WebCTRL 15

Channel Numbers in SuperVision 15

Transferring Memory 17

Transferring Memory in WebCTRL 17

Transferring Memory in SuperVision 18

Troubleshooting 18

Formatting the Module 18

LEDs 18

Protection 19

Production Date 19

Sample GFB 20

Automated Logic Corporation • 1150 Roberts Blvd. • Kennesaw, GA 30144 • 770/429-3000 • 770/429-3001 Fax •

www.automatedlogic.com • Copyright 2001 Automated Logic Corporation. All rights reserved. Automated Logic, the

Automated Logic logo, SuperVision, Eikon, Alert, and InterOp are registered trademarks of Automated Logic

Corporation. WebCTRL is a trademark of Automated Logic Corporation. BACnet

All other brand and product names are trademarked by their respective companies.

®

is a registered trademark of ASHRAE.

Page 2

Introduction

The InterOP8500 mounts directly to a Johnson

Controls panel, replacing the Johnson FIC-1n1

control board and the PCR-102. The

InterOP8500 uses the same mounting

brackets and can be powered by the existing

power supply (using a special adaptor cable).

However, in order to retain the UL listing, the

RPA-105 and the LPS-105 must be replaced by

the PWRSUP8500.

In addition, the InterOP8500 uses the Johnson

field termination board (FTB-102) for binary

I/O and analog input. Please note that slave

FICs must be replaced by separate, standalone InterOP8500 modules.

The InterOP8500’s edge connector plugs

directly into the field termination board’s

socket. Once connected, the InterOp8500

accesses the binary and analog I/O, as well

as an isolated 12VDC power supply for its

binary outputs. The InterOP8500 board

contains the microprocessor, a connection

port for the network connection, and a port

for I/O expansion. The InterOP8500 has 8

binary inputs, 15 analog inputs (which can be

set to either RTD or voltage mode), and 16

digital outputs.

The Access Port allows communication with

WebCTRL or SuperVision. The InterOP8500's

keypad port provides the interface for serial

communications with a BACview

BACview

BACview

2

keypad display. Refer to the

1

or BACview

2

Hardware Technical

1

or

Instructions for more information on small

and large keypad display.

NOTE

NOTE A 24VAC power supply is required for

NOTENOTE

a keypad.

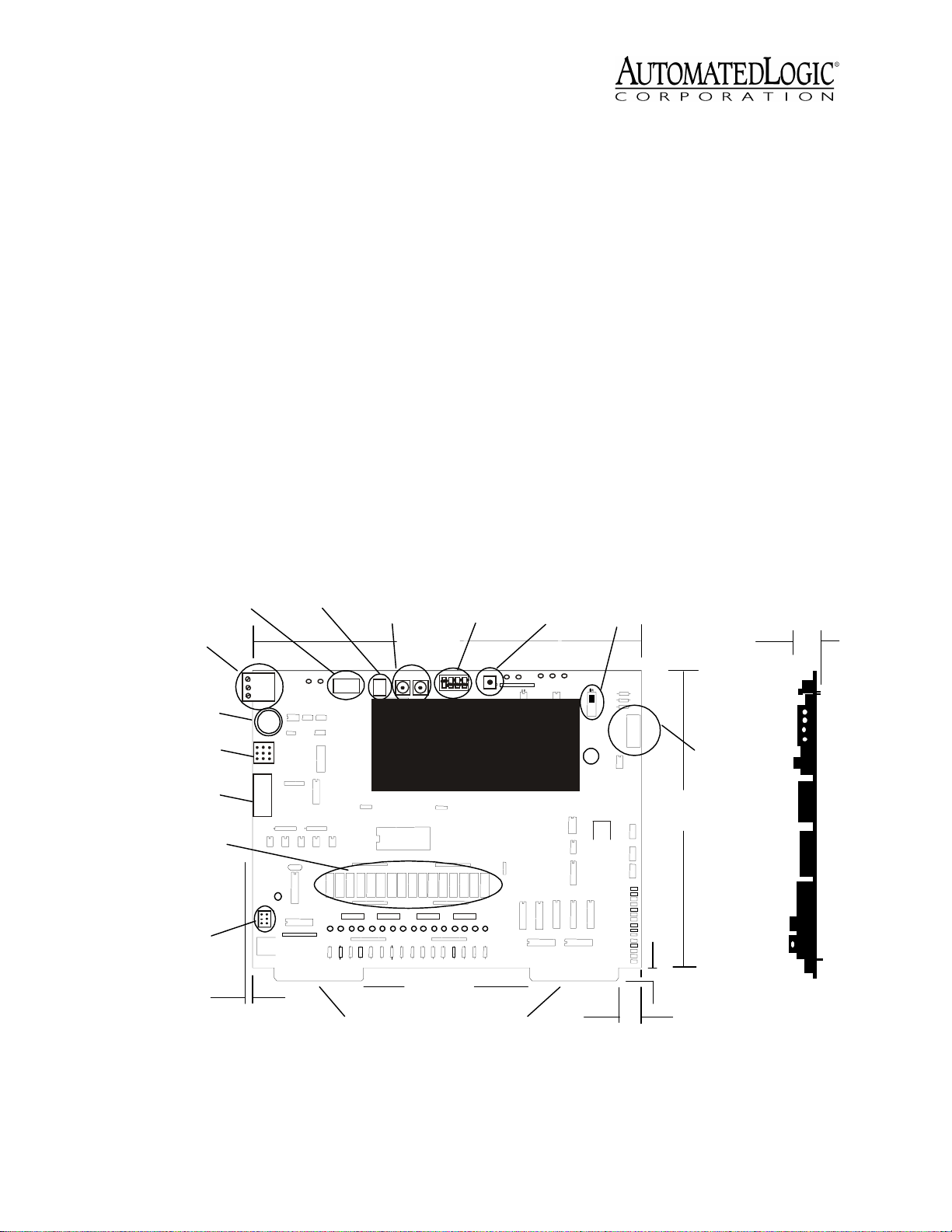

Keypad Port

CMnet

Terminal

Access

Port

Comm Mode

Jumper

Expander Port

Binary Output

HOA Switches

Binary I/O

PowerJumper

2/8"

.64 cm

Keypad

Power

Dual Rotary

Address

Binary I/O

Baud Rate

11 1/4"

28.58 cm

10's 1's

Binary Outputs

47/8"

12.38 cm

Switch

InterOp8500

Analog Inputs

Format

Button

Power

Switch

5/8"

1.59 cm

1"

2.5 cm

Power

Terminals

85/8"

21.9 cm

3/8"

.95 cm

Figure 1. InterOP8500 layout and dimensions

Revised 7/10/01 • InterOP8500 2 © 2001 Automated Logic Corporation

Page 3

The table below outlines the limitations and

s

requirements depending on whether you are

using WebCTRL or SuperVision to

communicate with your InterOP8500.

