Manual# 1006496

Configuration Manual

200E Series

DCU 210E/208E – Engine Panel

RP 210E/220E – Remote Panel

Configuration Manual - 200E Series Page ii

Configuration Manual

for the

Marine Pro 200E Series

~~~

DCU 210E/208E Diesel Engine Control Unit

RP 210E/220E Remote Panel

Revision

1.3

Revised

January 23, 2017

Revision history:

Rev.

Date

Description

1.0

15.10.2015

Release

1.1

18.03.2016

Firmware update

1.2

25.11.2016

Added RP 220E

1.3

22.01.2017

Synched to firmware 3.5P2

Copyright © 2017 by Auto-Maskin AS.

All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Auto-Maskin AS.

Configuration Manual - 200E Series Page iii

Table of Content

DOCUMENT INFORMATION ................................ 1

ABOUT THIS MANUAL .............................................. 1

Responsibilities .............................................. 1

MATCHING FIRMWARE ............................................ 1

ORDERING INFORMATION ......................................... 1

OVERVIEW OF THE 200 SERIES .................................. 2

DCU 210E Engine Panel ................................. 2

DCU 208E Engine Panel ................................. 2

Configuration ................................................. 2

RP 210E/220E Remote Panel ......................... 2

Ethernet Switch ............................................. 3

Expansion ...................................................... 3

FIRST POWER-ON ................................................... 4

Preparations .................................................. 4

First Power-On Wizard .................................. 4

CONFIGURATION ................................................. 5

CONFIGURATION- AND FIRMWARE FILES ...................... 5

DCU Web Server Configuration Interface ...... 5

USB memory with Configuration file ............. 5

Connecting to the DCU .................................. 5

Further connection settings ........................... 6

Logged in ....................................................... 7

DCU ................................................................ 7

RIO ................................................................. 8

SDU ................................................................ 8

Upload Wallpaper ......................................... 8

Versions ......................................................... 8

Troubleshooting ............................................ 8

MAIN DCU WEB SERVER MENU ................................. 9

Password ....................................................... 9

File ................................................................. 9

I/O CONFIGURATION ............................................ 10

Flexible I/O................................................... 10

Config Inputs ............................................... 10

Config Outputs............................................. 21

USER INTERFACE ................................................ 25

CONFIGURATION .................................................. 25

Header ......................................................... 25

Instruments ................................................. 25

PAGES ................................................................ 25

Page details ................................................. 25

Apply a signal to a slot ................................ 26

Edit a signal ................................................. 26

Insert a new Page ........................................ 26

Choose a Template ...................................... 26

Delete a Page .............................................. 26

FLOW CHARTS...................................................... 26

RP HOME VIEW CONFIGURATION ............................ 27

CONTROLS ........................................................... 27

Gear ............................................................. 27

SHORTCUTS ......................................................... 27

LANGUAGE .......................................................... 27

BUZZER ............................................................... 28

START/STOP/ PRELUBE ...................................... 29

PRELUBE ............................................................. 29

Prelube – Fixed Time.................................... 29

Prelube – Until Pressure .............................. 29

Oscillating .................................................... 29

DCU ENGINE START/STOP CONTROL ....................... 30

AUTOMATIC START ............................................... 30

STARTER 1........................................................... 30

STARTER 2........................................................... 30

AUTOMATIC STOP ................................................. 31

START/STOP BUTTONS .......................................... 31

Latched buttons ........................................... 31

Momentary buttons .................................... 31

E-Start .......................................................... 31

USER INTERFACE ................................................... 32

Language ..................................................... 32

Buzzer .......................................................... 32

ENGINE MODEL .................................................... 33

Engine Name ............................................... 33

SERVICE INTERVAL ................................................ 33

View Service Status ...................................... 33

Configure ..................................................... 33

COMMUNICATION ................................................ 33

Network Communication ............................. 34

Modbus RTU ................................................ 34

Configuration Manual - 200E Series Page iv

Modbus TCP ................................................. 34

J1939 Configuration .................................... 34

MISCELLANEOUS .................................................. 35

Alarm Configuration .................................... 35

Counters ...................................................... 35

Acknowledge Configuration ........................ 36

Event Log ..................................................... 36

Suppress DM1 faults .................................... 36

Engine Application Configuration ................ 36

System Voltage ............................................ 37

Factory Reset ............................................... 37

RP CONFIGURATION ........................................... 38

POWER-ON WIZARD ............................................. 38

ADMINISTRATION MENU ........................................ 39

DCU Connection / Connections .................... 39

DCU Alarms ................................................. 39

DCU Acknowledge ....................................... 39

IP Address .................................................... 40

Cameras ....................................................... 40

Station Location ........................................... 40

Functional Inputs ......................................... 40

Change Password ........................................ 41

Station priority ............................................. 42

Lock.............................................................. 42

System Voltage ............................................ 42

Reset to Factory Default .............................. 43

Configuration Manual - 200E Series Page 1

Document

Information

About this manual

This manual has been published

primarily for professionals and

qualified personnel.

The user of this material is assumed to

have basic knowledge in marine

systems, and must be able to carry out

related electrical work.

Warning!

Work on the low-voltage circuit should

only be carried out by qualified and

experienced personnel.

Installation or work on the shore

power equipment

must only

be carried

out by electricians authorized to work

with such installations.

Res p ons ibi l iti es

Warning!

It is the

sole responsibility of the

installer

to ensure that the installation

work is carried out in a satisfactorily

manner, that it is operationally in good

order, that the approved material and

accessories are used and that the

installation meet all applicable rules

and regulations.

Note! Auto-Maskin continuously

upgrades its products and reserves the

right to make changes and

improvements without prior notice.

All information in this manual is based

upon information at the time of

printing.

For updated information, please

contact your local distributor.

Matching firmware

This Configuration Manual is for the

200E Series of panels.

It has been updated to match the

following firmware releases.

Panel

Firmw.

Release

DCU 210E/ 208E

3.5 P2

January 2017

RP 210E/RP 220E

3.5 P2

January 2017

Ordering information

The Marine Pro covers a wide range of

compatible products within both the

200- and 400 Series. Please visit our

web site for more information.

http://auto-maskin.com/marine/

Configuration Manual - 200E Series Page 2

Overview of the 200

series

The drawing below shows a typical

layout.

DCU 210 E E n gin e P anel

The DCU 210E engine panel is the

main building block in the 200 Series.

Engine sensor values are displayed on

the color touch screen, and commands

and other user interaction is also here.

DCU 208 E En gin e P a nel

The DCU 208E is basically the same as

the DCU 210E, but without the color

touch screen.

It saves cost being used in smaller

engine rooms, where a remote panel is

all that is needed.

Con figu rat i on

An ordinary PC web-browser is used

to configure the DCU, using the inbuilt

web-server on the DCU.

RP 2 10E /22 0E Remo te P ane l

The optional RP remote panel brings

everything on the DCU to a remote

location, with the exact same user

interface. It does not need any

configuration, as it is reading the

configuration from the DCU.

As such, the RP can easily be

retrofitted.

The RP also supports one IP-camera to

be installed on the network.

Configuration Manual - 200E Series Page 3

Eth e rne t S w itc h

The Ethernet switch is not necessary if

only one DCU 210E and one RP

210E/220E is in use. These can then

be wired with an Ethernet cable

directly.

It is recommended to make use of an

Ethernet switch though, as it simplifies

PC configuration connection and

future expansion to remote panels

and/or camera interface.

Exp a nsi on

The basic system can be expanded

with more input and output channels

using the versatile RIO units (

Remote

I/O).

Currently, there are RIO units for

General I/O expansion, RIO 410

and RIO 210.

Exhaust temperature

monitoring, RIO 412

Generator monitoring, RIO 425

Load sharing, LSU 408

Configuration Manual - 200E Series Page 4

First Power-On

Pre para tio ns

First, make sure to consult the Quick

Installation Guide (QIG) that came with

the panel.

Installation

Install the panel according to

guidelines in the Installation manual.

Connections

Connect power to the panel according

to guidelines in the Installation

manual.

Fir st P ower -On Wi zar d

The DCU (not DCU 208E) will display

the

first power-on wizard

at the first

power up after delivery, or after a

factory reset of the panel.

All wizard settings can be changed

later.

Configuration Manual - 200E Series Page 5

Configuration

This section explains the configuration

of the DCU.

Configuration- and

Firmware files

The DCU may be configured either

using the built in web server, or by

inserting a USB memory stick with a

predefined configuration file.

DCU Web Ser ver Co n fig urat ion

Int erfa ce

The panel has a built in web server,

offering access to full configuration.

USB mem ory wi t h C onf i gur atio n

fil e

Insert a USB memory with the

configuration file(s) and follow the

guidelines appearing on the panel

screen.

Valid filename characters

a-z

A-Z

0-9

“_” (underscore)

“-“ (hyphen)

If other characters are being used,

then the panel may not “see” it.

Rename the configuration file to solve

the issue.

When the USB memory is inserted, the

panel asks for the administration

password (4 digits).

The panel then lists the configuration

file(s) available on the USB memory.

Select file(s) then select

COPY to copy

these files into the User Files area in

the panel. Note that this does not

activate the file; it is merely a copy of

the file into the panel.

Select a file, and then select

USE to

copy and activate this configuration

file.

Note! The DCU 208E does not have a

screen interface and hence this

method does not work on that unit.

