Manual# 1100269

Installation and

Configuration Manual

DCU 410/408 – Engine Control Unit

RP 410 – Remote Panel

FW 2.11

400 Series Installation and Configuration

400 Series Overview 1

Table of Content

Document Information .................................. 2

Ordering Information .................................... 3

About this manual ......................................... 3

Responsibilities .............................................. 3

400 SERIES OVERVIEW ........................................ 5

TYPICAL LAYOUT ..................................................... 5

Available units in the 400 Series .................... 5

PRECAUTIONS IN CLASSED SYSTEMS ........................... 7

DCU 410 ENGINE PANEL INSTALLATION .............. 8

MECHANICAL INSTALLATION ..................................... 8

Location ......................................................... 8

WIRE TERMINAL LAYOUT OVERVIEW .......................... 9

ELECTRICAL CONNECTIONS ..................................... 13

General ........................................................ 13

Grounding .................................................... 13

Primary Power Supply [1 – 2] ...................... 13

Secondary Power Supply [3 – 4] .................. 14

Power Supplies in General [1 – 4] ................ 14

Auxiliary Power Output [5 – 6] .................... 15

System On/Off [7 – 10] ................................ 16

Reserved [11 – 15] ....................................... 16

Switch Input Channels [16 – 26] .................. 16

4-20 mA Input Channels [27 – 31] ............... 17

PT100 Input Channels [32 – 43] ................... 17

Magnetic Pickup (Speed) Sensor [44 – 45] .. 18

CANopen/J1939#2 Interface (COM 5) [46 –

48] ............................................................... 18

CAN J1939 Interface (COM 4) [49 – 51] ....... 18

MODBUS RTU, RS-485 (COM 3) [52 – 56] .... 18

RIO 410 Link (COM 2) [57 – 59] ................... 19

SDU 410 Link (COM 1) [60 – 62] .................. 19

Configurable Relays [63 – 68] ...................... 19

Configurable 24VDC Outputs [69 – 72, 76-78]

..................................................................... 20

Common Alarm Relay [73 – 75] ................... 20

Shutdown Output [79] ................................. 20

ETS – Energize to Stop [80] .......................... 20

ETR – Energize to Run [81] .......................... 20

Running [82] ................................................ 20

Crank [83] .................................................... 21

Prelube Act. [84] .......................................... 21

24V Supply for Fixed Function Inputs [85] ... 21

Prelube Comp. [86] ...................................... 21

Start Disable [87] ......................................... 21

Automatic Mode [88] .................................. 21

Automatic Start [89] .................................... 21

Automatic Stop [90] .................................... 22

Remote Start /Stop [91 – 92] ....................... 22

Acknowledge [93] ........................................ 22

Shutdown Ovrd. [94] ................................... 22

In Gear [95] .................................................. 23

Configurable Inputs [96 – 97] ...................... 23

Shield (Grounding) [100] ............................. 23

Other Communication Interfaces ................ 23

Rear Lid Graphical Layout............................ 26

FIRST POWER-ON ................................................. 26

Preparations ................................................ 26

First Power-On Wizard ................................ 27

CONFIGURATION OF THE DCU ................................ 30

Configuration- and Firmware files ............... 30

Connecting to the DCU ................................ 31

Further connection settings ......................... 32

WEB SERVER CONFIGURATION ................................ 35

Home ........................................................... 35

Home – DCU ................................................ 38

Home – DCU – I/O Configuration ................ 40

Home – DCU – Interface Design .................. 63

Home – DCU – Start/Stop/Prelube .............. 65

Home – DCU – User Interface ...................... 72

Home – DCU – Engine Model ...................... 73

Home – DCU – Service Interval .................... 73

Home – DCU – Communication ................... 74

Home – DCU – Miscellaneous ...................... 78

Home – DCU – Language ............................. 84

COMMUNICATION INTERFACE LIST ........................... 85

DCU 410 AND DCU 408 CAPACITY ......................... 85

Functionality and content highlights ........... 85

Total I/O capacity ........................................ 86

RP 410 REMOTE PANEL INSTALLATION .............. 87

Location ....................................................... 87

GENERAL OVERVIEW ............................................. 88

ELECTRICAL CONNECTIONS ..................................... 89

Wire Terminal Layout Overview .................. 89

Rear Lid Graphical Layout............................ 90

SYSTEM CONFIGURATION ICON SELECTIONS ............... 90

ADD-ON MODULES ............................................ 96

SDU 410 SAFETY UNIT ......................................... 96

Wire Terminal Layout Overview .................. 97

Configuration of the SDU 410 ...................... 99

RIO 410 EXPANSION I/O .................................... 101

Wire Terminal Layout Overview ................ 101

RIO 410 Addressing ................................... 104

RIO 410 Configuration ............................... 104

RIO 425 GENERATOR INTERFACE UNIT .................. 106

MK-14 RELAY EXPANSION ................................... 108

2 400 Series Overview

400 Series Installation and Configuration

Document Information

Valid Versions

This Installation Manual is valid for the following firmware

releases of the DCU 410/408, and the RP 410.

Panel

Firmware

Release

DCU 410

2.11

June 2014

DCU 408

2.11

June 2014

RP 410

2.11

June 2014

Manual Revisions

Title:

400 Series Installation and Configuration

Revision:

June 10, 2015

Copyrights and Trademarks

Copyright © Auto-Maskin AS, 2015

Information given in this document may change without

prior notice. This document shall not be copied without

written permission from Auto-Maskin.

All trademarks acknowledged.

Contact Information

Auto-Maskin AS

Hvamsvingen 22

NO-2013 SKJETTEN

Norway

www.auto-maskin.com

2 400 Series Overview

400 Series Installation and Configuration

400 Series Installation and Configuration

400 Series Overview 3

Ordering Information

The following parts are available in Marine Pro.

Item

Part #

DCU 410 Engine Control Unit

1006450

DCU 408 Engine Control Unit

1006455

RIO 410 I/O Expansion Unit

1006453

RIO 425 Generator Interface Unit

1006409

RIO 412 Exhaust Monitoring Unit

1006454

SDU 410 Safety Unit

1006451

RP 410 Remote Panel Unit

1006452

MK-14 Relay Expansion

1121341

Ethernet Switch, 5 channels, 24V supply, DIN-rail

1050165

J1939 CAN bus Cable

1009110

IP Camera

1121258

About this manual

This manual has been published primarily for

professionals and qualified personnel. The user of this

material is assumed to have basic knowledge in marine

systems, and must be able to carry out related electrical

work.

Work on the low voltage circuit should only be carried out

by qualified and experienced personnel. Installation or

work on the shore power equipment

must only

be carried

out by electricians authorized to work with such

installations.

Responsibilities

It is the

sole responsibility of the installer

to ensure that

the installation work is carried out in a satisfactorily

manner, that it is operationally in good order, that the

approved material and accessories are used and that the

installation meet all applicable rules and regulations.

4 400 Series Overview

400 Series Installation and Configuration

Note! Auto-Maskin continuously upgrades its products

and reserves the right to make changes and

improvements without prior notice.

All information in this manual is based upon information

at the time of printing.

For updated information, please contact your local

distributor.

400 Series Installation and Configuration

400 Series Overview 5

400 Series Overview

Typical Layout

The following shows a typical layout. The SDU safety unit

is used in classed installations, whereas the RIO

expansion units are used to expand the I/O capacity.

The RP remote panels can be attached for remote

monitoring and control.

Available units in the 400 Series

DCU 410 and DCU 408 Engine Control Units

DCU 410 and DCU 408 are the engine monitoring and

control units. One panel is required for each engine.

The DCU 410 has a colour screen and buttons for user

interaction.

6 400 Series Overview

400 Series Installation and Configuration

The DCU 408 is the low cost version of the DCU 410,

without a user interface, and intended for use with

remote panels.

The DCU 410 and DCU 408 are hereafter referred to as

the “DCU”.

SDU 410 Safety Unit

The SDU 410 (hereafter referred to as the “SDU”) is the

safety unit, which is mandatory in a classed installation. It

is completely self-contained and separate from the DCU.

The DCU communicates with the SDU on a link.

RIO 410 I/O Expansion Unit

The RIO 410 (hereafter referred to as the “RIO”) is an

expansion I/O unit. A maximum of four RIO units can be

connected to any one DCU.

The DCU communicates with the RIO on a link, and when

connected, the DCU automatically detects the unit and

add it into its configuration.

RIO 425 Generator Interface Unit

The RIO 425 is a generator interface unit. It is linked to

the DCU, which will find it automatically.

When connected, a new page is made available on the

DCU – and on the remote panel RP 410 – that displays

generator parameters such as phase voltages, phase

currents, frequency, power, efficiency factor (Cos phi),

etc.