Specifications

Power 5VDC, 175mA (external), 275 mA

(internal).

12VDC, 25mA.

WebCTR L Super Vision

Module Driver DRV_InterO

P8500

Number of Function

Blocks*

Number of BACnet

Objects*

* depending on available memory

100 59

2000 1000

85M

For more information, see the appropriate

module driver document on the Automated

Logic website at www.automatedlogic.com.

12VDC, 175mA (external power), 25 mA

(internal power) supplied through the

card-edge connector.

24VAC, 300mA for use with the large

keypad/display.

Inputs 8 binary inputs, 15 analog inputs

(configurable for 1k ohm nickel RTD or 1

to 5V).

Input Resolution 12 bit A/D.

Digital Outputs 16 digital outputs,

12VDC, 300mA fused output.

Communication For WebCTRL, 156 kbps

BACnet-over-ARCNET and 9600 bps or

38.4 kbps EIA-485 BACnet MS/TP.

For SuperVision, 156 kbps BACnet-overARCNET, 9600 bps or 38.4 kbps Legacy

CMnet. Access Port:9600 bps or 38.4 kbps

EIA-485.

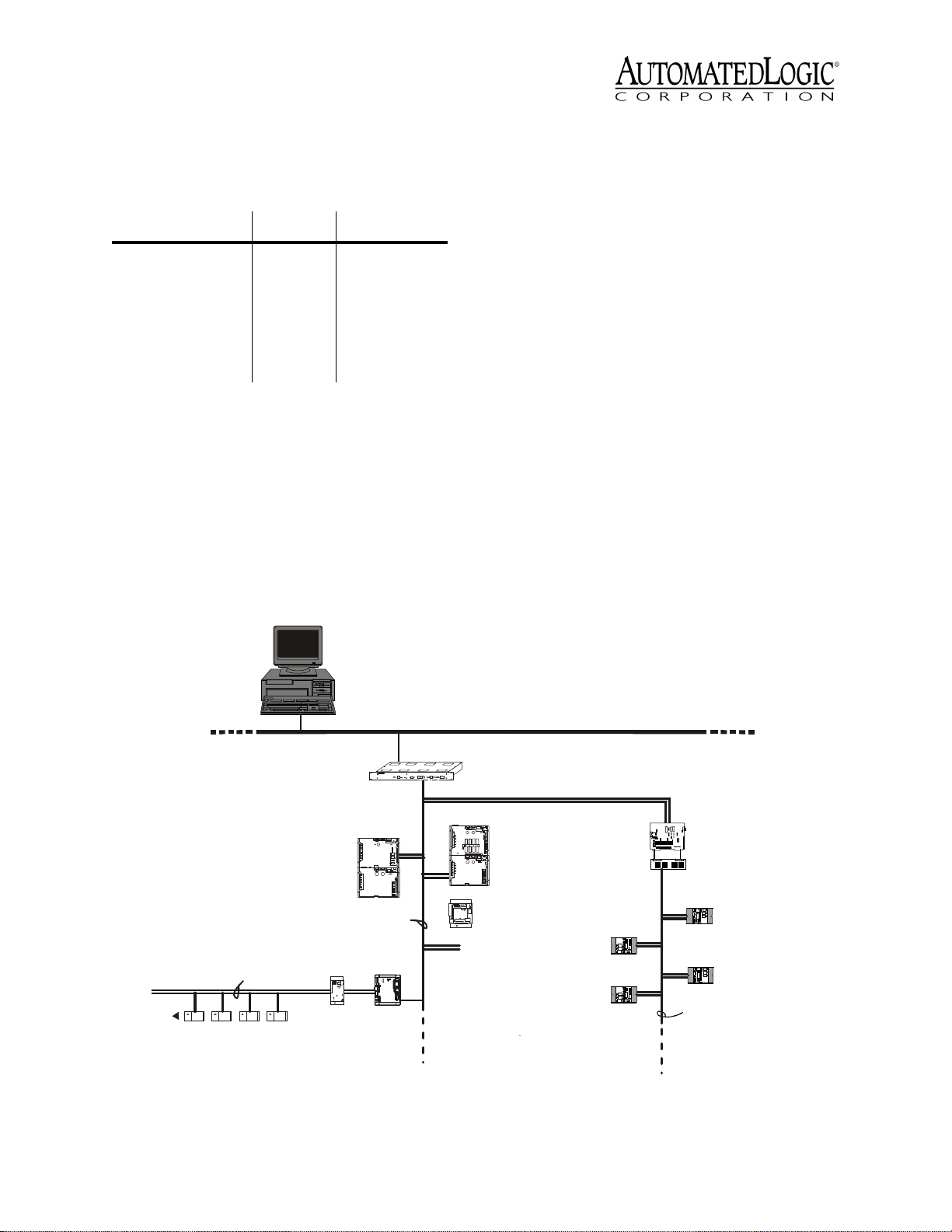

MX-Line

U-Line: 9600 bp s or 3840 0 b p s

U-Cards

LGRM-E

CMnet (ARC156)

UNI/32

TNPB

S-Line

Figure 2. Network Architecture

For WebCTRL, BACnet/IP.

For SuperVision, BAC net/Ether net.

MX-Line

Johnson

Field Device

Johnson

Field Device

InterO p85 00

John s o n Fie ld

Termination Board

Johnson

Field Device

Johnson

Field Device

John son I/O Dev ice

Revised 7/10/01 • InterOP8500 3 © 2001 Automated Logic Corporation

Page 4

Environmental Operating Range 0-

130 °F (-17.8 to 54.4 °C), 10 to 90%

relative humidity, non-condensing.

Status Indication Visual (LED) status of

CMnet communication, running, errors,

and power.

Memory 1MB Flash memory, 2MB non-

volatile battery-backed RAM (which

stores data even during power failures).

128 bytes of EEPROM.

Real Time Clock A battery-backed real

time clock that keeps track of time in the

event of a power failure.

Protection Surge and transient protection

circuitry.Optically isolated

communications.

Bat t e ry Seven-year lithium BR2330 battery

provides a minimum of 10,000 hours of

data retention during power outages.

Mounting

CAUTION

CAUTION Changes or modifications to this

CAUTIONCAUTION

unit not expressly approved by the party

responsible for compliance could void the

user's authority to operate the equipment.

place with the plastic retainers provided

in the panel.

