RAPTOR TC-1417

COMPACT TURRET LATHE

Safety Guidelines | Delivery & Set-Up Guide | Maintenance Schedule | Quick-Start Guide

800-476-4849 | 170 Aprill Drive | Ann Arbor, Michigan 48103 | USA

Thank You For Your Order!

Congratulations on your purchase of an AutoMate CNC Lathe. With proper setup and care, your

machine will provide many years of quality work and productivity.

This guide covers general instructions for setup and maintenance for the Automate CNC Lathe. In

addition to this guide you will also receive a machining operations and programming handbook

for the Siemens 808D control system. We strongly recommend keeping this setup guide with the

manual when your machine arrives.

Enjoy your new CNC Lathe!

This manual is specifically written for the

RAPTOR TC-1417 CNC LATHE

by

Detroit Machine Tools

170 Aprill Drive

Ann Arbor, MI

48103

For additional assistance or information,

you may contact us by

Phone: 800-476-4849

Fax: 800-431-8892

Email: sales@detroitmt.com

Web: www.detroitmachine.tools

Index

Safety Guidelines ……………………………………………………………………………. 3

Specifications …..…………………………………………………………………………… 14

Delivery & Setup ……………….………………………………………………….…… 16

Maintenance ………………………………………………………………..………………. 26

General operation …………………………………………………………………………. 30

Warranty ………………………………………………………………………………………. 31

Safety Guidelines

General Safety Guidelines - Safety

First!

Overview

General operational techniques and safety

procedures will be outlined in these

guidelines. Please note, for example, that

all rotating parts, wherever feasible, are

protected by specially designed covers and

shields. If the machine is operated in

accordance with the manufacturer’s

instructions, it will provide you with reliable

service. With machines of this nature,

serious accidents may occur due to

improper or careless operation. It is

strongly recommended that you read this

manual and accompanying manuals to

understand thoroughly the contents. Not

every example of improper operation or

unauthorized usage which may lead to

malfunction can be anticipated. If a

particular operation is not documented in

this manual as an authorized usage of the

equipment, it should be assumed that it is

an unauthorized or improper usage with

potential danger and should be avoided or

the manufacturer should be consulted

before use.

Safety

This machine is provided with various safety

devices to protect the operator and

machine, however these cannot cover all

aspects of safety. The operator must

thoroughly read and understand the

content of this manual before the machine

is turned on and operated. The operator

should also take into consideration safety

aspects related to their particular

environmental conditions, materials and

tools.

Always observe the safety instructions

inscribed on the name plates fixed to the

machine.

DO NOT remove or damage these name

plates

DO NOT attempt to operate or turn on the

machine until you have read and

understood the manuals supplied with the

machine.