USB memory with Firmware

file

A USB memory stick can be used to

install a new firmware in the DCU.

Note! If the memory unit has firmware

for both the DCU and the RP, and the

intention is to upgrade both panels,

then make sure to upgrade the RP

firmware first!

Con nect ing to t he D CU

It is possible to connect a laptop to the

DCU either directly or through a LAN

(Local Area Network).

Note! For use in an existing Ethernet

network, check the configuration of

the LAN with the LAN manager.

To connect to the DCU

Connect an Ethernet cable between the

laptop and the DCU port Ethernet port.

Configuration Manual - 200E Series Page 6

In the DCU menu, select Help –

Version Information. Note the IP

address. From factory, the IP

address is 192.168.0.101.

In the internet browsers

address field area, type the IP

address, eg.

http://192.168.0.101.

Press Enter, and note the login

screen.

In the login screen, type

- Username: dcu

- Password: 1234 (from factory)

Logged In?

Proceed to the Web Server

Configuration section, page 7.

Not Logged In?

Continue with connection settings as

described below.

Fur th er con n ect ion set tin g s

Change the IP address of the

DCU

If necessary, the IP address of the DCU

can easily be changed.

Note! The last digit in the IP address

becomes the engine number.

The DCU has a fixed IP address that is

set during the first power-on set up.

The IP address may also be changed

later, in the DCU panel menu here:

Menu – Settings –

Administration – Network

Configuration

IP address convention

The factory default IP address of the

DCU is 192.168.0.101. The first three

groups must be the same for all

components in the LAN, for instance

192.168.0.x, where x is the other unit

in the LAN.

Note! The x-number must be unique

within the LAN. Also, the two last

digits in x will represent the engine

number.

Example: A DCU with the IP address

192.168.0.104 will be named “Engine

#4”.

Factory defaults for the DCU

Factory defaults are valid at initial

startup only.

IP address: 192.168.0.101

Subnet Mask: 255.255.255.0

Default Gateway: 192.168.0.1

The IP address configuration will not

be kept, if a Factory Reset operation is

performed.

DHCP IP addresses range: 101 – 199

within the subnet defined by the DCUs

IP address.

Configuration Manual - 200E Series Page 7

Connection troubles

Make sure that the PC and the DCU is

connected to the same subnet.

If still a problem with configuring the

IP address check the following:

Use the ‘Connect a PC’ feature

From the DCU select “Connect a PC”

icon in the Settings Menu and

mark/toggle the Enabled check box.

In addition and after enabling you may

have to disconnect and reconnect the

Ethernet cable.

Use Static IP connection

Change computer IP settings for LAN

to static IP settings.

Web Server Configuration

Note! This chapter is not applicable for

the RP 210E/220E.

Log ged in

Once logged in, the DCU can be

configured.

When logged in, the browser displays

the Home screen.

The Home screen has the following

menu items.

Note! All changes to DCU, RIO and SDU

configuration is applied directly on

DCU, and not in the PC.

DCU

This is the top level menu for the DCU

configuration.

To access the DCU section, log in with

the following:

User Name: dcu

Password: 1234 (from factory)

Configuration Manual - 200E Series Page 8

RIO

This is the menu top level for the

optional expansion I/O modules RIO

210, 410, 412 and 425.

SDU

This is the menu top level for the

optional Shutdown unit modules SDU

404 and SDU 410.

Upl oad Wal lpa per

A personal wallpaper can be uploaded.

Ver s ion s

This top level menu item lists the

hardware and software version of the

DCU . If the DCU is connected to J1939

and the ECM data is transmitted, ECM

version will also be displayed.

Tip! If contacting Auto-Maskin for help

or questions regarding your product,

the data in the Versions page provide

vital data that might help speed up the

resolution to your enquiry.

Tro uble sho otin g

The troubleshooting section makes it

possible to troubleshoot I/O and

communication on the DCU, and the

RIO units.

Configuration Manual - 200E Series Page 9

Main DCU web server

menu

The menu is found here:

Home DCU.

This is the main menu for the DCU

configuration. The following is an

overview of the menu items.

Pas swor d

The DCU configuration is password

protected with a pin code.

Select this option to change the

password. First, type in the old

password and then the new password

twice.

Default password is “1234”.

Fil e

File handling.

Load any file

To change the configuration of the

DCU, load a different configuration

file.

Note! Panel will restart with the new

configuration file.

Factory Default

Select a file to activate a predefined

factory configuration file.

User Uploaded

This lists the files that are previously

user uploaded to this DCU.

Select a file to activate a new

configuration for the DCU.

Delete configuration file

The possibility to delete a user

uploaded configuration file.

Configuration Printout

This prints the current configuration

to screen.

To print to paper, use the browsers

print menu.

Save file as…

This saves the current configuration of

the DCU into a file on the PC. The

default file extension is .cfg.

Upload to DCU

Firmware

The firmware can be updated

whenever there is a new version

available.

Wallpaper

A personal wallpaper can be uploaded.

Make sure the file is in PNG format.

Configuration

A new configuration file can be loaded

into the DCU. Note that this menu

loads the file only. To activate the file,

choose the User Uploaded section as

described under File.

Configuration Manual - 200E Series

Page 10

I/O Configuration

The I/O section is found under:

Home DCU I/O Configuration.

It has menu items for flexible I/O,

input and output signals. These are

separated into three sections.

Note! Always remember to press the

Submit button after each change on

the configuration pages. No changes

are saved until this button is pressed!

Fle x ibl e I / O

This is where the Flexible I/O channels

are defined. Each channel can be used

for a variety of input and output

functions, such as:

24VDC Supply

0VDC

Switch Input

Configurable Output

4-20mA sensor

Voltage sensor

5V (#6)

J1939#2 (#20 and #21)

Note! Making changes to the flexible

I/O configuration may result in

damage to sensors connected to the

panel. It is recommended to

disconnect all sensors from the panel

before making changes.

After a flexible I/O channel has been

defined it will appear in the respective

menu as enabled.

Eg. Connector C1P1 has been defined

as a “4-20mA” channel in the Flexible

I/O section. It will now be available in

DCU Config Inputs 4-20mA.

Con fig Inp uts

This is where the I/O input channels

are configured, such as 4-20mA,

PT100 and switch inputs.

Engine Speed

This is where engine speed sensors

are configured, and the overspeed

setpoint is set. The majority of the

configuration is synchronized with

SDU.

Note! This section is central to any

installation. It provides the DCU with

data required to form an exact and

reliable reading of the engine speed.

HomeDCUI/O ConfigurationEngine Speed

Configuration Manual - 200E Series

Page 11

Source

The Engine Speed is constructed by

reading data from up to three sources

simultaneously. These three sources

are prioritized by the DCU. As long as

the RPM Primary Source is functional,

it is used to form the actual Engine

Speed. Should the RPM Primary Source

fail, the DCU uses the RPM Secondary

Source if available. Finally, the RPM

Third Source is used only when both

Primary and Secondary fails.

Each of the RPM Sources can be

configured to receive data from a

number of possible sensors.

Source

Comment

J1939

J1939 CANbus connected to

terminals C1P7-8.

J1939#2

J1939 CANbus #2 connected

to Flexible I/O #20-#21.

DCU

Magnetic pickup locally

connected to DCU,

terminals C4P1 and Flexible

I/O#18.

SDU

410

One of the two pickups

connected to the SDU safety

unit.

The SDU has a scheme for

selecting from its two

connected pickups.

SDU

404

Magnetic pickup locally

connected to SDU.

Local Pickup

If there is a pickup connected to the

DCU, or “DCU” is selected among the

sources above, then set the pulses per

revolution here.

General Configuration

RPM Rounding rounds off the

displayed value to nearest 1, 5 or 10

RPM.

RPM Setpoint is the RPM at which the

DCU indicates the engine is running,

and disconnects the cranker.

RPM Setpoint 2-5 are optional

setpoints that can be used in

conjunction with other sensors.

RPM Ready to take Load is a signal

that can be configured to an output. It

activates when that RPM is reached. It

deactivates when a stop command is

given, OR the speed drops below the

threshold, minus 15%.

RPM Nominal Speed is the engines

nominal speed, and is used to lower

the RPM Overspeed on the Overspeed

test to 95 % of the nominal speed.

General

Channel Use is the selection for where

the signal shall be displayed.

Select

DCU+RP to display the

instrument in the DCU and in the RP.

Select

DCU to display in DCU only, and

not in any connected RP.

Select

RP to display in any connected

RP only, and not in the DCU.

Display

These values define how the

instrument widget is presented.

Display Range Min is the minimum

value displayed, normally 0 (zero).

Configuration Manual - 200E Series

Page 12

Display Range Max is the maximum

value displayed. For an engine running

at 1500 rpm nominally, a typical

maximum setting would be 1800 RPM.

Display Major Divider is where the

instrument widget writes an RPM

value, normally every 500 RPM.

Display Minor Divider is the tickmarks

between the major divider marks,

normally every 100 RPM.

Display Multiplier is the multiplier

value. The value is printed in the RPM

meter.

Overspeed

RPM Overspeed is the setpoint where

the DCU indicates overspeed.

RPM Overspeed Delay is the delay – in

milliseconds – before alarm or

shutdown. Typical setpoint is 100ms.

RPM Overspeed Shutdown Enabled is

where the overspeed behavior is

selected. Select

Yes for the DCU to

shut down the engine. Select

No to

disable overspeed shutdown.