4. Place the brushed aluminum ALC label on

the door of the panel.

Connecting Expander Modules

Up to five expansion Mx modules can be

connected to an InterOP8500. The stack can

be arranged in a single column using the

optional expansion cable.

NOTE

NOTE Use only one expansion cable per

NOTENOTE

stack.

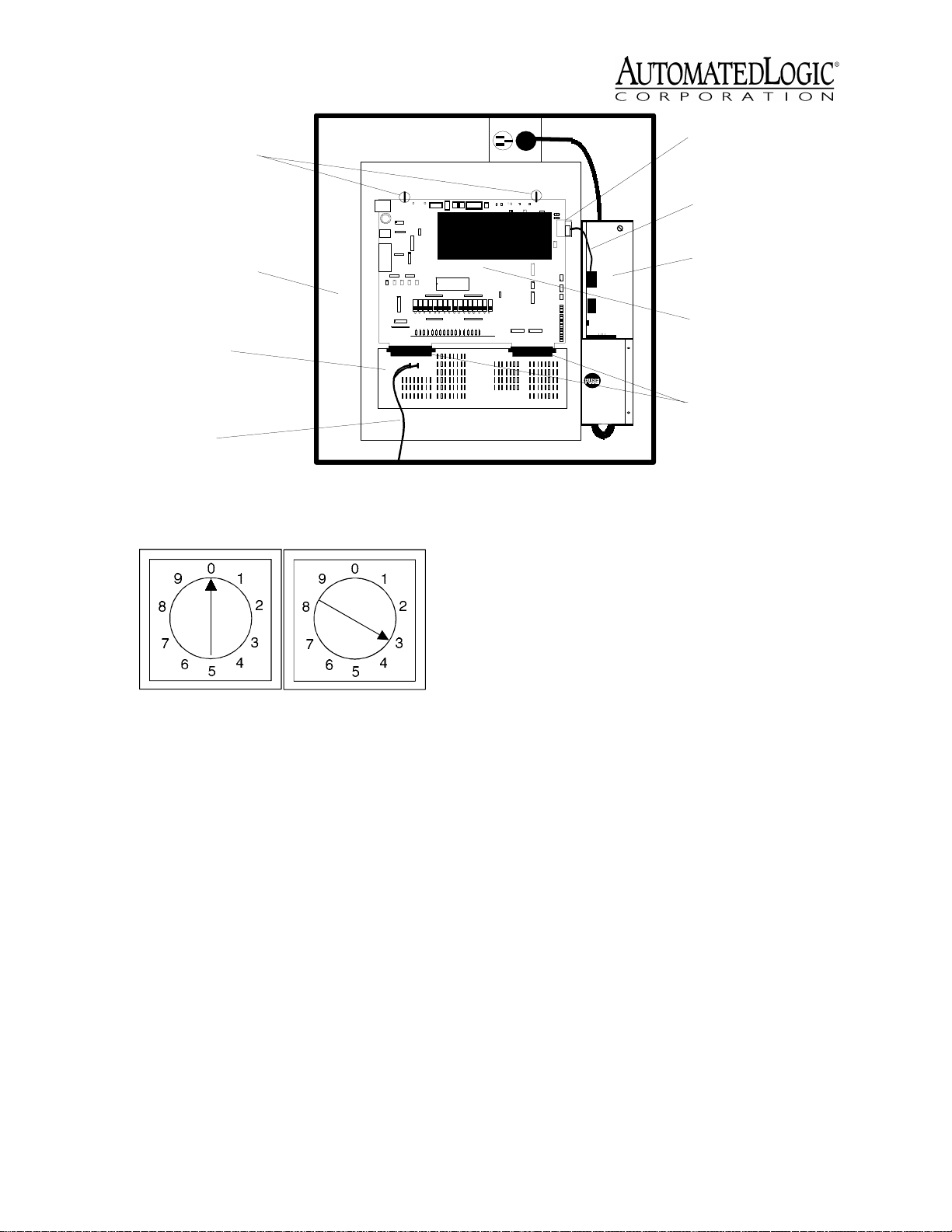

Addressing

Before setting or changing the address, make

sure the InterOP8500’s power is off. The

InterOP8500 only reads the address when the

module is turned on. After changing the

address, you must transfer memory to the

module. Refer to “Transferring Memory” on

page 17.

The InterOP8500 has two rotary switches for

addressing:

1. Remove all power to the Johnson Controls

panel.

2. Open the face of the Johnson Controls

panel. The panel may contain up to three

Johnson Controls boards which face the

front of the panel and a side-mounted

board.The facing boards are stacked

above one another and are located

adjacent to the field termination board.

Remove the facing boards and any cables

(called "RPA wires") connected to them.

3. The InterOP8500 mounts directly to the

field termination board using either the

PWRSUP8500 or the existing power

supply (RPA-105 and LPS-105) as shown

in Figure 3 on page 5 and Figure 5 on page

6. Connect the InterOP8500 edge

connectors to the field termination

board's socket. Lock the InterOP8500 in

• For WebCTRL systems, use the switches

to assign the device’s MAC (medium

access control) address on the BACnetover-ARCNET network segment. The

rotary switches define the MAC address

portion of the device’s BACnet address

which is composed of the network

address and the MAC address.

• For SuperVision systems, use the

switches to assign the device’s module

number.

One switch corresponds to the tens digit and

the other corresponds to the ones digit. For

example, if the module’s address is three, set

the tens switch to zero and the ones switch to

three, as shown in Figure 4 on page 5.

Revised 7/10/01 • InterOP8500 4 © 2001 Automated Logic Corporation

Page 5

Plastic Retainer s

InterOp-8500

Power Connector

Power Cab le

Johnson Controls

Panel

Johnson Field

T e rmination Board

(FTB-102)

to External

Power Supply

Figure 3. InterOp8500/PWRSUP8500 mounted in Johnson Controls panel

10's 1's

Figure 4. Setting the CMnet address

Power Wiring

The InterOP8500 module is designed to

accept power directly from either the

PWRSUP8500 or the existing Johnson power

supply (LPS-105 and RPA-105). In order to

retain the UL listing of your system, a field

inspection is required if using a Johnson

power supply or the RPA-105 and the LPS-105

must be replaced by the PWRSUP8500 or.

Refer to “Using the ALC Power Supply” on

page 6 for wiring with the PWRSUP8500, or to

“Using the Johnson Power Supply” on page 7

for wiring with an existing Johnson power

supply.