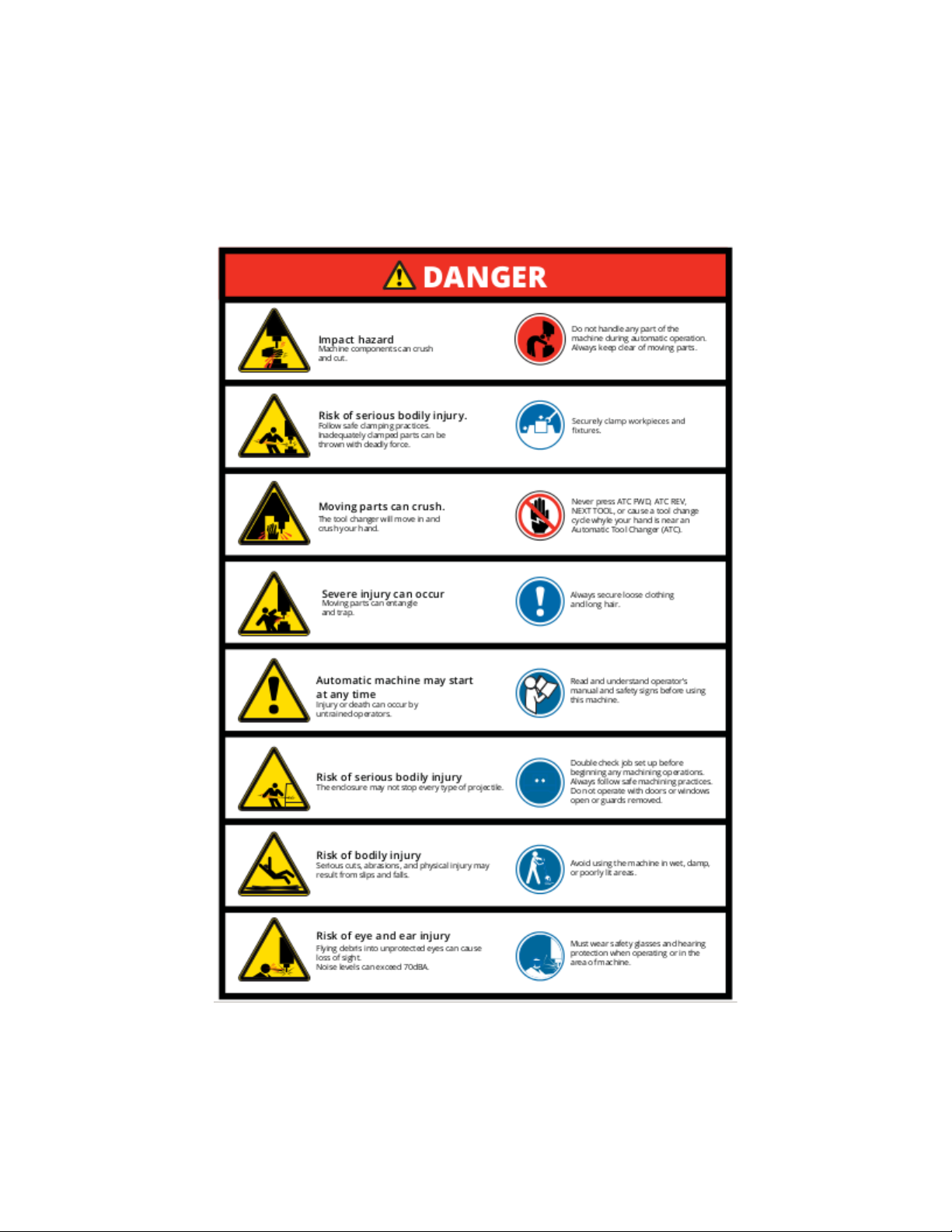

Safety Symbols Used In This Manual

Three categories of safety guidelines have

been used throughout this manual. Please

take note of these symbols and understand

their meanings.

Danger

If this action is not avoided, it could result in

serious injury or even death. It may also

cause permanent damage to your machine.

Warning

If this action is not avoided, it may cause

potential harm to your health resulting in

serious injury. This too has the potential to

cause serious damage to your machine.

Caution

If this action is not avoided, it may cause

potential harm to your health such as minor

to moderate injury. Not avoiding this action

could result damage to your machine.

DANGER SYMBOLS

WARNING SYMBOLS

Basic Points of Safety

There are high voltage terminals on the

electrical control panel, motors, junction

boxes and other equipment. DO NOT touch

any of these components under any

circumstances, when the power supply is

ON.

Make sure that all safety covers are fitted

and electrical boxes are closed and secured

before the power is switched to ON.

If any components or safety covers are to

be removed, first switch off or disconnect

the main plug.

without informing the other operator(s)

that you are about to do so.

DO NOT modify the machine in any way

that will affect safety.

Clothing & Safety

DO NOT subject the machine, control box,

operator panel, or electrical control panel

to a high voltage surge.

DO NOT change the parameters or

electrical setting values without good

reason. If it becomes necessary to change

the parameters or settings, first check with

an AutoMate technician to assure that it is

safe to do so. Be sure to note the original

values so that the control can be reset to

that value if necessary.

Memorize the position of the EMERGENCY

STOP BUTTON on the machine so that you

can press it immediately from any position

is case of emergencies.

DO NOT touch the tool holder while the

machine is running.

Under no circumstances, should you touch

a rotating tool holder or work piece while

the machine is in operation mode.

To prevent incorrect operation of the

machine, carefully check the position of the

switches before operation.

If in doubt, consult this manual or an

AutoMate technician for advice and

suggestions.

DO NOT paint, soil, damage, modify or

remove any of the safety name plates.

If the details become illegible or if the name

plate is lost, obtain a replacement from

Detroit Machine Tools and mount it at the

original location.

DO NOT remove any safety covers while the

machine is in automatic operation mode.

STOP all machine operations before

cleaning the machine or any of the

peripheral equipment. After a job has been

completed, set up each part of the machine

so it is ready to be used for the next series

of operations.

Always unplug the main plug when the

machine is not in use.

If more than one person is operating the

machine, DO NOT proceed to the next step

Tie back long hair to prevent entangling

with rotary tools.

DO NOT allow chips to accumulate in the

work envelope.

Always wear safety equipment.

Always wear a protective mask when

machining Magnesium alloys.

Never wear loose or baggy clothing.

DO NOT operate the machine while under

the influence of drugs or alcohol.

DO NOT operate the machine if you suffer

from dizziness.

ALWAYS USE GLOVES when loading and

unloading workpieces or tools and

removing chips from the work area to

protect your hands from sharp chips and

burns caused by heat generated during

machining.

Close all covers and junction boxes before

running the machine.

Check all electrical cables for damage to

prevent electrical shock.

Warm up the spindle and axis motion

before running the machine in automatic

mode.

DO NOT operate the keyboard or operation

panel switches when wearing gloves.

DO NOT disconnect the main power cable

without switching off the CNC and PC

connections.

Safety Aspects Related To Tools & Work

Holding

Always use proper cutting tools and work

holding clamps suitable for the work and

within the specifications of the machine.

DO NOT stall the machine during cutting

due to improper feed and depth of cut

suitable for the work piece material.

DO NOT operate the spindle above the

rated speed of the arbors/tool holders and

cutting tools you expect to mount and use

in any machining operation.

DO NOT handle coolant with bare hands to

avoid irritation.

Always use wire rope or slings as per

standards suitable for the load to be

supported.

DO NOT remove or adjust switches to

increase axis travel beyond the machine

specifications.

DO NOT wipe the workpiece or clear away

chips with your hand or a rag while the

spindle is in operation.

Replace worn tools as soon as they are

identified.

Take care not to place any part of your body

in possible pinch points on the machine.

Make sure the tool length to diameter ratio

is proper in order to minimize vibration due

to excessive overhang conditions.

Make sure the drawbar and the tool holders

are tightened to the proper cutting

conditions before actual cutting operations

begin.

Safety Aspects Related To

Maintenance

individuals with working knowledge of the

machine tool.

DO NOT remove or modify switches.

Clean the machine areas after maintenance

is completed.

Always disconnect the power to the

machine before carrying out any

maintenance work.

After the power has been switched off for a

minimum of 60 minutes, check voltage with

a multi-meter or equivalent meter to make

sure there is no residual voltage.

Maintenance of electrical and mechanical

components should only be carried out by

DO NOT use compressed air to clean the

machines.

Safety Aspects Related To The

Workplace

Always provide sufficient work space

around the machine and peripheral

equipment.

Protect all cables from being damaged by

cutting chips.