Individual Speed Sensors

Note that

any

speed signal can be

connected here, and that this is

treated separately from the Engine

Speed signal configured above.

By configuring these sensors it is

possible to view the current RPM from

a individual speed sensor as opposed

the standard Engine Speed sensor that

acts on many inputs at once.

All Individual Speed sensors are

configured the same way.

Channel Use

This selects the panel the instrument

widget is displayed on. It is possible to

display the instrument on

The DCU engine panel, and

The RP remote panel, or

A combination of the two.

Sensor Unit

There is no choice; select RPM.

Sensor Range Min/Max

These values are fixed

Display Unit

There is no choice; select RPM.

Display Range Min

Select the low end of the scale.

Display Range Max

Select the high end of the scale.

Display Major Divider

Select the major tickmarks. These are

labeled with RPM values.

Display Minor Divider

Select the number of minor tickmarks

between the major tickmarks.

Display Multiplier

Select a value multiplier of 1, 10, 100

or 1000.

Event

Select type of event for this channel.

Configuration Manual - 200E Series

Page 13

Engine Load

First, configure either a 4-20mA, 0-5V

input or the J1939 PGN 0Xf003, SPN

92. Select then the engine load source

from the dropdown menu. Engine load

can now be used as an additional

setting when configuring alarms.

Transmission

The transmission menu are used for

Gear control, to Indicate current Gear

or as start interlock.

Gear control is enabled under

Home DCU User Interface.

When enabled the “Backlight” button

will be replaced with “Gear” in

instrument view. Selecting “Gear” will

open a new page on the DCU with

functions for Gear control as described

below.

Gear

The gear source is used as start

interlock when a gear is engaged

and/or to display the current gear.

Select the gear feedback source used.

To display current gear go to:

Home DCU User Interface

and enable “Show Gear Indicator

Instead Of All Ok”. To get the Gear

indicator as an half height vertical bar

graph go to: HomeDCU Interface

designPages. Choose witch page and

slot the gear indicator shall be shown.

Shaft Lock

If the DCU gear control is used, the

shaft lock input will prevent gear

changes when active. Select a Shaft

Lock source from the pull down menu.

Note! The shaft lock source must be a

switch input.

RPM Interlock

If the DCU gear control is used, the

RPM Interlock input will prevent gear

changes when active. Select a RPM

Interlock source from the pull down

menu.

Note! The RPM Interlock source must

be a switch input.

Shaft Speed

If the DCU gear control is used, the

Shaft Speed can be displayed wherever

the user wants. To choose its

placement go to:

HomeDCUInterfacedesignPages

It is possible to enable “Mirrored view”

which will put the zero value on top of

the gauge.

Switch

There are 21 configurable channels

available as switch inputs. Each

channel can be configured as an

(ordinary) engine switch input channel,

or it can be configured to perform a

function, like Automatic Start.

Configuration Manual - 200E Series

Page 14

HomeDCUI/O ConfigurationSwitch

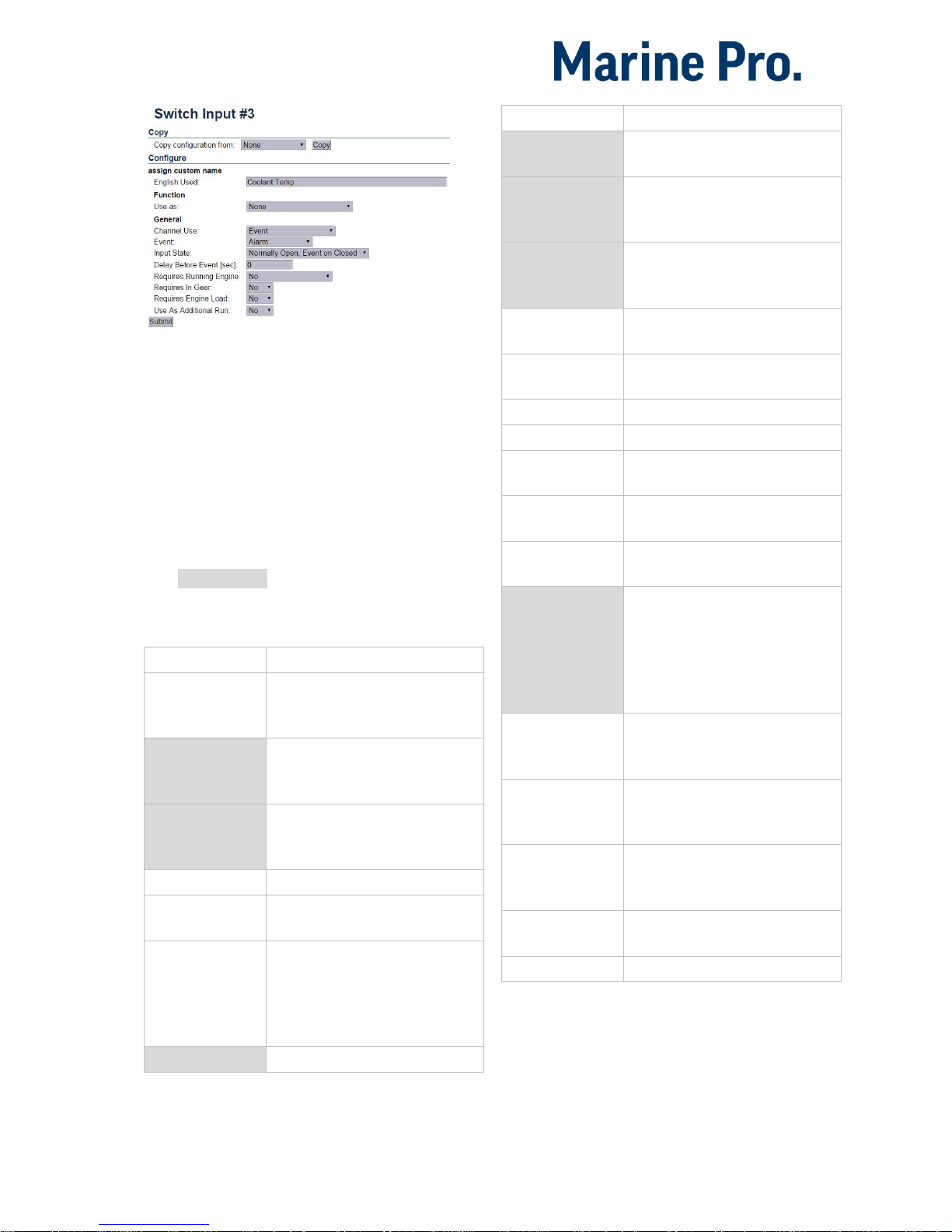

First, select any of the enabled switch

channels. Then, for each channel, set

the following parameters.

Available functions for Switch inputs

The following functions are available

for the switch inputs.

The highlighted functions are the most

typically being used.

Function Name

Description

None

The channel is being used as

an (ordinary) engine sensor

switch input

Local Mode

Sets the panel to local mode,

meaning all external

commands are blocked.

Remote Mode

Sets the panel to remote mode,

meaning all local commands

are blocked.

Backlight 100%

Force backlight to 100%

Prelube override

The configured prelube

sequence is aborted

Prelube

complete

Signal shall come from the

prelube system, notifying the

panel that the prelube

sequence is completed. The

panel will commence start.

Start disabled

Start is disabled

Function Name

Description

Automatic mode

The panel accepts automatic

start/stop signals

Automatic start

Panel will commence the start

sequence. Requires Automatic

mode.

Automatic stop

Panel will commence the stop

sequence. Requires Automatic

mode.

Remote start

Same as the local start button.

Disabled if panel in local mode.

Remote stop

Same as the local stop button.

Disabled if panel in local mode.

Local Start

Local Start button

Local Stop

Local Stop button

Local

Acknowledge

Used to acknowledge all events

in the alarm list

Local/Remote

Acknowledge

Used to acknowledge all events

in the alarm list

Remote

Acknowledge

Used to acknowledge all events

in the alarm list

Shutdown

override

Makes all the configured

shutdown channels into alarm

channels, so engine will not

shut down automatically.

Engine overspeed shutdown is

however always enabled.

In gear

From gearbox on prop.

Engines. Disables start

attempts.

In Gear (Ahead)

From gearbox on prop.

Engines to indicate Ahead

gear.

In Gear (Astern)

From gearbox on prop.

Engines to indicate Astern

gear.

Toggle Crank

mode

Toggle between crank modes.

Power On

Toggle Sleep mode.

Function Use as

Select None if the channel is to be

used as an ordinary engine switch

input.

Configuration Manual - 200E Series

Page 15

Select any of the other functions

described above to assign that

function to the input channel.

Channel Use

This describes how the channel is

used.

Select

Not in use if the channel shall

be disabled.

Select

Event if the channel shall make

any form of event. An event can be a

warning, an alarm or an engine

shutdown.

Select

Silent Event for an active

channel, but no panel alarms. The

event will be available on

communication only.

Event

If any type of event was selected under

Channel Use, then select the type of

event here. It can be a Warning, Load

Reduction, Alarm or a Shutdown.

If

None is selected, then the channel is

active but no events are created.

Input State

Normally Open means the contact

must close to make the event, whereas

Normally Closed means the contact

must open to make the event.

Delay Before Event

Choose the desired persistence time

before the channel activates the event.

This field is only available if the Event

field is selected.

1

An engine speed source can be either the magnetic

pickup or the SAE J1939 CANbus signal connected

to the DCU.