PWRSUP8500

(side-mounted)

InterOp-8500

Edge Connectors

Whenever possible, make sure the module's

power and communications connections are

working properly before connecting any

inputs and outputs. Care should be taken to

isolate power wiring from all other wiring

inside the enclosure. The high and low

voltage wiring must be kept as far apart from

each other as is possible to avoid noise

interference.

NOTE

NOTE To protect analog signals from stray

NOTENOTE

noise and to minimize EMI, use shielded

cable on all signal wires and low voltage

power wires.

When entering, exiting, or interconnecting

with the enclosure, it is better to use several

small openings than one large one. The 12V

binary outputs are powered by a separate

source supplied through the field termination

board.

CAUTION

CAUTION The InterOP8500 module is a

CAUTIONCAUTION

Class 2 device (less than 30VAC.) Take

appropriate isolation measures when

mounting an InterOp8500 module where

non-Class 2 devices or wiring are present.

Revised 7/10/01 • InterOP8500 5 © 2001 Automated Logic Corporation

Page 6

Johnson Controls

Panel

Plastic Retainers

LPS-105

InterOp-8500

Edge Connectors

Johnson Field

Termination Board

(FTB-102)

to External

Power Supply

Figure 5. InterOp8500/RPA-105 and LPS-105 mounted in Johnson Controls panel

Using the ALC Power Supply

The PWRSUP8500 power supply replaces both

the Johnson Controls LPS-105 and Johnson

RPA-105. The PWRSUP8500 is designed to fit

into the previous power supply's mounting

bracket and power the InterOP8500. The

PWRSUP8500 does not require any adaptor

cables. It connects directly to the

InterOp8500's power connector.

CAUTION

CAUTION The PWRSUP8500 module is a

CAUTIONCAUTION

120VAC device. Take appropriate isolation

measures when mounting a PWRSUP8500.

1. Turn the power switches off on the

InterOP8500 and the Johnson Controls

panel.

2. Unplug the LPS-105 from the power outlet

(see Figure 5).

3. Remove the power cable from the

InterOP8500 power connector.

ON

OFF

J20

J23

Panel Power

Switch

Grounding Wire

(green)

RPA-105

(side-mounted)

Power Adapter

Cable

4. Take out the mounting screw from the

face of the LPS-105 and remove the LPS105 from the Johnson Controls panel.

5. Take out the mounting screw from the

back of the RPA-105 and remove the RPA105 from the Johnson Controls panel.

6. Place the PWRSUP8500 in the same

brackets that the RPA-105 was in. Make

sure the edges of the PWRSUP8500 are in

the slots.

7. Replace the mounting screw in the back

of the PWRSUP8500 (see Figure 3 on page

5).

8. Connect the power cable of the

PWRSUP8500 to the InterOP8500 power

connector and plug the PWRSUP8500 into

the power outlet.

9. After verifying that you have +5V on the

red and +12V on the blue, referenced to

the Gnd (black), turn the InterOp8500

power switch on.

Revised 7/10/01 • InterOP8500 6 © 2001 Automated Logic Corporation

Page 7

Using the Johnson Power Supply

1. Verify that the InterOP8500 is addressed

correctly.

2. Turn the Johnson Controls panel power

switch off.

3. Turn the InterOP8500 power switch off

(see Figure 1 on page 2).

4. Use the Power Adaptor Cable shown in

Figure 6 to connect power from the

Johnson power supply to the InterOP8500.

There is only one way for the connectors

on the cable to properly connect to the

indicated J terminals - do not force the

connectors on the wrong terminal.

5. Connect a grounding wire from the

chassis of the panel to the earth ground

terminal of the InterOp8500. See Figure 5

on page 6 for wiring.

6. Turn the InterOP8500 power switch on.

7. Turn the panel power switch on.

8. Make sure that the Communications

Power, Logic Power +5V, and Power +12V

LEDs are lit (located at the top edge of the

InterOp8500 board). See “LEDs” on

page 18.

Network Communications

The InterOP8500 module supports several

communications options through its CMnet

port.

On a SuperVision system, the InterOP8500

module can connect to a BACnet-overARCNET network segment at 156 kbps, or to

a legacy CMnet at 9600 bps or 38.4 kbps.

When communicating at 156 kbps, the

network segment uses a unique

implementation of the industry standard

BACnet-over-ARCNET protocol called

ARC156. For a summary of the differences

between ARCNET and ARC156, please refer to

ARC156 CMnet Wiring Technical Instructions.

Use the appropriate wire for network

communications. When using an ARC156

network, use an A3ARC156 wire available

from:

Magnum Cable Corporation

Cleveland, OH 44110-0500

(800) 421-0820

Use a dedicated 22AWG to 18AWG twisted

pair wire for legacy CMnet (EIA-485) wiring.

For more information about CMnet wiring,

refer to the Technical Handbook or to ARC156

CMnet Wiring Technical Instructions.

1. Be sure the module’s power is off before

J23

wiring it to the network.

2. Check the network communication wiring

for shorts and grounds.

J3

Figure 6. Power Cable

J20

3. Connect the appropriate communications

wires to the module’s screw terminals as

shown in Figure 7 on page 8. Be sure to

follow the same polarity as the rest of the

network.

4. Make sure the module is configured for

the correct baud rate. All modules on the

Revised 7/10/01 • InterOP8500 7 © 2001 Automated Logic Corporation

Page 8

ARC156

network segment

Switch Number

38.4K baud

9600 baud

1 2 3 4

O

N

CMnet

Access p ort

Comm Mode port

Figure 7. Wiring the Terminals

network segment must use the same baud

rate.

On an ARC156 network segment (156

kbps), set the Comm Mode jumper to

ARC156 (see Figure 8 for the switch’s

location). The baud rate selection does

not matter in this case.

Comm Mode

CMnet

ARC156

Figure 10. Setting the baud rate DIP switch

You can verify that the InterOP8500 is

communicating on the network segment by

making sure the transmit and receive LEDs

are active.

Communicating with the Wo r k s tat i o n

When using SuperVision, you can connect a

workstation or portable computer directly to

the InterOP8500 module using an APT and the

module’s Access Port (see Figure 11). This

type of connection can be used to

troubleshoot the module or transfer memory.

If you are using an ARC156 network segment,

you can receive colors while connected to a

module’s Access Port if a gateway module is

on the network segment. You cannot receive

alarms through the Access Port, however.

Figure 8. Using an ARC156 Network Segment

If you are using a legacy CMnet (9600 bps

or 38.4 kbps), set the Comm Mode jumper

to CMnet, and use the baud rate DIP

switch to determine the baud rate (see

Figure 9 and Figure 10).