More Guidelines for Safe Machine Tool Operations

This machine is provided with various mechanical and electrical safety devices to protect the

operator and the machine. The safety devices include the interlock devices and emergency

stop switches. However, it is absolutely necessary that the operator familiarizes himself with

the instruction manual of the machine before operating the machine. The manufacturer

emphasizes that it is the sole responsibility of the operator to ensure that all operations using

the AutoMate CNC Lathe are carried out in a completely safe manner.

Neither the manufacturer, its representatives nor dealers can assume responsibility for any

mishaps, damage or personal injury which may occur as a result of improper operation or from

failure to observe the safety precautions mentioned in this manual.

Never operate a CNC machine without proper training or consulting the specific

operator’s manual for that particular machine and control type.

Never attempt to program a CNC machine without proper training or consulting the

specific programmer’s manual for that particular machine and control type.

CNC Machine Safety System

The built-in safety system on a CNC machine includes guards and protective devices which

should be securely fitted and always kept in position while the machine is being used. It may

include:

Emergency Stop Button

Used to shut down the machine immediately. It is located on the control panel and at other

points on the machine, for example the handheld unit.

Soundproof Casing

Reduces noise emission generated by the operating section and protects the operator from the

risk of flying objects or tool fragments.

Curtain Guards

Made of PVC and designed to protect the operator from the risk of airborne chips or tool

fragments.

Guard Fence

The fence marks the working area in which the machine moves. It protects the operator from

the risk of interference with moving parts. The guard may be of an open type or made of mesh.

General Personal Safety Rules

Below are some general personal safety

rules that you should use as a guide only.

You might like to add any other rules that

apply to you and your environment.

Check that the spindle direction is correct

for right-hand or left-hand operation.

Only use tools within the limits specified by

the manufacturer.

Always:

Wear safety glasses and hearing protection

when operating CNC machines.

Wear safety glasses when closely observing

cutting tools.

Wear safety boots or other suitable

footwear.

Keep long hair covered when operating CNC

machines.

Keep hands clear of moving parts during

machining operations.

Stand clear of the machine while it’s

running and warn others of the dangers of

being too close.

Avoid contact with cutting edges when

handling tools or changing tools by hand.

Only tighten tools to recommended torque

values.

Keep the area around machine clear of

obstacles.

Stack material where you can reach it but

where it is clear of the moving parts of the

machine.

Make sure that all guards are in position

while the machine is in operation.

Make sure that all work and fixtures are

clamped securely before starting machine.

Conduct a dry run to ensure the program is

correct.

Follow company policy on correct

procedures when handling or lifting parts or

tooling.

Turn the CNC machine off completely and

clean it up when you have finished using it.

Check that the machine is not operating

when loading a tool magazine.

Check that the tools are in good condition,

for example sharp and free of cracks.

Check that tools are set correctly.

Double check that the correct tool data is

entered into the CNC program.

Test tools before use.

Check that the seating surfaces are clean

before installing tools.

NEVER:

Wear loose clothing or jewellery.

Reach into a CNC machine while it is

running.

Place hands near a revolving spindle.

Leave the machine so that someone else is

able to start it by pressing the cycle start

button.

Use blunt tools.

Use cracked or chipped tools.

Use tools with damaged tungsten tips.

Use the machine table as a workbench.

Use compressed air to blow chips from the

parts of the machine, machine surfaces,

cabinets, controls or floor around the

machine.

encountered when working in the machine

shop.

Safety Methods For Carrying

1. Never twist your body - Change

direction by moving your feet.

2. Always have clear vision - Should

never have to move around objects

that could cause you to trip over or

bump into anything.

3. Slide the load - Uses less effort and

stress than lifting.

4. Place the load on the bench - Put

load on edge and slide it forward.

Personal Protective Equipment (PPE)

Before entering a machine shop you must

wear personal protective equipment at all

times.

Eye Protection

It is necessary to wear safety glasses,

goggles or face shields at all times in areas

where small flying fragments or dust can be

Hearing Protection

Hearing protection must be worn at all

times. Generally operators choice for

comfort depending on volume of sound.

Earplugs for less sound, earmuffs for louder

sound.

Footwear

Suitable footwear must be worn. A closed

shoe with leather uppers or safety boots

would be the most appropriate.

Clothing

It is important to remember that while you

are working in the machine shop you should

not be wearing loose clothing or jewelry

which may get caught in revolving cutters.

The moving parts of a machine revolve at

high speeds and if any loose clothing or

jewelry is caught in the revolving cutters,

you will be dragged into the machine

causing serious injury or death.

Risk Control

Long Hair:

Keep long hair covered.

Tie hair back.

Wear a hairnet.

Noise:

Wear earmuffs.

Wear earplugs.

Eyes:

Wear safety glasses.

Wear safety shield.

Footwear:

Wear closed shoe with non-skid sole.

Dust:

Wear dust mask.

Never dust yourself or a workmate down

with an air hose. (compressed air)

Chemicals:

Wear gloves or protective clothing.

Wear face mask.

Guards:

Guards on machines must be used at all

times.

Hazards

The three steps involved in dealing with hazards:

1. Spot the hazard - A hazard is anything that could hurt you or someone else, is unsafe, or

could cause an accident. Use all your senses to spot hazards. Look around, listen,

notice any strange smells (like smoke or chemicals) and use your knowledge about

things that might be dangerous.

2. Assess the risk - Figure out how likely it is for the hazard to hurt someone and how

badly. Always tell someone about hazards you cannot fix yourself and remember it is

more urgent to make the changes if the hazard is likely to cause serious injury.