Requires Running Engine

Typically, this shall be set to Yes for

pressure sensors, and to

No for all

other sensors.

Select any of the other setpoints to

activate the channel at other rpm

values.

Requires in gear

If gear is required to monitor event

Must be in gear (Switch)

Requires Engine Load

Initial Delay

If the requires above is set Yes, set the

persistence time after the engine is

running until the channel is enabled.

This field is only available if all

requires that is selected are fulfilled.

Use as Additional Run

If the DCU has one pickup source only,

we recommend adding an engine oil

pressure switch as an engine running

indication.

Note! Do not use any other pressure

sensors – or any other signals – as

engine running

indication!

If two engine speed (pickup)

sources1 are in use, then we

recommend leaving this off for

all switches, i.e. set to No.

Configuration Manual - 200E Series

Page 16

If one engine speed source only

is in use, then locate the engine

low oil pressure switch and use

this as the Additional Run

signal. Set to Yes.

4-20mA

First, select one of the enabled 420mA channels. Then, for each

selected channel, set the following.

HomeDCUI/O Configuration4-20mA

Channel Use

This selects the panel the instrument

widget is displayed on. It is possible to

display the instrument on

The DCU engine panel, and

The RP remote panel, or

A combination of the two.

It is also possible to suppress the

alarm events, as can be seen in the

following table overview.

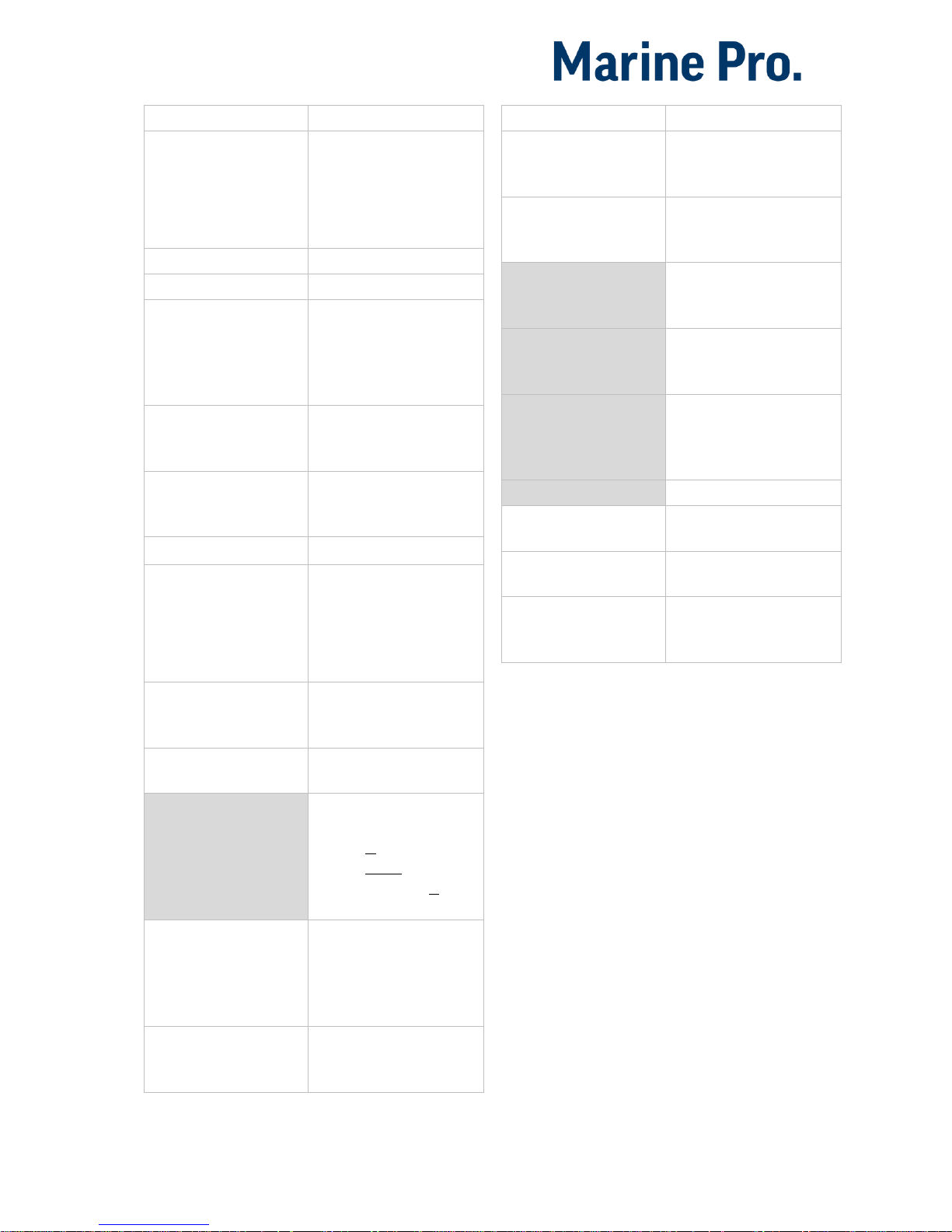

Type of use

DCU

RP

D E D E

Not in use

Event

x

x

DCU x

Type of use

DCU

RP

D E D E

DCU + Event

x x

x

RP x

RP + Event

x x DCU + RP

x x DCU + RP + Event

x x x x Silent Event

DCU + Silent Event

x

RP + Silent Event

x

DCU + RP + Silent Event

x x

D = Displayed on panel

E = Event

Event = warning, alarm or shutdown

Silent Event = no local event; on communication only

Note! Normally - and in most cases -

the selection should be “DCU + RP +

Event”, as bolded and outlined in the

table above. This makes sure the

channel is displayed in the DCU and in

the RP, if and when an RP is installed.

If for example a signal is necessary in

the DCU engine panel only, and not in

the RP remote panel, then select DCU

+ Event from the selection.

Sensor

Sensor Unit

Select the unit, as printed on the

sensor. An oil pressure sensor might

for instance be in

Bar

or

psi

.

Sensor Range Min/Max

Select the sensor range values for min

and max, as printed on the sensor.

Configuration Manual - 200E Series

Page 17

Display

Display Unit

For the above sensor, select the

desired displayed unit for US and

Metric values.

Display Range Min/Max

For the above sensor, select the

desired minimum and maximum

values displayed in the instrument, for

US and Metric values.

Display Major/Minor Divider

For the above sensor, select the

desired major and minor divisions in

the instrument, for US and Metric

values. The major divider number is

printed at each major divider.

Display Multiplier

Select a multiplication factor as

necessary.

An instrument with displayed range 010,000 would display as 0-1,000 with

a multiplication factor of 10. The

multiplication factor is printed in the

instrument (round gages only).

Update Metric/US

When the US section has been

completed, then the web server can

calculate the other section, and vice

versa.

Note! The application does not round

off values. It is highly recommended to

adjust the calculated values by hand,

and set sensible round-figure values.

Alarming

This section is always completed in the

currently panel selected system unit.

Event

Select the desired combination of

warning, alarm and shutdown. Select

“RPM dependent” for a setpoint that

varies with RPM, and complete the

boxes.

Threshold [unit]

Select the alarm threshold value in the

correct units.

Delay After Crossing Threshold

Set the persistence time before the

event. Value is in seconds.

Threshold Type

Set the event to appear on a rising

(higher) or falling (lower) signal. A

temperature fail is normally “too high”,

and a pressure fail is normally “too

low”.

Requires Running Engine

Set Yes to disable the event when the

engine is not running (enabled when

engine is running only).

Set

No the enable the event always.

Requires In Gear

Requires Engine Load

Initial Delay

If the requires above is set Yes, set the

persistence time after the engine is

running until the channel is enabled.

Use as Additional Run

If the DCU has one pickup source only,

we recommend adding an engine oil

pressure switch as an engine running

indication.

Configuration Manual - 200E Series

Page 18

Thermistor

First, select any of the two thermistor

channels.

Configuration

Then, for each selected channel, set

the parameters, as for the 4-20mA

section, see page 16.

HomeDCUI/O ConfigurationThermistor

Voltage sensor

There are 19 configurable channels

available as Voltage sensor inputs.

Select the desired Flexible I/O to be

used as a voltage input in the

Flexible I/O Configure Menu. There

are four different 0V to choose: #2,

#5, #12 and #18.

Choose “Voltage sensor” in the

“Function” drop down list. Take note

of which pin number corresponds to

Flexible I/O # selected.

Configuration

Select “Voltage sensor” from the I/O

configuration menu. Select the

appropriate Voltage Sensor # on the

left side menu. Use the drop down

menus to select Range, Unit and

display features. Alarm features can

also be set if desired.

Note! Flexible I/O # 6, pin C3P1 can be

configured as supply for 0-5V

sensors.

J1939

Select a SAE J1939 CANbus signal from

the list.

Home->DCU->I/O Configuration->J 1939

Select

Select from the left-hand side column

the first letter in the signal.

For instance, if looking for the “

Fuel

Rate” signal, select

D-F in the left

column.

Search

The right-hand side column can be

used to search for the desired signal.

Type the information available and hit

the

Search button.

Configuration

Once the signal is selected, the rest of

the configuration is exactly as for the

4-20 mA signal type; see page 16.

Configuration Manual - 200E Series

Page 19

Differential

A

differential

channel is a

logical

(and

not physical) channel, made up by two

physical channels.

The physical channels may be

hardwired or from the J1939 CANbus.

HomeDCUI/O ConfigurationDifferential

The differential channel will output the

difference between the two source

(physical) channels.

The sensor unit must be the same for

the two selected source signals, for

instance they must both be bar, and

not one bar and the other psi.