RIO 412 Exhaust Monitoring Unit

The RIO 412 is a compact unit with 20 thermocouple

channels. Each cylinder’s thermocouple is connected to a

predefined channel on the unit.

The DCU automatically detects the unit, and adds a new

page with exhaust temperature data, such as individual

cylinder temperature, average temperature, etc.

RP 410 Remote Panel Unit

The RP 410 (hereafter referred to as the “RP”) is the

remote panel for the DCU.

400 Series Installation and Configuration

400 Series Overview 7

One RP can monitor and control a maximum of eight DCU

engine units, and there can be an unlimited number of RP

units in the network. Each RP can monitor the same

engine, or it can monitor separate engines.

The RP communicates to the DCU on Ethernet.

Note! For redundant Ethernet connection use

managed

Ethernet switches.

Precautions in Classed Systems

Requirements

In a classed and type approved installation, the following

is required:

The DCU 410 and DCU 408 engine control units

requires:

o Separate power supplies to its primary and

secondary supply inputs.

o An engine speed sensor connected to the

DCU. This can be physical, or from the

J1939 CAN bus.

The SDU 410 Safety Unit requires:

o Minimum one engine speed sensor

connected to the SDU.

o Must be supplied by an alternative supply to

the DCU 410 primary supply.

Certification

All modules in the 400 Series are certified by major

classification societies.

Certificates can be obtained from the Auto-Maskin

website, or from your local distributor.

8 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

DCU 410 Engine Panel

Installation

Mechanical Installation

Location

The DCU is normally located in the engine room due to

the number of cables and wires from the engine sensors

and to reduce electrical noise levels, which might else

result from long cable stretches.

The DCU should be mounted at about eye level and the

user should have easy access to all buttons on the panel.

The DCU may be mounted on the engines supporting

structure provided shock absorbers are used either

between the structure and the engine, or between the

structure and the DCU. The DCU shall not be mounted

directly onto the engine due to vibrations.

The DCU should be mounted so that easy access to the

cable connections at the back is ensured. This might for

instance be accomplished by mounting it in a cabinet with

a hinged front panel.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 9

Wire Terminal Layout Overview

These are the wire terminals on the DCU back lid.

Power supply inputs /auxiliary power output

1

+24VDC Primary Supply

In 2 0V Primary Supply

In

3

+24VDC Secondary Supply (Redundant)

In 4 0V Secondary Supply

In 5 24VDC Supply Out, 1A

Out

6

0V Supply Out

Out

System On / Off

7

+24VDC 0.2A Supply for Power On

Out

8

Power On 24VDC

In 9 0V Opto Supply for Power On

Out

10

0V Supply for Power On

In

Reserved for future expansion

11

No connection

-

12

No connection

-

13

No connection

-

14

No connection

-

15

No connection

-

Switch Inputs Channels (8 channels)

16

+24VDC 0.2A Supply for Switch Inputs

Out

17

#1 Switch Input 24V

In

18

#2 Switch Input 24V

In

19

#3 Switch Input 24V

In

20

#4 Switch Input 24V

In

21

#5 Switch Input 24V

In

22

#6 Switch Input 24V

In

23

#7 Switch Input 24V

In

24

#8 Switch Input 24V

In

25

0V Opto For Switch Input

Out

26

0V For Switch Input

In

10 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

4-20 mA Inputs (4 channels)

27

+24VDC 0.2A Supply for 4-20 mA Sensors

Out

28

#1 4-20 mA Input

In

29

#2 4-20 mA Input

In

30

#3 4-20 mA Input

In

31

#4 4-20 mA Input

In

PT100 inputs (4 channels)

32

#1 PT100 A

In

33

#1 PT100 B

In

34

#1 PT100 C

In

35

#2 PT100 A

In

36

#2 PT100 B

In

37

#2 PT100 C

In

38

#3 PT100 A

In

39

#3 PT100 B

In

40

#3 PT100 C

In

41

#4 PT100 A

In

42

#4 PT100 B

In

43

#4 PT100 C

In

Pickup input (tacho / speed input)

44

#1 Pickup A

In

45

#1 Pickup B

In

CANopen /J1939#2 interface (COM 5)

46

#1 CANopen/J1939#2 Shield

-

47

#1 CANopen/J1939#2 L

-

48

#1 CANopen/J1939#2 H

-

CANJ1939 interface (COM 4)

49

#1 CAN J1939 Shield

-

50

#1 CAN J1939 L

-

51

#1 CAN J1939 H

-

MODBUS RTU (COM 3)

52

Modbus 0V

In

53

Modbus Shield

-

54

Modbus L

-

55

Modbus H

-

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 11

56

Modbus +24VDC Supply

In

RIO 410 Remote I/O Interface (COM 2)

57

RIO 410 Remote I/O Interface Shield

-

58

RIO 410 Remote I/O Interface L

-

59

RIO 410 Remote I/O Interface H

-

SDU 410 Safety Module Interface (COM 1)

60

SDU 410 Safety Module Interface Shield

-

61

SDU 410 Safety Module Interface L

-

62

SDU 410 Safety Module Interface H

-

Configurable Relays

63

#1 Configurable Relay NC

Out

64

#1 Configurable Relay C

Out

65

#1 Configurable Relay NO

Out

66

#2 Configurable Relay NC

Out

67

#2 Configurable Relay C

Out

68

#2 Configurable Relay NO

Out

Configurable 24VDC Outputs

69

#1 Configurable Output 24VDC

Out

70

#2 Configurable Output 24VDC

Out

71

#3 Configurable Output 24VDC

Out

72

#4 Configurable Output 24VDC

Out

Common Alarm Relay

73

Common Alarm Relay NC

Out

74

Common Alarm Relay C

Out

75

Common Alarm Relay NO

Out

Configurable 24VDC Outputs

76

#5 Configurable Output 24VDC

Out

77

#6 Configurable Output 24VDC

Out

78

#7 Configurable Output 24VDC

Out

Fixed 24VDC Outputs

79

Energize to Shutdown 24VDC

Out

80

Energize to Stop (ETS) 24VDC

Out

81

Energize to Run (ETR) 24VDC

Out

82

Engine Running 24VDC

Out

83

Crank (Start) 24VDC

Out

12 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

84

Prelube Activation 24VDC

Out

Fixed 24VDC Inputs

85

+24VDC Supply for Fixed Functional Inputs

Out

86

Prelube Complete 24VDC switch input

In

87

Start Disabled 24VDC switch input

In

88

Automatic Mode 24VDC switch input

In

89

Automatic Start (PMS) 24VDC switch input

In

90

Automatic Stop (PMS) 24VDC switch input

In

91

Remote Start 24VDC switch input

In

92

Remote Stop 24VDC switch input

In

93

Remote Acknowledge/Silence Alarm 24VDC

switch input

In

94

Shutdown Override 24VDC switch input

(engine protection override)

In

95

In Gear 24VDC switch input

In

96

#1 Configurable Input 24VDC switch input

In

97

#2 Configurable Input 24VDC switch input

In

98

0V Opto For Fixed Functional Inputs

In

99

0V For Fixed Functional Inputs

In

Ground (PE)

100

Ground

-

Ethernet MODBUS/TCP (COM 6)

COM 6

RJ45 Ethernet port

In/Out

Console (COM 7)

COM 7

DSUB-9 (RS-232) serial port

In/Out

MK-14 Relay Expansion Module Link (COM 8)

COM 8

DSUB-15

In/Out

USB Interface

USB

USB Memory Interface

In/Out

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 13

Electrical Connections

General

To protect against EMC noise, we recommend that all

cables are shielded.

Note! The screen of all cables shall be connected to

ground/hull, NOT to 0V!

Some cables shall be kept as separate from other signals

as possible – for instance the pickup signal. Others can be

in a shielded multi-cable.

Note! Connect shield at one end only.

Grounding

Note! Please keep ground and 0V separated!

In marine installations, ground and 0V volt should not be

connected together. In a ship installation, the hull is the

“ground” whilst the battery minus is the 0V.

In the DCU system, +24V and 0V are filtered to ground

using special filter components. This is done to reduce

electrical noise entering the system. If ground and 0V are

connected together, these filters do not work properly.

Note! Make a ground connection to terminal 100. Keep

this wire as short as possible, and at least 1.5mm2.

Terminals 46, 49, 53, 57, 60 and 100 are all ground

connections, internally connected to ground, and should

not

be connected to 0V.

Primary Power Supply [1 – 2]

The DCU is designed to run on 24VDC supply voltage.

Note! Make sure the primary supply power is sourced

directly from the battery, NOT from the starter of the

engine, as the voltage drop over the latter is significantly

higher.

Power Supply Requirements

Valid full functionality range: 18-32VDC.

14 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Minimum capacity: 5A

Note! There are fixed low battery voltage alarm setpoints.