3. Minimize the risk - Fix the hazard yourself if you can, or tell someone who is able to fix

it. The best way to fix the hazard is to get rid of it, but as this is not always possible,

there are some ways you can make the hazard less dangerous.

1. Substitute it for a less hazardous material or item.

2. Isolate it to an area where it’s further out of harm’s way such as a locked room.

3. Add safeguards, for example, put clear guards around cutting or slicing

equipment or warning signs for people to see.

4. Use personal protective equipment and clothing any time you are working with

hazardous materials and/or equipment.

Hazard Control

Electrical Hazards: Eliminate/install electric droppers instead of using extension cords.

Toxic Chemicals: Substitute/introduce less toxic materials (polishes, adhesives etc).

Noises: Enclose/install canopies to the noisiest machines.

Flying particles: Isolation, set aside specific areas for grinding.

Machining dust: Engineer controls, install and use dust extraction equipment.

Slip/Trip hazards: Adopt better housekeeping procedures.

Fatigue: Rotate job tasks among workers.

New equipment: Train all staff on every piece of equipment to assist hazardous breakdowns.

Dust/noise etc: Use personal protective equipment.

Final Safety Notice

AutoMate CNC machines have been proven to be safe and reliable. However, if abused or

operated improperly, any machine can cause injury to you or others. Please read this guide and

accompanying manuals carefully before you start machining. Proper use will create a safe

working environment and prolong the life of your machine.

Specifications

Travels Inch Metric

X Axis 9.5” 241mm

Z Axis 12.5” 317mm

Max Swing Over Bed 13.25” 340mm

Swing Over Carriage 5” 127mm

Spindle Inch Metric

Power 4 HP 3.0kw

RPM 100-2800 100-2800

Spindle Taper MT5 MT5

Spindle Bore 1.65” 41mm

Drive System Belt Belt

Axis Motors Inch Metric

X Power 6NM 6NM

Z Power 6NM 6NM

Rapids on X 120 IPM 3m/min

Rapids on Z 230 IPM 5.75m/min

Max Cutting Speed 100 IPM 2420mm/m

Accuracy Inch Metric

Repeatability .0004” 0.01mm

Tool Changer Tool Post Tool Post

Type N/A N/A

Capacity 6 6

Max Tool Height 0.78” 20mm

Speed (chip to chip) or Tool

General Inch Metric

Machine Weight 2425lbs 1100kg

Machine Dimensions (LxWxH) 61”x 53.5”x 66.9” 1550mm X 1359mm X 1699mm

Shipping Weight 2646 lbs 1200kg

Crate Dimensions (LxWxH) NYA NYA

Air for Pneumatic Chuck 90 PSI 620 kPa

Coolant Capacity 10 Gal 37 L

Power Requirements 220v 60 Hz 3 Phase 220v 60 Hz 3 Phase

DELIVERY & SET-UP

Tracking Your Shipment

The best way to be prepared is to know exactly when your machine will arrive. Once your

machine leaves our warehouse, you’ll be sent an email with the Tracking or PRO number to

track your shipment. You have multiple options to track your shipment as your AutoMate CNC

System makes its way to you.

By Phone

ESTES - 800.755.2728 - Press 3 and you will be directed to a live customer service

representative who can help you.

UPS - 800.PICKUPS - Select 1 and say your tracking number.

U.S. Mail - 800.275.8777 - Select desired language then select 5.

On The Web

ESTES - Go to www.estes-express.com On the right hand side of the screen there will be a box

that says “Enter PRO Number”. Enter your tracking number in that box.

UPS - Go to www.ups.com On the mains screen there will be a box to enter your tracking

number in. Enter number, track package.

U.S. Mail - Go to www.usps.com Click on the “Track and Confirm” option, enter your pro

number, click GO.

We make every effort to ship your complete order at one time. If you ordered a 4th axis rotary

table at the time of the machine order, the rotary table will be shipped with the machine. If

ordered at a separate time, it will be shipped via Estes as well. If you ordered the 4th axis with

an AutoMate 808D Advanced Control System with 4th axis option on your CNC Lathe, the board

is pre-installed into the control box.

Smaller items such as end mill adapters, end mills and general machine accessories are sent via

UPS Ground or US Mail. It is possible that you may see your machine arrive before your UPS

shipment. Please give any items shipped UPS or USPS 7-10 days for delivery. If your email

address was provided at the time of order, a detailed list of the items you ordered, along with

information on how they were shipped will be emailed to you. The associated tracking

numbers for your shipment will be emailed to you along with this setup guide.

We handle complex AutoMate CNC orders every day. Orders usually consist of at least one

crate and several boxes of varying sizes and weights. We work closely with Estes, UPS and USPS

to make sure you are getting fast, convenient delivery at a reasonable cost.

Your order may arrive in several installments over a period of 7-10 days after you receive this

letter.

PREPARING FOR DELIVERY

There are a number of things you can do to prepare your shop or work space for your new

AutoMate CNC Lathe. You will need a designated area with a level floor that is capable of

supporting your AutoMate CNC Lathe, plus the maximum allowable workpiece weight for your

specific model of CNC Lathe. (Please refer to the specification chart for the lathe you ordered

to obtain these numbers). As a rule, the supporting structure should be able to hold 5-6 times

the weight of the machine without any appreciable, permanent deformation.

Set-Up Clearances, Conditions & Location

Set up the Lathe in a location where you have plenty of working space. The chosen location for

your CNC Lathe should be a permanent location for the machine. Transporting machines are

hard on the machine and the people involved. Make sure the ground is as level as possible. It

will make leveling the machine much easier. The maximum temperature of your shop or

working environment should not exceed 125°. Humidity levels should not exceed 80%.