The differential channels can be

assigned to an instrument widget as

per normal.

Average

An

average

channel is a logical (and

not physical) channel, made up by up

to 20 analogue physical channels.

The average channel will output the

average between the up to twenty

source (physical) channels.

The sensor unit must be the same for

the selected source signals, for

instance they must all be bar, and not

one bar and the other psi.

The average channels can be assigned

to an instrument widget as per

normal.

Special

These signals do not naturally fit into

any other group.

Input Voltage

The input voltage is monitored with

fixed setpoints. The setpoints are as

follows:

24V System

Warning: <21V

Alarm: <18V

12V System

Warning: <11V

Alarm: <10V

Here, there is a possibility to add

another set of warning/alarm

setpoints, and also to configure a

widget for voltage display.

Calculated Fuel Rate

The DCU can calculate the fuel

consumption and present an

approximate figure.

Select the channel and configure as

above.

Engine Hours

If the engine hour signal is not

available on the J1939 CANbus, it can

be calculated by the DCU.

The appearance of the counter is

configured in this dialog.

Configuration Manual - 200E Series

Page 20

Instantaneous Fuel Economy

The DCU can calculate the

instantaneous fuel rate if calculated

fuel rate or measured fuel rate, and

vessel speed is provided.

Analog Modbus

The DCU can handle up to 50 analog

Modbus sensors. Sensor unit of

measurement and range can be set

with the drop down menu. The sensor

number corresponds to customer

selected address of sensor.

See the Communication I/O List under

Modbus Analog available online

here.

HomeDCUI/O ConfigurationAnalog Modbus

Digital Modbus

The DCU can handle up to 500 digital

Modbus sensors

. The DCU is designed

to handle digital sensors that behave

as switches. The sensors can be

configured from the drop down

menus. The sensor number

corresponds to customer selected

address of sensor.

See the Communication I/O List under

Modbus Digital available online

here.

HomeDCUI/O ConfigurationDigital Modbus

EGT

The EGT menus are used to configure

events associated with cylinder/turbo

values set in the RIO 412 exhaust

temperature monitor. EGT events can

also be set using EGT data received

over the J1939 interface.

Configuration Manual - 200E Series

Page 21

Con fig Out p uts

This is the section for the configurable

outputs, such as 12/24V outputs,

relay outputs etc.

Available functions

These functions are available to

configure to any output.

The highlighted functions are the most

typically being used.

Function Name

Description

Acknowledge button

The acknowledge button

is activated

Buzzer active

The buzzer is active

Shutdown in alarm list

There is a shutdown

event in the alarm list

Load Reduction in

Alarm List

There is a Load

Reduction event in the

alarm list

Alarm in alarm list

There is an alarm event

in the alarm list

Warning in alarm list

There is a warning event

in the alarm list

All faults

(Unacknowledged)

Any new event in the

alarm list

Common diagnostic

message

Any ECM-sourced

diagnostic message in

the alarm list

Ready state

The DCU is in Ready

state

Init. delay state

The time between

reception of the

automatic start signal

until the first start

attempt

Cranking state

Panel is cranking

(starting) the engine

Awaiting run state

Panel finished cranking

and is waiting for the

engine to spin up

Running state

Engine is running

Function Name

Description

Crank delay state

Crank rest time between

automatic start attempts

Delayed stopped state

State is active and timer

is running

Cooling state

Panel has activated the

Gen. Breaker Disconnect

signal and the engine is

now running on idle load

Stopping state

Engine is stopping

Stopped state

Engine has stopped/is

below 5 rpm. This state

is minimum 10 sec in

duration.

Blocked state

Engine cannot be

started, usually caused

by a shutdown that is

not acknowledged

Stopped for unknown

reason

The panel lost all signals

indicating that the

engine is running, but

no stop command was

ever given to the panel.

Out of fuel?

First start attempt

failed

The first in a sequence

of start attempts has

failed

Final start attempt

failed

During an automatic

start sequence, after the

final start attempt, +

crank rest time

In Local mode

The panel is in local

mode and will not

accept remote

commands

DCU Tacho Failure

The pickup (MPU) signal

is lost during engine run

Service Interval

One of the configured

service intervals are due

Engine Protection

Override

The panel is in

shutdown override state,

and shutdown channels

are now alarming only.

Overspeed setpoint is

always enabled.

Configuration Manual - 200E Series

Page 22

Function Name

Description

Engine Protection

Override /Emergency

Mode

Same as “Engine

Protection Override”

but also with

Emergency mode

activated.

Power on

The panel is powered

Power off

The panel is powered off

Supply Voltage Low

The supply voltage is

below the fixed setpoint.

Note different setpoints

for 12V and 24V

systems.

Speed Relay 1, 2, 3, 4

The function activates at

the configured rpm

value

Alarm or Ack Button or

Remote Acknowledge

The panel is being

acknowledged and the

buzzer is silenced

Common Start Failed

Start or crank failure

Common Stop Failed

Stop failed. A

configurable timer

(Engine Stopping

Time) passed without

the engine stopping.

Soft Button 1, 2, 3, 4

One of the soft buttons

at the bottom of the

screen is pressed.

Ready To Take Load

Engine rpm is above the

setpoint

Ready for PMS Start

Panel is ready for power

management start:

- Panel is in Auto

- Panel is not in Local

- Panel supply V. is OK

- Panel is in Ready state

New Alarm Pulse

Whenever a new event

appears in the alarm list,

this function activates

for a second, then deactivates automatically

In Manual mode

Panel is in manual mode

and will not start

automatically

Function Name

Description

Overspeed

Engine rpm is above

configured setpoint for

overspeed

In Remote Mode

Panel can be

commanded from

remote

ETR

Energize to Run. Active

when engine cranks or

runs.

ETS

Energize to Stop.

Activates when engine is

stopping

Shutdown

Engine is being stopped

automatically from a

sensor input, including

overspeed

Running

Engine is running

Crank

Panel is cranking/

starting the engine

Prelube Activation

The panel has activated

the prelube function

Emergency start/mode

Panel is in emergency

mode, or an E-Start

sequence is activated

In addition to the fixed functions

described above.

All configured events, e.g. a sensor

configured as a warning, alarm or

shutdown.

12/24V Outputs

The DCU has 19 configurable I/O

available as 12/24V outputs. The

function on each output is configured

here.

Select one of the enabled 12/24V

output channels.

Configuration Manual - 200E Series

Page 23

HomeDCUI/O Configuration12/24V Outputs

Then, for each channel, select the

desired function.

Relays

The DCU has two built in potential free

relay contacts, which can be assigned

a function.

Select one of the two relays.

HomeDCUI/O ConfigurationRelay Functions

Then, for each channel, select the

desired function.

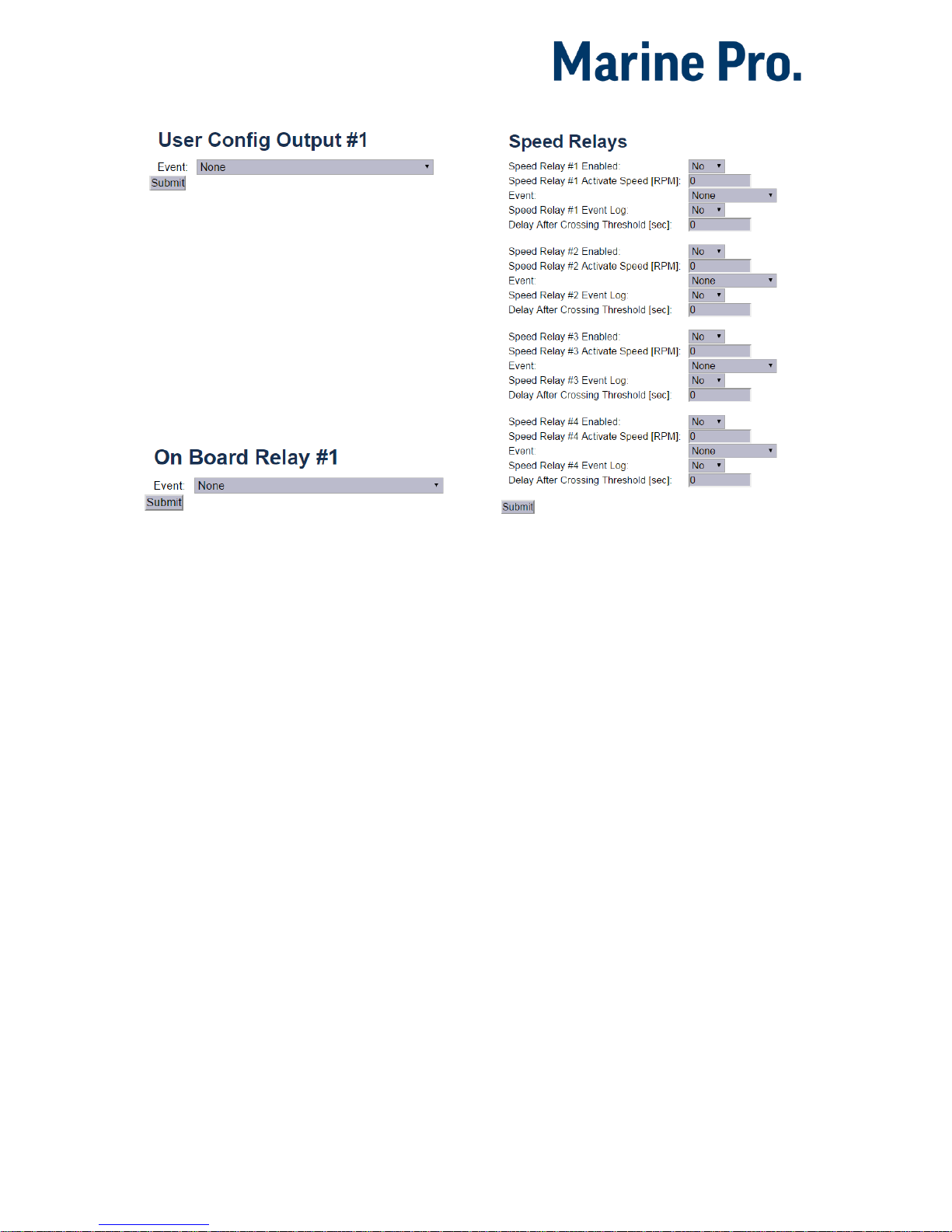

Speed Relays

A Speed Relay is a relay that activates

on a certain engine speed rpm, and

deactivates when below that rpm.