For the primary supply, these are at 21V and 18V. For the

Secondary supply, the setpoint is at 20V.

All these alarms are delayed.

Use a twisted pair wire to minimize the effect of noise on

the supply cables. Connect the cables straight from the

battery (and NOT the starter engine) and keep the cable

as short as possible.

Use at least 2.5mm2 wires for the power supply.

Secondary Power Supply [3 – 4]

It is recommended that the secondary supply is connected

to a redundant power supply to ensure sufficient supply

voltage upon cranking the engine.

Without a separate secondary supply, a crank can result in

a reboot of the DCU.

Power Supplies in General [1 – 4]

Mandatory straps when not using opto-coupling

The DCU support opto-coupled inputs and outputs on

several of its terminals.

When this capability is not used, the following straps

must be inserted.

Purpose

Strap

Comment

Power the DCU

7-8 and 9-10

Disconnect jumper 7-8 to

set the DCU into System

Off mode.

Activate Switch

Inputs

25-26

Disconnect this jumper if

an external 24V supply

(not terminal 16) is used

to activate the switch

inputs.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 15

Activate Fixed

Functions

98-99

Disconnect this jumper if

an external 24V supply

(not terminal 85) is used

to activate the functions.

Supply Selection

The DCU internal circuitry is sourced from either the

primary OR the secondary supply.

The primary supply has priority over the secondary

supply. If the primary supply voltage drops below 18V,

the DCU will immediately switch over and use the

secondary supply, but only if the secondary supply is

above 20V.

The primary supply is selected over the secondary supply

when the primary supply voltage again rises above 18V.

There is a two second delay when switching from

secondary to primary supply.

The DCU will run equally well – with full functionality – on

the secondary supply.

All voltage levels are +/- 5%.

Power Supply Low Alarms

The active supply (the supply currently feeding the DCU)

is monitored. This is normally the primary supply.

If the supply falls below 21V+30sec, this is

indicated with an amber alarm.

If the supply falls below 18V+30sec, this is

indicated with a red alarm.

Auxiliary Power Output [5 – 6]

The Auxiliary Power Output is intended to drive auxiliary

instruments, relays, Ethernet switches, etc. that should be

powered together with the DCU.

The Auxiliary supply is secured with an automatic fuse.

16 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

System On/Off [7 – 10]

The DCU has a System On/Off function. System On is the

normal mode of operation.

In System Off mode, the DCU internal circuitry is still

active, but it acts as powered off.

Normal operation

To power the DCU for normal operation, connect a strap

between terminals 7-8 and another strap between

terminals 9-10.

The DCU is now always on.

System Off

To set the DCU in System Off mode, remove the strap

between terminals 7-8.

The 24VDC supply at terminal 7 is secured with a 10mA

automatic fuse.

System On

To activate the DCU, connect terminals 7-8 again. The

DCU is immediately ready for use.

External supply

Alternatively, this function can be activated with an

external 24V supply. In this case, do not connect any

jumpers, and do not use terminals 7 and 10.

To activate the DCU (System On), connect a 24V supply to

terminal 8, and the 0V to terminal 9.

Reserved [11 – 15]

Not implemented in this release.

No connection to these terminals.

Switch Input Channels [16 – 26]

There are eight configurable switch input channels which

can be used to detect the status of switches in the

installation.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 17

The state of each channel is controlled by the voltage

between the +24V switch input terminal (terminals 17-

24) and the +0V opto terminal (terminal 25) as follows:

0 – 2V = logic “0”

8 – 32V = logic “1”

2 – 8V = undefined, avoid this area.

Further switch input details

Overvoltage protection: 40 VDC

Not connected = 0V (47 kohm pull-down).

The 24VDC on terminal 16 shall be used for the switch

input supply. It is secured with a 40 mA automatic fuse.

Normal Use

Terminals 25 and 26

shall

be strapped.

Terminals 17 - 24 connected to 24V (terminal 16)

through external switches.

Opto-coupled Use

Terminals 25 and 26 shall

not

be strapped.

External voltage input between terminals 17 - 24 (+24V)

and terminal 25 (0V opto) is electrically isolated from the

DCU by the means of integrated opto-coupled devices.

4-20 mA Input Channels [27 – 31]

There are four configurable 4-20 mA analogue sensor

inputs.

If the signal is out of range, a warning will be displayed.

Out of range is defined as:

<2 mA (broken)

>24 mA (short)

Update rate: 2Hz

PT100 Input Channels [32 – 43]

There are four PT100 input channels. The channels

support PT100 sensors with two or three wires.

Note! If connecting a two-wire PT100 sensor, then strap

the two wire terminals A and B at the DCU end.

18 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

If the signal is out of range, a warning will be displayed.

Out of range is defined as:

<90 ohm (short)

>390 ohm (broken)

Update rate: 2 Hz

Magnetic Pickup (Speed) Sensor [44 – 45]

Connect the magnetic pickup to terminals 44 and 45.

Please verify that the signal strength is between 4-32

Vpp.

Note! The signal waveform shall be a sinusoidal shape,

not a square.

Use a 2x 0.5 mm2 (minimum) twisted pair cable.

Note! The pickup cable shall be shielded to ground in the

pickup end. Do NOT connect shield to 0V.

Range: 0.1-10 kHz

CANopen/J1939#2 Interface (COM 5) [46 – 48]

This is a communication interface for remote panels or

equipment.

The CANopen interface is able to communicate all signals

available in the DCU.

Terminal 46 – CANopen/J1939#2 Shield

Terminal 46 - CANopen/J1939#2 Low

Terminal 46 - CANopen/J1939#2 High

CAN J1939 Interface (COM 4) [49 – 51]

Engine J1939 CAN bus interface for connection to the

engine ECM, electronic control module.

Terminal 49 - CAN Shield

Terminal 50 - CAN Low

Terminal 51 - CAN High

MODBUS RTU, RS-485 (COM 3) [52 – 56]

The MODBUS RTU may be connected either with common

0V or electrically isolated with an optocoupler.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 19

Terminal 53 - Shield

Terminal 54 - Low

Terminal 55 – High

Not Optoisolated Communication

Supply the Modbus section from the DCU as follows:

Terminal 56 to terminal 5 (24V)

Terminal 52 to terminal 6 (0V)

Optoisolated Communication

This requires the supply from the remote equipment to be

supplied into the DCU terminals

Terminal 56 (24V)

Terminal 52 (0V)

RIO 410 Link (COM 2) [57 – 59]

This is the link for the optional RIO 410 Remote I/O units.

A maximum of four RIO units can be connected.

Terminal 57 - Shield

Terminal 58 - Low

Terminal 59 - High

SDU 410 Link (COM 1) [60 – 62]

This is the link to the SDU 410 Safety Module.

Terminal 60 - Shield

Terminal 61 - Low

Terminal 62 - High

Configurable Relays [63 – 68]

There are two configurable relays on the DCU, Relay 1

and Relay 2. Each relay may be enabled or disabled.

If enabled, operation is controlled by selecting one of the

many possible events available through the configuration

web server.

The relay contact centre tap is secured with a 1A

automatic fuse.

20 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

For additional configurable relays, see the section about

the optional MK-14 unit.

Configurable 24VDC Outputs [69 – 72, 76-78]

There are seven configurable 24V outputs on the DCU,

Config 1 to Config 7. Each output may be enabled or

disabled.

If enabled, operation is controlled by selecting one of the

many possible events available through the configuration.

Common Alarm Relay [73 – 75]

The relay is activated in a normal situation, and releases

for any alarm.

The centre tap is secured with a 1A fuse.

Shutdown Output [79]

The shutdown output activates when the DCU activates an

automatic engine safety shutdown.

It does not activate for a normal engine stop.

ETS – Energize to Stop [80]

The ETS activates on a normal engine stop or an

automatic engine safety shutdown.

The signal stays activated a few seconds after the engine

has stopped.

ETR – Energize to Run [81]

The ETR activates when the DCU is about to start the

engine. It stays activated as long as the engine is running.

The ETR deactivates on any stop command.

Running [82]

This output activates when the engine is running. This is

normally when the engine has reached the running

setpoint, typically set at 400 rpm.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 21

The output deactivates at any stop command.

Crank [83]

The output activates to engage the engine starter. It is

disabled on a running engine.

Prelube Act. [84]

The Prelube Activation signal activates if the DCU is

configured to prelube the engine prior to a start.

24V Supply for Fixed Function Inputs [85]

Use this 24V supply output to power all the inputs in the

wire terminal range 86 to 97.

Prelube Comp. [86]

If the DCU is configured to perform a prelube cycle until

the sensed oil pressure is above a certain setpoint

(provided by the prelube equipment), then the DCU will

not continue onto the crank cycle until this signal

appears.

Start Disable [87]

If activated, the DCU is inhibited to perform any start

attempts .