Power Requirements

When searching for a location for your machine, it is also important to remember you will need

to be running power cables to it. You’ll want good access where your power source is

convenient to the power supply on the machine to minimize exposed wires and electrical

hazards.

Model Voltage Amps Phase

TC-1417 TURRET LATHE 220 30 3 Phase

220 Plug Configuration

Three phase machines are supplied without a plug as there are numerous connections for three

phase circuits.

Taking Delivery

Here are some recommendations for taking delivery of your AutoMate machine. In some cases,

you will pick up the crated machine at a trucking terminal. Before picking up your machine,

contact the designated terminal and ask about the loading arrangements for easy and timely

pickup. You may also arrange to have the machine delivered to your shop location if you have

not already done so.

Inspecting Your Shipment

When your machine arrives, thoroughly inspect each crate and carton for signs of loss or

damage. While a shipping company employee is present, open any crate or carton that shows

signs of loss or damage and examine the contents of the package with the employee. If any

damage is present, record an exact, detailed description of the results of the examination on

both the shipper’s and your delivery receipt. BE SPECIFIC. If damage is present, it is best to

document the damage even if you deem the damage as minor. Undocumented and unnoted

damage will result in a denied claim.

**NOTE: The crate is intended to protect the machine; damage to the crate does not

necessarily mean that your AutoMate CNC machine has been damaged. However, noting any

damage to the crate on the delivery receipt will make it much easier to substantiate a claim if

there actually is damage.

Loading The Machine

After you have inspected the crate and signed for the machine, a shipping company employee

will load your machine into your vehicle. The loading procedure depends upon your vehicle

and the facilities at the terminal. If the shipping company’s forklift is not restricted to the

loading dock, you can have the crate loaded directly into the truck or trailer bed with the

forklift. Regardless of how you load the machine, always be sure to tie the load down securely

so that it does not shift during transport.

Opening The Crate

Before opening the crate, remove the packing list from the plastic bag attached to the crate and

put the document in a safe place. **Wear leather work gloves and safety glasses for this

operation, especially when cutting the metal bands. These bands encircle the crate and are

under tension.

Step 1: Cut the metal bands encircling the crate with tin snips. (Depending on the machine,

there may not be metal bands.)

Step 2: Using a hammer and claw, remove the nails from the bottom crate cover which secure

the crate cover to the pallet.

Step 3: Once all the nails from the crate cover have been removed, remove the nails from one

side of the crate in order to pull the side off of the cover.

Step 4: After the side has been removed, and with the help of an associate, tilt the crate top

back off of the pallet.

**Note: The crate top is very heavy, it can weigh up to 100lbs, Make sure you’ve got assistance

when sliding the crate cover off of the pallet.**

Step 5: Set the crate aside. It is advised you keep the crate in the event you were ever to

return the machine for repair. **Note: Check the machine carefully for signs of damage,

especially if you noted damage to the crate earlier. If concealed damage is found, please call

Detroit Machine Tools at 800.476.4849 immediately.**

Removing Machine From Pallet

You will need a forklift with a minimum of 6’ forks to remove the AutoMate CNC Mill from the

pallet. If you do not own one, you can rent one from a local equipment rental shop. We highly

recommend a forklift over any other method of transporting this machine, accidents will be less

likely to occur due to the machine and crate not being 100% stabilized. A tipped or dropped

machine will result in significant damage to the machine and any individual located in its

vicinity. There are four bolts securing the machine to the pallet, use an adjustable wrench to

remove nuts located on the machine. Once have been removed, the attached bolts will likely

fall through. If the bolts do not fall through, just tap the screws through the casting and pallet.

Remove the sheet metal cover from the lower front of the machine. It is attached with several

Allen head cap screws. This will allow access to the bolts holding the machine to the “C”

channel.the nuts

The machine can be picked up from either the front or back. Shop floor layout will determine

which method is best for your situation. Molded into the base castings are slots for forklift

forks. Insert forks into base as far as they will go without hitting the electrical box or chip guard

enclosure. Lift the machine only high enough to slide pallet out from underneath. As always,

be cautious and try to keep sudden movements to a minimum. Once the pallet is removed,

gently lower the machine until it is a few inches off the ground. Locate the leveling screws and

pads that were shipped with the machine.

Leveling Machine

Adjusting machine tools so they are level is very important and has benefits that aren’t often

considered. Vertical machining centers produce more accurate parts that will last longer when

properly leveled. A machine tool that isn’t properly leveled will not lubricate evenly throughout

the machine and cause parts to wear unevenly.

1. Screw the threaded rod all the way down into the leveling foot.

2. Place the beveled washer over the threaded rod with the bevel down.

3. Unscrew the large adjusting ring of the leveling foot .5” above the base of the foot. This

will ensure that you will have both up and down movement available when leveling the

machine.

4. Install the leveling feet in each of the four locations on the machine and attach the foot

with the hex nut. DO NOT tighten the hex nut at this time, it must remain loose until

the leveling process is completed.

Once the leveling feet are installed, place the machine in it’s final location. Lower it slowly to

the floor. Sudden dropping of the machine can cause severe loss of precision. Then remove

the forklift and adjust the leveling screws as needed to make sure all four feet are securely on

the floor. This is a preliminary adjustment only.

Connecting The Electrical

All electrical work must be done according to the National Electrical Code and any other local

electrical codes and safety requirements. It is recommended that a licensed electrician perform

these tasks. 3 phase power must be connected to the L1, L2, and L3 terminals inside the

machine.

Power must be routed through an approved 40 amp breaker. Important!!! Wire size and length must

conform to local electrical codes. The neutral line is not used as a ground. A separate ground

conductor must be run to earth ground.

Connecting The Hydraulics (optional hydraulic chuck)

All hydraulic hoses for the machine are already installed on the machine itself. They require attachment

to the hydraulic power module.