For instance, speed relay #1 can be

configured to activate at 1200 rpm,

and will then deactivate at <1200 rpm.

HomeDCUI/O ConfigurationSpeed Relays

Set Event Log to Yes to create an event

in the log when the speed relay

activates.

The Speed Relay can now be assigned

to any configurable output.

J1939 Outputs

The DCU has a variety of predefined

messages available to be transmitted

over J1939.

J1939

The DCU is able to broadcast J1939

data by mapping any input signal to

any standard J1939 SPN as long as the

quantity of the signals match.

Select

Select from the left-hand side column

the first letter in the signal.

Configuration Manual - 200E Series

Page 24

For instance, if looking for the “Fuel

Rate” signal, select

D-F in the left

column.

Search

The right-hand side column can be

used to search for the desired signal.

Type the information available and hit

the

Search button.

Configuration

When the J1939 output signal to be

broadcasted and selected the DCU will

present a list of possible source

signals in a drop down combo box

called “Signal to be Transmitted”.

Note, any enabled input signal of the

same quantity.

Special

In this section special J1939 messages

is listed.

Configuration Manual - 200E Series

Page 25

User Interface

In this section aspects of the operator

user interface is defined.

The menu is found here:

Home DCU User Interface.

Configuration

Changes done in configuration will

apply to all pages.

Hea der

“Show Gear indicator Instead Of All

Ok

” should only be set to yes if

“ahead/astern” switches are used.

This will enable an arrow in the upper

right corner of the screen displaying

gear position.

Ins trum ents

“Green section on Gauges” will change

the outer line of all gauges to green. If

a warning or an alarming threshold is

set, this will still be red.

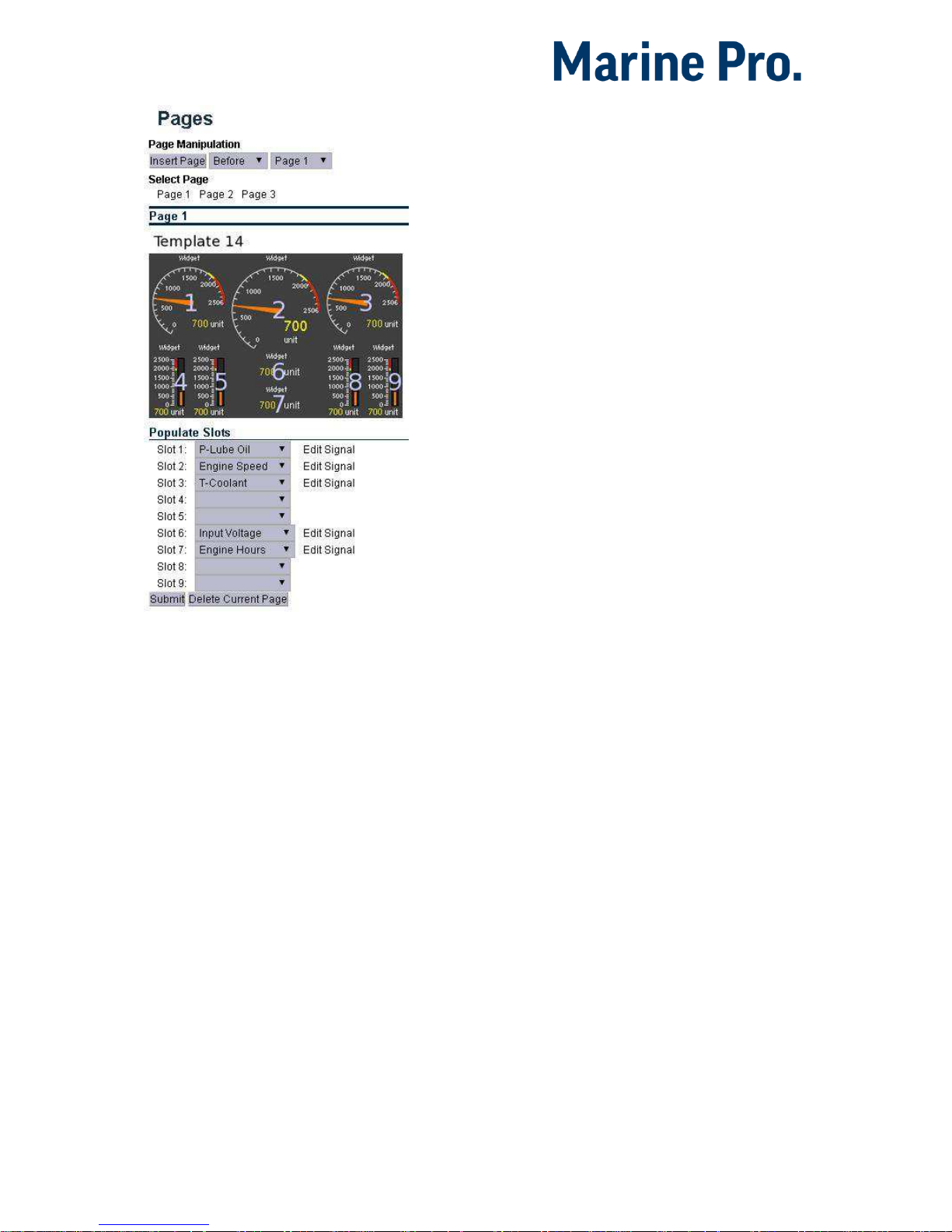

Pages

This is where the configuration of the

different pages is done.

A Page is a screen on the panel. The

panel can maximum have five

instrument screens.

A page is built using one of

several available templates.

A template has several slot

positions. A slot is simply an

area on the screen.

Each

slot

position can hold one

widget type. A widget is for

example a needle instrument or

a bar graph.

Each widget can be assigned a signal

HomeDCUInterface DesignPages

In the example above, two pages are

already created. Click on a page to

select it, for instance click on

Page 1.

Pag e de tail s

In the picture below, Page 1 is

selected.

Configuration Manual - 200E Series

Page 26

As can be seen above,

Page 1 is made

using Template 14.

There are

9 slot sections in the

template, each with a

Widget.

Slots 1, 2, 3, 6 and 7 are assigned a

signal.

App l y a si gnal to a s lot

To add a signal to a slot position,

select the drop-down list for the

desired slot, then select the signal

from the selection of available signals.

Only signals that have been configured

for use are visible in the drop-down

list.

Edi t a sig n al

Click on the Edit Signal link to edit the

signal.

Ins ert a n e w P age

Choose whether the new page is to

appear before or after an existing

page, then press the

Insert Page

button.

The pages will be renumbered

automatically.

Cho ose a T e mpl ate

A range of templates will be

presented. Choose a template and

start populating the page with

predefined signals.

The chosen template will appear at the

bottom of the screen. Select a signal

and press

Submit to clear the other

templates.

Del ete a Pa ge

First Select the page, and then press

the

Delete button.

There is no undo-function, so make

sure the correct page is deleted.

The pages will be renumbered

automatically.

Flow Charts

Flow charts are specialized pages that

displays signal data for a predefined

process. Flow charts are added to the

same display rotation as normal

pages.

Configuration Manual - 200E Series

Page 27

Currently there’s only one flowchart

available. This flowchart is only

applicable for Genset installations and

can be used to display specialized data

when the DCU is connected to a RIO

425 module.

RP Home View

Configuration

This section can be used to customize

the contents of the home screens of

Remote Panels (RP 410E or RP

210E220E) connected to this DCU.

Assign signals to dual and quad view.

Note, this settings will only affect how

connected RPs and have no impact on

the DCU itself.

Controls

Gear

“Enable Gear Control” will enable the

Gear Control and replace the backlight

button with “Gear” on the DCU.

“In Local Mode Only” will only allow for

gear changes to be done when the

DCU is in Local Mode.

“Automatic Neutral Gear On Shutdown”

instructs the DCU to request neutral

gear should a shutdown occur. Neutral

Gear is request when the RPM drops

below the configured RPM during the

shutdown sequence.

The Gear Control form is highly

dependent on how the Transmission

section in Config Inputs under I/O

Configuration is configured.

The “Gear” widget, displays current

gear status according to the Gear

Source for the Transmission Input.

Gear requests are performed by

setting dedicated Modbus registers. In

order to make full use of this function

an external PLC or similar is required

to read gear requests from the DCU

via Modbus, as well as physically order

the change of gear.

Shortcuts

This section allows overriding of the

default functions connected to the

four soft buttons while in looking at

data pages.

Select any function from the dropdown

boxes for each function button and

press submit.

Language

This is general section for language

related settings. Inspection of all or

only enabled signals can be inspected

or modified from here.