Automatic Mode [88]

In Automatic Mode, the DCU will perform automatic start

attempts if an automatic start signal is applied to terminal

89.

In this mode, the DCU will also react to an automatic stop

signal on terminal 90.

Automatic Start [89]

Apply this signal to start the engine according to the DCU

start configuration.

22 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Note that this terminal input is disabled if Automatic

Mode [88] is inactive. This signal has to be applied until a

running state is achieved.

Automatic Stop [90]

Apply this signal to stop the engine according to the DCU

stop configuration.

Note that this terminal input is disabled if Automatic

Mode [88] is inactive. This signal has to be applied until a

stopped state is achieved.

Remote Start /Stop [91 – 92]

Apply a signal to either of these inputs to activate the

function.

The Remote Start and Remote Stop works always, and

independent of the Automatic Mode setting [88].

Acknowledge [93]

The remote Acknowledge input acknowledges all new

(unacknowledged) alarms.

Shutdown Ovrd. [94]

The Shutdown Override (SO) input disables all DCU

shutdowns (automatic stop), but not the SDU shutdowns!

Note! In future firmware 2.11, the SO input to the DCU

will also set the SDU 410 in shutdown override mode.

Note! In systems where there is an SDU connected to the

DCU, make sure to activate Shutdown Override on the

DCU and on the SDU. In reality, the SDU will signal SO to

the DCU.

On the DCU, the SO is activated with a 24V signal

to terminal 94.

On the SDU, the SO is activated by closing a switch

over terminals 50 and 51. Note that the switch

requires a 10k resistor connected across it.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 23

Note! On the SDU, note that some channels may be

configured to disregard Shutdown Override mode.

Consult the SDU configuration section to verify this.

Note! Overspeed will always be enabled, even in

Shutdown Override mode. This is true for the DCU and

the SDU.

In Shutdown Override mode, if a shutdown channel is

activated, the DCU will indicate this with an alarm instead

of activating a shutdown.

The DCU will also display a “SO” symbol in the status bar

(top right) when Shutdown Override mode is active.

In Gear [95]

When In Gear is signalled, the DCU will prohibit start

(crank) attempts.

Configurable Inputs [96 – 97]

These two channels have a configurable function. The

function is configured using the web server.

Connect the input to 24V to activate the configured

function.

Shield (Grounding) [100]

Connect this terminal to shield. Please note that 0V and

shield shall be separated.

Other Communication Interfaces

Ethernet MODBUS/TCP (COM 6)

The DCU connects to a LAN (Local Area Network) or

directly to a PC through a standard CAT-5 network cable

connected to the RJ45 port (COM 6).

The IP setting of the DCU and/or the local PC’s need to be

set in order to access the DCU configuration from a PC.

24 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

The DCU has an inbuilt DHCP server for use in single PC

configuration. See page 31 for the configuration

procedure.

Note! This is not an autoMDIX port, crossover cable will

be needed when connecting directly between a DCU and

RP.

Console (COM 7)

This port is for factory service only.

No user connection.

MK-14 Relay Expansion Link (COM 8)

Connect the 15-pin DSUB-connector from the MK-14

optional relay expansion module.

The function to be present at each relay channel is

configured in the DCU web server. Select Home – MK-14.

USB Memory Interface

This interface is for USB memory stick only. It has two

main functions:

Load/Save a configuration file

Load a firmware file

It can also be used to load a new firmware file to any

connected RP 410 remote panel.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 25

26 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Rear Lid Graphical Layout

Back lid of the DCU 410 seen below.

First Power-On

Preparations

Installation

Install the DCU according to guidelines and suggestions,

see page 8.

Connections

Connect power according to guidelines and suggestions,

see page 13.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 27

First Power-On Wizard

The DCU will display a

first power-on wizard

at the first

power up after delivery, or after a factory reset of the

panel.

All the settings are available in the menu interface later.

Select Installation Language

Follow on-screen instructions.

Choose Administrator password

Follow on-screen instructions.

Select IP-address

Follow on-screen instructions.

Valid numbers in the first group is 1 – 254, second and

third group is 0 – 254 and fourth group is 2 – 254. Actual

numbers to use will depend on the network in which the

DCU is a member.

Note! The last two digits in the fourth group will set the

engine number for this DCU. For example, entering

192.168.0.211 becomes “

Engine #11”.

Read the chapter Connecting to the DCU to decide which

IP-address to use; see page 31.

Press Save when all four number groups are entered to

change the IP-address of the DCU, then press Next to

continue.

Press Next only, to continue without changing the IPaddress of the DCU.

System Type

Press

down arrow to select Engine Application.

Press

Edit enter Engine Application menu.

Choose between:

Auxiliary

Combined

Propulsion

Emergency

28 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Press OK to save this setting.

Press

down arrow to select nominal speed for the selected

Application.

Select Classed

Press right arrow to select classed type.

Press

edit to enter classed selection menu.

Not Classed

Classed

Primary RPM Source

Press

right arrow to select Primary RPM Source.

Press

edit to enter Primary RPM Source selection menu.

Not Used

CAN J1939

DCU TACHO

SDU TACHO

Secondary RPM Source

Press right arrow to select Secondary RPM Source.

Press

edit to enter Secondary RPM Source selection menu.

Not Used

CAN J1939

DCU TACHO

SDU TACHO

Third RPM Source

Press

right arrow to select Third RPM Source.

Press

edit to enter Third RPM Source selection menu.

Not Used

CAN J1939

DCU TACHO

SDU TACHO

DCU Pickup pulses/revolution

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 29

Press right arrow to select DCU Pickup pulses/rev.

Press

up arrow or down arrow to change each digit and

press left arrow or right arrow to scroll through digits to

change. Press

Cancel to keep the previous value. Press OK

to choose the new value.

Load a configuration

Press right arrow to load a configuration.

Press

up arrow or down arrow to select the configuration

menu entry, or press Next to use the factory default.

Press Edit to enter the configuration menu entry.

Press

left arrow or right arrow to scroll through available

configurations.

Press OK to choose configuration.

Press

Next to go to the next step.

Done

Press Finished. The DCU will proceed with the new

settings and display the main menu.

30 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Configuration of the DCU

The configuration of the DCU is outlined in this section.

Configuration- and Firmware files

The DCU may be configured in one of the following three

ways:

1) DCU Web Server Configuration Interface

The DCU has an inbuilt web server, offering access to full

configuration of the DCU.

Note! This is the primary configuration interface.

Approved browsers

The following browsers are approved for use. Other

browsers and versions may work.

Browser

Version

Internet Explorer™

7 or higher

Firefox™

5 or higher

Chrome™

13 or higher

2) DCU User Interface Menu

For quick and easy changes to the configuration, there is

a configuration entry point in the menu.

Note! This manual will not describe the panel menu

configuration interface in detail. Only the web server

menu operation is covered.

3) USB Memory Interface

Insert a USB memory with the configuration file(s) and

follow the guidelines appearing on the DCU screen.

Note! The configuration file name can only contain the

following characters:

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 31

- a-z

- A-Z

- 0-9

- “_” (underscore)

- “-“ (hyphen)

If other characters are being used, then the DCU will not

“see” it. Rename the configuration file to solve the issue.

Procedure:

When the USB memory is inserted, the DCU asks

for the administration password (4 digits).

The DCU then lists the configuration file(s)

available on the USB memory.

Select file(s), then select

COPY to copy these files

into the User Files area in the DCU. Note that this

does not activate the file; it is merely a copy of the

file into the DCU.

Select a file, and then select

USE to copy and activate this

configuration file.

Note! The DCU 408 does not have a screen interface and

hence this method does not work on that unit.

Firmware upgrade

The USB memory can be used to copy a new firmware to

the DCU and also any connected RP.

Note! If upgrading both DCU and RP firmware, make sure

to upgrade the RP firmware first!

Copy configuration file

This function copies the current configuration file to the

USB stick. It will name/label this file current_config.cfg.

Connecting to the DCU

It is possible to connect to the DCU either directly or

through a LAN (Local Area Network) Ethernet network.

Note! For use in an existing Ethernet, check the

configuration of the LAN with the LAN manager.

32 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

The components in Marine Pro, including the DCU, uses

fixed (not dynamic) IP-addresses, which must be set

manually.

To connect to the DCU

1. Connect an Ethernet cable between your laptop

and the DCU port COM 6 (Ethernet port).

2. In the

DCU menu, select Version Information. Note

the IP-address. From factory, the IP-address is

192.168.0.101.

3. In your web browser, type the IP-address, eg.

http://192.168.0.101 in the address field.

4. Press Enter, and note the login screen.

5. In the login screen, type

- Username =

dcu

- Password =

1234 (from factory)

Note! If the password is unknown, then use the

Encrypted PIN and send this to service@auto-

maskin.com to obtain the correct PIN.