Connect the two pressure lines and return line to the hydraulic power module. Hoses are

marked on the hose as to proper location on the module.

Connect the electrical cord from the hydraulic unit to the socket on the left end of the machine.

Also connect the cord for the foot switch that operates the hydraulic chuck.

Service the hydraulic reservoir with SAE 20 hydraulic fluid.

Connecting The Coolant

The coolant pump comes attached to the machine. Place the coolant pump into the coolant

tank. Slide the system in place against the rear of the machine then service the coolant tank

with water soluble based coolant solution. Then slide the chip tray in place over the top of the

coolant system.

DO NOT power up your machine until you completely read and understand your machines

safety and operations manual. If you have questions regarding safety or operation of your

machine, call an AutoMate CNC Technician at 800.476.4849 or email at Sales@smithy.com.

Powering Up The Machine

1. Once power has been hooked up by a qualified technician, close the door on the

electrical box located at the rear of the machine. This will prevent metal swarf, water,

oil and dust from contaminating electrical components.

2. Turn on the power switch, which is located on the side of the control/electrical box on

the rear of the machine.

3. Turn the key to “right” on the front of the operator’s control unit.

4. Make sure the emergency switches located on the front of the control unit are not

depressed.

5. Push the green start button on the front of the control unit. ***You should hear relays

pull in the back of the machine as well as see the Siemens Control Unit start up. If you

do not see activity on the display, check to see if power is properly being fed into the

electrical box.***

Powering Down The Machine

1. Press the “Emergency Stop” button located on the front of the control unit.

2. Press the “ Power” button on the control unit.

3. Turn the switch on the back of the machine to off.

Machine Home Position (808D Basic Only)

When a machine home position is requested, axis(s) are moved in the positive direction until

home limit switches are reached. The machine needs to reference itself from a known point on

the machine, in our case, the limit switches. This allows work and tool offsets possible. To

home the machine, make sure the control has “Ref. Point” selected, and push the directional

button for the axis you would like to move. See picture below:

Leveling Machine

Leveling X Axis

We will be using the top of the tailstock as the leveling point. You will need a precidion level

that reads .0005” in 10in.

Jog the Z axis all the way toward the lathe spindle.

Place the level on top of the tailstock and parallel with the X axis. Make sure the level

and the tailstock top are clean and free from debris. If necessary, use a small flat

polishing stone to remove any imperfections from the surface so the level will set solidly

on the surface.

Slide the tailstock as close to the lathe head as possible.

Then adjust the headstock end of the lathe to make it level using the leveling feet. It is

easier to adjust the high point down then adjust the low point up.

Move the tailstock to the far right end of the lathe and check the level at that position.

Using the leveling feet on the right end of the lathe, adjust this end until it is level.

Go back to the lathe head end and recheck the level. It may take several cycles back and

forth to get the final level at both ends. At this point there is no twist in the bed of the

lathe which was our prime objective.

Leveling The Z Axis

Turn the level so it is parallel with the Z axis.

Place the carriage in the middle of the area between the chuck and the right end of the

machine.

Adjust the two leveling feet on the right end of the machine until the Z axis is level. It is

important to turn the front and rear leveling feet the exact same amount so you do not

throw the X axis level out of adjustment.

Once the Z axis is level, you will need to go back to the procedure for the X axis and

perform the X axis leveling again to insure it was not thrown out of adjustment because

of changing the Z axis.

Once the machine is leveled completely, tighten the nuts on top of each leveling foot to lock

the foot to the machine. This will also keep the leveling foot from moving due to machine

vibration during operation.

General Maintenance

Area Of Maintenance Task How Often

General Work Area Check for cleanliness

Check for liquid spillage

Machine Work Area Clean machine

Clean chuck and spindle taper

Clean tool changer

Empty chip trays

Inspect area for any foreign matter, leaks or loose

items

Lubrication System Service oil level

Check for leaks

Check for oil film on ways

Oil tailstock barrel

Hydraulics Service oil level

Check for leaks

Coolant Service coolant level

Check coolant for contamination

Check for leaks

Check nozzles for damage

Machine External Check cable connections for tightness

Check cables for damage

Check doors and guards for operation and damage

Check machine for loose or missing fasteners

Safety Devices Check E-stop for proper operation At the start & end of work

At the start & end of work

At the start & end of work

At the start & end of work

At the start & end of work

At the start & end of work

At the start & end of work

Mechanical Maintenance

Daily Maintenance

Perform the following maintenance tasks at the beginning and end of each work day.

Area of Maintenance Maintenance Task How Often

Lubrication System Check for proper oil level

Check for distribution film of oil on all sliding

surfaces

Check for leaks

Coolant level (optional) Check for proper coolant level At the start of work

Machine Work Area Check for leakage and cleanliness At the start & end of

Cleaning Clean the work holding devices

Clean the Guards

Clean machine

Clean trays

External Wiring & Cables Check fit of cable connections

Check for damaged cable

Machine General Condition Check entire machine for loose or missing

fasteners

Chuck Clean the chuck

Clean the tailstock

Clean the tool post or gang tooling

At the start of work

work

At the start & end of

work

At the start of work

At the start of work

At the start of work

Periodic Maintenance

Perform these maintenance tasks as per the schedule below

Mechanical Maintenance Maintenance Task How Often

Axes Backlash Check and compensate if necessary 6 months

Ball Screw Guards Check condition 6 months or replace as necessary

Drive Belt Check condition

Check tension

Machine Base/Table Check for level & mounting bolts loosening 6 months

Electrical Maintenance Maintenance Task How Often

Electrical Cabinets Check for cleanliness

Check & secure any loose connections

Electrical Elements Check for proper working of push button switches 3 months

Proximity Switches Check for proper operations 3 months

Motors Check for condition & testing 1 month

Lubrication System & Machine Lubrication

This section covers the lubrication of your machine. There are two primary areas that require

lubrication: areas lubricated by the automatic lube system and the greased-for-life or “sealed” bearings.