NOTE

NOTE Setting the Comm Mode jumper

NOTENOTE

to CMnet disables the industry standard

BACnet-over-ARCNET (ARC156) protocol

for the network segment and enables the

proprietary ALC CMnet protocol.

Comm Mode

CMnet

Figure 9. Setting the Mode Select for CMnet

ARC156

InterOp-8500

APT

ACCESS

PORT

EIA-232

Port

Mode Select

TTL

Mode Select

Switch

Access

Port

485

Figure 11. Usi ng the Access Port

The baud rate of the Access port is

determined by the first switch on the eightposition DIP switch (see Figure 7). If you need

to change the switch’s position, turn the

InterOP8500 module off first. Once you have

adjusted the switch, turn the module back on.

Revised 7/10/01 • InterOP8500 8 © 2001 Automated Logic Corporation

Page 9

1. Connect the computer’s serial port to the

EIA-232 port of the APT using a standard

straight-through serial cable.

2. Set the APT’s Mode Select switch.

• On an ARC156 network segment, use

the TTL setting.

Table 2. Cable Selection Guide

Field

Device

AQ-4101

I/O

Typ e

BO 18 2 200/61

A1 18 3 250/76

Conduct

or Size

(AWG)

Number

Required

Maximum

Cable

Length

(ft/m)

• On a legacy CMnet, use the 485 setting.

3. Connect the Access port of the APT to the

Access port of the module.

4. In SuperVision, define the connection type

using Table 1.

Table 1. Connection Types

SuperVision

Ver s i o n

3.0 any n/a Access Port

2.6 ARC156 yes Direct Connect

2.6 ARC156 no Direct Network

2.6 legacy n/a Direct Network

Type o f

CMnet

Gateway

Present?

Use Connection

Type

Input/Output

The InterOP8500 is equipped with 8 binary

inputs, 15 analog inputs, and 16 binary

outputs. Any of the analog inputs can be used

as digital inputs. Table 2 summarizes the

requirements for conductors between the

Johnson Controls field devices and the

termination board.

All wiring to remote devices must be kept

separate from power wiring in the area.

Exposed drain wire at the termination board

should be kept as short as possible, not

exceeding two inches (5 centimeters). All field

devices should be terminated using a

correctly sized wire nut or, when terminals

are provided, a solderless crimp-type

connection should be made.

EPT-101

H-6210 A1 18 2 250/76

N-9510 BO 18 2 200/61

PC-6100 A1 18 2 250/76

PET-101 A1 18 2 250/76

RTB-101

PQ-1001 A1 18 2 250/76

TE-Series A1 18 2 250/76

V-9010 BO 18 2 200/61

V-9012 POS/

Power

Supply

BO 18 2 200/61

A1 18 3 250/76

BO 18 2 200/61

BI 18 2 1000/305

18 2 200/61

INC

—18 2 —

Analog Inputs

The InterOP8500 provides access to 15 analog

inputs through the Johnson Controls field

termination board. Use the formulas in the

“Calculating Offset and Gain” on page 12

section to read signals from these inputs.

There are four field terminals for each AI

point 1 through 7, and five for each AI point 8

through 15 (see Figure 12 on page 10). The

function of these terminals is as follows:

Termination Row 1 This terminal is for

analog inputs and is connected to a

multiplexer.

Termination Row 2 This terminal is

connected to a regulated +2.5VDC supply.

Revised 7/10/01 • InterOP8500 9 © 2001 Automated Logic Corporation

Page 10

Termination Row 3 This terminal is the

unswitched input signal common.

Termination Row 4 This terminal is not

used.

Termination Row 5 This terminal is the

switched input signal common and is

available only on AI points 8 through 15.

Table 3. Acceptable Analog Input Signals

Analog Input

Type Power Jumper? Switched?

RTD thermistor

0-5VDC linear

0-2.5VDC linear

4-20mA linear

(Offset/Gain

setup as

1-5VDC)

Internal Yes Unswitched

Internal No Switched or

Unswitched

Internal No Switched or

Unswitched

External (plus

No Unswitched

parallel 250

ohm resistor)

Unswitched and Switched Inputs

Unswitched inputs, the most common type of

input, reference the sensor to the module's

ground, the same ground referenced by all

other unswitched input sensors. This type of

input is for devices that are "floating,"

meaning that they are not ground referenced

anywhere. Examples would be RTD inputs or

dry contacts.

Switched inputs are selected one at a time,

and the circuit board's ground is then

referenced to the module's "Switched

Ground" lead. This feature allows modules

that are not floating, and that may have a

small amount of ground shift, to give stable

readings on their AIs. Examples would be 05VDC or 0-2.5VDC devices.

NOTE

NOTE The channel number is not affected

NOTENOTE

by the input's condition (switched or

unswitched).

Input from external

+12VD C P ower Supply

Binary Inputs

Binary Comm on

Unused

Analog Inputs

+2.5 VDC

Analog Com mon

(Unswitched)

Unused

4

2

3

1

5

8

BI #

1

1

2

3

+-

12 VDC

2

3

4

5

BO #

67

1

2

3

8

4

5

AI #

2

3

1

566677

4

11

2

3

4

Binary Outpu ts

Binary Com mon

Unused

2

3

4

5

89

10

Figure 12. I/O Terminals for the Field Termination Board

11

121314 15

Analog Inputs

+2.5 VDC

Analog Com mon

(Unswitched)

Unused

Switc hed

Comm on

Revised 7/10/01 • InterOP8500 10 © 2001 Automated Logic Corporation

Page 11

1. Turn the Johnson panel power switch off.

2. Determine the type of signal received by

the field termination board. Consult the

Johnson Controls manuals if necessary.

The InterOP8500 must be configured to

receive the same type of input as the

previously removed Johnson boards.

3. Set the InterOp8500 jumpers as follows:

• For RTD mode insert a jumper for the

individual input. The jumpers are

located along the lower right side of the

InterOP8500 board (see Figure 13).

NOTE

NOTE If using a solid-state current

NOTENOTE

switch on a digital input, the resistance

must drop low enough for the module to

recognize it.

• For voltage and potentiometer mode,

remove the jumpers. (Current mode can

be configured by adding an external

sense resistor. For 4-20mA use a 250

ohm resistor Figure 14). Turn the

InterOP8500's power switch on.