Logged In?

Proceed to the Web Server Configuration chapter, page

35.

Not Logged In?

Continue with connection settings as described below.

Further connection settings

Change the IP-address of the DCU

If necessary, the IP-address of the DCU can easily be

changed.

Note! The last digit in the IP-address becomes the engine

number.

The DCU has a fixed IP-address that is set during the first

power-on set up. The IP-address may also be changed

later, in the DCU panel menu:

Menu / Settings / Administration (locked/open) /

Miscellaneous / Network

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 33

The Administration folder is password protected by a

password. It will remain open for 60 minutes after valid

password.

Use the

up / down arrows

to select each of the four

groups of numbers and press

edit

to edit each group.

IP-address convention

The factory default IP of the DCU is 192.168.0.101. The

first three groups must be the same for all components in

the LAN, for instance 192.168.0.X, where X is the other

unit in the LAN.

Note! The X-figure must be unique within the LAN. Also,

the two last digits in X will represent the engine number.

Example: A DCU with the IP-address 192.168.0.104 will

be named “Engine #4”.

Connect the DCU to a single PC

First, make sure that the PC’s Ethernet network

configuration is set to automatically receive an IP-address

(as most PCs are). Then in the DCU panel menu:

Menu /Settings Connect a PC…

Press the

down arrow and then Toggle. The DHCP-server

will now be active for 10 min. Repeat if it takes longer

than 10 min to ready the PC.

Connect the PC to the DCU with a CAT-5 Ethernet cable.

The DCU’s DHCP-server will now automatically set up the

PC to communicate with the DCU. It may be necessary to

use a network reset/repair function for the PC’s Ethernet

connection in order for the PC to receive the new IPaddress.

Alternatively, set the IP-address of the PC manually to a

free IP-address in the same subnet as the DCU.

For instance, if the DCU’s IP-address is 192.168.0.101,

the PC may use any IP-address starting with 192.168.0

except 192.168.0.101.

34 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

To connect the DCU to a LAN with a DHCP

server

For use in a LAN with a DHCP server (Dynamic Host

Configuration Protocol), the IP-addresses to be used by

Marine Pro components must be set outside the IPaddress range used by the DHCP server. Most DHCP

servers are configured with an IP-address range that

leaves room for fixed addresses outside it.

If for instance the LANs subnet is 192.168.230 and the

DHCP’s IP-address range is set to 50 – 210, valid IPaddresses of the DCU would be for instance

192.168.230.211, 192.168.230.7 or 192.168.230.231.

Do

not

use the DCU inbuilt DHCP-server (the Menu /

Connect a PC… menu entry) in a LAN with its own DHCP

server, since two DHCP servers in the same LAN may

create conflicting IP-addresses.

Connection to a LAN using fixed IPaddresses

Set the IP-address of the DCU to a free/available IPaddress within the LAN’s subnet.

Factory defaults for the DCU

Factory defaults are valid at initial startup only.

IP-address: 192.168.0.101

Subnet Mask: 255.255.255.0

Default Gateway: 192.168.0.1

For later resets, the current IP configuration will be kept

even through the manual Factory reset operation.

DHCP IP-address range: 101 – 199 within the subnet

defined by the DCUs IP-address.

IP-address conflict

Two or more DCU units with the same IP-address should

not be connected in the same network. The result may be

that a PC or RP 410 remote panel will be able to address

one of the DCU units only.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 35

Change the IP-addresses until all units have a unique

address.

Web Server Configuration

Once logged in, the DCU can be configured. The following

are the Web Server main menu items.

Home

When logged in, the browser displays the following.

The Home screen lists the following menu items.

DCU

This is the top level menu for the entire DCU 410 (or DCU

408) configuration.

The configuration is saved in the configuration file,

located in the DCU.

RIO

This is the top level menu for the optional expansion I/O

modules RIO 410.

The configuration is saved in the DCU configuration file.

36 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

SDU

This is the menu top level for the SDU 410 safety unit

configuration.

The SDU 410 is mandatory in classed installation.

The configuration is saved in the SDU 410, and stored in

the DCU configuration file, located in the DCU.

Upload Wallpaper

A user wallpaper can be uploaded, and can be used as

background for instruments, popups and other dialogs.

MK-14

The relays on the optional relay module MK-14 can be

assigned a function here.

Versions

This top level menu item lists the hardware and software

version of the DCU, and the software version of the SDU.

Troubleshooting

The troubleshooting section makes it possible to

troubleshoot I/O and communication on the DCU, and

also the RIO units.

The following can be verified for the DCU:

Supplies

Switch inputs

4-20 mA inputs

PT100 inputs

Communication channels

J1939 Nodes

MK14 outputs

Outputs (functional 24V outputs and relays)

Inputs (functional inputs)

Run sources (engine running indications)

RPM sources (which sources are in use) and their

priority

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 37

The following can be verified for the RIO:

Versions

Supplies

Switch inputs

4-20 mA inputs

PT100 inputs

TC

0-5V

Outputs

38 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Home – DCU

This is the main menu for the DCU configuration. The

following is an overview of the menu items.

Password

The DCU configuration is password protected with a PIN

code.

Select this option to change the password. First, type in

the old password, and then the new password twice.

If the password is unknown, then use the Encrypted PIN

and send this to

service@auto-maskin.com to obtain the

correct PIN.

File

Load any file

To change the configuration of the DCU, load a new

configuration file.

Factory Default

From here, a predefined factory configuration file

can be opened.

User Uploaded

This lists the files previously uploaded to this DCU.

Pick a file to select a new configuration for the

DCU.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 39

Delete Configuration File

Delete any number of configuration files on the DCU.

Configuration Printout

This gives a quick overview of the current configuration.

Save file as

This saves the current configuration of the DCU into a

file. The default file extension is .cfg.

Save CANopen EDS-file

This saves the CANopen I/O electrical datasheet to a file

on your PC.

Upload to DCU

Uploaded files are files transferred to the DCU.

The inbuilt firmware can be updated whenever there is a

new firmware available.

A new configuration file can be loaded into the DCU panel

Firmware update

Select the new DCU panel firmware to upload. The

file name shall be “dcu410_release.tar.gz”.

The latest firmware release can be obtained from the

Auto-Maskin web site at http://www.automaskin.com/marine_pro/index.php#123

Note! The DCU and RP firmware needs to be matched,

meaning they must have the same major and minor

firmware number, unless he DCU is loaded with firmware

2.11. In which case this 2.11 firmware is compatible with

all RP firmware down to 2.5

For instance, DCU 2.2p2 is a match with RP 2.2, but DCU

2.3 is not a match with RP 2.2.

40 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Wallpaper

Select a picture file for the DCU. The file must be of

type .png. Only one user wallpaper may be

uploaded. Uploading a new file will remove the old

one.

Configuration file upload

Select a user configuration file for the DCU. The file

must be of type

file_name.cfg

.

When uploaded, the file is stored in the DCU, and

is later available for use from the User Uploaded

files section, see page 38.

Home – DCU – I/O Configuration

The I/O section holds menu items for input and output

signals. These are separated into two sections.

Config Inputs

This is where the I/O input channels are

configured, such as 4-20 mA, PT100 and switch

inputs.

Config Outputs

This is the section for configurable outputs. A

signal or function can be assigned to a 24V output

or a relay.

Note! Always remember to press the Submit button after

each change on the configuration pages. No changes will

be saved until this button is pressed!

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 41

Engine Speed

This is where engine speed sensors are configured, and

the overspeed setpoint is set.

Source

The DCU can read engine speed from up to three sensor

sources.

Source

Comment

J1939 #1

J1939 #2

J1939 CAN bus connected to terminals 49-51

(COM 4) or 47-48 (COM5)

DCU

Magnetic pickup locally connected to DCU,

terminal 44 and 45.

SDU 410

One of the two pickups connected to the SDU

safety unit.

The SDU has a scheme for selecting from its two

connected pickups.

SDU 404

Magnetic pickup locally connected to SDU.

Priorities

The engine speed sources are prioritized. The DCU will

use the sensor assigned as the primary source first.

42 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

If the primary source is lost, then the secondary

source will be used. If the secondary source is lost,

then the third source will be used.

Local Pickup

If there is a pickup connected to the DCU, or “DCU” is

selected among the sources above, then set the flywheel

teeth count here.

General Configuration

RPM Rounding rounds off the displayed value to

nearest 1, 5 or 10 RPM.

RPM setpoint is the RPM at which the DCU indicates

the engine is running. There are also four

additional RPM setpoints that can be used as

additional input to switch /functions.

RPM Ready to take Load is a signal that can be

configured to an output relay. It activates when

that RPM is reached. It deactivates when a stop

command is given, OR the speed drops below the

threshold minus 15%.