Please remember proper lubrication is very important, it greatly affects the performance and longevity

of your machine. If the machine is operated without supplying the lubricating oil, it will cause seizure of

the sliding surfaces. Before operating, visually inspect the oil on the actual machine surfaces. Use only

recommended lubrication oils which are clean and free from contaminants/debris. Periodically clean

the tank and strainers, if provided, inspect the equipments functioning or lube supply pipes for damage

to ensure optimum machine performance.

6 months or replace as necessary

3 months

Lubricating Points Lubricating System & Recommended Oil Grade Quantity

Headstock Bearings Grease

Kluber Isoflex BU-15

Ballscrews & Guide Ways Automatic lube system

Mobil-1-Vactra #2

Ball Screw Bearings Grease

Kluber Isoflex NBU-15

Ball Screws and Guide Ways

The ball screws, linear guide ways and dovetail slides are lubricated by the automatic lubrication system.

Follow the lubrication schedule in the table above. Lube pumps are set at the factory, please call for

instructions on changing timing. The amount of oil required will depend on your shop environment. A

thin layer of lubrication should be present on the slides at all times.

Headstock & Spindle Bearings

The bearings are of a precision class of accuracy. The spindle bearings are lubricated for life with high

grade grease, such as Kluber Isoflex NBU-15. This grease maintains its lubrication properties at both low

and high temperatures (-70°F to 120°F). There is no lubrication required for these bearings. If the

spindle starts making abnormal noises or gets very warm above (120°F) check for damage of the spindle

bearings after stopping the machine completely. The spindle should be warmed up for approximately

15-20 minutes when the machine has been stopped for a long period (i.e. 5 or more days).

Life Grease

1 Liter

Life Grease

Periodic Maintenance Tasks

Axis Bearing Adjustment and Backlash

Backlash is the amount of movement the screw makes before the table engages. There are a number of

signs that may indicate that there is excessive backlash with your system:

Rough/uneven surface finishes

Dimension inaccuracies

Table shakes under machining force

Even if none of these signs are present, it is recommended to check for backlash compensation every 36 months depending on your usage of the machine. Please note: Siemens 808D Software has provisions

that compensate for backlash within the program. This section of the manual is addressing mechanical

backlash compensation. There are four main mechanical reasons for backlash:

1. Preloaded ball nut is damaged and is causing axial play between the nut and the screw. If the

ball nut is damaged, the only solution to this is to replace the ball screw and ball nut assembly.

2. The end support bearings are damaged. If you find that the end bearings are damaged, follow

the procedure below for replacing the bearings.

3. The ball nut mounting screws are loose. Tighten the bolts and make sure the bolts or housing

threads are not damaged before tightening.

4. The end bearing tightening nut is loose.

Linear Motion Guide & Bearing Maintenance

Unlike dovetail guide ways, linear motion guides are free from wear. It requires neither adjustment of

the gibs due to uneven wear nor maintenance to restore the original accuracy. Linear guides use a

forced lubrication system to provide and maintain a uniform film over moving parts. This not only

prevents smoother motion but assures less maintenance than other systems. Linear guide ways

require constant lubrication in a very small quantity, all handled effortlessly through the automatic oiler.

There are no adjustments required for such bearings and guides.

Make sure the linear bearings are not splashed with coolant directly, the lubricant may be contaminated

or compromised if it comes in contact with coolant. Coolant may wash off or emulsify the lubricant

significantly degrading the lubrications performance. Once sign of such case is the increased noise when

the Z axis slide moves up and down at high speed. Make sure lubrication supply is present by checking

the ends of the lubrication supply piping for the proper oil flow.

Machine Operation - Quick Start Guide

Keyboard Layout

1. Horizontal Soft Keys

2. Vertical Soft Keys

3. Alpha Keypad

4. Numeric Keypad

5. Navigation/Help Keypad

6. Programming Keypad

Warranty

AutoMate CNC Machine Tool Warranty Agreement

Detroit Machine Tools LIMITED WARRANTY CERTIFICATE Covering AutoMate CNC and Talon

CNC Equipment Effective August, 1, 2015

Detroit Machine Tools. (“DetroitMT” or “Manufacturer”) provides a limited warranty to all new

mills, turning centers and rotary machines (collectively, “CNC Machines”) and its components

(except those listed below under Limits and Exclusions of Warranty) (“Components”) that are

manufactured by DetroitMT and sold by DetroitMT under the AutoMate CNC and Talon CNC

brands or its authorized distributors as set forth in this Certificate. The warranty set forth in this

Certificate is a limited warranty and it is the only warranty by Manufacturer and is subject to

the terms and conditions of this Certificate.

Limited Warranty Coverage

Each CNC Machine and its Components (collectively, “CNC Products”) are warranted by

Manufacturer against defects in material and workmanship.

This warranty is provided only to the final purchaser and end-user of the CNC Machine (a

“Customer”). The period of this limited warranty is one (1) year for AutoMate CNC equipment,

one (1) year, for Talon CNC equipment, and eighteen (18) months for Z-MaT equipment. The

warranty period commences on the date the CNC Machine is delivered to the Customer’s

facility. Customer may purchase an extension of the warranty period from DMT or an

authorized DMT distributor (a “Warranty Extension”).