It also provides a shortcut to

customized names for service

intervals.

Configuration Manual - 200E Series

Page 28

Buzzer

Automatic Buzzer Off is a function that

may be used during the configuration

phase of a DCU. When active, any new

event that triggers the Buzzer, will be

automatically silenced by the DCU.

Each new event will only produce a

single short buzzer beep.

This setting is automatically turned off

after 10 hours or when the DCU is

powered off.

Configuration Manual - 200E Series

Page 29

Start/Stop/

Prelube

This menu section covers the manual

and automatic start and stop

sequence.

Prelube

The DCU can prelube the engine at

certain regular intervals, and/or before

start.

Pre lube – Fix e d T ime

This will activate the Prelube function.

Note that this function must be

assigned to an output.

Prelube Time

Set the number of seconds the DCU

shall prelube before start.

Typical setting:

5-30 seconds

Pre lube – Unti l P r es sure

This will prelube until the DCU

receives a signal telling it that prelube

is finished.

The Prelube Complete input signal

must be configured on one of the ten

switch input channels.

Prelube Timeout

The DCU expects to receive the

Prelube Complete signal within this

timer period.

Typical setting:

5-30 seconds

Override Allowed

Select if a prelube should be possible

to manually override, to continue the

start sequence with an incomplete

prelube sequence.

Note! The override is done in the DCU

Menu Settings Prelube Override

Action Upon Timeout

Select the action for when the Prelube

Timeout timer elapses.

Select Allow Start to continue

cranking the engine anyway.

Select Abort Start to abort the

start sequence. The DCU will

indicate with a Prelube Failure

alarm.

Osc i lla tin g

The DCU can prelube the engine

continuously, in a never ending

sequence.

The sequence is disabled while the

engine is running.

Oscillating Enabled

Set to Yes to enable oscillating

prelube.

Oscillating On-Time

Set the number of seconds the DCU

shall lubricate the engine.

Typical setting:

60 seconds

Configuration Manual - 200E Series

Page 30

Oscillating Off-Time

Set the number of minutes between

each lubrication action.

Typical setting:

60 minutes

DCU Engine

Start/Stop Control

Automatic Start

The DCU can start the engine

automatically. The following

conditions must be met:

A channel must be configured

as Automatic Start and

activated.

The DCU must be in the

Automatic mode of operation:

Menu Settings Mode

Initial Start Delay

When the start sequence activates, this

timer must elapse before the DCU will

do the first start attempt.

Typical setting:

1 second

No. of Start Attempts

The total number of start attempts.

Typical setting:

3 attempts

Prelube Before Each Start

Attempt

Select Yes to prelube before each start

attempt.

Select

No to prelube before the first

attempt only.

Starter 1

Cranking Time

The time the starter engine is

engaged.

Typical setting:

5-7 seconds

Delay Between Start Attempts

If the engine did not start after the

previous attempt, it will delay this

many seconds until it does the next

start attempt.

Note! The timer starts when the engine

rpm is less than 5rpm.

Typical setting:

5-7 seconds

Starter 2

Enable Secondary Starter

Select Yes for dual starting.

Select No for just starting the one

engine.

Configuration Manual - 200E Series

Page 31

Automatic Stop

The DCU can stop the engine

automatically. The following

conditions must be met:

A channel must be configured

as Automatic Stop and

activated.

The DCU must be in the

Automatic mode of operation:

Menu Settings Operation

Mode

Delay Before Disconnecting

Generator Breaker

When the automatic stop condition is

applied, the DCU will wait this many

seconds, and then activate a signal to

disconnect the generator breaker, if

any.

The Disconnect Generator Breaker

signal is not a standard output signal,

and must be configured to a suitable

24V or relay output.

Typical setting:

1-60 seconds

Cooling Time

After the previous timer has elapsed,

the engine will continue to run (with

no load) for this amount of time to

cool down.

When the timer has elapsed, the DCU

will stop the engine.

Typical setting:

1-10 minutes

Start/Stop Buttons

The Start and Stop button can be

configured to be Latched or

Momentary.

Note! The selection is valid for the

Start and Stop button.

Lat c hed bu t ton s

Set the Hold Buttons to Start/Stop to

No for a latched button interface.

The button will latch- and the

operator can let go. The panel will

finish the start/stop sequence.

Mom enta ry b utt ons

Set the Hold Buttons to Start/Stop to

Yes for a momentary (hold-tostart/stop) button interface.

The button must be pressed until the

engine has started/stopped.

E-S tart

To allow the operator an Emergency

Start option (E-Start) then set the

Allow E-Start option to Yes, otherwise

set it to

No.

The

E-Start will automatically do the

following

Configuration Manual - 200E Series

Page 32

Override any prelube sequence

Set shutdown override

User Interface

A few of the user interface aspects are

configured here, like languages and

buzzer.

Lan guag e

In this section, the signal descriptions

can be manually translated to other

languages.

All Signals

Press All Signals to display all signals

available in the DCU.

The page displays three rows of signal

text.

The following rules apply:

The first row is the English

Default description. This

description is being used if it is

not changed.

The second row is the English

Used description. This

description is being used by the

panel. If the description says

default, then the default

description is being used.

The third row is the 2nd

language. This description will

be used when that language is

selected by the panel operator.

English

Default

English Used

2nd Language

Engine Oil

Press.

Engine Oil

Pressure

Motoroljetrykk

Engine Speed

[default]

Motorturtall

The [default] field means that the

English default text (left column) will

be used.

Select any [default] text to change the

signal text description.

Enabled Signals Only

This is the same as for All Signals,

except that only signals that are in use

are listed.

Service

The four Service intervals will indicate

with a text. The default text can be

changed.

As above, press the [default] field to

change the default text.

Buz zer

Control the panel buzzer behavior.

Buzzer Off

Select Yes to suppress the buzzer

automatically.

The buzzer will activate as before, but

the DCU will automatically silence the

buzzer.

Configuration Manual - 200E Series

Page 33

Engine Model

Set the engine name.

Eng i ne Name

The default name is “Engine”.

Name the engine better, for example

“Auxiliary” or “Doris”.

Note! The last two digits in the DCU IP

address becomes the engine number.

If the IP address is 192.168.0.110,

then the engine in this example is

named “Auxiliary #10”.

Service Interval

See and configure regular service

intervals.

Vie w Se rvi c e S tat u s

This will list the number of hours until

next service is due.

HomeDCUService IntervalConfigure

Con figu re

Up to four different service intervals

can be configured.

The default text “Service x” can be

changed by selecting the

assign

custom name link.

Service Enabled

Select Yes to enable this service

interval timer.

Next Service At

Select the hour counter value in the

DCU for the

first

service. Note that this

occurs one time onlIP addressy.

This is useful if the first service should

have a shorter interval than the regular

service intervals.

Then Every

Select the service interval in hours.

The DCU will indicate every time this

number of hours has elapsed.

Example

Current DCU hour counter is 140

hours.

Next Service At: 150 hours

Then every: 250 hours

The first service notification will

appear in 10 hours, then every 250

hours.

All hours are engine running hours.

Communication

All the panel communication

interfaces.

Configuration Manual - 200E Series

Page 34

Netw ork Co mmun ica ti on

Set the IP address, netmask and

gateway for the DCU.

The default values are as follows:

IP address: 192.168.0.101

Netmask: 255.255.255.0

Gateway: 192.168.0.1

Make sure the IP address is unique on

the network.

If installing the DCU in an already

established ship Ethernet environment,

consult the network manager to obtain

an IP address.

Note! The last two digits becomes the

engine number, as part of the engine

name.

Example

The Engine name is “Auxiliary”, the IP

address is selected as 192.168.0.110.

The engine name then becomes

“Auxiliary #10”.

Mod bus RTU

The DCU has an built in Modbus RTU

communication interface.

Modbus Parameters

Baudrate: 9600-115200

Databits: 8

Stop bit: 1

Parity: Even

In addition maximum Timout can be

specified. Default value is 20 [s].

Address

Set the Modbus ID number for the RS485 channel.

The number can be any integer in the

1-32 range, and must be unique on

the Modbus network.

Modbus I/O List

The Communication I/O List is

available online

here.

Mod bus TCP

The DCU has a built in Modbus TCP

communication interface.

If a Modbus TCP connection is

detected and lost, an alarm will be

raised after the set Maximum Timeout

in seconds.

J19 39 C onfi gur atio n

Configure how the SAE J1939 CANbus

works.

Source Address

The default panel source address is

242 (0xF2).

Request Address

This is used to ask nodes for on

request PGNs. Type in the node

address.

Allowed Addresses

This makes it possible to filter units

on the CANbus, so that the DCU is

reading data from specific units only.

Normally, all sources are accepted.

Configuration Manual - 200E Series

Page 35

Allowed DM1 Addresses

This makes it possible to filter units

on the CANbus, so that the DCU is

reading data from specific units only.

Normally, all sources are accepted.

Miscellaneous

These configuration items do not

naturally belong in other sections.

Note! Do not skip this section, as it

highlights important configurations.

Ala rm C onf igur atio n

Configure how the SAE J1939 CANbus

acts alarming wise.

J1939 CANbus broken wire

alarm when engine not running

Some engines electronic control

modules (ECM) stops sending CAN

traffic when the engine is not running

or when stopping a running engine.