RPM Nominal Speed is the engines nominal speed,

and is used to calculate the overspeed setpoint and

RPM overspeed test setpoints.

General

Channel use is the selection of where the signal

shall be displayed. Select DCU+RP to display the

instrument in the DCU and in the RP.

Display

The values here define how the instrument widget is

presented.

Display Unit is the signals unit, here RPM.

Display Range Min is the minimum value displayed,

normally 0 (zero).

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 43

Display Range Max is the maximum value

displayed. For an engine running at 1500 rpm

nominally, a typical maximum setting would be

1800 RPM.

Display Major Divider is where the instrument

widget writes an RPM value, normally every 500

RPM.

Display Minor Divider is the ticked marks between

the major divider marks, normally every 100 RPM.

Display Multiplier is the multiplier value. The value

is displayed in the RPM meter.

Overspeed

RPM Overspeed is the setpoint where the DCU

indicates overspeed.

RPM Overspeed Delay is the delay – in milliseconds

– before alarm or shutdown. Typical setpoint is

100ms.

RPM Overspeed Shutdown Enabled is where the

overspeed behaviour is selected.

Select

Yes for the DCU to shutdown the engine.

Select No to disable overspeed shutdown.

Note! Disabling DCU overspeed is valid for the DCU only.

The SDU is able to shutdown the engine.

44 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

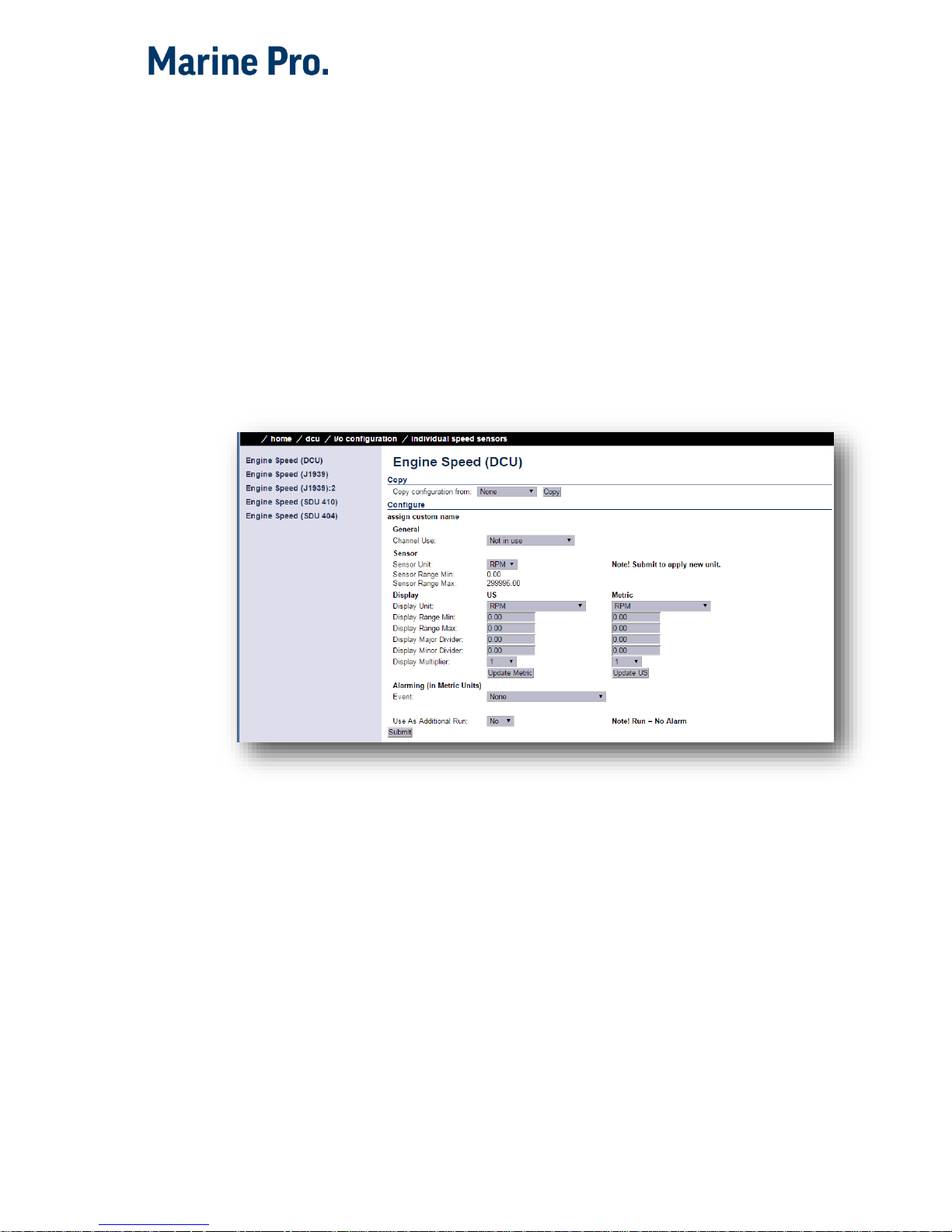

Individual Speed Sensors

This is where the display and alarm settings of the three

different types of speed sensors available, can be

configured.

Engine Speed (DCU)

Engine Speed (J1939)

Engine Speed (J1939):2 (If enabled)

Engine Speed (SDU 410)

Engine Speed (SDU 404)

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 45

Engine Load

First, configure either a 4-20mA, 0-5V input or the J1939

PGN 0Xf003, SPN 92. Select then the engine load source

from the dropdown menu. Engine load can now be used

as an additional setting when configuring alarms.

46 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Gear

First select gear source from the dropdown menu.

In Gear Switch

This is fixed input 95 on the DCU 410

Ahead/Astern Switches

Configure 2 switch inputs as functions

Ahead and

Astern.

J1939 Transmission Current Gear (SPN 523)

The gear settings can now be used as additional settings

for alarms, or shown directly on the DCU. This is done by

going to / home / dcu / user interface.

Select Gear indicator and select to show instead of all ok

symbol.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 47

Switch

First, select any of the eight switch channels. Then, for

each channel, set the following parameters.

General

Channel Use

Set to

Event if in use. An event can be a warning,

an alarm or a shutdown scenario.

Set to

Silent Event for an active channel, but no

panel alarms. The event will be available on

communication only.

Event

Select from Warning, Alarm, Load reduction or

Shutdown.

Input State

Select NO (normally open), or NC (normally closed).

NO means the contact must close to make the

event, whereas NC means the contact must open to

make the event.

Note!

Normal

denotes a running engine with no

alarm.

Delay Before Event

Choose the desired persistence time before the

event triggers.

Typical values:

Engine Oil Pressure Low: 2 seconds.

Engine Coolant Temp. High: 5-10 seconds.

48 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Requires Running Engine

Select

Yes if the switch normally changes state

when the engine goes from standstill to running,

or vice versa.

This means the switch will alarm only when the

DCU senses the engine is running.

Typical setting: Set to Yes for all pressure switches.

Several different RPM set points are available.

Requires In-Gear

This means the switch will alarm only when the

DCU has a high input on In-gear input.

Requires Engine Load

This means the switch will alarm only when the

DCU has reached the configured % load.

Initial Delay

Note! Available only if On Run Only is selected.

The switch event is disabled for this many seconds

after the engine is running. After the timer has

elapsed, the channel is enabled.

Typical value: 5-10 seconds.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 49

Use as Additional Run

If the DCU has one pickup source only, it is

recommended to add an engine oil pressure switch

as an engine running indication.

Note! Do not use any other pressure sensors – or

any other signals – as the engine running

indication!

If two or more engine speed (pickup) sources1 are

in use, then it is recommended leaving this off for

all switches. Set to

No.

If one engine speed source only, locate the engine

oil pressure switch and use this as the Additional

Run signal. Set to

Yes.

1

An engine speed source can be the magnetic pickup connected to the DCU,

the J1939 CAN bus signal connected to the DCU, or the speed signal coming

from the connected SDU 410 safety unit.

50 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

4-20 mA

First, select any of the four 4-20 mA channels. Then, for

each selected channel, set the following.

General

Channel Use

This selects the panel the instrument widget is

displayed on. It is possible to display the

instrument on

o the DCU engine panel, and

o the RP remote panel, or

o a combination of the two.

It is also possible to suppress the alarm events, as

can be seen in the following table overview.

Use

DCU

RP

Config.

outputs

Display

Event

Display

Event

Not in use

Event x x

x

DCU x

x

DCU + Event

x x x

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 51

Use

DCU

RP

Config.

outputs

Display

Event

Display

Event

RP

x x

RP + Event

x x x

DCU+RP

x x x

DCU + RP + Event

x x x x x

Silent Event

x

DCU + Silent Event

x x

RP + Silent Event

x x

DCU + RP + Silent Event

x x x

Display = the signal is displayed in a gauge, or a numerical format.