Mechanical Components

Detroit Machine Tools innovative customer contact and care strategies have been tested and

proven in over 25 years of real-world experience. Our methods of direct sales, internet-based

sales and support - in text and image, Skype ® and phone support is the process that enables us

to provide you high value equipment and services at reasonable prices. You will be a successful

DetroitMT tool owner if you are capable with a wrench and meter, have a general knowledge of

electrical and machinery repair and maintenance, and know how to operate safely while

working on your machine. DetroitMT does not maintain factory technicians to send to your

operation. if you do not have the required skills or do not feel you can safely support your

machine -- you will need to find someone in your area to support you. We can help you locate a

technician that can help you, if you are unable to find one through your efforts.

Manufacturer’s sole liability, and customer’s exclusive remedy, with respect to any and all

DetroitMT products shall be limited to repairing or replacing, at the discretion of manufacturer,

the defective DetroitMT product under this warranty.

Disclaimer of Warranty

This warranty is manufacturer’s sole and exclusive warranty and is in lieu of all other warranties

of whatever kind or nature, express or implied, written or oral, including, but not limited to, any

implied warranty of merchantability, implied warranty of fitness for a particular purpose, or

other warranty of quality or performance or non-infringement. All such other warranties of

whatever kind are hereby disclaimed by manufacturer and waived by customer.

Limits and Exclusions of Warranty

Components subject to wear during normal use and over time, including, but not limited to,

paint, window/shield finish and condition, light bulbs, seals, chip removal system, etc., are

excluded from this warranty. Manufacturer’s specified maintenance procedures must be

adhered to and recorded in order to maintain this warranty. This warranty is void if

Manufacturer determines that (i) any DetroitMT Product was subjected to mishandling, misuse,

abuse, neglect, accident, improper installation, improper maintenance, improper storage, or

improper operation or application, (ii) any DetroitMT Product was improperly repaired or

serviced by Customer, an unauthorized service technician, or other unauthorized person, (iii)

Customer or any person makes or attempts to make any modification to any DetroitMT Product

without the prior written authorization of Manufacturer, and/or (iv) any DetroitMT Product was

used for any non-intended use. This warranty does not cover damage or defect due to an

external influence or matters beyond the reasonable control of Manufacturer, including, but

not limited to, electrical current conditions, theft, vandalism, fire, weather condition (such as

rain, flood, wind, lightning, or earthquake), or acts of war or terrorism.

Without limiting the generality of any of the exclusions or limitations described in this

Certificate, this warranty does not include any warranty that any DetroitMT Product will meet

any person’s production specifications or other requirements or that operation of any

DetroitMT Product will be uninterrupted or error-free. Manufacturer assumes no responsibility

with respect to the use of any DetroitMT Product by any person, and Manufacturer shall not

incur any liability to any person for any failure in design, production, operation, performance or

otherwise of any DetroitMT Product other than repair or replacement of same as set forth in

this warranty above.

Limitation of Liability and Damages

Manufacturer will not be liable to customer or any other person for any compensatory,

incidental, consequential, punitive, special, or other damage or claim, whether in an action in

contract, tort, or other legal or equitable theory, arising out of or related to any DetroitMT

product, other products or services provided by manufacturer or an authorized distributor,

service technician or other authorized representative of manufacturer (collectively, “authorized

representative”), or the failure of parts or products made by using any DetroitMT product, even

if manufacturer or any authorized representative has been advised of the possibility of such

damages, which damage or claim includes, but is not limited to, loss of profits, lost data, lost

products, loss of revenue, loss of use, cost of downtime, business good will, any damage to

equipment, premises or other property of any person, and any damage that may be caused by a

malfunction of any DetroitMT product. All such damages and claims are disclaimed by

manufacturer and waived by customer. Manufacturer’s sole liability, and customer’s exclusive

remedy, for damages and claims for any cause whatsoever shall be limited to repair or

replacement, at the discretion of manufacturer, of the defective DetroitMT product as provided

in this warranty.

Customer has accepted the limitations and restrictions set forth in this Certificate, including,

but not limited to, the restriction on its right to recover damages, as part of its bargain with

Manufacturer or its Authorized Representative. Customer realizes and acknowledges that the

price of the DetroitMT Products would be higher if Manufacturer were required to be

responsible for damages and claims beyond the scope of this warranty.

Entire Agreement

This Certificate supersedes any and all other agreements, promises, representations or

warranties, either oral or in writing, between the parties or by Manufacturer with respect to

subject matter of this Certificate, and contains all of the covenants and agreements between

the parties or by Manufacturer with respect to such subject matter. Manufacturer hereby

expressly rejects any other agreements, promises, representations or warranties, either oral or

in writing, that are in addition to or inconsistent with any term or condition of this Certificate.

No term or condition set forth in this Certificate may be modified or amended unless by a

written agreement signed by both Manufacturer and Customer. Notwithstanding the foregoing,

Manufacturer will honor a Warranty Extension only to the extent that it extends the applicable

warranty period.

Transferability

This warranty is transferable from the original Customer to another party if the CNC Machine is

sold via private sale before the end of the warranty period, provided that written notice thereof

is provided to Manufacturer and this warranty is not void at the time of transfer. The transferee

of this warranty will be subject to all terms and conditions of this Certificate.

Miscellaneous

This warranty shall be governed by the laws of the State of Michigan without application of

rules on conflicts of laws. Any and all disputes arising from this warranty shall be resolved in a

court of competent jurisdiction located in Washtenaw County, Michigan. Any term or provision

of this Certificate that is invalid or unenforceable in any situation in any jurisdiction shall not

affect the validity or enforceability of the remaining terms and provisions hereof or the validity

or enforceability of the offending term or provision in any other situation or in any other

jurisdiction.

Loading...

Loading...