15

14

Unsw itched Inputs

Jumper in Place =

RTD Mode

Switched Inputs

Jumper Removed =

Voltage M ode

Figure 13. Analog Input Jumpers

13

12

11

10

Grip

Here

9

8

7

6

5

4

3

2

1

120 VAC

XX VAC

ungrounded

Field Termination

Board

As specified by the

sensor manufacturer.

Sensor

Isolated

DC Power

Supply

4-20mA

Transducer

250 ohm

resistor

InterOp8500

Connect to Analog Input

Connect to Analog Common (unswitched)

Figure 14. Analog Input Wiring for 4-20 mA Signal

Revised 7/10/01 • InterOP8500 11 © 2001 Automated Logic Corporation

Page 12

4. For each input, enter the point identifiers.

• In WebCTRL, enter the point number

and the point type on the Properties

page. For linear inputs, set the

minimum value and maximum value to

scale the point to engineering units.

For example, consider a 1 to 4.5V humidity

sensor with a relative humidity of 20 to 90%.

The voltage span is 3.5 volts (4.5V - 1V). The

user unit span is 70% (90% - 20%). Calculate

the gain and offset for a humidity sensor like

this:

• In SuperVision, enter the channel

number, offset, and gain using the

Configure Points or Point Help feature.

Valid channel numbers are listed in

“Channel Numbers in SuperVision” on

page 15.

5. To verify each input’s operation, have

each sensor create a known value and

compare it to the condition reported on

the FB’s Properties page in WebCTRL or

Status page in SuperVision.

Calculating Offset and Gain

You may need to calculate the offset and gain

for analog inputs to ensure the correct value

is read by the InterOP8500. You can also use

the custom translation table on the module

driver Parameter page to read nonlinear

signals from these inputs. Refer to the

“Channel Numbers in SuperVision” on

page 15 for details.

GAIN

= 70%

= 70% 178.5

= 0.392

OFFSET

Here is an example of a 0 to 2.5V V-9012

feedback sensor with a range of 0 to 100%

relative humidity. The voltage span is 2.5V

(2.5V - 0) and the user unit span is 100%

(100% - 0%). Calculate the gain and offset for

a V-9012 feedback sensor like this:

GAIN

= 0. 392

= 0.392 51.2

= 19.07

= 100%

= 100% 127.5

= 0.78

256 3.5 volt s

*

5 volt s

256 1 vol t

*

*

5 volts

*

256 2.5 volt s

*

5 volt s

Use this formula to calculate the gain for an

analog input point:

GAIN

= us er unit

256 voltage span

*

5 volt s

OFFSET

= 0.78

= 0.392 0

= 0

256 0 volts

*

*

*

5 volts

Binary I/O Power Jumper

Use this formula to calculate the offset for an

analog input point:

OFFSET

Revised 7/10/01 • InterOP8500 12 © 2001 Automated Logic Corporation

= GAIN

256 mi n i mu m volt age

*

*

5 volts

The InterOP8500 provides a jumper (see

Figure 1 on page 2 for location) for selecting

between internal and external power for

Binary I/O points. The InterOP8500 provides

isolation for externally powered devices and

no isolation for internally powered devices. If

binary outputs are present, they must be

externally powered and the jumper must be

set to the External position (see Figure 15 on

page 13). If no binary outputs are present,

Page 13

then binary inputs can be internally powered

(no isolation) or externally powered

(isolated). Note the orientation of the

jumpers.

Grip

Here

analog supply ground coming from the RPA-

105.

NOTE

NOTE All eight binary input terminals are

NOTENOTE

electrically connected on the field termination

board. To prevent ground loops, electrically

isolate the sources of the binary input signals

from each other.

Internal Power

(no isolation)

Figure 15. Binary I/O Power Jumper

External Power

(isolated)

Binary Inputs

The InterOP8500 provides 8 binary inputs

with direct connection to the Johnson field

termination board. The inputs are for signals

in the range of -38VDC up to +38VDC. A

digital input microblock indicates On for any

voltage between -38.0VDC and 0.9VDC; it

indicates Off for any voltage between 2.5VDC

and 38.0VDC. These inputs are capable of

counting up to 1,000 pulses per second for

use in pulse-counting configurations. Each

binary input can sense either a set of nonenergized contacts, or a two-state DC voltage

level.

The field termination board contains three

terminals for each binary input point (see

Figure 12 on page 10):

Binary Outputs

The InterOP8500 provides 16 binary outputs

with a direct connection to the field

termination board. The 16 binary outputs

have suppression. The binary output power

requirement is 13.2VDC, which should be

supplied by an external Class 2 power supply.

The output of this external power supply is

connected to a pair of field terminals located

on the field termination board (see Figure 12

on page 10 for location). The maximum load

through each binary output is 200mA.

The field termination board has terminal

capacity for between 8 and 16 points

depending upon the types of output signals

provided. Each of the eight BO points located

on the termination board consists of six field

terminals. Each of these six field terminals

can provide either one or two independently

controlled binary output points. The function

of these terminals is as follows:

Termination Row 1 This terminal is

connected to an input buffer (each input

has a separate buffer).

Termination Rows 1-2 These terminals

are independently connected to either

+12VDC or isolated common (depending on

Termination Row 2 This terminal is the

input signal common.

Termination Row 3 Do not use terminal 3

unless you need to connect an earth

ground.

The common terminals for the binary inputs

application).

Termination Rows 3-4 These terminals

are connected to isolated common. They are

used with terminals 1 and 2 for fixed-polarity

signals.

are joined to the common terminals for the

binary outputs. All common terminals are

joined to the isolated 12VDC supply's

Termination Rows 5-6 These terminals

are unused.

negative terminal through the field

NOTE

NOTE Terminals 1, 2, 3, and 4 must not be

termination board. This binary ground is

isolated and independent of the logic and

Revised 7/10/01 • InterOP8500 13 © 2001 Automated Logic Corporation

NOTENOTE

grounded. Voltages from field devices must

Page 14

not be fed back into the binary output

terminals.

Three types of output signals are available:

momentary, position, and maintained. The

momentary signal is used to control a

maintained or momentary relay

configuration. The position signal is intended

to control an actuator with a position

transducer or other interface device. The

maintained signal is intended to control a

two-position device by delivering a

maintained 0 or 12VDC signal.

Manual Operation

The HOA switches (SW3 through SW18),

located as shown in Figure 1 on page 2, allow

each binary output to be in placed in Auto,

On, or Off mode (as shown in Figure 16).

AUTO

OFF

ON

SW3 SW4 SW5 SW17 SW18

LED8 LED9 LED10 LED22 LED23

Figure 16. InterOp8500 HOA switches

AUTO

OFF

ON

To verify each output’s operation, lock the

output to a known condition using the

Function Block’s Properties page in WebCTRL

or Parameter page in SuperVision. Be sure the

equipment operates as specified.

SuperVision, assign each switch a digital

input in the FB using channel numbers 81

through 80. Channel 81 corresponds to HOA

switch number one, channel 82 corresponds

to HOA switch two, and so on. Switches 10

through 15 use channel numbers 8A through

8F, and switch 16 uses channel number 80.

An off status means the HOA switch is in Auto

mode. An on status means the HOA switch is

in Manual mode.

Table 4. HOA Switch Positions

Output

Configuration On Off Auto

Normally open

output

Normally closed

output

Results on

Properties page

in WebCTRL* or

Status page in

SuperVision**

* use point type of HOA Status Feedback and point

number

** use channel numbers 81 - 80

DO

contacts

closed

DO

contacts

open

ON ON OFF

DO

contacts

open

DO

contacts

closed

determined

by FB

programming

determined

by FB

programming

Each digital output can be placed in Manual

or Auto mode by setting the HOA switches

(see Figure 1 on page 2 for the switches’

location). Table 4 shows the status of the

digital output based on the output’s

configuration and the HOA switch position.

You can monitor the status of the HOA

switches through WebCTRL or InterOP8500.

In WebCTRL, assign each switch a digital

input in the FB using the point number and

the HOA Status Feedback point type. In

Revised 7/10/01 • InterOP8500 14 © 2001 Automated Logic Corporation

Page 15

Point Identifiers

A point can be identified in WebCTRL by its

point number and point type; in SuperVision,

a point is identified by its channel number. On

both systems, expander number zero

represents I/O points on the InterOP8500.

Point Identifiers in WebCTRL

Enter the point identifiers in Eikon for

WebCTRL before the FB is made or on the

point’s Properties page in WebCTRL. Set the

type, number, and any other required

parameters for each point on the

InterOP8500.

1. Select a physical point type from the Point

Type field.

NOTE

NOTE To determine the physical point

NOTENOTE

type of an analog input, see Table 3 on

page 10.

2. If the physical point type is linear, enter

the appropriate minimum and maximum

present values on the microblock’s dialog

box.

For example, on a 0-5VDC sensor, enter 0

as the minimum and 5 as the maximum.

3. Enter the number of the input or output in

the Input or Output Number field.

NOTE

NOTE Points are numbered starting with

NOTENOTE

1 for each point type. For example, HOA

Status output numbers would start at 1

and could go up to 16; likewise, RTD input

numbers would start at 1 and could go up

to 15.

4. Enter an expander number if needed.

Channel Numbers in SuperVision

The following table shows the valid channel

numbers for each point on the InterOP8500.

The offset and gain values used depend on

the type of sensor or actuator attached to the

I/O point. You can select the channel number,

offset, and gain using SuperVision’s Point

Help feature or Configure Points utility.

Alternatively, you can preconfigure the points

by manually entering the channel number,

offset, and gain in Eikon using the values

shown in the following tables.

Table 5. Digital Output Channel Numbers

Point Signal T ype

DO 1

DO 2

DO 3

DO 4

DO 5

DO 6

DO 7

DO 8

DO 9

DO 10

DO 11

DO 12

DO 13

DO 14

DO 15

DO 16

† Use digital input microblocks to

monitor the status of HOA Switches.

Digital

HOA Status†1181

Digital

HOA Status†1282

Digital

HOA Status†1383

Digital

HOA Status†1484

Digital

HOA Status†1585

Digital

HOA Status†1686

Digital

HOA Status†1787

Digital

HOA Status†1888

Digital

HOA Status†1989

Digital

HOA Status†1A8A

Digital

HOA Status†1B8B

Digital

HOA Status†1C8C

Digital

HOA Status†1D8D

Digital

HOA Status†1E8E

Digital

HOA Status†1F8F

Digital

HOA Status†1080

Channel

Number

Revised 7/10/01 • InterOP8500 15 © 2001 Automated Logic Corporation

Page 16

Table 6. Input Channel Numbers

Point Signal Type

RTD 51

UI 1

mA or V olts 31

Digital 71

RTD 52

UI 2

mA or V olts 32

Digital 72

RTD 53

UI 3

mA or V olts 33

Digital 73

RTD 54

UI 4

mA or V olts 34

Digital 74

RTD 55

UI 5

mA or V olts 35

Digital 75

RTD 56

UI 6

mA or V olts 36

Digital 76

UI 7 RTD 57

mA or V olts 37

Digital 77

RTD 58

UI 8

mA or V olts 38

Digital 78

RTD 59

UI 9

mA or V olts 39

RTD 5A

UI 10

mA or V olts 3A

Channel

Number †Range Offset Gain

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

0.00

15.25‡

0.00

§§

0.00

15.25‡

0.00

§§

0.00

15.25‡

0.00

§§

0.00

15.25‡

0.00

§§

0.00

15.25‡

0.00

§§

0.00

15.25‡

0.00

§§

0.00

15.25‡

0.00

§§

0.00

15.25‡

0.00

§§

0.00

15.25‡

0.00

§§

0.00

15.25‡

0.00

§§

Table 6. Input Channel Numbers

Point Signal Type

RTD 5B

UI 11

mA or V olts 3B

RTD 5C

UI 12

mA or V olts 3C

RTD 5D

UI 13

mA or V olts 3D

RTD 5E

UI 14

mA or V olts 3E

RTD 5F

UI 15

mA or V olts 3F

† Celsius values can only be displayed in SuperVision when the Function

Block is made in Eikon v2.0 or later with the Metric option enabled. Refer to

the Eikon User’s Guide for more information.

§ Use the Point Configuration or Point Help feature available in SuperVision

v2.0 or later.

‡ Any adjustments needed to calibrate the RTD are done as offset adjustments

in the microblock.

Channel

Number †Range Offset Gain

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

-50° to 250° F

-46° to 121° C

4 to 20mA

0 to 5V

0.00

0.00

§§

0.00

0.00

§§

0.00

0.00

§§

0.00

0.00

§§

0.00

0.00

§§

15.25‡

15.25‡

15.25‡

15.25‡

15.25‡

Table 7. Maintained Binary Output

Channel Numbers across sections 1 and 3

Johnson Channel “xA”

(wired across terminal sections 1 and 3) ALC Channel

1A 11

2A 12

3A 13

4A 14

5A 15

6A 16

7A 17

8A 18

Revised 7/10/01 • InterOP8500 16 © 2001 Automated Logic Corporation

Page 17

Table 8. Maintained Binary Output

Channel Numbers across sections 2 and 4

Johnson Channel “xB”

(wired across terminal sections 1 and 3) ALC Channel

1B 19

2B 1A

3B 1B

4B 1C

5B 1D

6B 1E

7A 1F

8A 10

Table 9. Position Binary Output Channel

Numbers across sections 1 and 2

Channel Number Open Channel Number Closed

11 19

12 1A

13 1B

14 1C

15 1D

16 1E

17 1F

18 10

Transferring Memory

You should download memory whenever you

make changes to your modules (for example,

change the module number, upgrade the

module driver, or change the FB).

The InterOP8500 module can store one

module driver and several FBs. The number

of FBs stored depends on the software you

are using (see the table on page 3).

NOTE This type of download should be

performed with caution. When the module is

automatically restarted before and after

transferring memory, any equipment

controlled by the module is shut down and

restarted. Downloading memory also

overwrites all Function Blocks in the module

causing the module to lose any stored data.

Transferring Memory in WebCTRL

The InterOP8500 module using the

DRV_InterOP8500 module driver can store up

to 100 FBs, depending on their size. You must

be logged in to WebCTRL with the appropriate

privilege to download memory.

1. Click the CFG button at the bottom of the

navigation pane.

2. Click Download in the CFG tree control.

3. Click the Memory, Parameters, or

Schedules boxes, depending on what you

want to download.

NOTE A memory download includes a

parameter and schedule download.

4. Expand the tree in the action pane, click

the module you want to download to,

then click Add. Click on and Add any

other modules you want to download to.

5. Click the Execute Download button.

If any downloads failed, they are listed in

the Failures section under the tree in the

action pane. To retry a failed download,

click on the module in the Failures list,

click Add, and click the Execute

Download button again.

NOTE Since a failed download indicates

a system problem, you should never clear

a failure. Locate and resolve the problem,

then retry the download.

6. Click the Properties button to refresh the

screen. This removes the items from the

Download Items list.

Revised 7/10/01 • InterOP8500 17 © 2001 Automated Logic Corporation

Page 18

Transferring Memory in SuperVision

The InterOP8500 module using the 85M

module driver can store up to 59 FBs,

depending on their size.

1. Log in to SuperVision on a workstation

connected to the module network. You

can also connect directly to the module

using the Access Port; see

“Communicating with the Workstation” on

page 8.

2. Navigate to the module driver and look at

the module status report in SuperVision to

make sure the module type and number

agree with the module.

• To view the module status report in

SuperVision v3.0, click Tools Troubleshooting - Module Status.

• To view the module status report in

SuperVision v2.6b, press the Esc key,

type MO ,,module address,15 and

press Enter.

3. Transfer memory to the module.

• In SuperVision v3.0, click Tools Troubleshooting - Transfer Memory to

Module.

NOTE Since the module is automatically

formatted when you transfer memory, you

should only manually format the module if

communication was not established after the

memory transfer.

1. Turn the module’s power off. Make sure

the module’s address switches are not set

to ‘0 0’.

2. Press and hold the Format button (see

Figure 1 on page 2 for location).

3. While continuing to hold the Format

button, turn the module’s power on.

4. Continue to hold the button until the Error

LED flashes three times in sync with the

Run LED.

5. Release the Format button.

6. Transfer memory to the module. Refer to

“Transferring Memory” on page 17.

LEDs

The InterOP8500 module has several LED

indicators to show the status of certain

functions. Table 10 on page 19 explains the

Run (LED 3) and Error (LED 4) LED signals in

detail to assist troubleshooting.

• In SuperVision v2.6b, download

memory for This Module.

4. When the memory transfer is finished,

check the module status report again.

Make sure the FB List shows all the FBs

you intended to transfer.

Troubleshooting

LED 1 Rx - lights when the InterOP8500

receives data through the network segment.

LED 2 Tx - lights when the InterOP8500

transmits data over the network segment.

LED 5 Communications Power - Indicates

power is being supplied to the

communications circuitry.

Formatting the Module

If you are unable to communicate with a

module after transferring memory, you can,

as a last resort, manually format the module

to try to restore communication. Formatting

the module erases all memory, so you need to

transfer memory back to the module once it is

formatted.

Revised 7/10/01 • InterOP8500 18 © 2001 Automated Logic Corporation

LED 6 Logic Power +5V - indicates power is

being supplied to the logic circuitry.

LED 7 Power +12V - indicates power is

being supplied to the analog circuitry.

LED 8-23 Binary Outputs - indicates 12V

on the individual output.

Page 19

LED 24 Output Power - indicates power is

being received from field termination board

from the external power supply for binary

outputs and isolated binary inputs.

Table 10. LED Signals

Run LED Error LED Condition

2 flashes

per second

2 flashes

per second

2 flashes

per second

2 flashes

per second

2 flashes

per second

Off Normal

1 flash,

then pause

2 flashes,

alternating

with Run

LED

2 flashes,

in sync

with Run

LED, then

pause

3 flashes,

then off

Normal, but module is

alone on the CMnet

(this sequence doesn’t

occur in WebCTRL)

Five minute auto-restart

delay after system error

Module is configured for a

different baud rate than the

rest of the network

segment

Module has just been

formatted

Protection

The InterOP8500 module is protected by

internal solid state Polyswitches on the

incoming power and network connections.

These Polyswitches are not replaceable and

will reset themselves if the condition that

caused the fault returns to normal.

Production Date

To determine when a module was

manufactured, check the module status

report for the module in WebCTRL or

SuperVision. Refer to the appropriate user’s

guide for more information about the module

status report.

A sticker on the back of the module also

shows the date the module was

manufactured. The first three characters on

the sticker indicate the type of module. The

next two characters show the year and month

of manufacture.

2 flashes

per second

2 flashes

per second

5 flashes

per second

5 flashes

per second

7 flashes

per second

14 flashes

per second

4 flashes,

then pause

On Exec halted after frequent

On Exec start-up aborted, Boot

Off Firmware transfer in

7 flashes

per second,

alternating

with Run

LED

14 flashes

per second,

alternating

with Run

LED

Two or more devices on

this network have the

same ARC156 network

address

system errors or GFBs

halted

is running

progress, Boot is running

Ten second recovery

period after brownout

Brownout

Revised 7/10/01 • InterOP8500 19 © 2001 Automated Logic Corporation

Page 20

Sample GFB

Figure 17. Sample GFB

Revised 7/10/01 • InterOP8500 20 © 2001 Automated Logic Corporation

Loading...

Loading...