Event = warning, alarm or shutdown.

Silent Event = no local event, but event on communication only.

Note! Normally, and in most cases, the selection should

be “DCU + RP + Event”, as highlighted in the table above.

This makes sure the channel is displayed in the DCU and

in the RP, if – or when – the RP is installed.

Sensor

Sensor Unit

Select the unit, as printed on the sensor. An oil

pressure sensor might for instance be in Bar or psi.

Sensor Range Min and Max

Select the sensor range values for min and max, as

printed on the sensor.

Display

Display Unit

For the above sensor, select the desired displayed

unit for US and Metric values.

Display Range Min and Max

For the above sensor, select the desired minimum

and maximum values displayed in the instrument,

for US and Metric values.

52 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Display Major and Minor Divider

For the above sensor, select the desired major and

minor divisions in the instrument, for US and

Metric values. The major divider number is

displayed at each major divider.

Display Multiplier

Select a multiplication factor as necessary.

An instrument with displayed range 0-10,000

would display as 0-1,000 with a multiplication

factor of 10. The multiplication factor is displayed

in the instrument (round gages only).

Update Metric and US

When

the US section has been completed, then the

web server can calculate the other section, and vice

versa.

Note! The application does not round off values. It

is highly recommended to adjust the calculated

values by hand, and set sensible round figure

values.

Alarming

This section is always completed in the currently selected

system unit. To switch unit, simply press the Unit button

on the DCU 410 front panel.

Event

Select the desired combination of warning, alarm

and shutdown. Select “RPM dependent” for a

setpoint that varies with RPM, and complete the

boxes.

Alarm Threshold [unit]

Type in the alarm threshold value, in the correct

units.

Delay After Crossing Alarm Threshold

Set the persistence time before the event. Value is

in seconds.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 53

Threshold Type

Set the event to appear on a rising (higher) or

falling (lower) signal. A temperature fail is normally

“too high”, and a pressure fail is normally “too

low”. In addition, a high and low threshold set

point can be configured.

Requires Running Engine

Select between one of the following.

o Set

Yes to disable the event when the engine

is not running (enabled when engine is

running only).

o Set

No the enable the event always.

o Choose between other RPM setpoints if

configured in the engine speed

configuration.

See menu / dcu / io configuration / engine speed/

Initial Delay

If

Yes above, set the persistence time after the

engine is running until the channel is enabled.

Requires In Gear

This means the event will alarm only when the DCU

has a high input on the

In Gear input.

Requires Engine Load

This means the switch will alarm only when the

DCU has reached the configured % load.

Use As Additional Run

o If the DCU has one pickup source only, it is

recommended to add an engine oil pressure

switch as an engine running indication.

Note! Do not use any other pressure sensors

– or any other signals – as the engine

running indication!

o Typical setting:

54 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

If two or more engine speed (pickup)

sources2 are in use, then it is

recommended leaving this off for all

switches. Set to

No

.

If one engine speed source only,

locate the engine oil pressure switch

and use this as the Additional Run

signal. Set to

Yes

.

PT100

First, select any of the four PT100 channels.

Then, for each selected channel, set the parameters, as

for the 4-20 mA section, page 50.

24V Inputs

First, select any of the two 24V input channels.

Note! These are

fixed function

inputs, and not the general

switch input channels, as described on page 45.

These two inputs can be given a function from a list of

available functions. The current available functions are:

Local Mode

Remote mode

Backlight 100%

Prelube Override

2

An engine speed source can be the magnetic pickup connected to the DCU,

the J1939 CAN bus signal connected to the DCU, or the speed signal coming

from the connected SDU 410 safety unit.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 55

Local Start

Local Stop

Local Acknowledge

Local/Remote Acknowledge

In Gear (Ahead)

In Gear (Astern)

Toggle Crank Mode

Activate the function

The function is activated when the input is connected to

24V.

Deactivate the function

The function is deactivated when the input is left open, or

connected to 0V.

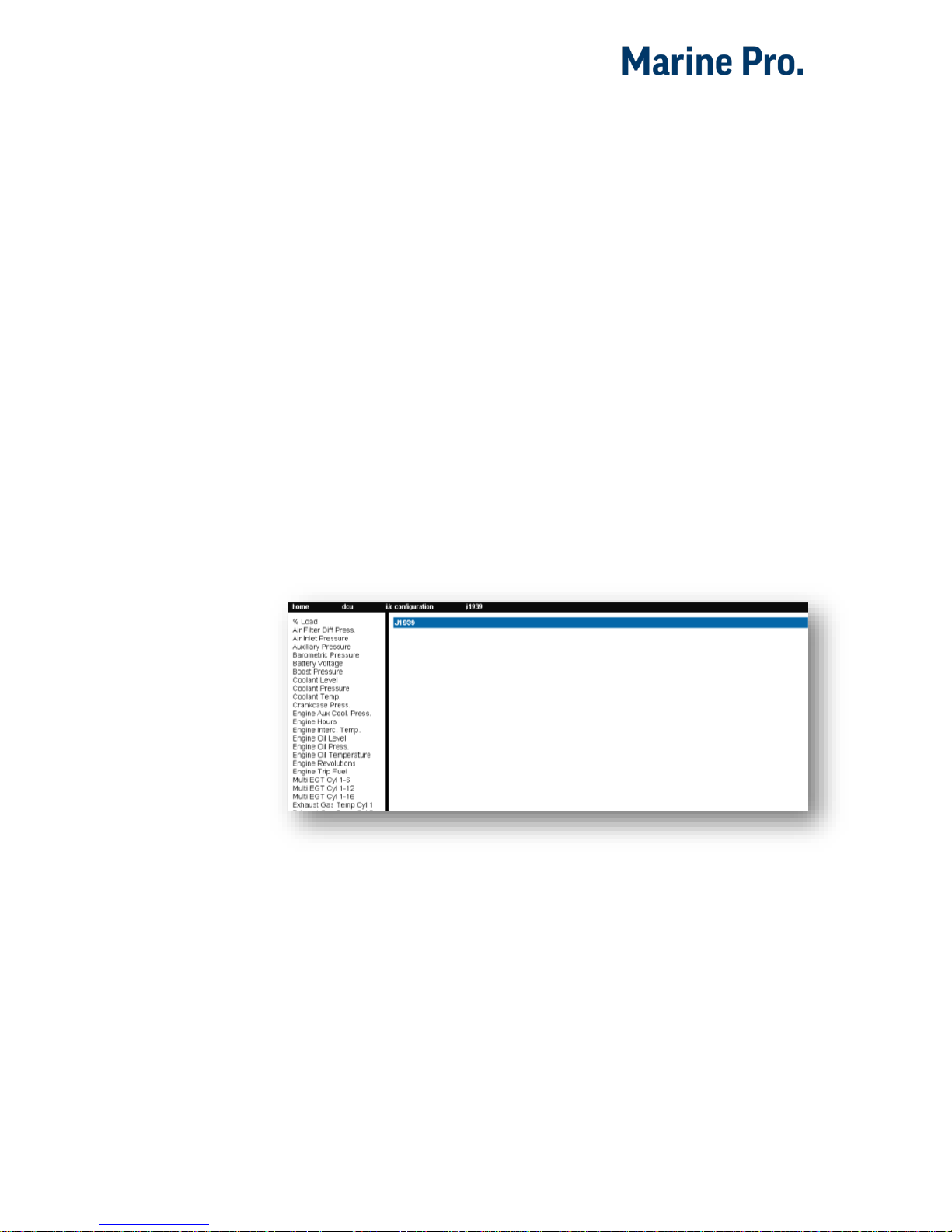

J1939

Select a J1939 CAN bus signal from the list.

Then, for each selected channel, set the parameters as for

the 4-20 mA section, page 50.

Differential

A

differential

channel is a

logical

(not physical) channel,

made up by two physical channels. The physical channels

may be hardwired or from the J1939 CAN bus.

56 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

The differential channel will output the difference

between the two source channels. The sensor unit must

be the same for the two selected source signals, for

instance they must both be bar, and not one bar and one

psi.

Select one of the five differential channels.

Then, select two signals of the same unit type. The

differential channel result can be assigned to an

instrument widget.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 57

Average

An

average

channel is a

logical

(not physical) channel,

made up by two or more physical channels. The physical

channels may be hardwired or from the J1939 CAN bus.

The differential channel will output the average between

the two or more source channels. The sensor unit must

be the same for the selected source signals, for instance

they must both be bar, and not one bar and one psi.

Select one of the three differential channels.