To avoid nuisance alarms in these

situations, set this setting to

No.

J1939 CANbus Red Lamp

Severity

Configure how the ECM Red Lamp

signal is to be handled by the DCU.

Either the DCU will disregard of it, or it

may be an Alarm or an engine

Shutdown.

J1939 Amber Warning Lamp

Enabled

Select if the ECM Amber Lamp shall

indicate with a Warning or be disabled.

Cou nter s

The DCU calculates and stores engine

running hours.

Counter Source

Set the counter source to be either

from the J1939 CANbus, or from a

locally generated counter in the DCU.

Typically, on an electronic

engine this shall be set to

J1939.

Likewise, if there is no CANbus

on the engine, this setting must

be Local for the counters to

work.

Update Local Engine Hours

This updates the local counter to any

new value.

Note! This only works when the

Counter Source is Local. If the Counter

Source is J1939, the DCU counter

setting will be overwritten by new

values coming on the CANbus.

Fuel Consumption

The DCU can calculate

approximate

fuel consumption values.

The values must be completed from

the engine datasheet.

The signal is then to be configured

under

Configuration Manual - 200E Series

Page 36

Home DCU I/O Configuration

Special.

Ack n owl edg e Co nfi gura tion

Configure if Acknowledge All is to be

allowed or not.

If allowed, a long-press (1 sec) on the

Acknowledge button will acknowledge

all alarms simultaneously.

Default setting is

No.

If this is set to Yes and the alarm list is

full of alarms it is possible to

acknowledge alarms that are not

visible in the alarm list.

Eve nt L og

The DCU has an built in event log.

Everything

This displays a list of all events in

chronological order.

Alarms Only

This displays a list of all warning,

alarm and autostop (shutdown) events.

User Interaction Only

This displays a list of all button

presses.

Commands Only

This displays a list of all remote

commands to the DCU.

Events Only

This displays a list of all events that

are not alarms, for instance Power On.

Save As…

The current list of events is saved into

a text file on the PC.

Sup pres s DM 1 f ault s

Select the combinations of SPN and

FMI messages that are to be

suppressed.

Eng i ne Appl ica tio n Co nfi gura tio n

Configure how the engine is to be

used.

The configured selection gives the

operator different panel Mode

selections as follows:

Auxiliary

Operator Mode selections

Automatic

Manual

Local

Combined

Operator Mode selections

Emergency

Harbor

Local

Propulsion

Operator Mode selections

Remote

Local

Emergency

Operator Mode selections

Emergency

Configuration Manual - 200E Series

Page 37

Local

Sys tem Vol tage

The 200 Series is designed to be used

in either 12VDC or 24VDC

installations.

Select the correct system voltage for

this application.

Fac t ory Res et

Do a factory reset of the panel.

The panel will restart.

Configuration Manual - 200E Series

Page 38

RP

Configuration

The RP remote panel reads the engine

configuration from the DCU panel, so

no detailed configuration is necessary.

In addition to the Power-On wizard,

this chapter explains the

Administration section of the panel.

Power-On Wizard

When power is first applied, the RP

210E/220E will perform a first poweron startup wizard.

Finish the steps to proceed with the

installation.

Note! Everything in the startup-wizard

can be changed in the panel menu

later.

Select installation language

The selected language is used during

the installation process only. The

operator can change language in the

menu later.

Select administrator password

First, the RP asks for the default

password. From factory, this is

1234.

Next, the RP asks for the administrator

password, which must be typed twice.

Select IP address

The IP address shall be unique on the

ethernet network.

The RP 210E/220E default address is

192.168.0.201.

If installing several panels, make sure

they all have unique addresses.

Select Panel location

Select the location that best matches

the location of the panel.

This information is used on other RP

remote panels only.

Scan for DCUs

Press the Search button to search for

DCU engine panels in the network.

The RP 210E can connect to one DCU

engine panel only.

The RP 220E can connect to two DCU

engine panels.

If the engine panel is not ready at this

time, simply proceed. This step can be

revisited in the RP panel menu later.

Done

The RP startup wizard has now

finished.

If no DCU panel has been attached,

then the RP menu is displayed.

Configuration Manual - 200E Series

Page 39

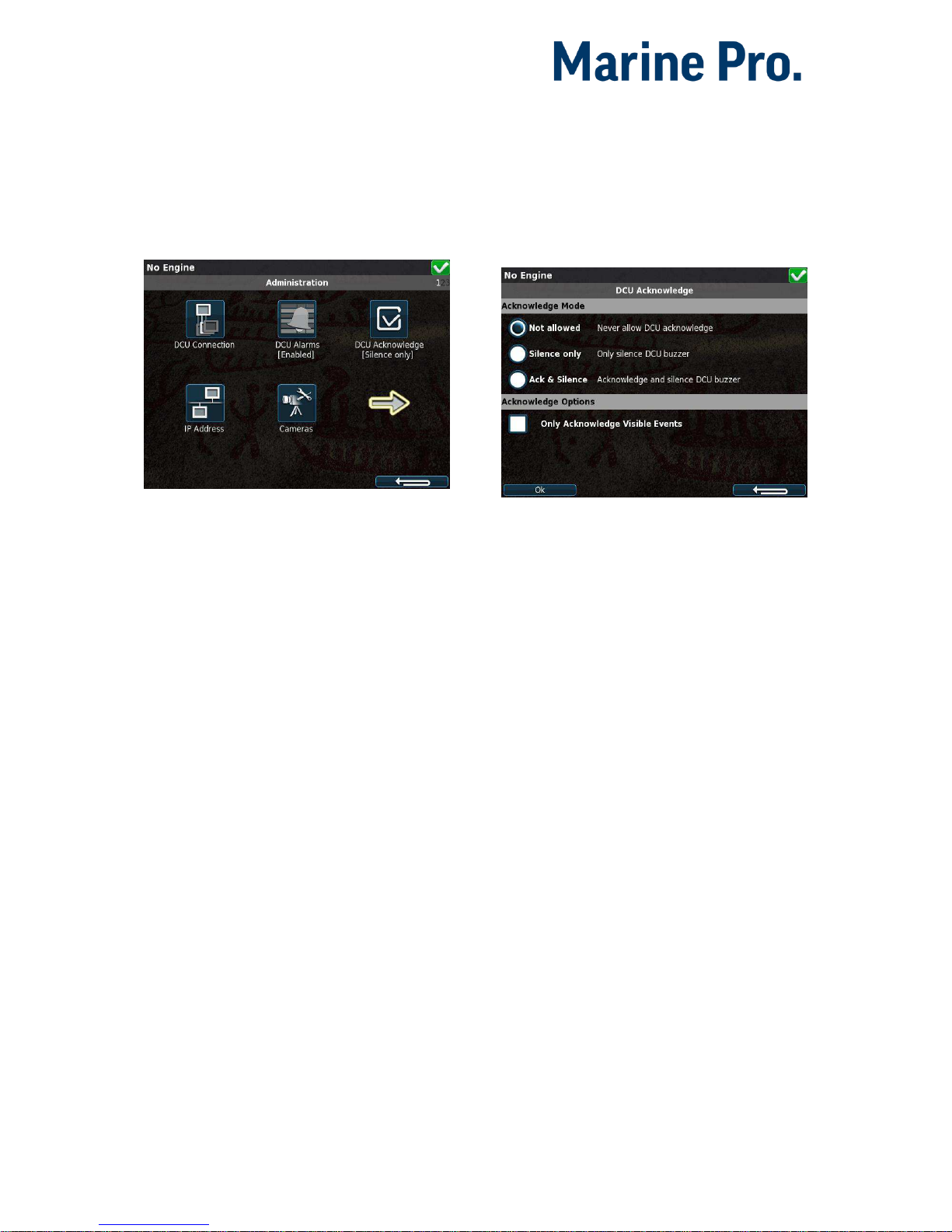

Administration Menu

The RP administration menu has

installation selections that should be

considered for each installation.

In the RP menu, select

Settings, then

Administration to see the menu

selections.

Type the

Administration password

made during the startup wizard.

DCU Co n nec t ion / Con nect i ons

In the DCU Connection menu, press

the Search button. The panel will list

all available DCU engine panels on the

network.

For the RP 210E, select an engine and

press the

Ok button.

For the RP 220E, select up two engines

and press the

Ok buton.

The RP has now saved the connection

and will be displaying the instruments

pages from the connected DCU.

DCU Ala rms

If enabled, the RP will display all

alarms from the DCU engine panel.

If disabled, the RP will not display any

alarms from the DCU engine panel.

DCU Ack now l edg e

This controls how the RP shall handle

alarm reset and acknowledge.

Not Allowed

The RP cannot acknowledge any

alarms.

Select this only if the alarms are to be

acknowledged in another panel

instead.

Silence Only

The buzzer can be silenced, but the

alarms cannot be acknowledged.

Ack & Silence

Full acknowledge control, just as on

the local DCU engine panel.

Only Acknowledge Visible

Events

Check this option to not be able to

acknowledge all alarms with a longpress (1 sec) on the Acknowledge

button.

Configuration Manual - 200E Series

Page 40

Uncheck this option to force

acknowledge of one alarm at a time.

IP Addr ess

If necessary, change the RP panel IP

address.

Always make sure that

The three first digits are equal

for all panels in the network.

The last digit is unique in the

ethernet network.

Changing the RP IP address does not

require a new DCU Connection to be

performed.

Cam eras

Connect an IP camera to the ethernet

network, and key in the Camera IP

address. The RP can connect and

display images from one IP camera.