58 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

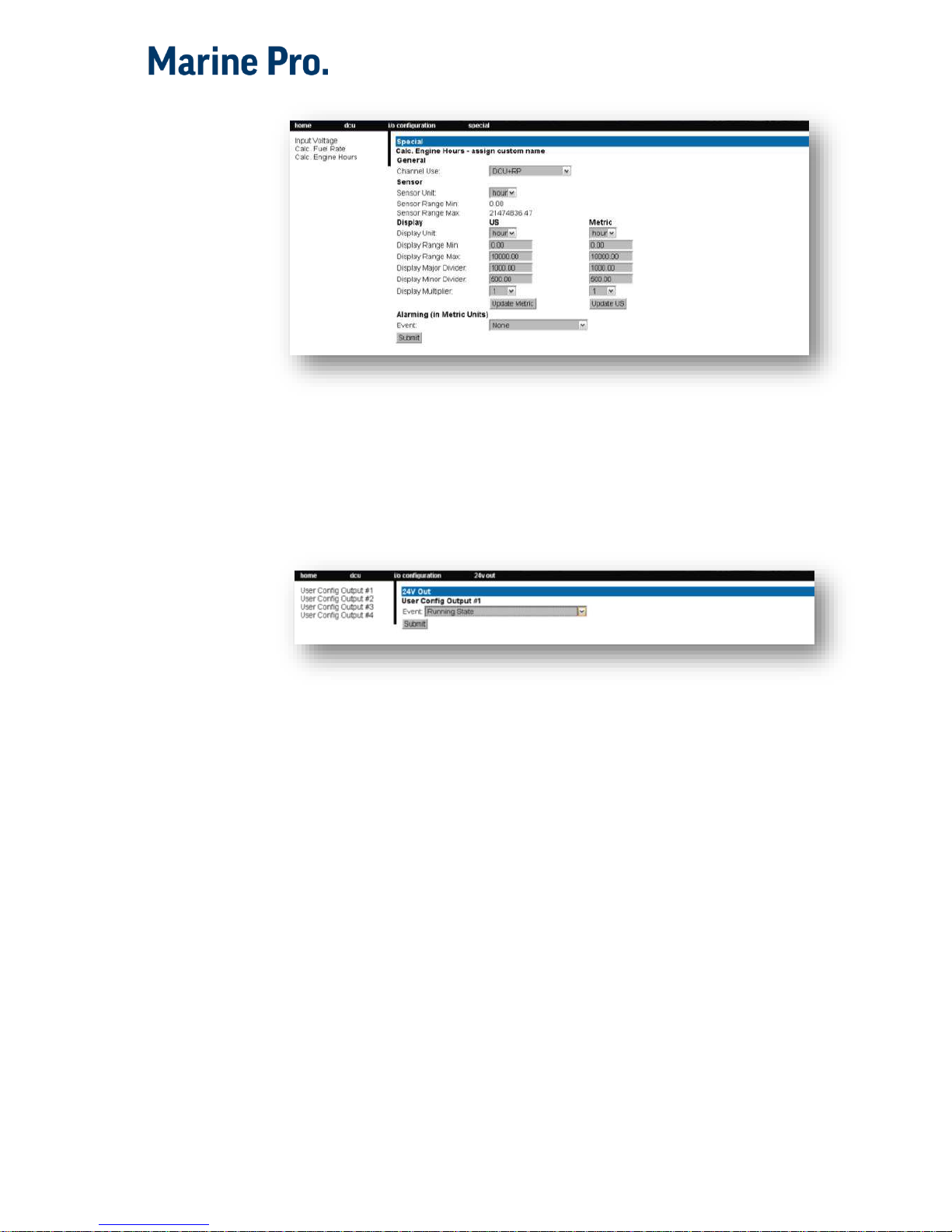

Special

These are a group of “special” signals as follows.

Input Voltage

This is the supply voltage

used in the DCU

, and is the

same as the voltage supplied out on terminals 5-6.

The Input Voltage is the channel that monitors

either

Supply or Supply 2, whichever the DCU chooses.

Set the desired ranges for use in a gauge or bargraph.

For an alarm, set an event and complete the dialog.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 59

Calculated Fuel Rate

The DCU can calculate the fuel consumption and present

an approximate figure.

Note! The Boost Pressure MUST be connected to 4-20 mA

channel #2.

Select the channel and configure accordingly.

Calculated Engine Hours

If the engine hours are not sourced from the J1939 CAN

bus, it is being calculated internally by the DCU.

The appearance of the counter is configured in this

dialog.

It is possible to set an alarm or other event connected to

the engine hours.

60 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Instantaneous Fuel Economy (DCU)

The DCU has seven 24V outputs. The function on the

output is configured here.

Analog Modbus

The DCU has 50 analog Modbus registers that users can

write to from external devices. The values can be used as

signal sources, and set up in the same way as 4-20 mA

sensors. Please see the communication manual for further

technical description of the registers.

Digital Modbus

The DCU has 500 digital Modbus registers that users can

write to from external devices. The values can be used as

signal sources, and set up in the same way as switch

sensors. Please see the communication manual for further

technical description of the registers.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 61

EGT (Exhaust Gas Temperature)

Cylinder Deviation Event

The deviation is the difference between the cylinder value

and the average value. Deviation is positive (above zero) if

the cylinder value is above the average, and negative

(below zero) if the cylinder value is below the average.

Turbo Deviation Event

The deviation is the difference between the turbo value

and the average value. Deviation is positive (above zero) if

the turbo value is above the average, and negative (below

zero) if the turbo value is below the average.

24V Outputs

The DCU has seven 24V outputs. The function on the

output is configured here.

Select one of the seven 24V output channels.

Then, for each channel, select the desired function.

Relays

The DCU has two inbuilt potential free relay contacts,

which can be assigned a function.

62 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Select one of the two relays. Then, for each channel,

select the desired function.

Speed Relays

A Speed Relay is a relay that activates on a certain engine

speed rpm, and deactivates at the same rpm-1.

For instance, speed relay #1 can be configured to activate

at 1200rpm, and will then deactivate at 1199rpm.

Set Event Log to Yes to create an event in the log when

the speed relay activates.

The Speed Relay can be assigned to any configurable

output.

J1939 Outputs

The DCU can transmit J1939 on Idle Bus.

J1939 outputs.

Each channel can be configure to transmit different

SPN/PGN signals.

Special

Transmit Nominal speed to engine (SPN 515)

Start Stop over J1939 (SPN 3452)

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 63

Home – DCU – Interface Design

This is the section where templates are populated with

the already configured signals from the I/O section.

A

page

on the DCU is built up with a

template

. A

template

has several

slot

positions. Each

slot

position can hold a

widget

type, which in turn can be assigned a

signal

.

Configuration

Chose if the DCU is to display green section on bars when

the signal is within parameter.

Option for displaying J1939 switchover from J1939#1 to

J1939#2.

Pages

This is where the configuration of the different pages is

done.

In the example below, three pages are created.

Insert a new Page

Choose whether the new page is to appear before or after

an existing page, then press the Insert Page button. The

pages will be renumbered.

64 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

Choose a Template

A range of templates will be presented. Choose a

template and start populating the page with predefined

signals.

The chosen template will appear at the bottom of the

screen. Select a signal and

Submit it to clear away the

other templates.

Delete a Page

First Select the page, and then press the

Delete button.

The pages will be renumbered!

Edit the Signal

If the chosen signal is not correctly configured, press Edit

Signal to edit it.

RP Home View Configuration

The RP 410 home page displays certain parameters from

each connected DCU.

This is configured in each DCU.

400 Series Installation and Configuration

DCU 410 Engine Panel Installation 65

Home – DCU – Start/Stop/Prelube

Settings

There are several settings for Start/stop on the DCU.

General

The DCU Engine Start/stop can be configured to three

different modes.

Exclusive, the DCU has exclusive control of the

engine start/stop. Warnings will be given for

unexpected state changes.

Shared, the DCU has shared control of the engine

start/stop. No warnings will be given for

unexpected state changes.

Deactivated, the DCU is not in control of the

engine start/stop. No warnings will be given for

unexpected state changes.

66 DCU 410 Engine Panel Installation

400 Series Installation and Configuration

The Start and Stop button can be configured to be

Latched

or

Momentary

.

Note! The selection is valid for the Start and Stop button.

Disable Local Start/Stop Buttons

Disable the local start/stop buttons on the DCU.

Hold Button to Start/Stop

Set to Yes for a momentary Hold-To-Start/Stop

button. The button must be pressed until the

engine has started/stopped.

Set to

No for a latched button. The button needs to

be pressed momentarily, after which the DCU

completes the start/stop sequence as if the button

was held continuously.

Typical setting:

No (gives a latched button operation, which is

normally preferred).

Allow E-Start

This will give the option of starting with prelube override

and shutdown override.

Only Allow Local Start In Local or Emergency Mode

Typical setting is

Yes.

If setting is

No, local start/stop will work in any mode of

operation.

Allow Automatic Start/Stop in All Operation Modes: